Temperature control method and device for baking device and baking system

A baking temperature and baking device technology, applied in the direction of temperature control, control/regulation system, non-electric variable control, etc., can solve the problem of difficulty in improving the production efficiency of valve refractory castables, difficulty in maintaining consistency in baking process, Increase in product manufacturing costs and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

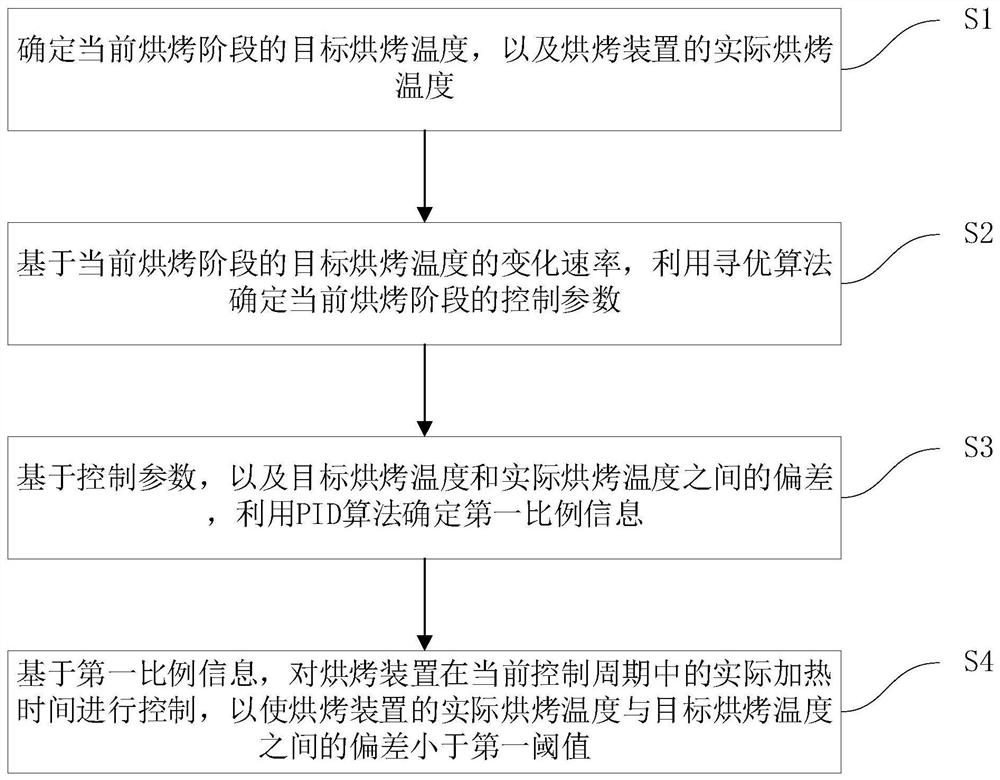

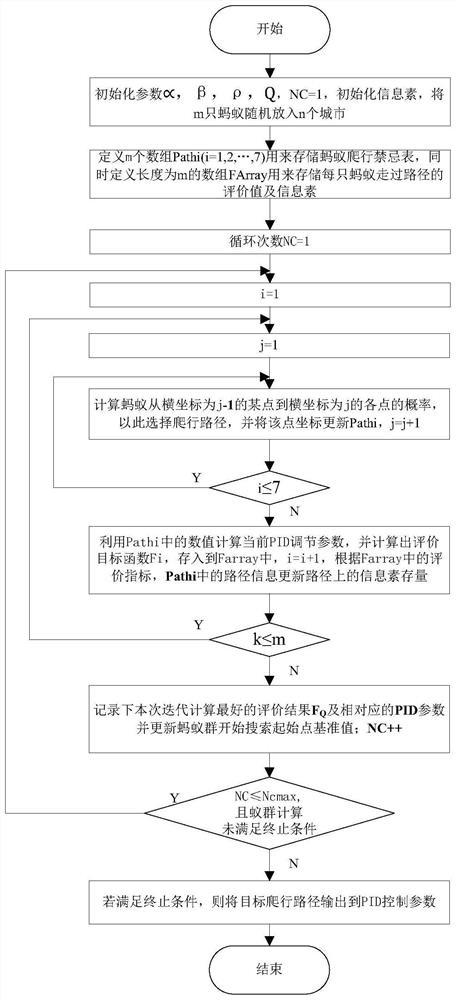

[0066] Various aspects and features of the present application are described herein with reference to the accompanying drawings.

[0067] It should be understood that various modifications may be made to the embodiments applied for herein. Accordingly, the above description should not be viewed as limiting, but only as exemplifications of embodiments. Those skilled in the art will envision other modifications within the scope and spirit of the application.

[0068] The accompanying drawings, which are incorporated in and constitute a part of this specification, illustrate embodiments of the application and, together with the general description of the application given above and the detailed description of the embodiments given below, serve to explain the embodiments of the application. principle.

[0069] These and other characteristics of the present application will become apparent from the following description of alternative forms of embodiment given as non-limiting exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com