Baked tobacco upper tobacco leaf with stem cutting collecting bulk baking method and baking structure

A curing method and tobacco leaf technology, which are applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems of upper tobacco leaves falling off and roasting, poor ventilation, and disorderly lodging of tobacco leaves, so as to increase the amount of tobacco loaded and avoid tobacco leaf weaving. Pole link, obvious effect of saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

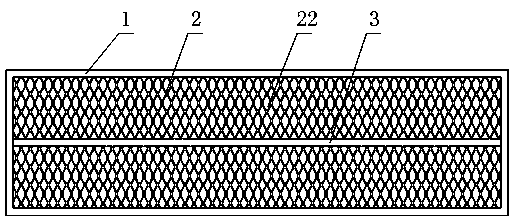

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

[0040] A method for cutting and bulk-packing the upper part of flue-cured tobacco leaves with stems,

[0041] A, when 4~6 pieces of upper tobacco leaves are fully mature, 4~6 leaves of upper tobacco leaves together with stems are harvested at one time;

[0042] B. Loading tobacco on the metal mesh air distribution board: first place a metal mesh air distribution board horizontally in the air-flow descending loose leaf barn, first shake off 4 to 6 upper tobacco leaves with stems, and align the stems After the base, hold the position between the stems with both hands, and stack them upright, with the petiole down and the tip up to the partition wall at an angle of 15°, evenly and directly leaning against the vertical stack on the metal mesh wind distribution board, so as to It is advisable to push it naturally without excessive extrusion; for the cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com