A centralized method for collecting and roasting 6‑8 upper tobacco leaves

A technology of tobacco leaves and leaves, which is applied in the field of centralized harvesting and curing of 6-8 upper tobacco leaves, which can solve the problems of high tobacco proportion in the upper part, failure to meet market demand, low curing quality, etc., and achieve the effect of reducing the output ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

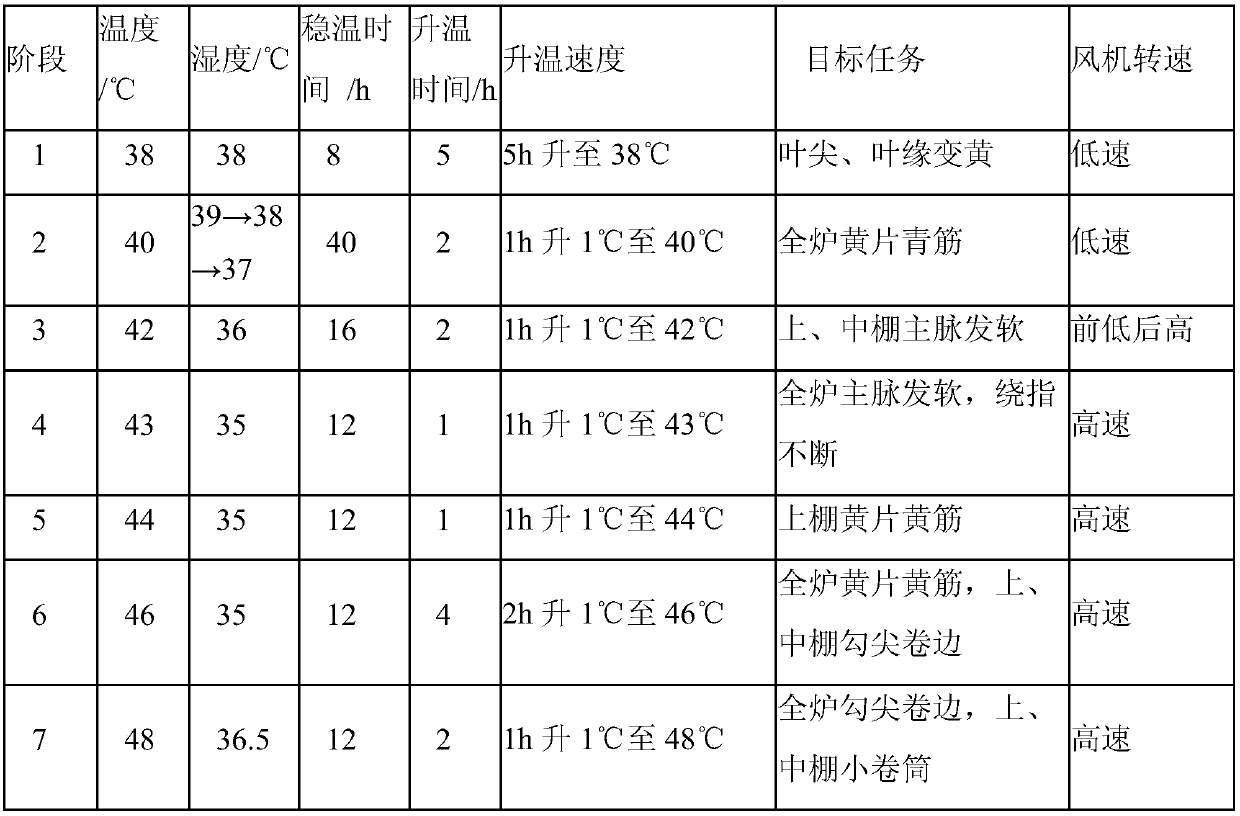

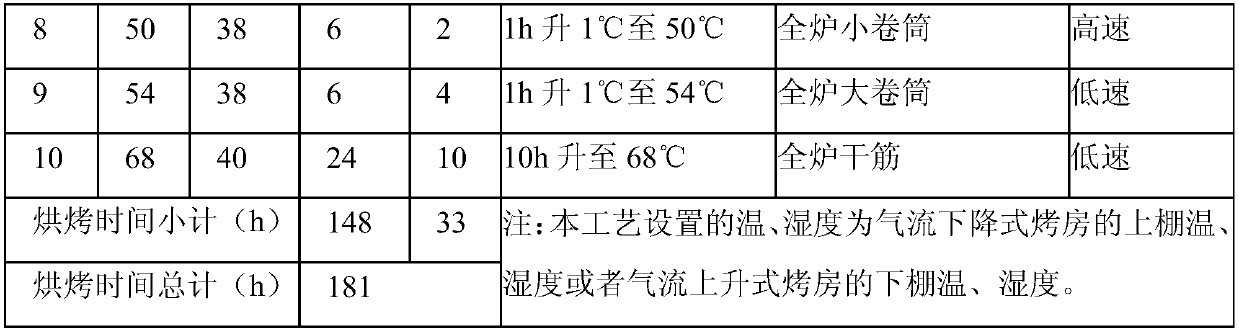

[0048] The method for intensively collecting and roasting the top 6-8 tobacco leaves comprises the following steps:

[0049] 1) The upper 6-8 leaves are fully mature at one time and harvested in two rounds: after the treatment of unsuitable tobacco leaves, the upper 4-5 leaves in the middle and the 2-3 leaves in the top are harvested respectively, and the upper 6 leaves are harvested separately. -8 leaves, 90-100% yellowing of the leaf surface, all the main veins are white and shiny, more than 2 / 3 of the branch veins are white, the angle between the stem and leaf is between 80-90°, the leaves are curved and arched, and the leaf surface is shrunken ;

[0050] 2) Tie pole:

[0051] Rod binding: lean the backs of the tobacco leaves, align the leaf bases, and expose 6 cm of the petiole, evenly distributed, two pieces per bundle, 70 bundles per rod, 140 pieces, 4-5 leaves in the middle, and the weight of a single rod is 8Kg. The top 2-3 leaves weigh 9Kg per pole;

[0052] 3) Fur...

Embodiment 2

[0061] Other steps are with embodiment 1, wherein step 2) is:

[0062] 2) Tie pole:

[0063] Rod binding: lean the backs of the tobacco leaves, align the leaf bases, expose the petiole by 7 cm, and distribute evenly, two pieces per bundle, 80 bundles of tobacco per rod, 160 pieces, 4-5 leaves in the middle and the weight of a single rod is 10Kg, The top 2-3 leaves weigh 11Kg per pole.

Embodiment 3

[0065] Other steps are with embodiment 1, wherein step 2) is:

[0066] 2) To smoke:

[0067] Tobacco clamping: discharge the tobacco leaves evenly, align the base of the leaf against the baffle of the operating table, insert the pins at a distance of 8 cm from the base of the leaf, weigh 11Kg per clamp for 4-5 leaves on the middle, and 13Kg per clamp for the top 2-3 leaves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com