Continuous casting tundish submerged nozzle on-line roasting apparatus and roasting method

A continuous casting tundish and baking device technology, applied in casting equipment, casting melt containers, metal processing equipment and other directions, can solve the problems of high cost, difficult use and maintenance, etc., to ensure baking quality, low noise, The effect of uniform baking temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

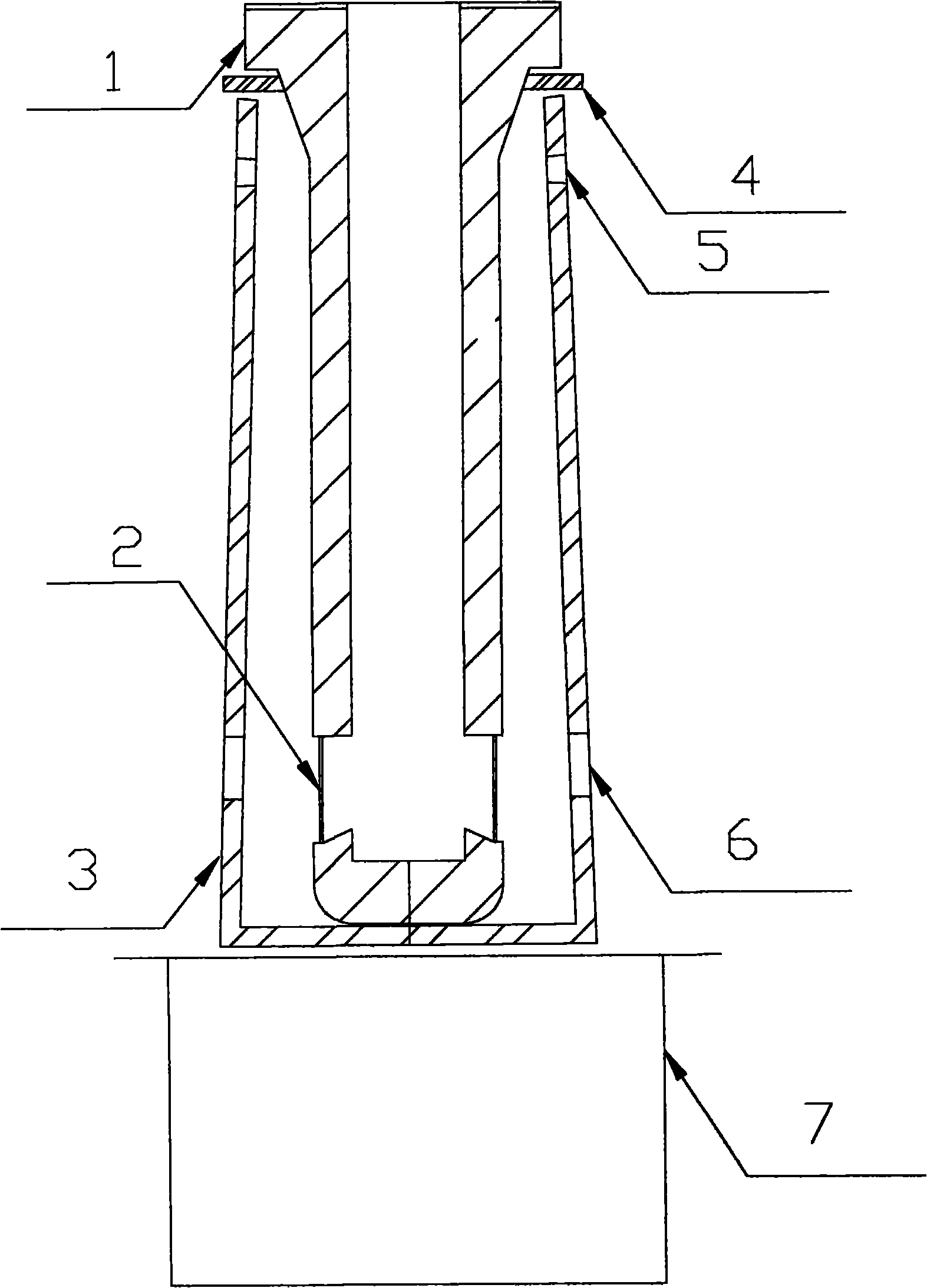

[0017] The invention includes a tundish roaster, a tundish upper nozzle, a nozzle quick-change mechanism, a submerged nozzle, a sealing ring, a baking cover, and a support frame; The iron sleeve is in close contact, the lower part of the sealing ring 4 is the baking cover 3, the upper edge of the baking cover 3 is in close contact with the sealing ring 4, and the bottom is lifted by the support frame 7.

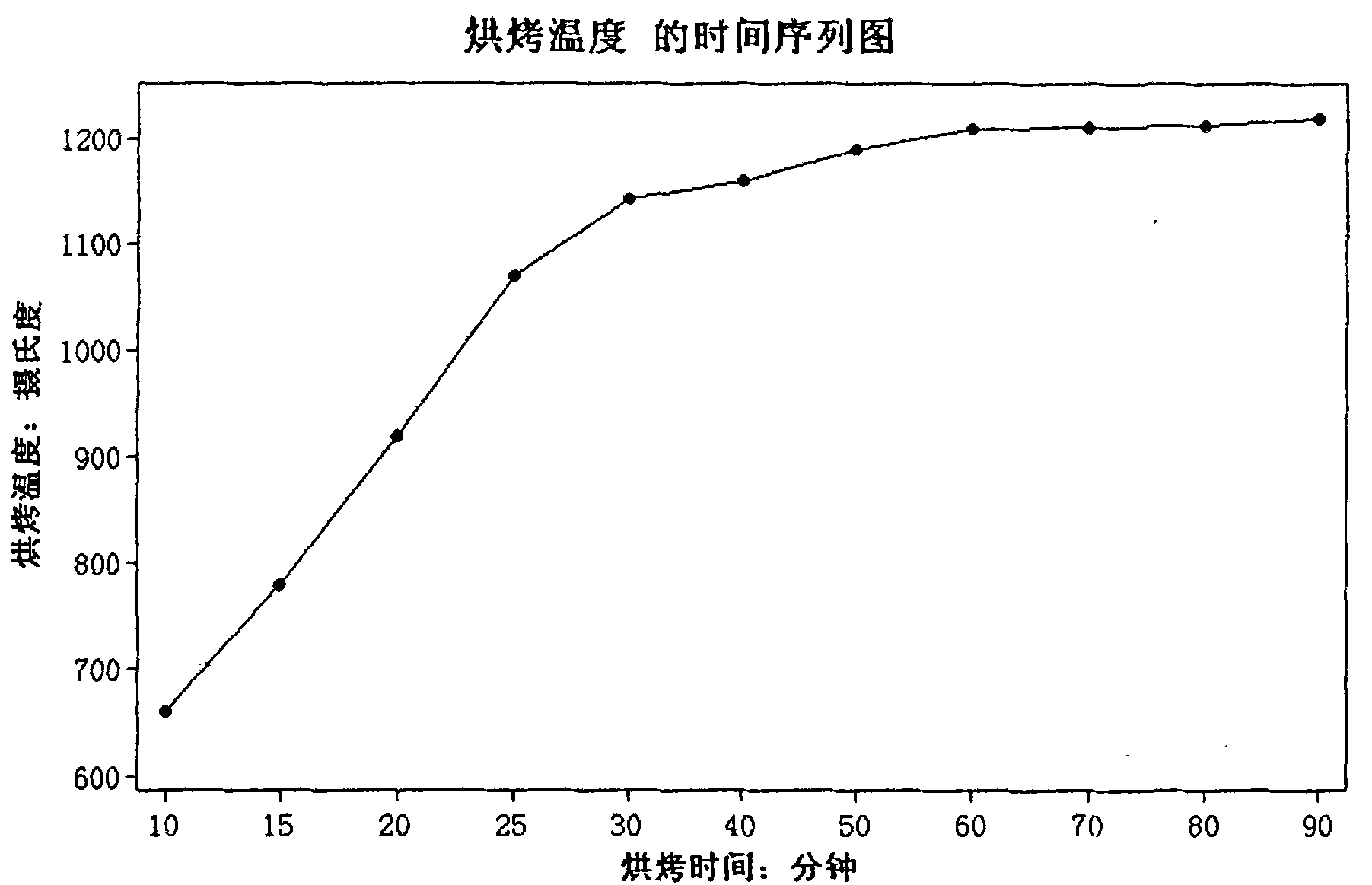

[0018] The present invention uses a baking device to seal the gap between the burner of the roaster and the tundish cover and the stopper hole before baking, and manually adjust the valve opening of the tundish roaster to: 25% to 35%, the combustion of gas in the tundish will generate a positive pressure of 0.3 to 1.5Mp, and the heat generated by the combustion will overflow from the upper nozzle and overflow groove of the double-flow tundish. After baking for 25 to 35 minutes, , the temperature inside the tundish can reach 1050-1150°C, then adjust the valve opening of the tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com