Air source heat pump type tobacco curing barn with auxiliary heat device

A technology of air source heat pump and flue-cured tobacco room, which is applied in the fields of tobacco, tobacco preparation, application, etc. It can solve the problems of low working efficiency of air heat source pump heating, roasted tobacco leaves, and the curing temperature cannot reach the set temperature, etc., to achieve guarantee Safe baking, guaranteed baking temperature, and improved baking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

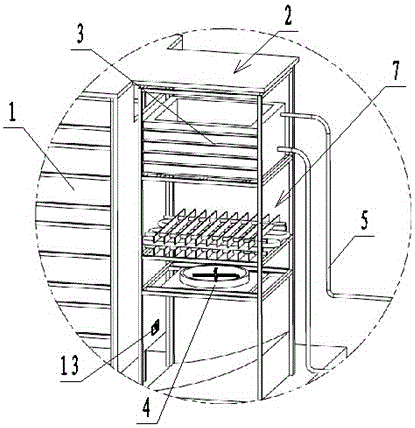

[0019] An air source heat pump type tobacco flue-curing room with auxiliary heating device, comprising a tobacco loading room 1 and a heating room 2 arranged at one end of the smoking room 1, a heat exchanger 3 is arranged on the inner cavity of the heating room 2, and a heat exchanger 3 is installed in the heating room An axial flow fan 4 is arranged in the middle of the inner cavity of 2, and the heat exchanger 3 is connected to an air source heat pump 6 through a pipe 5, and an electric heating device 7 is arranged between the heat exchanger 3 and the axial flow fan 4.

[0020] As a further improvement, the electric heating device 7 is connected with a current regulating device 11, and a temperature sensor 13 is provided at the lower part of the inner cavity of the heating chamber 2 close to the air inlet of the smoke chamber 1, and the temperature sensor 13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com