RH vacuum chamber baking system

A vacuum chamber and baking device technology, which is applied to casting melt containers, manufacturing tools, metal processing equipment, etc., can solve the problems of unfavorable temperature rise in the lower part of the vacuum chamber, difficulty in heating the lower part of the vacuum chamber, and the heating speed cannot be too fast. Avoid heat loss, shorten drying and baking time, and ensure baking speed and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

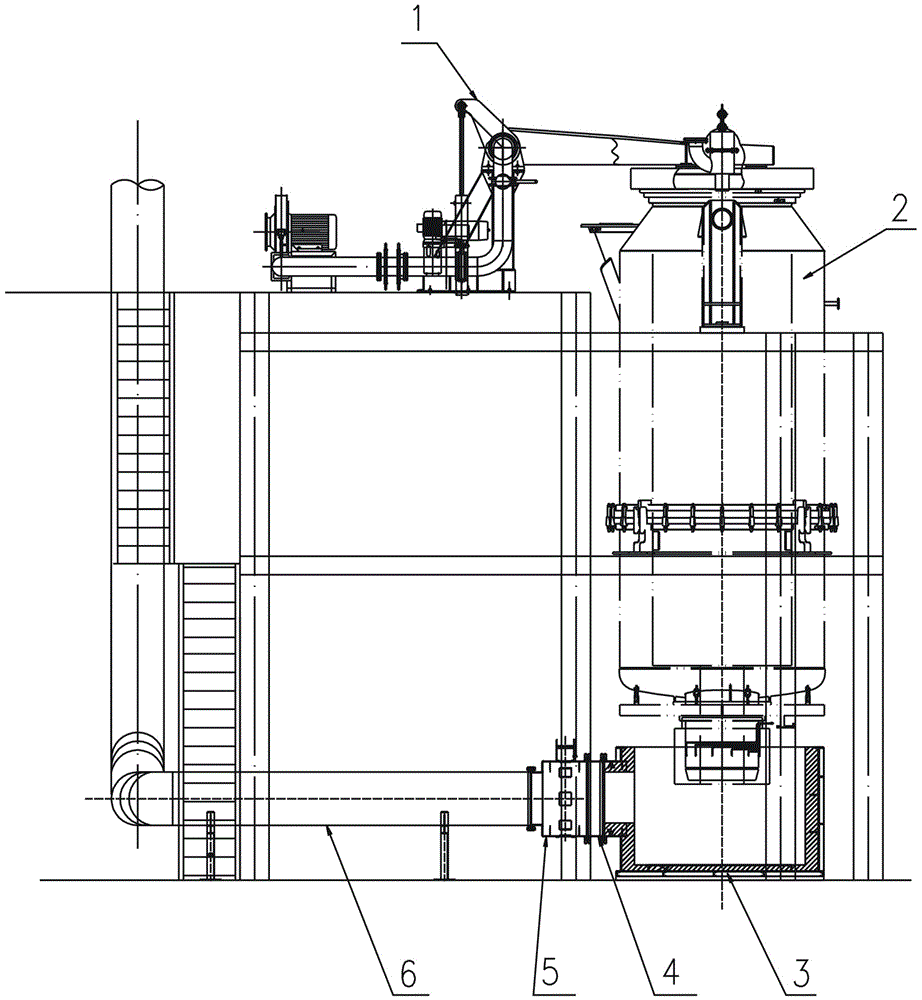

[0029] Such as figure 1 , 2 As shown, a RH vacuum chamber baking system includes a vacuum chamber baking device 1 and a vacuum chamber 2. A baking cover is arranged on the vacuum baking device 1. The cover plate is sealed with the upper part of the vacuum chamber. To prevent the baking heat from escaping. The lower part of the vacuum chamber insertion tube is sealed with the exhaust gas box 3, the exhaust gas box 3 is provided with an exhaust port, the exhaust port of the exhaust gas box 3 is connected with the air mixing device 5 through the control valve 4, and the air mixing device 5 is connected with the exhaust gas pipeline. 6 connections.

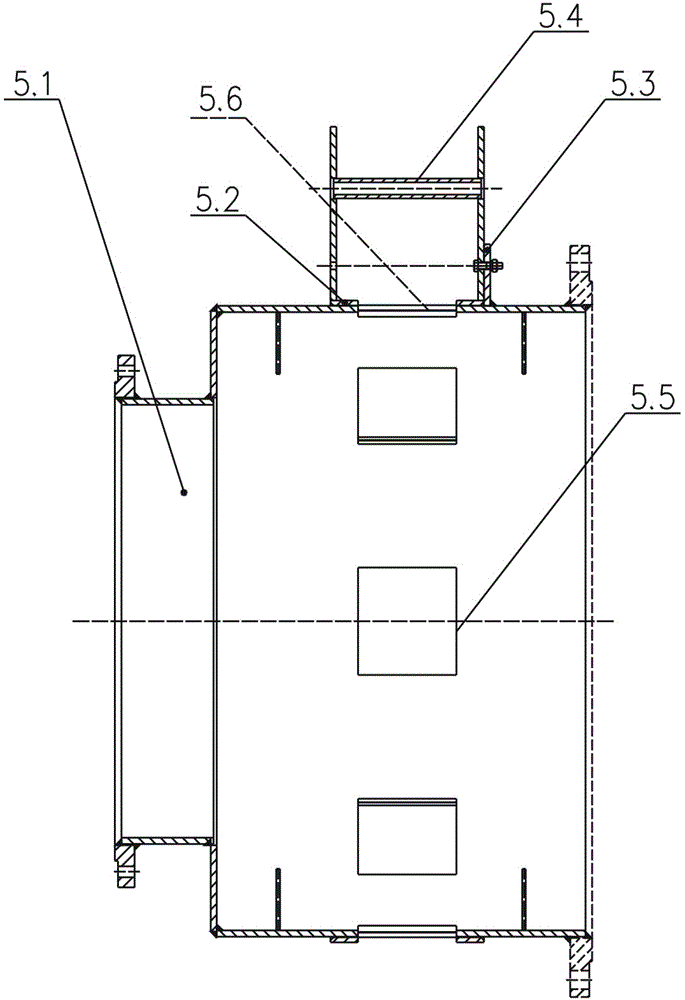

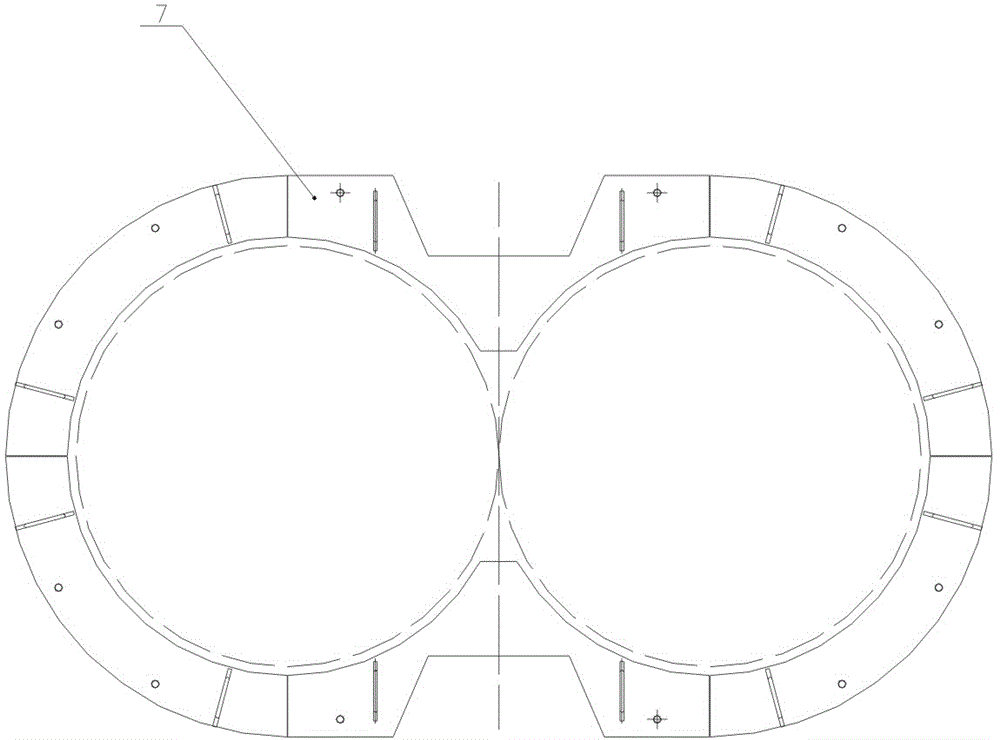

[0030] In this embodiment, the exhaust gas box is a fixed exhaust gas box, which includes a fixed exhaust gas box body and a cover plate 7. The fixed exhaust gas box body and the cover plate are respectively provided with refractory material linings. The structure diagram of the cover plate 7 is as follows image 3 shown. This kin...

Embodiment 2

[0037] Such as Figure 4 As shown, the structure of embodiment 2 is basically the same as that of embodiment 1. The difference lies in the structure of the exhaust gas box 3. Since the vacuum trolley can only make the vacuum chamber move in translation, in order to adapt to different working conditions on site, the exhaust gas box 3 can be designed Into a movable exhaust gas box to meet the needs of different working conditions. The exhaust gas box 3 in this embodiment comprises a left exhaust gas box 8 and a right exhaust gas box 9, the left and right exhaust gas boxes are symmetrically arranged, and when the left and right exhaust gas boxes are connected together, they are configured with the vacuum chamber insertion tube, Both sides of the exhaust gas box are provided with guide rails 10, and both sides of the left exhaust gas box 8 and the right exhaust gas box 9 are equipped with guide wheels to cooperate with the guide rails 10, so that the left exhaust gas box 8 and the...

Embodiment 3

[0040] Such as Figure 5 , 6 As shown, the structure of embodiment 3 is basically the same as that of embodiment 2, the difference lies in the structure of the exhaust gas box. The exhaust gas box includes an exhaust gas box 13 with a square opening on one side, a movable shutter 14 and a cover plate 7, and the movable shutter 14 is hinged to the bottom of the exhaust gas box 13 through a U-shaped hinge block 15, A cylinder 17 is arranged obliquely below the outside of the exhaust gas box 13, and the piston rod 16 of the cylinder is hinged to the outside of the movable shutter 14. By controlling the expansion and contraction of the piston rod 16, the opening of the exhaust gas box 13 and the movable shutter 14 The ends are merged into an exhaust gas box, and the cover plate 7 is sealed with the insertion tube of the vacuum chamber. The vacuum chamber baking system composed of the movable exhaust gas box can be set at the maintenance position or the standby position, and it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com