Preparation method of porous ceramic plate and high-precision ceramic porous platform

A technology of porous ceramic plates and ceramics, applied in ceramic products, applications, household appliances, etc., can solve the problems of broken, material bending, large hole diameter, etc., and achieve the effect of preventing bending and breaking, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

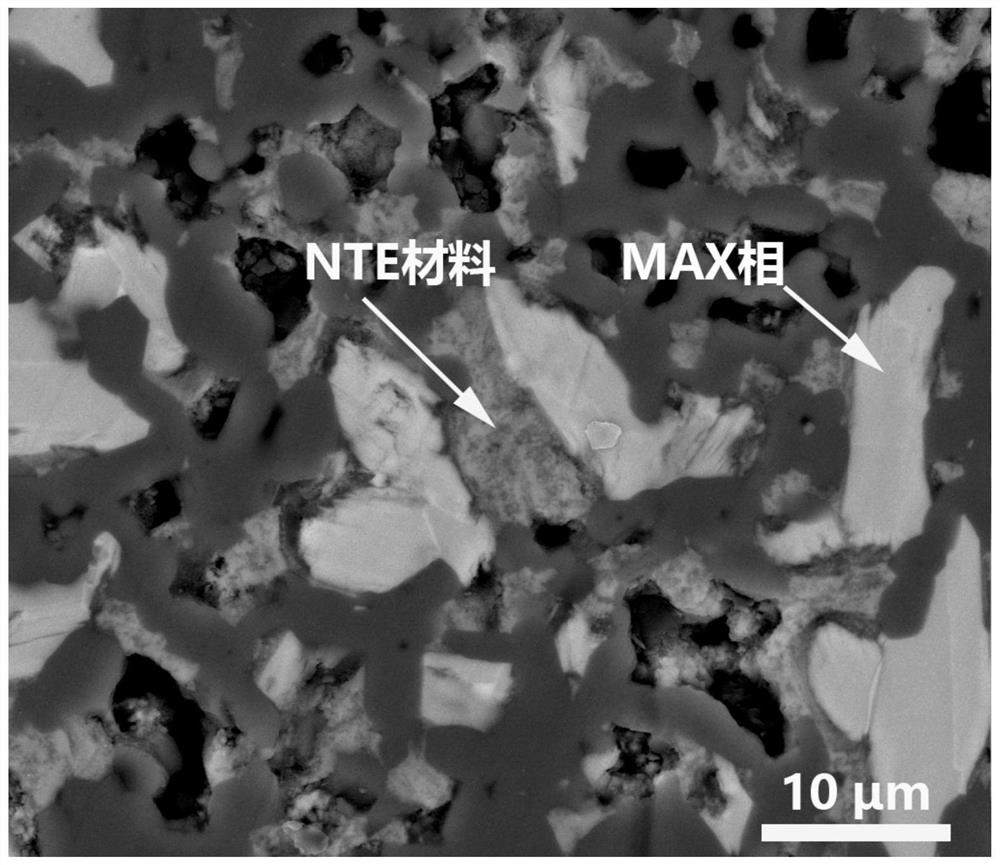

[0036] S1, based on alumina, MAX phase ceramic Ti 3 AlC 2 Powder and Zr(P 1-x V x ) 2 o 7 The raw materials are mixed according to the molar ratio of 60:20:20 to obtain the mixed material, and the mixed material is sieved to control the particle size of the mixed material between 2 μm and 75 μm;

[0037] S2. Under stirring conditions, mix the mixed material with PVB (polyvinyl butyral) in a ratio of 60:40 and put them into a roller mill for grinding and mixing. The grinding and mixing time is 1 to 12 hours to obtain a mixed material

[0038] S3, put the mixture into a mold, the mold can be made of graphite material, its shape is square or round, the mold is placed in a one-way press for pre-compression, the pre-compression pressure is 50-100 Between MPa, hold the pressure for 1 to 5 minutes, press and form to obtain a green body;

[0039] S4, at a temperature of 300 o C, the holding time is 2 hours, and the heating rate is 1 o Under the condition of C / min, the green bo...

Embodiment 2

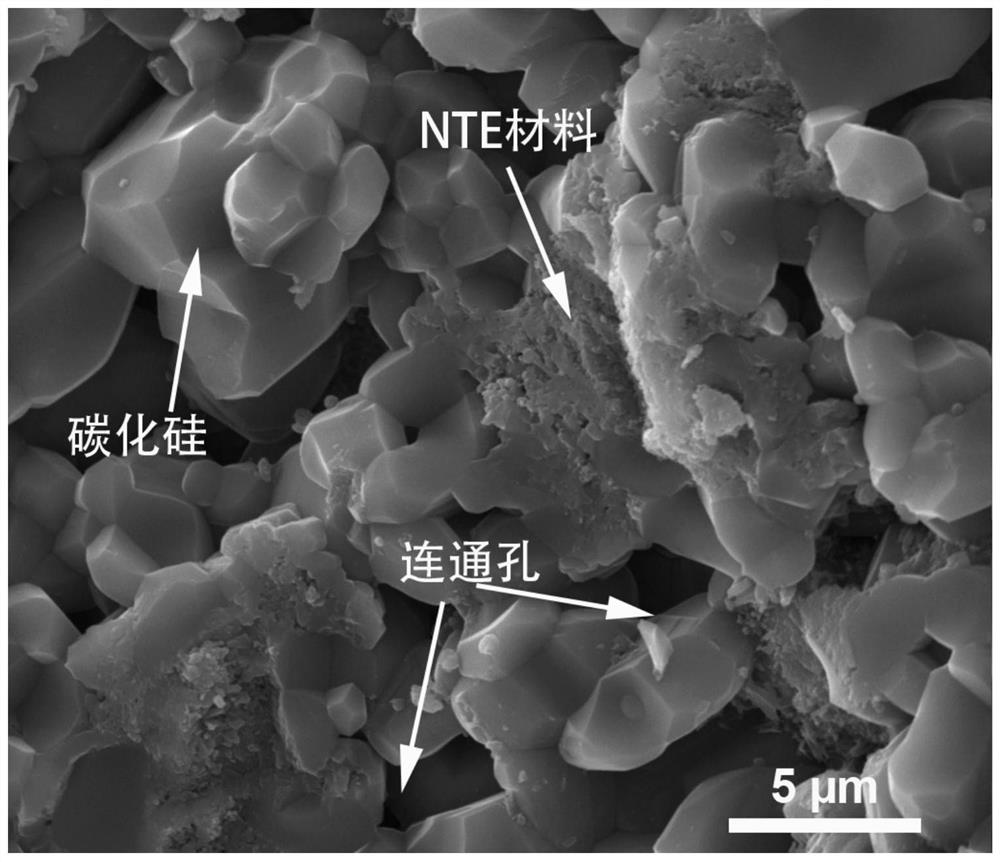

[0043] S1, based on silicon carbide, MAX phase ceramic Ti 3 AlC 2 Powder and (Zr, Hf)W 2 o 8 The raw materials are mixed according to the molar ratio of 80:10:10 to obtain the mixed material, and the mixed material is sieved to control the particle size of the mixed material between 2 μm and 75 μm;

[0044] S2, under stirring conditions, mix the mixed material with PMMA (methyl methacrylate) in a ratio of 50:50 and put them into a roller mill for grinding and mixing, and the grinding and mixing time is 1 to 12 hours to obtain the mixed material;

[0045] S3, put the mixture into a mold, the mold can be made of graphite material, its shape is square or round, the mold is placed in a one-way press for pre-compression, the pre-compression pressure is 50-100 Between MPa, hold the pressure for 1 to 5 minutes, press and form to obtain a green body;

[0046] S4, at a temperature of 500 o C, the holding time is 2 hours, and the heating rate is 1 o Under the condition of C / min, t...

Embodiment 3

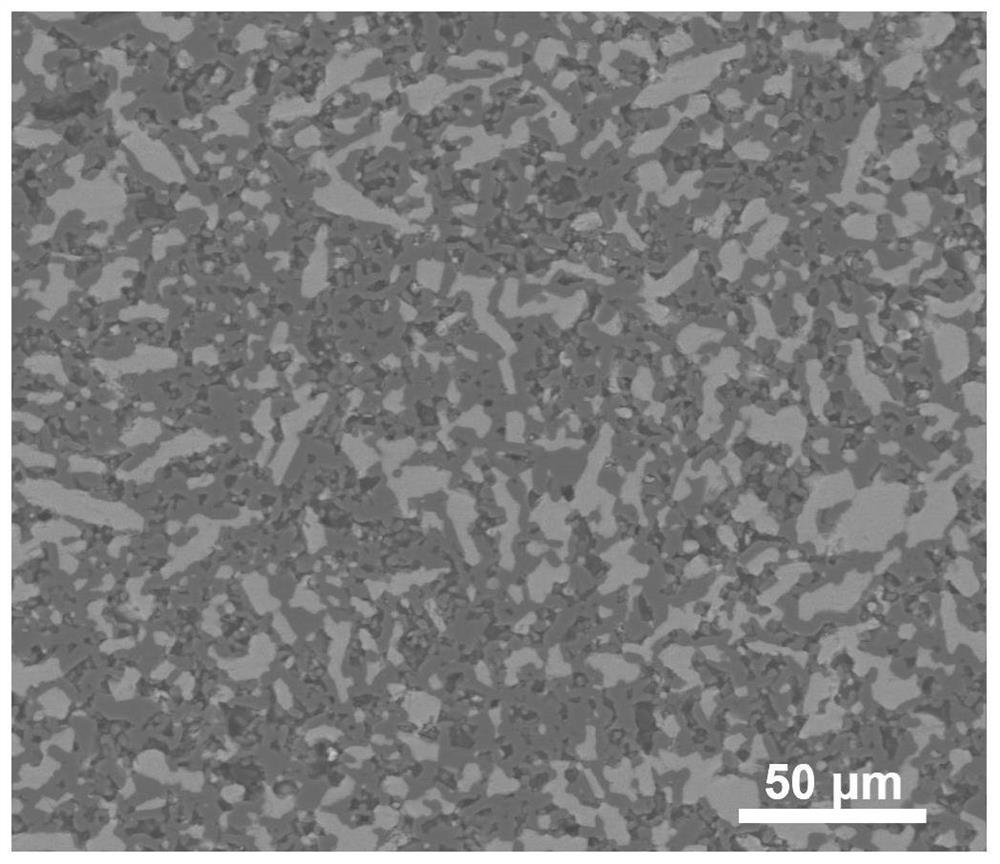

[0050] Cordierite, MAX phase ceramic Ti 3 AlC 2 Powder and Zr(P 1-x V x ) 2 o 7 The raw materials are mixed according to the molar ratio of 40:35:25 to obtain the mixed material, and the mixed material is sieved to control the particle size of the mixed material between 2 μm and 75 μm;

[0051] S2, under stirring conditions, mix the mixed material with PVB (polyvinyl butyral) in a ratio of 70:30 and put them into a roller ball mill for grinding and mixing, and the grinding and mixing time is 1 to 12 hours to obtain the mixed material;

[0052] S3, put the mixture into a mold, the mold can be made of graphite material, its shape is square or round, the mold is placed in a one-way press for pre-compression, the pre-compression pressure is 50-100 Between MPa, hold the pressure for 1 to 5 minutes, press and form to obtain a green body;

[0053] S4, at a temperature of 300 o C, the holding time is 2 hours, and the heating rate is 1 o Under the condition of C / min, the green ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com