Blended yarn bleaching equipment

A technology of blended yarn and equipment, applied in the field of blended yarn bleaching equipment, can solve the problems of low efficiency of blended yarn bleaching process, and achieve the effects of improving energy utilization rate, increasing conveying distance, and increasing contact effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

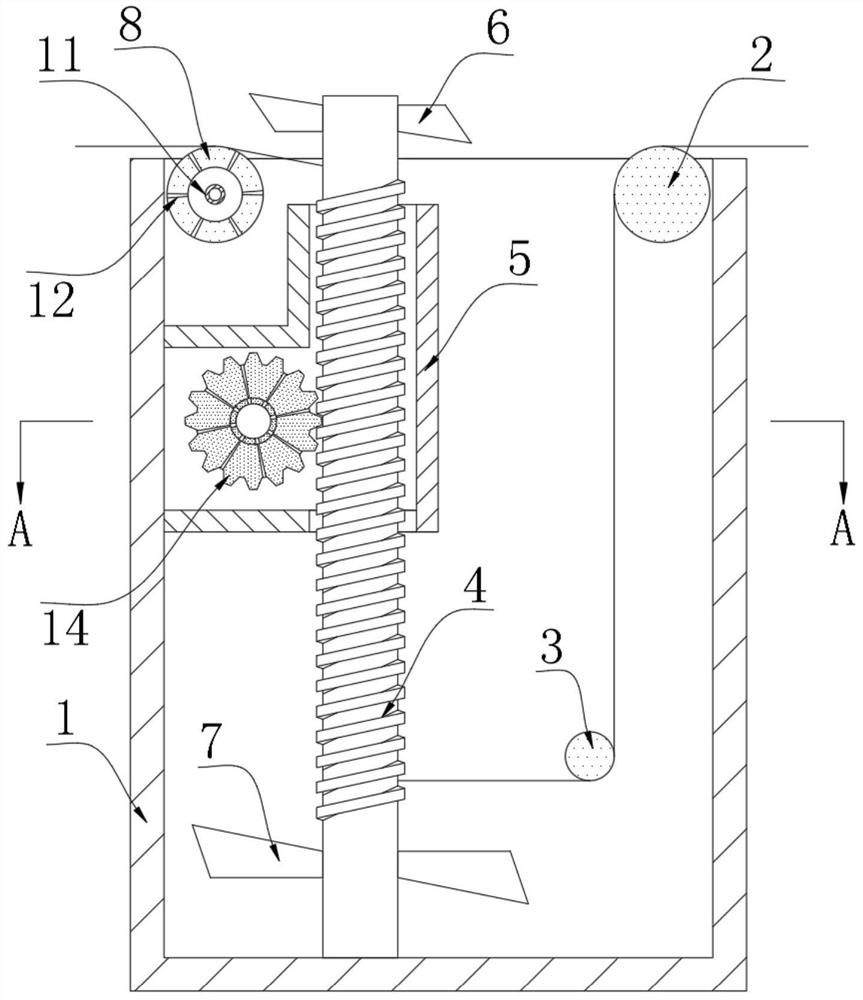

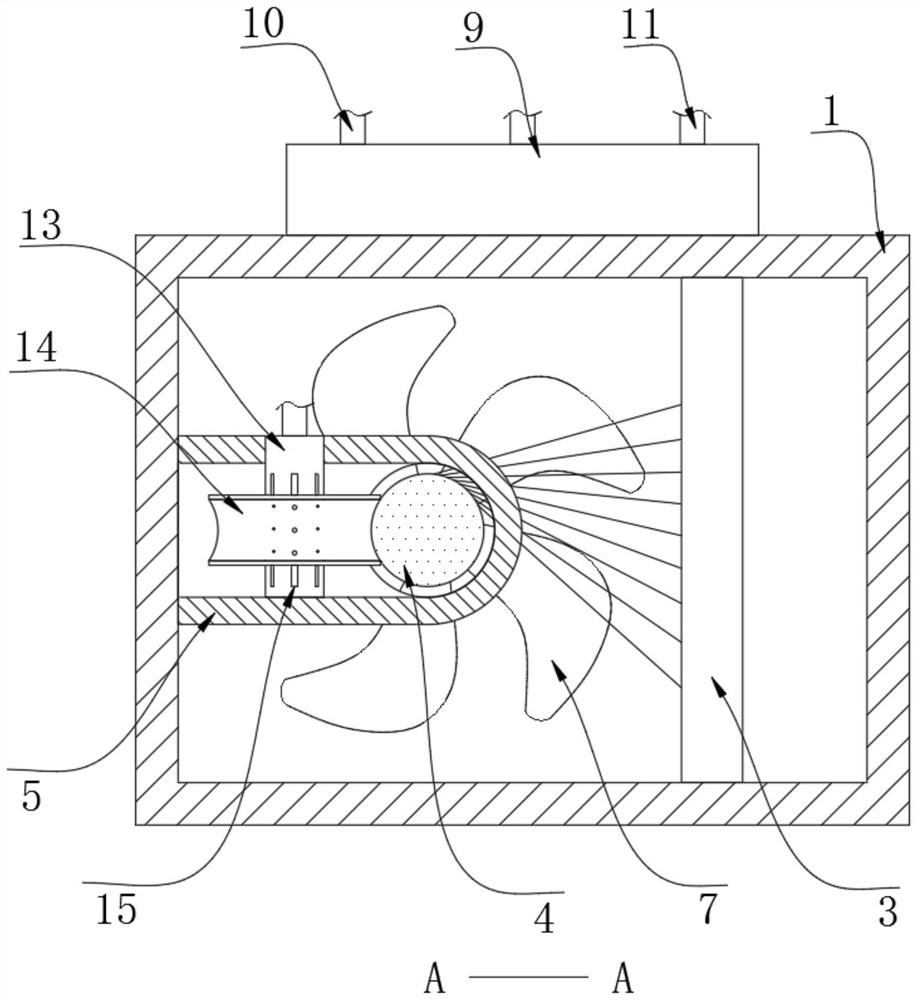

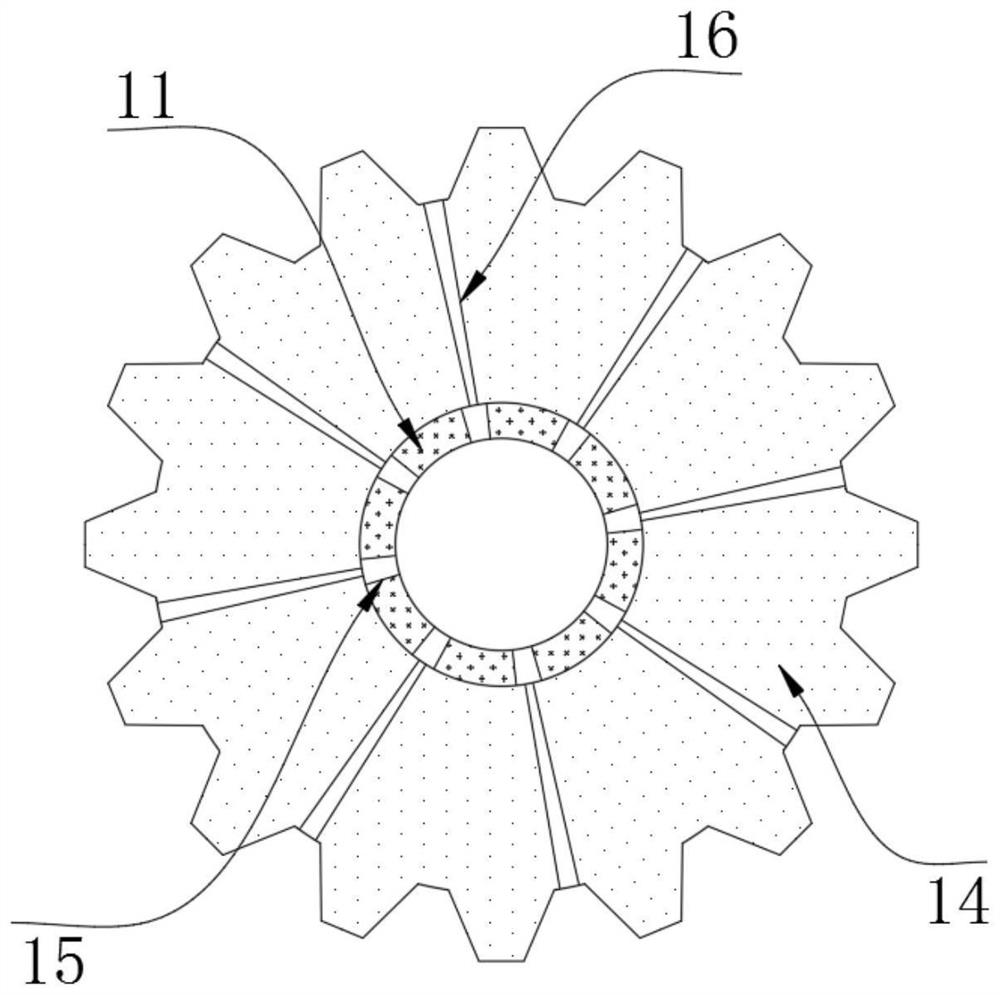

[0020] refer to Figure 1-3 , a blended yarn bleaching equipment, comprising a treatment box 1, the inner wall of the treatment box 1 is rotatably connected with an input roller 2 and a guide roller 3, the inner bottom of the treatment box 1 is rotatably connected with a worm 4, and the upper circumferential side wall of the worm 4 A rotating blade 6 is fixed, and a stirring blade 7 is fixed on the lower peripheral side wall of the worm 4. The stirring blade 7 rotates with the worm 4 to stir and pump the bleaching solution upwards, so that the bleaching solution will not settle and the yarn can be impact, improve the bleaching effect, the inner wall of the treatment box 1 is rotatably connected with the output roller 8 and the drying box 5, the worm 4 runs through the drying box 5, the outer wall of the treatment box 1 is fixed with a vortex tube 9, and the hot and cold outlets of the vortex tube 9 are respectively connected with The cold flow pipe 11 and the heat flow pipe 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com