Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Easy soldering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

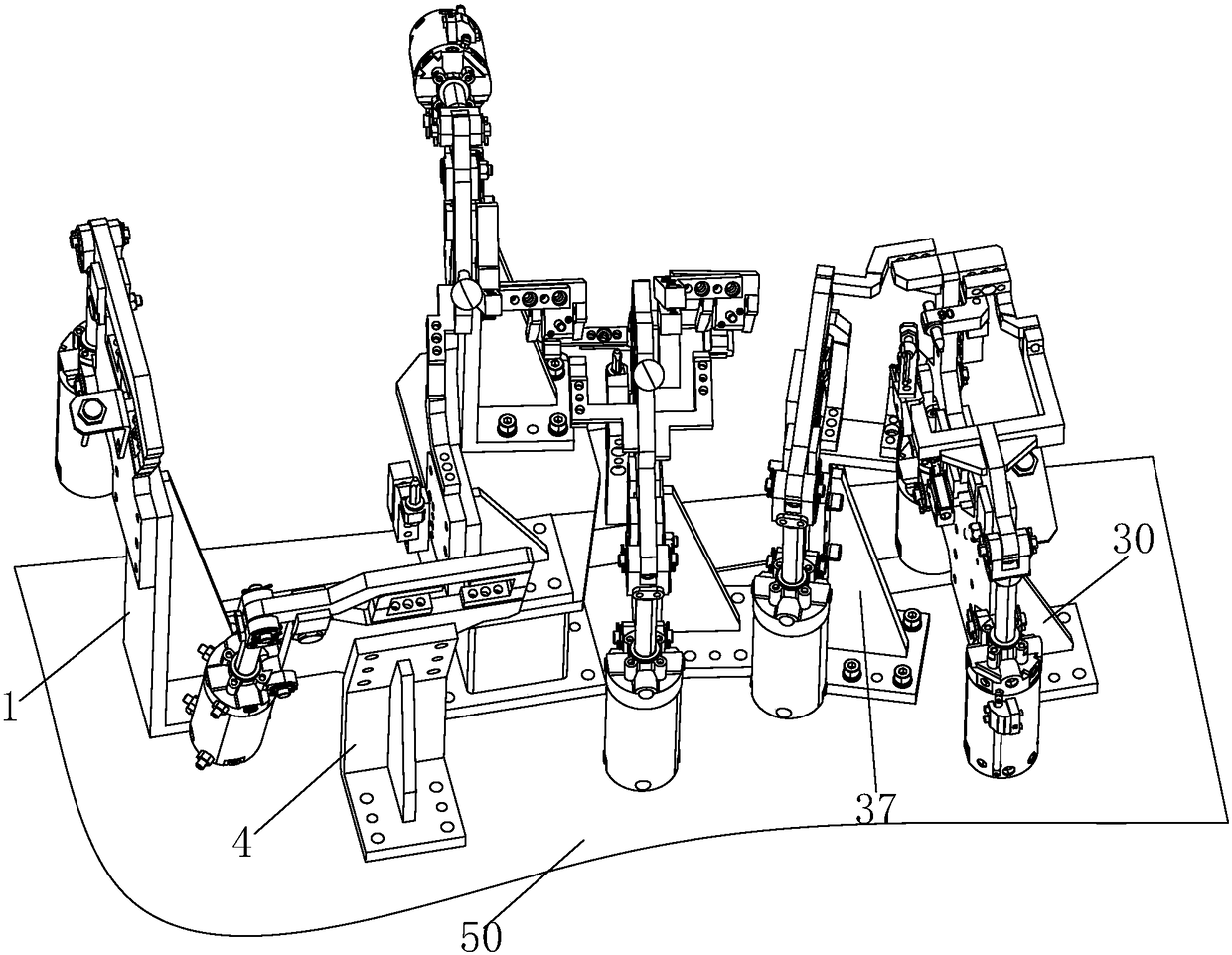

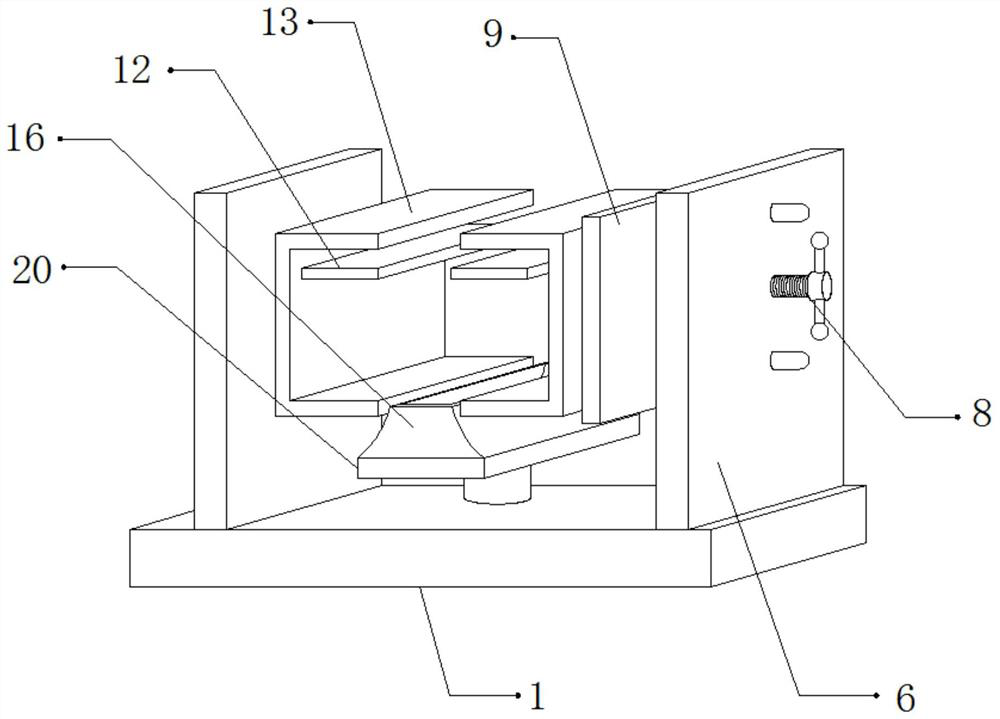

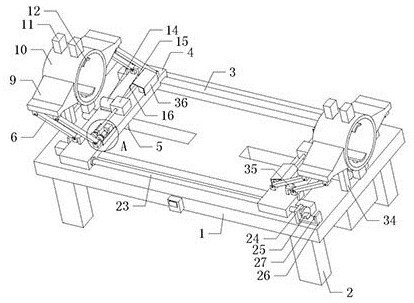

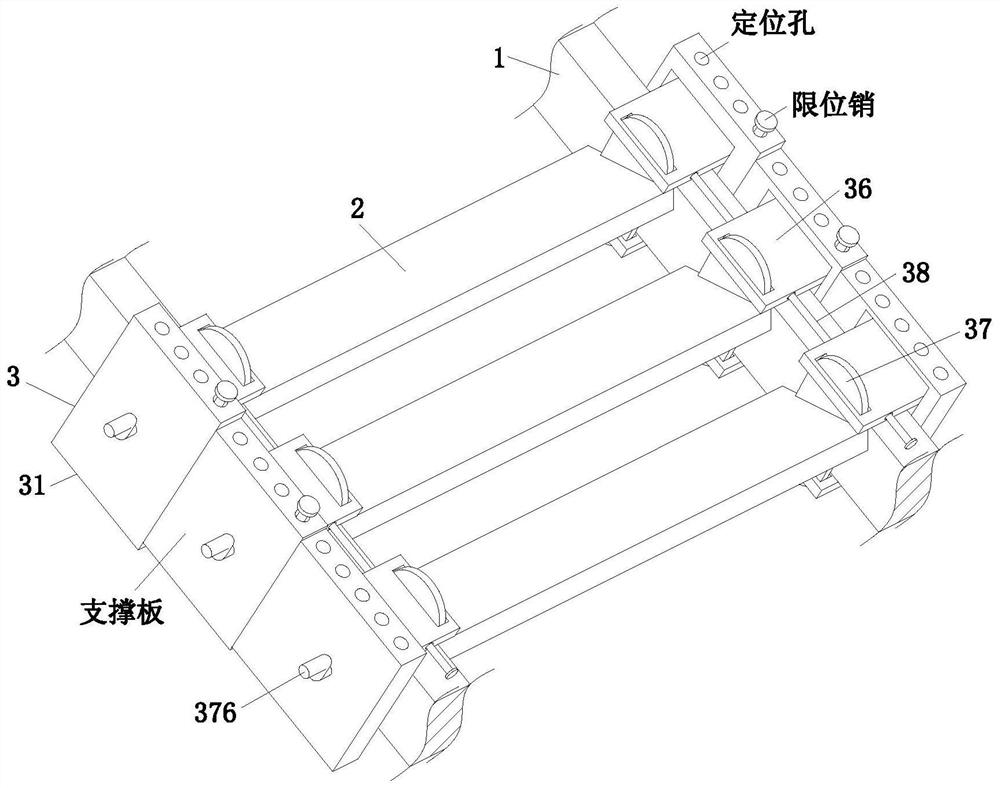

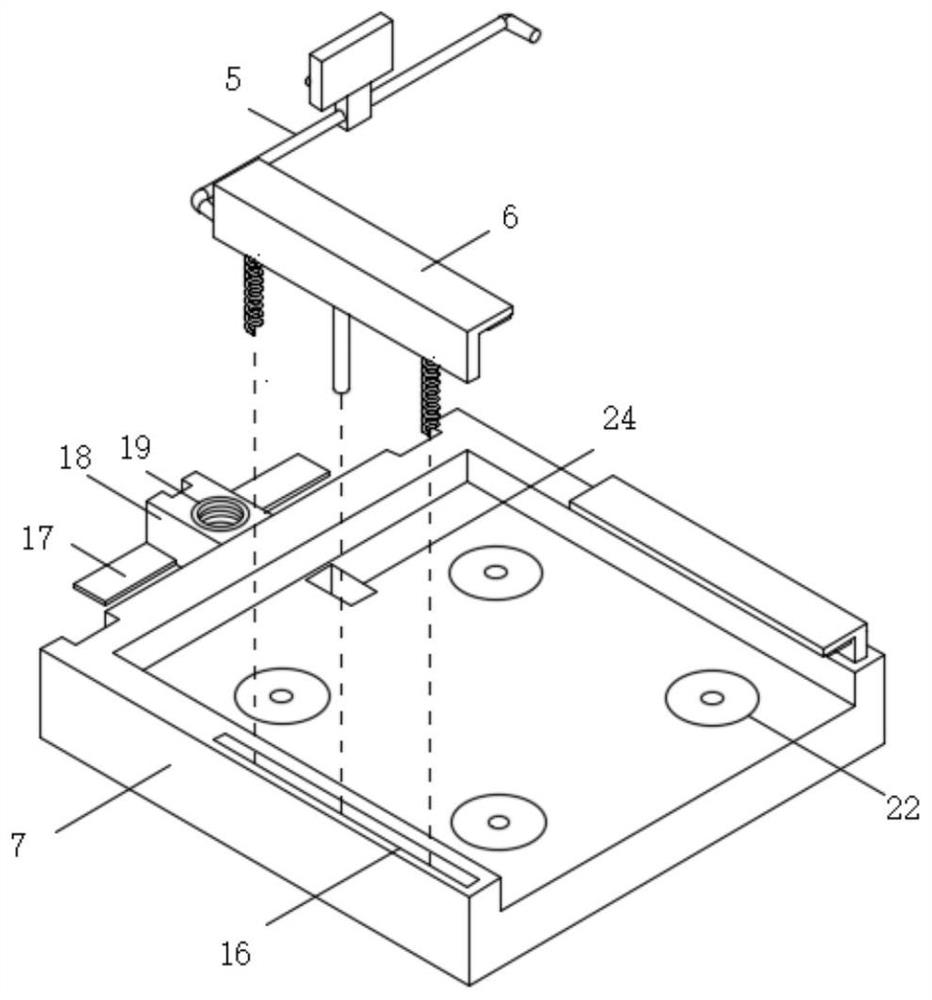

Middle combined clamping tool for welding front assemblies of inner plates of left and right side walls of automobile

InactiveCN108080870AGuaranteed accuracyEasy solderingWelding/cutting auxillary devicesAuxillary welding devicesRelative precisionMachining

The invention relates to a middle combined clamping tool for welding front assemblies of inner plates of left and right side walls of an automobile. The middle combined clamping tool for welding frontassemblies of inner plates of left and right side walls of the automobile comprises a middle supporting device, a side plate supporting device, a middle accessory positioning and pressing device anda right accessory positioning and pressing device; and the middle accessory positioning and pressing device and the right accessory positioning and pressing device are successively distributed on theright side of the middle supporting device. The middle complicated structures of the front assemblies of the inner plates of the left and right side walls of the automobile are designed specially, bythe tool, all components involved in the middle can be clamped and positioned, relative precision of the various components is ensured, the space utilization rate is high, and the production and manufacturing cost is reduced. In addition, automated welding treatment of an external welding robot is facilitated, the production efficiency and the quality of products are greatly improved, the degree of automation is high, and batched production and machining are realized favorably.

Owner:ANHUI DACHANG TECH

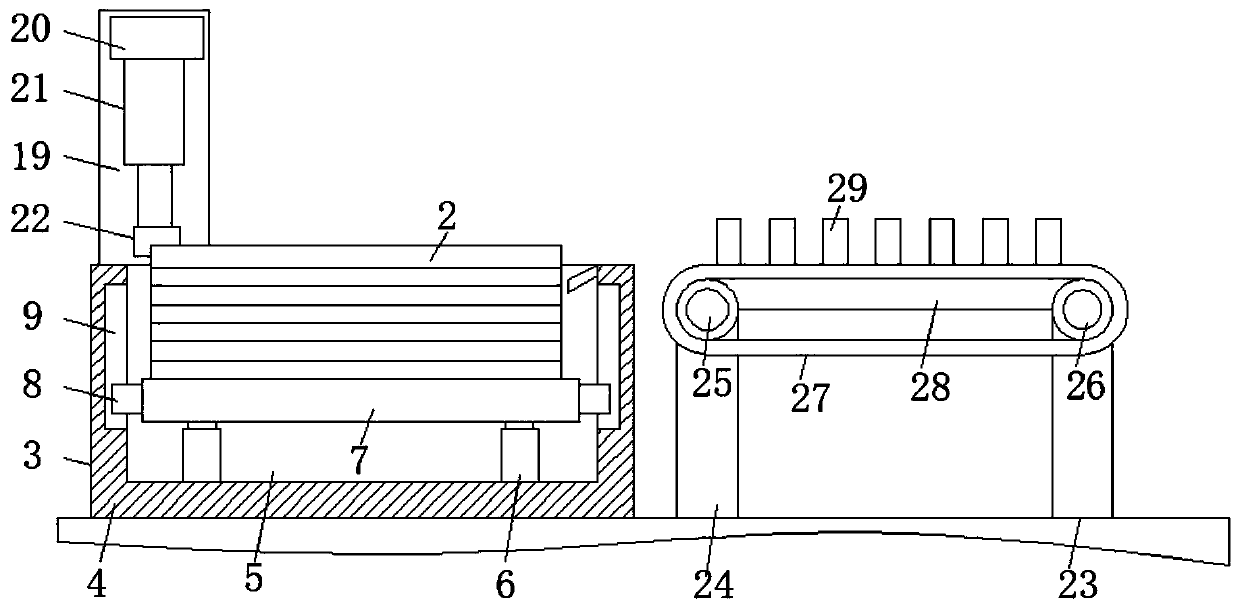

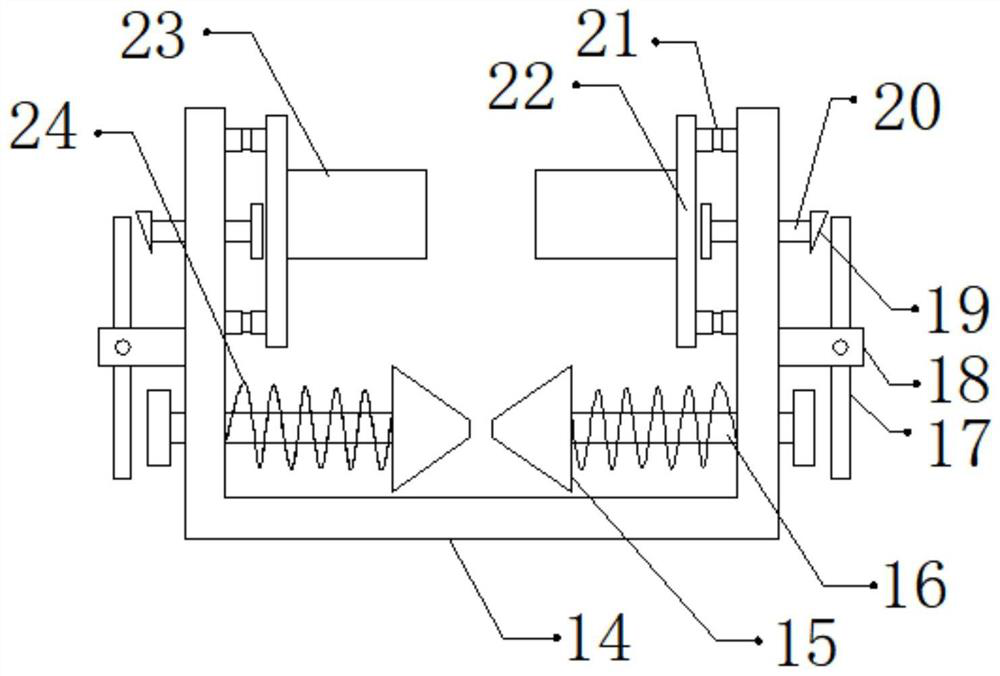

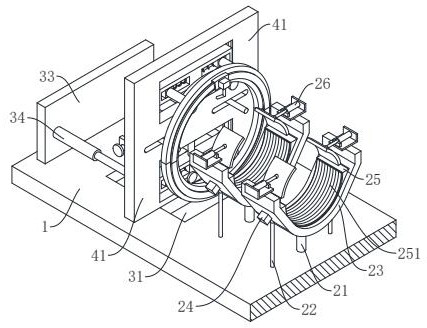

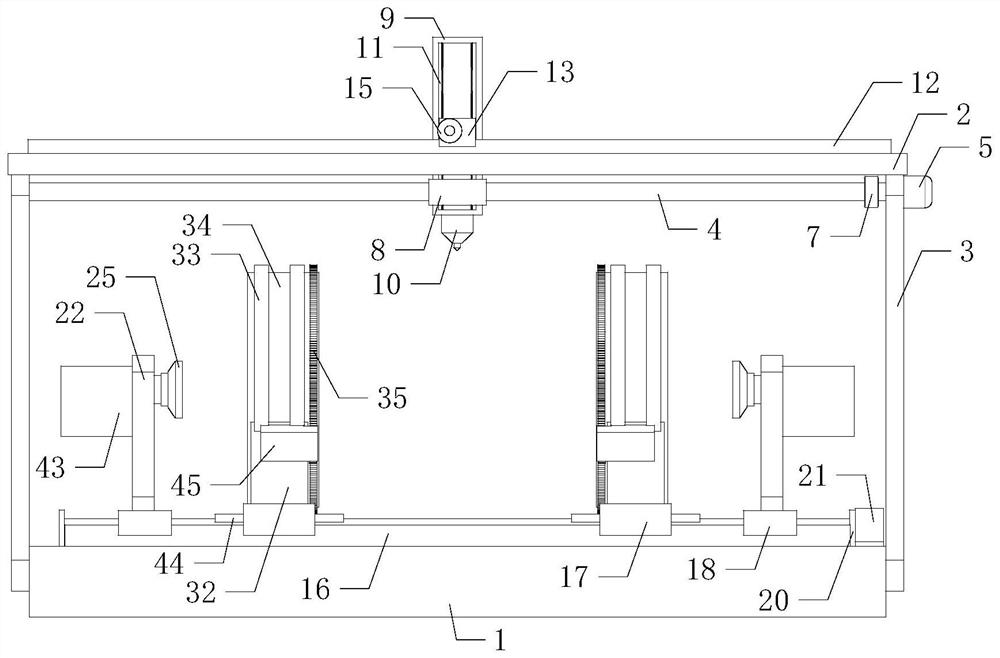

Alignment assembly machine and alignment assembly process for manufacturing pipe truss steel structure

InactiveCN111644783ASolve assembly difficultiesEasy solderingWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingIndustrial engineering

The invention relates to an alignment assembly machine and alignment assembly process for manufacturing pipe truss steel structure. The pipe truss steel structure manufacturing alignment assembly machine comprises a fixed base, a conveying device, pushing frames and a feeding device, the conveying device is arranged in the middle of the upper portion of the fixed base, the pushing frames are symmetrically installed at the front end and the rear end of the fixed base in a sliding fit mode, and the feeding device is arranged at the right end of the fixed base. The problems that when a traditional pipe truss steel structure is manufactured, a steel structure pipe truss is generally welded in a manual welding mode, generally, a longitudinal installation pipe is locked and fixed manually, thena transverse pipe is positioned and fixed to the longitudinal installation pipe, and therefore the longitudinal installation pipe and the transverse pipe are welded together; only one transverse connecting pipe can be manually welded at a time, the positioning and fixing process of the transverse connecting pipe is tedious during welding, equidistant synchronous fixing is needed, and therefore theproductivity of the steel structure pipe truss is low.

Owner:熊美俊

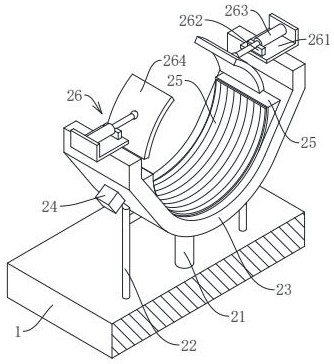

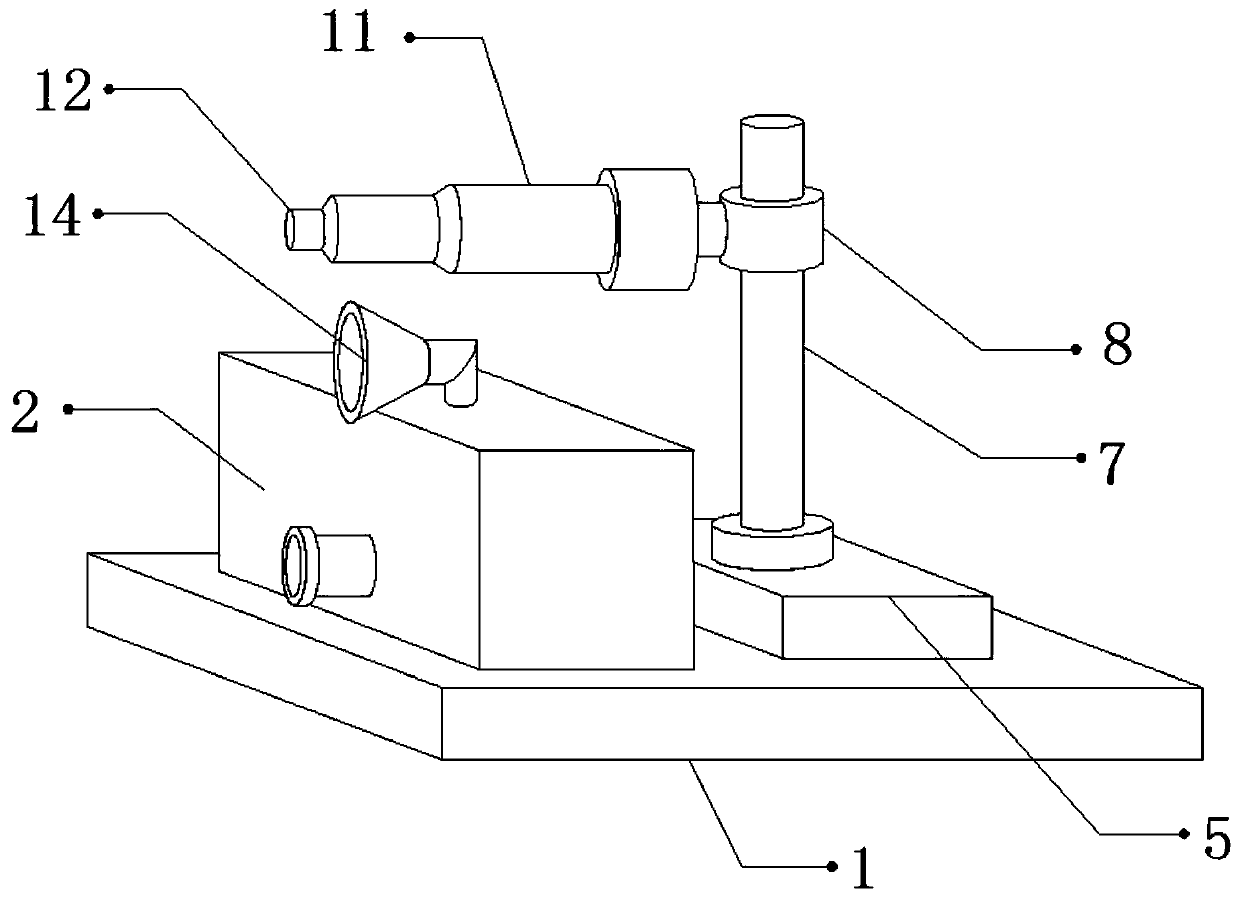

Automatic workpiece welding equipment and using method thereof

InactiveCN112453770AGuaranteed stabilityEasy solderingWelding/cutting auxillary devicesAuxillary welding devicesScrew threadBevel gear

The invention relates to the technical field of welding equipment, and discloses automatic workpiece welding equipment and a using method thereof. The automatic workpiece welding equipment comprises abase, a two-way threaded rod is rotationally mounted in the base, two clamping rods are in threaded connection with the outer side of the two-way threaded rod, the bottom ends of the two clamping rods are slidably mounted on the inner wall of the bottom of the base, the top ends of the two clamping rods extend to the outer side of the base, threaded rods are rotatably mounted on the two sides ofthe top of the base, the bottom ends of the two threaded rods extend into the base, four first bevel gears are rotatably mounted in the base, and the two first bevel gears on the same side in the fourfirst bevel gears are engaged with each other. The automatic workpiece welding equipment is reasonable in design, the horizontal adjusting function can be conducted on a welding device, and thereforewelding treatment is conducted on different positions, then, through an arranged rotating wheel, a spray head can swing in a reciprocating arc shape, and therefore the cooling efficiency of workpieces is improved.

Owner:合肥华赞自动化科技有限公司

Production technology of pole lug of lithium ion battery with high sealing property and electrolyte leakage preventing effect

ActiveCN108134042AImprove welding effectImprove adhesionSecondary cellsCell component detailsElectrical conductorSodium-ion battery

The invention discloses a production technology of a pole lug of a lithium ion battery with high sealing property and electrolyte leakage preventing effect. The production technology comprises the following steps A to H: performing bright rolling and matt rolling on substrate metal material, and electrochemical polishing and passivating; cleaning and drying; cutting the rolled strip-shaped metal conductor into segments; cleaning by ultrasonic waves, and drying; using deionized water to treat, and drying; finally, adhering a strip-shaped macromolecular insulation film onto the section shape metal conductor. The pole lug of the lithium ion battery produced by the production technology has the advantages that because the surface roughness of the metal conductor is increased, the effective contact area between the metal conductor and the macromolecular insulation film is increased, the adhesion force is effectively increased, the metal conductor and the macromolecular insulation film can be more stably adhered, the sealing property of a battery cell is improved, and the welding property of the metal conductor is improved; the surface activity of the metal conductor is reduced, the electrolyte erosion-resistant ability is enhanced, the sealing property of the battery cell is further improved, and the electrolyte leakage of the lithium ion battery is prevented.

Owner:赣州市中金高能电池材料股份有限公司

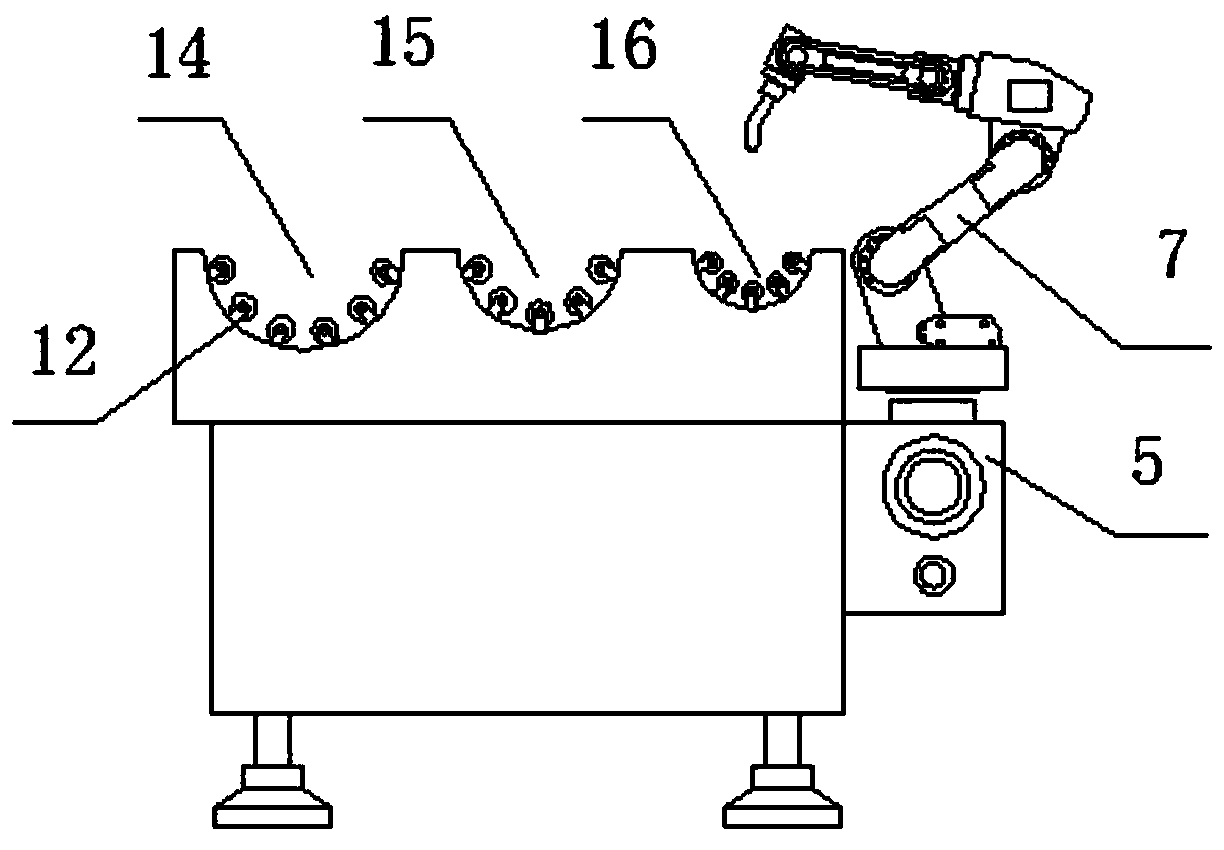

Robot welding production line

InactiveCN110369917AGood positioning effectImprove efficiencyWelding/cutting auxillary devicesAuxillary welding devicesSteel tubeIndustrial engineering

The invention discloses a robot welding production line. The robot welding production line comprises a machine frame; a steel tube welding table is arranged on the upper side of the machine frame; a first clamping groove, a second clamping groove and a third clamping groove are formed in the upper side of the steel tube welding table; a screw rod is arranged on one side of the machine frame and isconnected to a sliding base in a threaded mode; a welding robot is arranged on the upper side of the sliding base through a rotating base; an electric welding head is arranged at one end of the welding robot; a PLC control cabinet is arranged at one end of the machine frame; and the input end of the welding robot is electrically connected to the output end of the PLC control cabinet. According tothe robot welding production line, through the first clamping groove, the second clamping groove and the third clamping groove, the steel tube can be clamped and placed, welding treatment can be carried out on the steel tube through the welding robot, the positioning effect on the steel tube is good, and therefore the welding efficiency can be improved.

Owner:中山博思德自动化设备有限公司

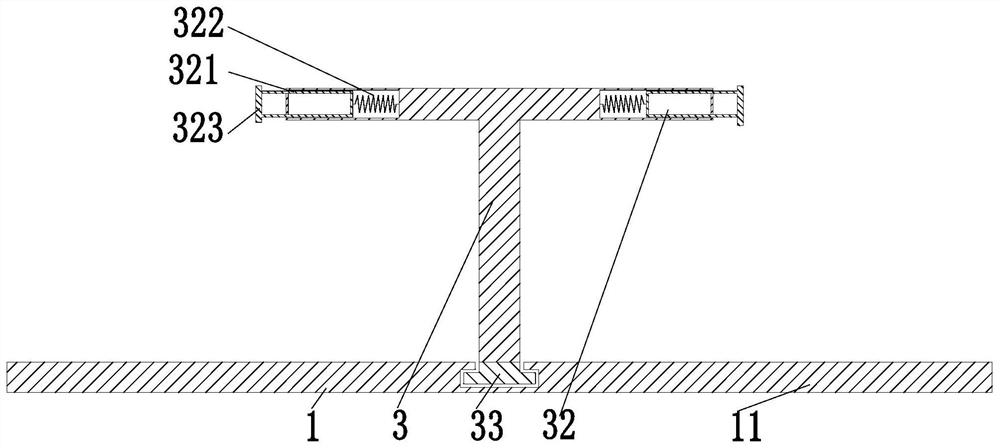

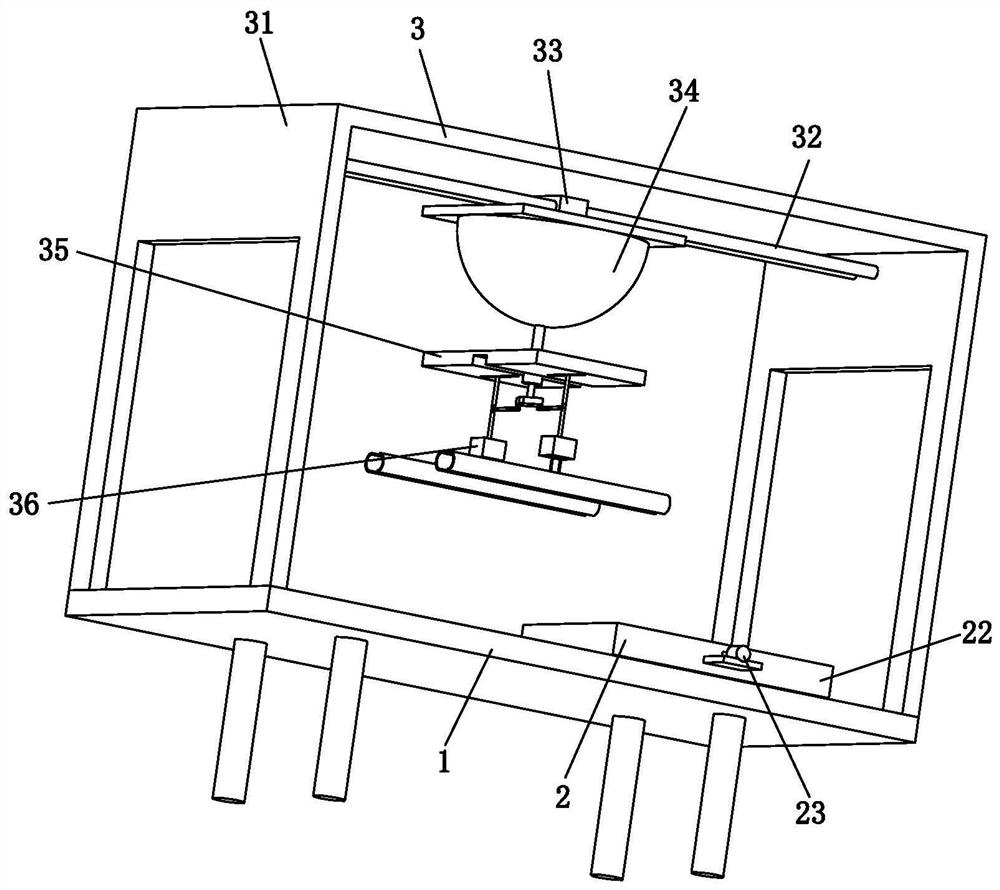

Welding forming auxiliary tool system for building construction PC embedded parts

InactiveCN113231767AGood fixed effectReduce manpower inputWelding/cutting auxillary devicesAuxillary welding devicesProcess engineeringManufacturing engineering

The invention relates to a welding forming auxiliary tool system for building construction PC embedded parts. The auxiliary tool system comprises a workbench, a conveying device and an alignment device. The system can solve the following problems possibly occurring in the welding process of existing building construction PC embedded parts: a, embedded part components are manually supported and fixed so as to complete the welding process between the embedded part components, the mode can be carried out only through cooperation of multiple persons, the welding efficiency is low, the production efficiency of enterprises is low, and thus the income of an enterprise is reduced; and b, the number of the embedded part components which are manually supported at a time is small, the fixing effect is poor, and the embedded part components are prone to shaking due to manual reasons in the welding process, so that the welding quality is affected, and the finished product quality of the building construction PC embedded parts is reduced.

Owner:武汉星润装饰工程有限公司

Feeding mechanism used for welding of plates of engineering machine

PendingCN110789989AAvoid damageImprove stabilityConveyorsWelding/cutting auxillary devicesEngineeringMachine

The invention discloses a feeding mechanism used for welding of plates of an engineering machine, and relates to the technical field of engineering machines. The feeding mechanism comprises an operation table, plate bodies, a storage and taking device, a pushing device and a transfer device. The bottom of the storage and taking device and the upper surface of the operation table are fixedly mounted. The plate bodies are located in the storage and taking device. The pushing device and the upper surface of the operation table are fixedly mounted. Through the arrangement of the pushing device andthe transfer device, the pushing device can drive the plate bodies to shift from the storage and taking device to be finally in contact with the transfer device, the plates pushed from the pushing device can be transferred through the transfer device, and therefore the plate bodies are stably transferred to the place waiting for machining, and subsequent welding treatment is facilitated; and in the whole process, manual carrying is not needed any more, the situation that the plates are damaged is avoided, and the advantages that stability of plate feeding is improved and meanwhile feeding efficiency is improved are achieved.

Owner:苏州陈泰利金属科技有限公司

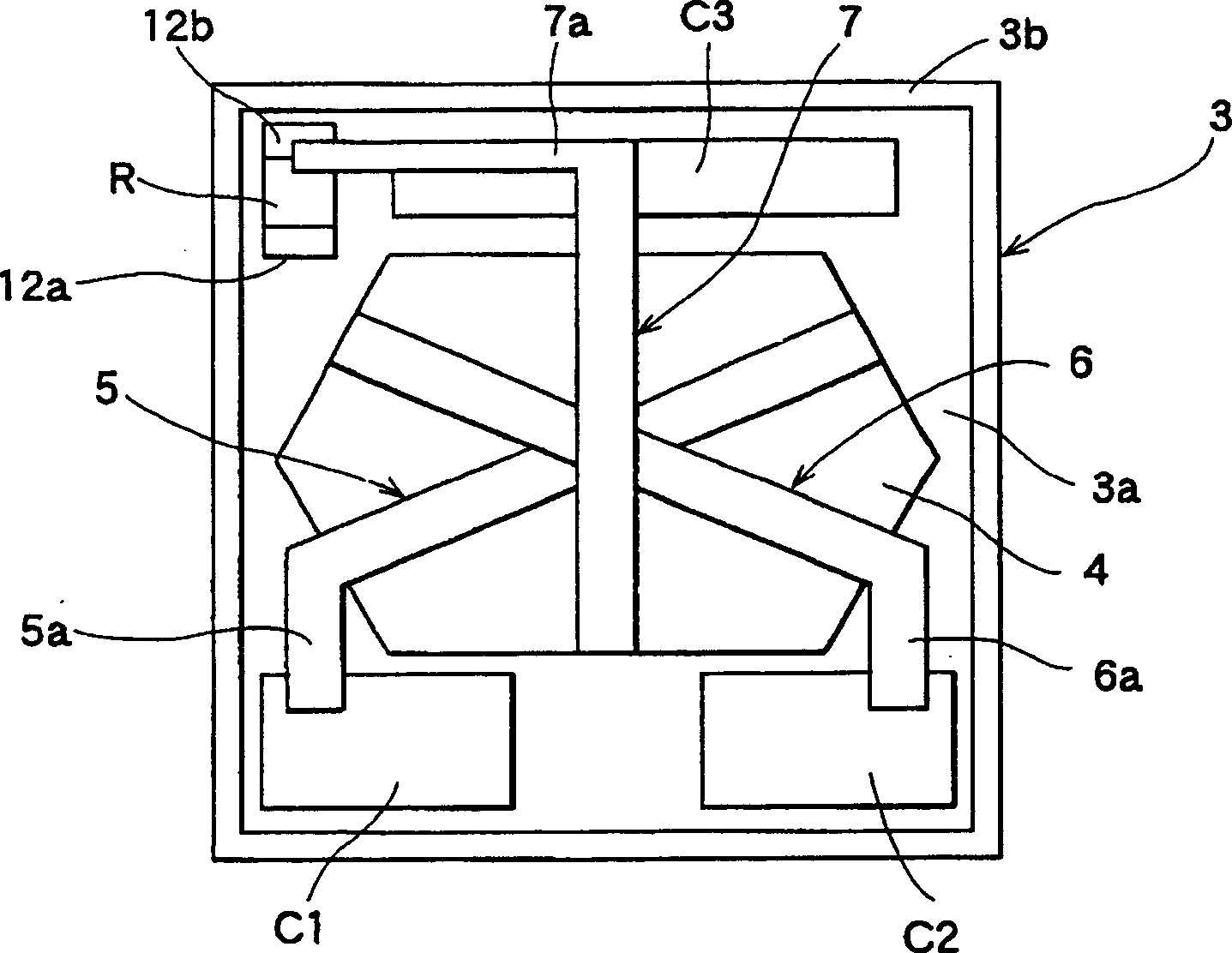

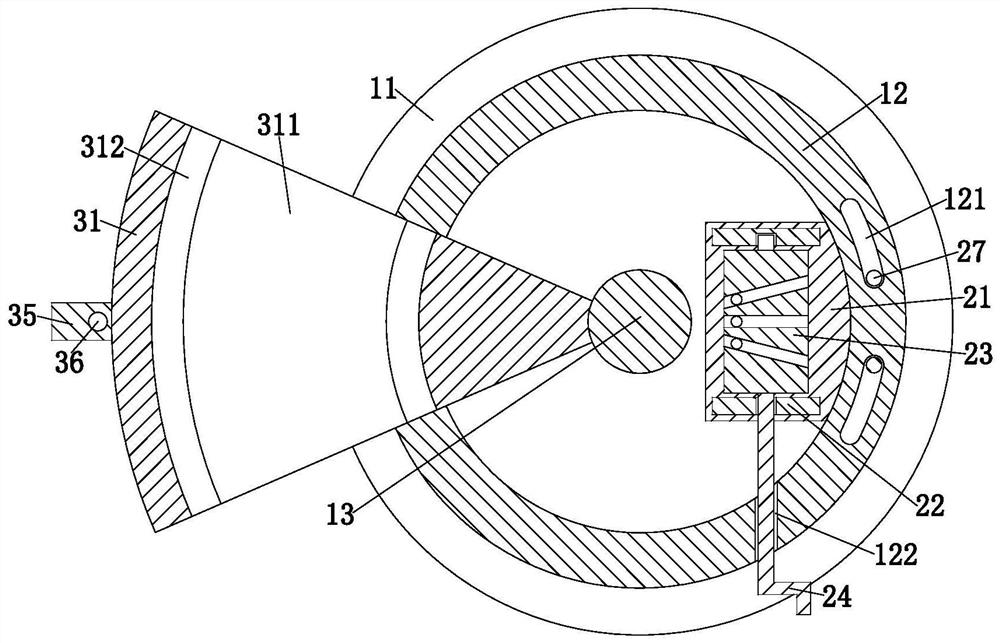

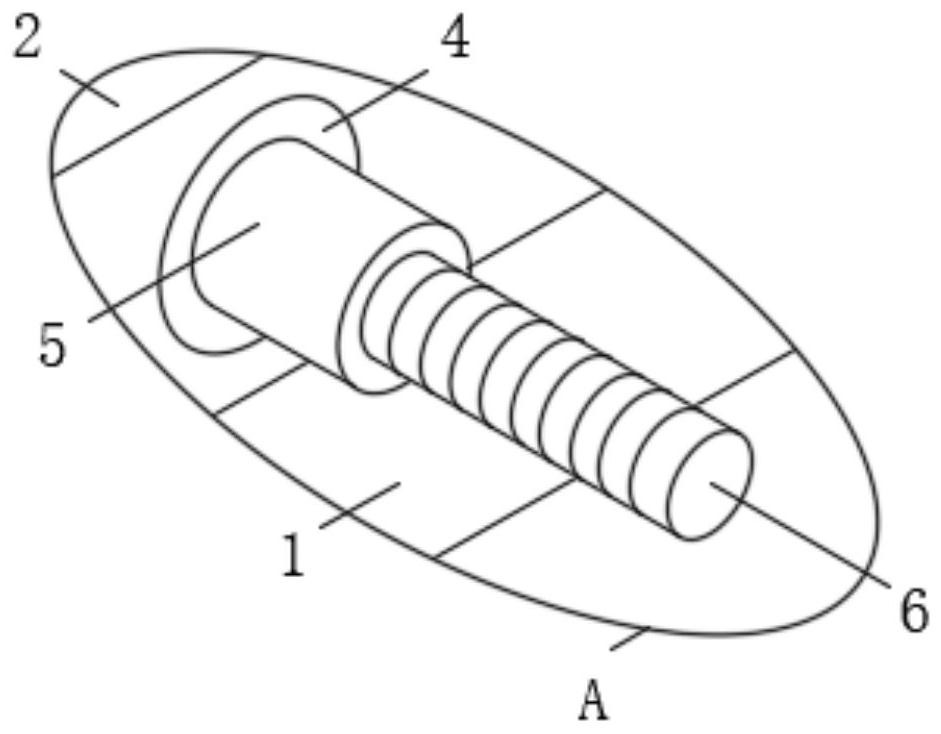

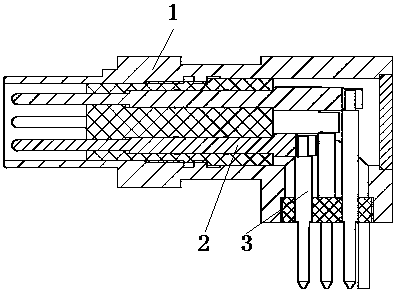

Non-reciprocal circuit element

InactiveCN1812187AFacilitate thinningImprove productivityWaveguide type devicesProduction rateElectrical conductor

The invention provides a non-reciprocal circuit element comprising: a ferrite component (4); a first, a second, and a third center conductors (5, 6, 7) arranged at planes sandwiching a dielectric and being different in the vertical direction, wherein a portion of center conductors crosses each other in the vertical direction; a magnet (2) arranged on the center conductors; a first yoke (1) covering the top surface of the magnet (2); and a second yoke (3) for constituting a magnetic closed circuit with the first yoke (1). A first recess (3c) is arranged at the bottom plate (3a) of the second yoke (3), and a lower part of the ferrite component (4) is accommodated in the first recess (3c). According to the accommodation, thinning is attained, and a thin non-reciprocal circuit element is provided. The invention provides a thin, highly productive and inexpensive non-reciprocal circuit element.

Owner:ALPS ALPINE CO LTD

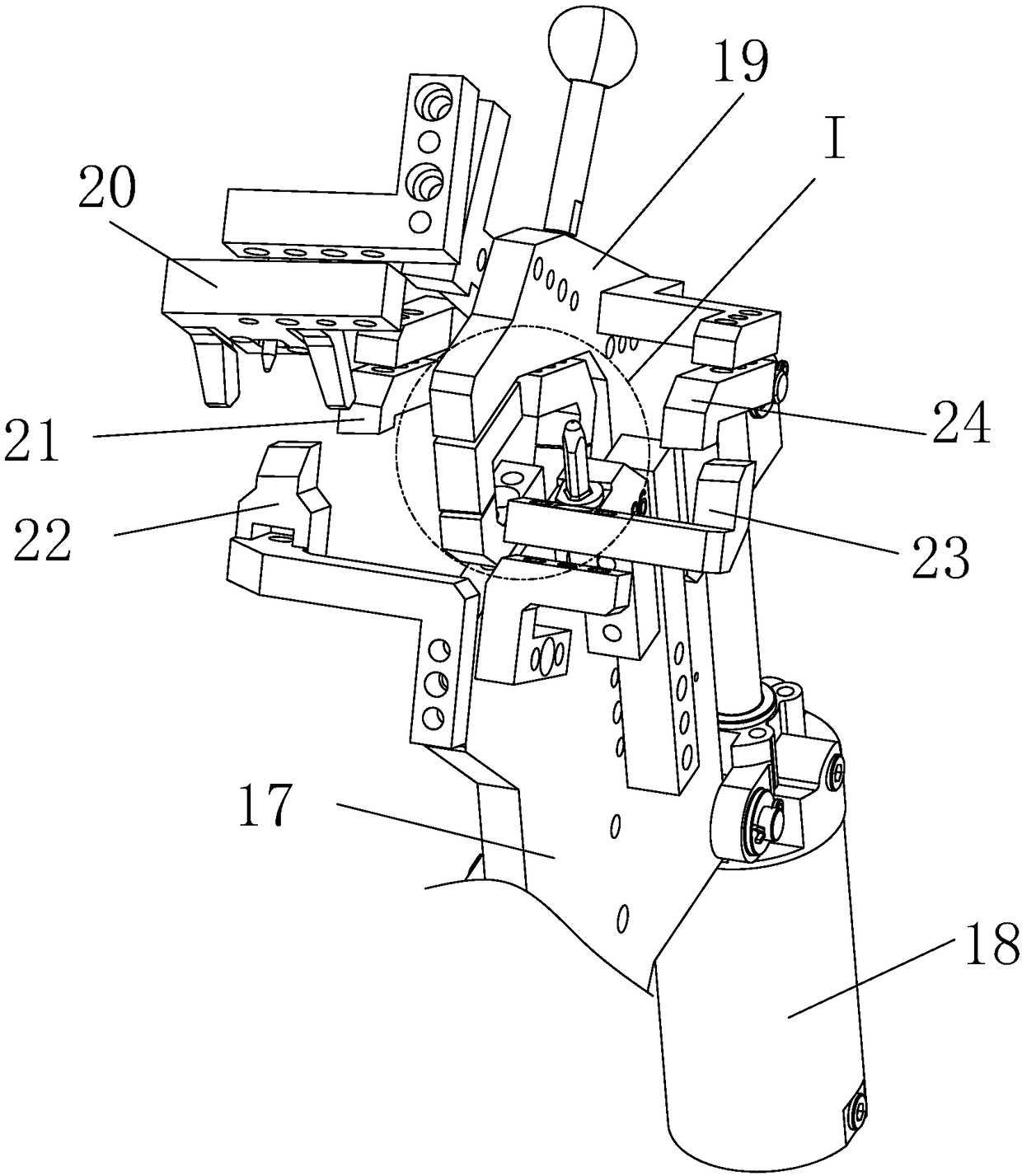

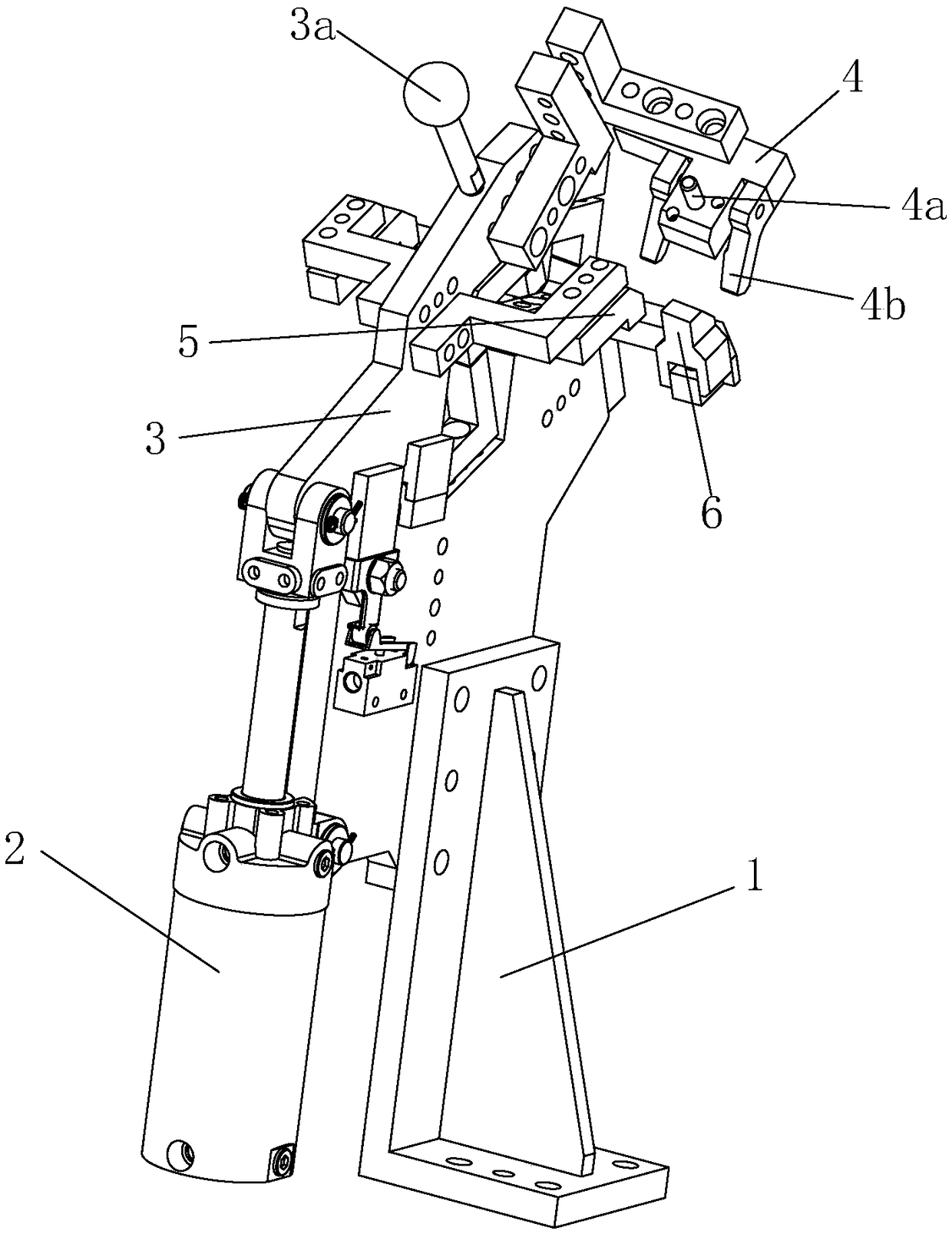

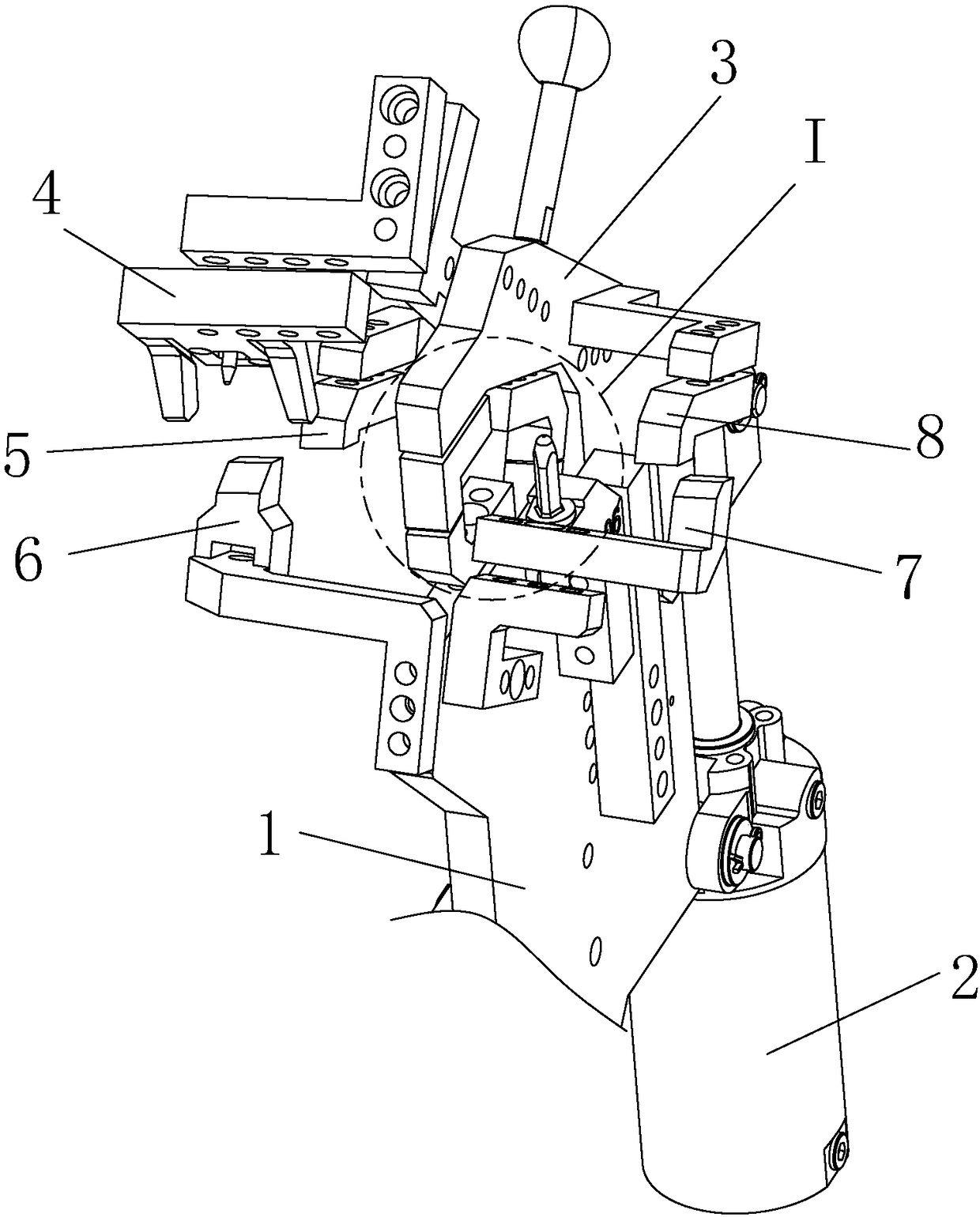

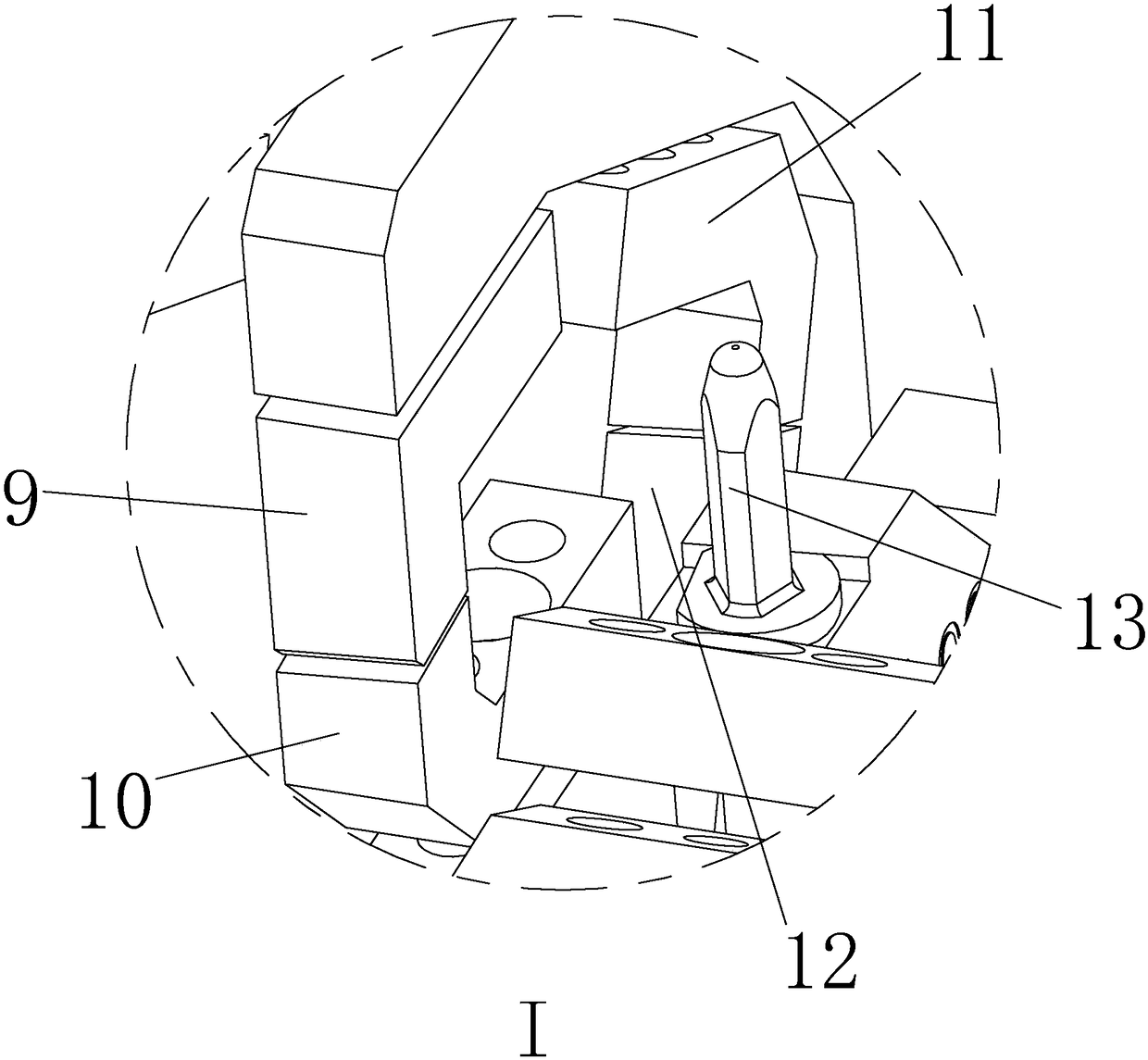

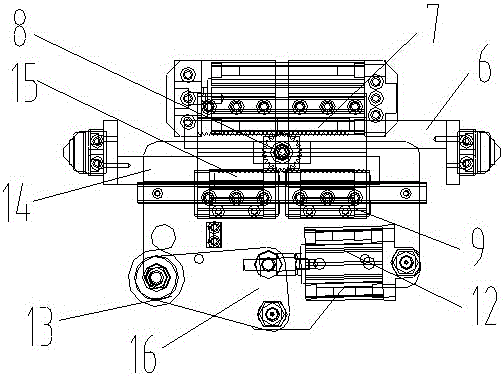

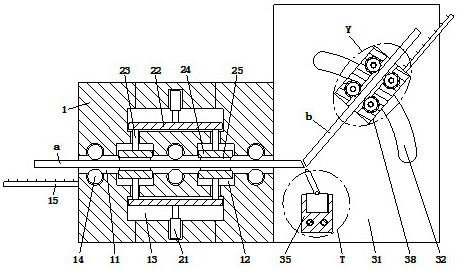

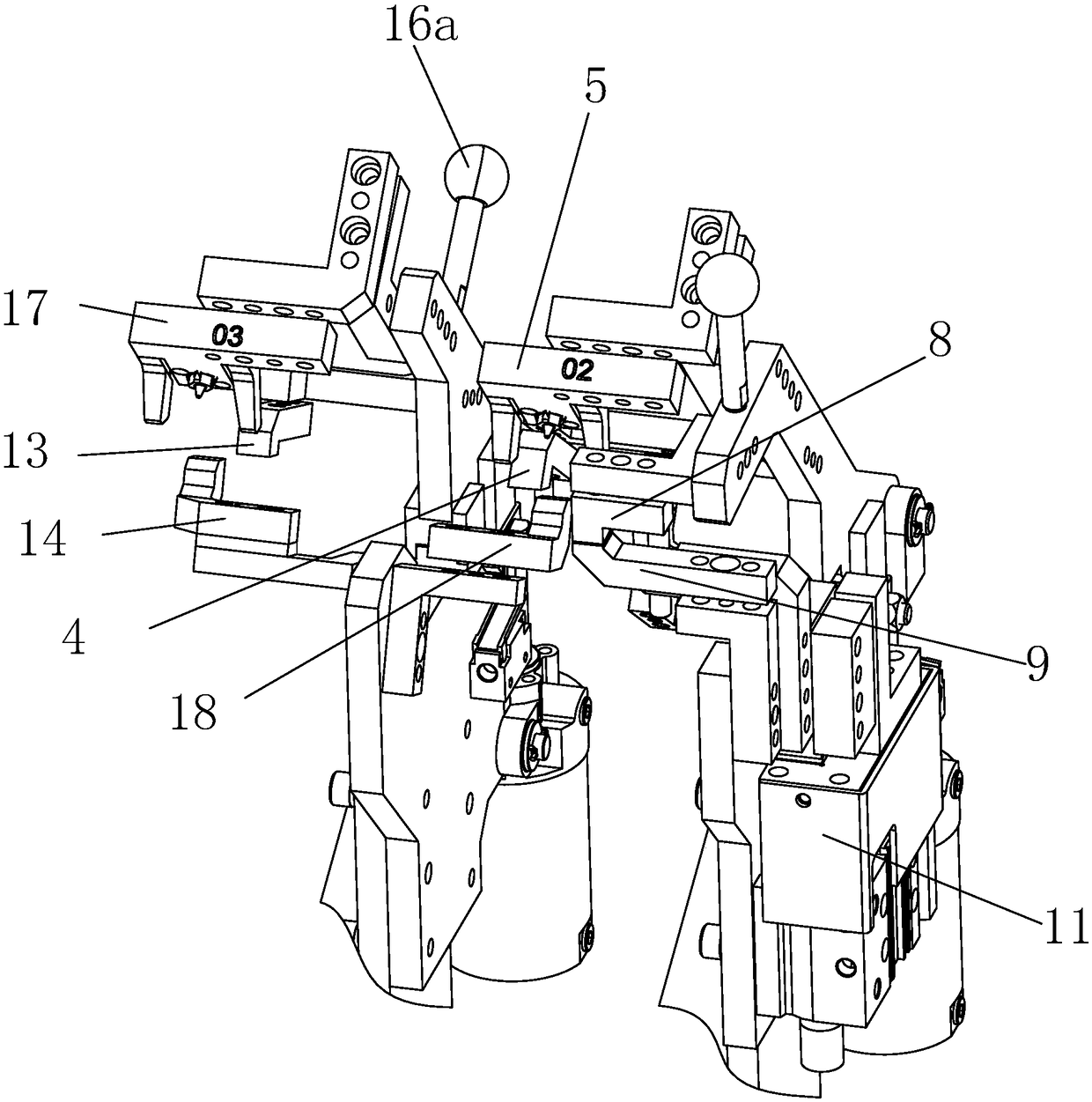

Middle positioning fixture for vehicle left and right side wall inner plate front assembly welding

ActiveCN108311840ASolve the problem of difficult positioning and clampingGuaranteed positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAutomation

The invention relates to a middle positioning fixture for vehicle left and right side wall inner plate front assembly welding. The middle positioning fixture comprises a rack, a cylinder mounted on the rack, a pressing arm pulled by the cylinder to rotate around the rack, a middle positioning block mounted on the pressing arm, a first upper staggered pressing block, a first lower staggered pressing block mounted on the rack for cooperating with the first upper staggered pressing block to realize staggered pressing, a second lower staggered pressing block mounted on the side, far from the firstlower staggered pressing block, of the mounting rack, and a second upper staggered pressing block mounted on the pressing arm and used for cooperating with the second lower staggered pressing block to realize staggered pressing. The middle positioning fixture is reasonable in structural design, solves the problem of difficulty positioning and clamping of two lug bases by a staggered clamping mode, guarantees the positioning precision of the lug bases by dint of the middle positioning block, is convenient for an external welding robot to automatically weld, greatly improves the production efficiency and the product quality, and is higher in automation degree.

Owner:ANHUI DACHANG TECH

Automobile metal plate welding equipment

InactiveCN113500277AImprove distributionAvoid burnsWelding/cutting auxillary devicesDirt cleaningSuction forceEngineering

The invention discloses automobile metal plate welding equipment which comprises a fixing plate. Channel steel sliding rails are slidably connected to the outer walls of the two sides of the fixing plate, a fixing base is fixedly connected to the outer walls of the bottoms of the two channel steel sliding rails, a plurality of buffering pads are arranged between the fixing base and the fixing plate, and an annular groove is formed in the outer wall of the top of the fixing plate. A plurality of balls are slidably arranged on the inner wall of the annular groove, sliding blocks are connected to the outer walls of the balls in a rolling mode, supporting rods are fixedly connected to the two sides of the outer wall of the top of each sliding block, a supporting frame is fixedly connected between the outer walls of the opposite sides of the two supporting rods, and a threaded rod is rotatably connected to the lower end of the supporting frame through a bearing. Harmful gas is absorbed into an annular through opening through suction force generated when an air bag sucks air, so that the harmful gas is purified through a purification mechanism, and meanwhile, convex teeth are distributed in the annular through opening in a meshing mode, so that the harmful gas is conveniently distributed in the annular through opening.

Owner:南京越然汽车用品有限公司

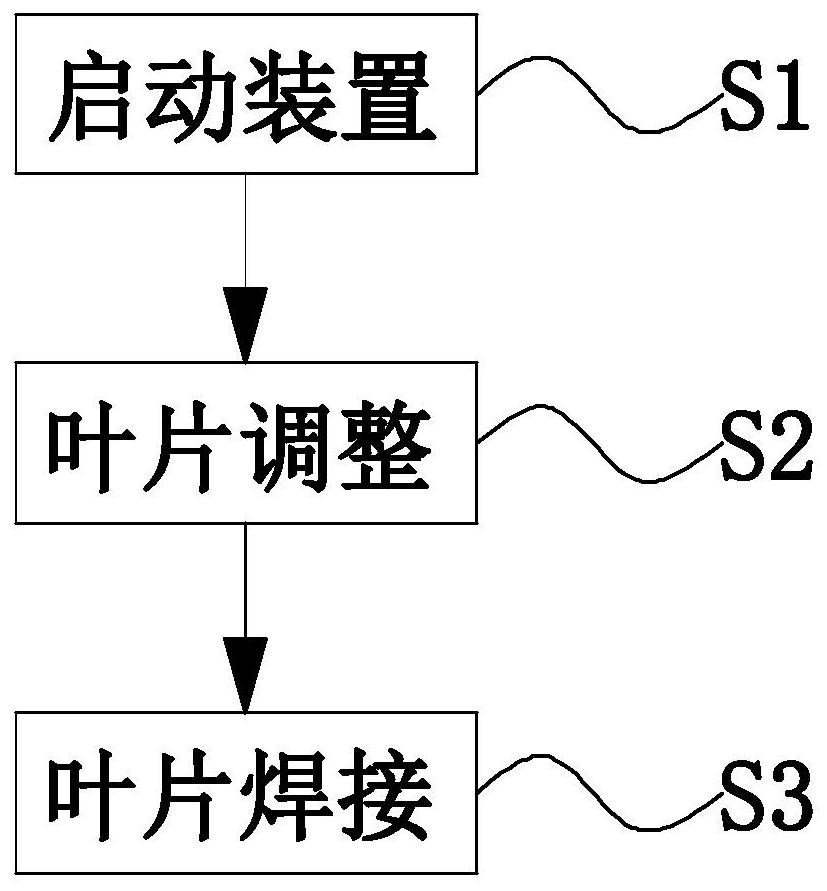

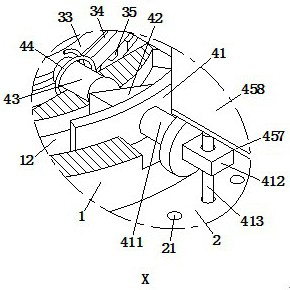

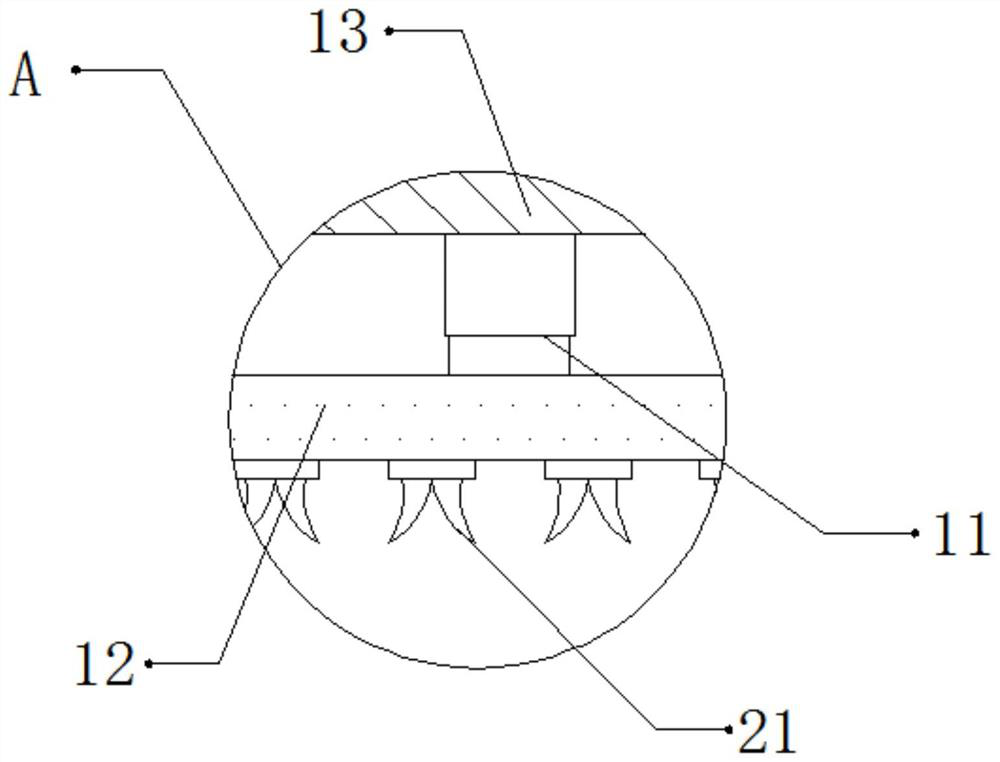

Steam turbine impeller production and manufacturing process

ActiveCN112589307AReduce angle errorAvoid installing one by oneWelding/cutting auxillary devicesAuxillary welding devicesImpellerManufacturing technology

The invention provides a steam turbine impeller production and manufacturing process. The steam turbine impeller production and manufacturing process adopts the following steam turbine impeller production and manufacturing device, the steam turbine impeller production and manufacturing device comprises a base, an adjusting unit and an executing unit, linkage grooves are formed in the right side ofthe upper end of the base in a front-and-back symmetry mode, the adjusting unit is slidably arranged in the linkage grooves, and the executing unit is installed at the upper end of the base. According to the steam turbine impeller production and manufacturing process, firstly, the problems that most of blades are mounted one by one during production and processing of an existing impeller, and thedistance between the blades cannot be effectively adjusted, so that errors exist during blade mounting, repeated calibration is needed, and unnecessary workload is increased are solved; and secondly,the problems that blades and an annular frame are generally clamped and fixed during production and machining of the existing impeller, however, due to the fact that the blades are prone to falling off in a clamping mode, potential safety hazards exist, and the cost is wasted are solved.

Owner:NINGBO TIANKUN MACHINERY MFG

Steel structure connecting structure welding equipment

InactiveCN114248051AReduce labor costsImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSteel columns

The invention relates to the technical field of steel structures, in particular to steel structure connecting structure welding equipment which comprises a workbench, bearing plates, a welding unit and a clamping unit, the bearing plates are fixedly installed on the outer wall of the workbench in a bilateral symmetry mode, the welding unit is arranged in the workbench, and the clamping unit is installed on the outer wall of the workbench; the steel structure welding device can solve the following problems existing during steel structure welding: some small enterprises generally adopt a manual operation mode to weld steel beams and steel columns in order to save the machining cost, so that the steel columns and the steel beams cannot be effectively fixed, the phenomenon of inclination between the steel beams and the steel columns is easily caused, and the welding quality is influenced. The welding effect is influenced; according to the welding device, circumferential welding treatment can be conducted on a steel beam and a steel column, the welding efficiency can be improved, the steel beam and the steel column can be clamped and limited correspondingly, and therefore the defects of gaps, deflection and the like during welding can be effectively avoided, and the welding effect can be enhanced.

Owner:东营硕明信息技术有限公司

Grade feeding vehicle for square tube processing of welding machine

InactiveCN108393622AEasy to carryEasy solderingWelding/cutting auxillary devicesAuxillary welding devicesLocking plateEngineering

The invention discloses a grade feeding vehicle for square tube processing of a welding machine. The grade feeding vehicle comprises a moving frame, wherein moving seats are arranged on the four corner positions of the moving frame, and moving wheels are arranged at the bottom of the moving seats. A supporting seat is arranged on the middle position of the moving frame, a supporting tube is arranged on the top of the supporting seat, a positioning tube is arranged on the top of the supporting tube, the positioning tube is horizontally arranged, and the moving frame is arranged at the end of the positioning tube. Locking plates are arranged on both sides of the bottom of the moving frame, the positioning tube is installed between the locking plates, a locking tube is inserted between the positioning tube and each locking plate, and a locking handle is inserted to the outer end of the locking tube. Supporting frames are arranged at both ends of the moving frame, positioning pieces are arranged at the top of the supporting frames, the positioning pieces are provided with positioning grooves, the positioning pieces are provided with locking pieces, and locking grooves are formed in thelower part of the locking pieces. Carrying of a square tube can be facilitated, and the welding treatment of the square tube can be facilitated through the welding machine.

Owner:刘路清

A production process of lithium-ion battery tabs with high sealing and anti-leakage

ActiveCN108134042BImprove welding effectImprove adhesionSecondary cellsCell component detailsElectrical conductorMegasonic cleaning

The invention discloses a production process of lithium-ion battery tabs with high sealing and anti-leakage. In the production process, the base metal material is subjected to bright rolling and dull rolling through steps A-H, and then electrochemically polished and polished. passivation, cleaning and drying it, and then cut the strip-shaped metal conductor into sections, ultrasonic cleaning and drying it, and treating it with deionized water and drying it, and finally strip The polymer insulating film is pasted on the segmented metal conductor. The lithium-ion battery tab produced by this process increases the surface roughness of the metal conductor, which increases the effective contact area between the metal conductor and the polymer insulating film, so it can effectively improve the adhesion and make the two bonds more stable, thereby Improve the sealing performance of the battery cell and improve the welding performance of the metal conductor. At the same time, it reduces the surface activity of the metal conductor and enhances its ability to resist electrolyte erosion, thereby further improving the sealing performance of the battery cell and preventing lithium-ion batteries from leaking.

Owner:赣州市中金高能电池材料股份有限公司

An auxiliary welding device for auto parts

ActiveCN111318845BSpeed up the flowEasy to handleWelding/cutting auxillary devicesAuxillary welding devicesCentrifugal forceFastener

The invention discloses an auxiliary welding device for auto parts, which comprises a fixing seat, fixing plates are fixed on both sides of the top outer wall of the fixing seat, and two through holes are opened on one side of the outer wall of the fixing plate, and the two The inner walls of the two through holes are slidingly connected with guide rods, the outer walls of one side of the two guide rods are fixed with a connecting plate, and the outer wall of one side of the connecting plate is connected with a rotating shaft through a bearing, and one of the other fixed plates The side outer wall is rotatably connected with a rotating rod through a bearing, and a U-shaped frame is fixed on one side of the rotating rod and one side of the rotating shaft, and a hydraulic rod is fixed on the top outer wall of the fixing seat. The invention can prevent the auto parts from slipping from the inside of the splint due to the centrifugal force generated during rotation and affect the welding of the auto parts, can prevent the arc generated during welding from causing burns to the eyes of the operator, and can disperse the arc to avoid the damage caused by the arc. Damage to the operator's eyes.

Owner:WUHAN HUAZI DONGJIANG AUTO PARTS

Automatic welding equipment for metal pipe fittings

InactiveCN114769930AAchieve fixationMaintain stabilityWelding/cutting auxillary devicesAuxillary welding devicesButt jointPipe fitting

The invention relates to the technical field of pipe fitting machining, in particular to metal pipe fitting automatic welding equipment which comprises a workbench, a supporting unit, a bearing unit and a welding unit. An existing welding machine has the following problems that friction force between an upper clamping plate and a lower clamping plate of the welding machine and a pipe fitting lacks, the pipe fitting lacks stability, the pipe fitting is prone to rotating in the welding process, and the welding effect on the pipe fitting is prone to being affected; the welding ends of the pipe fittings cannot be supported or fixed, so that the pipe fittings are prone to dislocation in the welding process, and then the welding precision is affected. The corrugated pipe can be fixed through an arc-shaped pressing plate and an attaching layer, a flange plate is fixed through a connecting column and a stabilizing belt, and the flange plate is prevented from shaking; the corrugated pipe and the flange plate can be in butt joint and fixed, and therefore the situation that the welding precision is affected due to dislocation between the corrugated pipe and the flange plate is prevented.

Owner:徐州好合智能装备有限公司

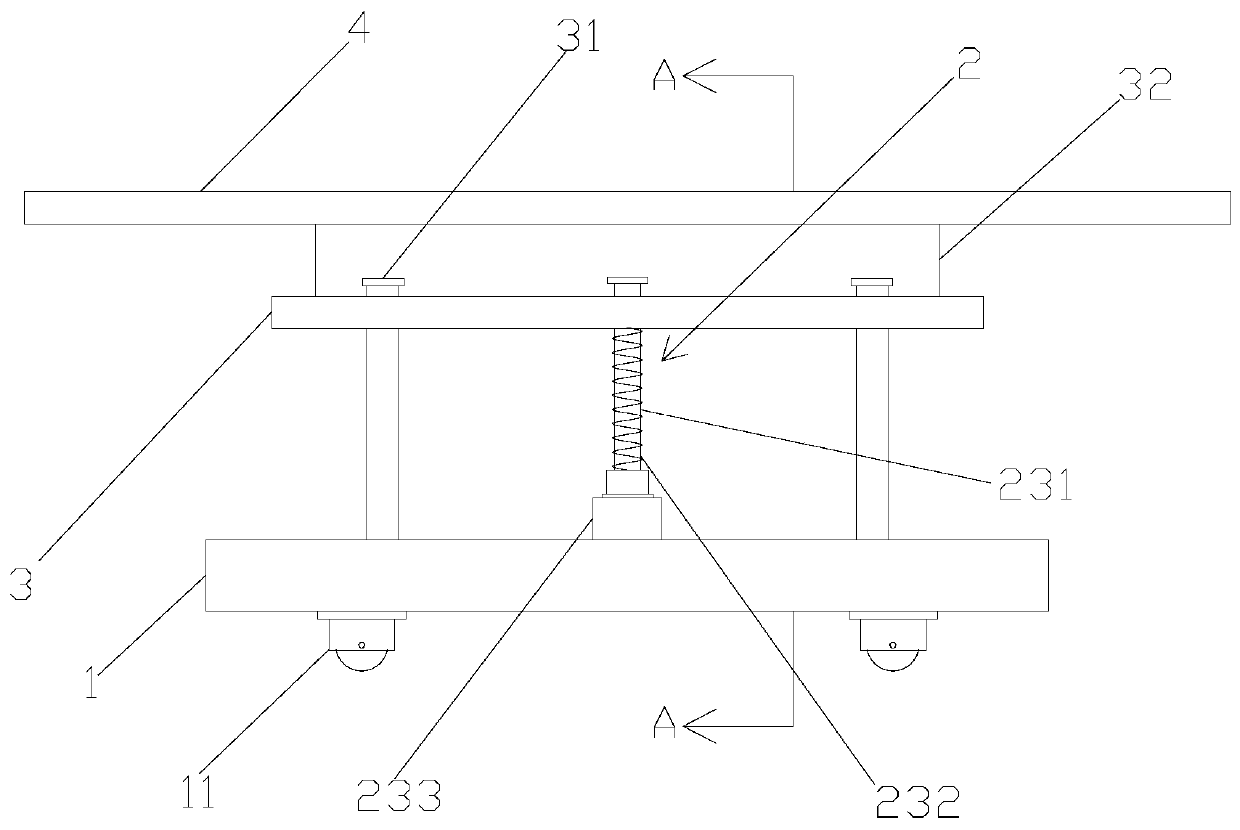

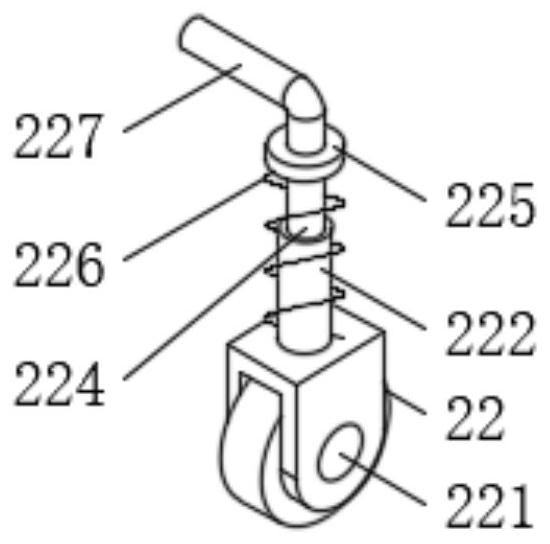

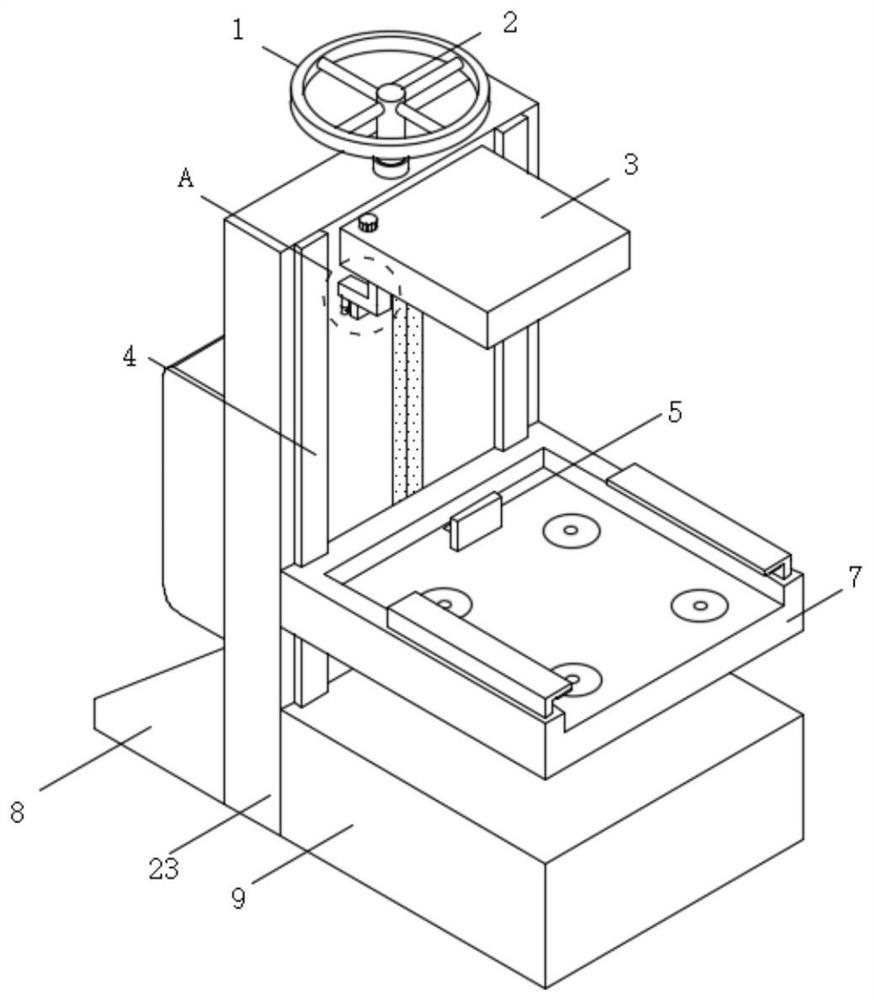

Clamp lifting supporting table

ActiveCN110722315AReduce impact forceEasy solderingWelding/cutting auxillary devicesAuxillary welding devicesCushioningIndustrial engineering

The invention provides a clamp lifting supporting table which comprises a base with the bottom provided with moving wheels, a lifting mechanism, a moving plate and a supporting plate installed on themoving plate. Multiple connecting rods are connected between the moving plate and the supporting plate. The lifting mechanism is arranged between the base and the moving plate. The lifting mechanism comprises a moving part, first cushioning parts and second cushioning parts connected to the two sides of the first cushioning parts. One end of the moving part is connected with the moving plate, andthe other end of the moving part is connected with the first cushioning parts. The moving part comprises a connecting part, moving sleeves and a fixing rod, the connecting part is overall in an inverted Y shape, one end of the connecting part is connected with the moving plate, and the other two ends of the connecting part are connected with the moving sleeves arranged on the fixing rod in a sleeving manner. In addition, the moving sleeves can move on the fixing rod so as to compress the first cushioning parts on the two sides, and therefore the connecting part can be buffered by the first cushioning parts and the second cushioning parts when being pressed towards the fixing rod.

Owner:重庆经纬驰汽车部件有限公司

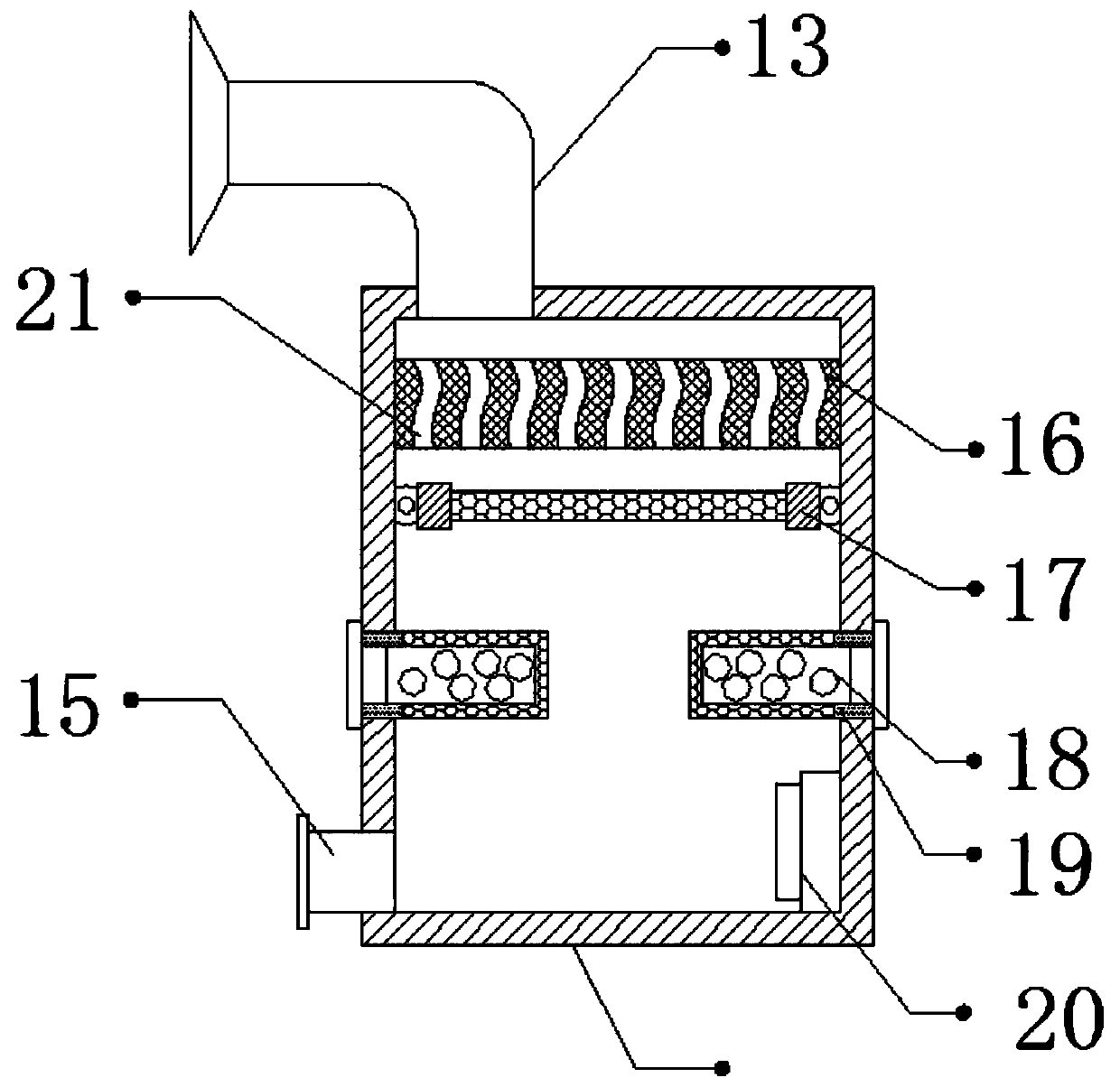

An automatic docking equipment for automobile muffler production

ActiveCN112059515BEasy to isolate and protectAvoid harmWelding/cutting auxillary devicesAuxillary welding devicesMechanical equipmentSlide plate

The invention relates to the technical field of mechanical equipment, in particular to an automatic docking device for the production of automobile mufflers, which can effectively simplify the docking method by performing automatic docking processing on the muffler parts, save physical strength and time during manual operation, and simultaneously The accuracy of the docking position of the muffler parts is improved, the stability and firmness of the parts are improved, which facilitates subsequent welding work, effectively improves product production quality, and improves practicability and reliability; including workbench, four sets of outriggers, two sets of second One guide rail, two sets of slide plates and two sets of push plates. The left and right sides of the middle of the workbench are horizontally provided with through grooves that penetrate up and down. The tops of the four sets of legs are evenly installed on the outside of the bottom of the workbench. The guide rails are installed horizontally on the top front side and the rear side of the workbench respectively.

Owner:山东艾泰克环保科技股份有限公司

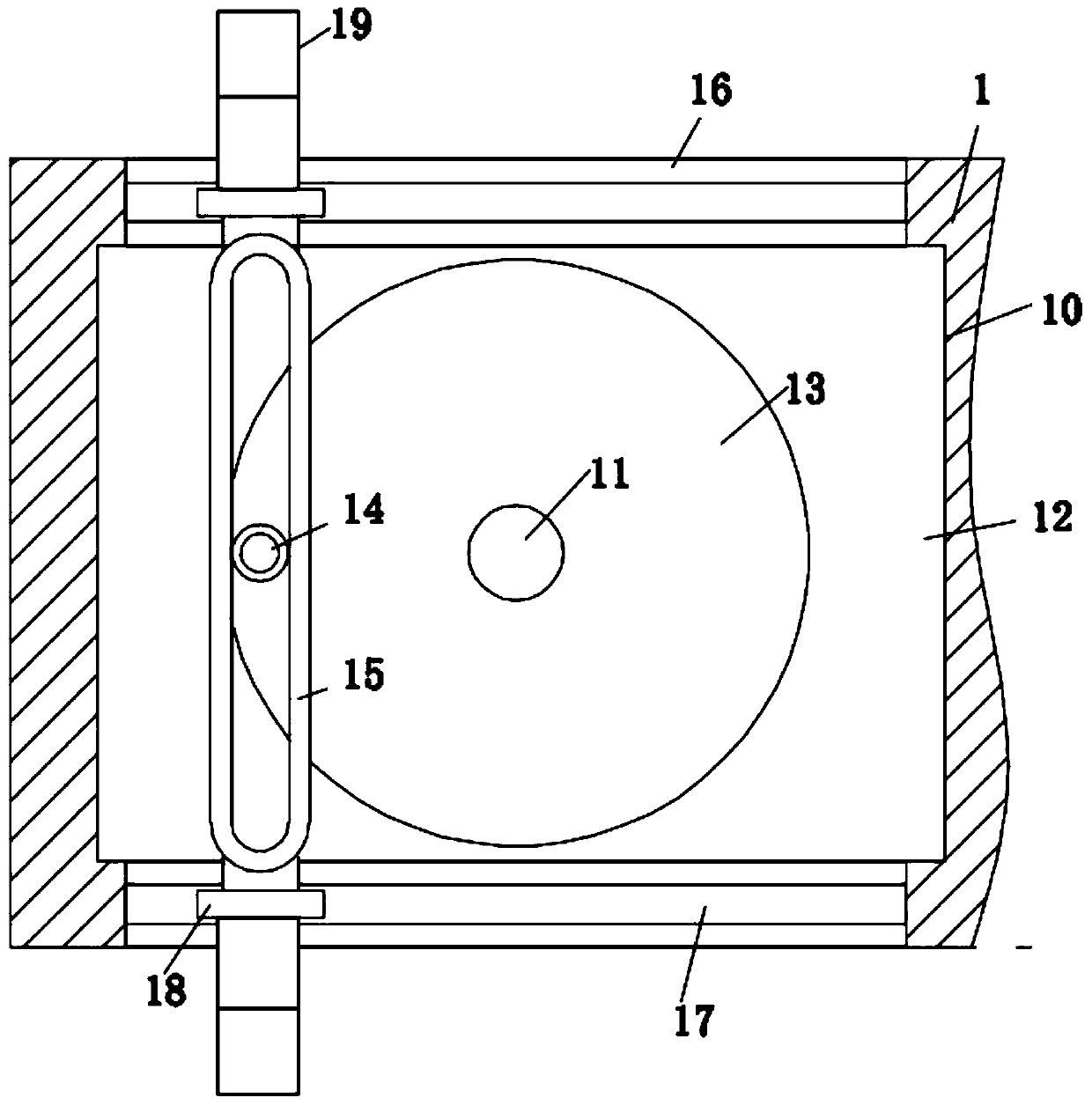

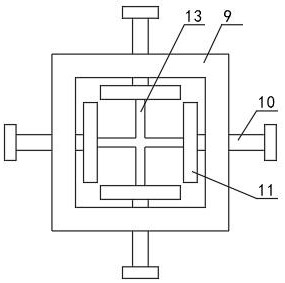

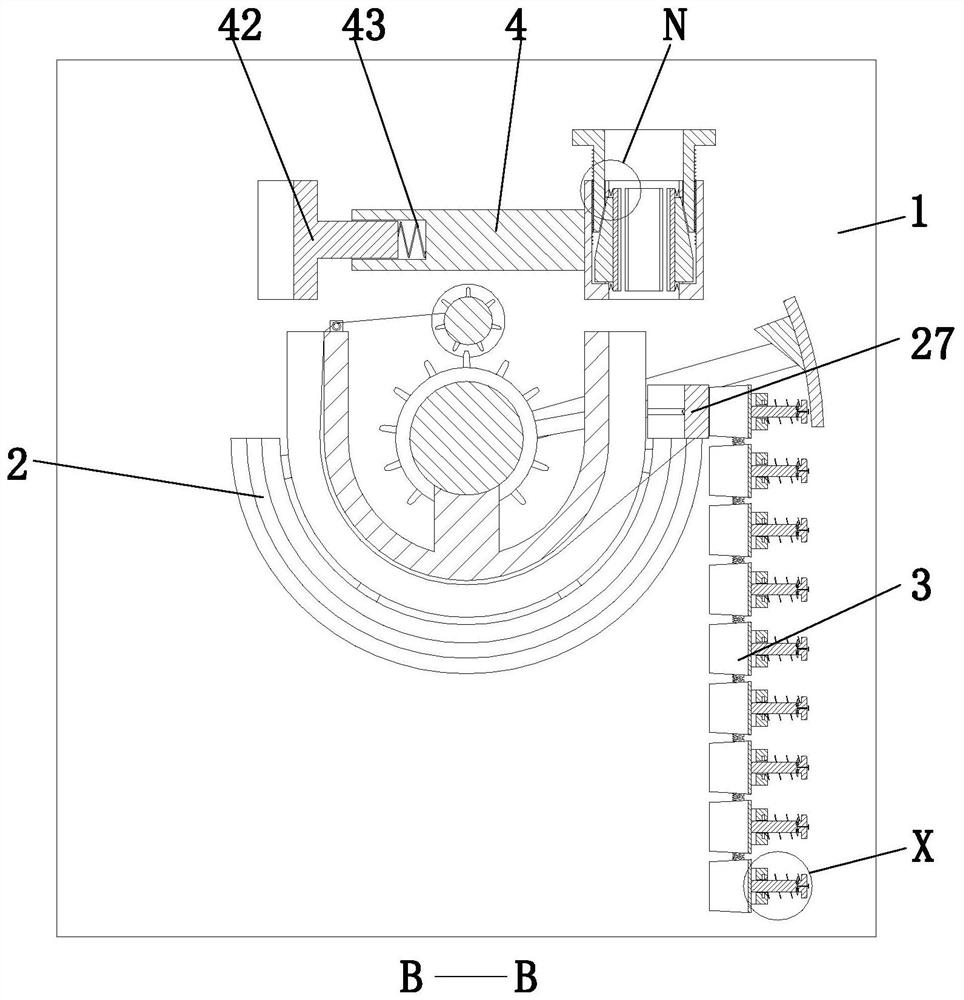

Fixed seam expanding device and welding equipment for thin-walled plate cylinder

ActiveCN104999190AReduce labor intensityPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesGear wheelWeld seam

The invention discloses a fixed seam expanding device and welding equipment for a thin-walled plate cylinder, belongs to cylinder welding equipment in the technical field of welding, and aims to provide the fixed seam expanding device for the thin-walled plate cylinder, so that a welding seam is expanded and the accurate positioning for the seam is facilitated. The technical scheme is that the fixed seam expanding device comprises a substrate, wherein a telescopic synchronous gear is arranged on the substrate; an upper expansion telescopic link is arranged above the telescopic synchronous gear, and an upper telescopic synchronous rack is connected onto the upper expansion telescopic link; a lower expansion telescopic link is arranged below the telescopic synchronous gear, and a lower telescopic synchronous rack is connected onto the lower expansion telescopic link; the upper telescopic synchronous rack and the lower telescopic synchronous rack are meshed with the telescopic synchronous gear by corresponding to the upper side and the lower side of the telescopic synchronous gear respectively. The fixed seam expanding device for the thin-walled plate cylinder is applicable to cylinder welding and used for expanding the welding seam.

Owner:CHENGDU HANYAN TECH

Automatic welding equipment for vehicle-mounted fuel tank production

ActiveCN112475606AEasy to limitImprove isolationWelding/cutting auxillary devicesAuxillary welding devicesIn vehicleFuel tank

The invention relates to the technical field of mechanical equipment, in particular to automatic welding equipment for vehicle-mounted fuel tank production. The automatic welding equipment can conveniently improve the distribution uniformity of welding spots on a fuel tank, effectively improve the strength and the welding quality of a welding machine by performing automatic welding treatment on the fuel tank, and meanwhile, simplify the welding mode, effectively save physical strength during manual welding, improve working efficiency and improve practicability and reliability. The automatic welding equipment comprises a workbench, a top beam, four first supporting plates, two first lead screws and a first motor, a power device is transversely arranged at the top of the workbench, adsorption devices are arranged on the left side and the right side of the top of the power device, the two adsorption devices are opposite in direction, two fixing devices are arranged between the two adsorption devices, and the two fixing devices are opposite in direction, the bottoms of the two fixing devices are installed on the left side and the right side of the power device correspondingly.

Owner:山东艾泰克环保科技股份有限公司

Post-welding prestress shaping and strengthening method for light alloy medium plate

InactiveCN112570491AImprove stabilityGuaranteed mechanical propertiesEdge grinding machinesGrinding drivesPre stressPolishing

The invention discloses a post-welding prestress shaping and strengthening method for a light alloy medium plate and belongs to the technical field of welding shaping and strengthening. The method comprises the following partial step of S1, processing a weldment: carrying out single-sided welding and double-sided forming on the light alloy medium plate by adopting parameters of a welding process,and keeping a workpiece in a clamped state after welding and cooling the workpiece. In the invention, shaping and strengthening is carried out by means of a firing pin ultrasonic shot blasting device.By replacing the firing pin working heads of different sizes, shaping and strengthening functions are achieved, so that the method is convenient to operate and efficient, and polishing and welding work can be completed synchronously. By carrying out polishing, a welding surface is of a bevel structure, so that it is convenient to weld the light alloy medium plate which is heavy. The medium plateis preheated by means of heat energy generated by polishing a low-temperature rigid structure, so that the probability of generating a weld joint can be reduced on an energy-saving basis, and influence on stress is weakened.

Owner:浙江思印科技有限公司

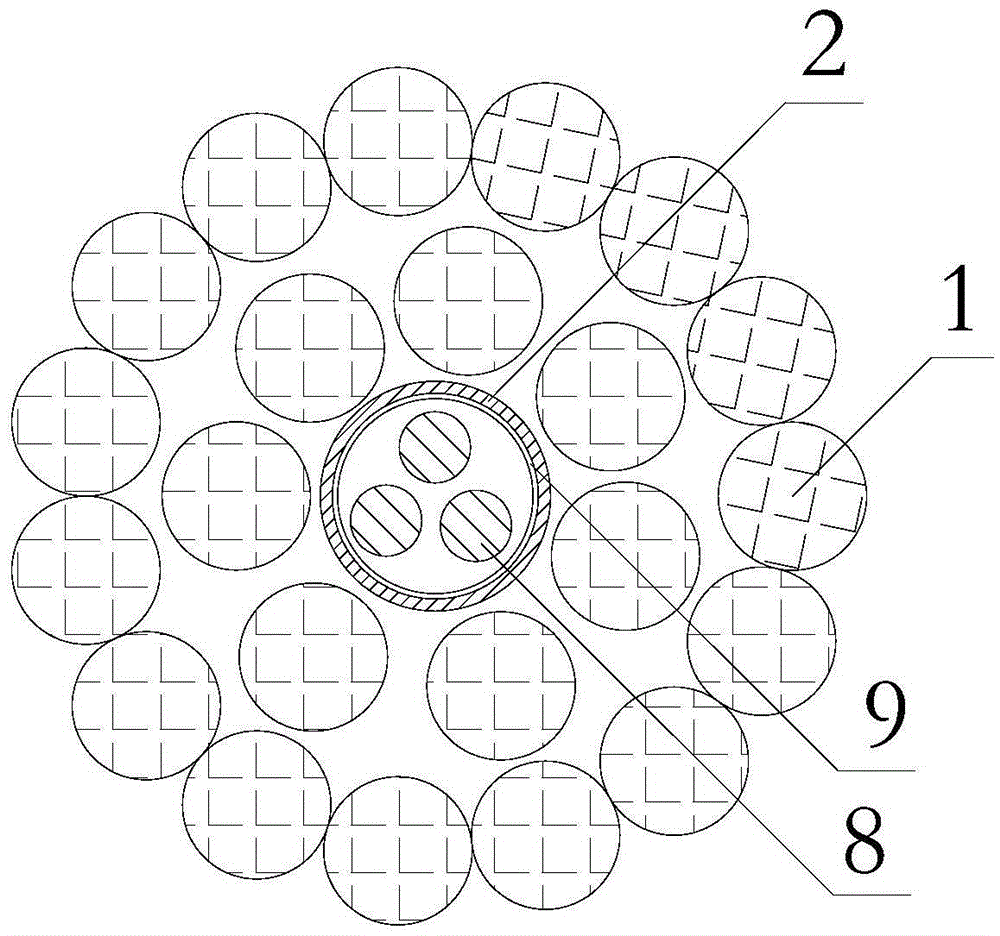

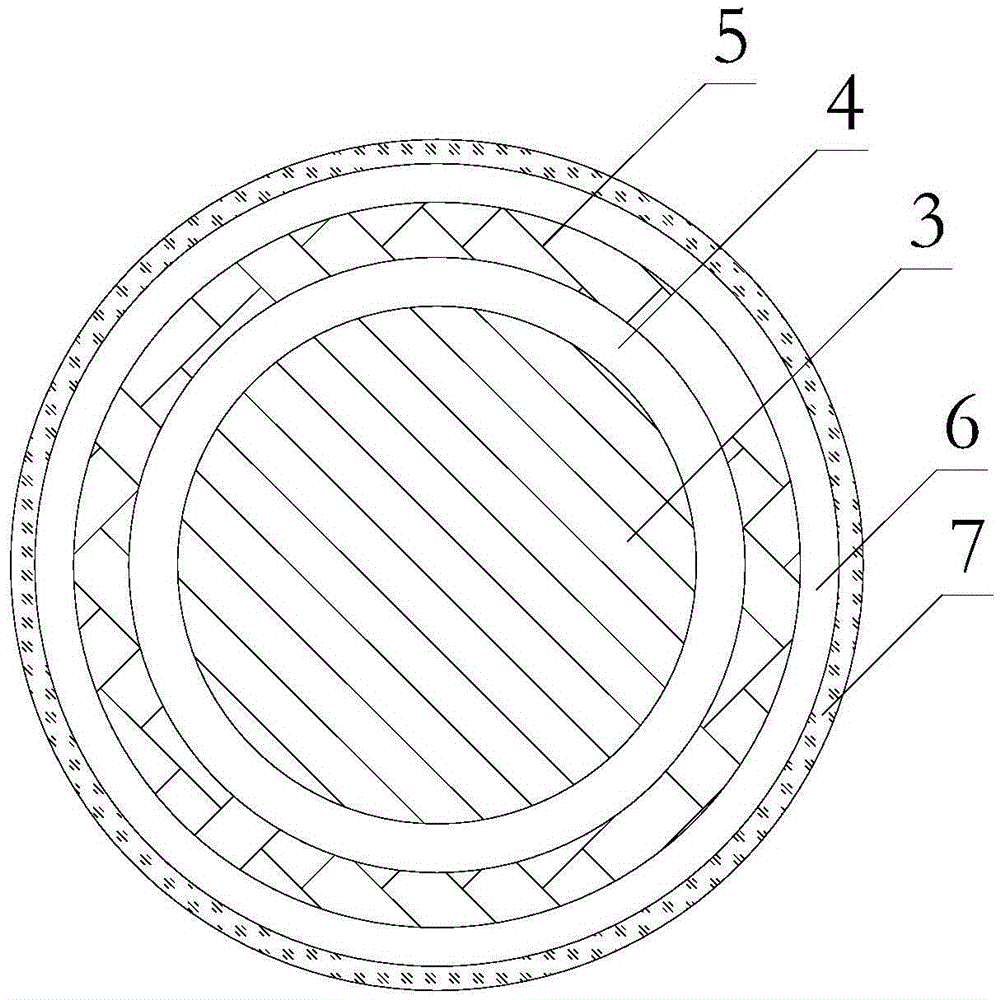

Enameled wire harness

InactiveCN105632626AImprove toughnessImprove bending resistanceFlexible cablesFlexible conductorsEngineeringProtection layer

The invention relates to an enameled wire harness. The enameled wire harness comprises multiple strands of enameled wires and a hollow structured support pipe, wherein the multiple strands of enameled wires and the support pipe are twisted to form the harness, the support pipe is arranged at the central position of the multiple strands of enameled wires, each strand of enameled wire comprises a wire core, an intermediate layer and a protection layer, and the intermediate layer and the protection layer sequentially wraps the surface of the wire core from inside to outside. In the enameled wire harness, the multiple strands of enameled wires are twisted together, a shielding layer is arranged on the surface of each strand of enameled wire, and thus, mutual interference among the enameled wires can be prevented from affecting the circuit stability; and moreover, with the arrangement of the support pipe, the toughness of the whole enameled wire harness can be improved, the bending resistant capability of the enameled wire harness is enhanced, and the service lifetime of the enameled wire harness is prolonged.

Owner:WUHAN BROS ELECTRICAL CO LTD

Differential connector and installation structure of bent contact

ActiveCN110212345AEasy to operateSimple assemblySecuring/insulating coupling contact membersCoupling contact membersElectrical conductorStructural engineering

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

A thin steel plate welding equipment for tooling processing of petroleum accessories

ActiveCN114043120BImprove stabilityImprove applicabilityWelding/cutting auxillary devicesAuxillary welding devicesSheet steelWelding defect

The invention relates to the technical field of tooling processing of petroleum accessories, in particular to a thin steel plate welding equipment for tooling processing of petroleum accessories, which includes a base, a fixing unit and a welding unit, the fixing unit is installed inside the base, and the welding unit is arranged on the base Right end; the present invention can solve the problems existing in the welding between thin steel plates: two thin steel plates are usually butted manually, so that the angle between the steel plates cannot be effectively controlled, so that the two thin steel plates lack precision when butt jointed, and it is easy to cause two Large gaps and dislocations appear at the joints of the two thin steel plates, thereby affecting the welding effect; the present invention can respectively limit and fix the two thin steel plates, so that the stability of the thin steel plates during welding can be improved, thereby avoiding welding defects; The invention can adjust the angle between two thin steel plates, thereby enhancing the welding effect and improving the applicability of the equipment.

Owner:山东柏源技术有限公司

A multifunctional steel structure welding device

ActiveCN113458700BPrevent rotationGuaranteed stabilityWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsEngineering

The invention discloses a multifunctional steel structure welding device, which comprises a bottom plate, a corresponding plate is arranged on the top of the bottom plate, the corresponding plate includes a first frame plate and a second frame plate, and a welding head. The present invention rotates the spacer sleeve, and the screw effect of the spacer sleeve and the movable screw makes the two clamping frames close to each other. At this time, when the two clamping frames clamp the elastic member, the second frame plate pairs with the clamping frame. The reaction force of the limiting sleeve and the driving force of the clamping frame, the two clamping frames use the ring groove to tightly clamp the collar, avoid the rotation of the clamping device and the limiting device, and ensure the stability of the steel structure welding; reverse Turn the limit sleeve, the elastic rebound of the elastic part makes the two clamping frames separate, and the clamping device and the limiting device can be rotated to facilitate all-round welding of the welding joints of the two steel structures and ensure the welding of the steel structures Effect.

Owner:南通金沃金属制品有限公司

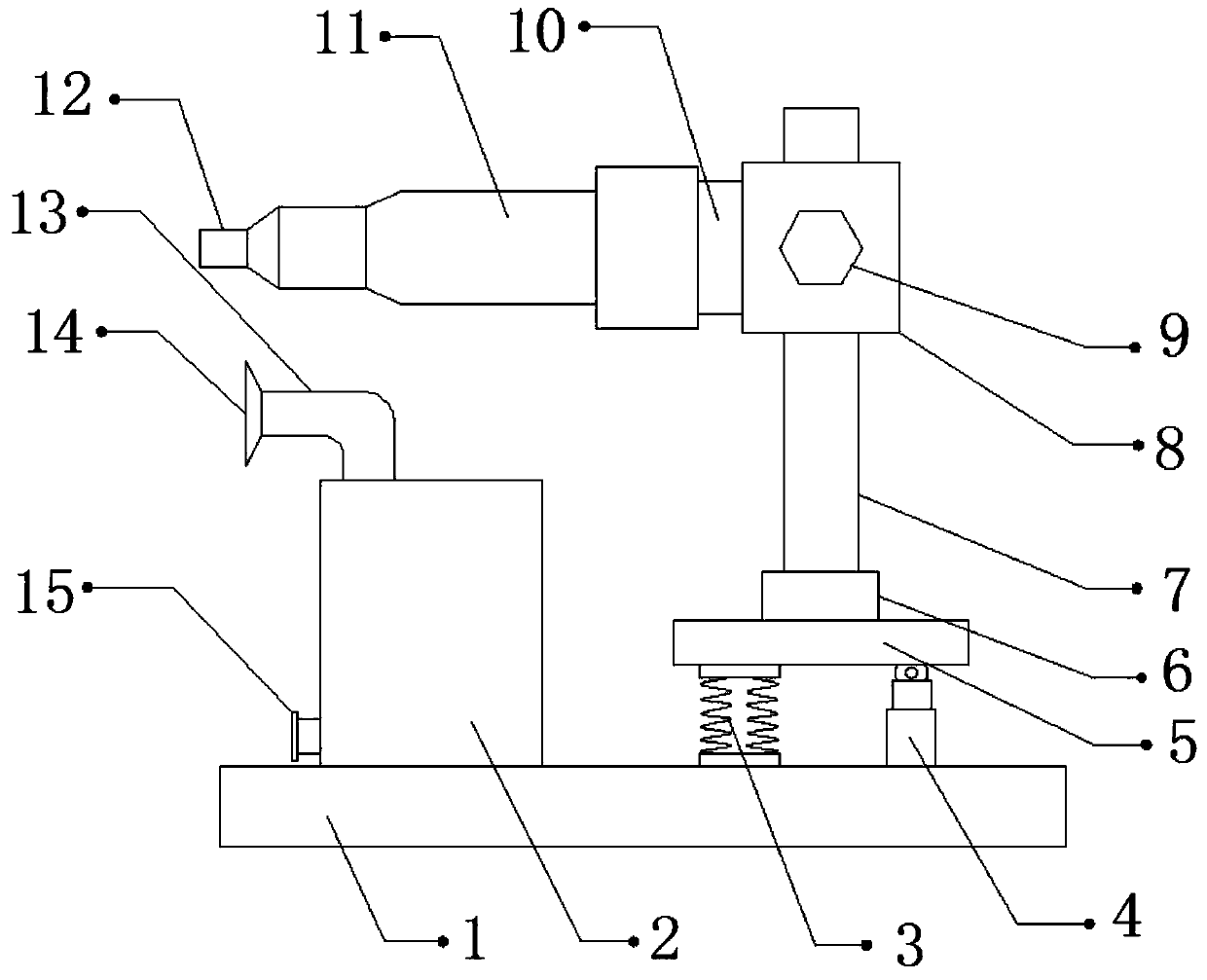

Welding mechanism for recycling waste lithium batteries

InactiveCN110814486AEasy solderingImprove convenienceWaste accumulators reclaimingBattery recyclingProtecting eyeStructural engineering

The invention discloses a welding mechanism for recycling waste lithium batteries. The welding mechanism includes a fixed base, a hydraulic rod is fixed to one side of the outer wall of the top of thefixed base, a supporting plate is connected to the outer wall of the top of the hydraulic rod through a hinge, a spring is fixed between one side of the outer wall of the bottom of the supporting plate and one side of the outer wall of the top of the fixed base. A damping bearing is fixed to the outer wall of the top of the supporting plate, and a supporting rod is rotatably connected to the inner wall of the damping bearing. A sliding sleeve is slidably connected to the outer wall of the supporting rod, a fixed shaft is fixed to the outer wall of one side of the sliding sleeve, a welding gunis fixed to the outer wall of one side of the fixed shaft, and a welding head is arranged on the outer wall of one side of the welding gun. The welding mechanism can adjust the angle and height of welding, can prevent the situation that environment is polluted due to the fact that smoke generated during welding is discharged to the outside world, can protect eyes of people, and prevent the eyes of people from being damaged by arc generated during welding.

Owner:湖南金凯循环科技股份有限公司

Prefabricated steel structure manufacturing and processing method

The invention provides a prefabricated steel structure manufacturing and machining method. A prefabricated steel structure manufacturing and machining device is adopted in the prefabricated steel structure manufacturing and machining method, and comprises stair rib plates, steel plates and fixing units, the stair rib plates are symmetrically arranged, and the steel plates are arranged on the inner side walls of the stair rib plates at equal intervals through the fixing units. The method can solve the following problems that firstly, when a traditional steel structure stair is processed, the steel plates are manually lifted to the stair rib plates mostly, and then the steel plates are supported and fixed by workers, so that the stability is poor, the fixing effect is poor, the workers are prone to be fatigue due to long-term high-strength work, and the steel plates are prone to shift; and secondly, in general, after the steel plates are supported and fixed to the stair rib plates by the workers, the stair rib plates are marked, and then the inclination angles of the steel plates are manually adjusted so that the adjustment precision cannot be ensured, and the processing precision is influenced.

Owner:武汉辉创博远建设工程有限公司

Coating vacuum cavity welding auxiliary equipment for LOW-E glass production

The invention discloses coating vacuum cavity welding auxiliary equipment for LOW-E glass production, and belongs to the technical field of glass production and manufacturing. The coating vacuum cavity welding auxiliary equipment comprises a glass mounting base and a main mounting frame, and side supporting bases and a base are fixedly mounted on the outer walls of the two sides of the main mounting frame correspondingly; an air bag and a material storage assembly are arranged on the side supporting bases and the base and located on the outer surface of the main mounting frame correspondingly, an air guide pipe is arranged at the top of the air bag, and a square guide pipe is fixedly mounted at the top end of the air guide pipe; according to the equipment, the material storage assembly and the air bag are arranged outside, through the design, no electronic structure is used, automatic timing spraying of the welding anti-splashing agent is achieved, the problem of splashing of some materials in a high-temperature welding area can be effectively solved, the construction safety of workers is effectively guaranteed, meanwhile, the connection tightness of the welding area is higher, the welding surface is not prone to erosion, the welding effect is improved, the step of manually adding a welding splash-proof agent is omitted, the process efficiency is improved, and operation is easy.

Owner:南京苏洋玻璃有限公司

A boiler economizer molding manufacturing device and method thereof

ActiveCN112091094BAvoid unusable phenomenaAvoid wastingMetal-working feeding devicesPositioning devicesPipe fittingProcess engineering

The invention relates to a boiler economizer forming device and method thereof, comprising a bottom plate, a bending unit, an auxiliary unit and a support unit, a bending unit is installed on the top of the bottom plate, an auxiliary unit is installed on the right end of the bending unit, and A supporting unit is arranged behind the curved unit. The present invention can solve the problem that existing equipment cannot protect the pipe diameter at the bend of the economizer pipe fittings when bending and forming the economizer pipe fittings, thus destroying the integrity of the pipe fitting structure and easily There is a phenomenon that the pipe fittings cannot be used, which leads to waste of materials and reduces the effect of the bending and forming of the economizer pipe fittings. Inconsistencies in the width of the space, and can not ensure that the bent economizer pipe fittings are in a horizontal position, which is not convenient for welding between economizer pipe fittings, and increases the difficulty of economizer assembly and other problems.

Owner:ZHEJIANG HAITE BOILER CO LTD

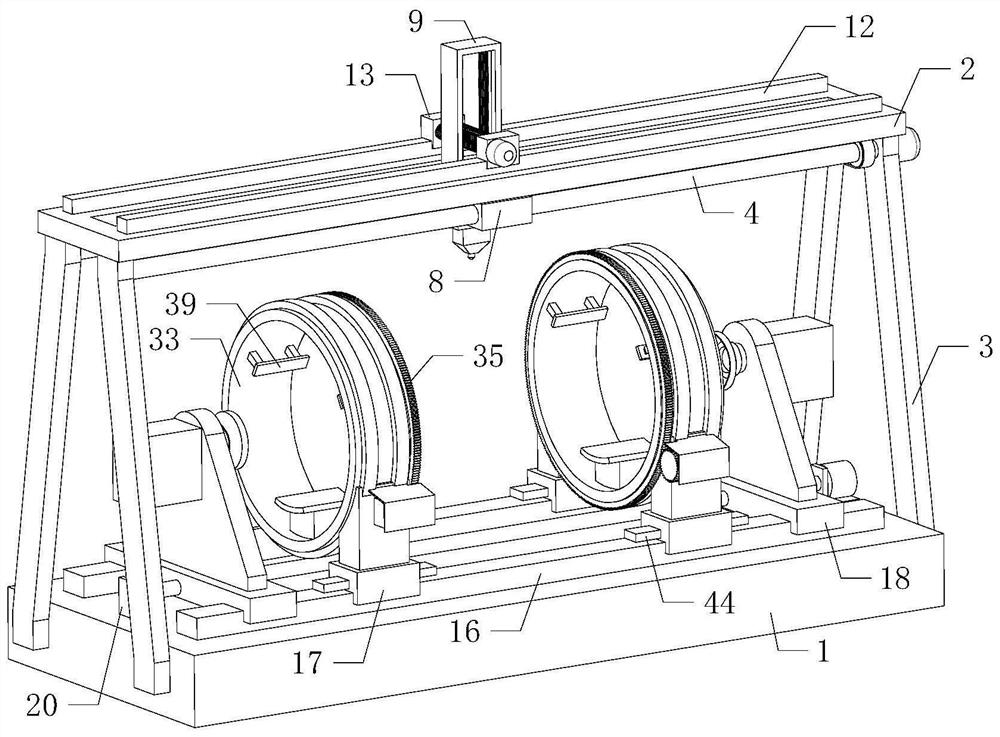

Left portion positioning and clamping tool for automobile left and right side inner plate front assembly

ActiveCN108237369AAccurate clamping and positioningEasy solderingWelding/cutting auxillary devicesAuxillary welding devicesAutomationWelding

The invention relates to a left portion positioning and clamping tool for an automobile left and right side inner plate front assembly. The tool comprises a left end automatic positioning and clampingdevice and a left auxiliary clamping device which is distributed on the right side of the left end automatic positioning and clamping device and is matched with the left end automatic positioning andclamping device to achieve positioning and clamping. The tool is reasonable in structural design and high in space utilization rate; clamping of the left portion of the front part assembly of the automobile left and right side inner plate front assembly can be achieved through a tool clamp, it is guaranteed that two lug bases can be accurately positioned and clamped, an external welding robot canconveniently and automatically conduct welding, the effective efficiency and the product quality are greatly improved, and the automation degree is high.

Owner:ANHUI DACHANG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com