Welding mechanism for recycling waste lithium batteries

A waste lithium battery and welding mechanism technology, which is applied in battery recycling, waste collector recycling, welding accessories, etc., can solve the problems of angle and height adjustment that cannot be welded, and the welding effect of waste lithium batteries, etc., to facilitate welding processing and improve convenience. Sex, damage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

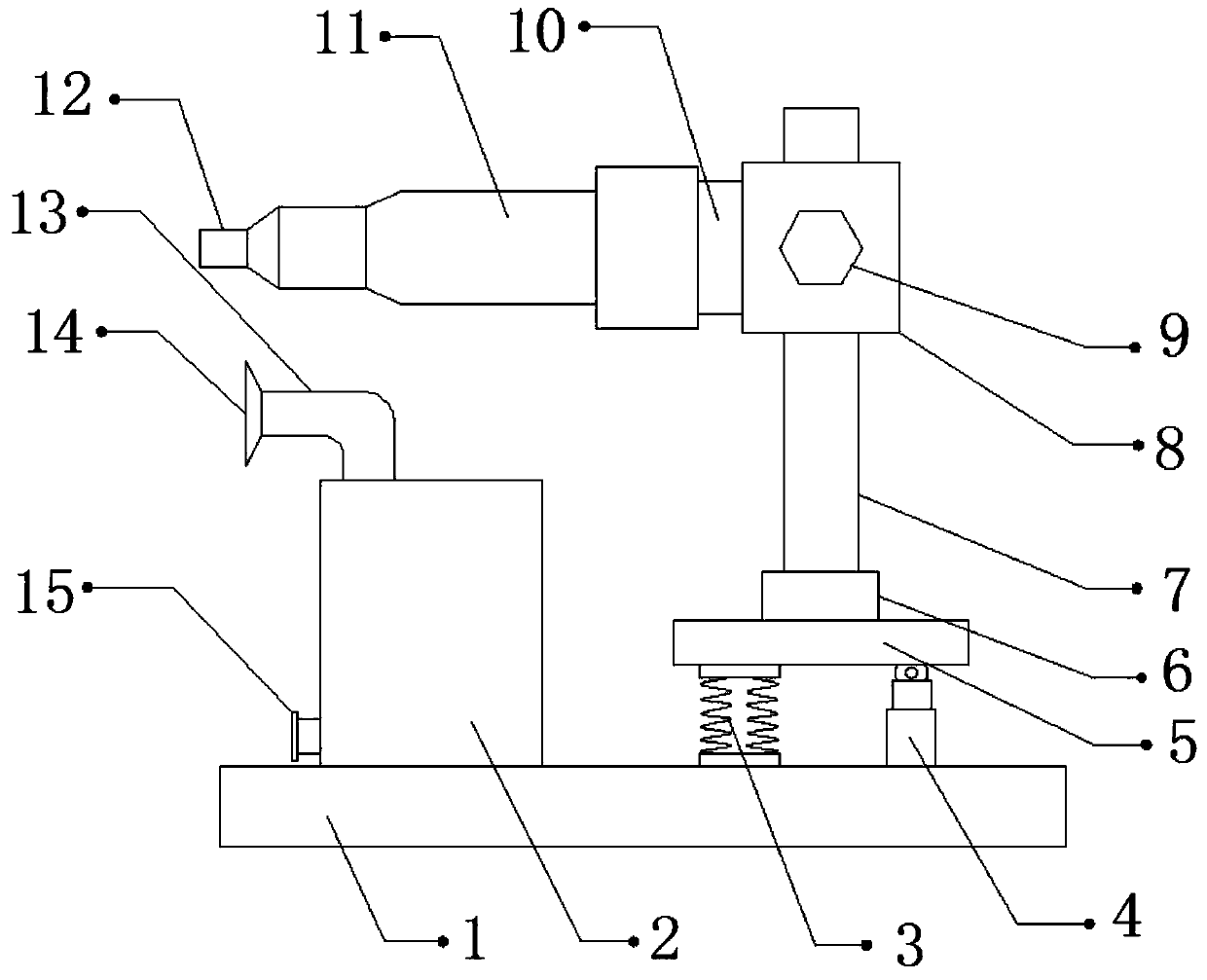

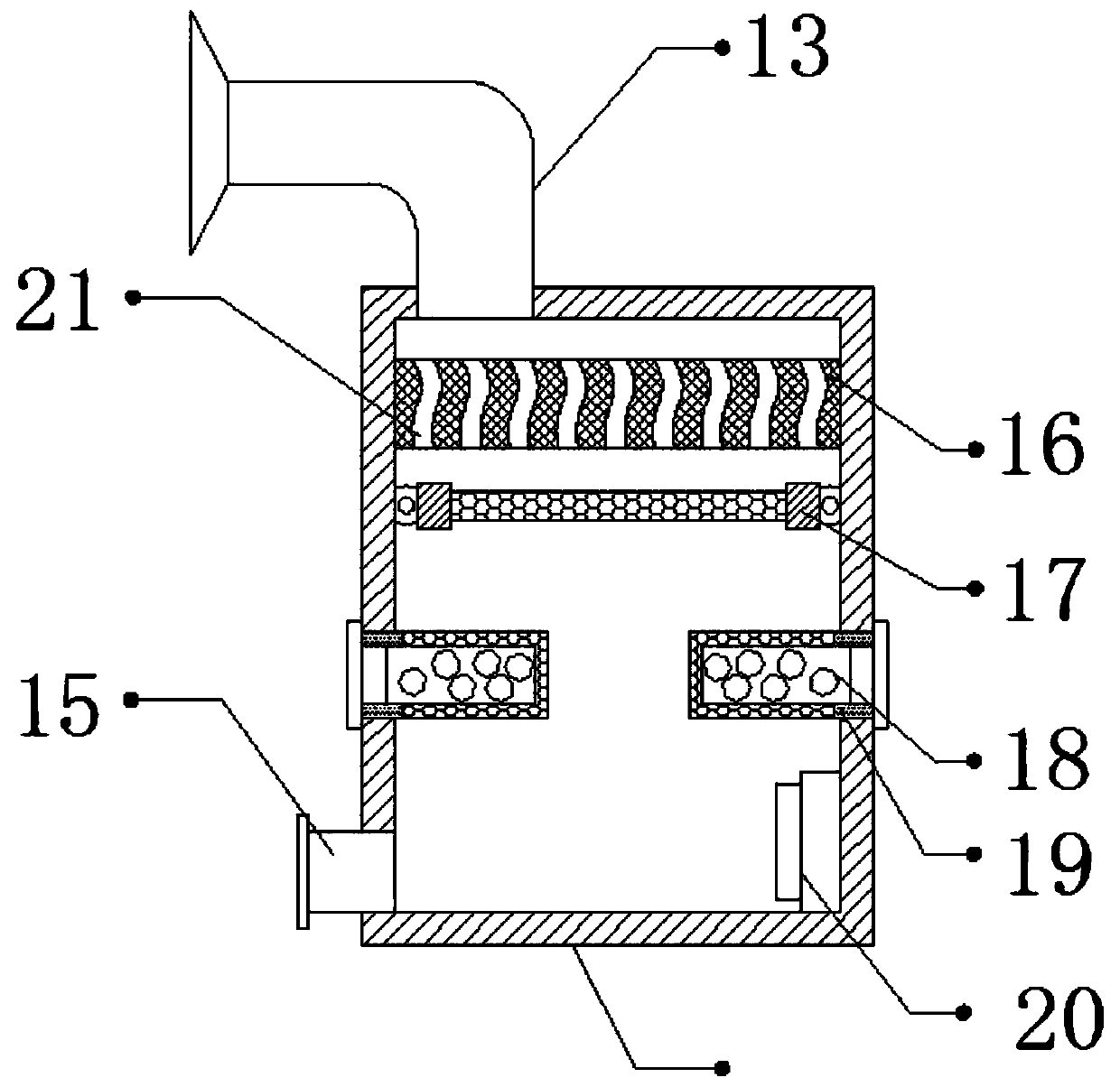

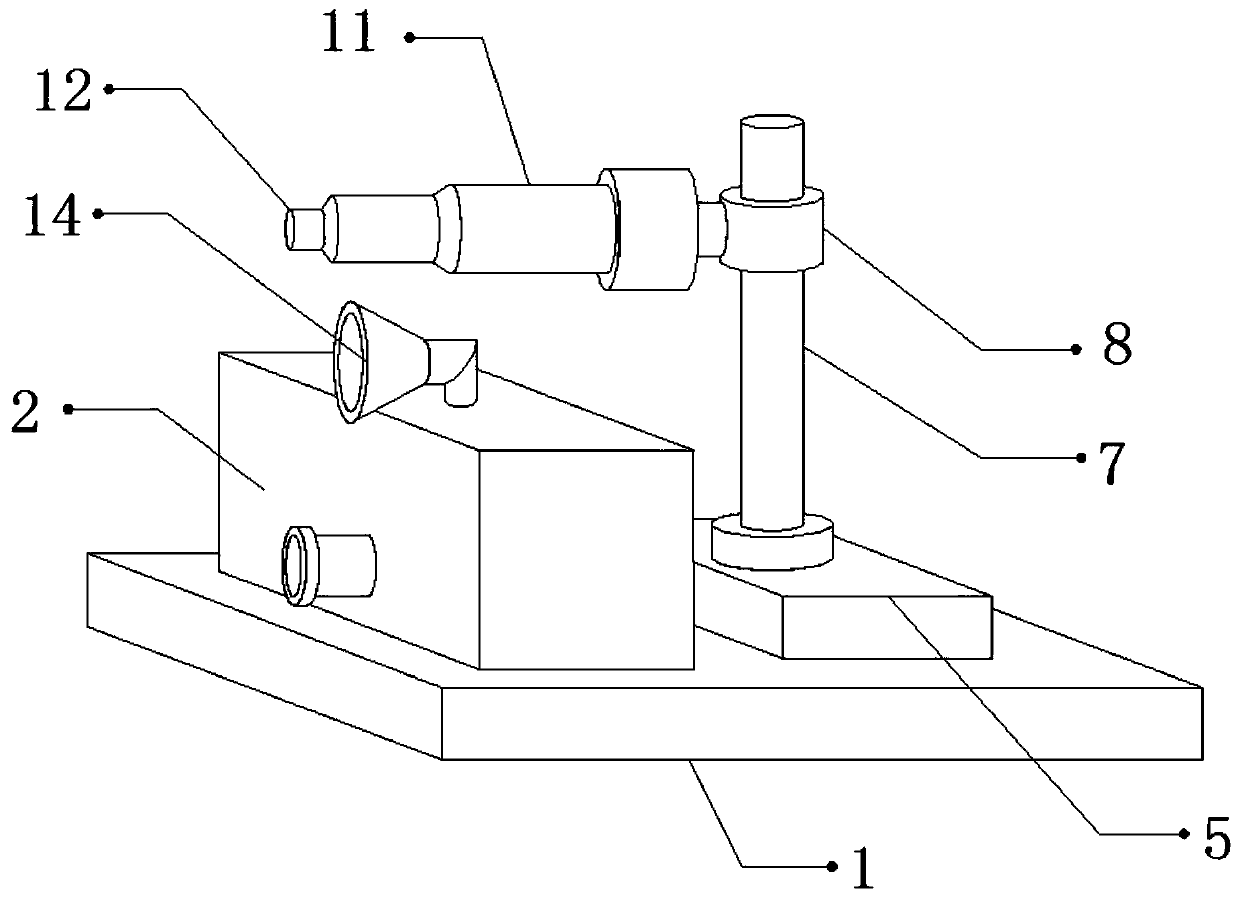

[0028] refer to Figure 1-3 , a welding mechanism for recycling waste lithium batteries, comprising a fixed seat 1, one side of the top outer wall of the fixed seat 1 is connected with a hydraulic rod 4 through a bolt, and the top outer wall of the hydraulic rod 4 is connected with a support plate 5 through a hinge, and the support A spring 3 is connected between one side of the bottom outer wall of the plate 5 and one side of the top outer wall of the fixed seat 1 by bolts, the top outer wall of the support plate 5 is connected with a damping bearing 6 by bolts, and the inner wall of the damping bearing 6 is rotationally connected with a support Rod 7, the outer wall of support rod 7 is slidingly connected with sliding sleeve 8, and the outer wall of one side of sliding sleeve 8 is connected with fixed shaft 10 by bolt, and the outer wall of one side of fixed shaft 10 is connected with welding torch 11 by bolt, and one side of welding torch 11 The outer wall of the side is pr...

Embodiment 2

[0032] refer to Figure 4 , a welding mechanism used for recycling waste lithium batteries. Compared with Embodiment 1, the outer wall of one side of the welding torch 11 is connected with a protective cover 22 by bolts, which can protect people's eyes and prevent the electric arc from affecting people's eyes. Causes burns to eyes.

[0033] Working principle: When in use, the angle of the welding torch is adjusted through the hydraulic rod 4 and the spring 3. At the same time, the height of the welding torch 11 can be adjusted through the sliding sleeve 8 and the fastening bolt 9. After the adjustment is completed, the welding torch 11 and the welding head 12. Weld the waste lithium battery. During welding, smoke will be generated. The smoke will be absorbed into the purification box 2 through the suction hood 14 and the bellows 13, and the smoke will be slowed down through the guide plate 16 and the guide hole 21. The flow rate of the gas is so that the activated carbon filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com