An auxiliary welding device for auto parts

A technology for auto parts and auxiliary welding, applied in auxiliary devices, auxiliary welding equipment, welding protection devices, etc., can solve the problems of inability to clean dust, influence of parts welding, welding interference of auto parts, etc., to improve the flow speed, The effect of preventing burns and preventing damage to the eyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

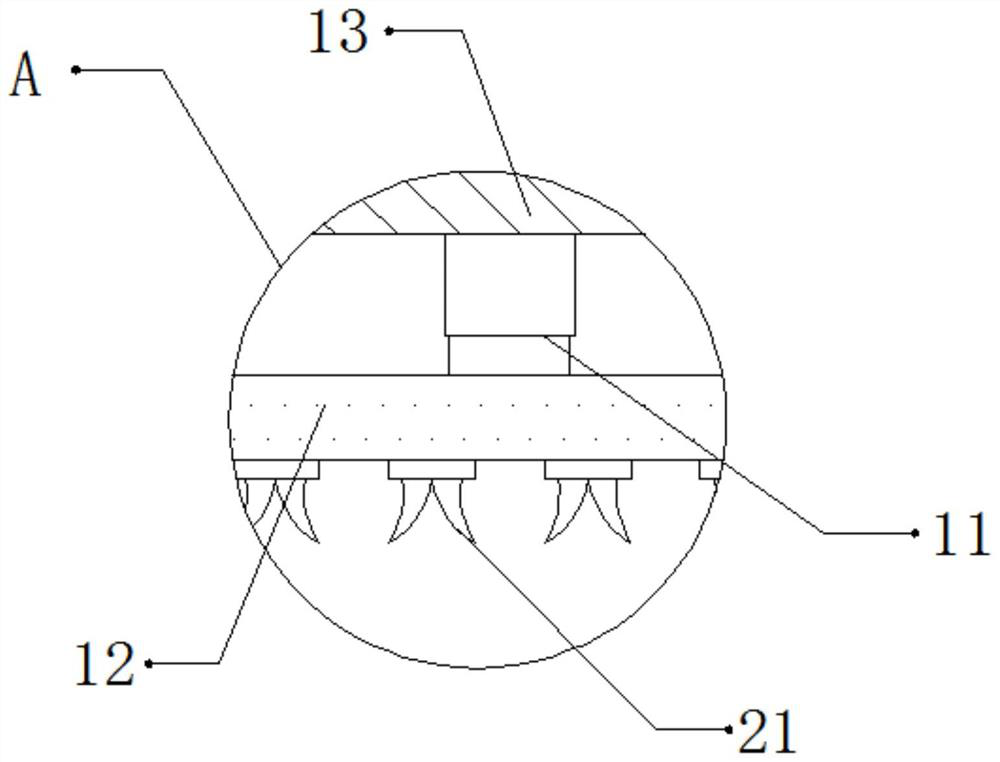

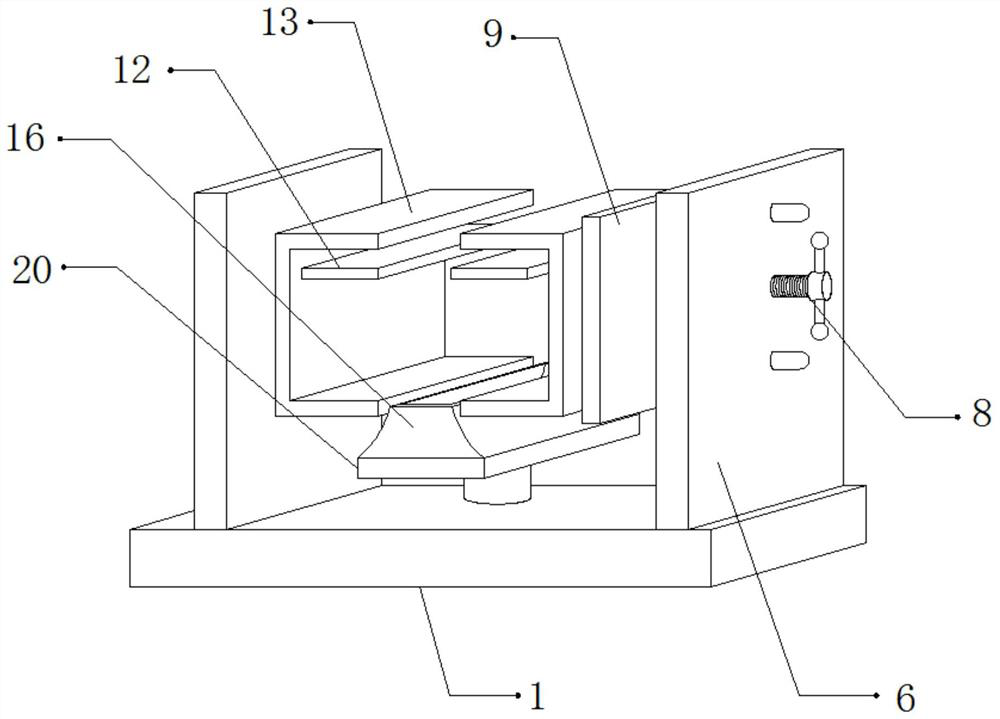

[0027] refer to Figure 1-3 , an auxiliary welding device for auto parts, comprising a fixed seat 1, the two sides of the outer wall of the top of the fixed seat 1 are connected with a fixed plate 6 by bolts, and the outer wall of one side of the fixed plate 6 is provided with two through holes, and two The inner walls of the through holes are all slidably connected with guide rods 7, and the outer walls of one side of the two guide rods 7 are connected with a connecting plate 9 by bolts, and one side of the outer wall of the connecting plate 9 is connected with a rotating shaft 10 through bearing rotation, and the other fixed plate One side outer wall of 6 is connected with rotating rod 14 through bearing rotation, and one side outer wall of rotating rod 14 and one side outer wall of rotating shaft 10 are all connected with U-shaped frame 13 by bolt, and the top outer wall of fixed base 1 is connected with hydraulic pressure by bolt. Rod 2, and the top outer wall of the hydra...

Embodiment 2

[0031] refer to Figure 4 , an auxiliary welding device for auto parts. Compared with Embodiment 1, the outer wall of one side of the fixing seat 1 is connected with a protective plate 22 by bolts, and the shape of the protective plate 22 is corrugated, and the protective plate 22 is transparent. The material can protect the eyes of the operator so that the auto parts can be welded to prevent the arc generated during welding from causing burns to the eyes of the operator. At the same time, the corrugated protective plate 22 can refract the arc. Thereby dispersing the arc to prevent the arc from causing damage to the operator's eyes.

[0032]Working principle: When in use, place two auto parts inside the U-shaped frame 13, start the electric telescopic rod 11, and the electric telescopic rod 11 will drive the splint 12 to move down, thereby clamping the auto parts through the splint 12 Fixed, the frictional force between the auto parts and the clamping plate 12 can be increase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com