A thin steel plate welding equipment for tooling processing of petroleum accessories

A technology for welding equipment and thin steel plates, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problem of large gaps at the joints of two thin steel plates, the inability to ensure the angle of the two steel plates, and lack of butt joints between two thin steel plates, etc. problems, to avoid burn-through and pits, improve welding efficiency, and enhance the effect of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following embodiments of the present invention in conjunction with the accompanying drawings are described in detail, but the present invention may be implemented in a variety of different ways defined and covered by the claims.

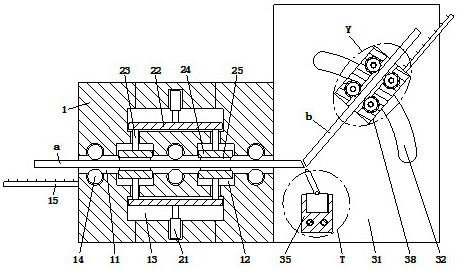

[0032] See Figure 1 and Figure 2 , a kind of petroleum accessories tooling processing with thin steel plate welding equipment, comprising a base 1, a fixed unit 2 and a welding unit 3, the base 1 is installed inside the fixed unit 2, the welding unit 3 is provided at the right end of the base 1.

[0033] See Figure 1 and Figure 2, the base 1 runs through the inside from left to right to open a feed hole 11, the upper side wall and the lower side wall of the via hole 11 are symmetrically opened with a concession slot 12, the concession slot 12 is opened on the side away from the via hole 11 there is a slip groove 13; The base 1 is fixed on the lower left end of the fixed side with a scale ruler 15; By the No. 1 scale 15 can be convenient to obs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com