Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82results about How to "Reduce angle error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

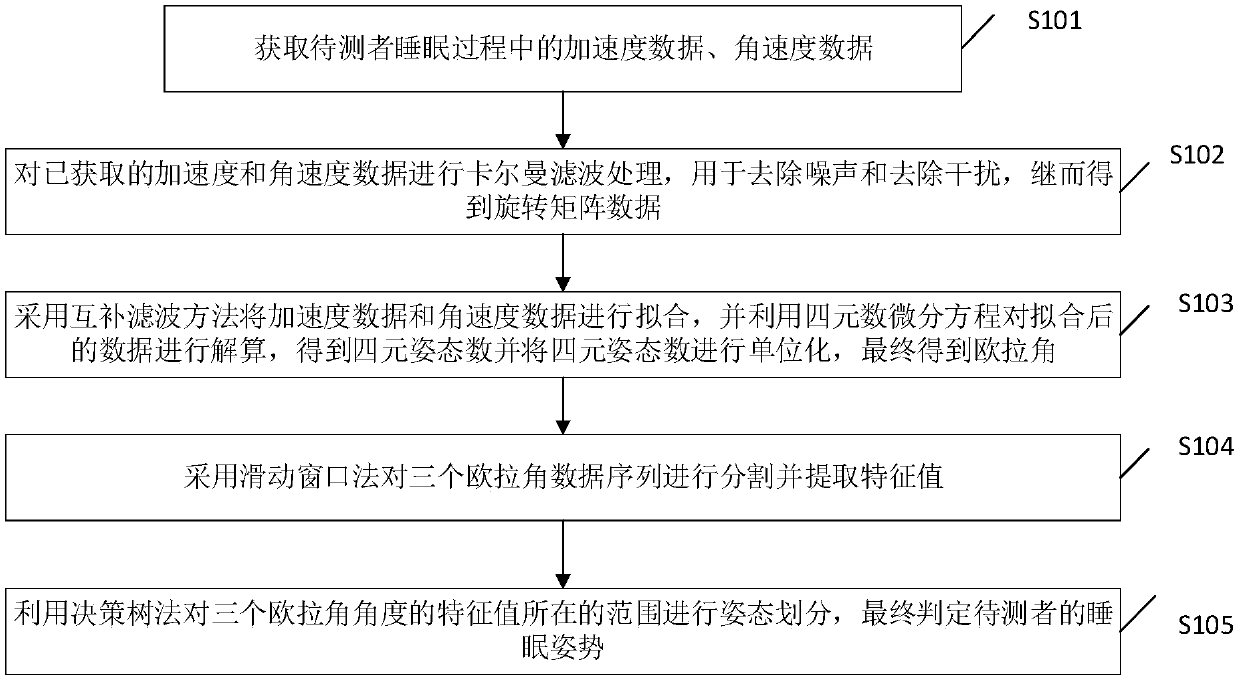

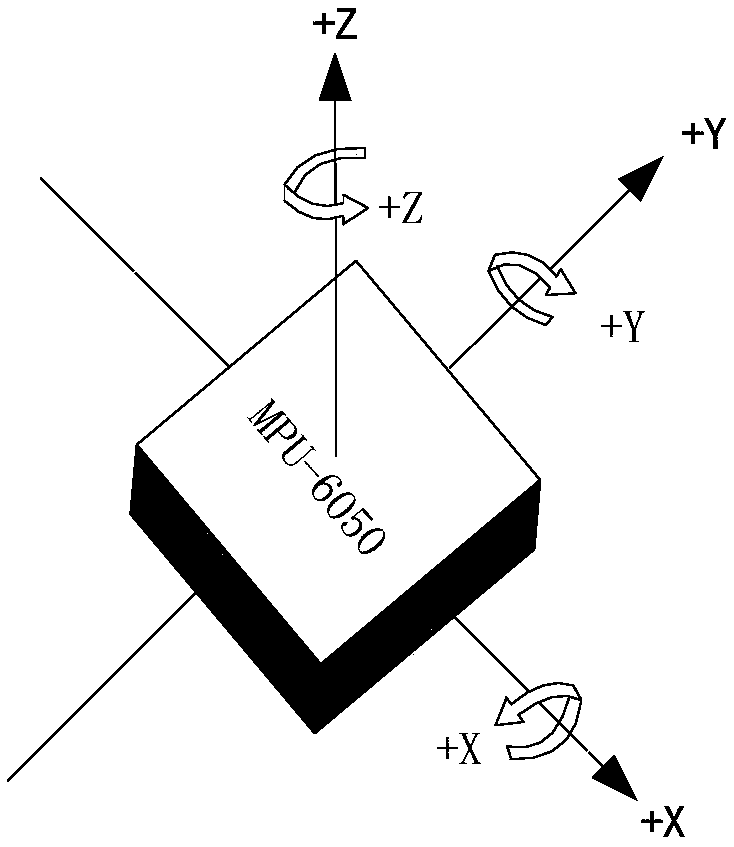

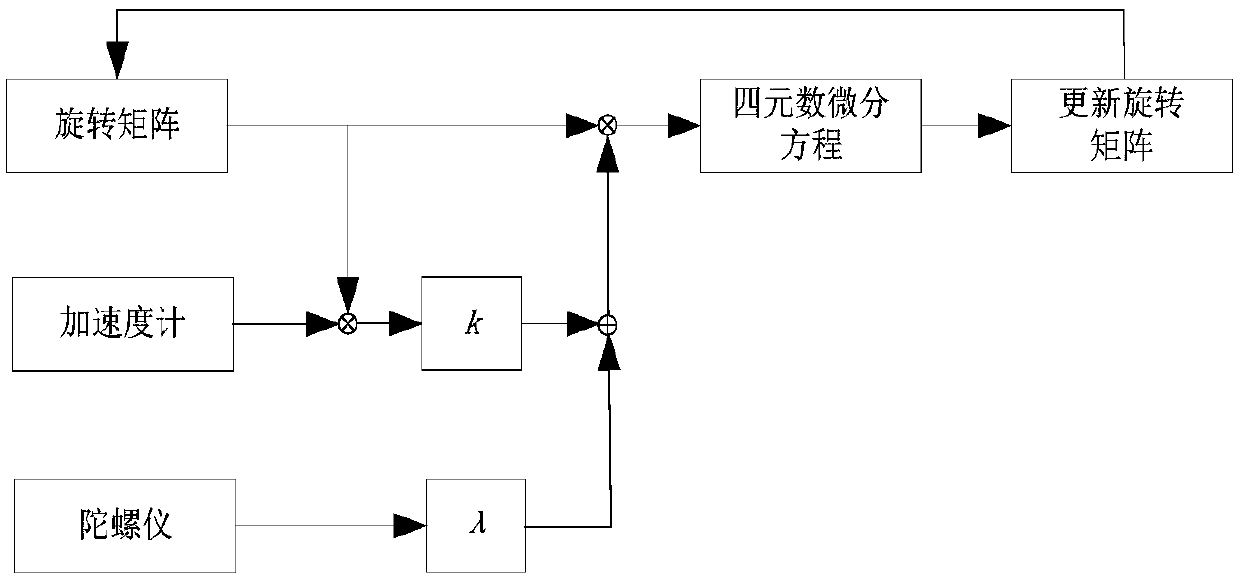

Sleeping-posture judgment method based on MPU-6050

InactiveCN108670263ASimple structureEasy to calculateDiagnostic recording/measuringSensorsComplementary filterDecision taking

The invention discloses a sleeping-posture judgment method based on MPU-6050. The sleeping-posture judgment method includes the steps that acceleration data and angular speed data of a to-be-detectedperson in the sleeping process are obtained; the obtained acceleration data and the obtained angular speed data are subjected to Kalamn filtering, noise is removed, and thus rotation matrix data is obtained; the acceleration data and the angular speed data are fitted with the complementary filtering algorithm, the fitted data is resolved through a quaternion differential equation, the quaternary posture number is obtained, and is unitized, and eulerian angles are finally obtained; three eulerian angle data series are cut with the sliding window method, and characteristic values are extracted;ranges of the characteristic values of the three eulerian angles are subjected to posture division with the decision tree method, and the sleeping posture of the to-be-detected person is finally judged. According to the sleeping-posture judgment method based on the MPU-6050, the sleeping posture is effectively detected, and the method can assist persons in improving the sleeping quality and promoting good health.

Owner:HARBIN UNIV OF SCI & TECH

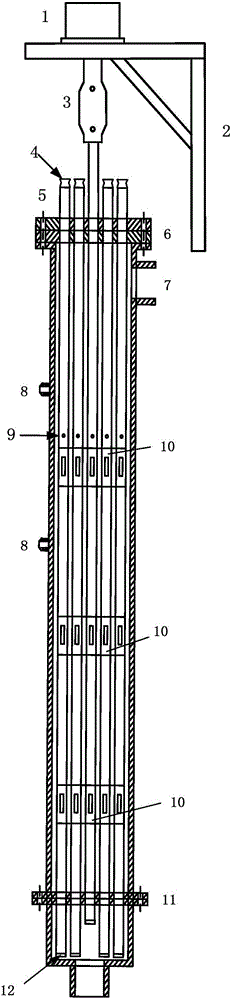

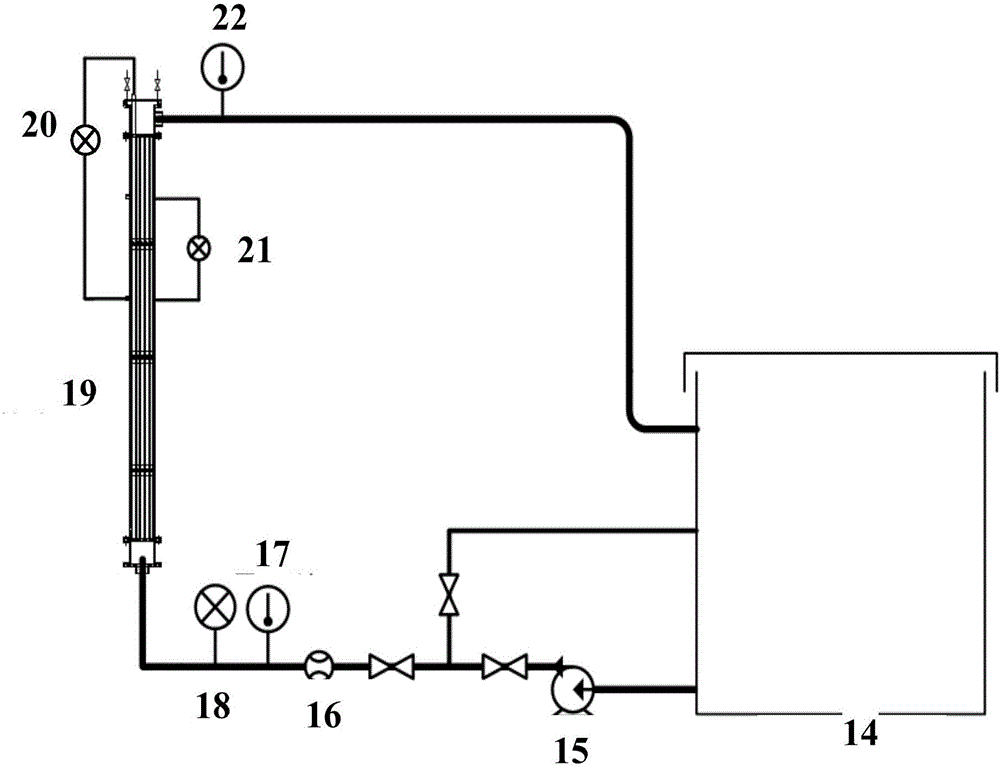

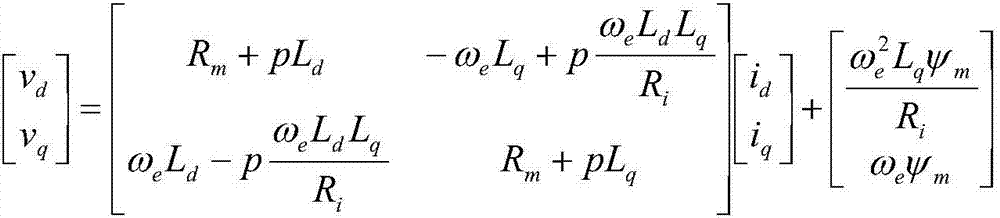

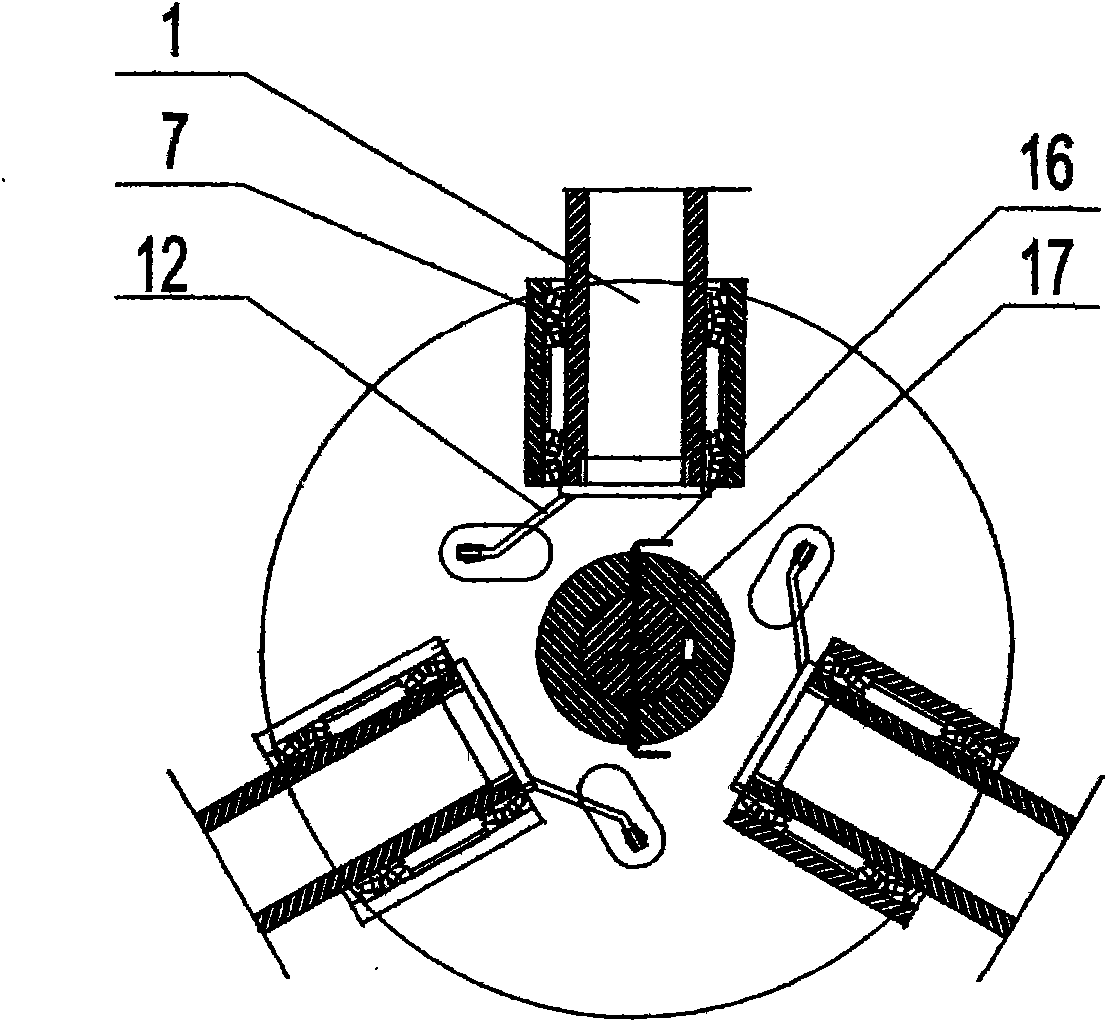

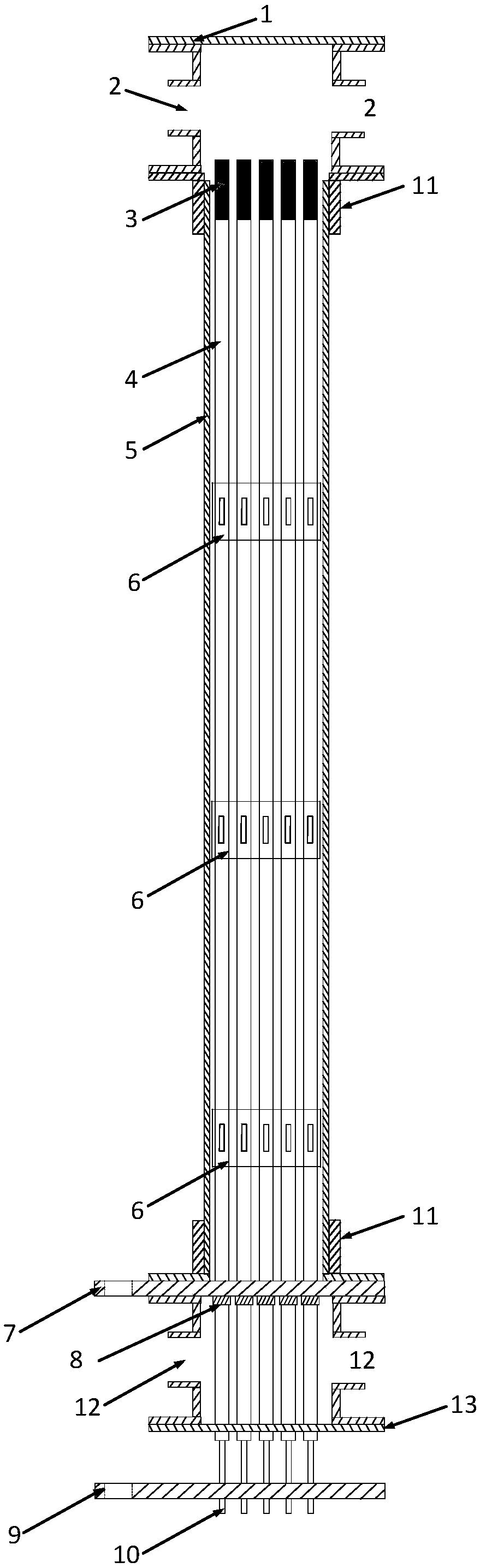

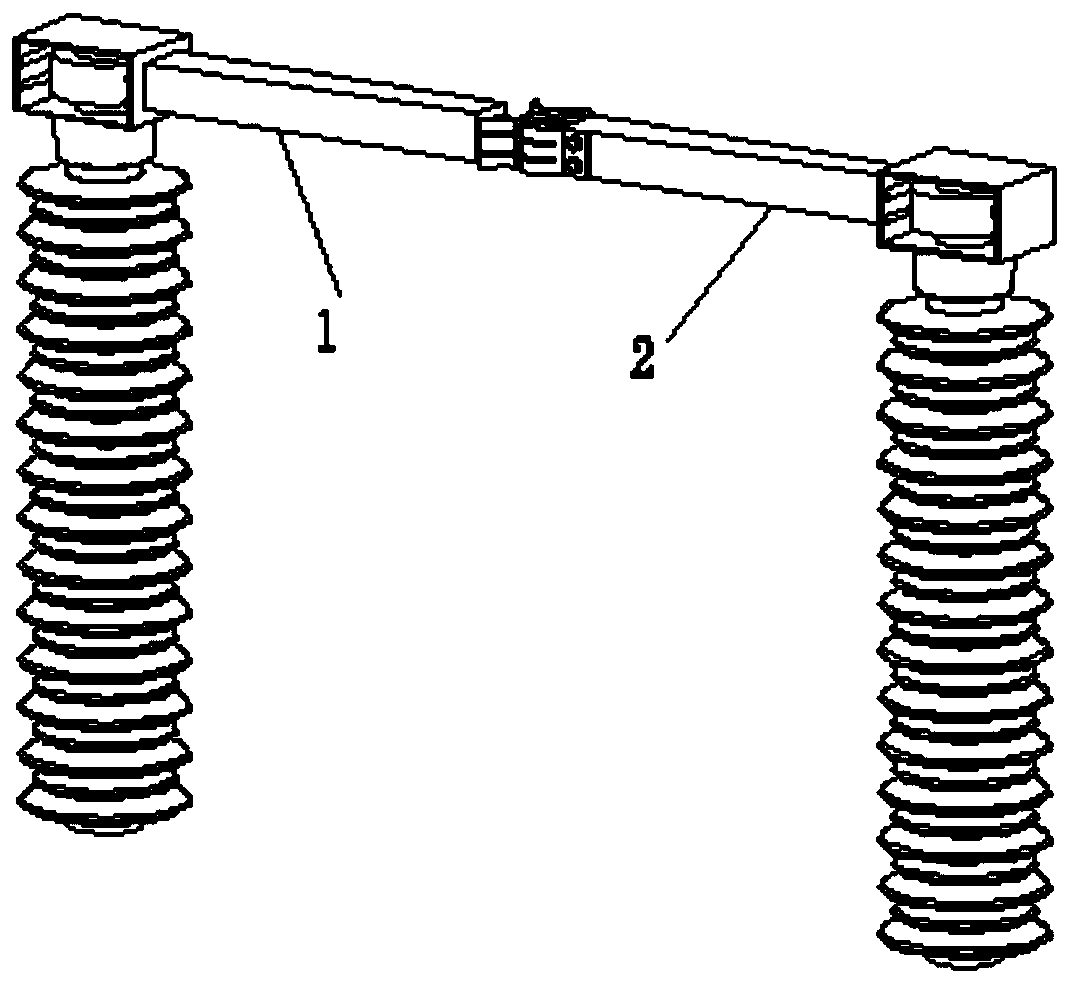

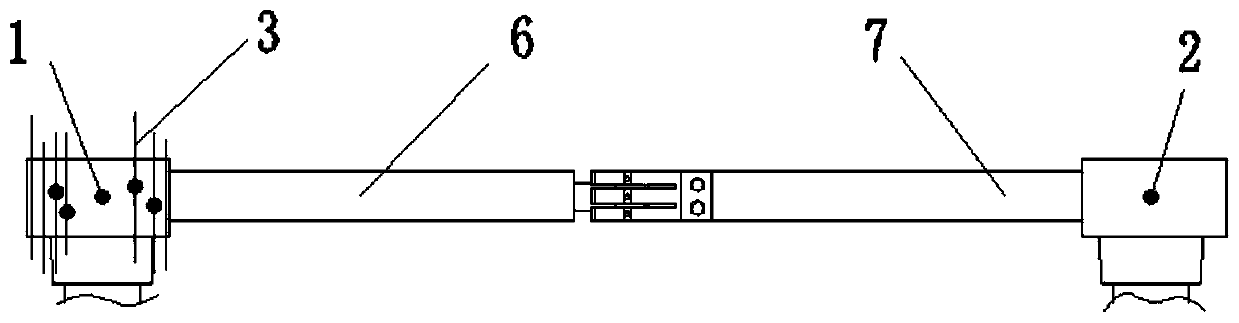

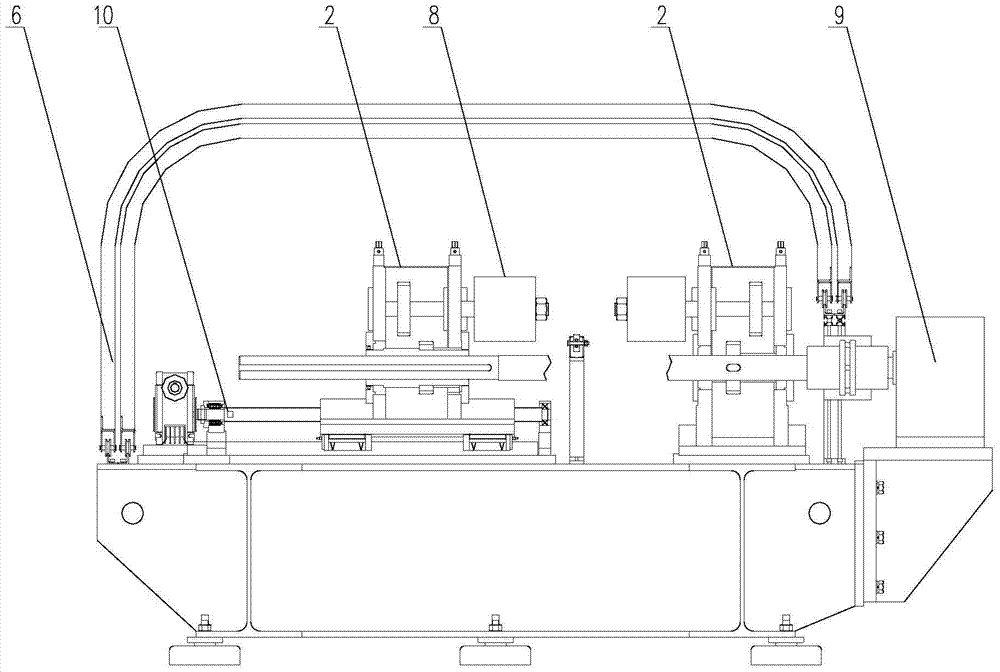

Rod bundle channel flow pressure measuring test device

ActiveCN106683722AEasy to moveSmooth rotationNuclear energy generationNuclear monitoringRotary stageCoupling

The invention provides a rod bundle channel flow pressure measuring test device, which comprises a water storage tank, a pressure measuring body, and a centrifugal pump, a regulating valve and a thermometer sequentially connected with the water storage tank through a pipeline, wherein the pressure measuring body comprises a rod bundle channel barrel, a rod bundle channel formed by rod bundles arranged in the rod bundle channel barrel; the upper ends of the rod bundles are connected with a high-accuracy rotating disk arranged on a rotating table support through a coupler; two body pressure ports formed up and down are formed in the rod bundle channel barrel; a pressure guiding port is formed in each rod bundle of the rod bundle channel; a sealing rubber plug is arranged at the lower end of each rod bundle; a fast adapter is arranged at the upper end of each rod bundle; pressure difference transmitters are respectively arranged between each pressure guiding port and each fast adapter as well as between the two body pressure ports. The rod bundle channel flow pressure measuring test device provided by the invention can simulate single-phase flow in a reactor rod bundle channel so as to research a resistance characteristic of the rod bundle channel, and is simple in structure, low in cost, accurate and convenient to acquire data, and wide in research working condition range.

Owner:HARBIN ENG UNIV

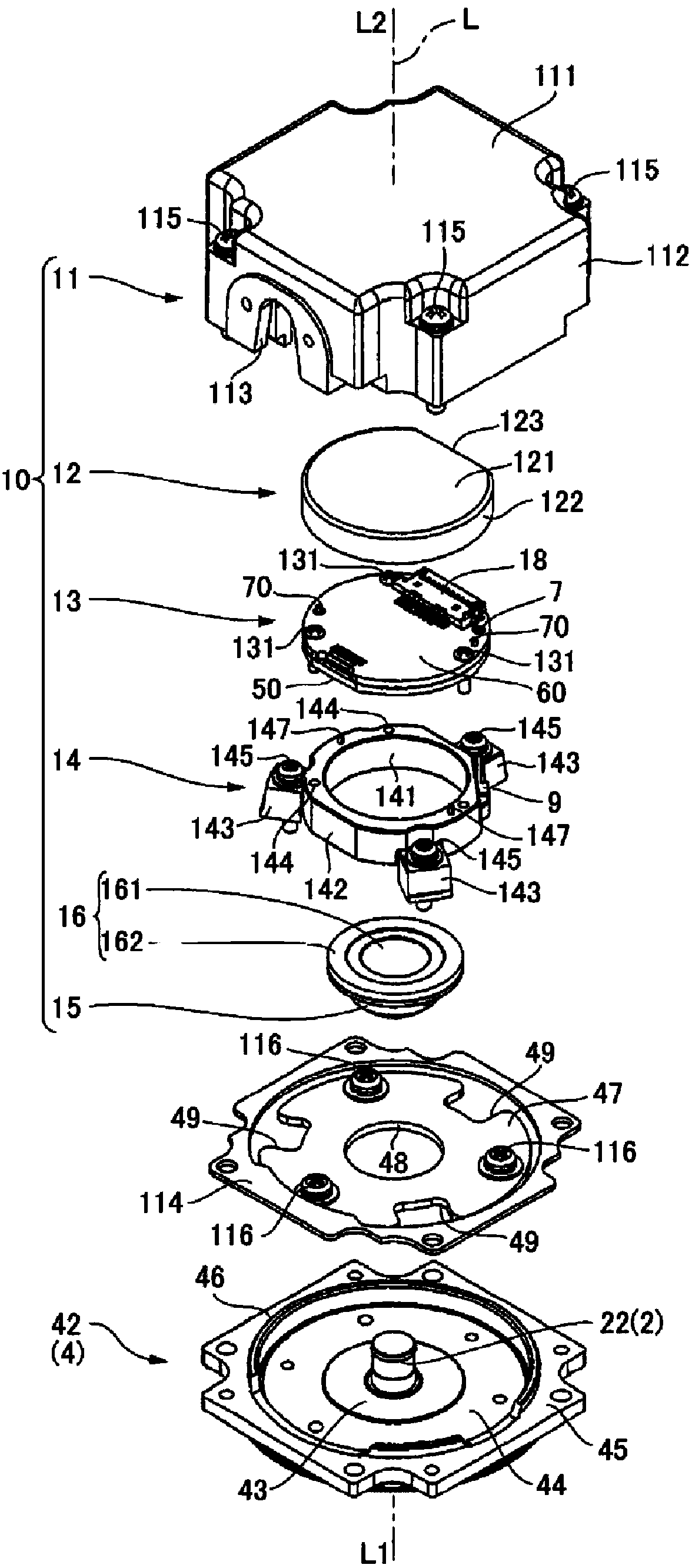

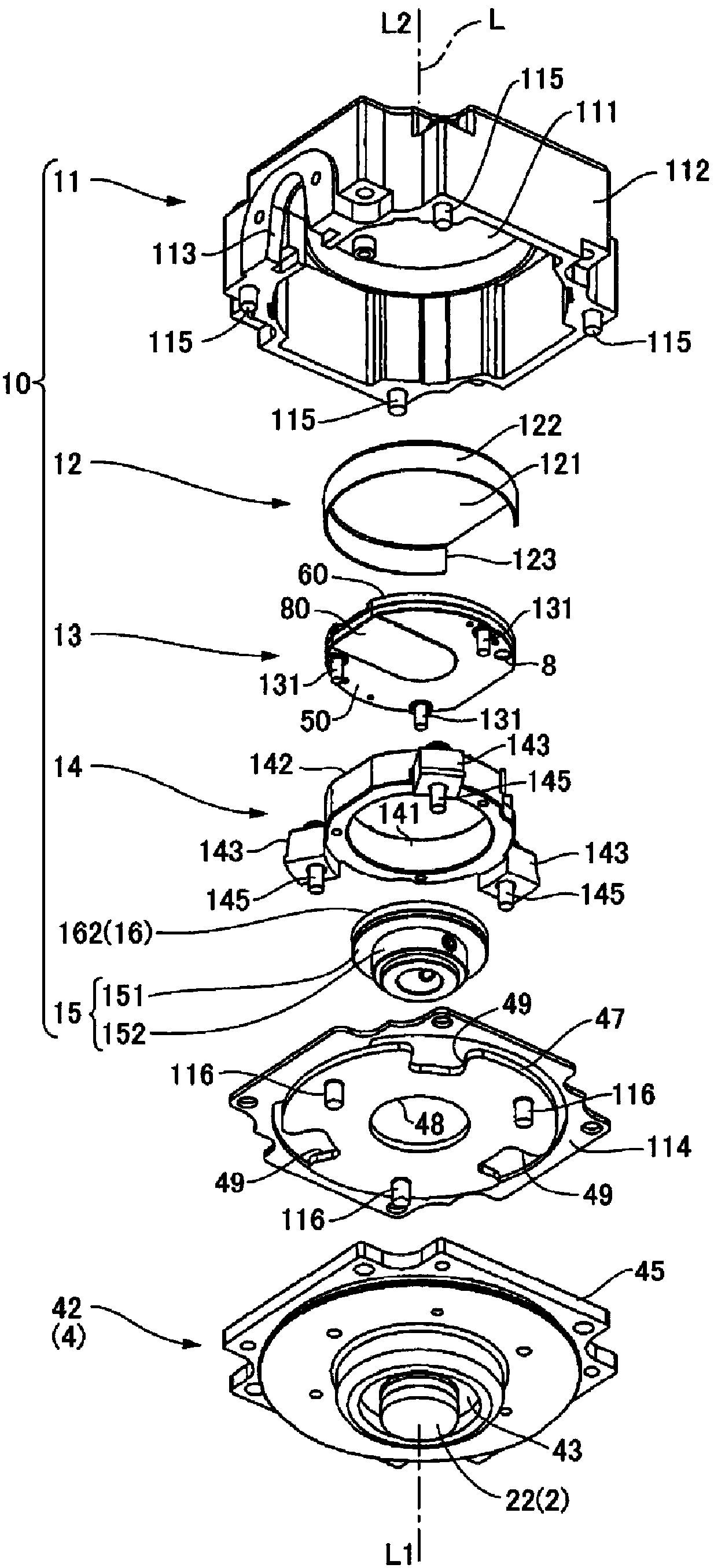

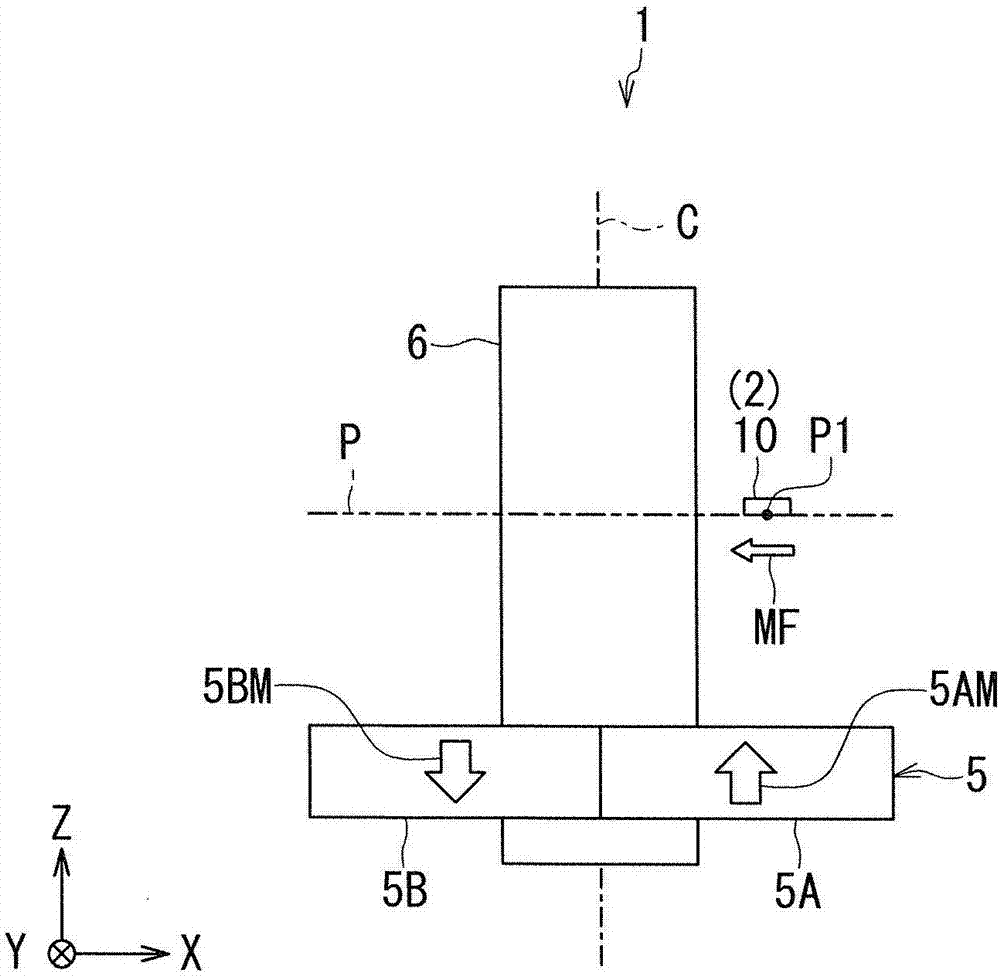

Motor

ActiveCN109120108AImprove shielding effectReduce angle errorAssociation with grounding devicesMagnetic circuit rotating partsMagnetic noiseMagneto

A motor can reduce the influence of magnetic noise, electromagnetic wave noise and electrical noise on a coder. The motor (1) may include a coder (10) configured to detect rotation of a turning shaft(2). The coder (10) comprises a substrate (60) equipped with a magneto sensitive element (17). The substrate (60) is coated with a substrate holding rack (50) being in signal grounding electrical connection with the coder circuit from the magnet (16) size, and one side, opposite to the substrate holding rack (50) is coated with a first shielding part (12) of signal grounding level, and a second shielding part (80) of the magneto sensitive element (17) fixedly coats the substrate holding rack (50). The substrate (60) is completely covered by the part of the signal grounding level, and the magneto sensitive element (17) and the coder can completely shield electrical noise. The motor can enhance the shielding effect on the magnetic noise and the electromagnetic wave noise and can enhance theshielding effect of the electrical noise.

Owner:NIDEC SANKYO CORP

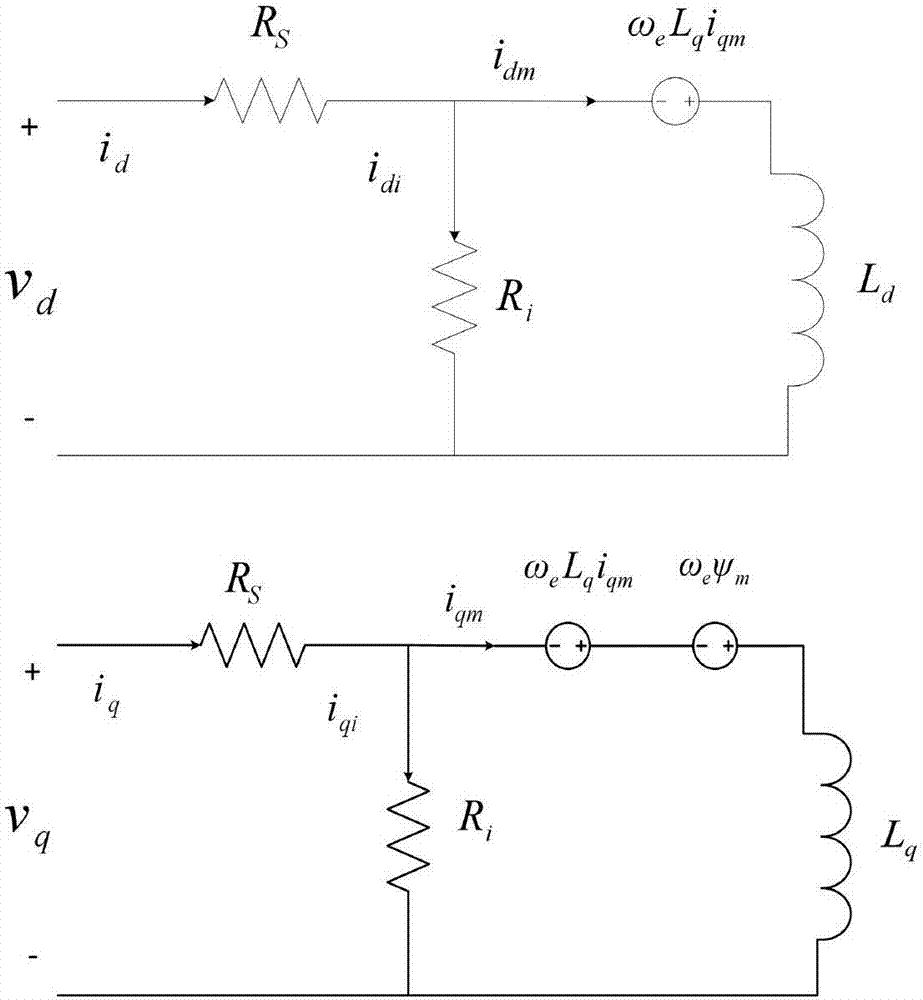

Iron core loss-based direct torque control method for ultra-high-speed permanent magnet synchronous motor

ActiveCN107493051AFast torque responseImprove robustnessElectronic commutation motor controlVector control systemsUltra high speedElement analysis

The invention provides an iron core loss-based direct torque control method for an ultra-high-speed permanent magnet synchronous motor. The invention discloses an iron core loss-based mathematical modeling method for the ultra-high-speed permanent magnet synchronous motor; a voltage equation, a flux linkage equation and a torque equation are adopted in motor rotary speed control by adopting the direct torque control method, wherein the flux linkage value is obtained by three-phase current calculation through a finite element analysis method; and iron core loss is taken into consideration in the voltage equation, and the iron core loss is converted into equivalent resistance. The method disclosed in the invention can be applied to the ultra-high-speed permanent magnet synchronous motor control system based on sensor-less rotary speed estimation; and angular error caused by iron core loss in the sensor-less rotary speed estimation can be effectively lowered.

Owner:NANJING UNIV OF SCI & TECH

Probe bending device for temperature sensor production

InactiveCN110421034AAchieve the effect of automatically clamping and fixing the probeEasy to operateKnittingNeedlesEngineeringRotating disc

The invention discloses a probe bending device for temperature sensor production. The probe bending device comprises a support seat, wherein a mounting cavity is formed in the support seat; a first rotating rod which is vertically arranged is rotatably mounted on the inner wall of the bottom end of the mounting cavity; a driven bevel gear is fixedly mounted on the outer side of the first rotatingrod; the top end of the first rotating rod extends to the outside of the mounting cavity, and a rotating disc which is horizontally arranged is fixedly mounted; a first bending rod which is verticallyarranged is fixedly mounted on the middle position of the top end of the rotating disc; a second bending rod which is vertically arranged is fixedly mounted at one side, located at the first bendingrod, of the top end of the rotating disc; a mounting hole is formed in one side of the support seat; a second rotating rod which is horizontally arranged is rotatably mounted in the mounting hole; andone end of the second rotating rod extends into the mounting cavity. The probe bending device is ingenious in structure, capable of rapidly bending the probe, simple to operate, small in angle error,high in bending efficiency and labor-saving and convenient to use.

Owner:中电鼎康(天长)科技有限公司

Angular transducer and angular transducer system

ActiveCN108225381AReduce angle errorConverting sensor output electrically/magneticallyLeast squaresSensor system

The invention relates to an angular transducer and angular transducer system. The angular sensor has a plurality of synthetic magnetic field information generation unit and an angle operation unit. The plurality of synthetic magnetic field information generation units detect a synthetic magnetic field of a detection object magnetic field and a noise magnetic field apart from the detection object magnetic field in a plurality of mutually different detection positions and generate a plurality of pieces of synthetic magnetic field information containing information of at least direction in direction and intensity of the synthetic field. In each of the plurality of detection positions, the direction of the detection object magnetic field changes corresponding to the angle of the detection object. The angle operation unit generates an angle detection value according to the plurality of pieces of synthetic magnetic field information by using a least square method.

Owner:TDK CORPARATION

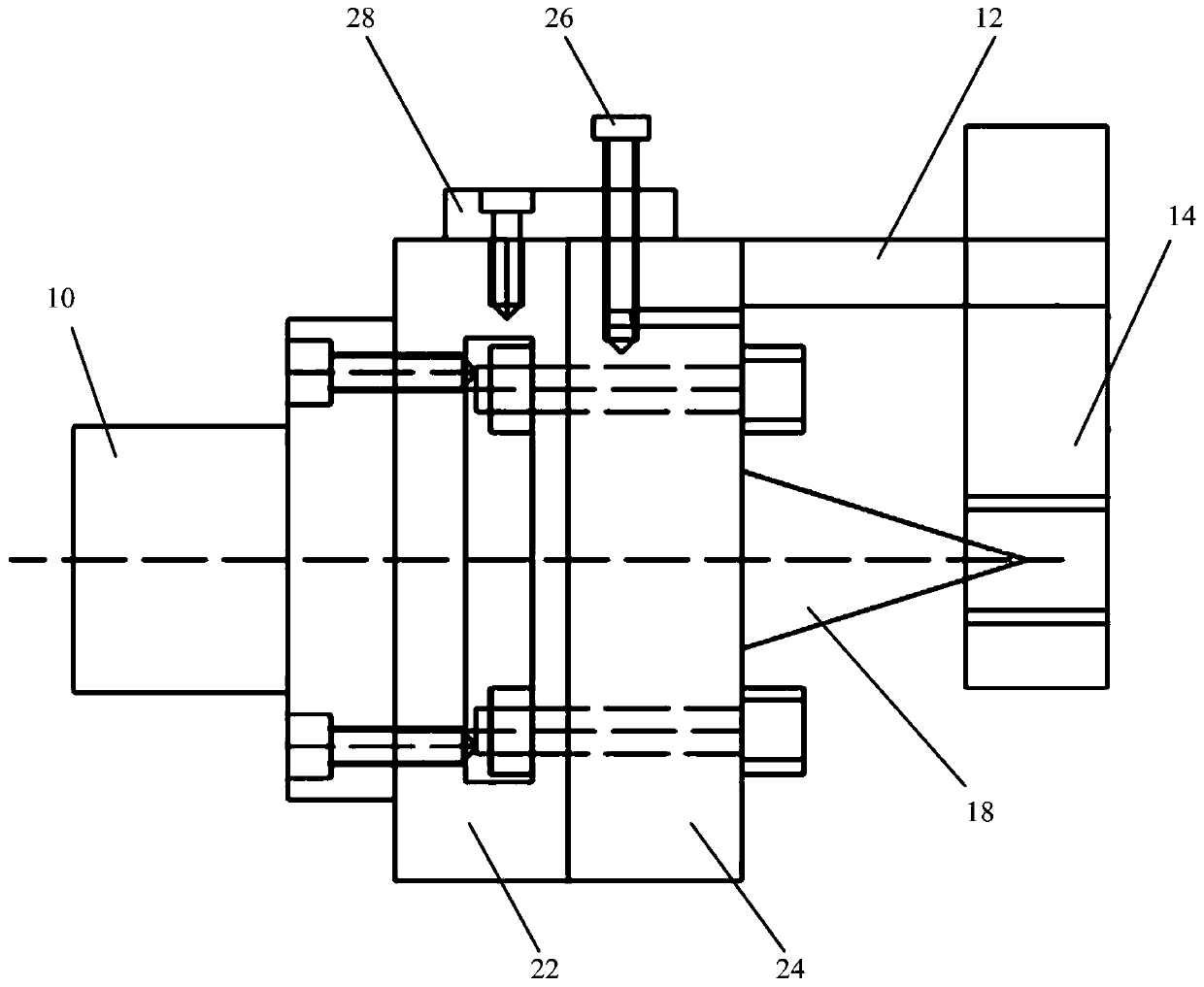

Positioning tool of eccentric shaft and machine tool

PendingCN110202430AGuaranteed accuracyRealize clamping positioningRevolution surface grinding machinesGrinding work supportsMachine toolEngineering

The invention provides a positioning tool of an eccentric shaft and a machine tool. The positioning tool comprises a chuck assembly, a transmission part eccentrically fixed to the chuck assembly, an angle positioning jacket, a front tip, and a rear tip, the angle positioning jacket is connected with the transmission part and is provided with a positioning hole, the positioning hole is conical, andis used for radially fixingthe eccentric shaft, the front tip is fixedly arranged on the chuck assembly, the rear tip is fixedly arranged on the machine tool, and the front tip and the rear tip are used for abutting against the two axial ends of the eccentric shaft. Through the technical scheme, different specifications of eccentric shafts can be rapidly clamped and positioned, the machining precision of the eccentric shaft can be improved, the scrappage is reduced, the positioning tool is simple in structure, only few parts like a spline positioning sleeve need to be replaced, the replacingwork intensity of the positioning tool of the eccentric shaft can be reduced, and the replacing efficiency of the positioning tool is improved.

Owner:ZHEJIANG JINYUE MACHINERY TECH DEV

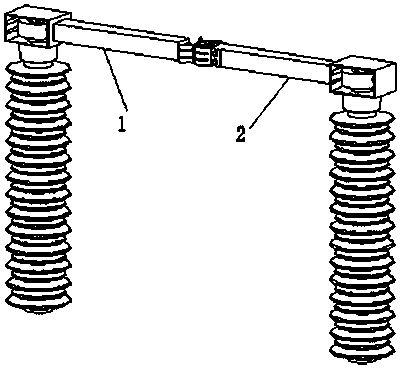

Real-time detection method for state of split knife switch

PendingCN110942443ARealize automatic positioningImprove accuracyImage enhancementImage analysisSample imageEngineering

The invention provides a real-time detection method for the state of a split knife switch, and the method comprises the steps: collecting a real-time monitoring video of the split knife switch, obtaining each frame of image of the video, establishing a boundary line model of a knife switch arm of the type, and storing the boundary line model as a model file; obtaining sample images through multiple ways, training the sample images through deep learning to obtain a training model, then detecting each frame of image to obtain a knife switch area and a knife switch state in the image, and positioning a knife switch in the image in combination with a model file; performing detection according to a positioning result, and calculating an initial included angle between the left knife switch arm and the right knife switch arm; estimating a system error, determining a correction included angle between the left knife switch arm and the right knife switch arm in the next frame of image, judging the real-time state of the knife switch in each frame of image until the knife switch is detected to stop moving, and verifying the final state of the knife switch movement in the video; according to the method, the problem of low real-time detection precision of the state of the split knife switch is solved.

Owner:南京鑫和汇通电子科技有限公司

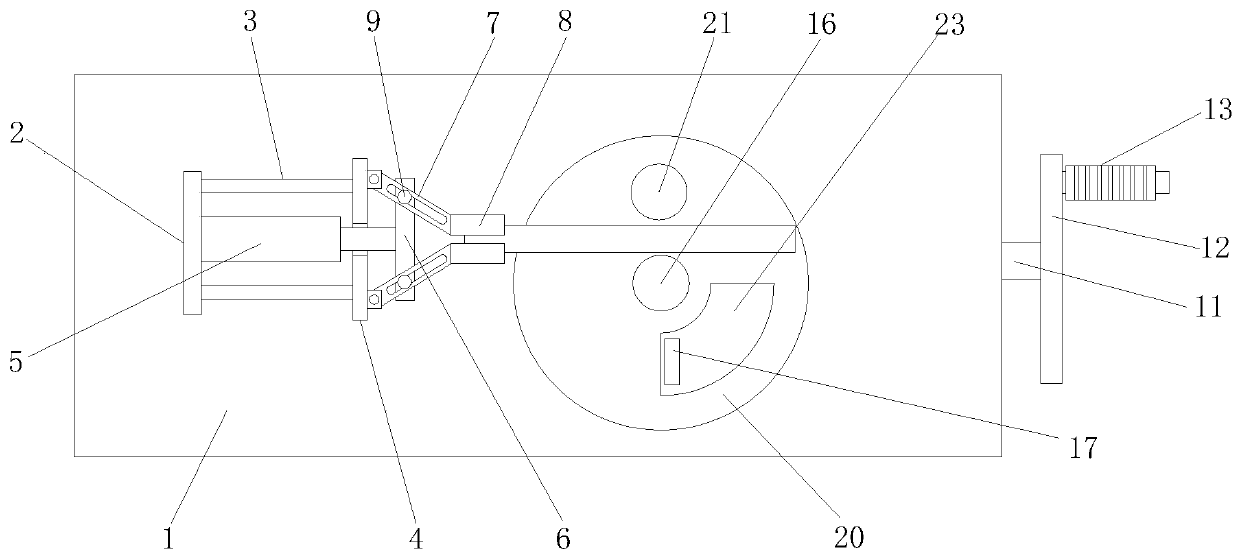

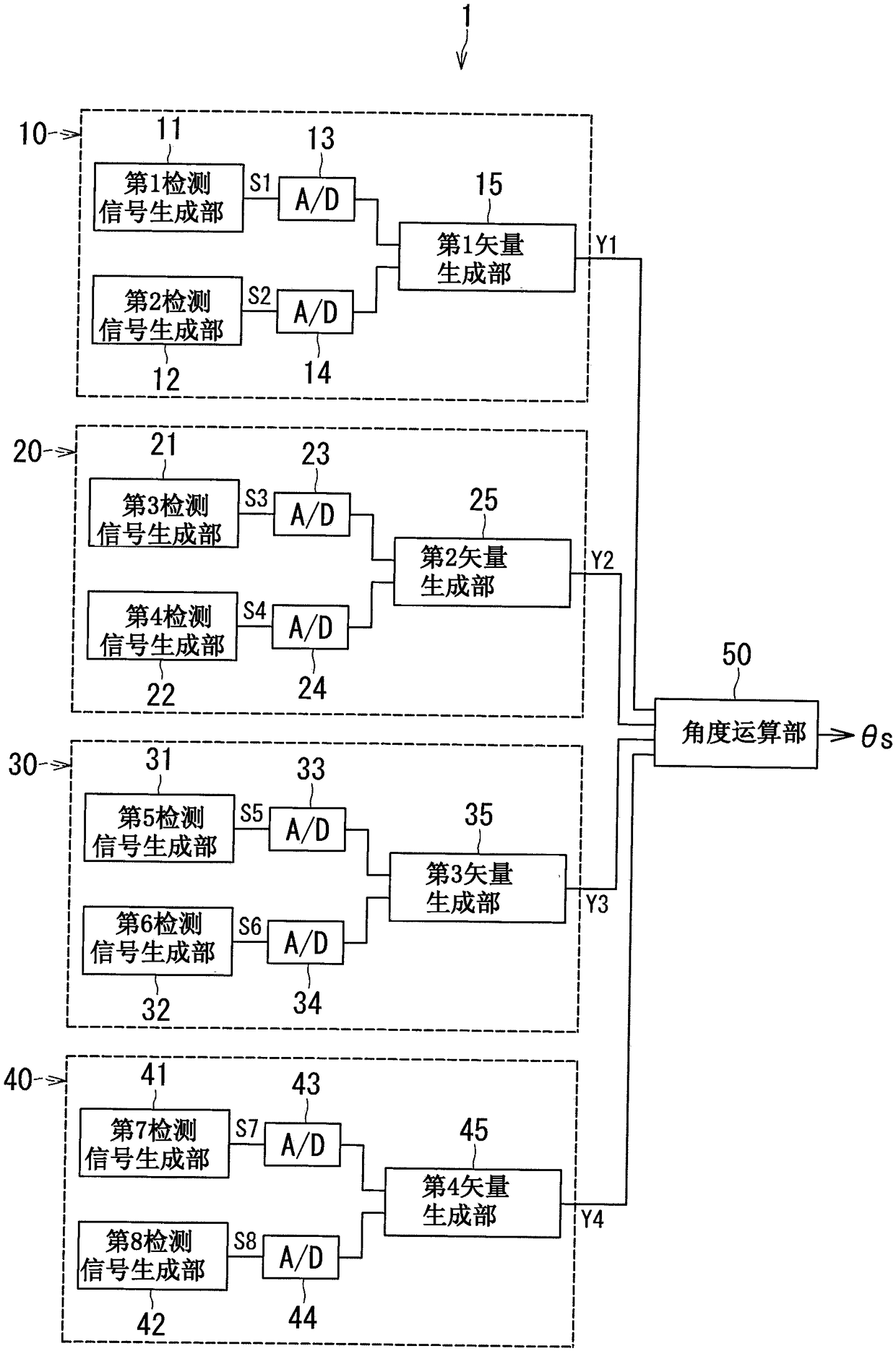

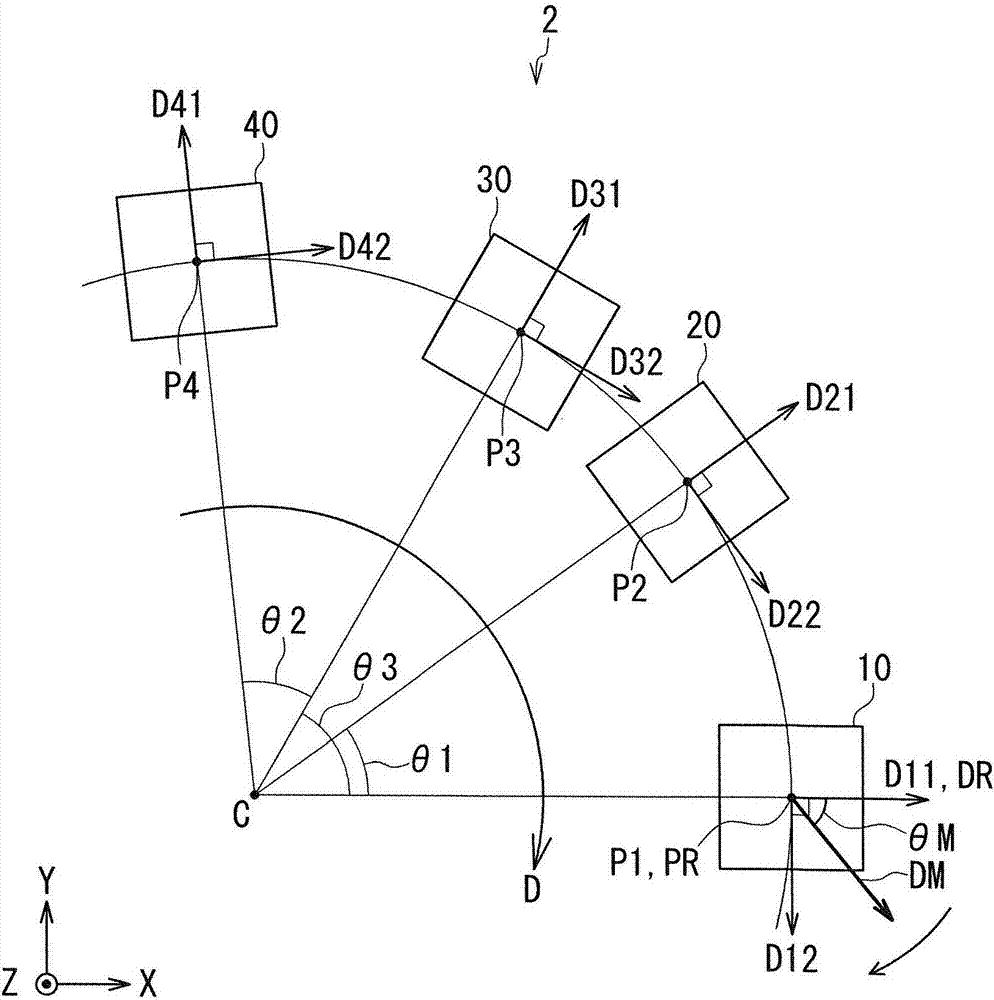

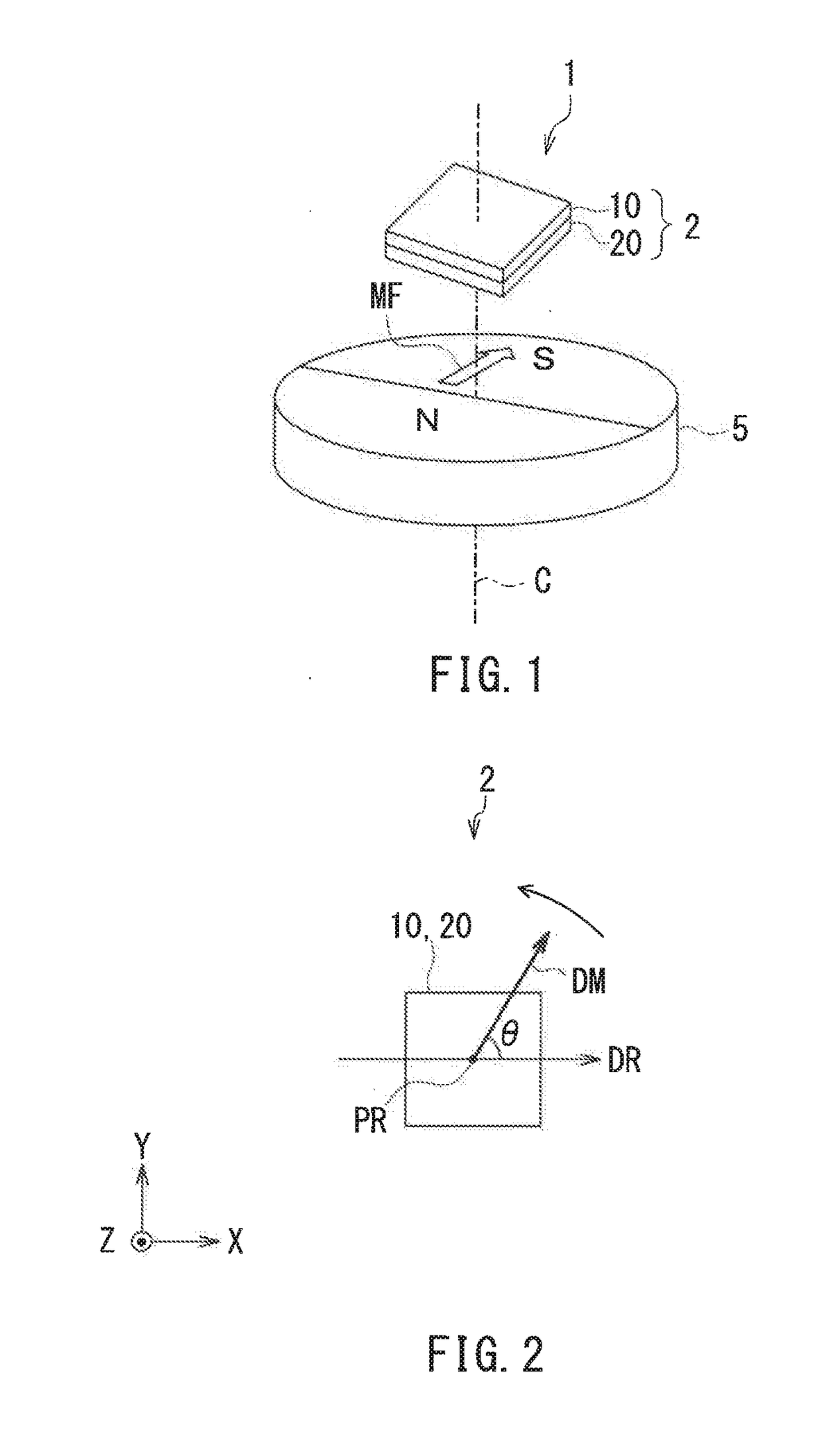

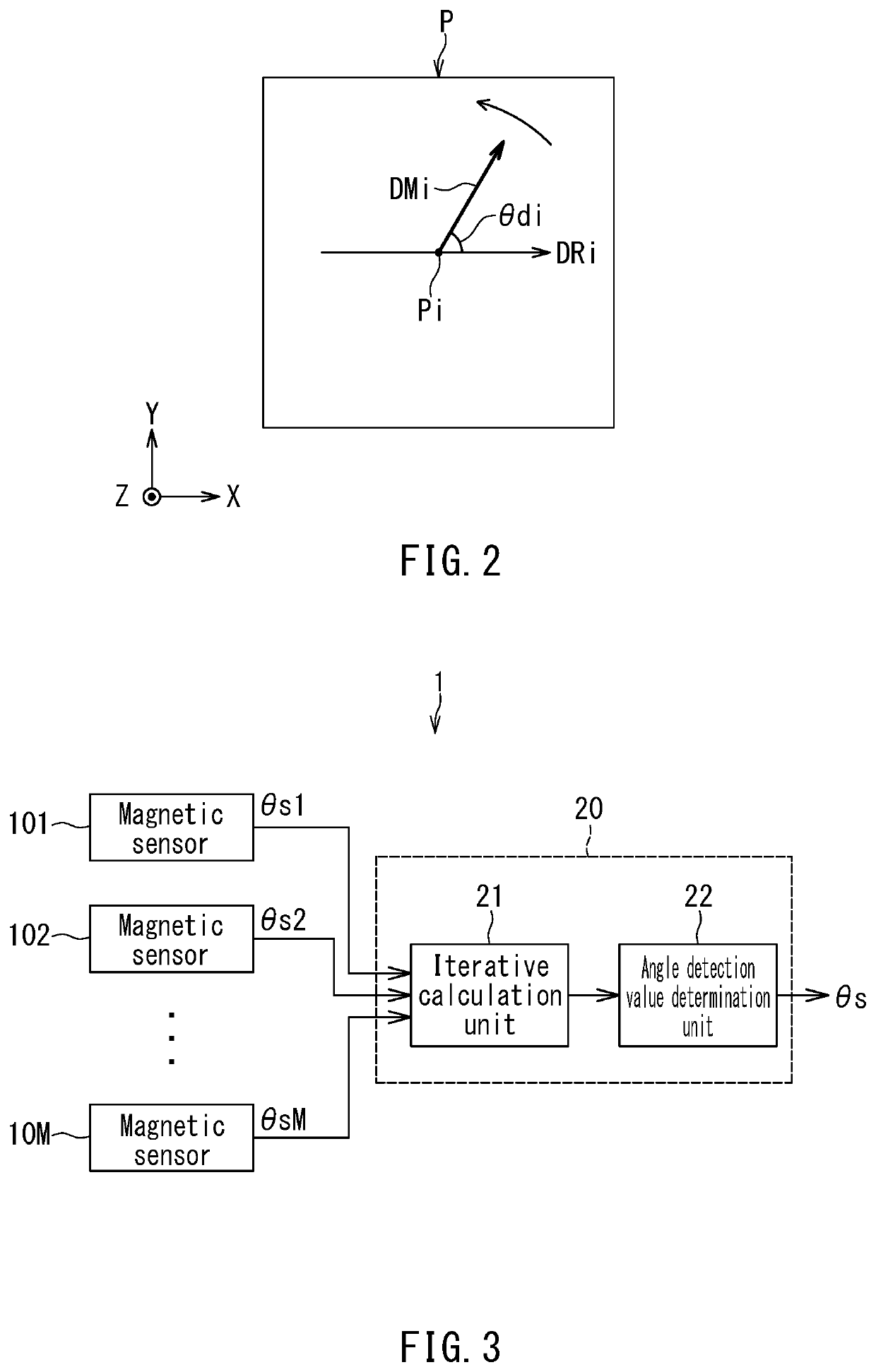

Angle sensor and angle sensor system

ActiveCN107543564AReduce angle errorConverting sensor output electrically/magneticallySoftware engineeringMechanical engineering

The invention relates to an angle sensor and an angle sensor system. The angle sensor includes a first to a fourth detection unit and an angle detection unit. Each of the first to the fourth detectionunit generates two detection signals. The first to the fourth detection unit are arranged in a positional relationship that establishes predetermined phase relationships among the detection signals they generate. The angle detection unit performs operations using the detection signals to generate a first and a second signal in which an error component corresponding to a fifth or higher-order harmonic and an error component corresponding to a harmonic of the order other than the fifth order are lower than those in the detection signals. The angle detection unit then calculates a detected anglevalue on the basis of the first and the second signal.

Owner:TDK CORPARATION

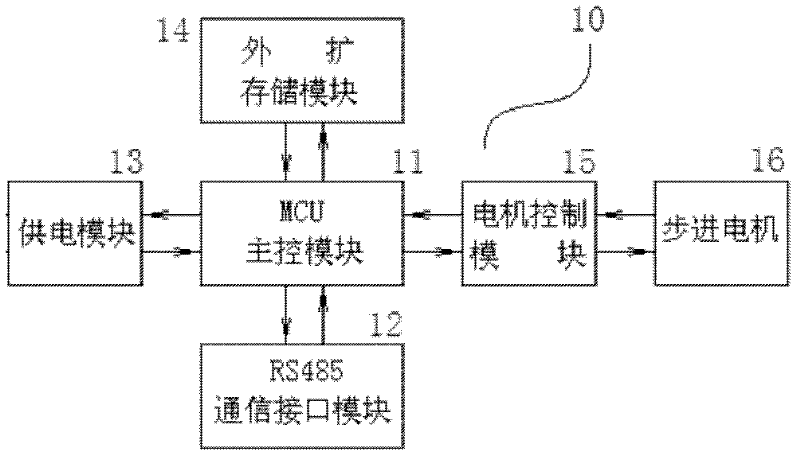

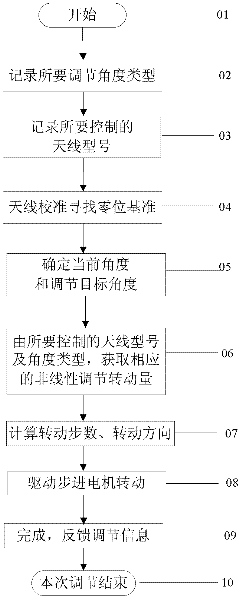

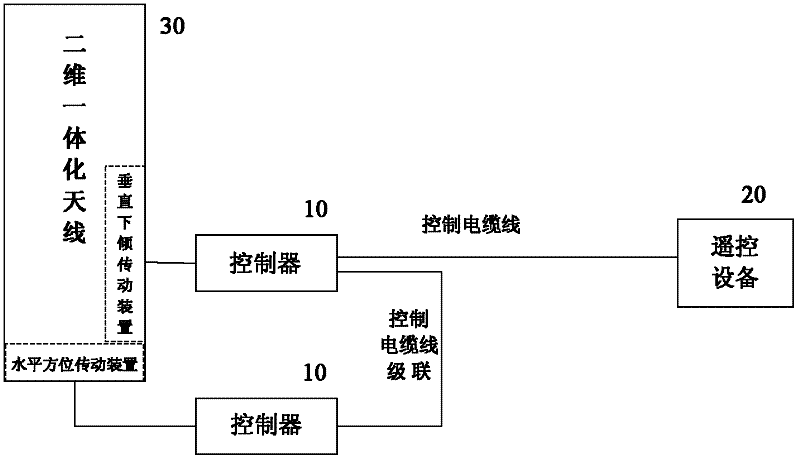

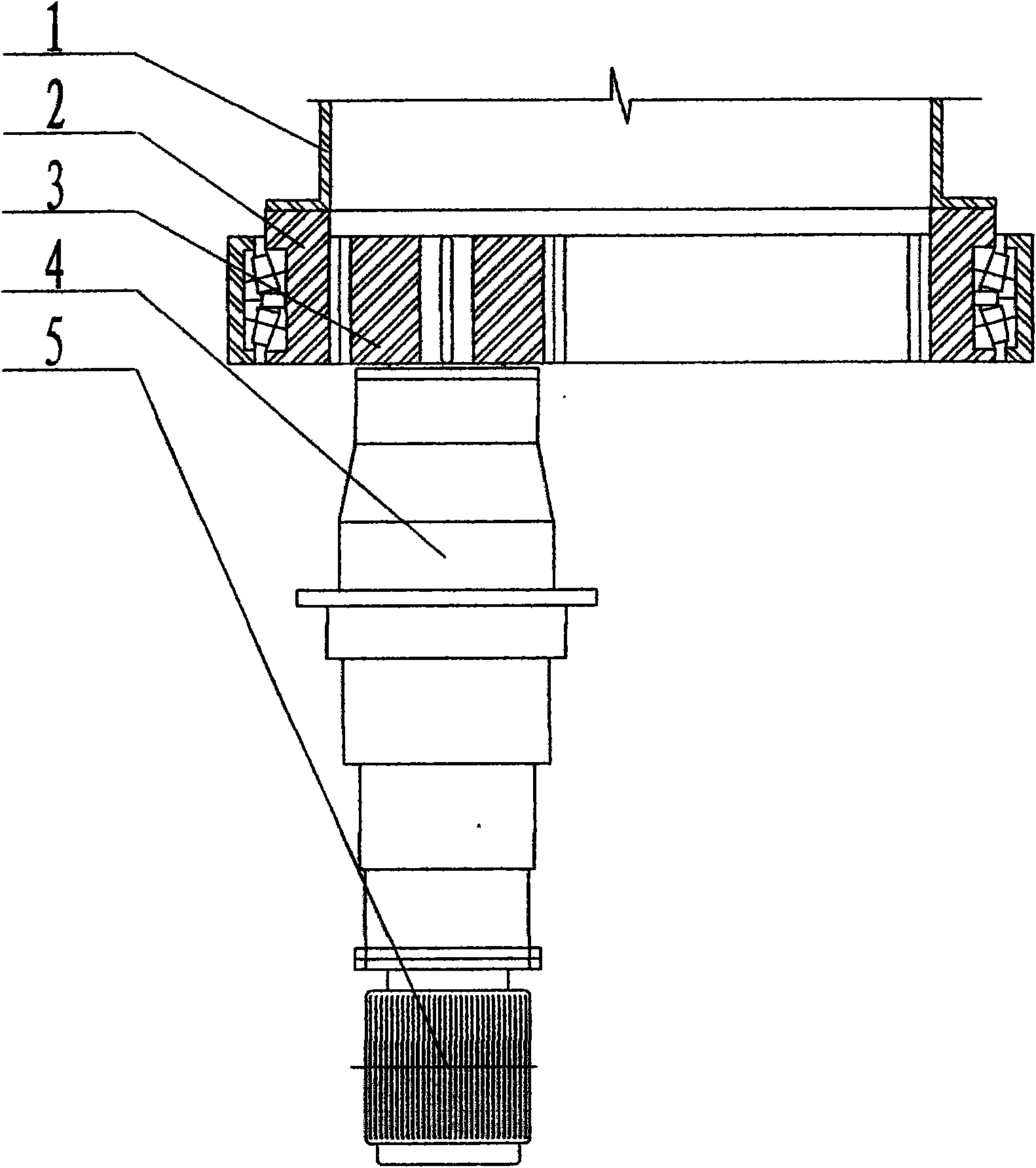

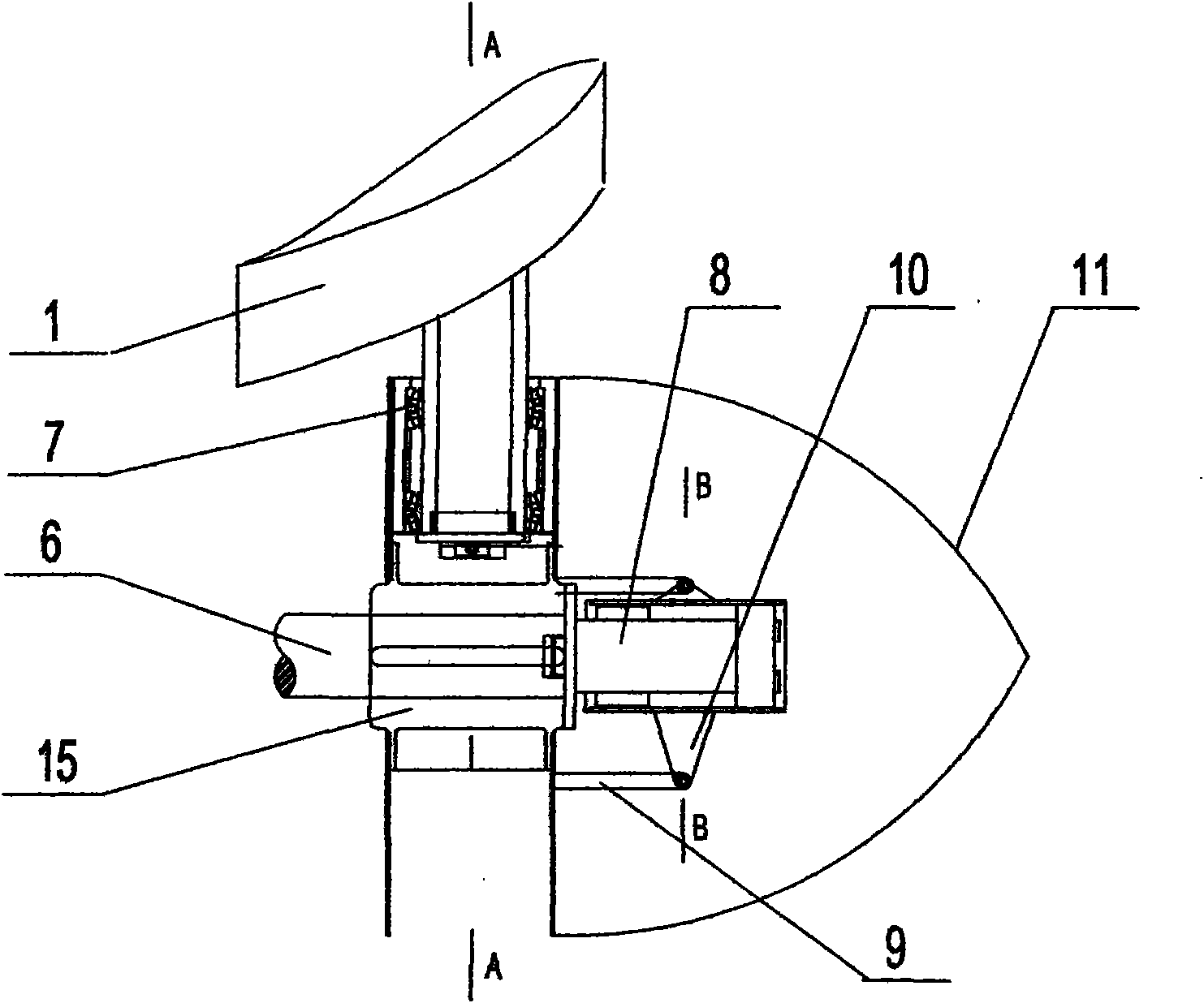

Multi-dimensional angle adjusting method with universality and nonlinearity for base station antennas

ActiveCN102496780AImprove job safety and flexibilityReduce maintenance costsAntennasEngineeringAzimuth

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

Blade pitch changing device of wind power generation device

InactiveCN101644230ALow failure rateImprove reliabilityWind motor controlMachines/enginesAngle modulationEngineering

The invention relates to the improvement of a blade pitch changing device of a wind power generation device, which is characterized in that a blade angle deflection driving mechanism consists of rocker bar members, pull rods and an axially telescopic power mechanism, wherein the rocker bar member is fixed on each blade shaft, the pull rods drive the rocker bar members to rotate, the axially telescopic power mechanism drives each pull rod to synchronously and axially move, and both ends of each pill rod are respectively connected with a rocker and a movable axially telescopic mechanism throughmovable pivots. The blade pitch changing device has the biggest characteristics that the blade pitch changing device is greatly simplified, the weight is greatly lightened, the megawatt-level weight is less than one fifth of the weight in a gear type, the reliability and the angle modulation consistency are good, and the blades are simply installed and adjusted, thereby being completely used for adjusting the blade pitch of a megawatt-level wind power generation device.

Owner:YIXING HUATAI INT GRP IND

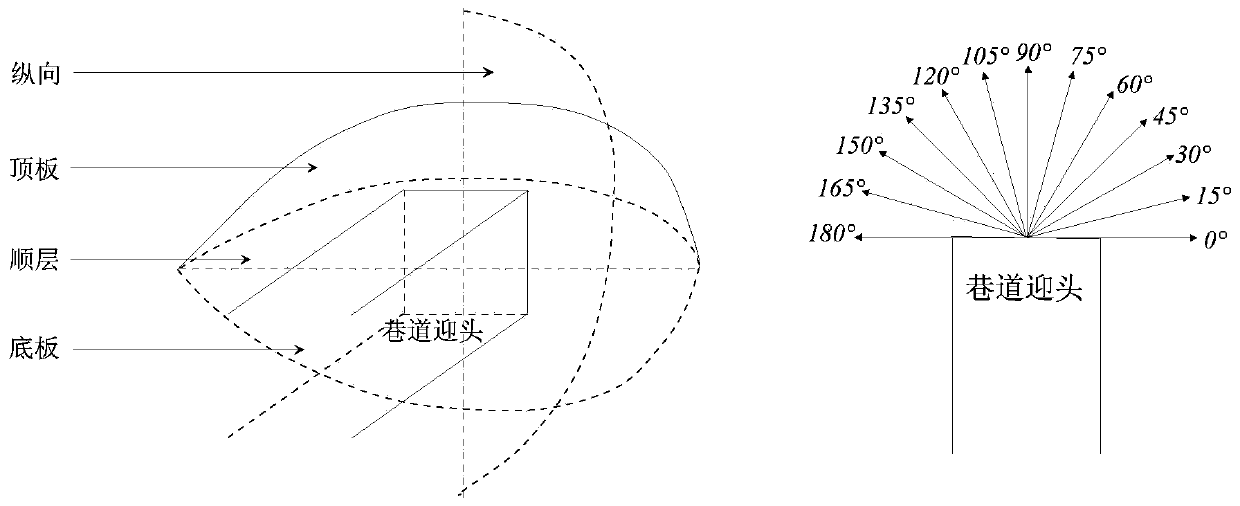

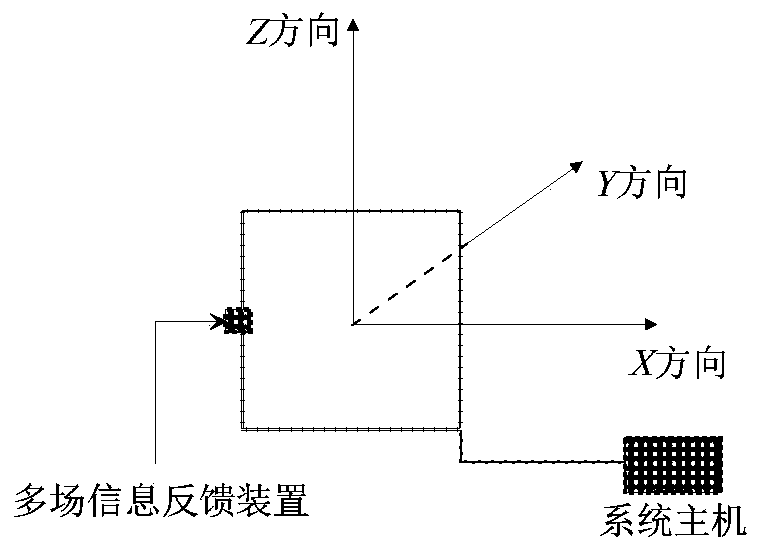

Mine transient electromagnetic automatic observation method based on multi-field information feedback

ActiveCN109696710AAchieve random placementRealize out-of-order measurementElectric/magnetic detection for well-loggingAcoustic wave reradiationMeasurement pointMulti field

The invention discloses a mine transient electromagnetic automatic observation method based on multi-field information feedback, which belongs to the technical field of mine safety comprehensive prevention and control. The adopted observation system includes a mine transient electromagnetic detection system host, transmitting and receiving coils and a multi-field information feedback device. The observation method comprises steps: zero-point correction is carried out on the multi-field information feedback device, and a multi-field information initial value is acquired; transient electromagnetic measurement points are arranged according to the design of a detection scheme, a conventional observation system is arranged, the transmitting and receiving coil is arranged at each transient electromagnetic measurement point, and transmitting of transient electromagnetic primary field signals and receiving of induction secondary field signals are completed in sequence; data are acquired and processed; and other steps. The mine transient electromagnetic detection field environment can be reflected more accurately, and through real-time feedback and acquisition and storage of multi-field information transient electromagnetic data, random placement of mine transient electromagnetic underground transmitting and receiving coils, disorder measurement and automatic observation can be realized, and the transient electromagnetic detection efficiency and the resolution are improved.

Owner:CCTEG CHINA COAL RES INST

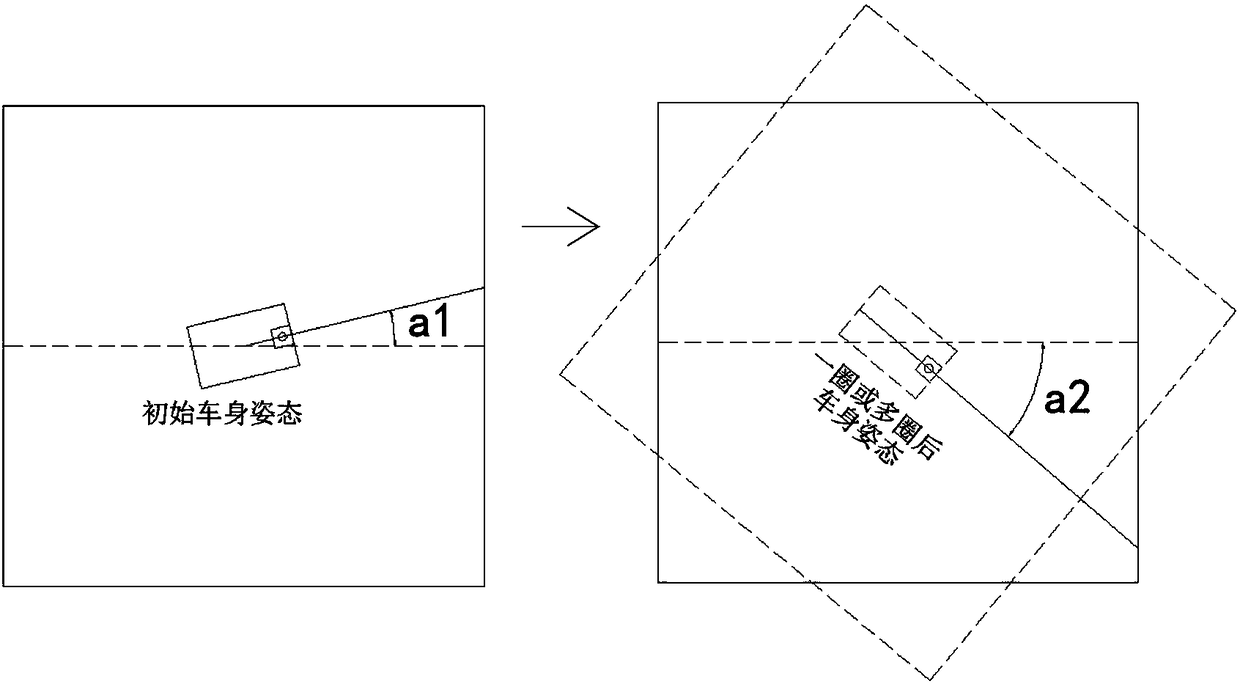

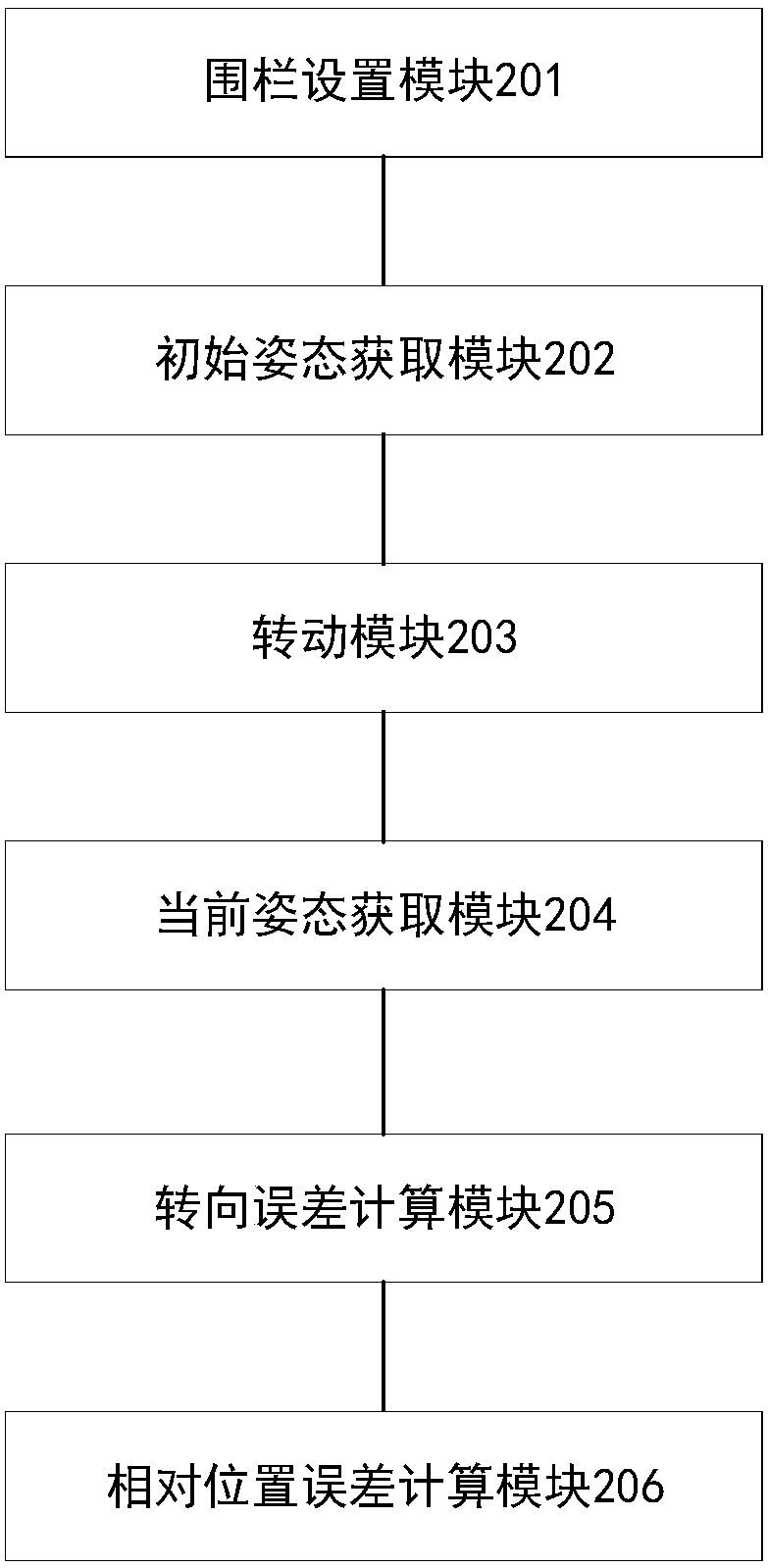

Robot steering error calibration method, device and system

The invention discloses a robot steering error calibration method, device and system. Firstly, a rectangular fence is arranged; after a robot enters the fence, a laser radar mounted on the robot scansthe environment, four side lines of the fence are monitored, and the initial attitude angle of the robot relative to the fence is obtained; the robot is controlled to rotate by an angle in situ; through the laser radar, the current attitude angle of the robot relative to the fence is obtained; according to the initial attitude angle, the current attitude angle and the rotating angle, the steeringerror of the robot is calculated. According to the steering error, the relative location error of a left wheel and a right wheel of the robot is calculated, the opposite position error of the wheelsis calibrated, in the robot subsequent motion process, compensation can be carried out according to the error, and the angle error of the robot during turning motion is reduced.

Owner:浙江立石工业互联科技有限公司

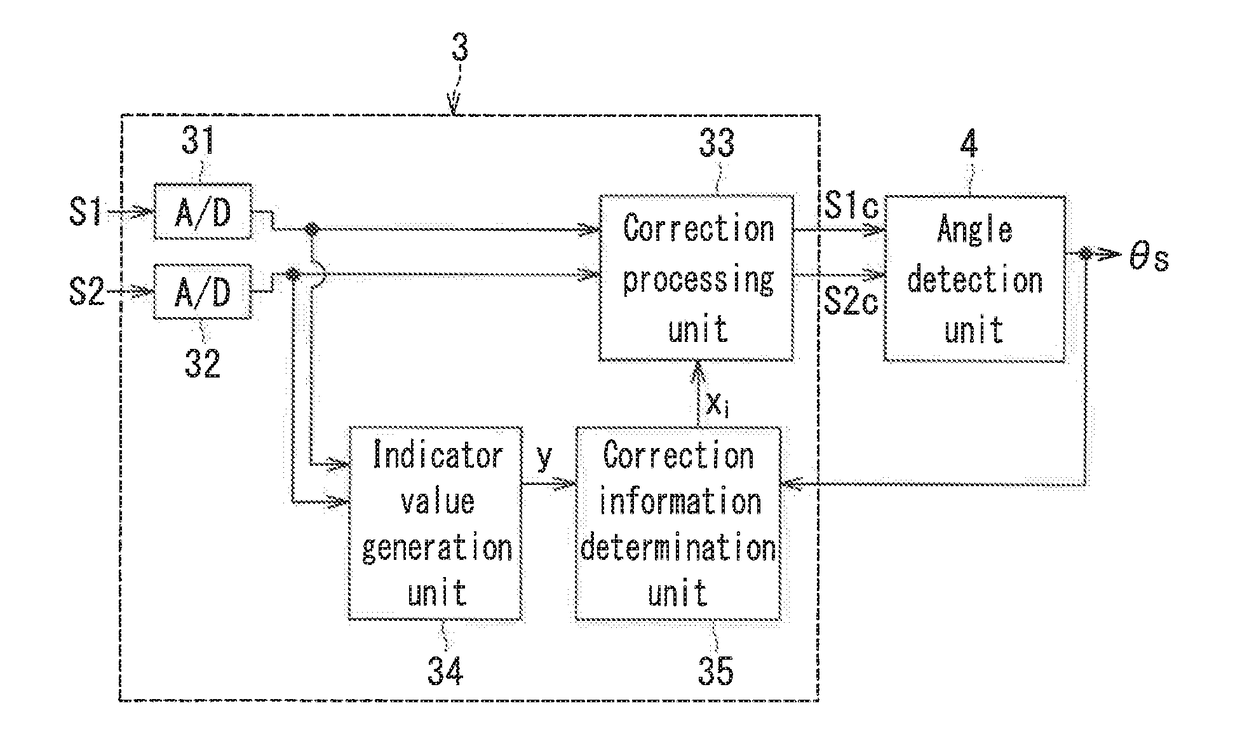

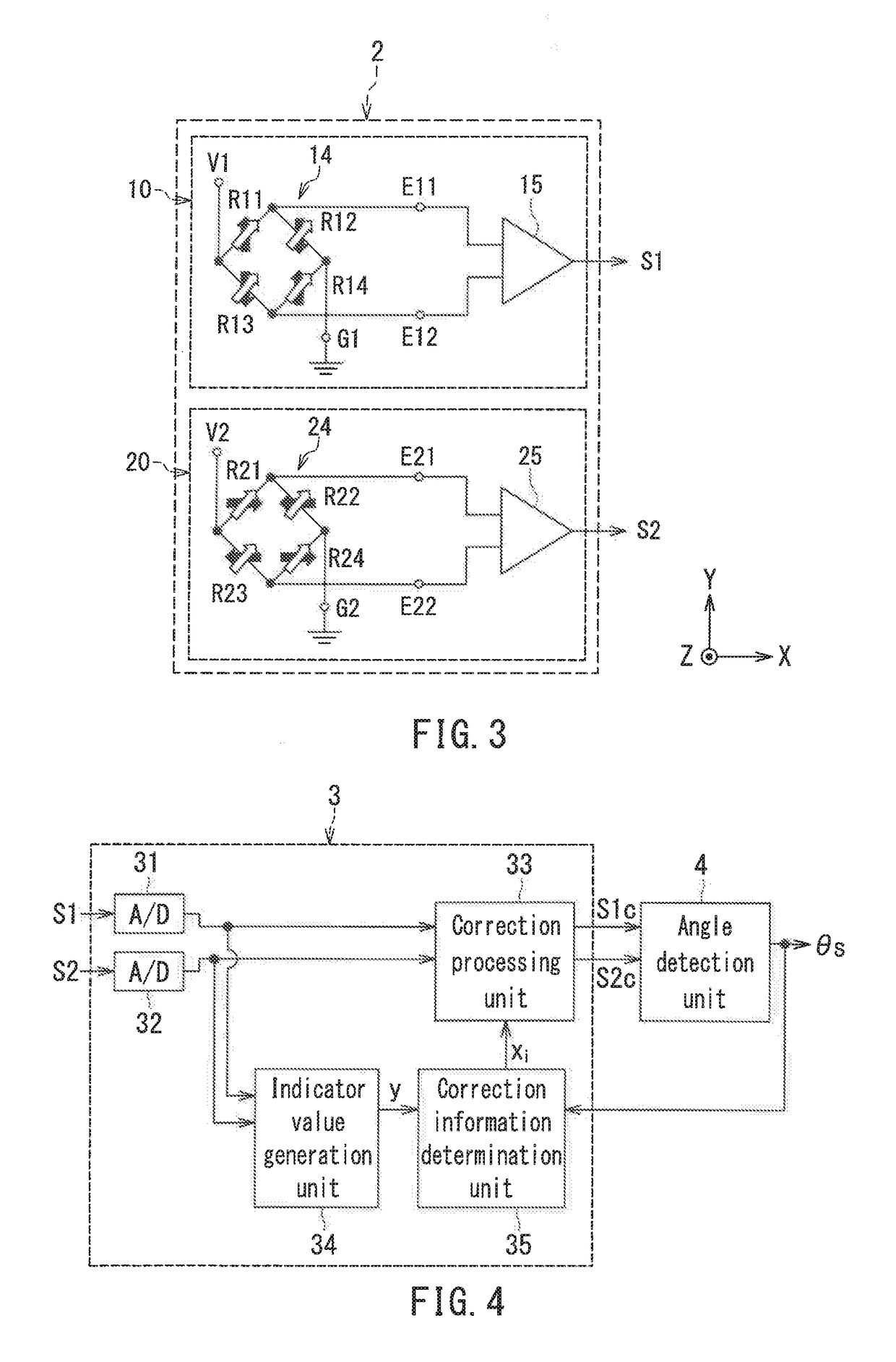

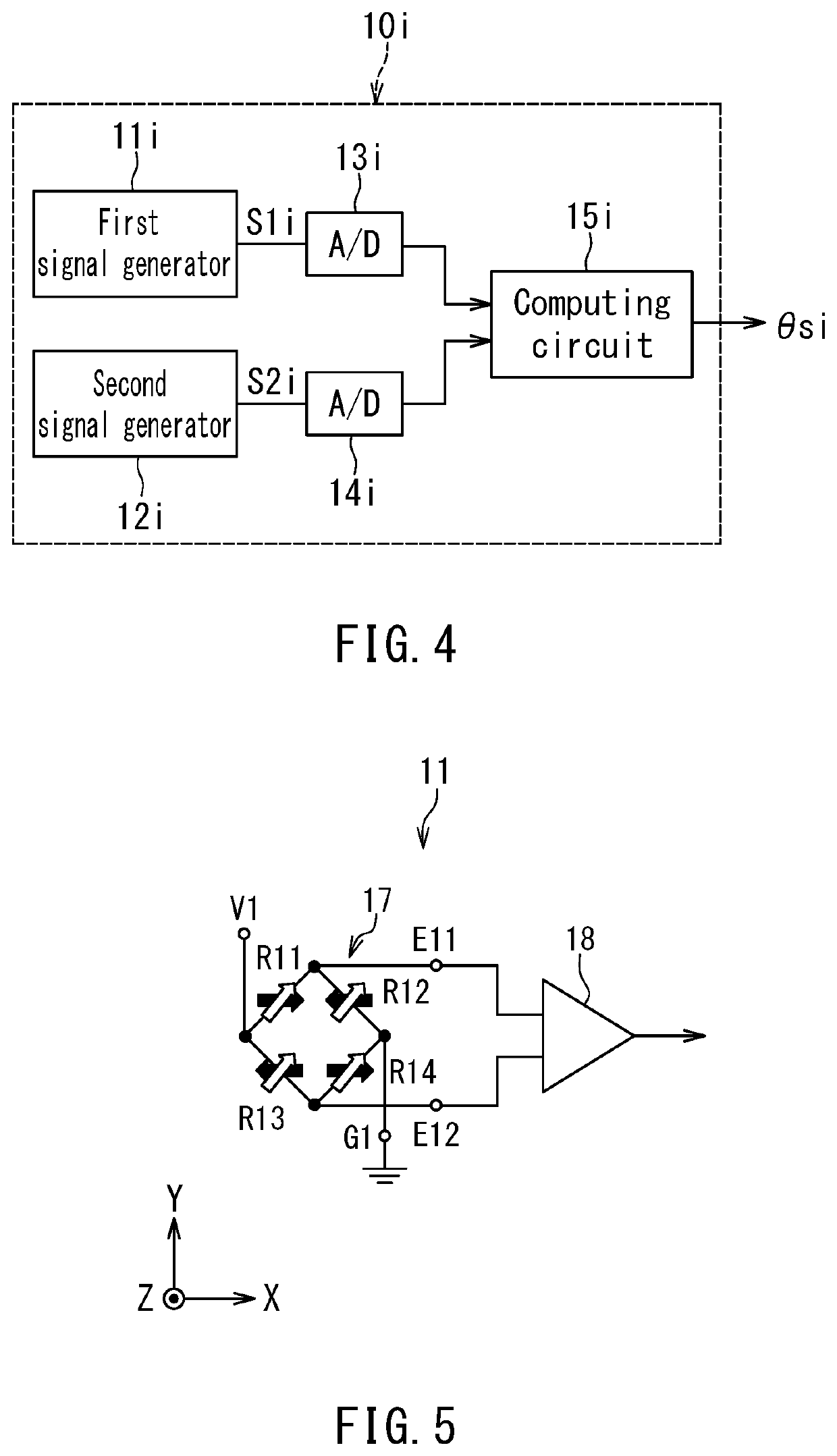

Correction apparatus for angle sensor, and angle sensor

ActiveUS20180172481A1Reduce angle errorReduce errorsConverting sensor output electrically/magneticallySelf adaptiveReal-time computing

A correction apparatus for an angle sensor includes a correction processing unit, an indicator value generation unit, and a correction information determination unit. The correction processing unit performs correction processing on a plurality of detection signals to reduce an error of a detected angle value. The details of the correction processing are determined according to correction information. The indicator value generation unit generates, on the basis of the plurality of detection signals, an indicator value having a correspondence with the error of the detected angle value. The correction information determination unit generates an estimated indicator value using a function that takes one or more values each having a correspondence with the correction information as one or more variables, and determines the correction information by adaptive signal processing so as to reduce the difference between the indicator value and the estimated indicator value.

Owner:TDK CORPARATION

Method for detecting shape and center of optical fiber and optical fiber coupling lens

The invention discloses an optical fiber coupling lens which comprises an outer sleeve, at least four lens groups and independent plate glass. The independent plate glass is arranged at the front part of the outer sleeve and is positioned outside a front lens group. The invention also discloses a method for detecting the shape and the center of an optical fiber, which comprises the following steps of: firstly, capturing light energy of the optical fiber by the optical fiber coupling lens so as to form the spherical aberration after the captured light energy passes through the optical fiber coupling lens; and then analyzing the light energy with the spherical aberration by an image analyzer so as to judge the shape and the center of the optical fiber. The optical fiber coupling lens disclosed by the invention is provided with the independent plate glass, and thus, the lens can have a certain spherical aberration and the energy distribution is changed after the energy passes through the lens, so that an image which can be conveniently observed and judged is formed by the captured optical fiber energy. According to the method for detecting the shape and the center of the optical fiber, which is disclosed by the invention, by considering the light energy passing through the optical fiber coupling lens as the spherical aberration, the energy distribution is changed after the energy passes through the lens, so that the image which can be conveniently observed and judged is formed.

Owner:南京东利来光电实业有限责任公司

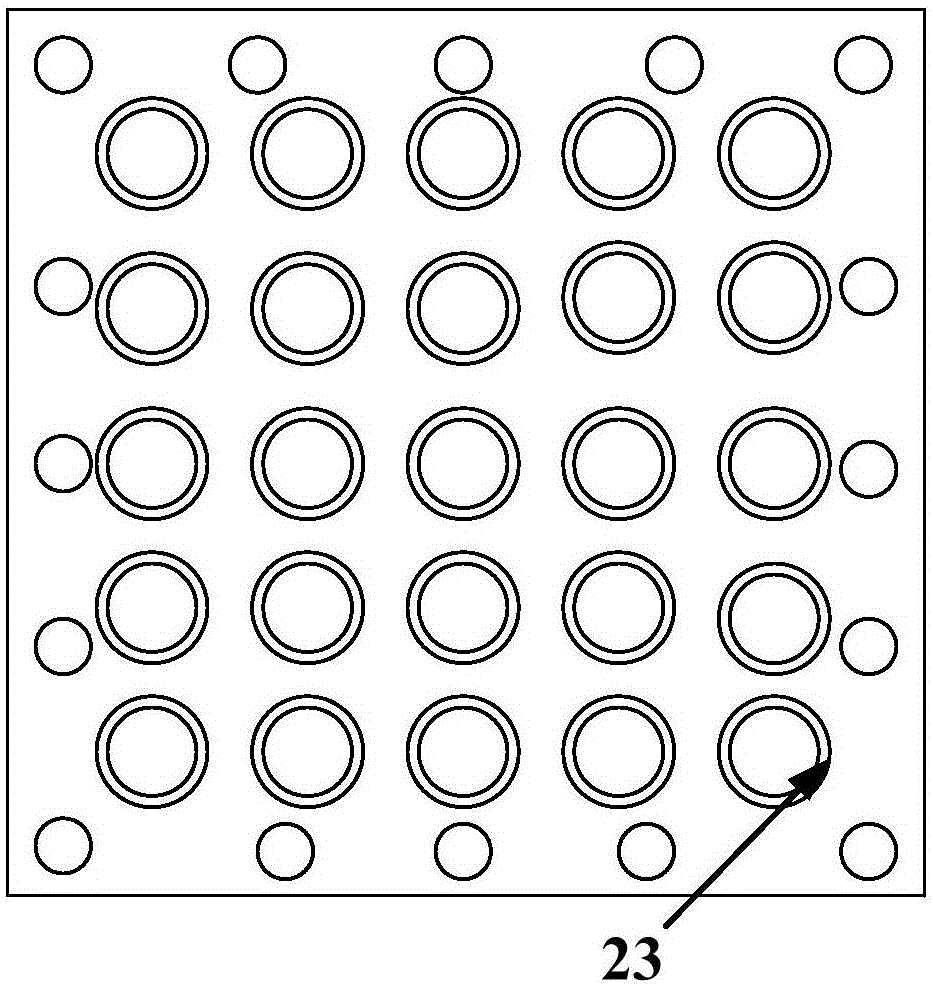

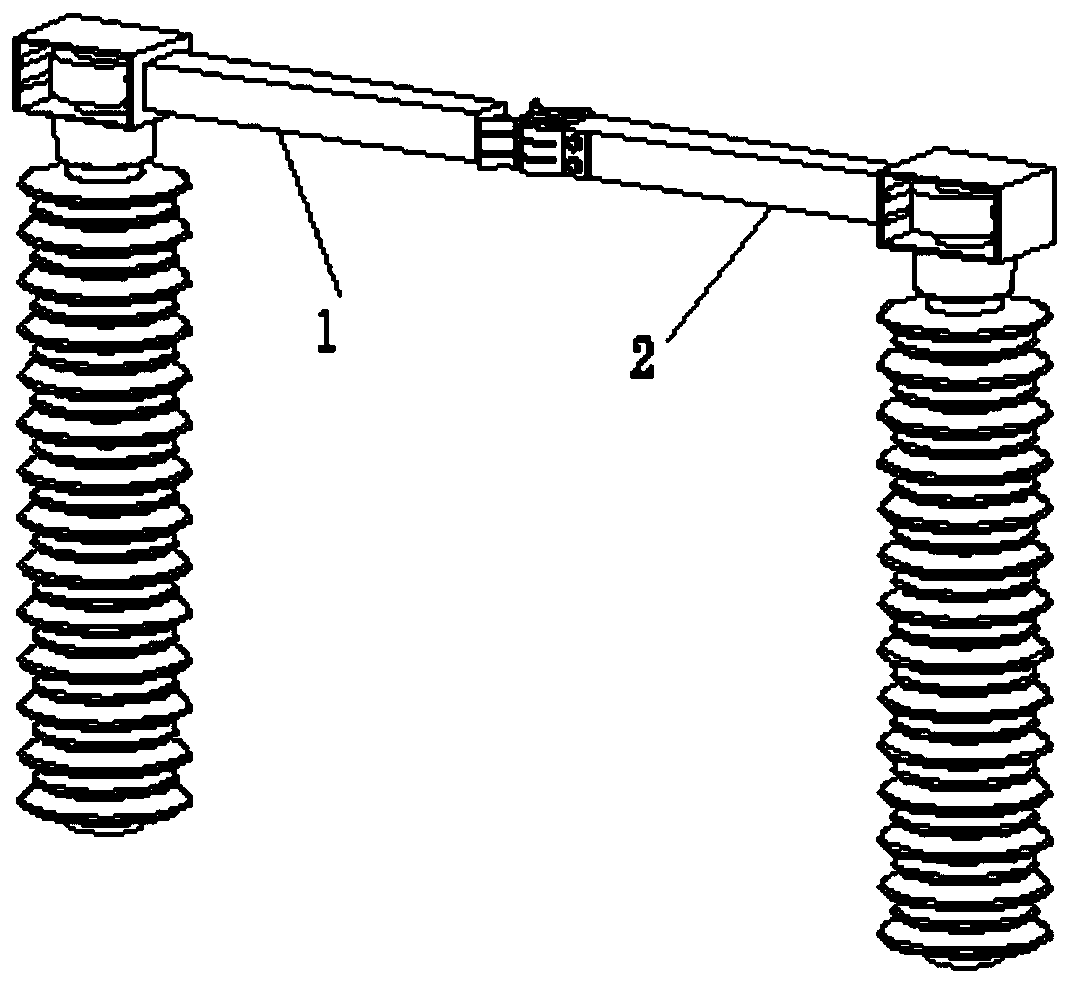

Rod bundle channel visualization experiment body suitable for heating boiling conditions

PendingCN109273116AIncrease the scope of visualizationReduce angle errorNuclear energy generationNuclear monitoringSteel tubeTemperature measurement

The invention provides a rod bundle channel visualization experiment body suitable for heating boiling conditions. The experiment body comprises a square quartz channel, an outlet and an inlet respectively disposed at the upper end and the lower end of the square quartz channel and a simulated fuel rod bundle disposed in the square quartz channel. The lower end of the simulated fuel rod bundle isconnected to the square quartz channel through a sealing flange. The experiment body is further provided with a positive conductive copper bar and a negative conductive copper bar, and the positive conductive copper bar is disposed at the upper end of the inlet of the body. The simulated fuel rod bundle includes a connecting copper head and a conductive copper rod and a stainless steel tube whichare arranged at the lower end of the connecting copper head. The conductive copper rod is disposed inside the stainless steel tube, and the outer surface of the conductive copper rod is provided withan insulating tube. The stainless steel tube is connected with the positive conductive copper bar, and the conductive copper rod is connected with the negative conductive copper bar. The experiment body solves the problem that the traditional wall temperature measurement method and a visualization experiment cannot be combined, can achieve measurement study of an inner flow field temperature fieldof the rod bundle channel under high temperature and two-phase conditions, and has the advantages of simple design and low cost.

Owner:HARBIN ENG UNIV

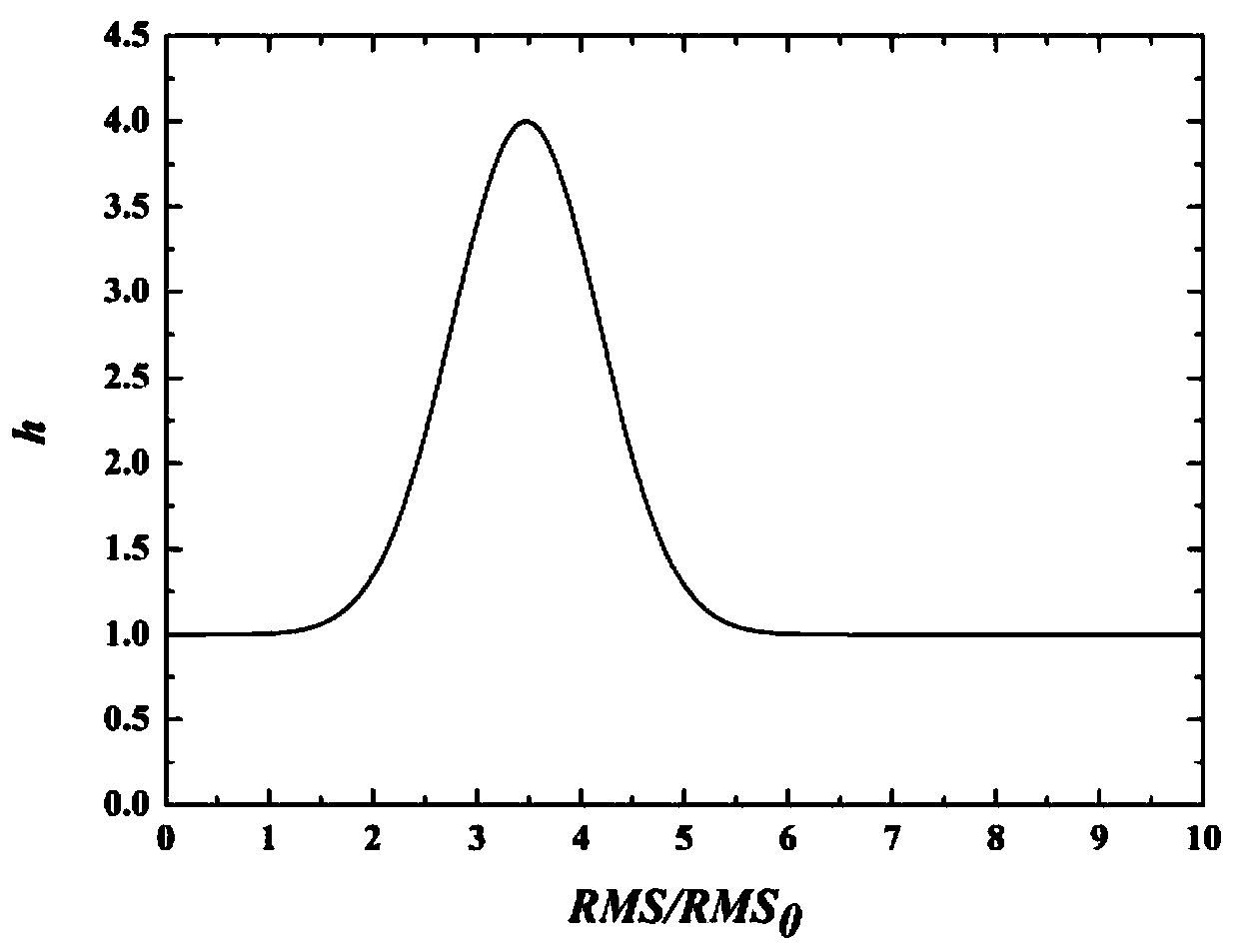

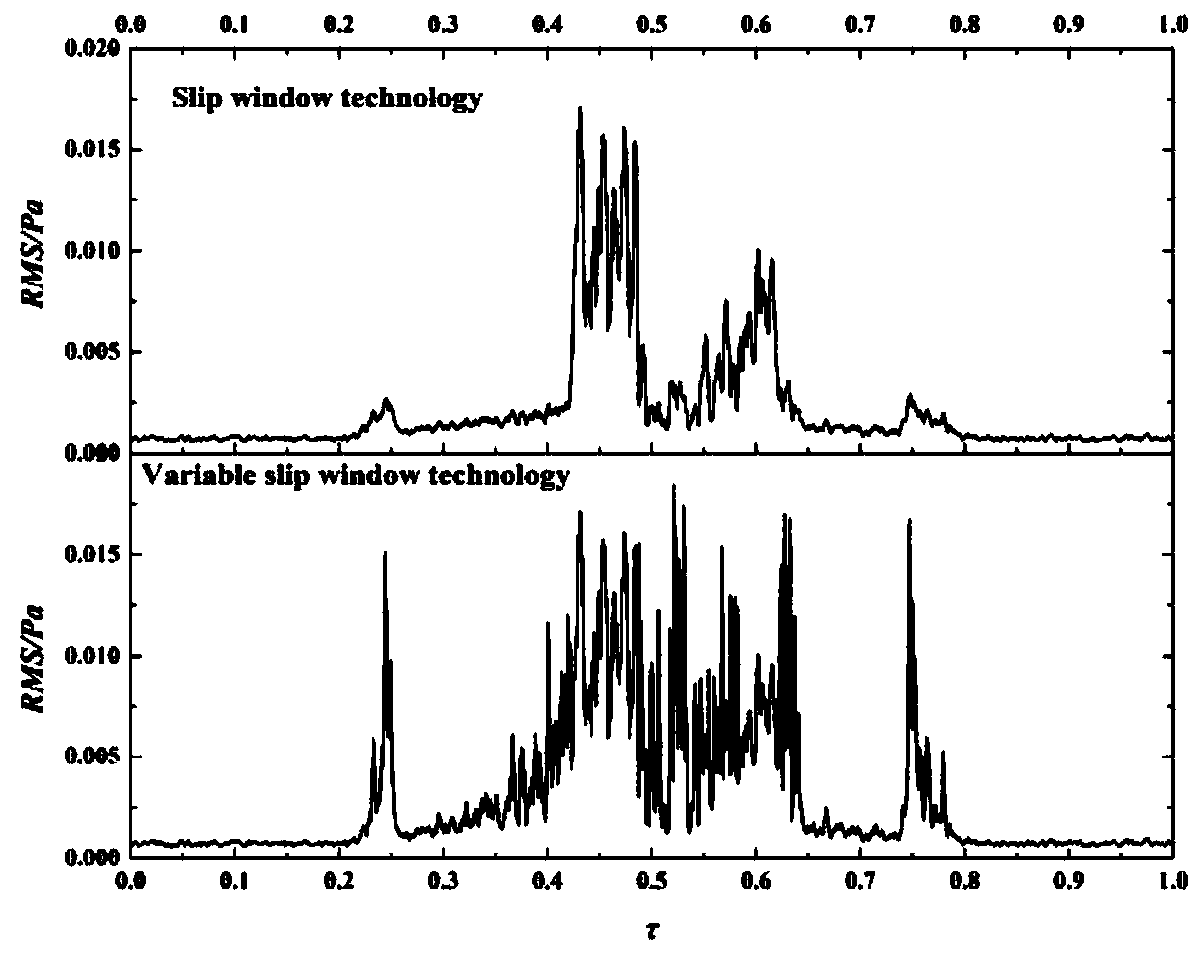

A variable slip window technique applied to dynamic airfoil transition judgment

ActiveCN109740284AImprove featuresResolve transitionSpecial data processing applicationsSlide windowWindow Width

The invention discloses a variable sliding window technology applied to dynamic airfoil transition judgment. In the technology, a pulsating pressure root-mean-square value (RMS) is calculated by usinga formula 1 shown in the specification. A variable rectangular window form is constructed in the technology, wherein W = h (2) as shown in the formula 2. According to the technology, the window widthis narrowed while the window function is increased; the window width is widened while the window function is decreased, in the technology, the change rule of a window function and a window width is controlled by a formula 3; a window function h is described by the formula 4, and the pitch oscillation rule of the airfoil profile is shown in the specification, wherein m * h = m0; alpha=alpha0+A sin(2pi ft) (5). The method effectively solves the problem that the uncertainty of the angle of attack at the feature position is large.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

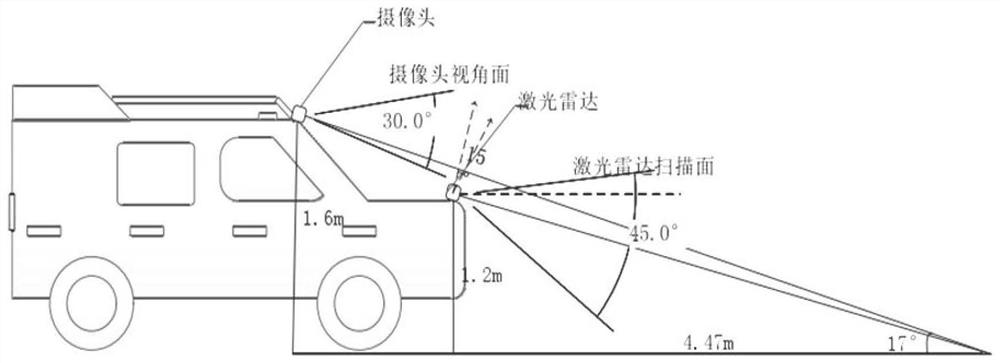

Terrain sensing method and system thereof, storage medium and computer equipment

ActiveCN113465728AReduce the degree of deviationReduce distance errorSubsonic/sonic/ultrasonic wave measurementInternal combustion piston enginesEngineeringRoad surface

The invention belongs to the technical field of terrain perception, and discloses a terrain perception method and a system thereof, a storage medium and computer equipment, a Kinect depth camera is utilized to obtain data information related to terrain parameters, and automatic identification of a road surface danger level is realized; a speedometer auxiliary method is combined with a Kalman filtering algorithm to remove laser radar motion distortion; and SLAM mapping and navigation algorithm optimization in ROS is realized. According to the method, the robot is globally positioned on the X axis and the Y axis, the distance error is smaller than 10 cm, and the angle error is smaller than 0.2 rad; the size error between the grid map and the real environment is less than 1cm; the deviation degree between the real navigation path of the robot and the algorithm estimation path is less than 10cm; the mobile robot can carry out loopback when mapping is carried out in an environment with a similar structure; and the variance of the preprocessed point cloud data collected by the laser radar is less than 0.1.

Owner:CHONGQING VOCATIONAL INST OF ENG

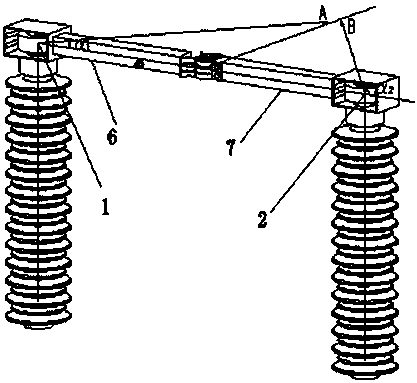

Real-time tracking detection method for state of split knife switch

PendingCN110675452AEasy to handleImprove stabilityImage enhancementImage analysisEngineeringImage pair

The invention provides a real-time tracking detection method for the state of a split knife switch. The real-time tracking detection method comprises the steps: collecting a real-time monitoring videoof the split knife switch, obtaining each frame of image of the video, building a boundary line model of a knife switch arm of the type, and storing the boundary line model as a model file; acquiringa first frame image of the video, positioning a knife switch in the first frame image, and extracting tracking feature points; performing detection according to a positioning result, and calculatingan initial included angle between the left knife switch arm and the right knife switch arm; and tracking and positioning the knife switch arm in the next frame of image, estimating a system error, determining a correction included angle between the left knife switch arm and the right knife switch arm in the next frame of image, judging the real-time state of the knife switch in the next frame of image until the knife switch is detected to stop moving, and verifying the final state of knife switch movement in the video. According to the real-time tracking detection method, the problem of low real-time detection precision of the state of the split knife switch is solved.

Owner:南京鑫和汇通电子科技有限公司

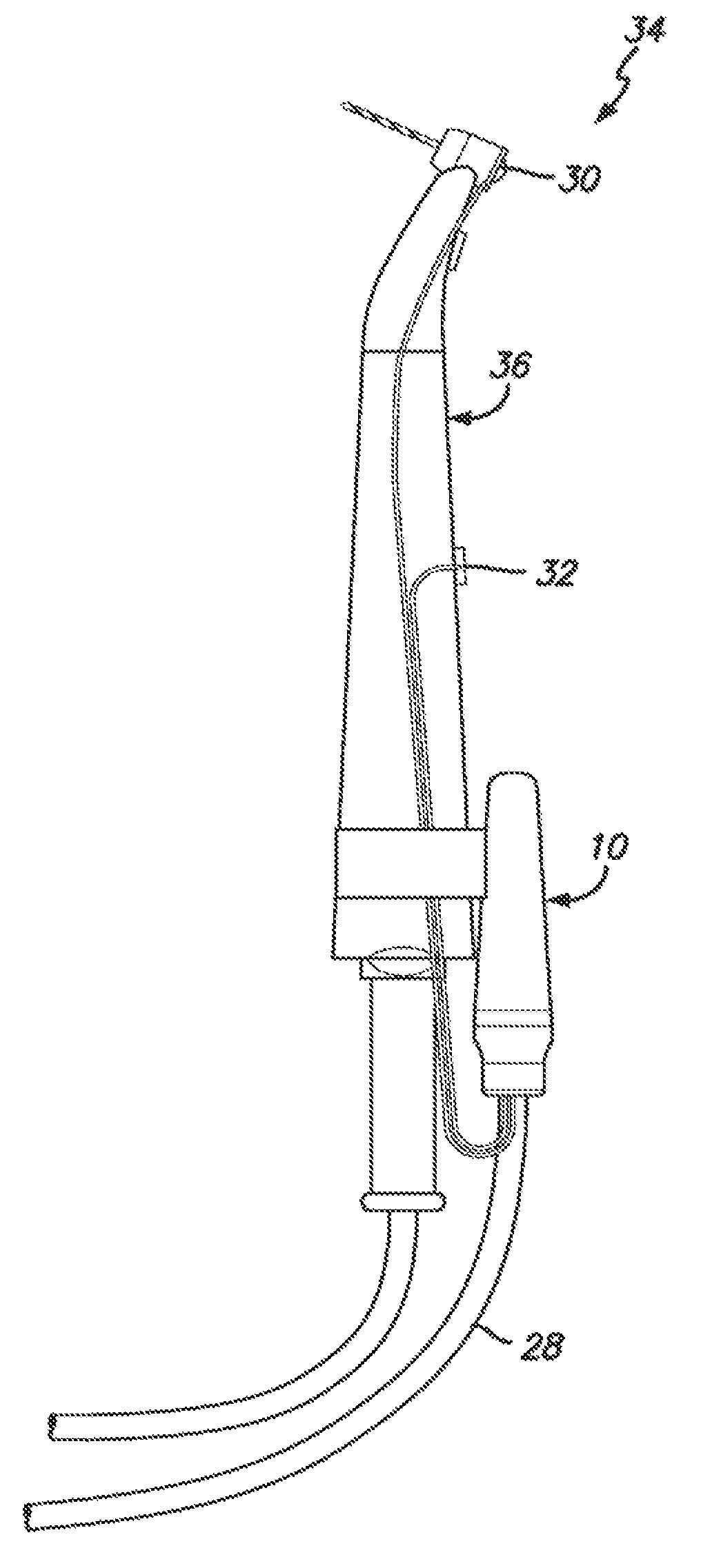

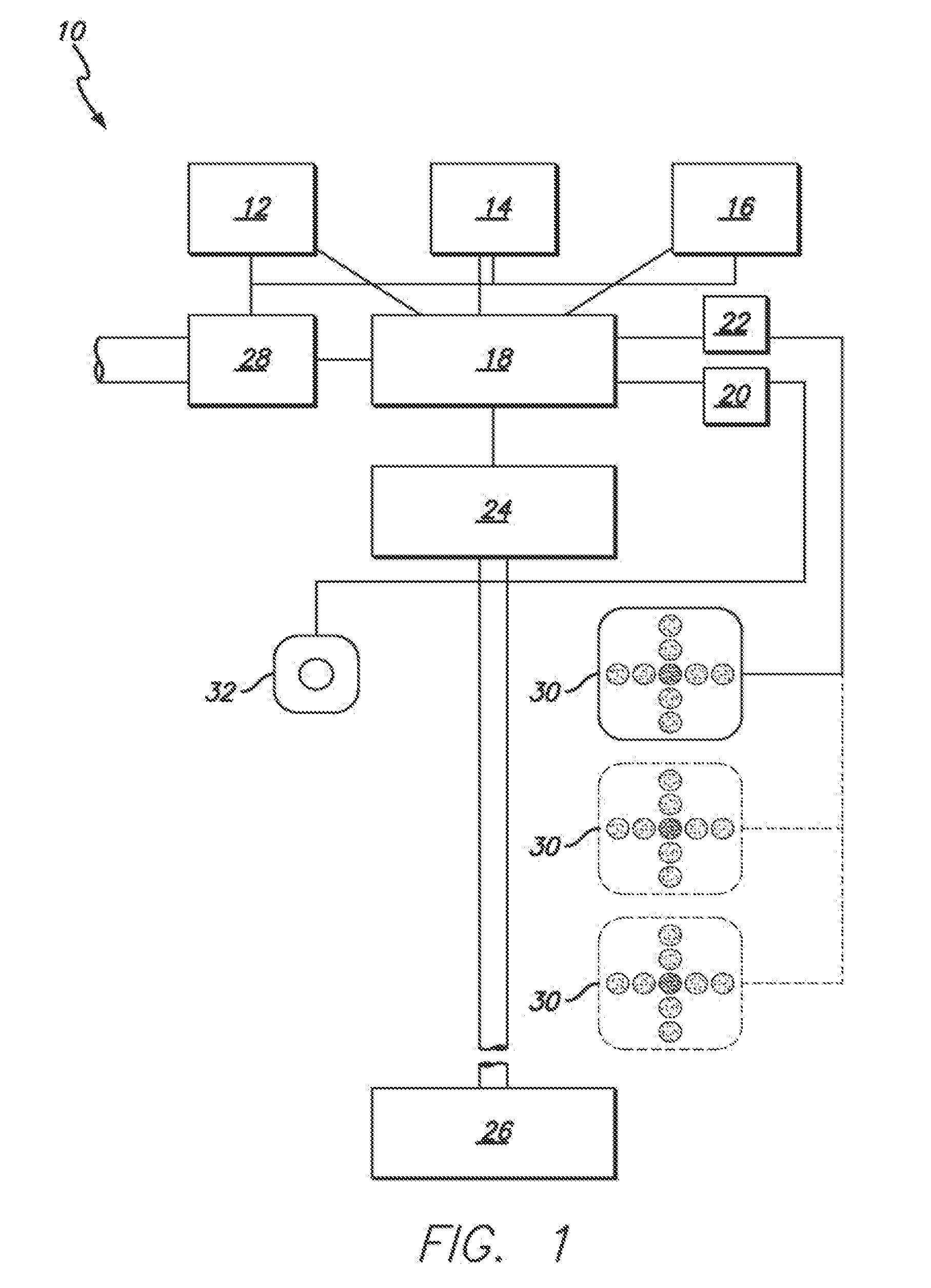

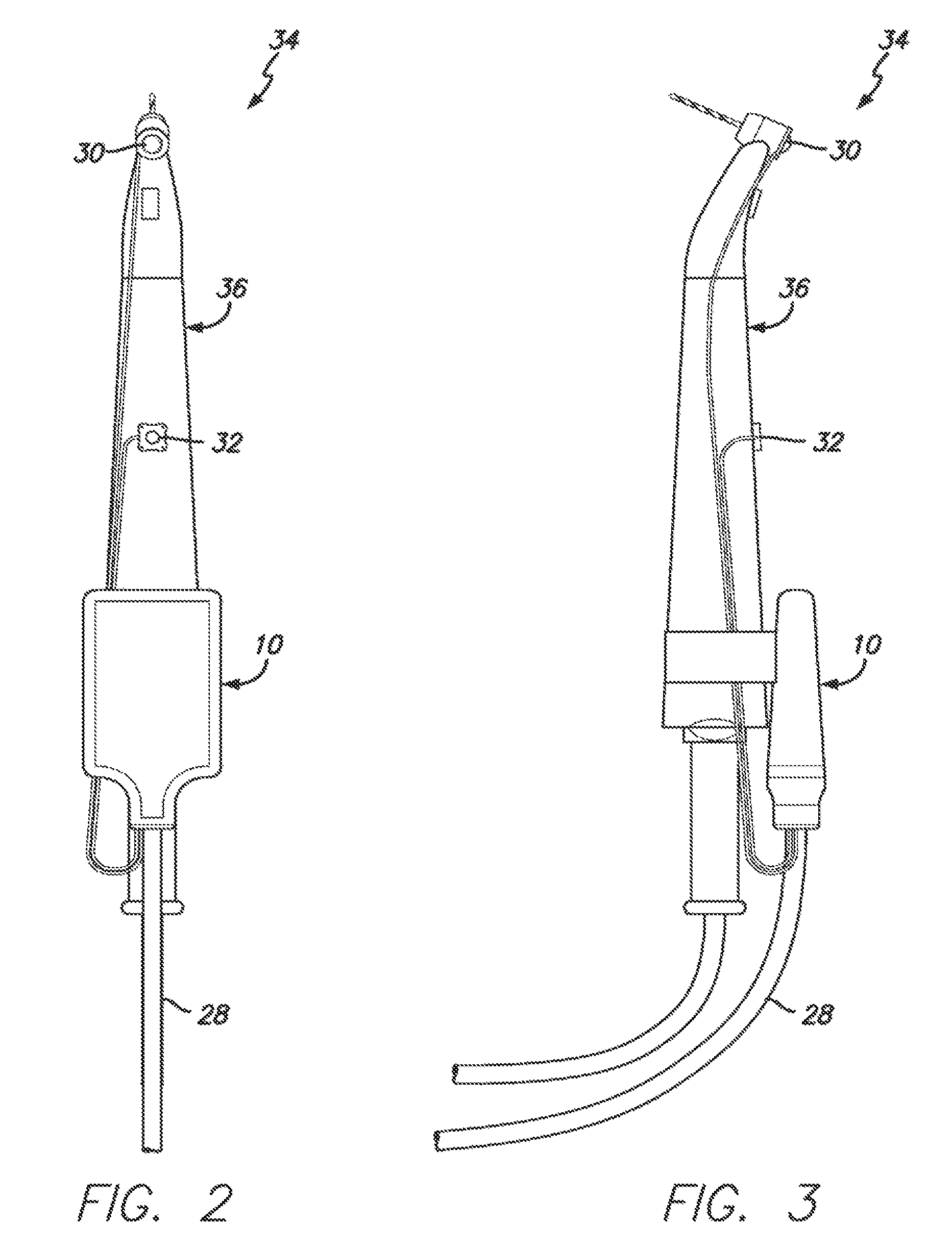

Method and device for reducing angulation error during dental procedures

ActiveUS9179987B2Reduce angle errorReduce the angleDental implantsDiagnosticsDental proceduresDental Procedure

A method for reducing angulation error during the placement of dental implants or other dental procedures. Two or more sensors are used to monitor realtime orientation of a dental handpiece. One or more signal emitters are used in order to notify the user that a first orientation of the dental handpiece has been identified and recorded. One or more signal emitters are used to notify the user that the dental handpiece has been repositioned into a second orientation having a predetermined spatial relationship to the first orientation.

Owner:LOMA LINDA UNIVERSITY

Real-time accurate detection method for state of split knife switch

PendingCN110717409ARealize automatic positioningImprove applicabilityImage enhancementImage analysisSample imageSystem error

The invention provides a real-time accurate detection method for the state of a split knife switch, and the method comprises the steps: collecting a real-time monitoring video, and building a model file; acquiring sample images, training the sample images by using deep learning to acquire a training model, detecting each frame of image to acquire a knife switch area, a knife switch state and an insulator area in the image, positioning a knife switch arm and an insulator in the image in combination with a model file, and calculating the credibility of a knife switch according to a positioning result; detecting the image meeting the credibility condition according to the positioning result, and calculating an initial included angle between the left disconnecting link arm and the right disconnecting link arm; estimating a system error, determining a correction included angle between the left knife switch arm and the right knife switch arm in each frame of image, judging a real-time stateof the knife switch in each frame of image until the knife switch is detected to stop moving, and verifying a final state of knife switch movement in the video; according to the invention, the problemof low real-time detection precision of the state of the split knife switch is solved.

Owner:南京鑫和汇通电子科技有限公司

Angle sensor and angle sensor system

ActiveUS20200166381A1Improve accuracyReduce angle errorUsing electrical meansConverting sensor output electrically/magneticallyComputational physicsSensor system

An angle sensor includes a plurality of magnetic sensors and a processor. The plurality of magnetic sensors generate a plurality of detection values representing directions of a composite magnetic field, which is a composite of a magnetic field to be detected and a noise magnetic field. The processor assumes a group of estimated unknowns. The group of estimated unknowns is a set of estimated values of a first, a second, and a third unknown. The first unknown corresponds to an angle detection value. The second unknown corresponds to the direction of the noise magnetic field. The third unknown corresponds to the strength of the noise magnetic field. The processor executes a process for determining the group of estimated unknowns a plurality of times, and assumes an estimated value of the first unknown in the last determined group of estimated unknowns as the angle detection value.

Owner:TDK CORPARATION

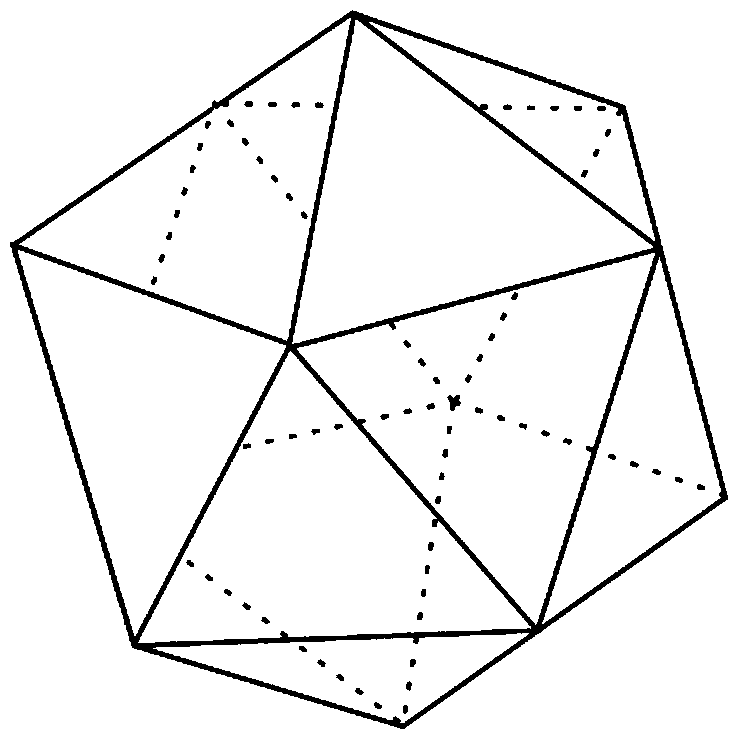

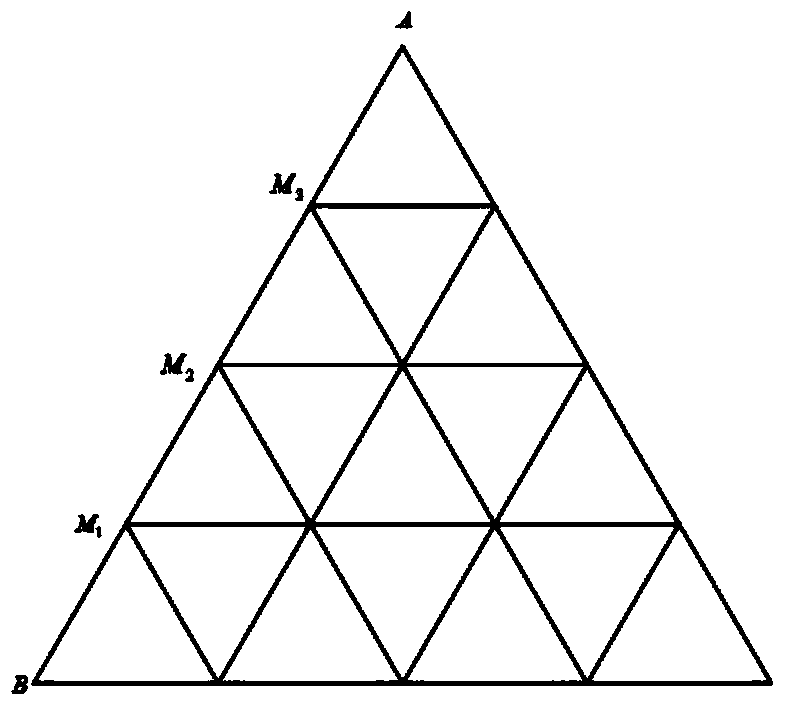

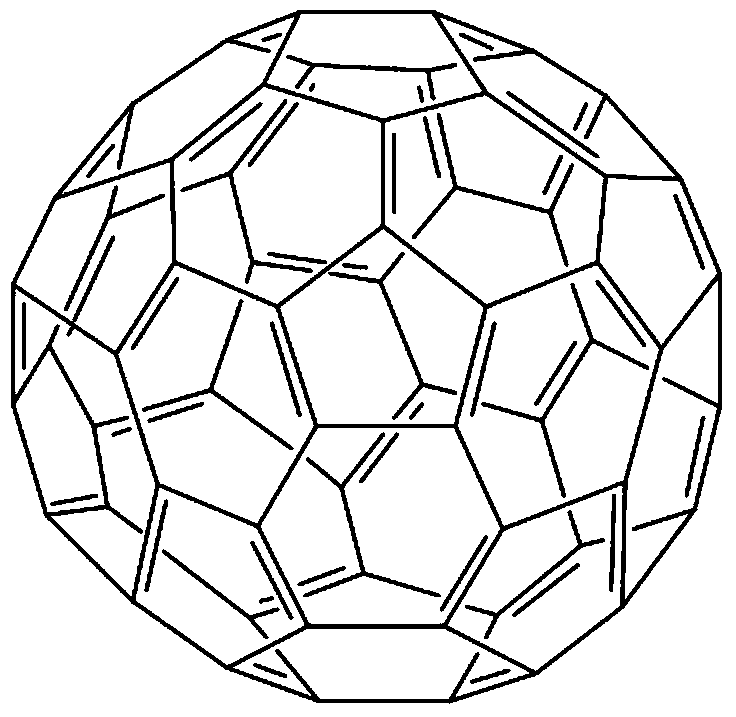

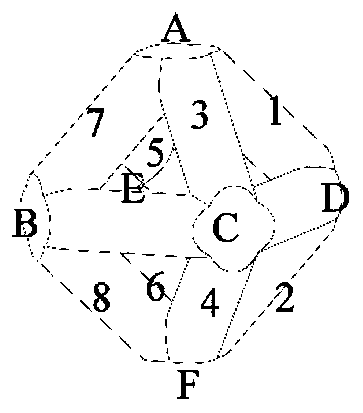

Method for generating equally-segmented ray beams for positive ray tracing

InactiveCN103986536AReduce angle errorGood spatial symmetryTransmission monitoringClassical mechanics

The invention relates to a method for generating equally-segmented ray beams for positive ray tracing. The method includes the steps that a source is placed in the center of an irregular polyhedron; the center of each face of the irregular polyhedron is connected with the vertex of the face; a triangle on each face is subjected to geometrical segmentation till a ray beam formed by the source and the vertex of each triangle meets the preset condition. According to the method, equally-segmented ray beams are approximately generated through the irregular polyhedron, positive ray tracing can be achieved faster, and angle errors between the equally-segmented ray beams can be reduced.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

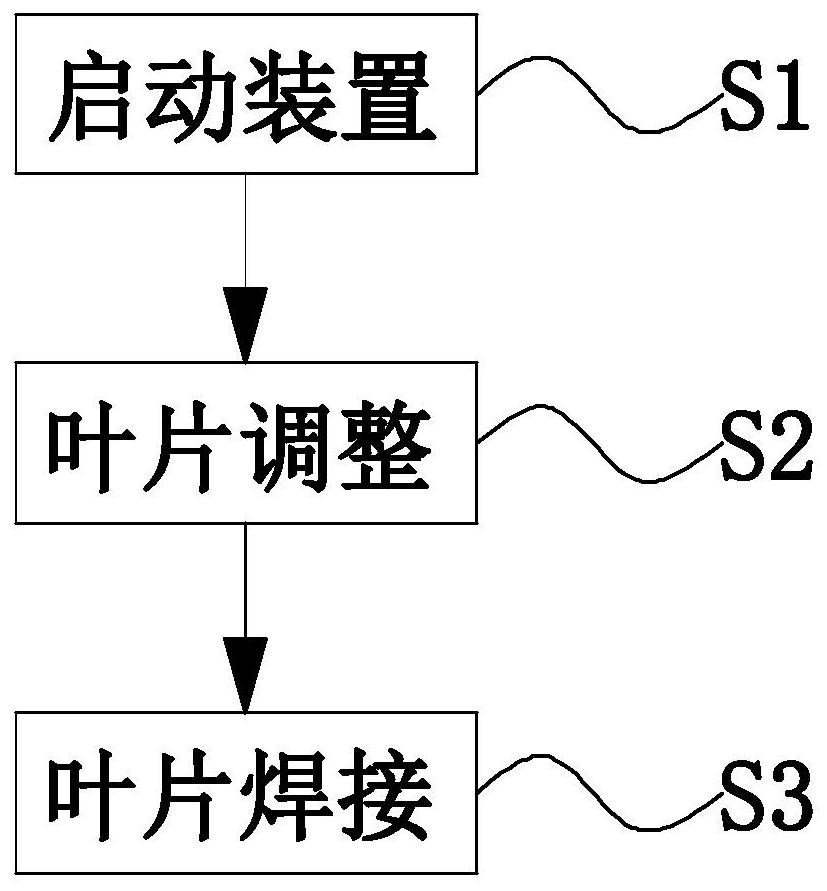

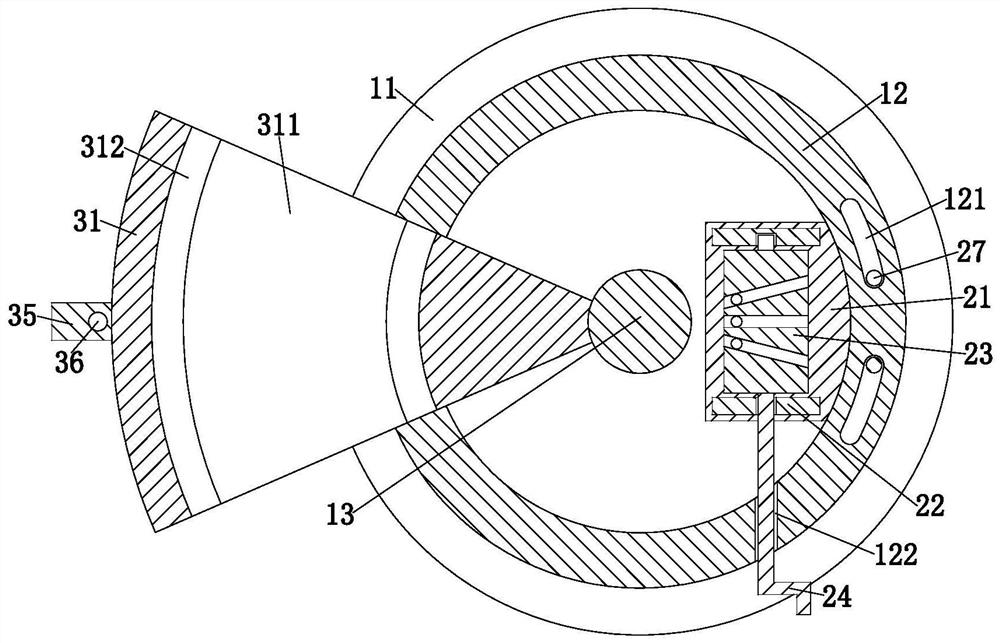

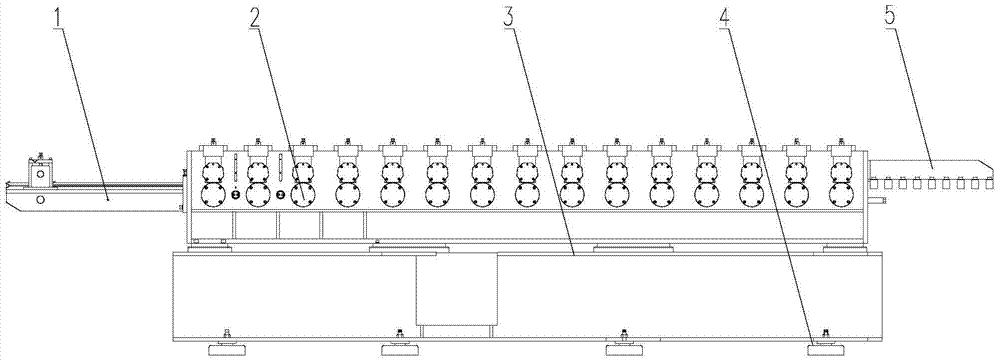

Steam turbine impeller production and manufacturing process

ActiveCN112589307AReduce angle errorAvoid installing one by oneWelding/cutting auxillary devicesAuxillary welding devicesImpellerManufacturing technology

The invention provides a steam turbine impeller production and manufacturing process. The steam turbine impeller production and manufacturing process adopts the following steam turbine impeller production and manufacturing device, the steam turbine impeller production and manufacturing device comprises a base, an adjusting unit and an executing unit, linkage grooves are formed in the right side ofthe upper end of the base in a front-and-back symmetry mode, the adjusting unit is slidably arranged in the linkage grooves, and the executing unit is installed at the upper end of the base. According to the steam turbine impeller production and manufacturing process, firstly, the problems that most of blades are mounted one by one during production and processing of an existing impeller, and thedistance between the blades cannot be effectively adjusted, so that errors exist during blade mounting, repeated calibration is needed, and unnecessary workload is increased are solved; and secondly,the problems that blades and an annular frame are generally clamped and fixed during production and machining of the existing impeller, however, due to the fact that the blades are prone to falling off in a clamping mode, potential safety hazards exist, and the cost is wasted are solved.

Owner:NINGBO TIANKUN MACHINERY MFG

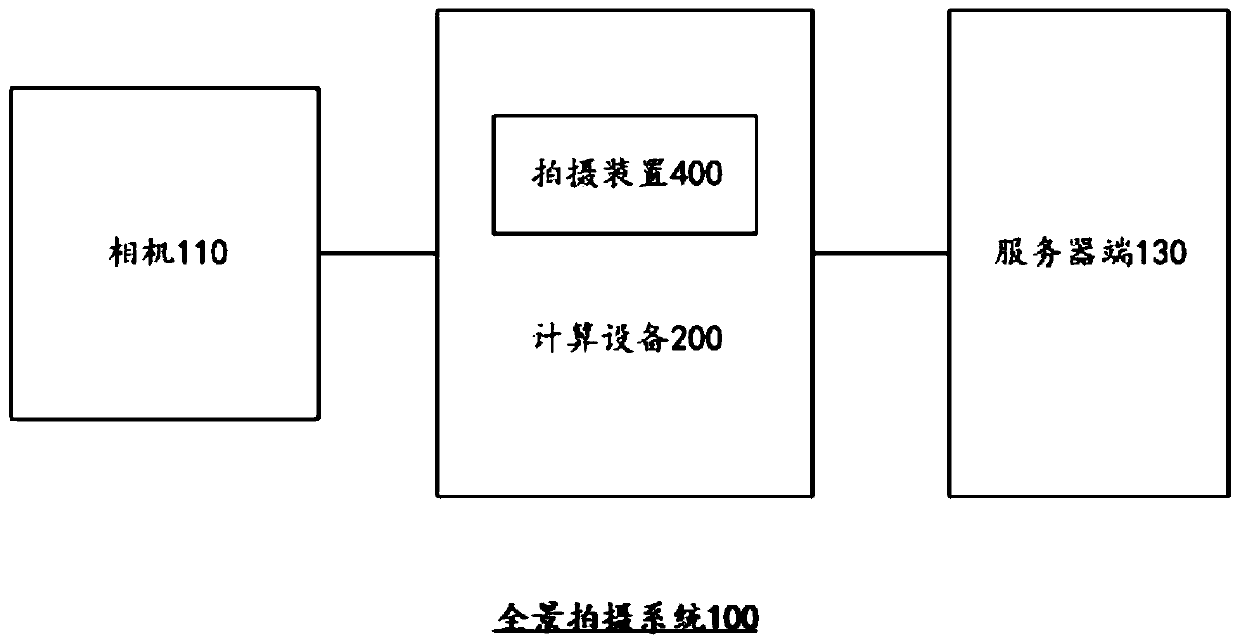

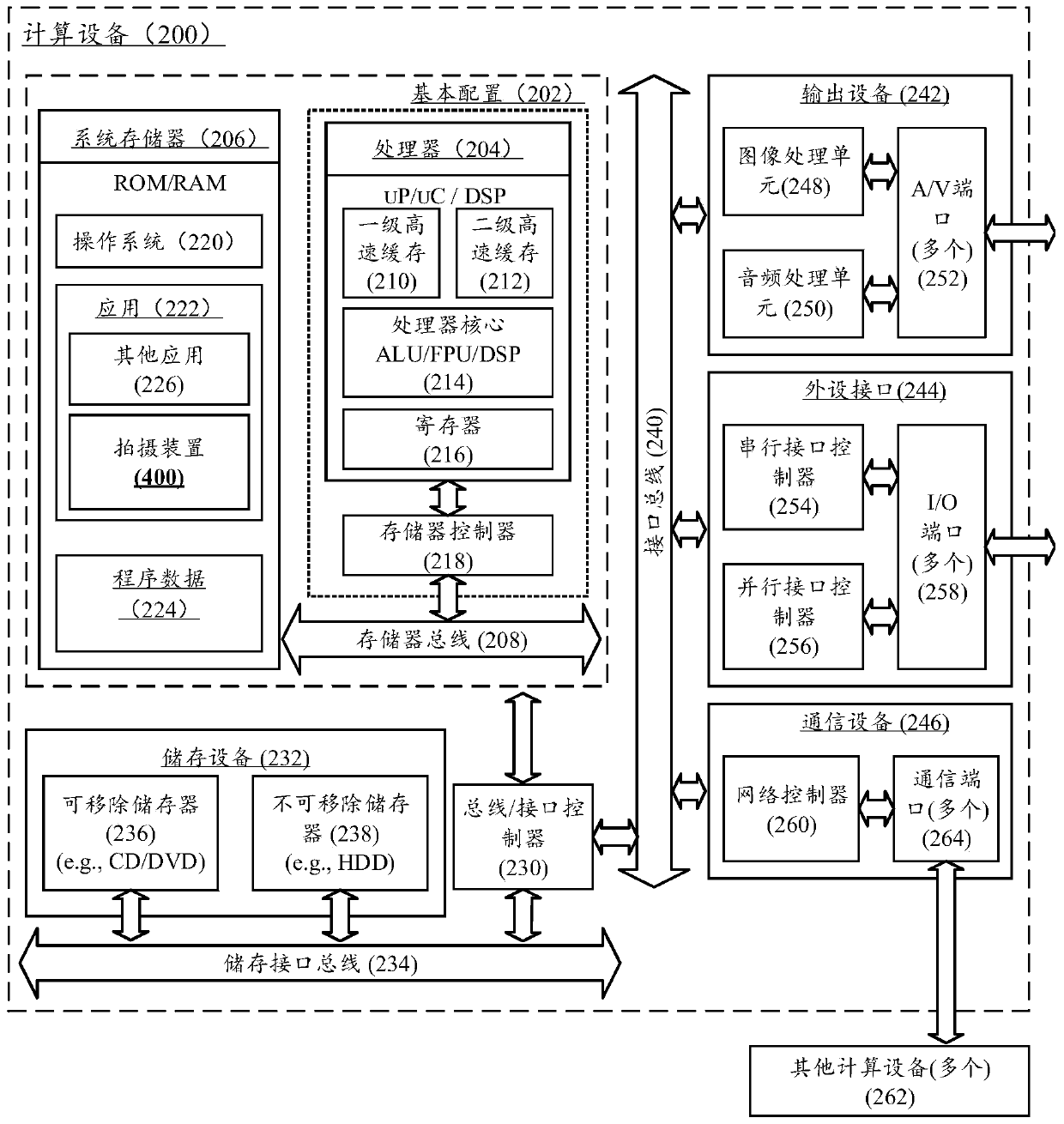

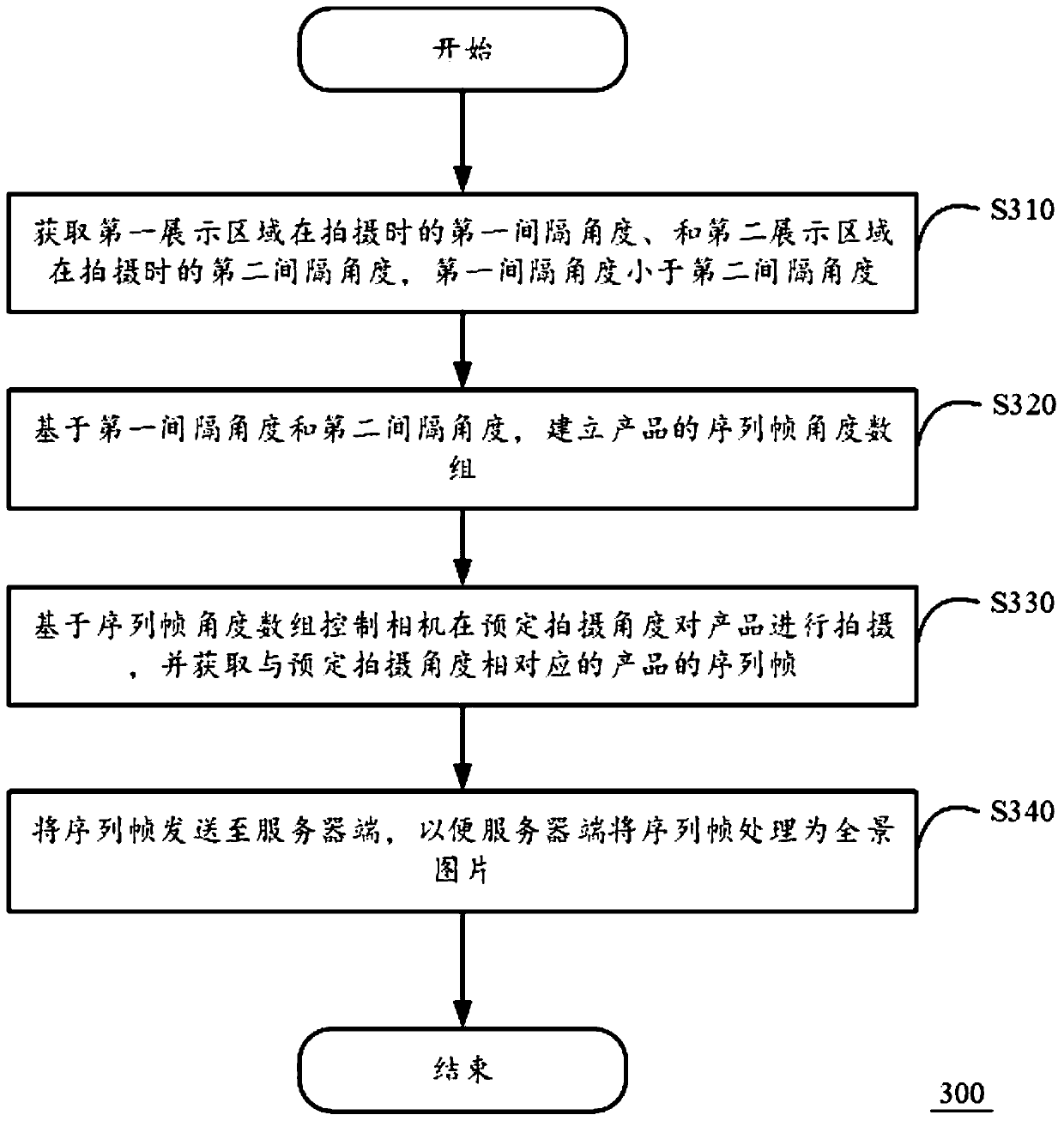

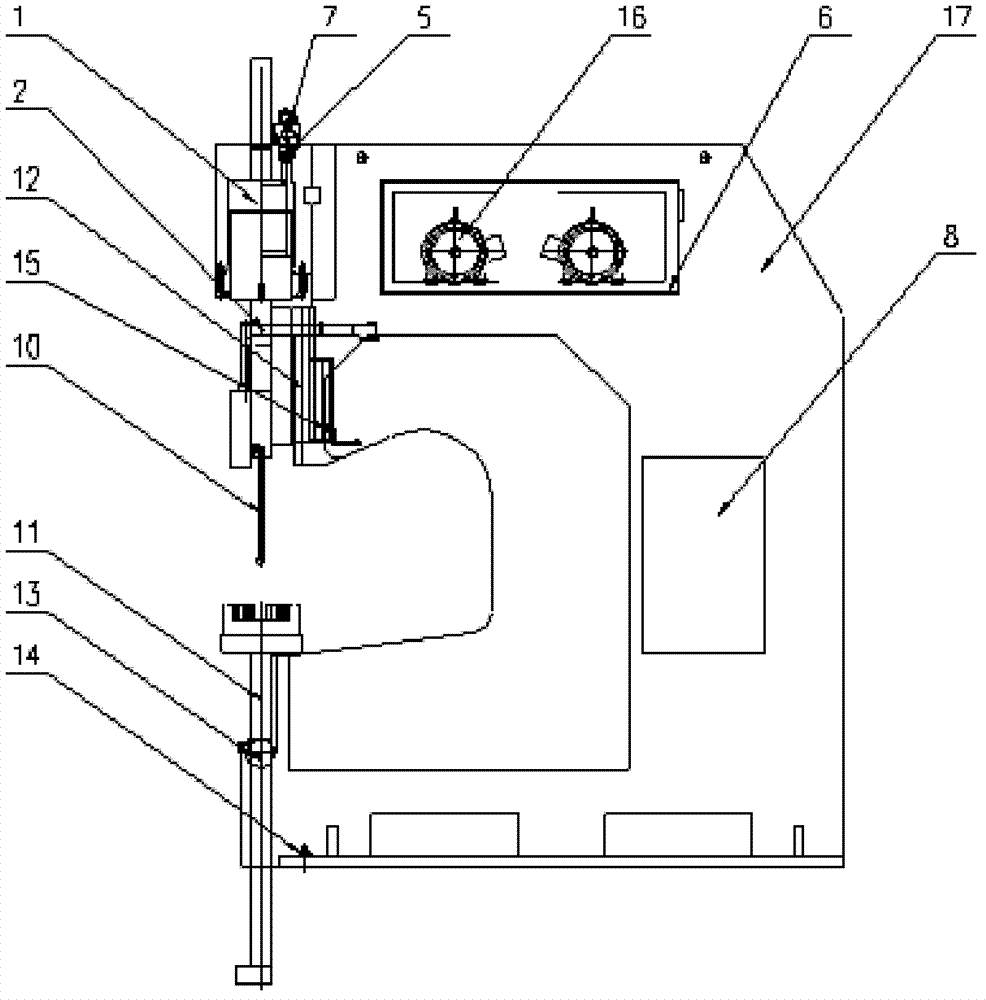

Photographing method, photographing device and panoramic photographing system

ActiveCN110769159AReduce angle errorImprove standardizationTelevision system detailsColor television detailsComputer graphics (images)Panorama

The invention discloses a photographing method. The photographing method is executed in a computing device, and the computing device is suitable for controlling a camera to photograph a product, and the product comprises a first display area and a second display area. The photographing method comprises the steps: acquiring a first interval angle of the first display area during shooting and a second interval angle of the second display area during shooting, wherein the first interval angle is smaller than the second interval angle; establishing a sequence frame angle array of the product basedon the first interval angle and the second interval angle; controlling a camera to photograph the product at a preset photographing angle based on the sequence frame angle array, and obtaining a sequence frame of the product corresponding to the preset photographing angle; and sending the sequence frame to a server, so that the server processes the sequence frame into a panoramic picture. The invention also discloses a corresponding photographing device and a panoramic photographing system. According to the technical scheme, the product sequence frame pictures can be shot automatically, and product details and key areas can be displayed to customers more clearly and completely.

Owner:海南车智易通信息技术有限公司

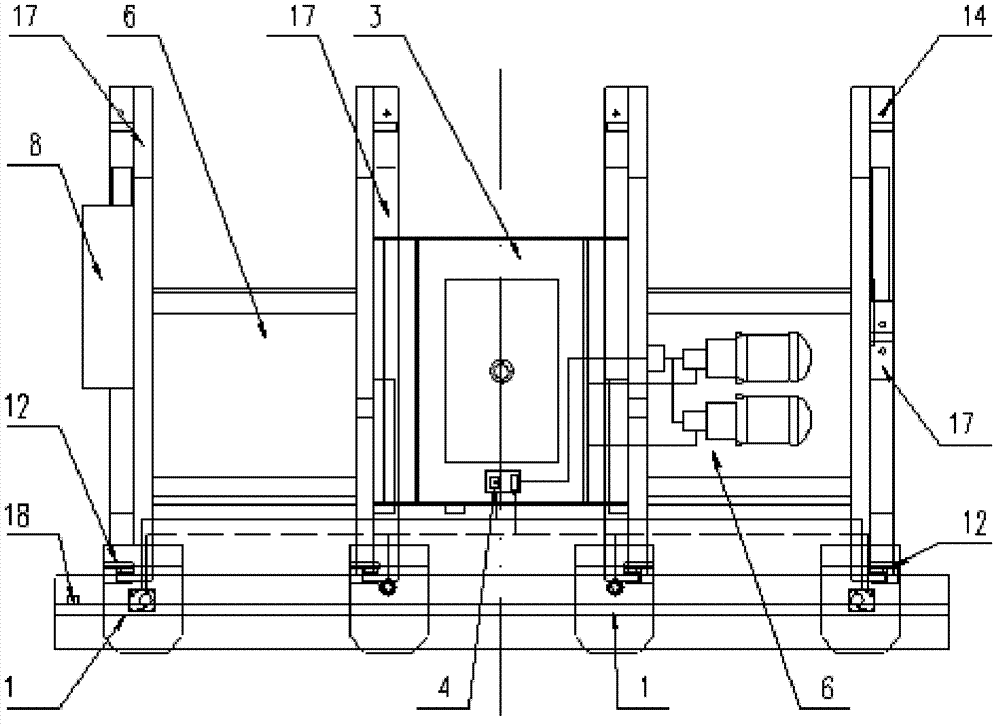

Electro-hydraulic control multi-cylinder linkage bending machine

The invention discloses an electro-hydraulic control multi-cylinder linkage bending machine which mainly comprises oil cylinders, wall plates, connecting beams, an oil tank, sliding blocks, a workbench, a mould, a hydraulic system, an electrical system, a numerical control system and the like. The single equipment comprises one hydraulic assembly and two synchronous blocks; two grating scales are respectively arranged on two sides of the machine; the synchronous operation of the sliding blocks is detected, data is fed back to the numerical control system, and four oil cylinders are controlled by servo valves to bend synchronously downwards. Due to the adoption of the device, the cost of the materials needed by the synchronous bending of two cylinders is saved greatly, the product bending effect is improved, and the difficulty of purchasing the raw materials (steel) is reduced.

Owner:ANHUI DONGHAI MACHINE MFG CO LTD

Topological information guided acquisition method for internal geometric data of three-dimensional lattice structural members

ActiveCN110570526ASolve the problem that the size characteristics of the internal lattice elements of the three-dimensional lattice material cannot be measuredImprove measurement efficiencyImage enhancementImage analysisDot matrixComputed tomography

The invention relates to a topological information guided acquisition method for internal geometric data of three-dimensional lattice structural members, which comprises the following steps of scanning three-dimensional lattice structural members through CT (Computed Tomography), extracting all closed contour feature lines from each frame of obtained image data in sequence, and finding out centralpoints of the closed contour feature lines; separating three-dimensional dot matrix units in the three-dimensional dot matrix structural members, and enabling the central point of the rod members contour feature lines in each separated three-dimensional dot matrix unit to correspond to rod members; obtaining a skeleton line of the rod piece by fitting the central points of all the rod piece contour feature lines corresponding to the same rod piece; and carrying out point multiplication on the space vectors corresponding to any two skeleton lines to obtain an included angle between the rod members corresponding to the two skeleton lines. According to the invention, the internal geometric data characteristics of the three-dimensional lattice structural members can be rapidly measured, and the final performance of the three-dimensional lattice structural members can be evaluated.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A labyrinth forming device

Owner:ANHUI WEIJIA EQUIP & TECH

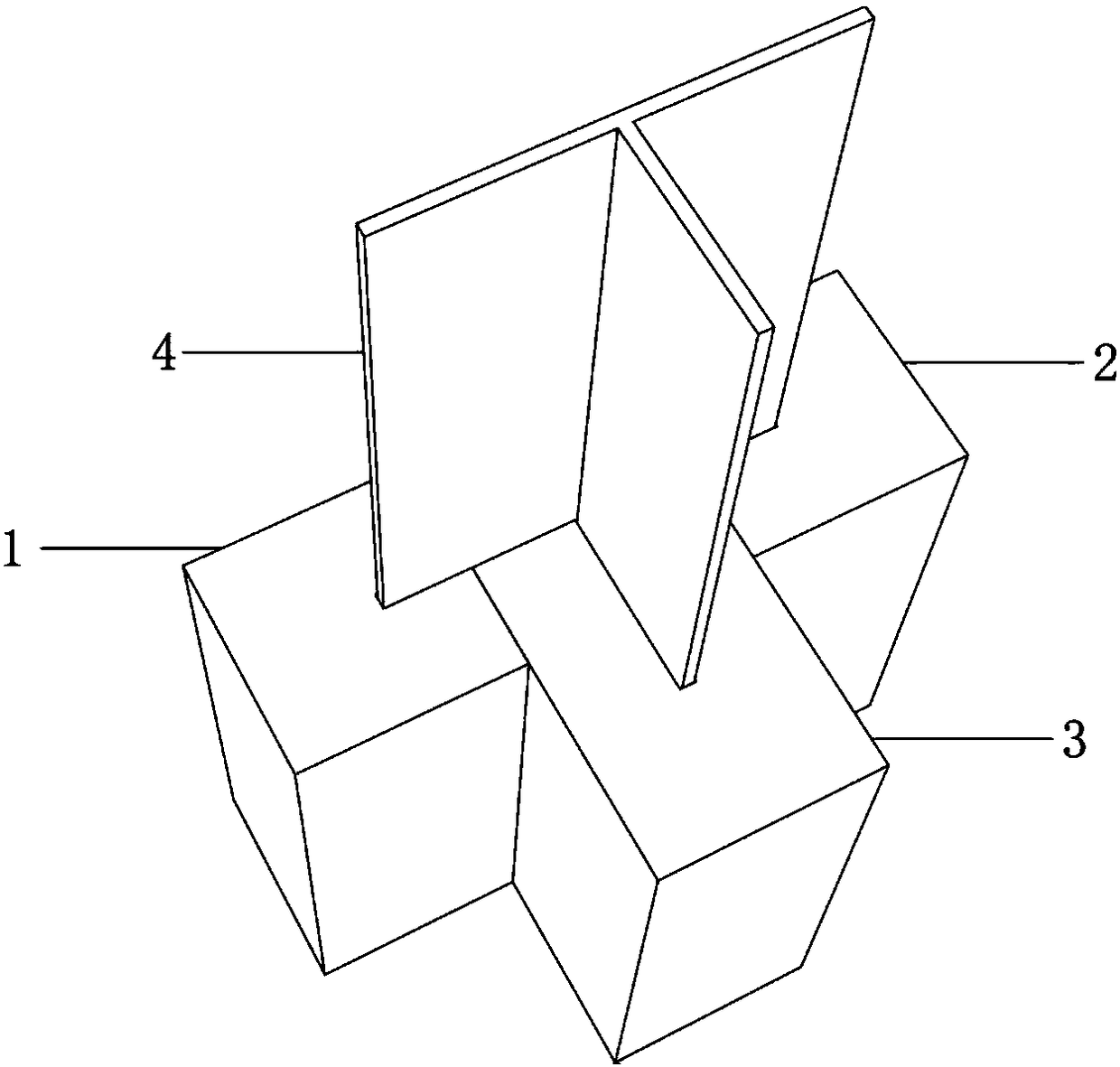

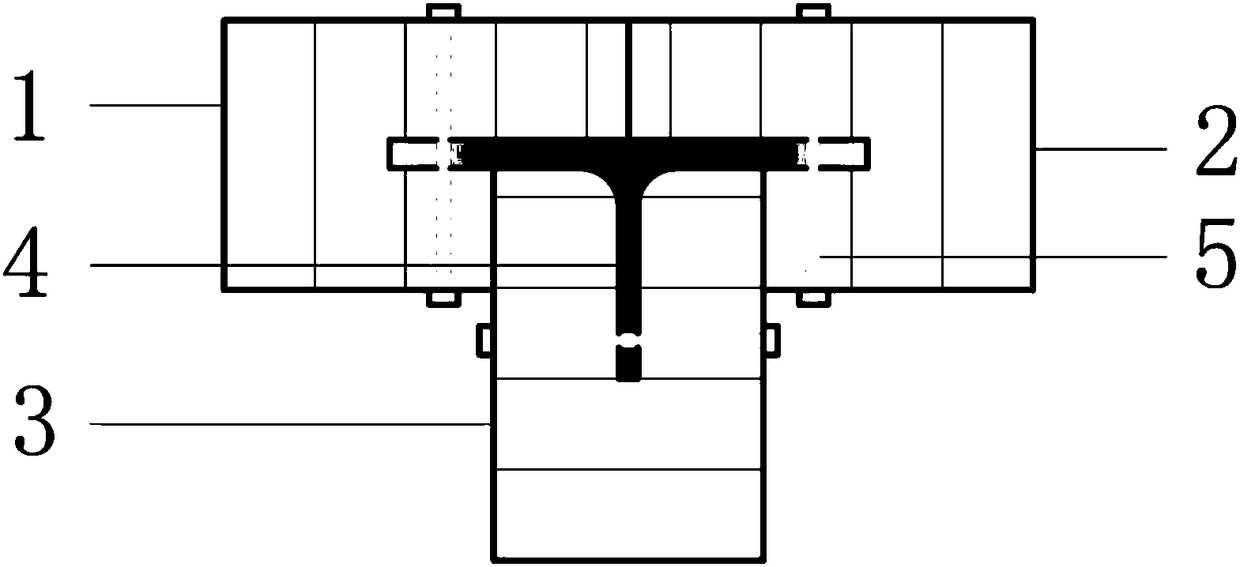

T-shaped steel-wood composite column and manufacturing method thereof

InactiveCN108104373AHigh precisionSmall size errorStrutsPillarsStructure buildingBuilding construction

The invention relates to the technical field of constructional engineering, and concretely relates to a T-shaped composite column member combined by angle steel and wood materials and a production method thereof. In a modern assembly type timber structure building, during installation and construction, errors may exist between walls which are vertically connected, and a new wood standardized member is needed for on-site accurate installation process. The invention aims at providing the T-shaped steel-wood composite column with higher bearing capability, the product is used for supporting and connecting in prefabricated timber structure buildings, in order to reduce dimension and angle errors in construction connection processes.

Owner:BEIJING FORESTRY UNIVERSITY

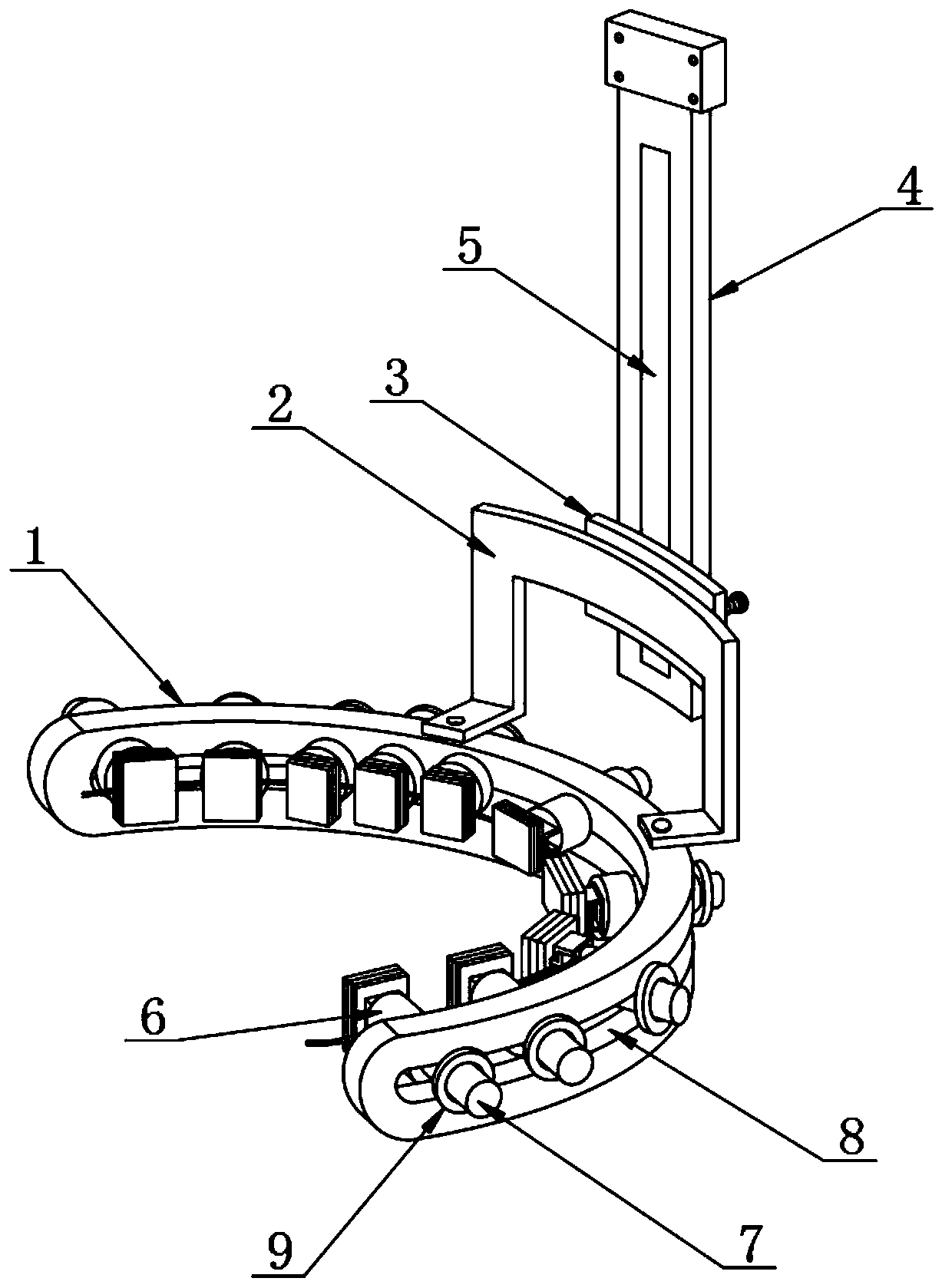

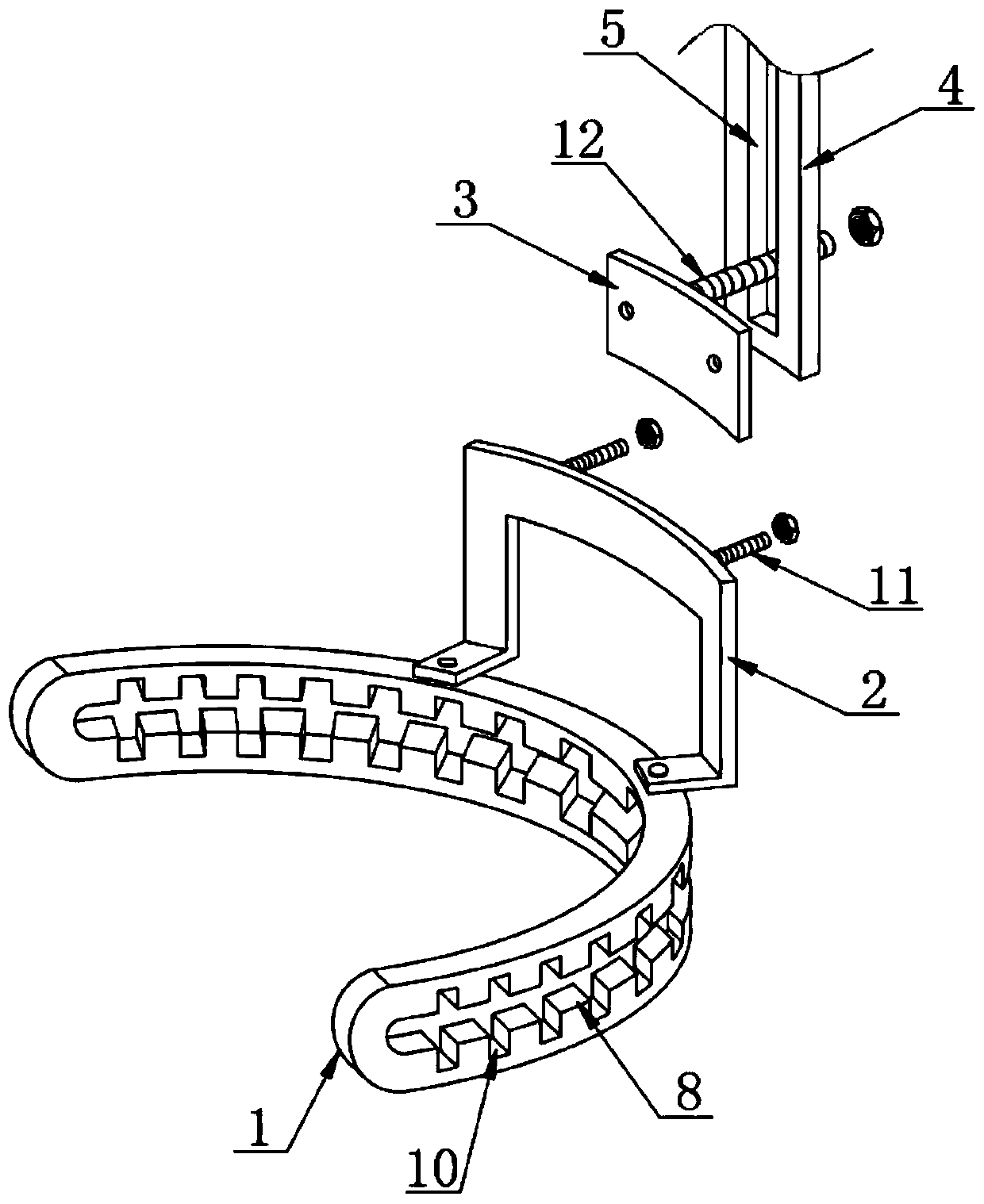

Orthodontic force measuring equipment for tooth correction

The invention discloses orthodontic force measuring equipment for tooth correction, and relates to the technical field of tooth correction. The orthodontic force measuring equipment for tooth correction comprises an arc-shaped frame, wherein the upper end of the arc-shaped frame is connected with a connecting support frame; the outer side surface of the upper end of the connecting support frame isconnected with an adjusting plate; the outer side surface of the adjusting plate is connected with a connecting plate; the middle part of the connecting plate is provided with an adjusting groove; the middle part of the surface of the arc-shaped frame is provided with a transverse groove; and vertical grooves are correspondingly formed in the surface of the arc-shaped frame and are positioned atthe upper end and the lower end of the transverse groove. According to the orthodontic force measuring equipment, the adjusting plate, a transverse adjusting rod and a longitudinal adjusting rod are used for cooperation; in addition, the vertical grooves cooperate with the transverse groove, so that the adjustment of a measuring mechanism is more accurate; and meanwhile, the arch wire clamping plate is matched with the effects of reset springs and slide blocks, so that the fast positioning and fixation on an arch wire is realized. The problems of binding complexity and insufficient binding firmness during the arch wire fixation by a traditional measuring device are solved, so that the accuracy and the efficiency of the tooth orthodontic force measurement are improved.

Owner:陈昕

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com