Electro-hydraulic control multi-cylinder linkage bending machine

An electro-hydraulic control and bending machine technology, which is applied in the field of bending machines, can solve the problems such as the angle size and straightness of the processed sheet cannot meet the requirements, the two wall panels have a large span, and the slider is bent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

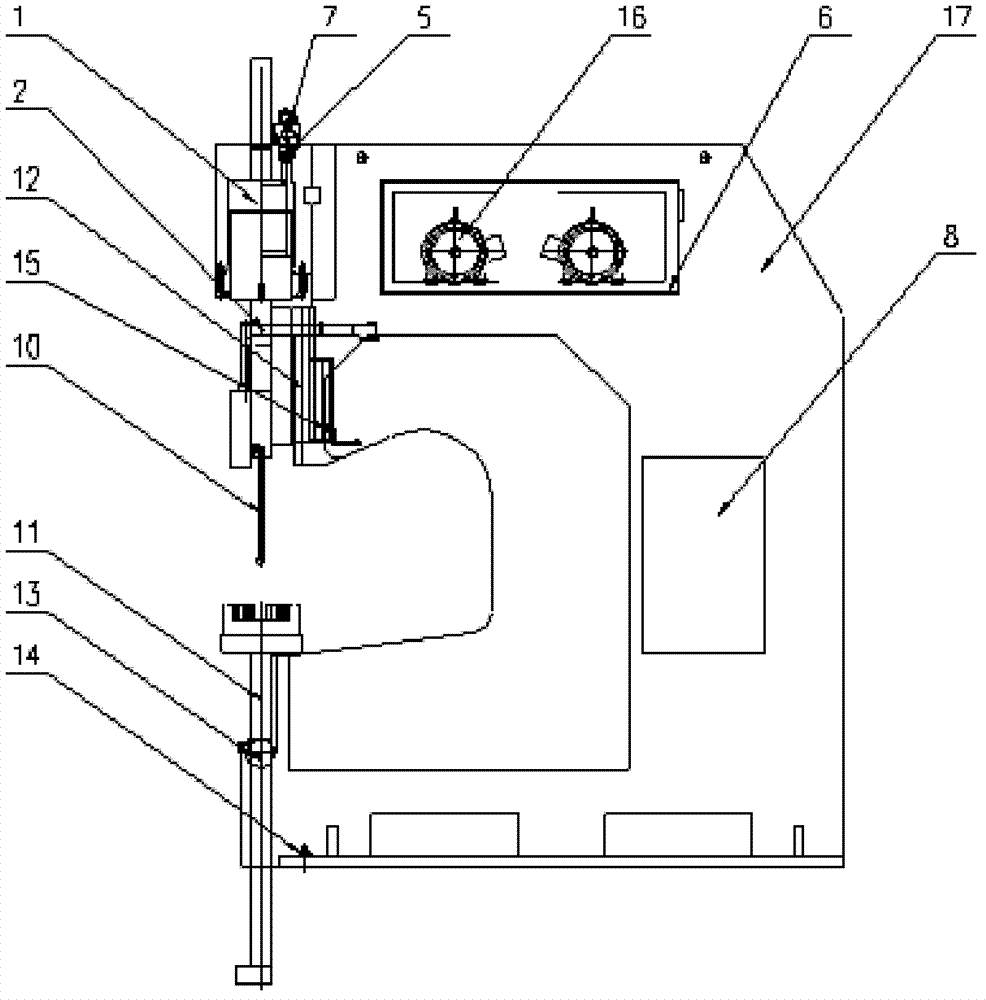

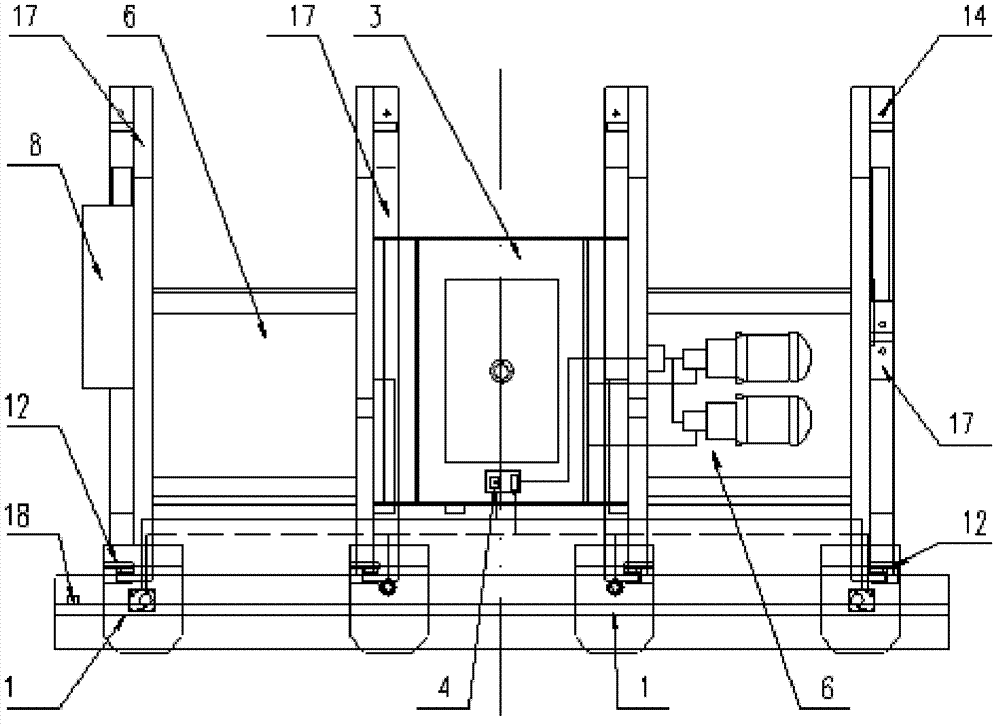

[0013] Referring to the accompanying drawings, the electro-hydraulic control multi-cylinder linkage bending machine includes a machine foot plate 14, a wall plate 17, a frame is fixedly installed on the machine foot plate 14, and an organic foot plate 14, a workbench 11, an electrical system 8, and a numerical control system are installed on the frame. 9. There are eight wall panels 17, and a fuel tank 3 is installed between every two wall panels 17, and the wall panels 17 are fixedly connected by connecting beams 6, and the fuel tank 3 and the connecting beam 6 connect the four wall panels 17 together To form the frame, the two frames form a group and are connected by a synchronous switch 18; the machine foot plate 14 is connected to the workbench 11 through the adjustment block 13, and the mold 10 is installed on the workbench 11; on the eight wallboards 17 Oil cylinder 1 is installed on them, and synchronous valve 7, liquid filling valve 5, liquid filling valve 5, synchronou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com