T-shaped steel-wood composite column and manufacturing method thereof

A manufacturing method and technology of composite columns, which are applied in the direction of columns, pier columns, pillars, etc., can solve the problems that special-shaped columns have not been studied and used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

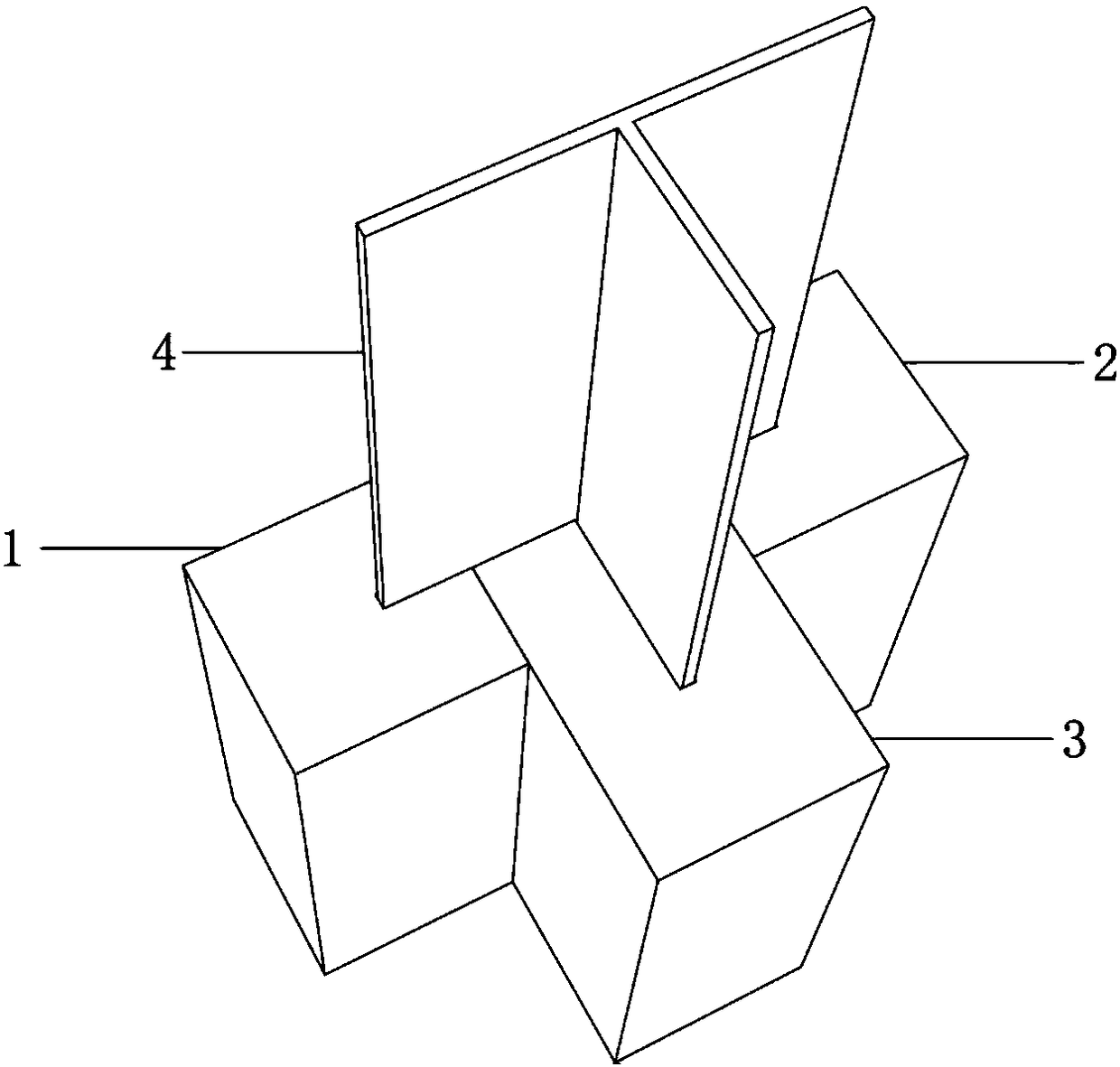

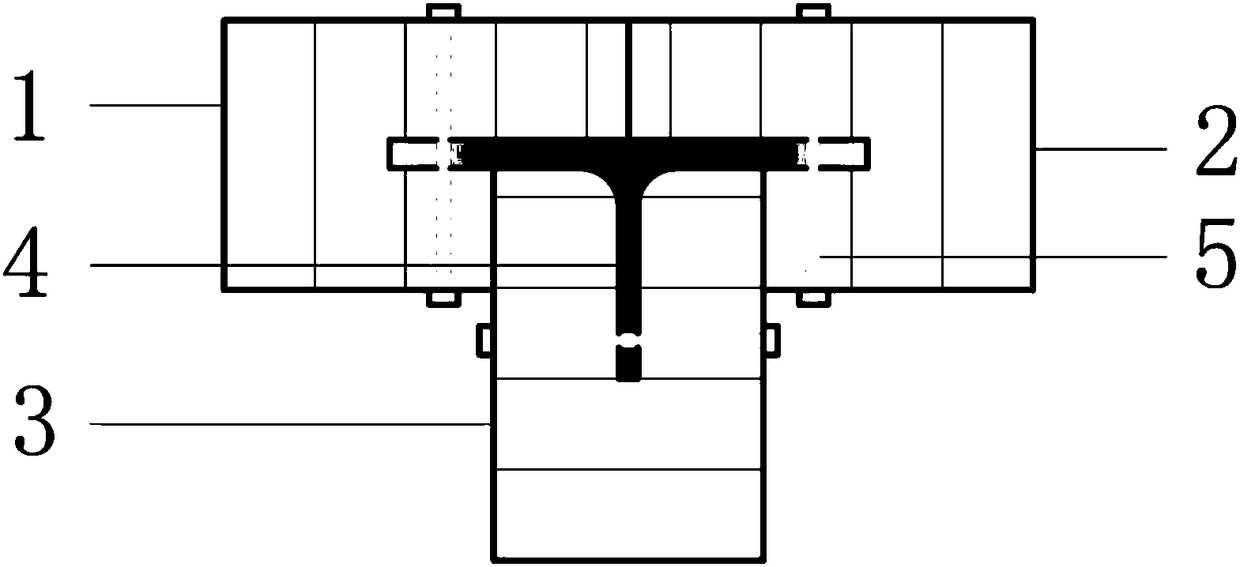

[0029] Combine below Figure 1-4 , taking a T-shaped steel-wood composite column composed of glulam and T-shaped steel for structure as an example to further illustrate the present invention.

[0030] The listed T-shaped steel-wood composite column has a thickness of 113mm and a limb length of 226mm, which is a relatively reasonable size in practice, and the actual construction process is not limited to the materials and dimensions of this example. The specific structure of this example is as follows:

[0031] 1. figure 1 Shown is a schematic diagram of the structure of the composite column that is formed by vertical positive connection and connected by adhesive; figure 2 It is a cross-sectional view of a composite column that is assembled in a vertical positive connection and connected with an adhesive; image 3 Shown is a cross-sectional view of a composite column connected by a vertical butt joint method; Figure 4 Shown is a cross-sectional view of a composite column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com