Electric arc spraying device for machining

An arc spraying and mechanical processing technology, applied in coating, fusion spraying, metal material coating technology and other directions, can solve the problems of easy falling off of the coating, affecting the effect of spraying, etc., to achieve fast gas flow, improve efficiency, prevent The effect of dust accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

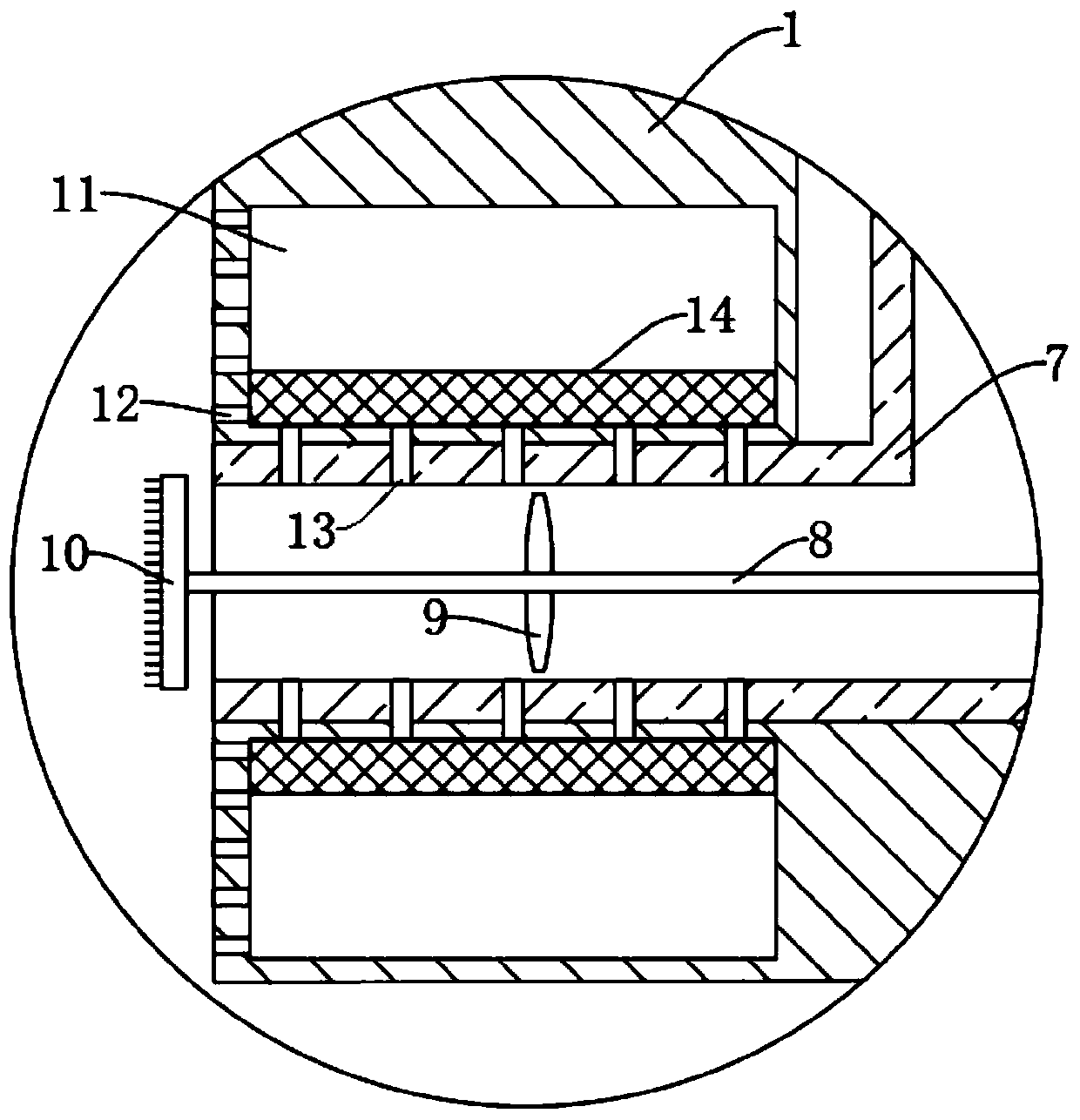

[0022] refer to Figure 1-2 , an arc spraying device for mechanical processing, comprising a spray gun body 1, two conductive tips 2 are installed in the spray gun body 1, a metal wire 3 is arranged in the conductive tip 2, a vortex tube 4 is embedded in the spray gun body 1, and the vortex tube The upper and lower sides of 4 are respectively equipped with cold air pipe 5 and hot air pipe 6, and the outlet end of hot air pipe 6 is located between two metal wires 3, and the lower end of hot air pipe 6 is fixedly connected with a conduit 7 communicating with the inside thereof, and the end of conduit 7 A rotating shaft 8 is rotatably connected to the inner wall, and a plurality of axial flow fan blades 9 are fixedly connected to the side wall of the rotating shaft 8. The end of the rotating shaft 8 far away from the conduit 7 is fixedly connected to a brush plate 10, and the side of the brush plate 10 away from the spray gun body 1 is provided Has multiple bristles.

[0023] It...

Embodiment 2

[0032] refer to image 3 , different from Embodiment 1, the side wall of the spray gun body 1 is fixedly connected with a glass sleeve 11, the glass sleeve 11 is made of high temperature resistant material, and the upper and lower ends of the brush plate 10 are in contact with the inner wall of the glass sleeve 11 Frictional contact, the surface of the brush plate is coated with high temperature and wear-resistant materials, and in this embodiment, there is no need to set the square cavity 11, the through hole 12, the negative pressure hole 13 and the filter screen 14. The surface coating of the brush plate 10 can be made of high-temperature wear-resistant material for boiler pipes, which is a variety of high-temperature-resistant and wear-resistant inorganic non-metallic materials that are close to the expansion coefficient of steel. Celsius, and can generate static electricity in the process of continuous friction with the inner wall of the glass sleeve 11 .

[0033] In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com