Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Printing effect is clear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

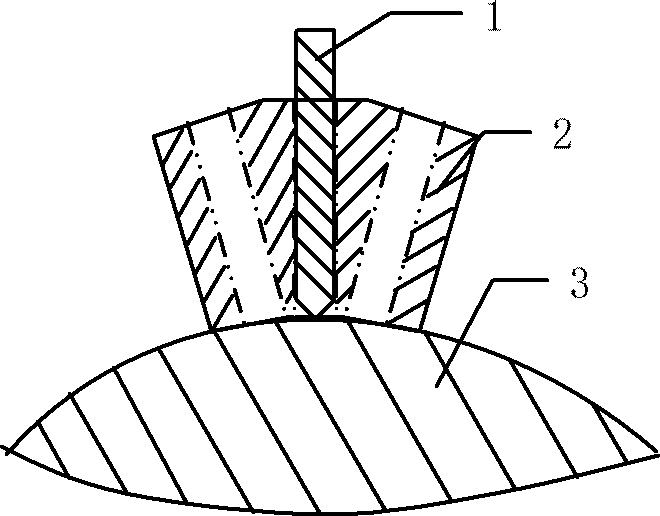

Laser engraving processing method and device for ultra-soft printing roller

InactiveCN102343705AImprove yieldThe edge of the mesh hole is neatForme preparationLaser engravingEngineering

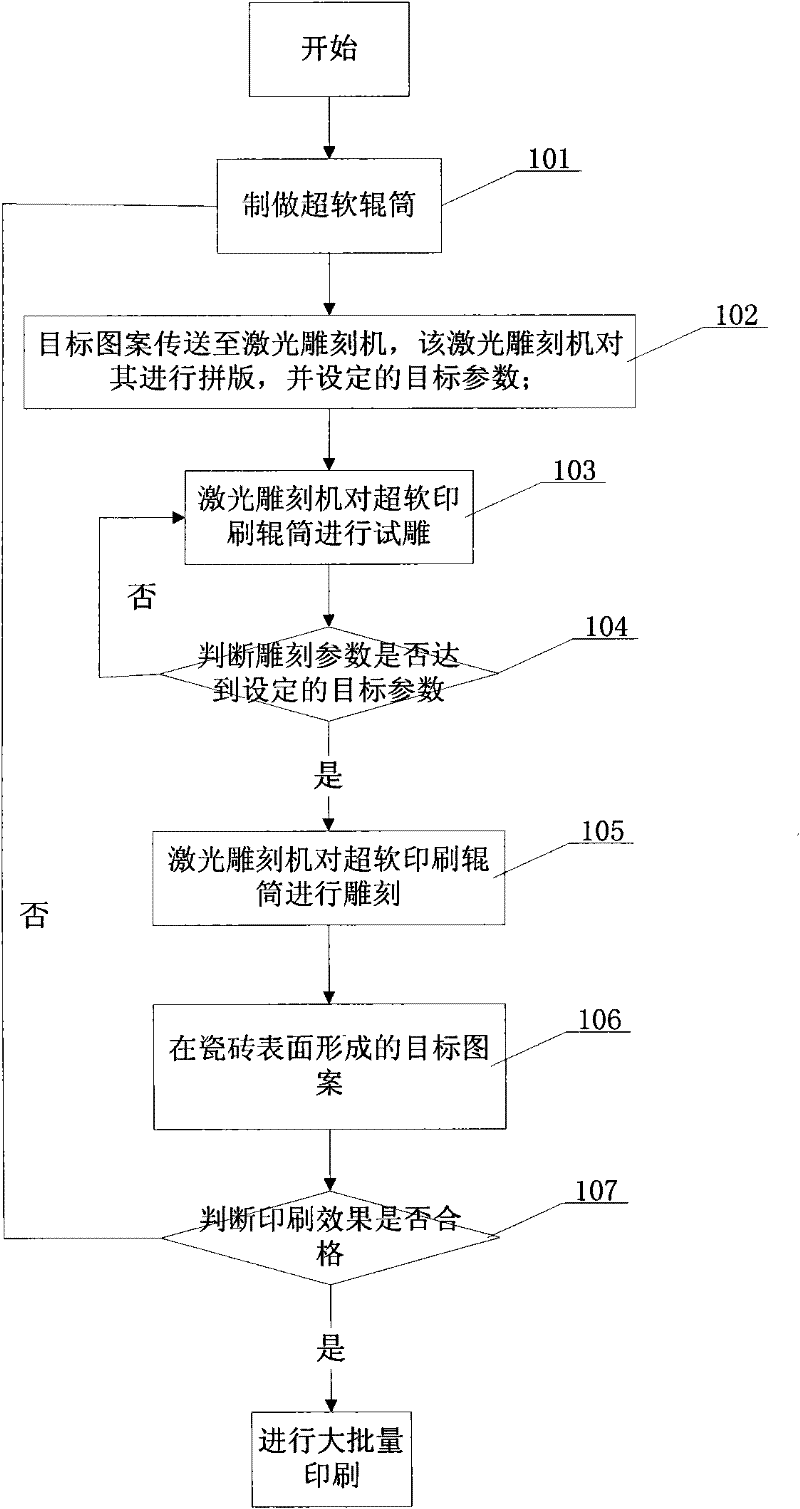

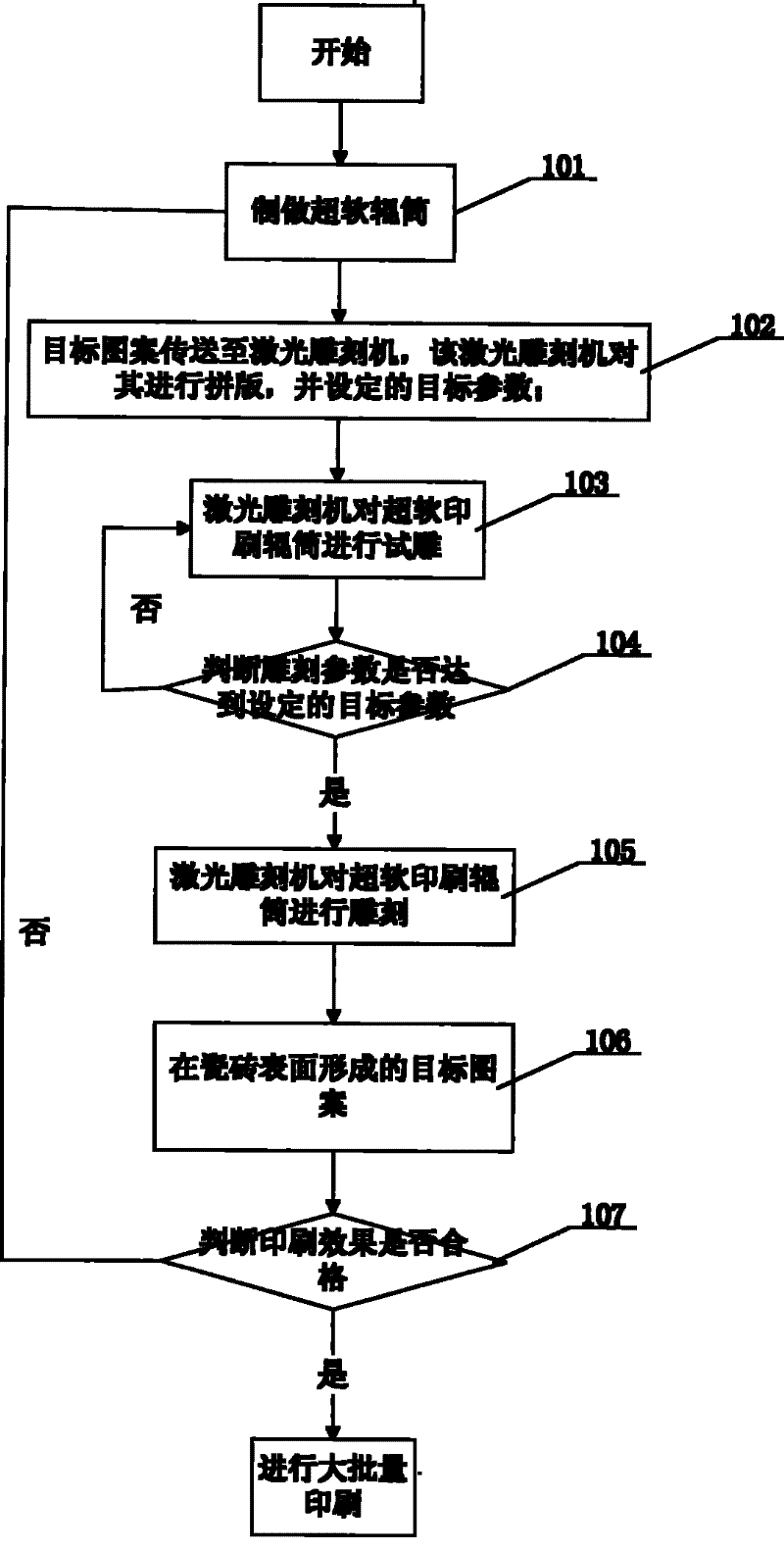

The invention relates to a laser engraving processing method for an ultra-soft printing roller, comprising the following steps: 1) processing silica gel into the ultra-soft printing roller; 2) transmitting a target pattern to a laser engraving machine through a PC, carrying out imposition on the target pattern by the laser engraving machine, and setting target parameters for laser engraving by the laser engraving machine; 3) carrying out pilot engraving on the ultra-soft printing roller by the laser engraving machine; 4) determining whether the engraving parameters reach the set target parameters, if yes, executing the step 5), if not, returning to the step 3); 5) engraving the ultra-soft printing roller by the laser engraving machine to form complete and burnished printing network points on the silica gel surface after engraving; 6) filling glaze materials in the network points to form the target pattern on the surface of the ceramic tile; and 7) determining whether the printing effect is qualified, if not, returning to the step 1). Compared with the prior art, the invention has the advantages of high laser engraving wires, delicate printed pattern, high yield of the ceramic tile product and the like.

Owner:SHANGHAI YUNAN PLATE MAKING

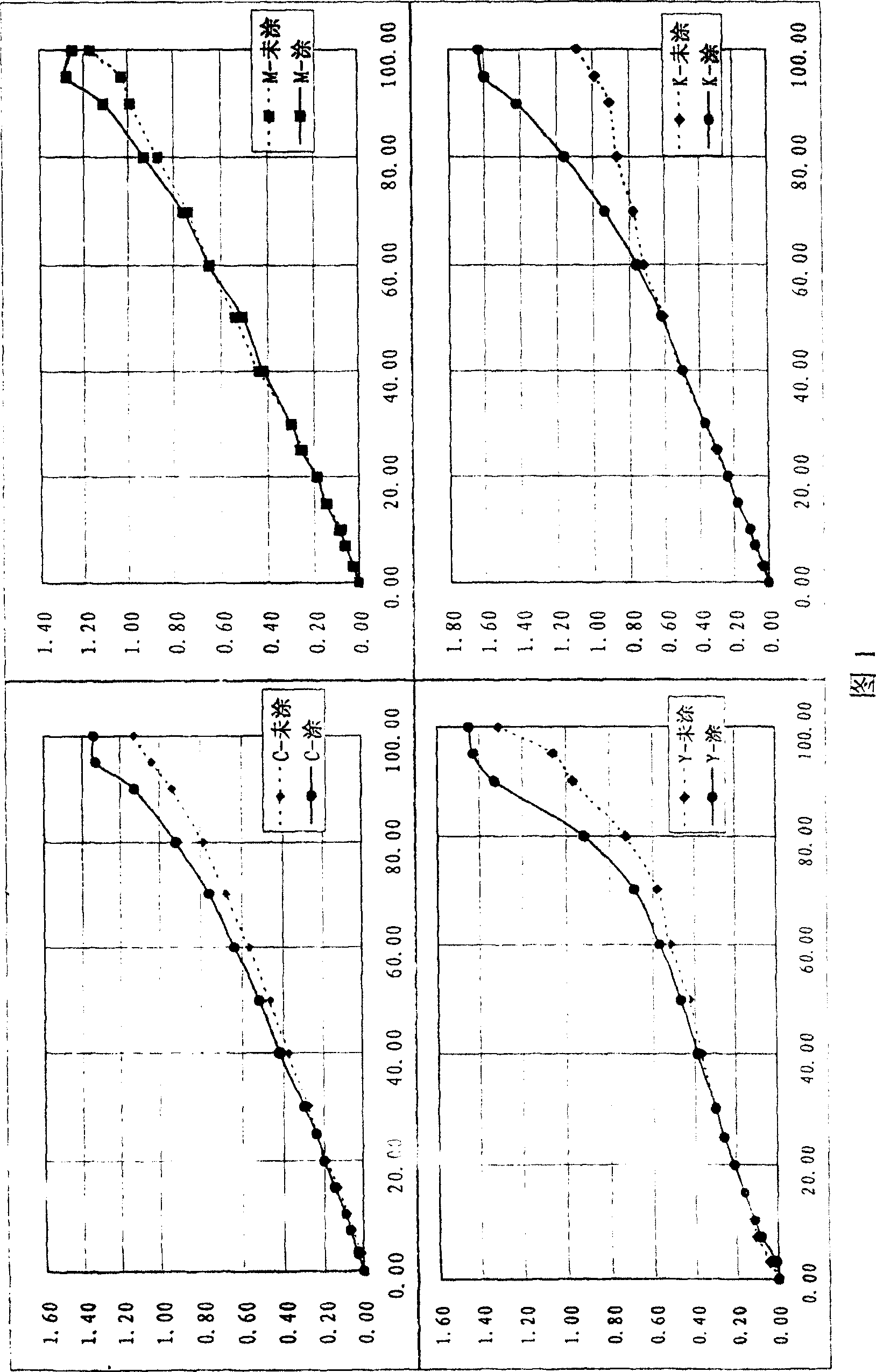

Method for preparing polyocarboxy acid type pigment ink

The invention relates the method for preparation of polycarboxylic acids type color ink, comprising the following steps: using the benzoyl peroxide or azo-diisobutyronitrile as initiating agent, preparing the polycarboxylic acids type macromolecular dispersing agent with acroleic acid, methyl acrylate and methyl methacrylate; hydrolyzing the polycarboxylic acids type macromolecular dispersing agent, sequential adding the ultra-fine color, polyatomic alcohol, dissolvent and water, stirring, emulsifying, disintegrating, adjusting pH, and getting the polycarboxylic acids type color ink. The polycarboxylic acids type color ink is used for the fields of computer ink-jet printer and textile ink-jet printing. The ink possesses the advantages of dispersion stability, good water resistance and light resistance and storage stabilization.

Owner:QINGDAO UNIV

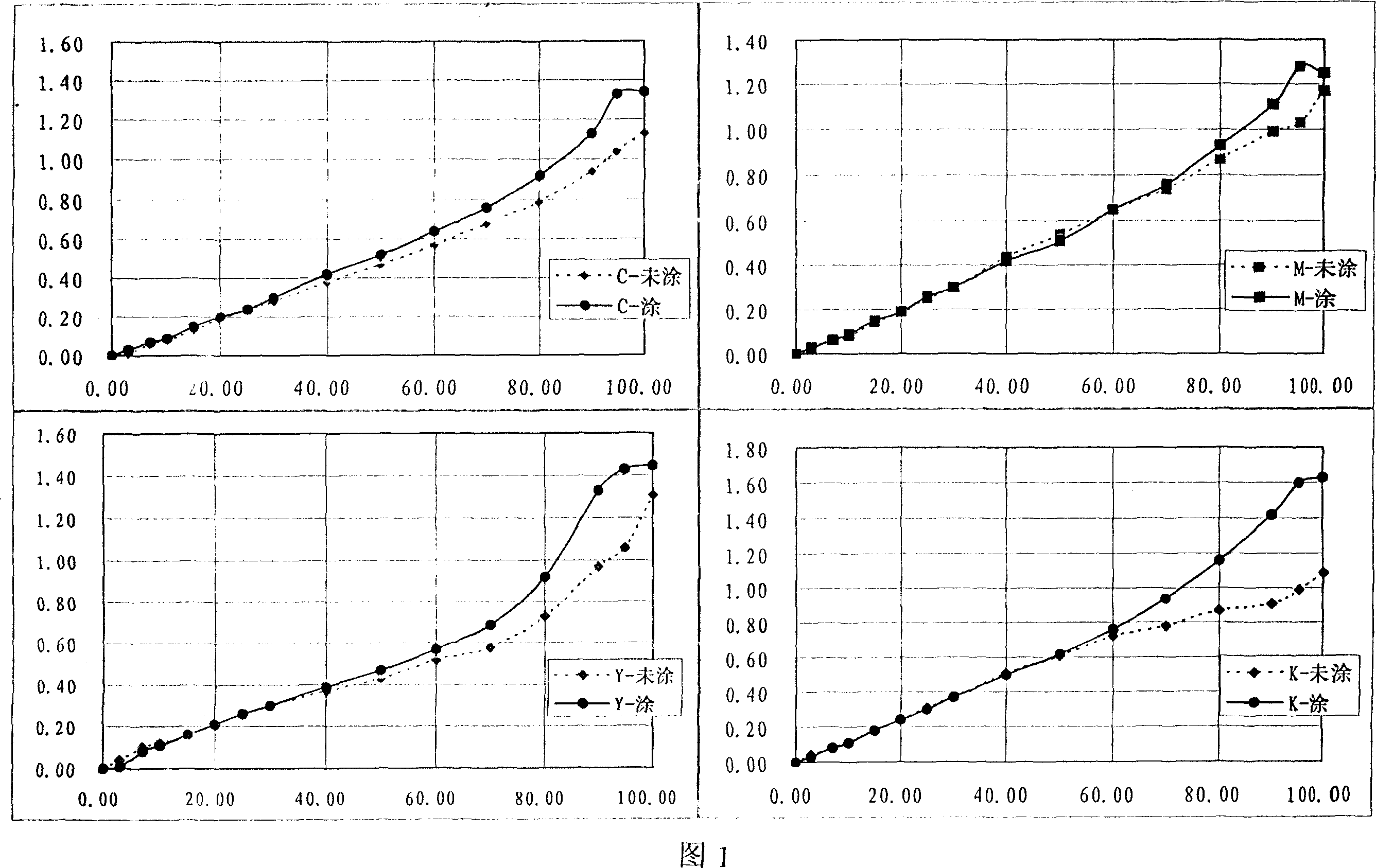

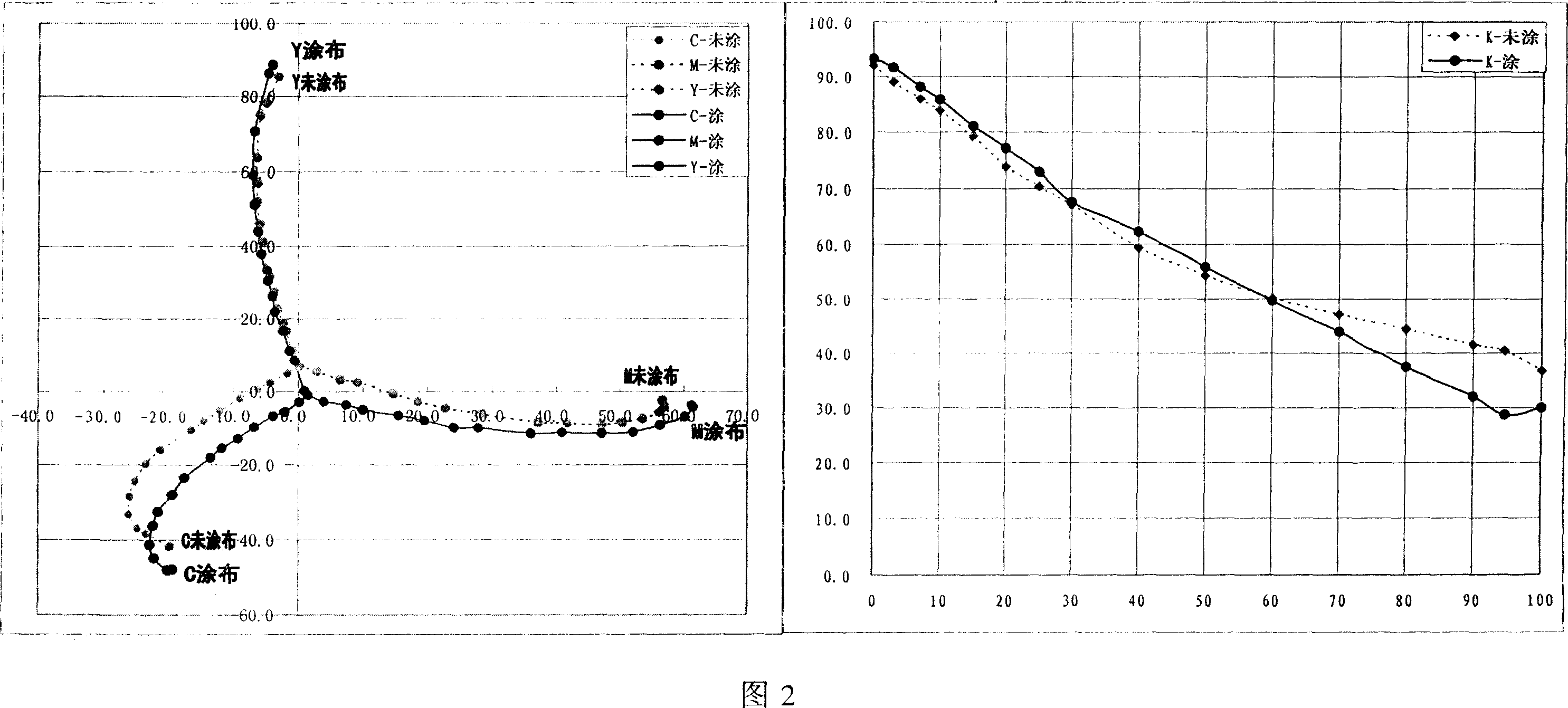

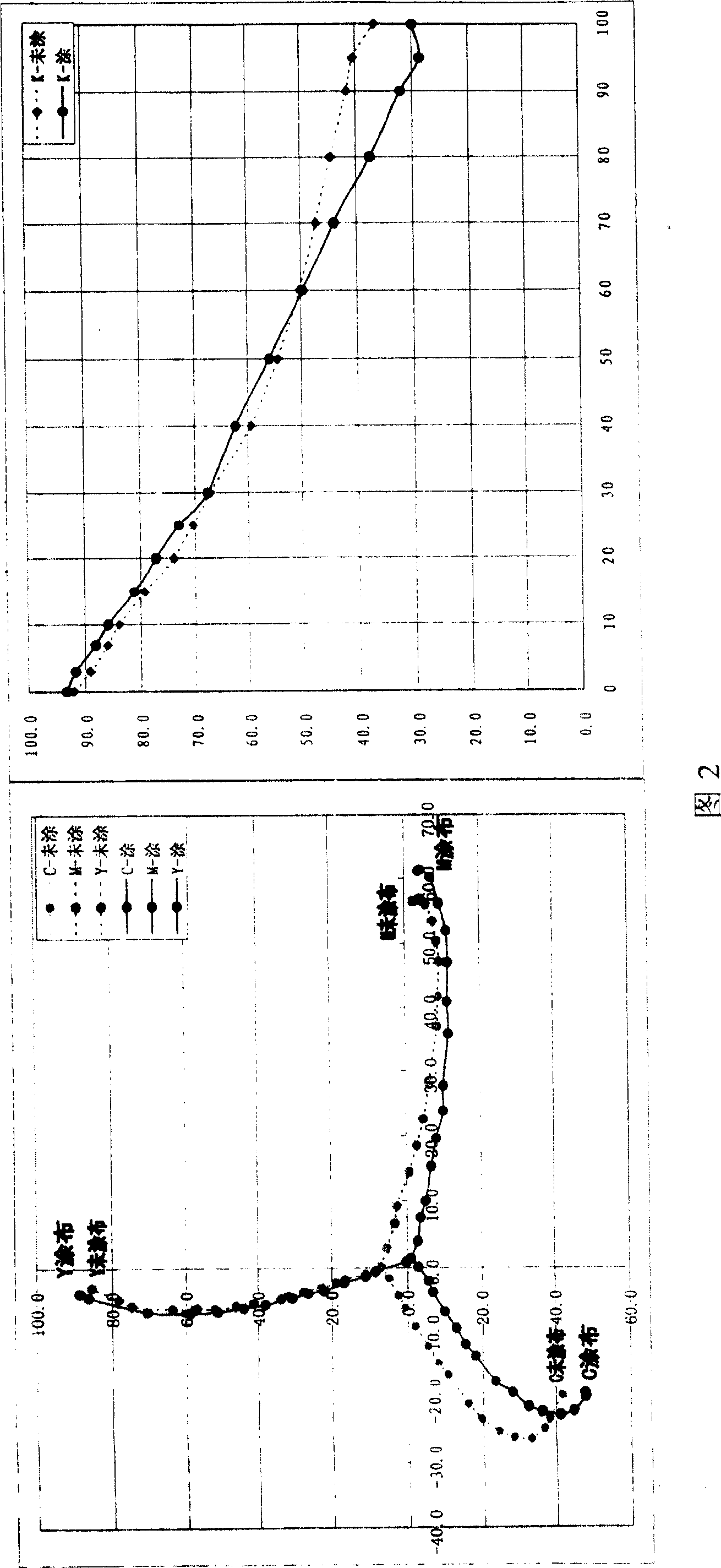

Ink-jet printing coating and ink-jet printing simulation material prepared by the same

The invention discloses a kind of ink jet coating and its materials for coating. The ink jet coating is composed of the following components by weight share: 8~2wt% of fixing agent, 2~10.8wt% of absorbent, 0.5~10wt% of adhesives, 0.2~2.5wt% of surfactant, 1.2~7.4wt% of UV-resistant, and a rest amount of deionized water. The invention solves the problems of proliferation, poor contrast and poor color saturation.

Owner:BEIJING SUNRAINBOW CULTURE & ARTS DEV CO LTD

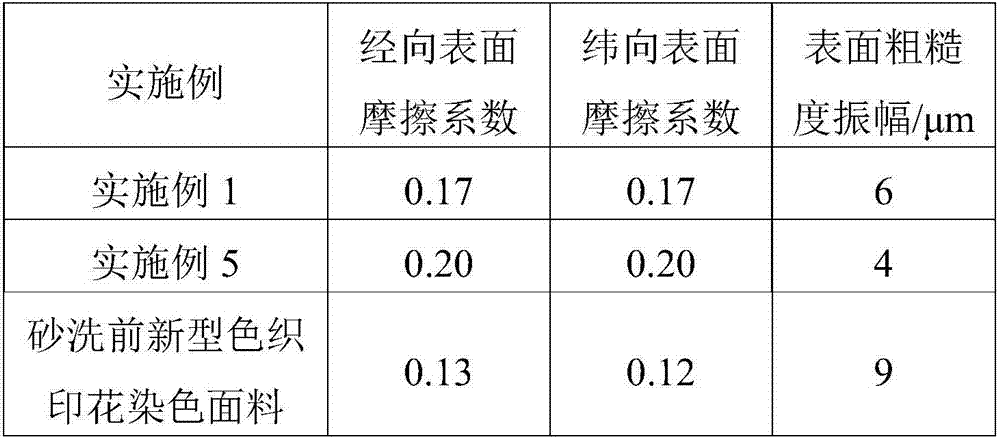

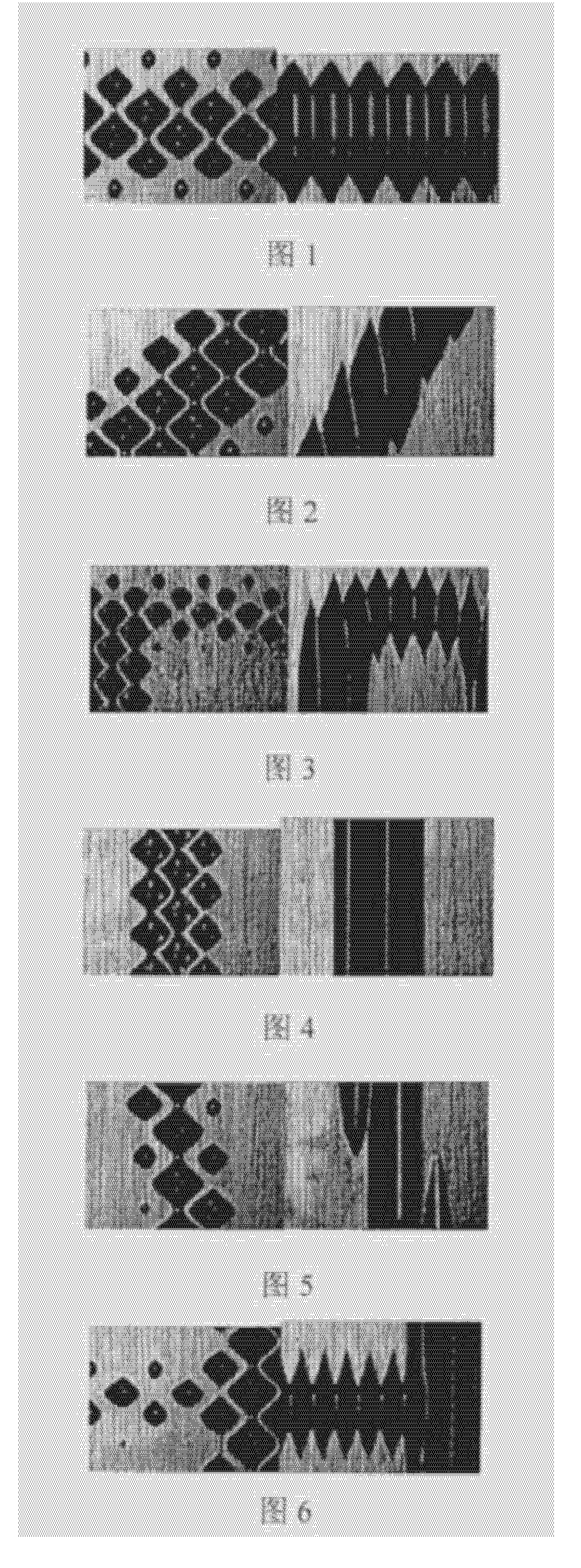

Novel yarn dyeing, printing and dyeing fabric and production method thereof

The invention discloses novel yarn dyeing, printing and dyeing fabric and a production method thereof. The novel yarn dyeing, printing and dyeing fabric is produced by adopting high quality yarns through the process that yarn dyeing, dyeing and printing are combined. Compared with the prior art, the novel yarn dyeing, printing and dyeing fabric has the advantages of simpleness in production process, high production efficiency, rich and colorful patterns, exquisite hand feel and texture feeling, and a sense of dignity and generosity is created; in addition, full-cotton yarns of different colors are taken as weft yarns, color of the reverse of the yarn dyeing fabric can be enriched, and meanwhile, waste of dyed yarns can be greatly reduced.

Owner:张伟夫

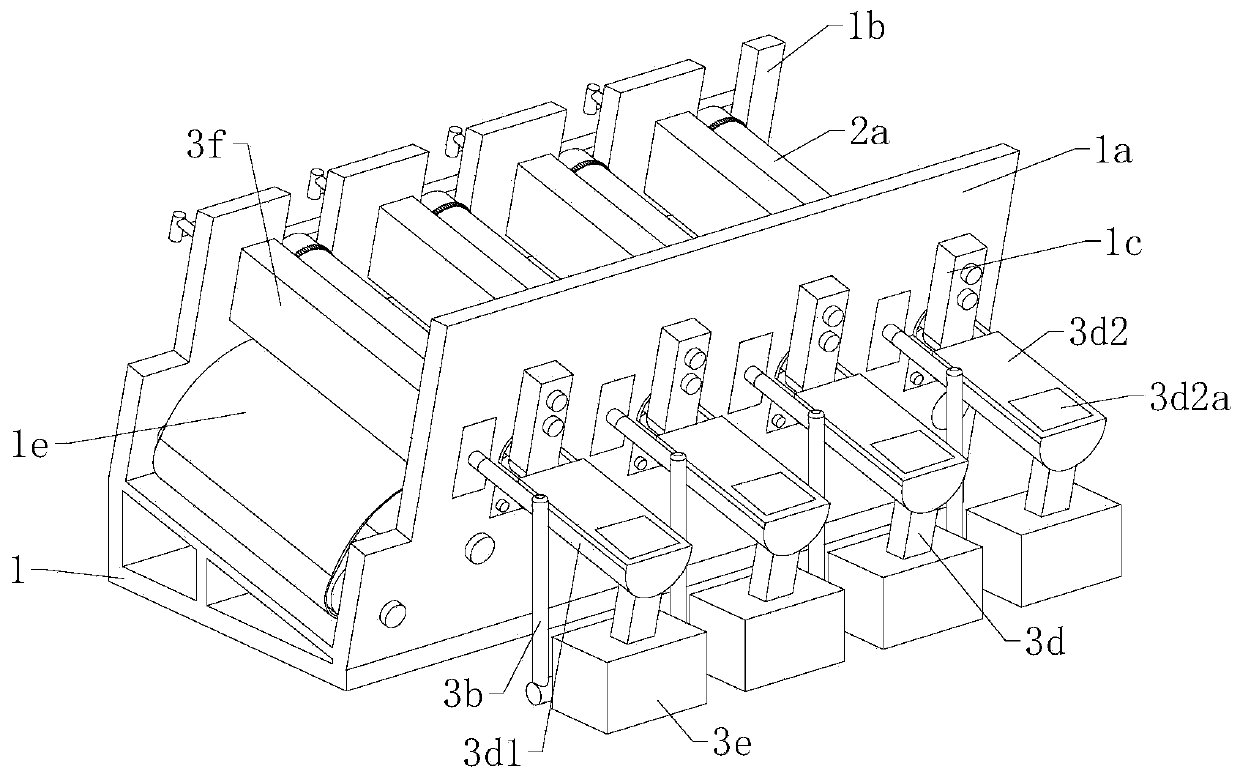

Slurry circulation and recycling device for oblique circular screen printing

InactiveCN110001198AUniform coverageQuick coverageScreen printersPrinting press partsScreen printingSlurry

The invention relates to the field of circular screen printing, in particular to a slurry circulation and recycling device for oblique circular screen printing. The slurry circulation and recycling device for oblique circular screen printing comprises a supporting frame, a circular screen roller, a dye mechanism and a rotating mechanism, wherein the supporting frame is vertically arranged; the circular screen roller is obliquely arranged at a certain angle with the supporting frame; the two ends of the circular screen roller are connected with the supporting frame; the dye mechanism is connected with the supporting frame at a certain angle; the two ends of the dye mechanism are connected with the supporting frame; the dye mechanism is connected with the two ends of the circular screen roller; the rotary mechanism is connected with the circular screen roller, and the dye mechanism comprises a dye pipe, a first feeding pipe, a second feeding pipe, a return pipe, a dye barrel and a slurryfeeding pump. An inclined design is adopted in a circular screen, the circular screen is covered with dye by the inclined circular screen, uniform covering of the dye is achieved, the printing effectis clear, the dye return speed is high, the dye cannot solidify and block the inclined circular screen, the residual dye recycling efficiency is high, the dye recycling effect is good, and the working efficiency of circular screen printing and dyeing is improved.

Owner:ZHEJIANG FURUN DYEING & PRINTING

A color printing production method and production device for corrugated plastic boxes

InactiveCN102275335APrinting effect is clearStrong three-dimensional senseBox making operationsPaper-makingClear LayerColor printing

The invention discloses a method for making color printing on corrugated plastic boxes. First, the printed color printing film and face paper are wound around the same hot roller, and the color printing film is heat-adhesively transferred to the face paper under the action of extrusion force. The surface paper with color printing is formed, and then the lining paper, corrugated paper and surface paper with color printing driven by the hot roller are sequentially transported to the forming hot roller synchronously from bottom to top, so that the lining paper, corrugated paper and color printing The surface papers are superimposed and bonded to form, and then sent to the cutting machine for cutting after cooling, so as to make a corrugated plastic box with color printing. The present invention can print various color printings on the corrugated plastic box. The color printing not only has clear printing effect, lifelike, clear layers, strong three-dimensional effect and good visual effect, but also the printing is firm and does not fade or fade. The method is simple, the labor intensity is low, the working environment is good, the operation is simple and easy to control, and the color printing of different sizes of layouts and the batch operation of corrugated plastic boxes of different sizes can be realized at the same time.

Owner:黎志保

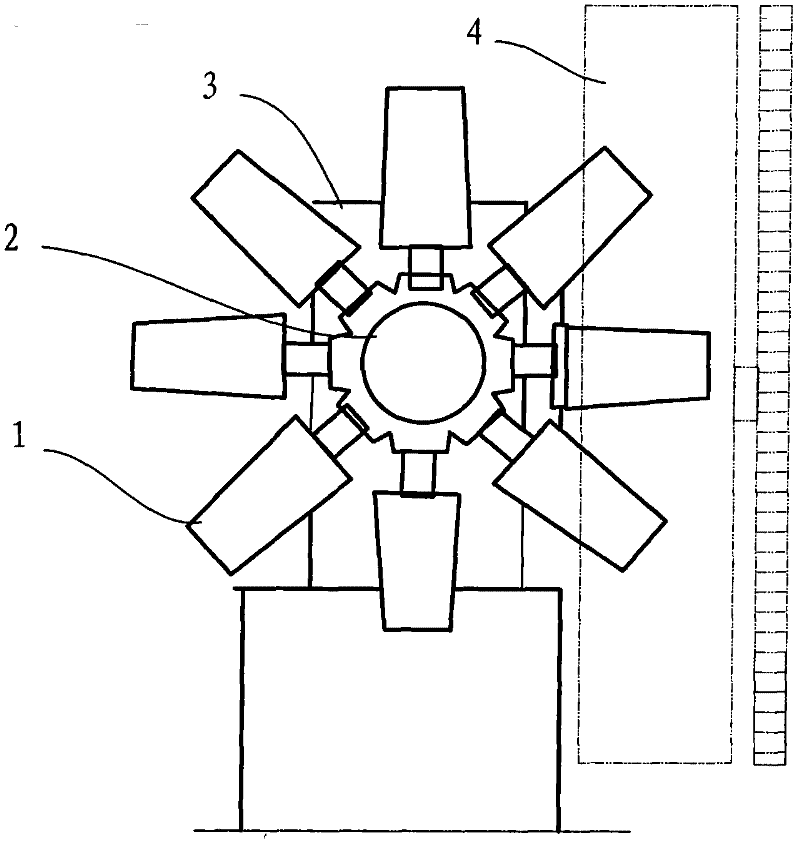

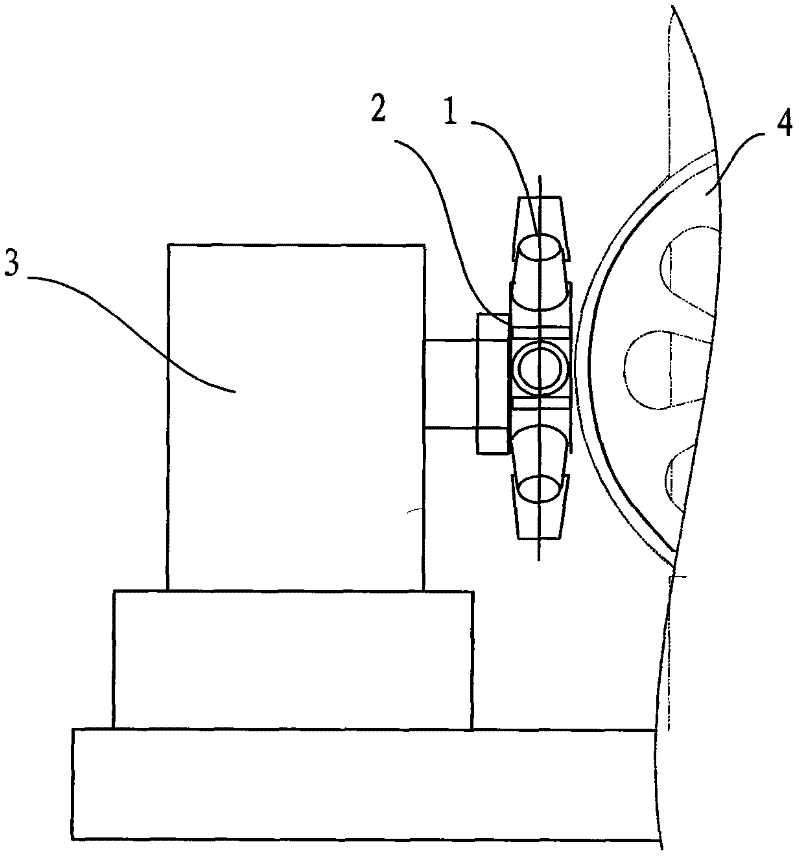

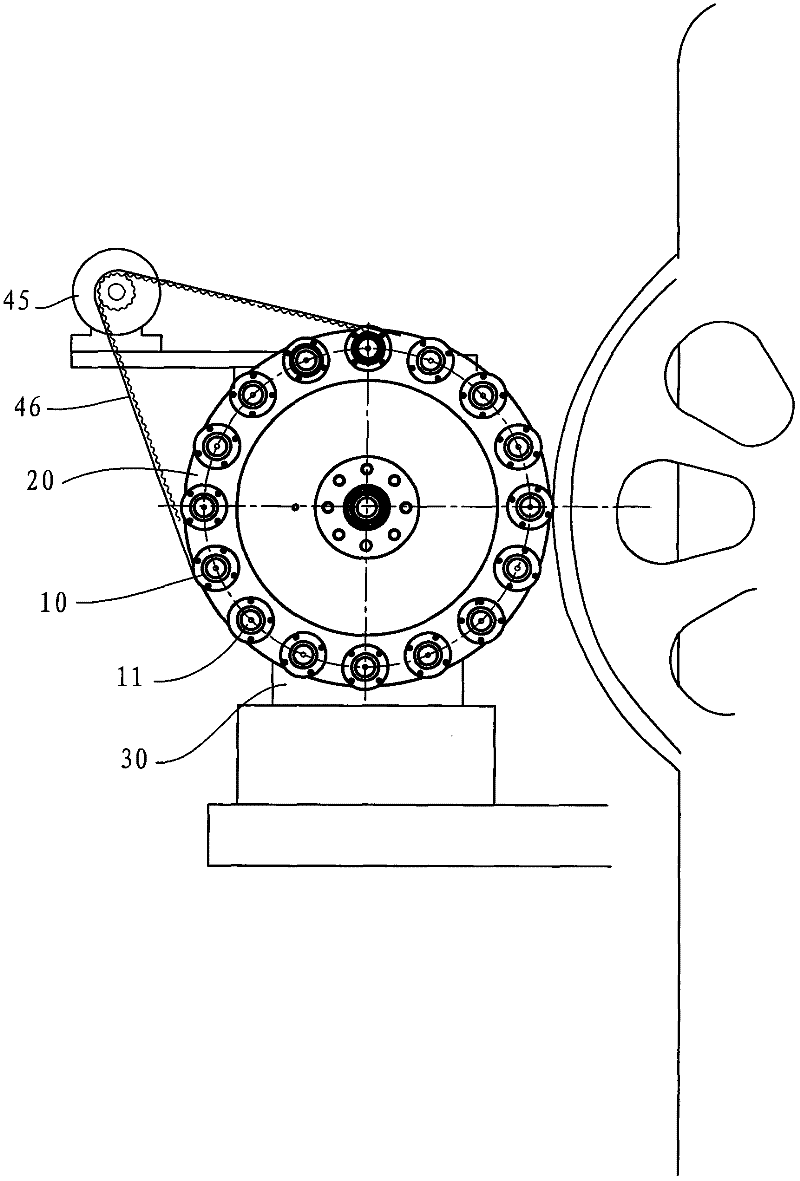

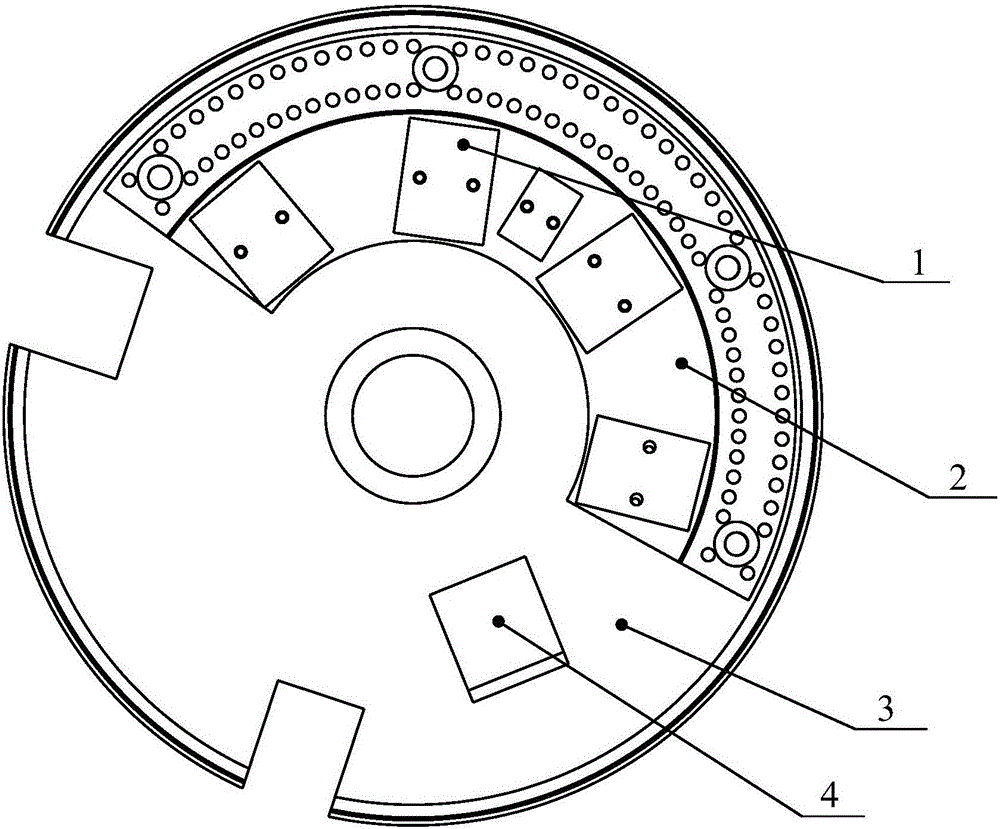

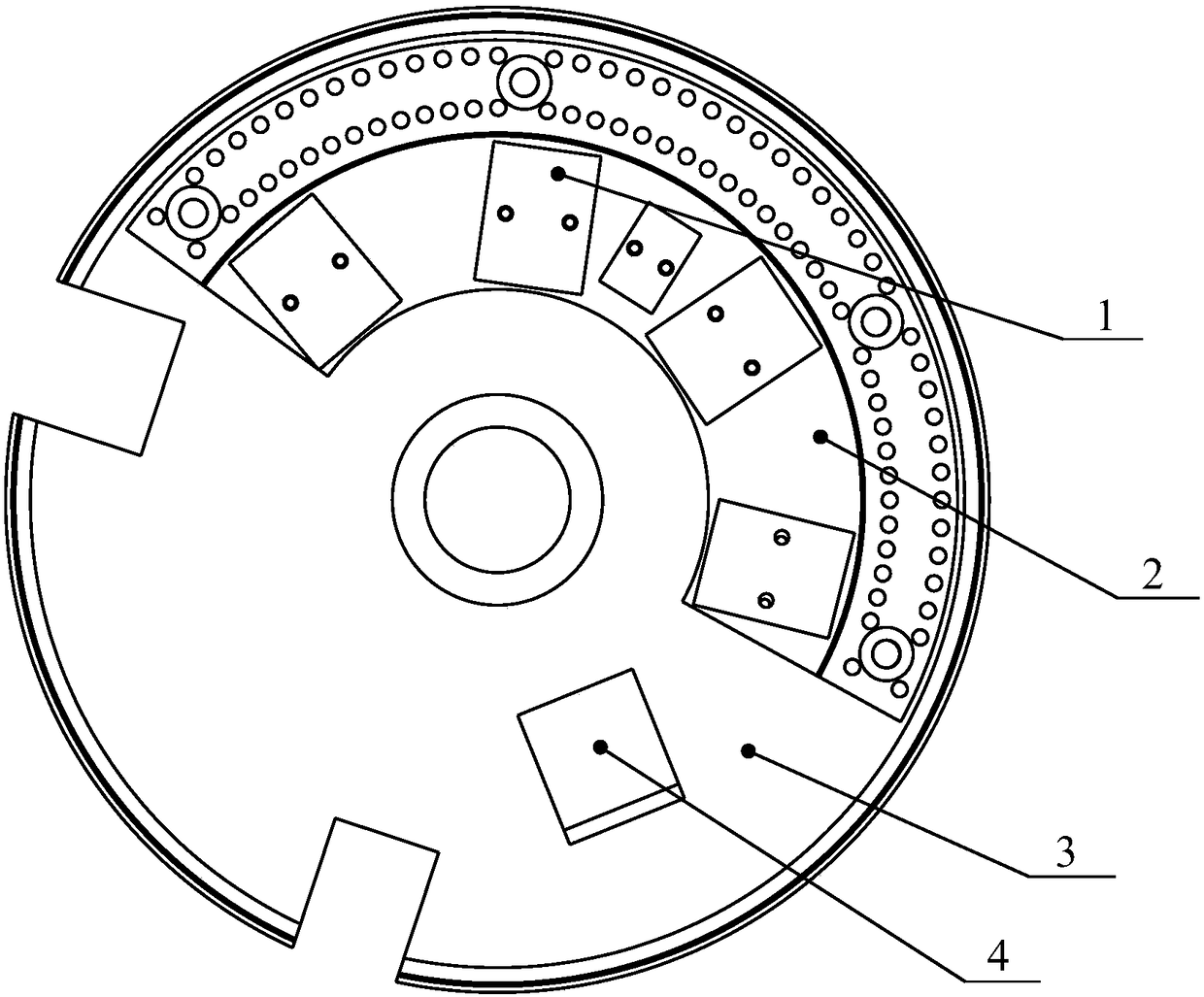

Multi-station synchronous transmission step indexer for curved surface printing machine

The invention relates to curved surface printing equipment, in particular to a multi-station synchronous transmission step indexer of a curved surface printing machine. The step indexer comprises an indexing turntable, an intermittent driving device, a die handle driving system and a gas circuit system, wherein the die handle axis on the indexing turntable is parallel to the axis of the indexing turntable; the die handle driving system comprises a planet gear, a circular inner gear ring fixed seat, a fixed seat supporting rod, a circular inner gear ring, a driving motor and a transmission device; the circular inner gear ring fixed seat is fixed on a shell of the intermittent driving device through the fixed seat supporting rod; the indexing turntable is fixed with an output shaft of the intermittent driving device; a plurality of die handles are pivoted in bearing holes on the periphery of the indexing turntable through a die handle shaft; the planet gear is fixedly arranged at the other end of the die handle shaft; the circular inner gear ring is pivoted at the periphery of the circular inner gear ring fixed seat and engaged with the planet gear; and the circular inner gear ring is connected with the driving motor through the transmission device. All the die handles on the indexing turntable are accurately synchronous with the indexing turntable and a big transfer printing drum, so that the printing effect is clearer.

Owner:GUANGDONG LONGXING PACKAGING IND

Ink-jet typing artificial material and method for preparing the same

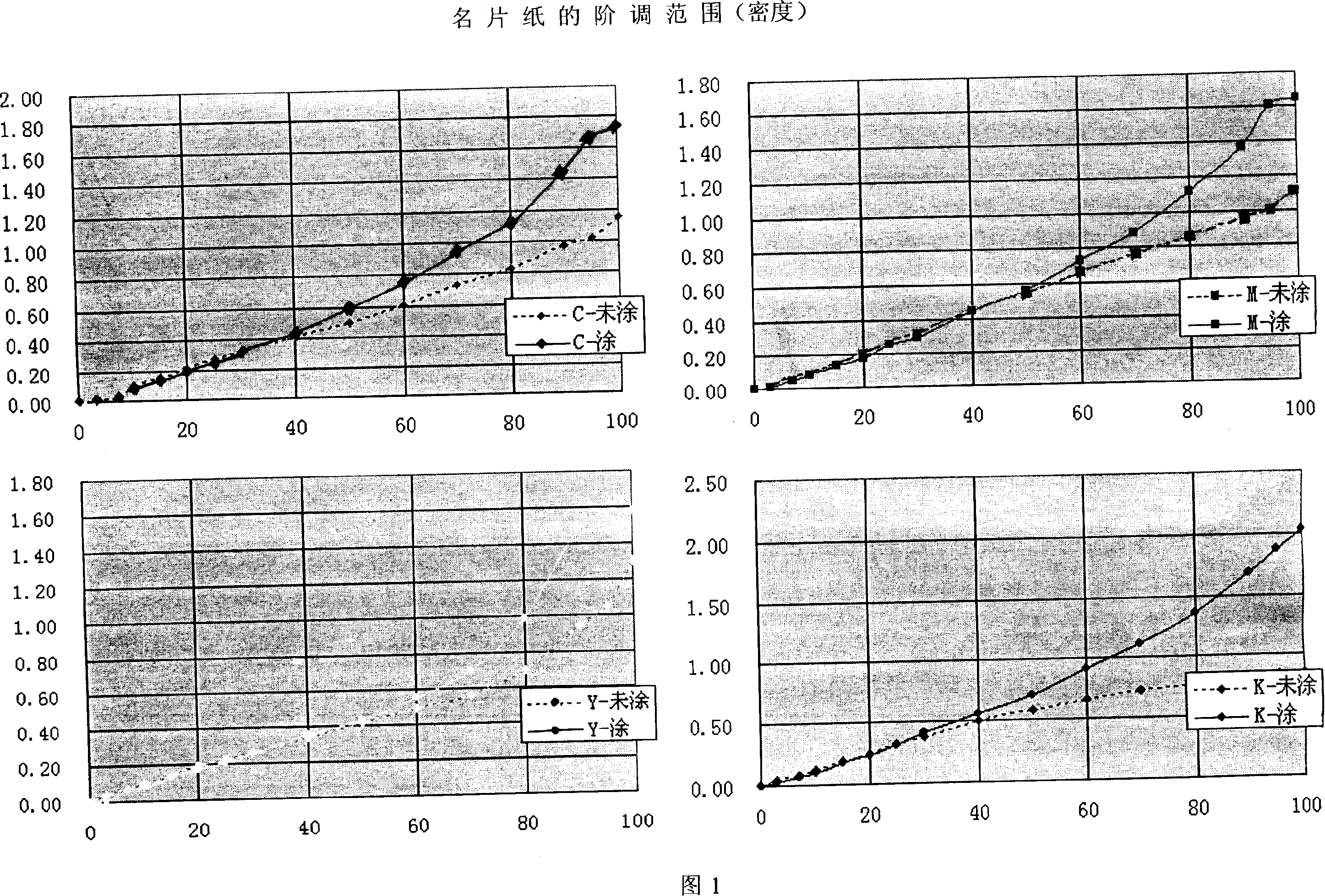

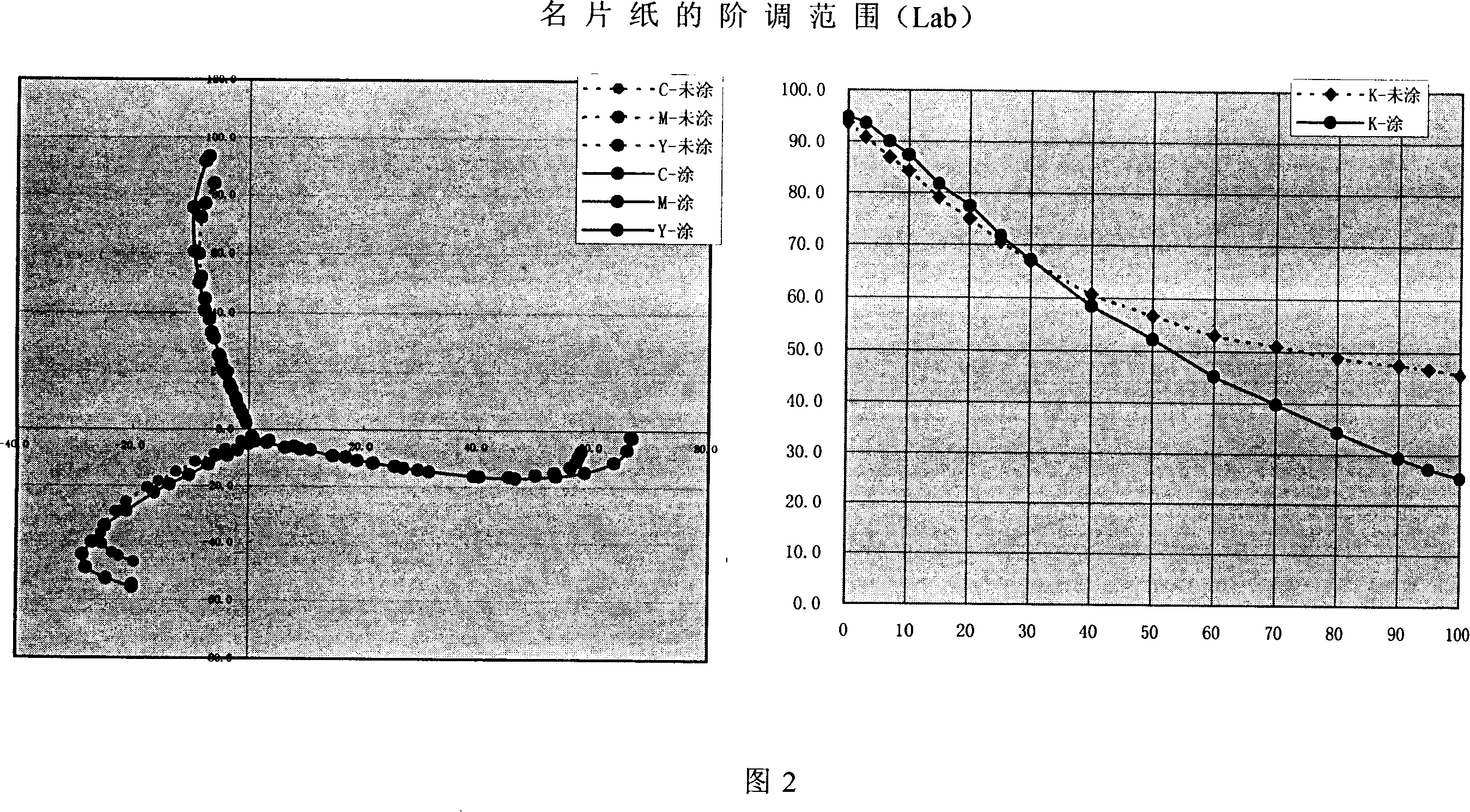

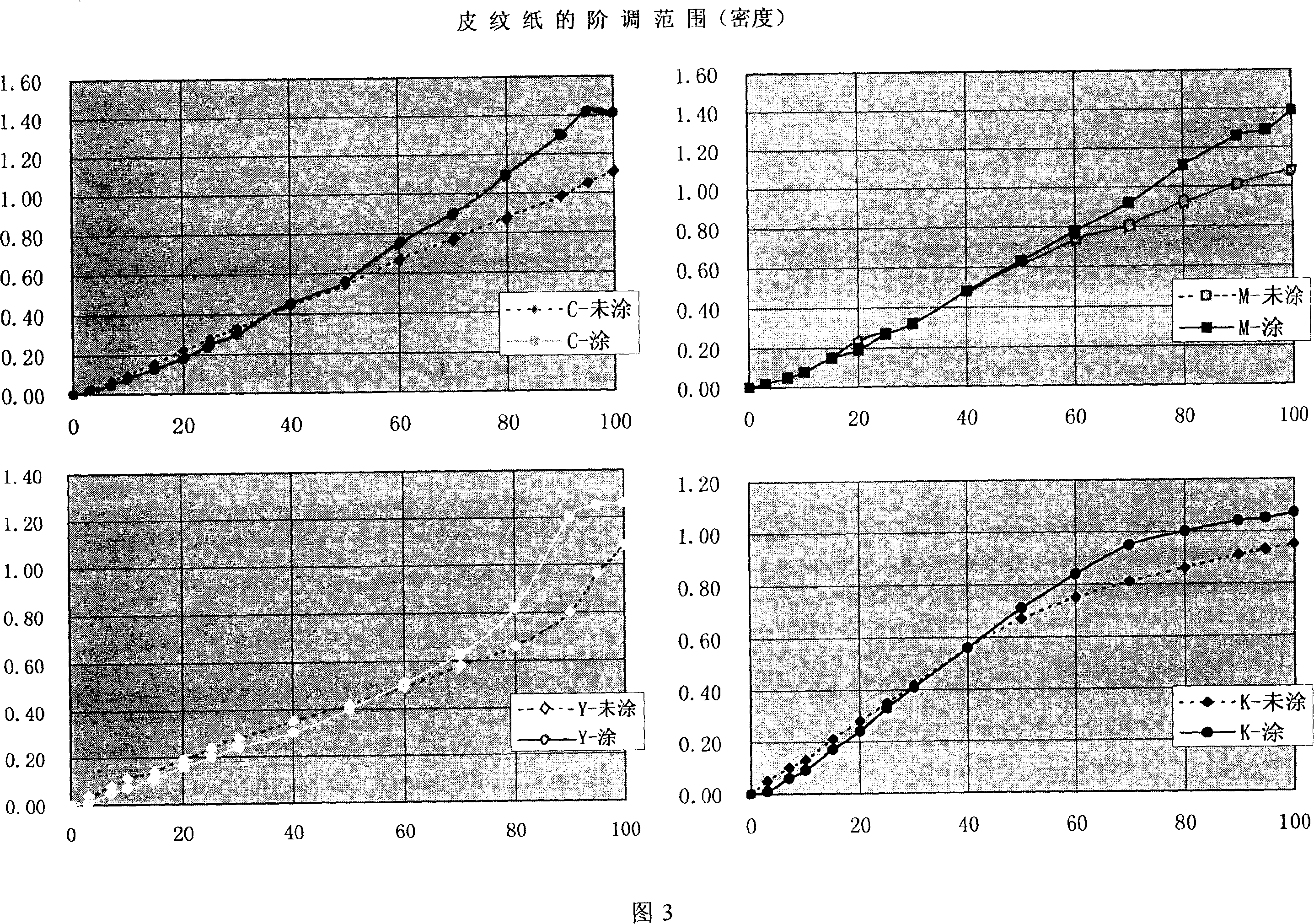

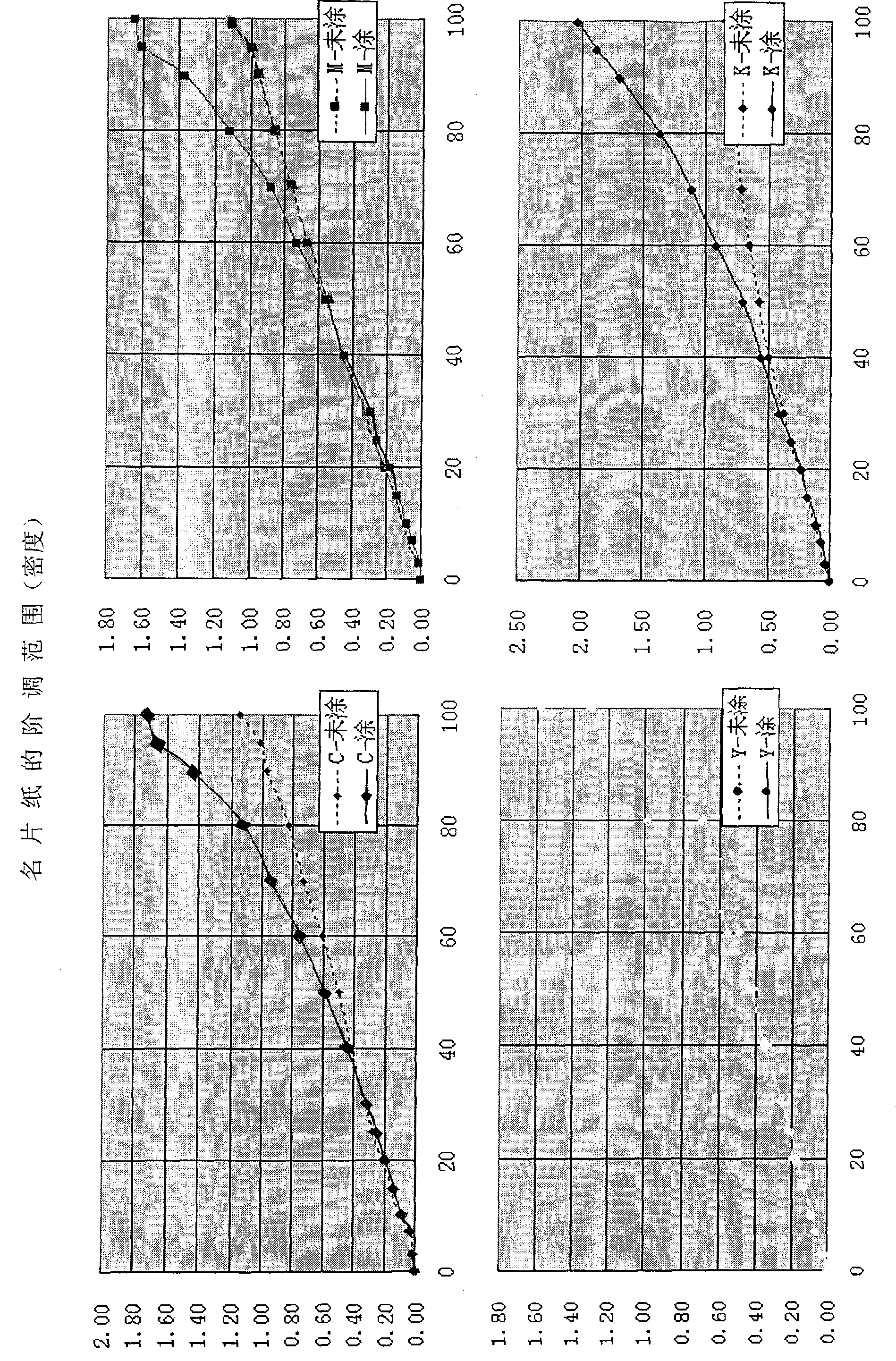

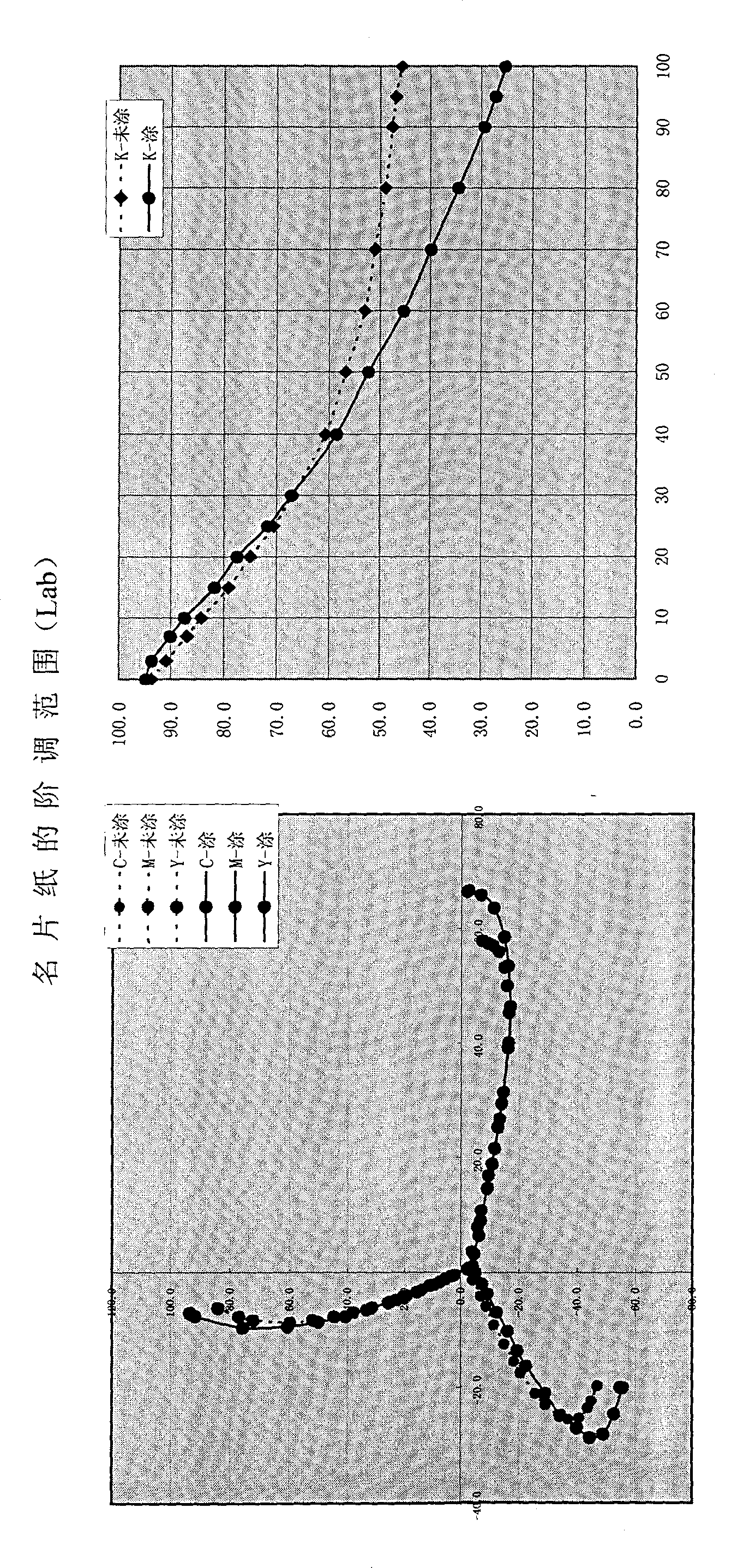

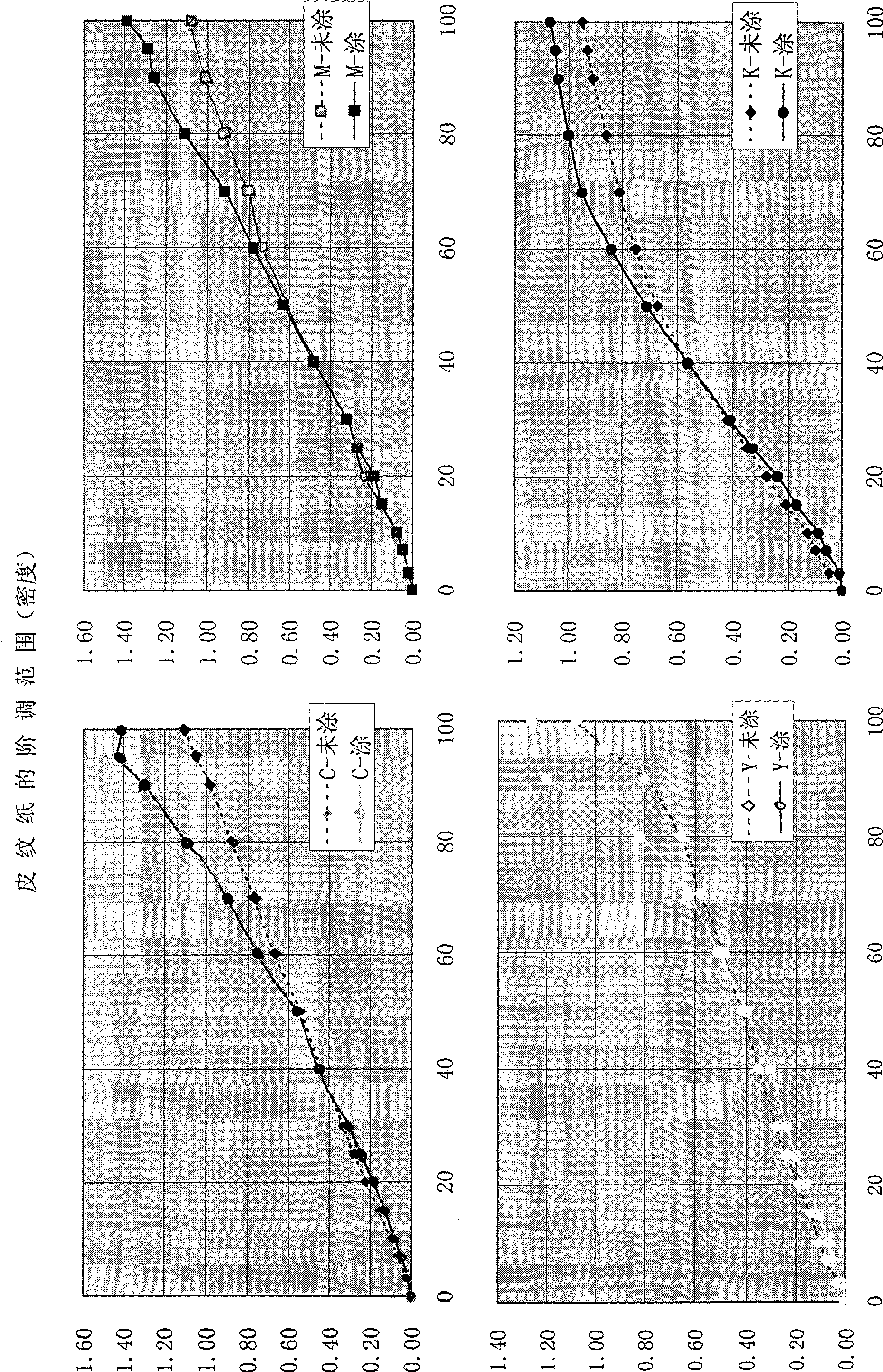

InactiveCN101112840ALow priceRealistic effectCoated paper substratePretreated surfacesBusiness cardArtificial materials

The invention discloses an ink injection printing simulation material which sprays a layer of ink injection printing coating on a business card paper, a dermatoglyph paper, an offset paper or cover paper; the ink injection printing coating has the spraying quantity ranging from 5g- 15g / m2; the ink injection printing coating consists of the components and the contents of fixing agent ranging from 2-8wt percent, water absorbent ranging from 2-10.8wt percent, adhesive ranging from 0.5-10wt percent, surfactant ranging from 0.2-2.5 wt percent, ultraviolet screening agent ranging from 1.2-7.4wt percent, and the deionized water with the allowance. After the ink injection printing coating of the invention is coated on the ink injection printing simulation material such as the business card paper, ermatoglyph paper, offset paper or cover paper, the papers has the advantages of low cost, strong waterproof strength, good stiffness, clear printing effect and exact color restoration.

Owner:BEIJING SUNRAINBOW CULTURE & ARTS DEV CO LTD

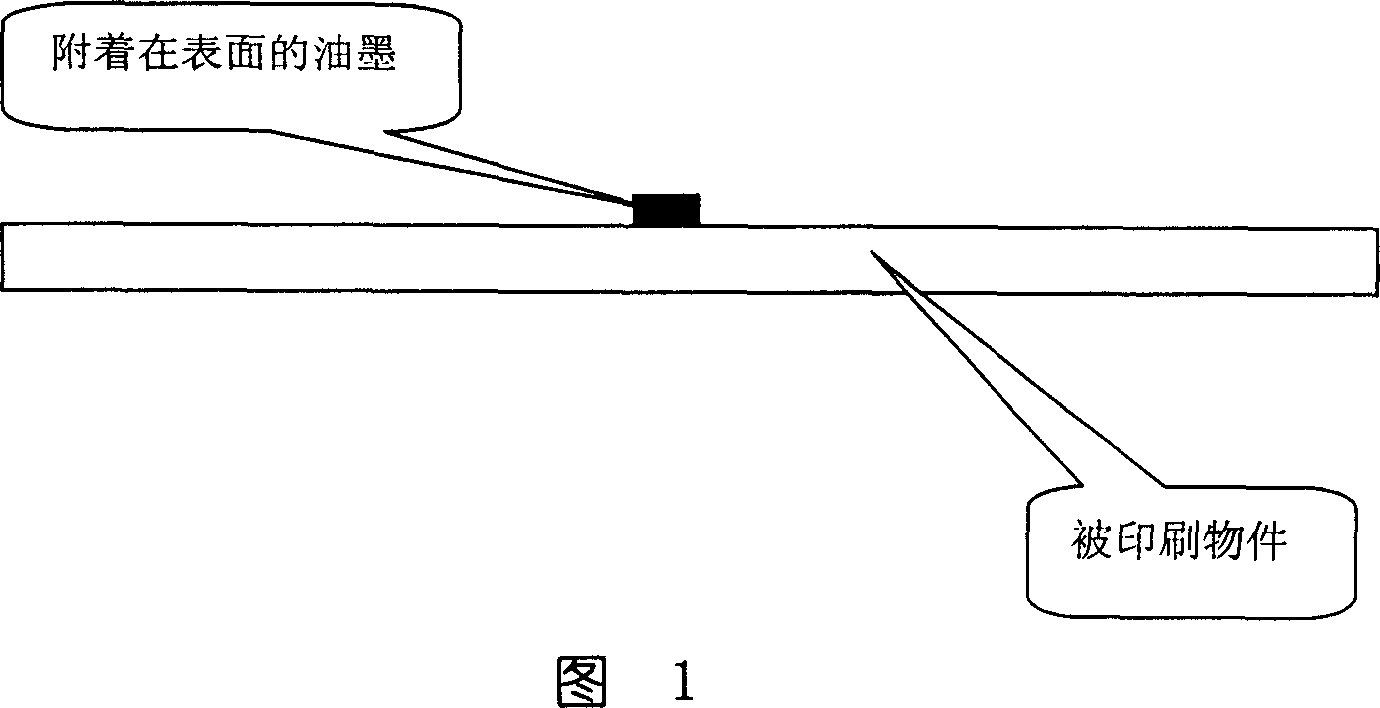

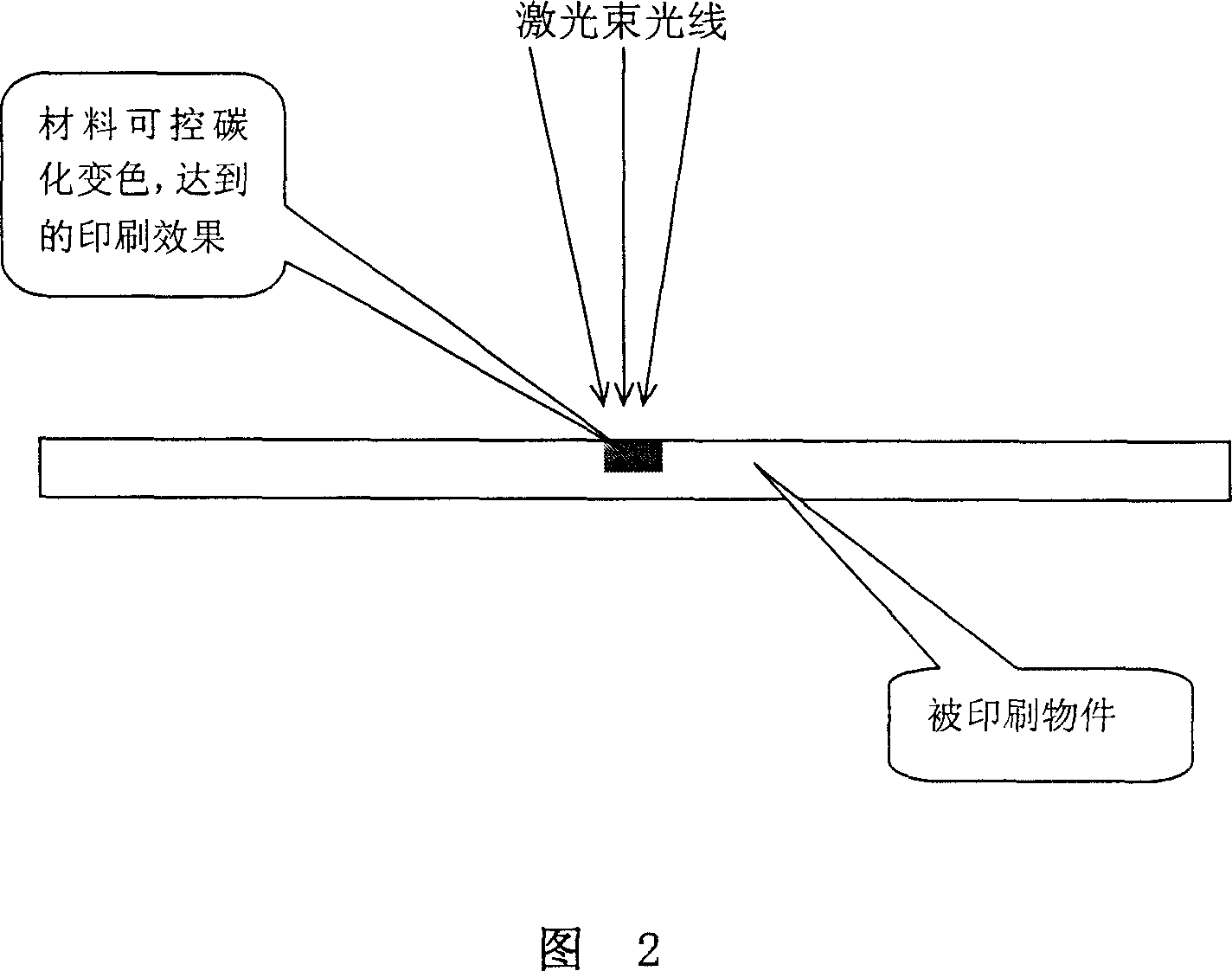

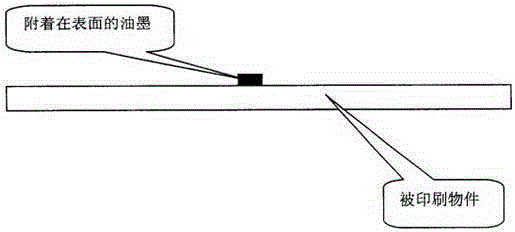

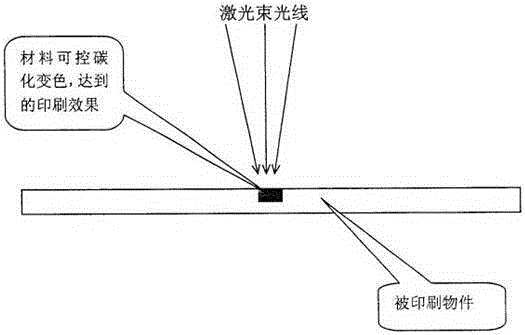

Non-contact non-printing consumable material laser direct printing nano material and printing method thereof

The present invention discloses one kind of nanometer material for direct no-contact laser printing without consumed printing material. The nanometer material consists of plastic or composite base material and mixed coloring agent and photocatalyst TiO2 in the amount of 0.02-10 wt% and average granularity of 0.05-3.00 micron. The present invention also discloses the direct no-contact laser printing method, which can form moisture-proof, scrape resisting, wear resisting and weather resisting permanent patterns and writing on the nanometer material. The direct laser printing is performed through controlling the laser lighting, and has the features of high speed, high precision, no printing material consumption, lasting printed patterns and writing. The present invention may be used widely in different industries.

Owner:李向阳

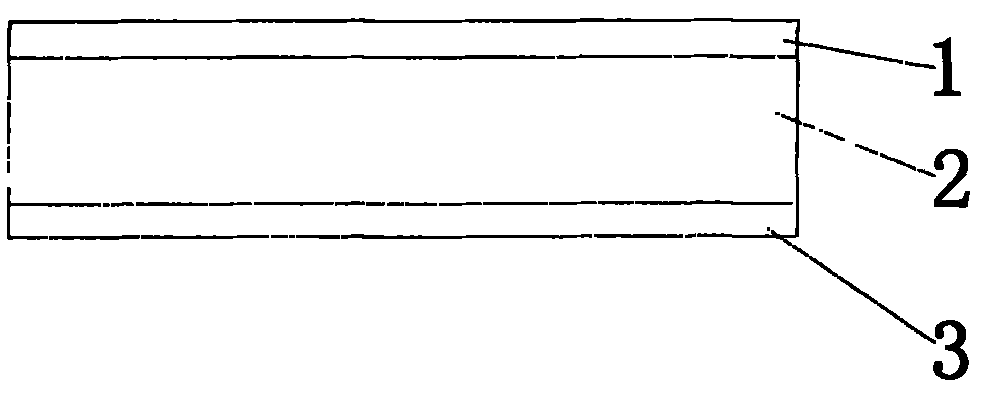

Modified polyolefins paper without plant fibre

InactiveCN101462387BOpaqueChemically resistantSynthetic resin layered productsHandwritingOrganic chloride compound

The invention discloses modified polyolefin paper without plant fiber. The modified polyolefin paper is formed by a first matrix layer without the plant fiber, a second matrix layer without the plant fiber and a third matrix layer without the plant fiber which are compounded into a whole, wherein the first matrix layer and the third matrix layer are respectively prepared by 20 to 30 percent of ethylene-acrylic acid modified copolymer EAA, 45 to 60 percent of metallocene high-density polyethylene mHDPE, and 20 to 25 percent of activated ultrafine inorganic powder by using an aluminate F-2 type coupling agent, and the second matrix layer is prepared by 60 to 90 percent of activated ultrafine inorganic powder, 2 to 5 percent of maleic anhydride and 8 to 35 percent of high-density polyethylene. The modified polyolefin paper has the advantages of good ink receptivity and softness. Therefore, the modified polyolefin paper can not only be used as industrial paper, packing paper and household paper, but also be used as cultural paper, and enlarges the use range. The modified polyolefin paper has higher foldability and rigidity, has the longitudinal and transverse tearing strength which are superior to those of plant fiber paper, has good surface flattening, good handwriting, and clear printing performance, saves printing ink, has simple production technology, protects forest resources, saves energy sources and water, reduces the discharge of organic chlorides and harmful gas, has no waste, and protects the environment.

Owner:宋旭

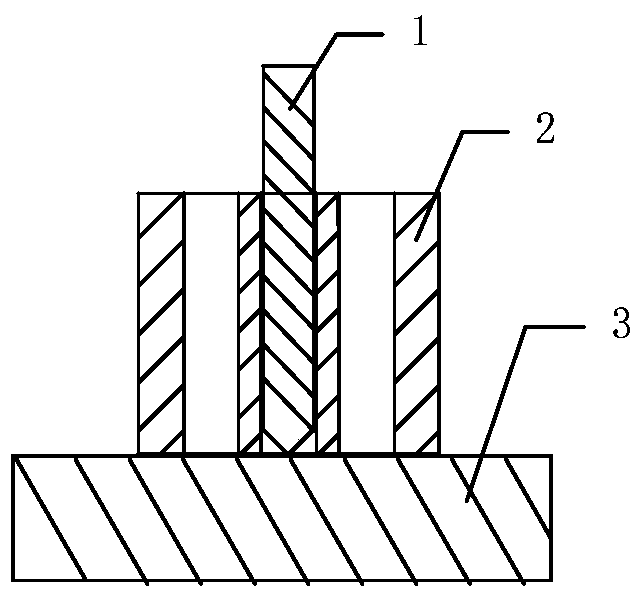

Superfine carving method of small characters

InactiveCN101987528APrinting effect is clearThe printing effect is realForme preparationGraphicsPower flow

The invention relates to a superfine carving method of small characters, which comprises the following steps of: separately carving a pattern carved by an electric carving machine during makeup; adjusting a carving head of the carving machine, and setting an AC signal on a P card; retracting sliding feet to enable the current to be maintained within a balance range, and trying to carve; detecting whether the width of the highlight slot and a normal highlight value are the same, maintaining the current within the balance range, and if yes, completing carving; retracting to the trial carving position and trying to carve again after carving is completed, measuring whether the width of the highlight slot is changed, and if not, completing carving. In the invention, a DC control signal of the original carving current is used for carving, the pattern carved on a copper layer is formed from slots with different lengths rather than traditional net points, and the edge is neat. The space of the original net wall is also carved into an ink holding slot, so the ink quantity of the same characters is two times of the original ink quantity. Meanwhile, printing resistance can achieve nearly two times of normal carving, the ink quantity is two times of normal value, and the printing effect of characters is clear and real.

Owner:SHANGHAI YUNAN PLATE MAKING

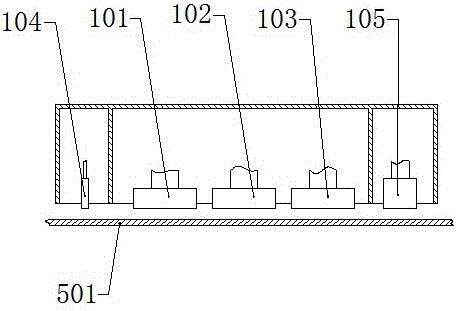

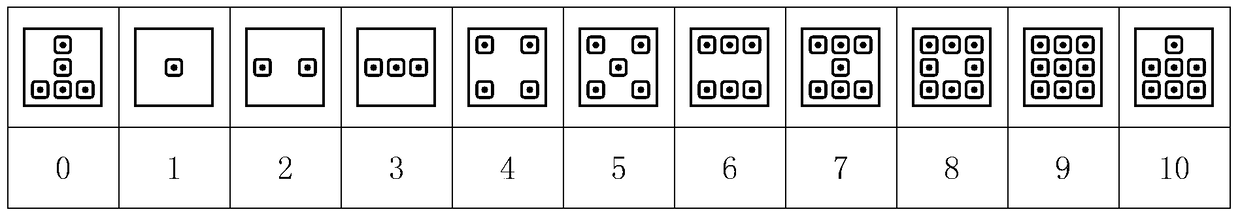

Device for printing serial number marks on cylindrical metal surface and using method thereof

The invention provides a device for printing serial number marks on a cylindrical metal surface and a using method thereof, and belongs to the technical field of machines. A fixing support is made of metal and is of an axial symmetry structure, the upper surface of the fixing support is rectangular, three through holes with the same shape and size are formed in the upper surface, and the directions of the three through holes are numbered to constitute ten kinds of printing marks which correspond to the ten numbers form 0 to 9. The head portions of point mode prefixes are cones, the head portions of linear prefixes are isosceles triangle bodies, the shape of the cross sections of the trunks of the point mode prefixes and the linear prefixes is the same as the shape of the cross sections of the through holes of the fixing support, the cross sections of the trunks of the point mode prefixes and the linear prefixes are smaller than the cross sections of the through holes, and the length of the cross sections of the trunks of the point mode prefixes and the linear prefixes is larger than the thickness of the fixing support. A contrast graph of direction mark serial numbers and figures is printed referring to the prefixes, the printing direction corresponding to the figures of imitated serial numbers is chosen for marking the serial numbers, the fixing support is placed on the metal surface of a cylinder, the corresponding prefixes are sequentially inserted into the through holes in the corresponding directions of the fixing support, the metal prefixes are sequentially knocked by a hammer until all printing tasks are completed. The device for printing the serial number marks on the cylindrical metal surface and the using method thereof have the advantages that using is flexible and safe, labor is saved and printing is clear.

Owner:BAOTOU IRON & STEEL GRP

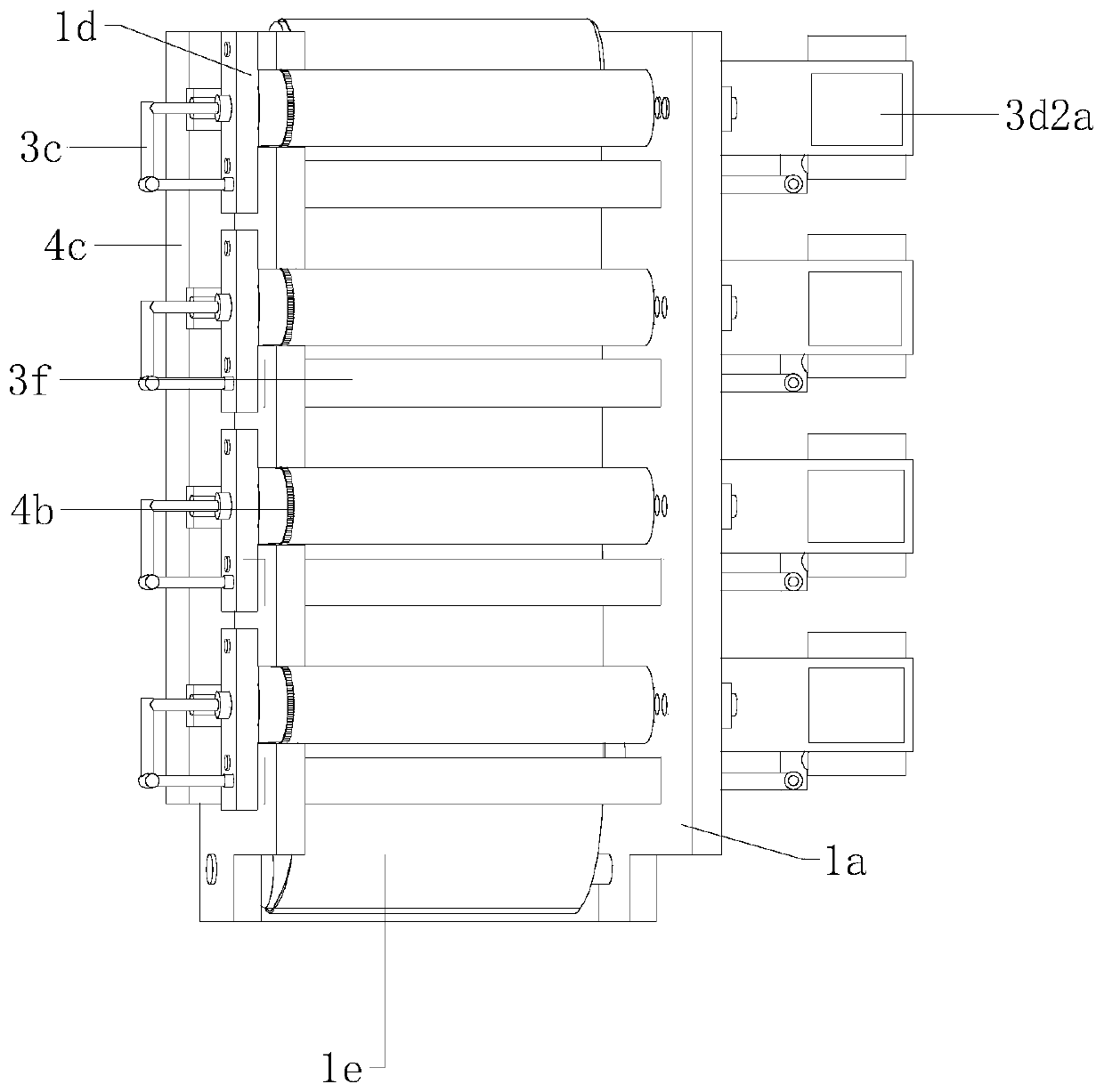

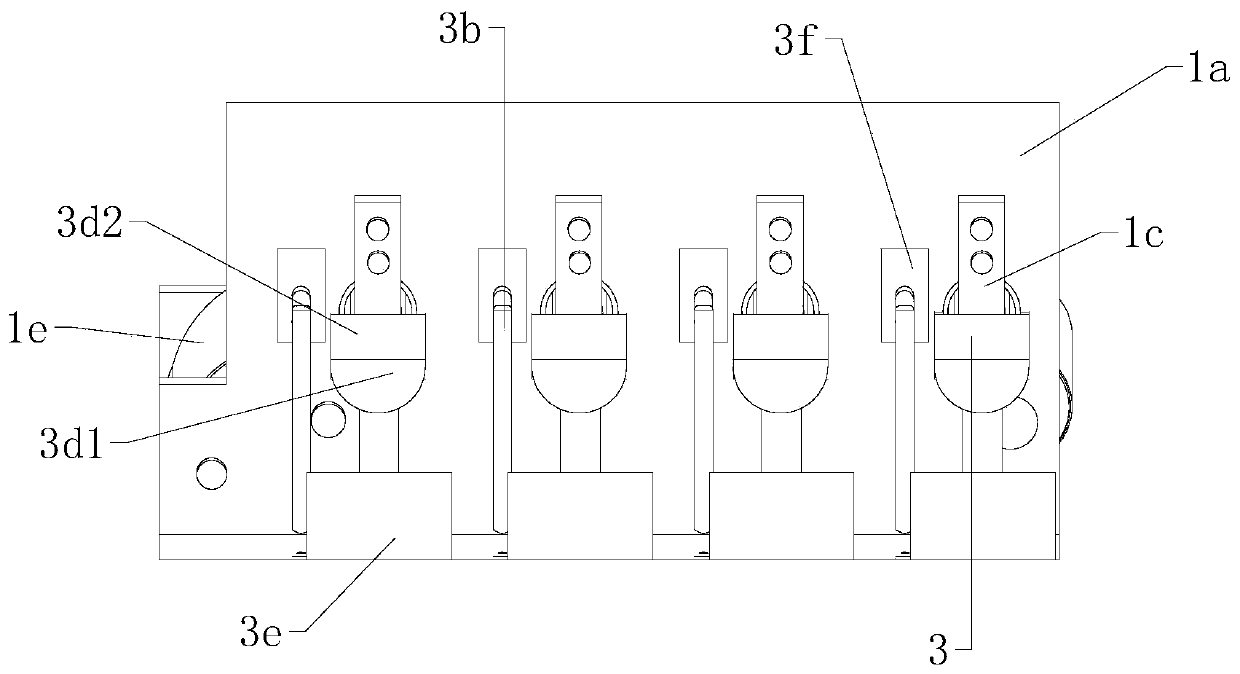

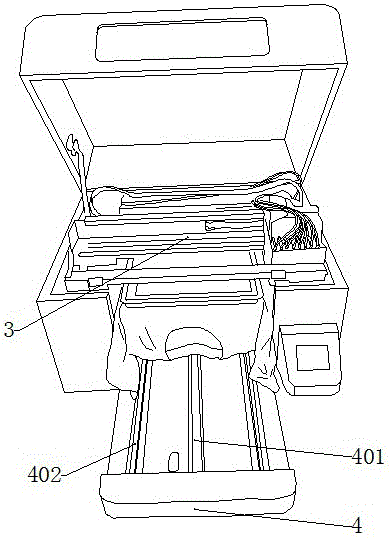

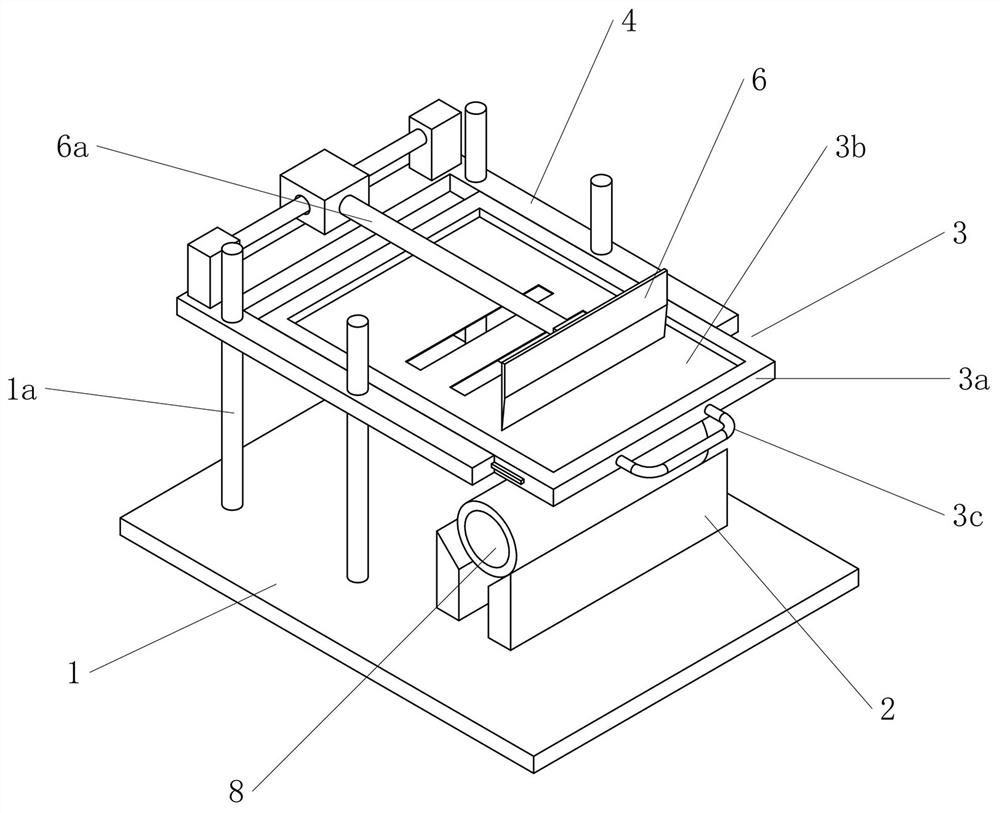

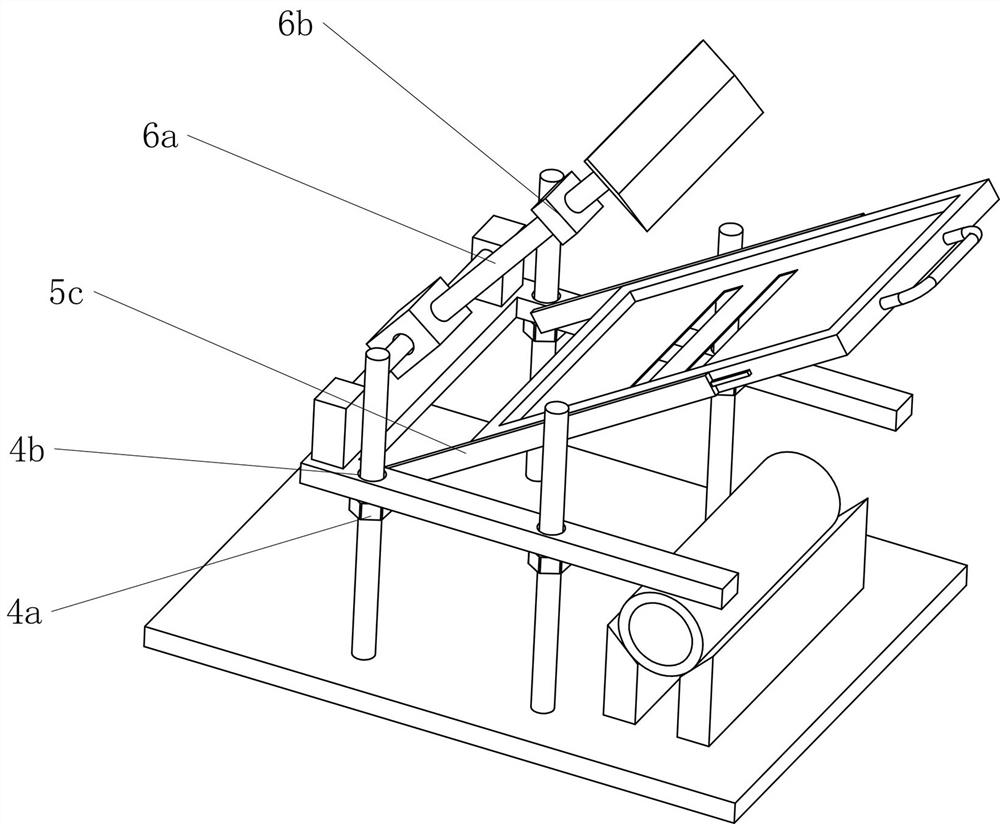

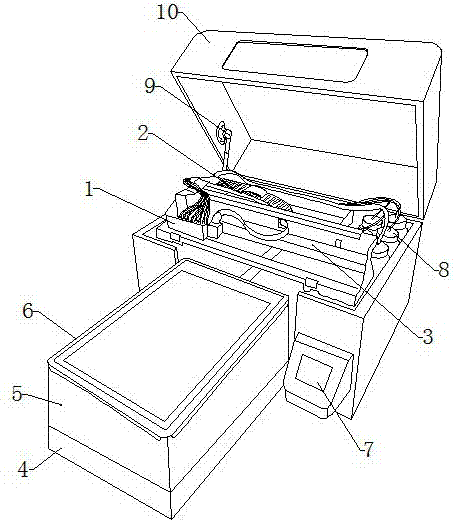

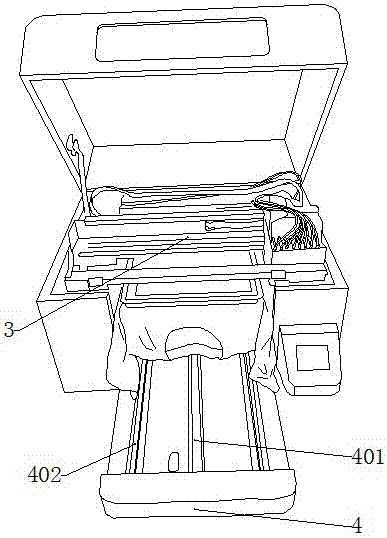

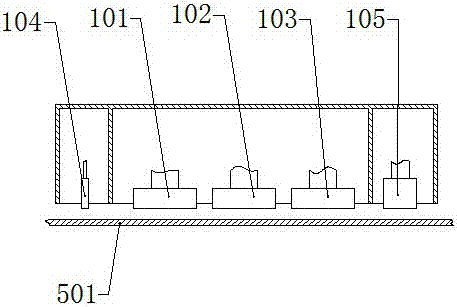

Automatic paperboard printing ink printing equipment

ActiveCN112297608AUniform printingPrinting effect is clearRotary pressesOther printing apparatusPrinting inkManufacturing engineering

The invention relates to printing equipment, in particular to automatic paperboard printing ink printing equipment. The provided automatic paperboard printing ink printing equipment can automaticallyprint paperboards and improve the printing uniformity at the same time. The automatic paperboard printing ink printing equipment comprises a base, a supporting table, a printing mechanism, a support and an ascending mechanism, wherein the base is provided with the supporting table; the supporting table is provided with the printing mechanism; the base is provided with the support; and the supportis provided with the ascending mechanism. Through the design of the printing mechanism, under the cooperation of the ascending mechanism, paperboards can be printed, manual printing of the paperboardsis not needed, and therefore the paperboards can be printed more evenly. Through the design of the ascending mechanism, the paperboards can be moved upwards to be better matched with the work of theprinting mechanism, so that the printing effect on the paperboards is clearer. Through the design of a discharging mechanism, the purpose of automatic pigment discharging can be achieved, and the probability that the printing effect is poor due to lack of pigments is reduced.

Owner:东莞市旗峰纸业有限公司

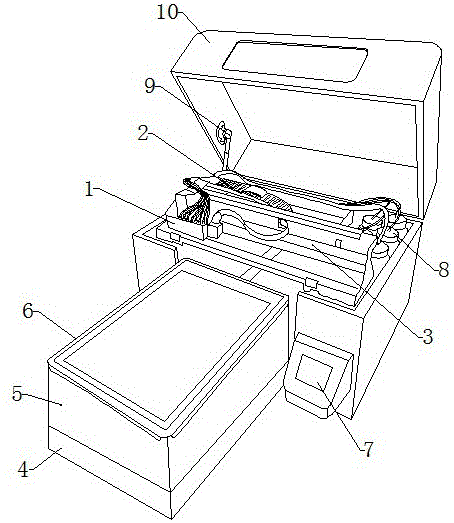

Print printing device

InactiveCN106042658ACompact structureImprove efficiencyTypewritersElectrical and Electronics engineeringNozzle

The invention relates to a print printing device comprising a printing trolley. The printing trolley is arranged on a printing trolley guide rail which is arranged horizontally. Under the printing trolley, a printing base is arranged along the length direction of the printing trolley guide rail. A printing plate is arranged on the printing base. The printing trolley is equipped with a first nozzle used for spraying pretreatment liquid, a second nozzle used for spraying white ink, and a third nozzle used for spraying color ink. The invention aims to provide a print printing device which adopts three nozzles to spray pretreatment liquid, white ink and color ink respectively so as to improve the printing efficiency.

Owner:杭州印象数码科技有限公司

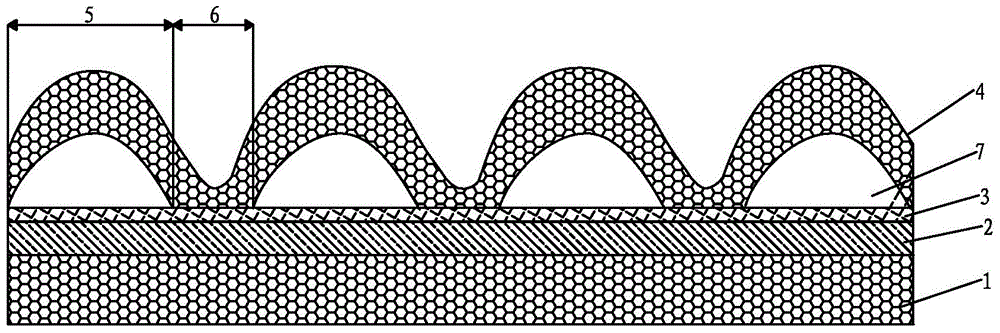

Magic tape and manufacturing method thereof

PendingCN106263305AImprove composite fastnessSolve the problem of air leakageHaberdasheryMagic teeWoven fabric

The invention discloses a magic tape and a manufacturing method thereof. The magic tape comprises an inner non-woven fabric layer, a surface non-woven fabric layer and a thin film interlayer, wherein an oil ink layer is printed on the thin film interlayer; the surface non-woven fabric layer and the inner non-woven fabric layer are hot-pressed and laminated on two surfaces of the thin film interlayer; a plurality of air cushion areas and fixed areas are formed between the surface non-woven fabric layer and the thin film interlayer; and each fixed area is located between every two adjacent air cushion areas. According to the magic tape disclosed by the invention, the three layers of materials are molded and combined through hot-pressing, so that the magic tape is lower in using temperature, higher in speed, softer and higher in combining fastness; oil ink can be printed on the thin film layer by virtue of normal equipment, so that a printing effect is fuller and clearer and the utilization rate of the oil ink is reduced, and subsequently, overall manufacturing cost is reduced; and meanwhile, properties are improved and efficiency is improved.

Owner:科思达(厦门)卫生制品有限公司

Nanometer material for non-contact printing-consumable-free laser direct printing and printing method thereof

InactiveCN106674948AGood light scattering propertiesGood coloring performancePrintingWeather resistanceTitanium dioxide

The invention discloses a nanometer material for non-contact printing-consumable-free laser direct printing. The nanometer material is prepared by mixing 0.02 to 10 percent by weight of colorant which is 0.05 to 3.00 mu m in average particle size and titanium dioxide serving as a photocatalyst into plastic or a compound substrate thereof. The invention further discloses a non-contact printing-consumable-free laser direct printing method. By adopting the printing method, graphics and texts with high moisture resistance, waterproofness, scratch resistance, abrasion resistance, weather resistance and a permanent characteristic can be printed on plastic and a compound which contain titanium dioxide in a contactless way at high accuracy without any ink consumable. The material can be directly printed by only controlling laser illumination; the method has the characteristics of high speed, high accuracy, freeness from printing consumables, permanent graphics and texts and the like, can be widely applied to various industries, in particular to consumable-free instant digital non-contact direct printing of high-waterproofness and scratch-resistant tags, does not need platemaking, is low in cost, and is convenient and rapid.

Owner:重庆市鹏程印务有限公司

Cylindrical workpiece surface printing device

PendingCN112339405ASave manpower and material costsImprove work efficiencyScreen printersMetal frameworkEngineering

The invention relates to the field of product workpiece surface spraying and printing, and specifically relates to a cylindrical workpiece surface printing device. A positioning component set used forfixing a cylindrical workpiece is installed on the upper surface of a work table in the surface of the cylindrical workpiece, and the cylindrical workpiece surface printing device further comprises aprinting mold plate composed of a metal frame and a printing silk screen fixed to the center position of the metal frame. The printing mold plate is installed on a guide supporting frame through a guide supporting structure and can move in the front-back direction of the device. A printing scraper is further installed on the guide supporting frame, and the end portion, located under the printingscraper, of the printing scraper is opposite to the center of the positioning component set and is attached to the printing screen. When the printing die plate is pulled out, the cylindrical workpiecerotates and moves along with the movement of the printing die plate under the action of friction, the printing scraper conducts smearing along the surface of the cylindrical workpiece, and the printing process of the surface of the cylindrical workpiece is completed at a time in the pulling process.

Owner:ZHEJIANG MILITARY IND GRP CO LTD

Printing equipment

InactiveCN106042658BCompact structureImprove efficiencyTypewritersElectrical and Electronics engineeringNozzle

The present invention relates to printing and printing equipment, including a printing trolley, the printing trolley is arranged on the guide rail of the printing trolley, the guide rail of the printing trolley is arranged horizontally, and a printing base is arranged below the printing trolley along the direction perpendicular to the length of the printing trolley guide rail A printing plate is arranged on the printing base; a first nozzle for ejecting pre-treatment liquid, a second nozzle for ejecting white ink and a third nozzle for ejecting color ink are installed on the printing carriage. The purpose of the present invention is to provide a method that adopts three nozzles to respectively eject the pretreatment liquid, the white ink and the color ink, so as to improve the printing efficiency.

Owner:杭州印象数码科技有限公司

Water soluble woven bag printing ink

The invention relates to the technical field of woven bag production, in particular to water soluble woven bag printing ink. The water soluble woven bag printing ink comprises the following ingredients: 40-70 parts of water soluble acrylic emulsion, 25-45 parts of water-based colour paste, 15-20 parts of polystyrene, 1-3 parts of surfactant, 0-1 part of a defoaming agent and 1-15 parts of water, wherein the surfactant is sulfated castor oil; the defoaming agent is non-silicon polyether mineral oil; and the water based colour paste comprises the following ingredients (in percentage): 10-20% of water soluble acrylic resin, 4-6% of a dispersant, 0.5-1.5% of a defoaming agent, 28-65% of pigment and 10-40% of water, wherein the dispersant is glycerol monostearate, and the defoaming agent is the non-silicon polyether mineral oil. The water soluble woven bag printing ink has clear printing effect as well as relatively high wear resistance and rub resistance and can be widely applied to printing of woven bags.

Owner:ANQING PETROCHEM PLANT UNION CHEM FACTORY

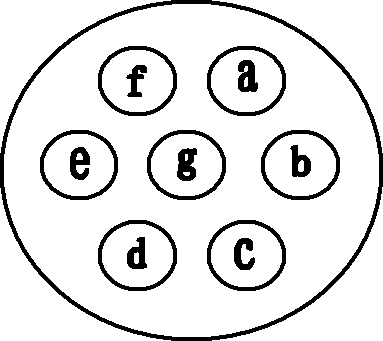

Device for printing serial number mark on surface of spherical metal and method for using device

ActiveCN103625127AReduced fatigue impactExtended service lifeTypewritersOther printing apparatusHard metalSerial code

The invention discloses a device for printing a serial number mark on the surface of spherical metal and a method for using the device, and belongs to the technical field of machinery. A fixing support is made from metal, and is of a three-dimensional symmetrical structure; the upper surface and the lower surface of the fixing support are spherical surface; the center of the fixing support is provided with a through hole; the periphery of the central through hole is uniformly provided with six through holes which are same with the central through hole in shape and size; the positions of the seven through holes are numbered for forming eleven print marks which correspond to eleven numbers 0-10 respectively; each dot mode word head is made from hard metal materials; the head part of the dot mode word head is a cone; the cross section of the body of the dot mode word head is the same with the cross section of the through hole of the fixing support in shape, and is smaller than the cross section of the through hole in area; the length of the body of the dot mode word head is larger than the thickness of the fixing support. Referring to a dot mode word head printing position mark code and number contrast chart, a printing position mark code corresponding to a number to be used is selected, the fixing support is placed on the surface of the spherical metal, the dot mode word heads are inserted into through holes of the fixing support at the corresponding positions, a hammer is used for knocking the metal word heads in sequence until all printing tasks are completed. The device and the method disclosed by the invention has the characteristics of being flexible to use, safe, labor-saving, clear in printing and the like.

Owner:BAOTOU IRON & STEEL GRP

A kind of UV-heat dual curing glass ink and preparation method thereof

Owner:天津市合成材料工业研究所有限公司

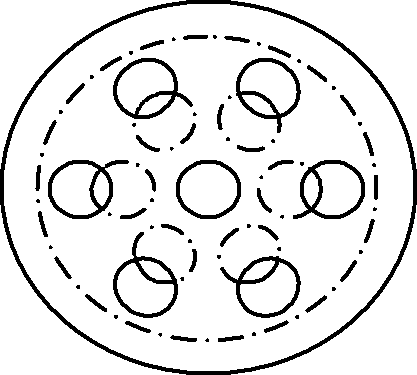

A device for printing number marks on hard metal surfaces and its application method

The invention relates to a device for stamping serial number marks on the surface of hard metal and a using method thereof, and belongs to the technical field of machinery. A fixing support is made of metal and is of a cuboid structure, the square upper surface is evenly divided into a sudoku, a perpendicular through hole is formed in the center of each lattice and is numbered, the shape and the size of the cross sections of all the perpendicular through holes are identical, eleven kinds of stamping marks are formed through combination and correspond to the numbers from zero to ten. The head portion of a dot-type character head is a cone, the shape of the cross section of the body of the dot-type character head is identical with that of the cross section of the through holes of the fixing support, the cross section of the dot-type character head is smaller than that of the through holes, and the length of the dot-type character head is larger than the thickness of the fixing support. A stamping orientation mark serial number and digit contrast diagram is referenced, the mark serial numbers corresponding to digits to be numbered are selected, the fixing support is laid on the surface of the hard metal, the dot-type character head is inserted into the through holes, with the corresponding orientation, of the fixing support in sequence, and the metal character head is beaten through a hammer in sequence until all the stamping work is completed. The device for stamping the serial number marks on the surface of the hard metal has the advantages of being flexible in using, safe, clear in stamping and the like and saving labor.

Owner:BAOTOU IRON & STEEL GRP

Method for manufacturing barcode wristbands

InactiveCN101789201BSolve the situation that is easy to breakBreak will notStampsIdentification meansPunchingBarcode

The invention relates to a method for manufacturing barcode wristbands. The method comprises the following steps of: printing, positioning and tracking a black line, adhering, carrying out die cutting, pressing a tearing line and punching, wherein the step of printing, positioning and tracking the black line is to print, position and track the black line on synthetic paper; the step of adhering is to adhere one surface with the glue of a removable film to the surface of another roll of synthetic paper; the step of carrying out die cutting is to carry out die cutting on the synthetic paper with a cutter to form a plurality of shapes of the barcode wristbands; the step of pressing the tearing line is to press the tearing line between two barcode wristbands; the step of punching is to punch each barcode wristband; and the synthetic paper is a pp film or a pe film or a pvc film or a pet film. The identity information of patients and the disease information of the patients can be clearly recorded on the barcode wristbands produced by the method; the barcode wristbands can be worn on the wrists of the patients, are convenient for a doctor to treat, and effectively avoid the medical negligence. The manufacturing method is simple and the use is convenient.

Owner:邵崇雷

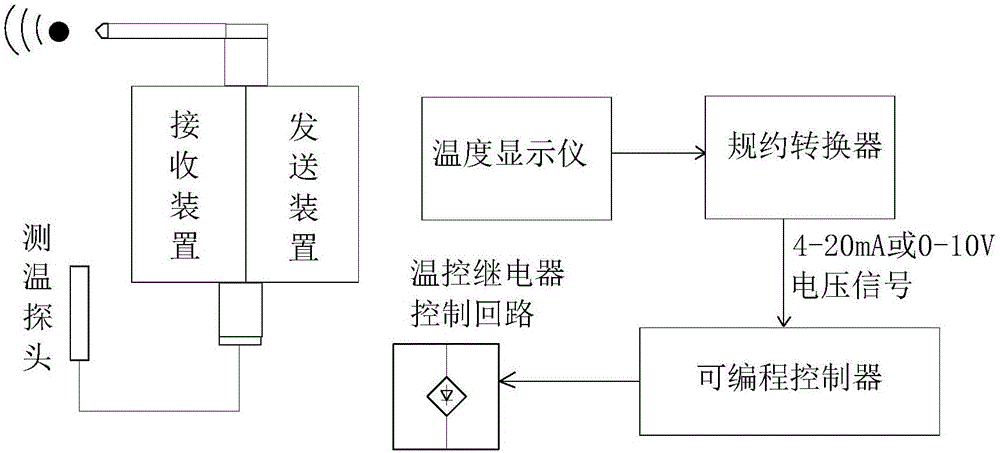

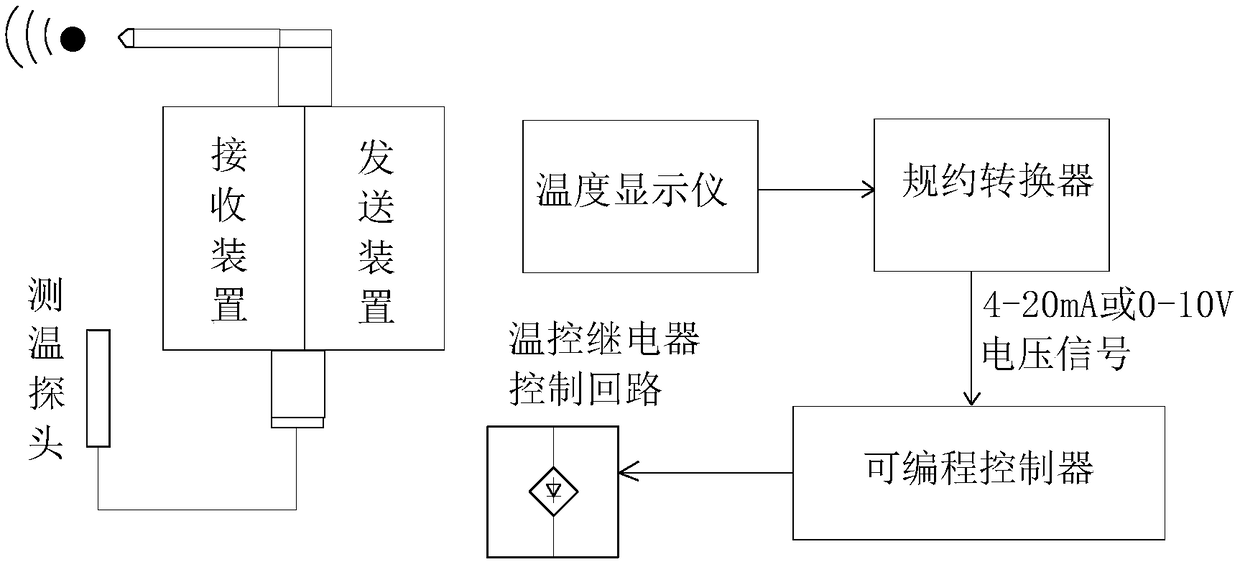

Lettering block heating controller based on wireless temperature sensor and method

ActiveCN106585081ARealize heating control functionPrecise heating controlRotary pressesPrinting press partsTemperature controlProtocol converter

The invention discloses a lettering block heating controller based on a wireless temperature sensor and a method and relates to the field of inkwriter equipment of a sheath process in a communication optical cable production process. The controller comprises the wireless temperature sensor, a programmable controller and a temperature control relay control loop. The wireless temperature sensor comprises a sending device, a receiving device, a temperature display instrument, a protocol converter and temperature measurement probes and is fixedly installed on an inking wheel of an rotary inkwriter; the inkwriter comprises a meter counting disc and a lettering disc, the meter counting disc is provided with a lettering block and heating blocks, and the lettering disc is provided with a base; the base is provided with a crescent-moon-shaped plate and an installation block; and the temperature measurement probes are installed in the heating blocks of the inkwriter, the heating blocks are installed on the crescent-moon-shaped plate of the rotary inking wheel, the sending device is fixedly installed on the installation block, and the installation bloc is fixed to the base. By means of the lettering block heating controller based on the wireless temperature sensor and the method, heating of the lettering block on lettering rotating equipment can be precisely controlled.

Owner:FENGHUO COMM SCI & TECH CO LTD

Method for penetrated coating for ink-jet printing material

InactiveCN100494567CFast batchLow priceSurfactants additionPaper/cardboardPulp and paper industryContrast ratio

A penetration coating method for ink-jet printing material is carried out by preparing stock: color-fixing agent 2-8wt%, absorbent 2-10.8wt%, binder 0.5-10wt%, surface activator 0.2-2.5wt%, anti-ultraviolet agent 1.2-7.4wt% and deionized water residues, agitating, mixing to obtain ink-jet printing coating, coating it on rice paper or silk paper surface and drying. The color is accurate, stiff and vivid; it has better contrast, saturation and penetrability.

Owner:BEIJING SUNRAINBOW CULTURE & ARTS DEV CO LTD

Ink-jet typing artificial material and method for preparing the same

InactiveCN100532118CLow priceRealistic effectCoated paper substratePretreated surfacesBusiness cardArtificial materials

Owner:BEIJING SUNRAINBOW CULTURE & ARTS DEV CO LTD

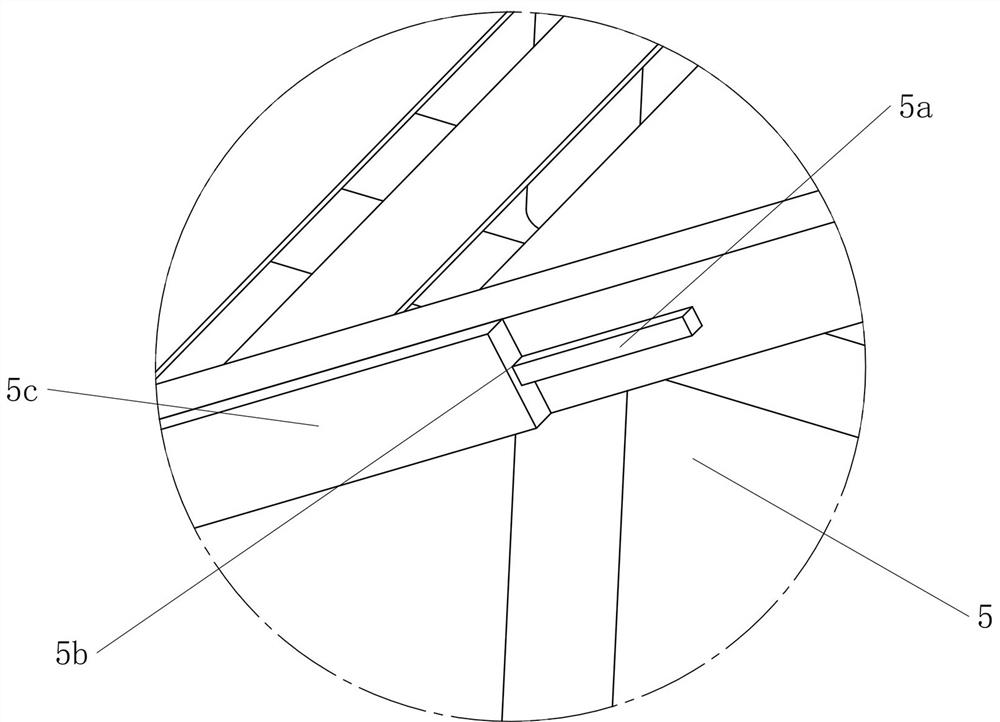

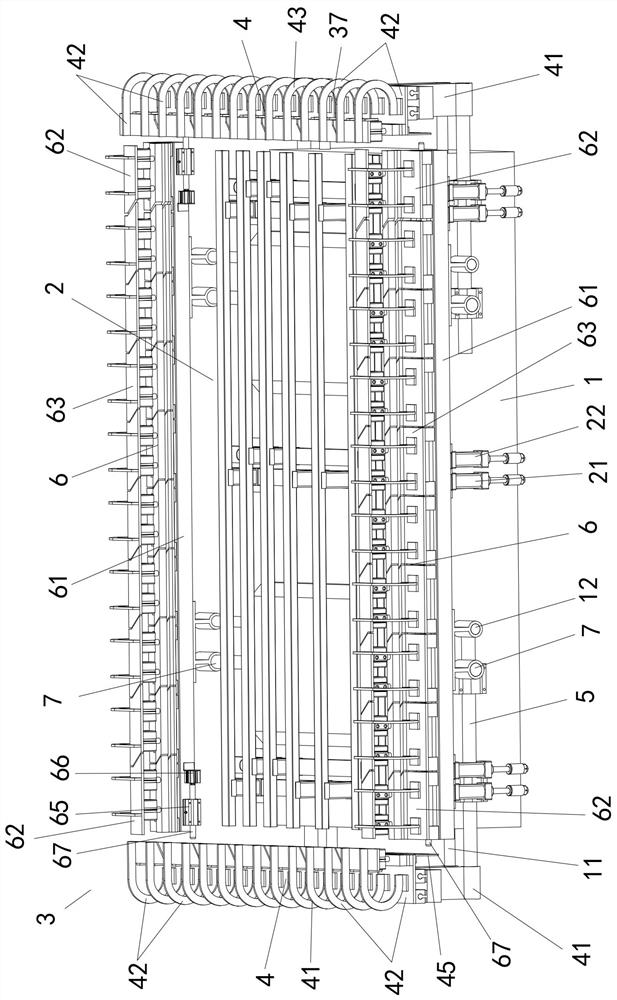

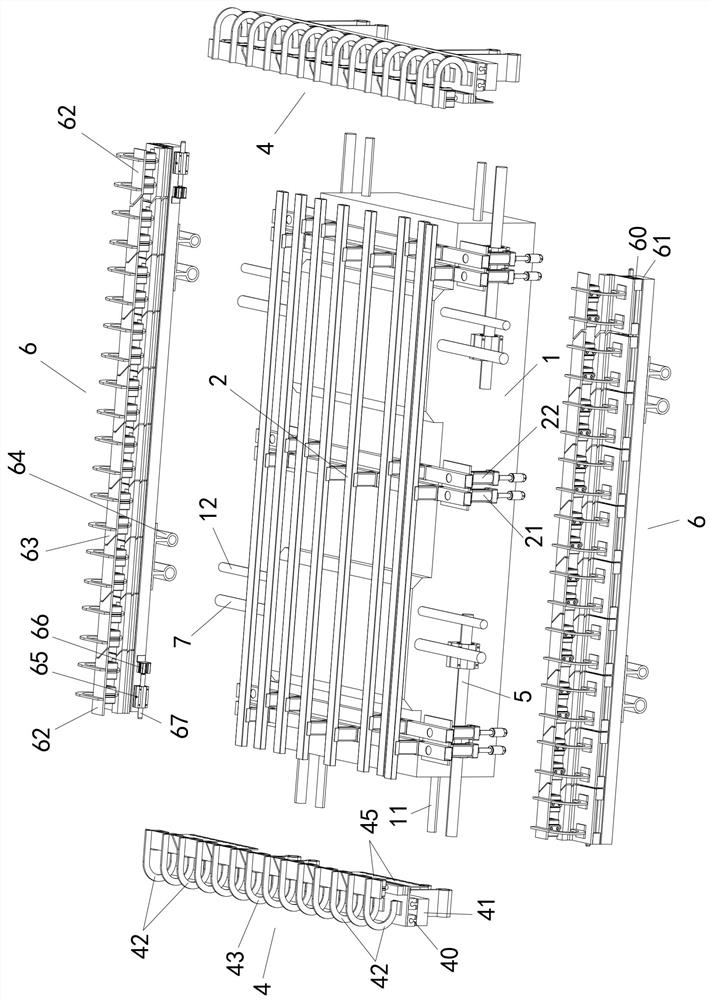

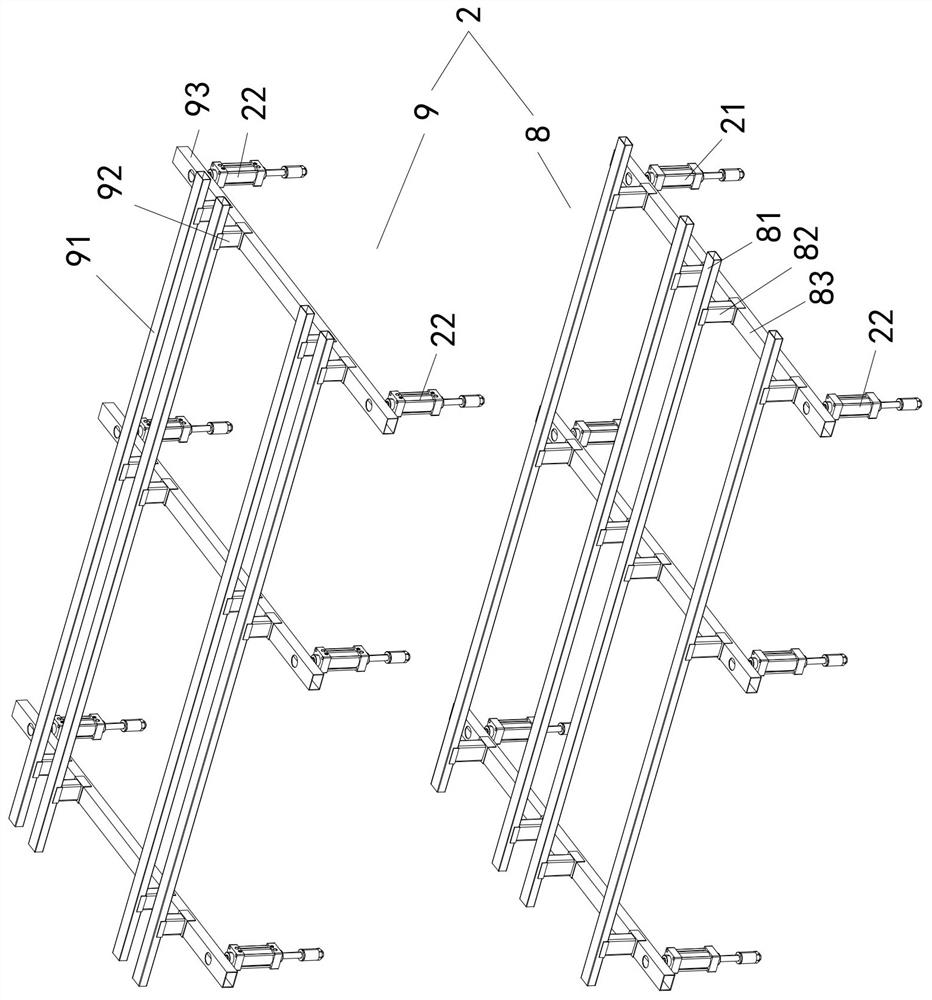

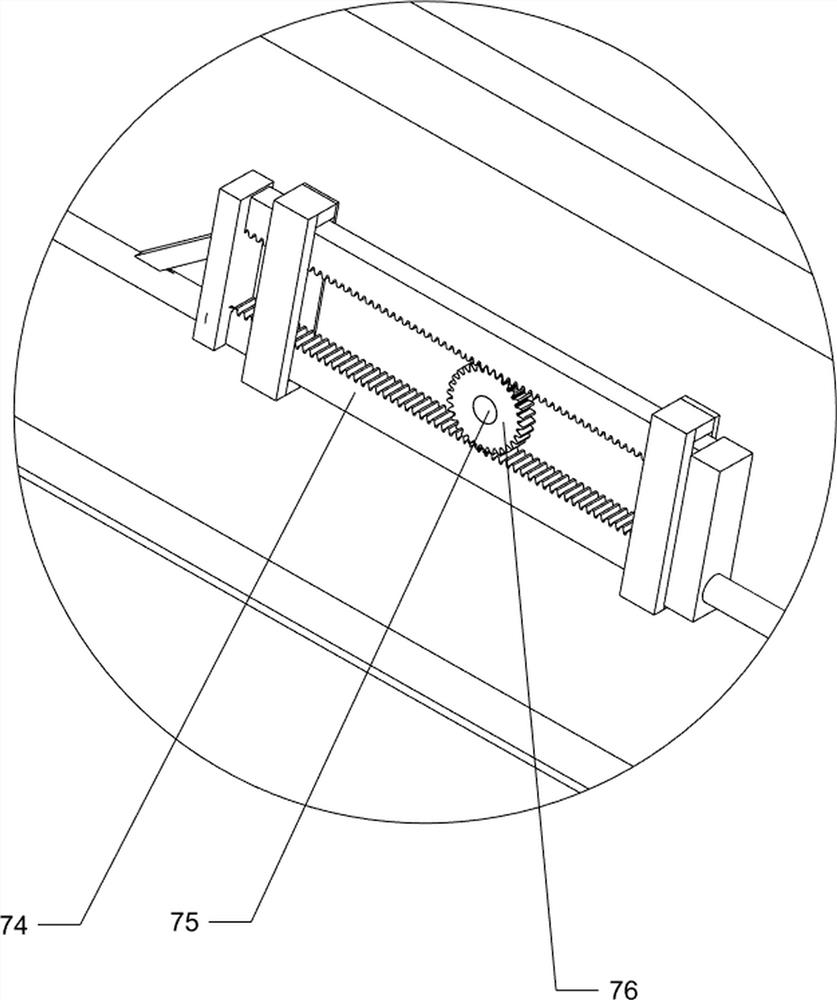

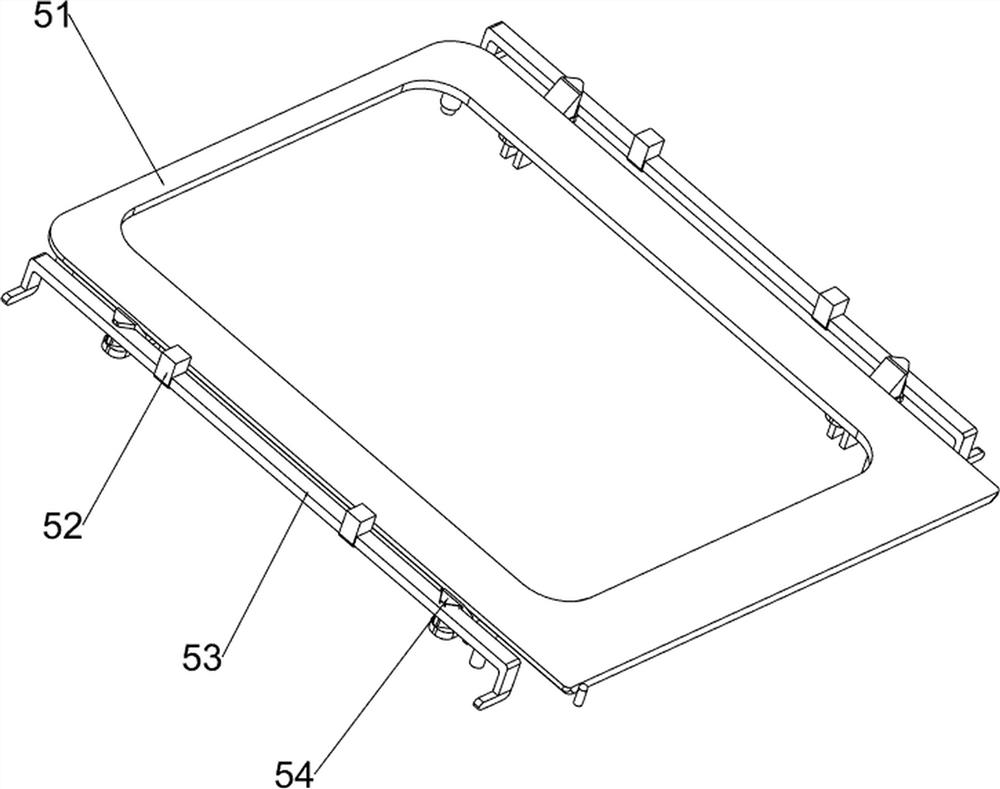

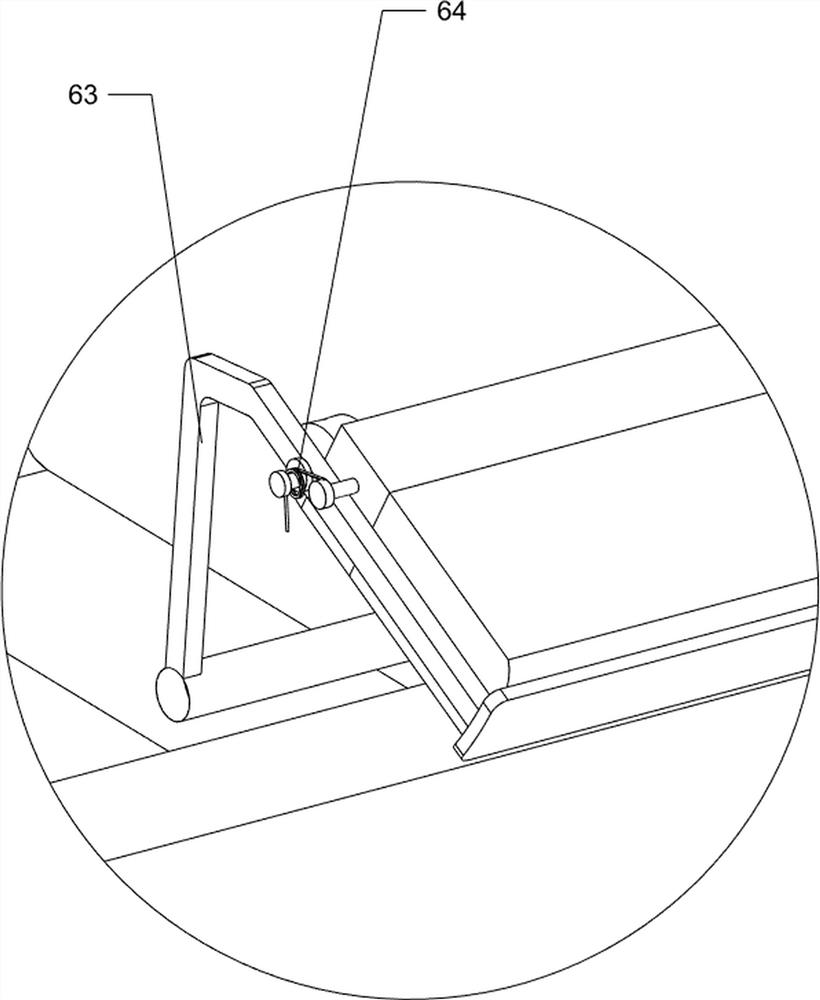

Net pulling machine and net pulling process thereof

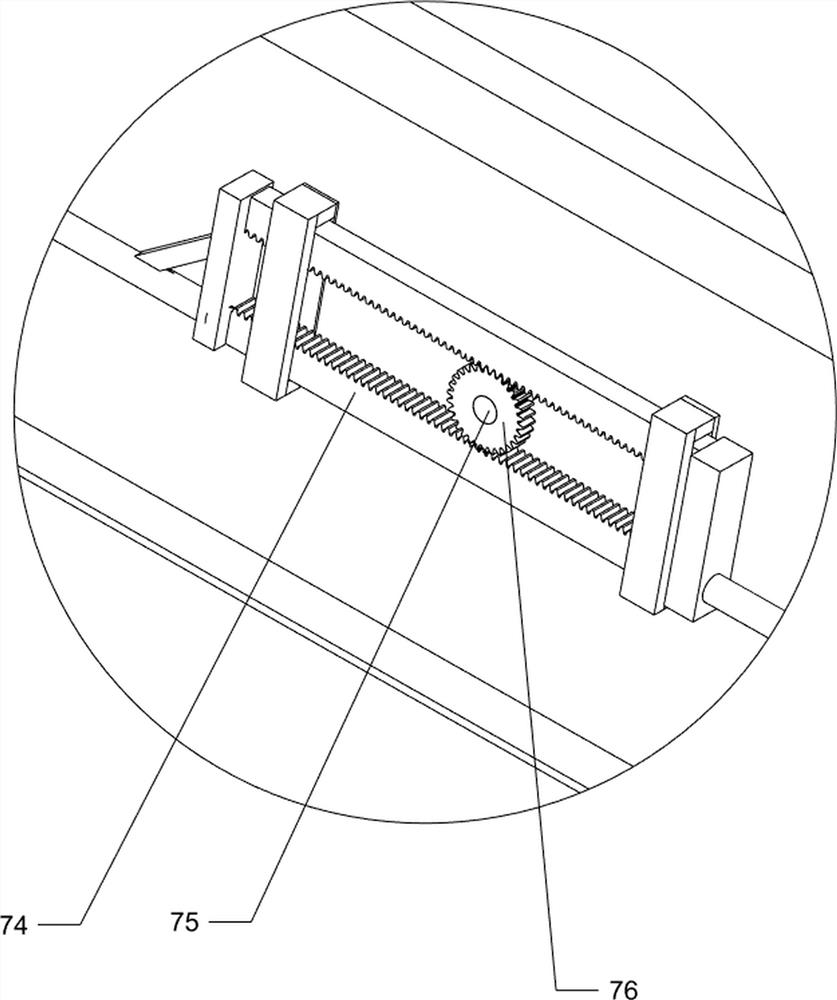

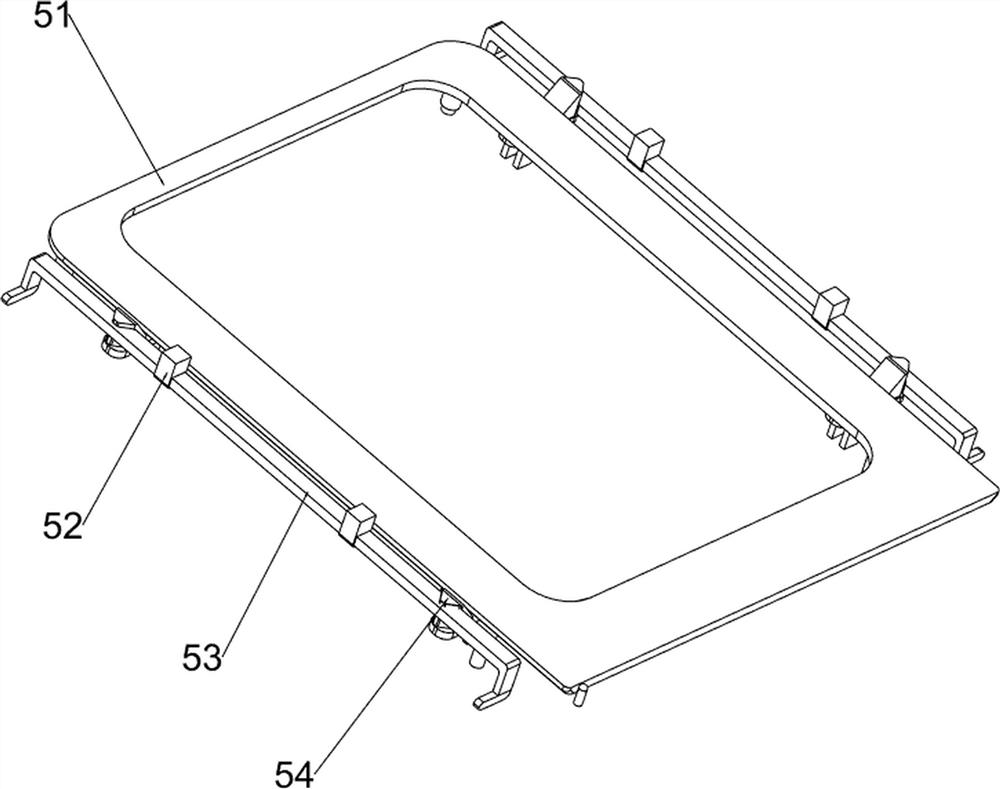

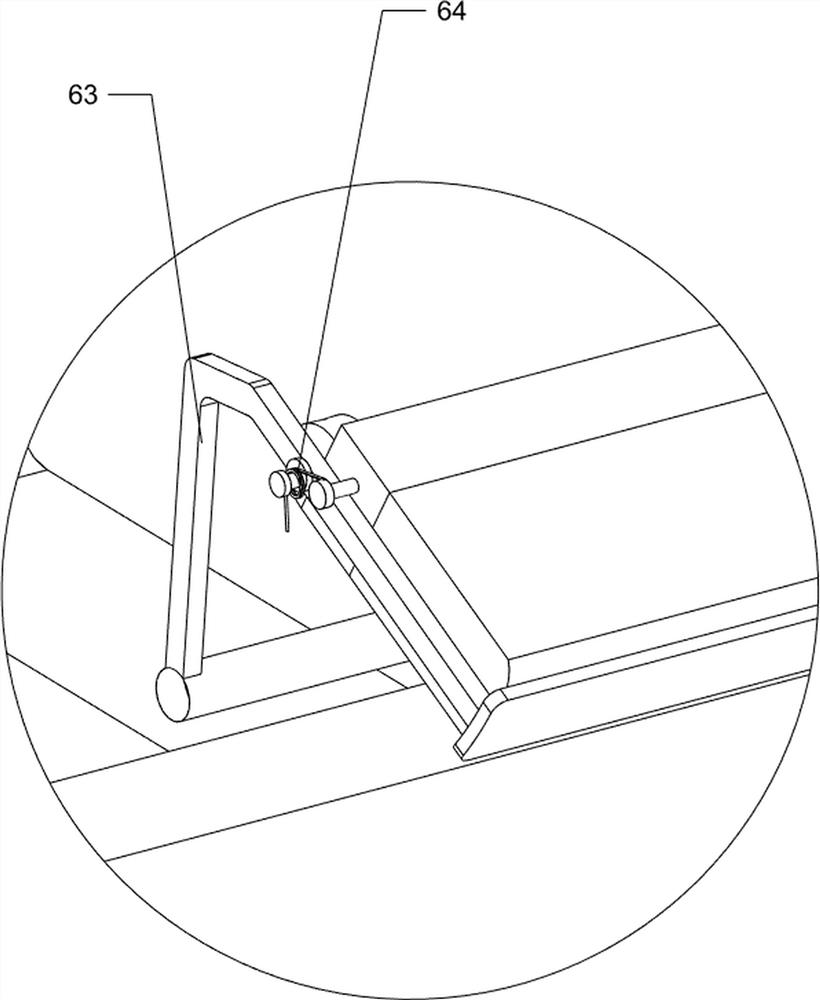

PendingCN113232401AUniform tensionAvoid Inconsistent Pore SizesForme preparationScreen printingMachine

The invention discloses a net pulling machine which comprises a machine base. A workbench and a net pulling device arranged on the periphery of the workbench are arranged at the top of the machine base; the net pulling device comprises X-axis clamping devices, X-axis moving devices, Y-axis clamping devices and Y-axis moving devices; the X-axis clamping devices and the X-axis moving devices are arranged at the left end and the right end of the machine base correspondingly; and the Y-axis clamping devices and the Y-axis moving devices are arranged at the front end and the rear end of the machine base correspondingly. According to the net pulling device of the net pulling machine, through cooperation of first X-axis chucks, second X-axis chucks, first Y-axis chucks and second Y-axis chucks, a silk screen can be evenly tensioned, so that the situation that the aperture of the silk screen is inconsistent is avoided, and the silk screen printing effect is improved.

Owner:佛山市顺德区广楹自动化设备有限公司 +1

A kind of cardboard ink automatic printing equipment

ActiveCN112297608BUniform printingPrinting effect is clearRotary pressesOther printing apparatusPaperboardPrinting press

The invention relates to a printing device, in particular to a cardboard ink automatic printing device. The invention provides a cardboard ink automatic printing equipment which can automatically print the cardboard and improve the uniformity of printing. An automatic cardboard ink printing equipment, comprising: a base and a support platform, the base is provided with a support platform; a printing mechanism, a printing mechanism is provided on the support platform; a support, a support is provided on the base; a lifting mechanism, a lifting mechanism is provided on the support mechanism. Through the design of the printing mechanism, the present invention can print the cardboard with the cooperation of the lifting mechanism, without manual printing on the cardboard, so that the printing of the cardboard is more uniform; through the design of the lifting mechanism, the cardboard can be moved upwards, more With the work of the printing mechanism, the printing effect on the cardboard is clearer; through the design of the unloading mechanism, the purpose of automatically unloading the pigment can be realized, and the probability of poor printing effect due to lack of pigment can be reduced.

Owner:广东旗峰纸业包装有限公司

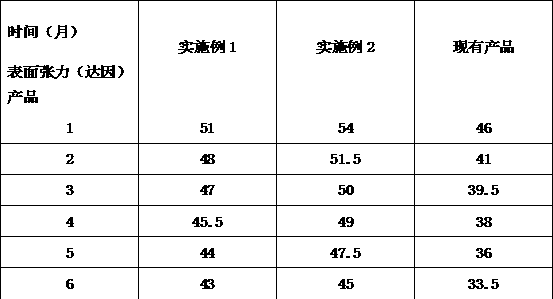

A kind of BOPP thin film for precision printing and preparation method thereof

ActiveCN107932942BGuaranteed flatnessReduce print identification confusionDuplicating/marking methodsSynthetic resin layered productsPolymer scienceThin membrane

The invention discloses a BOPP thin film used for precise printing and a preparing method of the thin film. The thin film is formed by compositing of a modified function layer, a transparent surface layer, a supporting core layer and a transverse surface layer in a four-layer co-extrusion manner, and the proportion of all layers if 2:1.5:5:1.5, according to the raw material ratio of all layers ofthe thin film, the modified function layer comprises 91 to 96% of co-polypropylene, 2 to 5% of a special modified material, 1 to 2% of an anti-adhesion agent and 1 to 2% of an antioxidant, the supporting core layer comprises 85 to 92% of homo-polypropylene, 3 to 5% of a stiffness agent, 2 to 5% of an antistatic agent, and 3 to 5% of a slipping agent, and the transparent surface layer comprises 75to 88% of co-polypropylene, 4 to 10% of a slipping agent, 5 to 10% of anti-adhesion agent and 3 to 5% of an antioxidant. Through modifying and blending of raw materials and the corresponding adjustment of the process, all layers can be supplemented, on the premise of ensuring that the BOPP thin film has the intrinsic physical property, surface tension of one side of the thin film function layer can be effectively enhanced, the attenuation velocity is reduced, the ink attaching force and coloring force can be improved, and the performance of precise printing is met.

Owner:GUANGDONG WEIFU PACKAGING MATERIAL

Printing block heating controller and method based on wireless temperature sensor

ActiveCN106585081BRealize heating control functionPrecise heating controlRotary pressesPrinting press partsTemperature controlEngineering

The invention discloses a lettering block heating controller based on a wireless temperature sensor and a method and relates to the field of inkwriter equipment of a sheath process in a communication optical cable production process. The controller comprises the wireless temperature sensor, a programmable controller and a temperature control relay control loop. The wireless temperature sensor comprises a sending device, a receiving device, a temperature display instrument, a protocol converter and temperature measurement probes and is fixedly installed on an inking wheel of an rotary inkwriter; the inkwriter comprises a meter counting disc and a lettering disc, the meter counting disc is provided with a lettering block and heating blocks, and the lettering disc is provided with a base; the base is provided with a crescent-moon-shaped plate and an installation block; and the temperature measurement probes are installed in the heating blocks of the inkwriter, the heating blocks are installed on the crescent-moon-shaped plate of the rotary inking wheel, the sending device is fixedly installed on the installation block, and the installation bloc is fixed to the base. By means of the lettering block heating controller based on the wireless temperature sensor and the method, heating of the lettering block on lettering rotating equipment can be precisely controlled.

Owner:FENGHUO COMM SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com