Method for penetrated coating for ink-jet printing material

A technology of inkjet printing and coating method, which is applied in the direction of fiber raw material treatment, surfactant addition, anticorrosion agent/antioxidant addition, etc. It can solve problems such as poor contrast, poor color saturation, ink diffusion, etc., and achieve stiffness Good, simple method, realistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

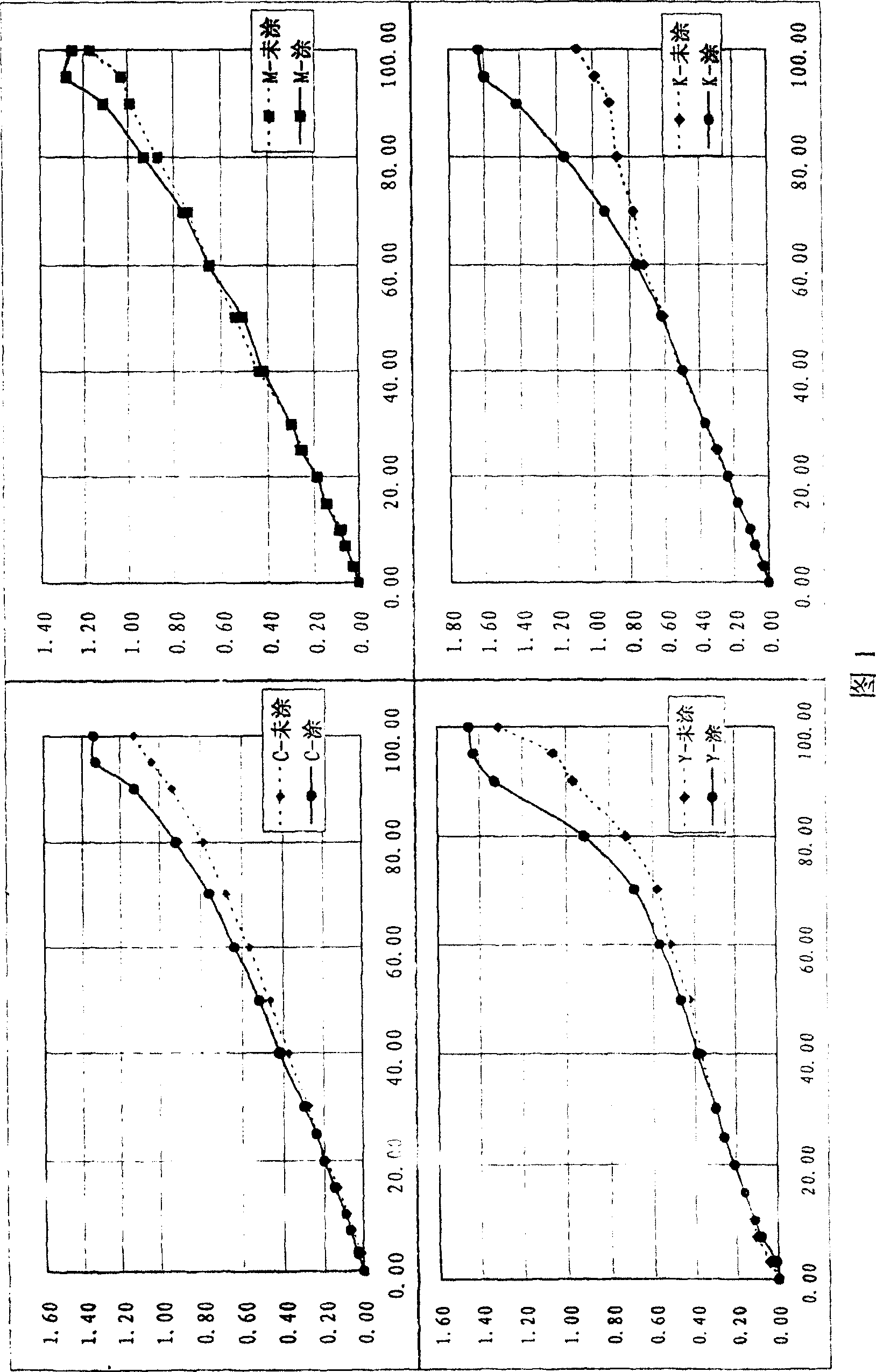

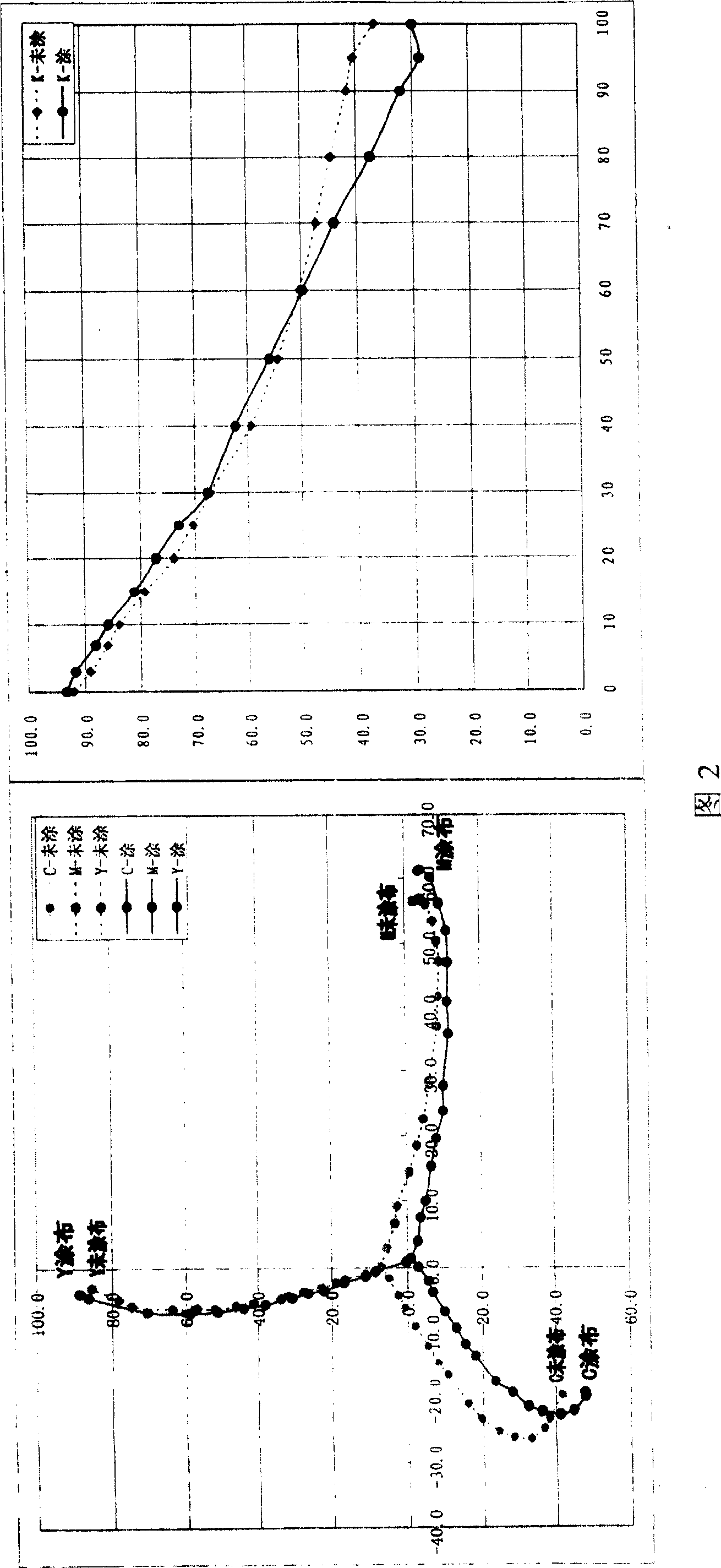

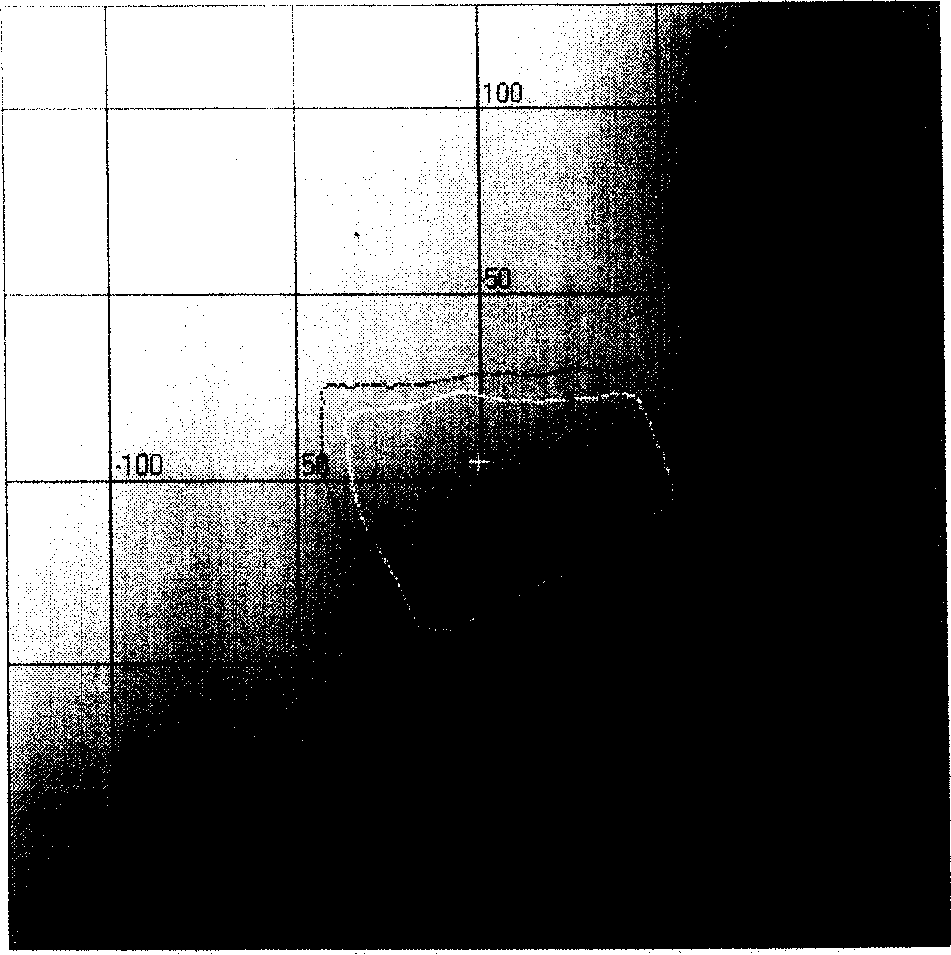

Image

Examples

Embodiment 1

[0046] Fixing agent Y 2~6%

[0047] Nanoscale silicon dioxide 3~5%

[0048] Polyvinyl alcohol 0.5~2%

[0049] UV—531 1.2~2.4%

[0050] Sodium dodecylbenzenesulfonate 0.2~0.5%

[0051] Deionized water 93.1~84.1%

[0052] The above-mentioned % are all % by weight.

[0053] According to the above-mentioned components and content, and according to color-fixing agent Y (color-fixing agent), nano-scale silicon dioxide (water-absorbing agent), polyvinyl alcohol (adhesive), UV-531 (anti-ultraviolet agent), dodecylbenzene The raw material sequence of sodium sulfonate (surfactant) is to add deionized water in turn, and under the condition of 30°C, with a stirrer speed of 320 rpm, fully stir and mix evenly, and then use a mesh number of 300 mesh yarn core The ink-jet printing coating of the present invention is obtained by filtering through a sieve once.

[0054] Spread rice paper or silk paper on the desktop or glass, and use an air pressure spray gun to coat the prepared ink-jet ...

Embodiment 2

[0057] Fixing agent M 3~8%

[0058] Nanoscale aluminum oxide 4~10%

[0059] Sodium polyacrylate 0.5~0.8%

[0060] UV-9 2~4%

[0061] Styrene-acrylate copolymer emulsion 5-9%

[0062] Hexadecyl trimethyl ammonium bromide 1~2%

[0063] Deionized water 84.5~66.2%

[0064] The above-mentioned % are all % by weight.

[0065] According to the above components and content, and according to color fixing agent M (fixing agent), nano-scale aluminum oxide (water absorbing agent), sodium polyacrylate (water absorbing agent), styrene-acrylate copolymer emulsion (adhesive), UV -9 (anti-ultraviolet agent), cetyltrimethylammonium bromide (surfactant) raw material order, add deionized water successively, under 10 ℃ of conditions, with the agitator stirring speed of 350 revs / min, After fully stirring and mixing evenly, the ink-jet printing paint of the present invention is obtained by filtering twice with a 200-mesh yarn core filter.

[0066] Spread rice paper or silk paper on the deskto...

Embodiment 3

[0069] Fixing agent Y 1~4%

[0070] Fixing agent M 2~3%

[0071] Polyvinyl alcohol 2~5%

[0072] Vinyl acetate-ethylene copolymer 6~10%

[0073] Ciba BT-202 1.6~3.4%

[0074] OP—10 1.5~2.5%

[0075] UV-9 2~4%

[0076] Deionized water 83.9~68.1%

[0077] The above-mentioned % are all % by weight.

[0078] According to the above components and content, and according to color fixing agent Y (color fixing agent), color fixing agent M (color fixing agent), polyvinyl alcohol (water absorbing agent), vinyl acetate-ethylene copolymer (adhesive), Ciba BT -202 (anti-ultraviolet agent), UV-9 (anti-ultraviolet agent), OP-10 (surfactant) raw material sequence, add deionized water in turn, and stir with a stirrer at 300 rpm at 20°C speed, fully stirred and mixed evenly, and then filtered through a 300-mesh yarn core filter to obtain the inkjet printing coating of the present invention.

[0079] Spread rice paper or silk paper on the desktop or glass, and use an air pressure spray gu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com