Ink-jet typing artificial material and method for preparing the same

An inkjet printing and coating technology, which is applied in paper coating, fiber raw material processing, textiles and papermaking, etc., can solve the problems of losing "special" paper and destroying the special properties of base paper, etc., and achieves clear printing effect, low cost, and easy to pass through the machine. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Fixing agent Y 2~6%

[0060] Nanoscale silicon dioxide 3~5%

[0061] Polyvinyl alcohol 0.5~2%

[0062] UV—531 1.2~2.4%

[0063] Sodium dodecylbenzenesulfonate 0.2~0.5%

[0064] Deionized water 93.1~84.1%

[0065] The above-mentioned % are all % by weight.

[0066] According to the above-mentioned components and content, and according to color-fixing agent Y (color-fixing agent), nano-scale silicon dioxide (water-absorbing agent), polyvinyl alcohol (adhesive), UV-531 (anti-ultraviolet agent), dodecylbenzene The raw material sequence of sodium sulfonate (surfactant) is to add deionized water in turn, and under the condition of 30°C, with a stirrer speed of 320 rpm, fully stir and mix evenly, and then use a mesh number of 300 mesh yarn core The ink-jet printing coating of the present invention is obtained by filtering through a sieve once.

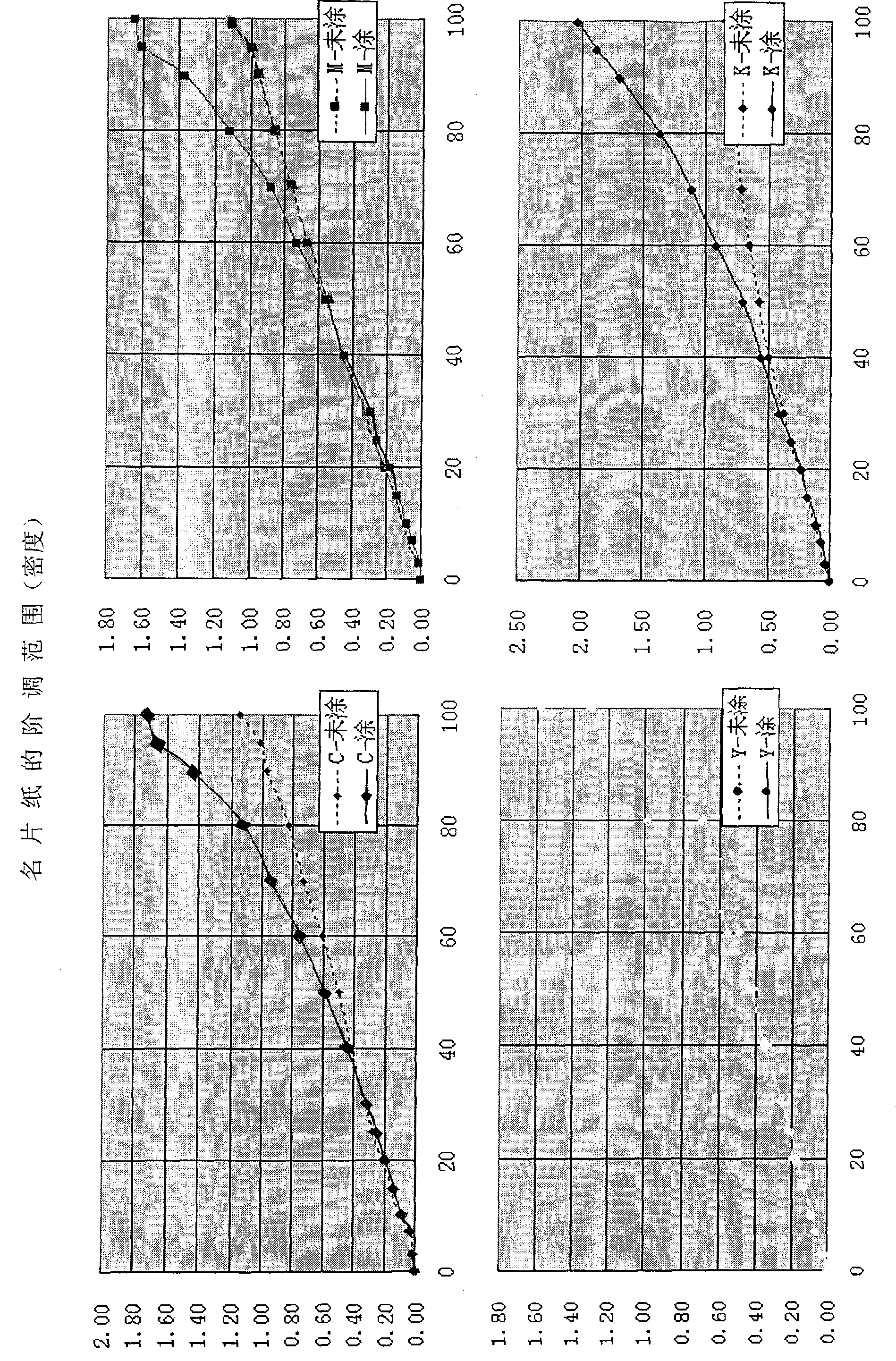

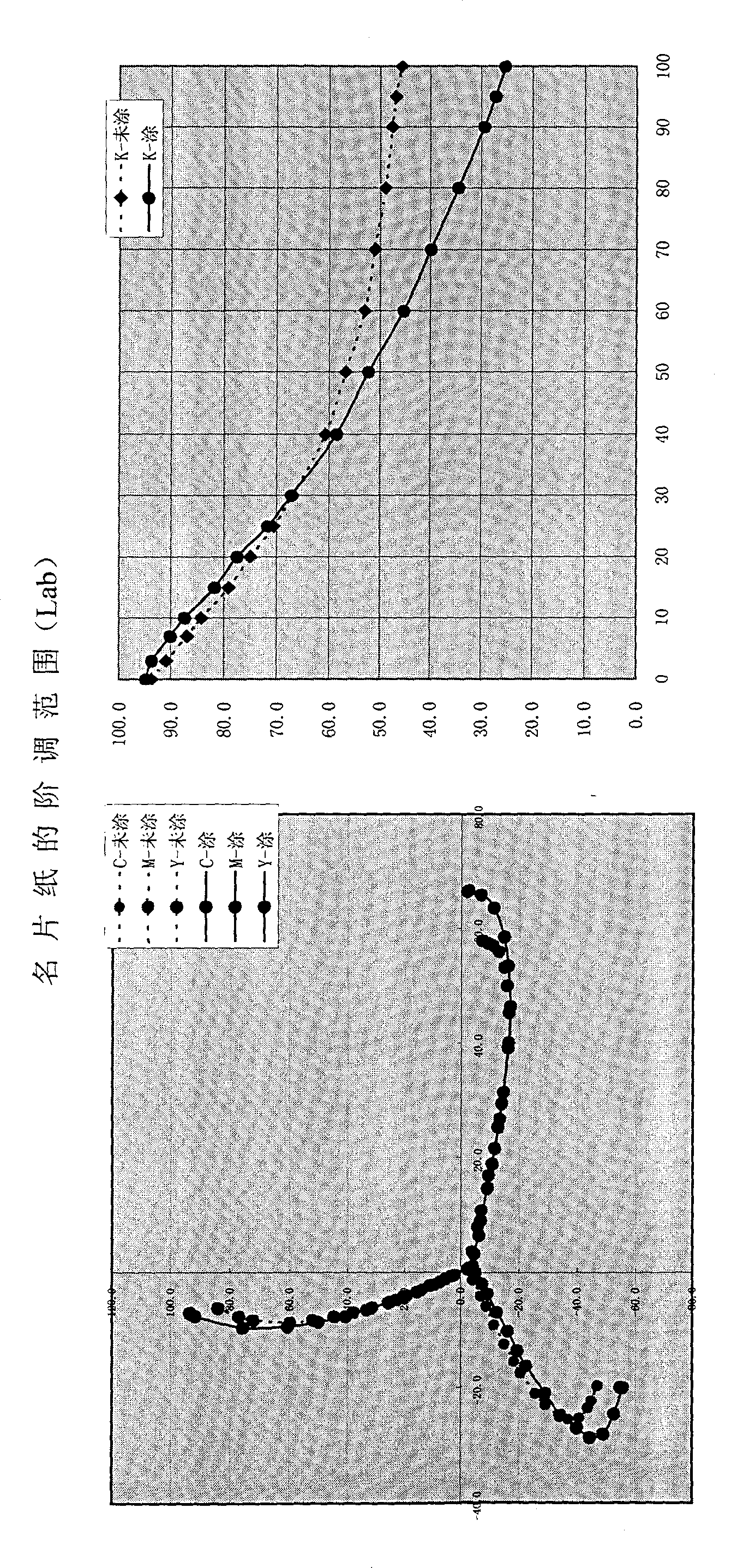

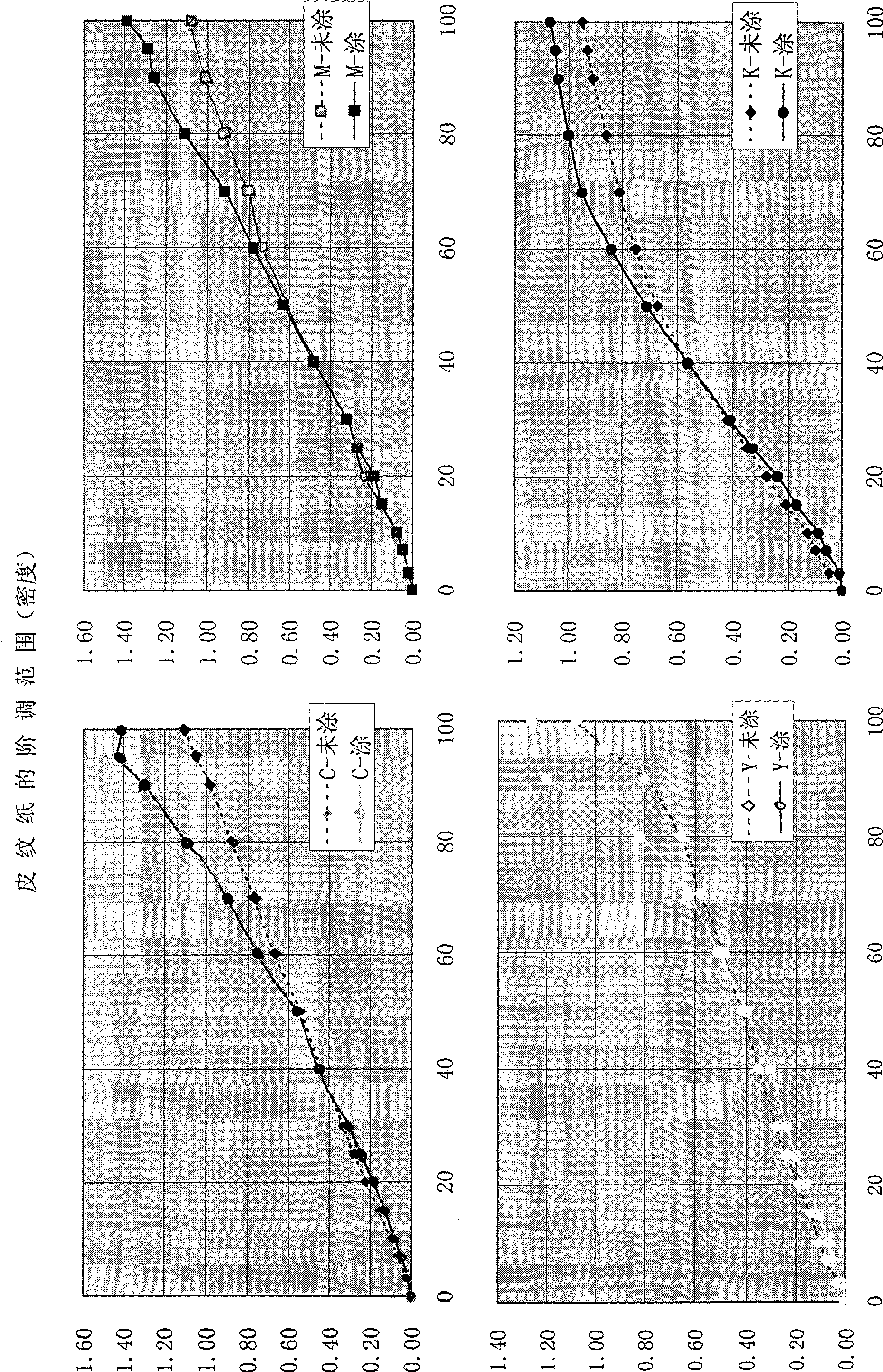

[0067] Spread the business card paper, leather paper, Monken paper and cover paper on the desktop or glass, and use the air pre...

Embodiment 2

[0083] Fixing agent M 3~8%

[0084] Nanoscale aluminum oxide 4~10%

[0085] Sodium polyacrylate 0.5~0.8%

[0086] UV-9 2~4%

[0087] Styrene-acrylate copolymer emulsion 5-9%

[0088] Hexadecyltrimethylammonium bromide 1~2%

[0089] Deionized water 84.5~66.2%

[0090] The above-mentioned % are all % by weight.

[0091] According to the above components and content, and according to color fixing agent M (fixing agent), nano-scale aluminum oxide (water absorbing agent), sodium polyacrylate (water absorbing agent), styrene-acrylate copolymer emulsion (adhesive), UV -9 (anti-ultraviolet agent), the raw material sequence of cetyltrimethylammonium bromide (surfactant), add deionized water successively, under 10 ℃ of conditions, with the agitator stirring speed of 350 revs / min, After fully stirring and mixing evenly, the ink-jet printing paint of the present invention is obtained by filtering twice with a 200-mesh yarn core filter.

[0092] Spread the business card paper, leath...

Embodiment 3

[0099] Fixing agent Y 1~4%

[0100] Fixing agent M 2~3%

[0101] Polyvinyl alcohol 2~5%

[0102] Vinyl acetate-ethylene copolymer 6~10%

[0103] Ciba BT-202 1.6~3.4%

[0104] OP—10 1.5~2.5%

[0105] UV-9 2~4%

[0106] Deionized water 83.9~68.1%

[0107] The above-mentioned % are all % by weight.

[0108] According to the above components and content, and according to color fixing agent Y (color fixing agent), color fixing agent M (color fixing agent), polyvinyl alcohol (water absorbing agent), vinyl acetate-ethylene copolymer (adhesive), Ciba BT -202 (anti-ultraviolet agent), UV-9 (anti-ultraviolet agent), OP-10 (surfactant) raw material sequence, add deionized water in turn, and stir with a stirrer at 300 rpm at 20°C speed, fully stirred and mixed evenly, and then filtered through a 300-mesh yarn core filter to obtain the inkjet printing coating of the present invention.

[0109] Spread the business card paper, leather paper, Monken paper and cover paper on the deskto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com