Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Prevent blocking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

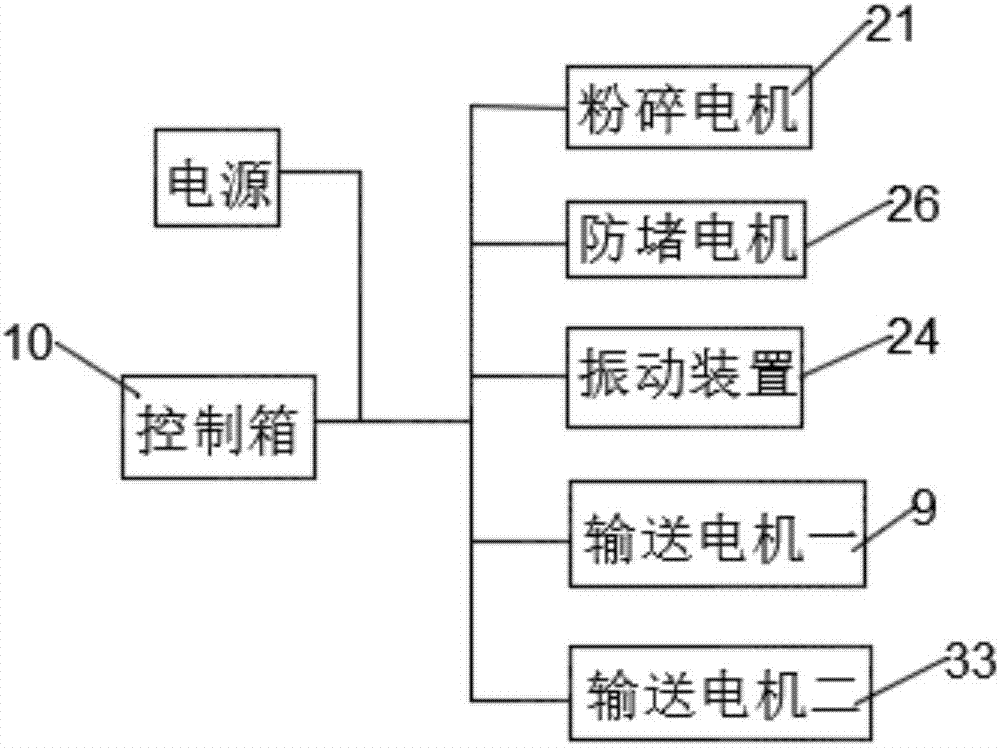

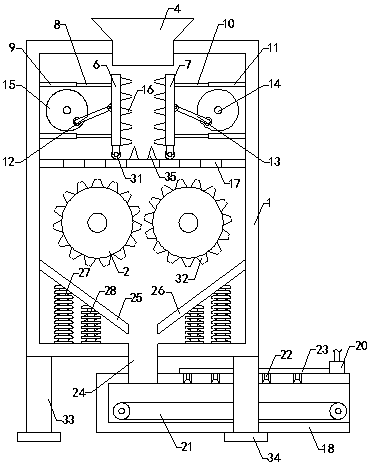

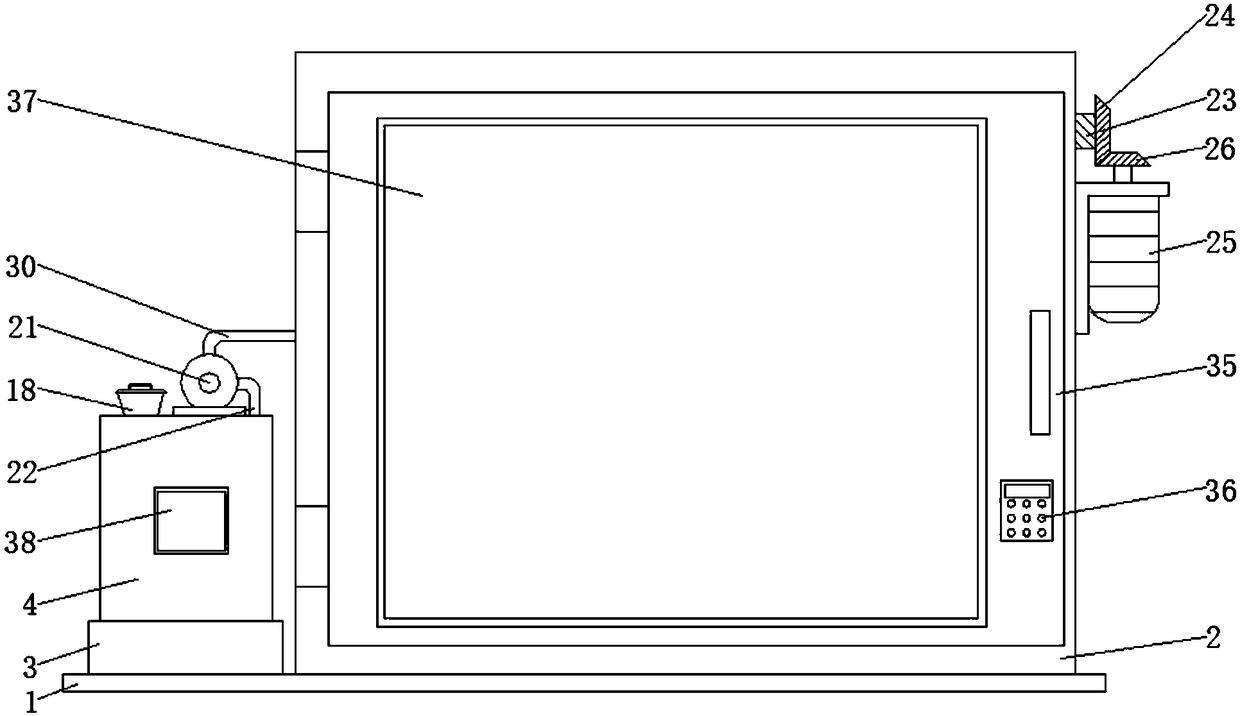

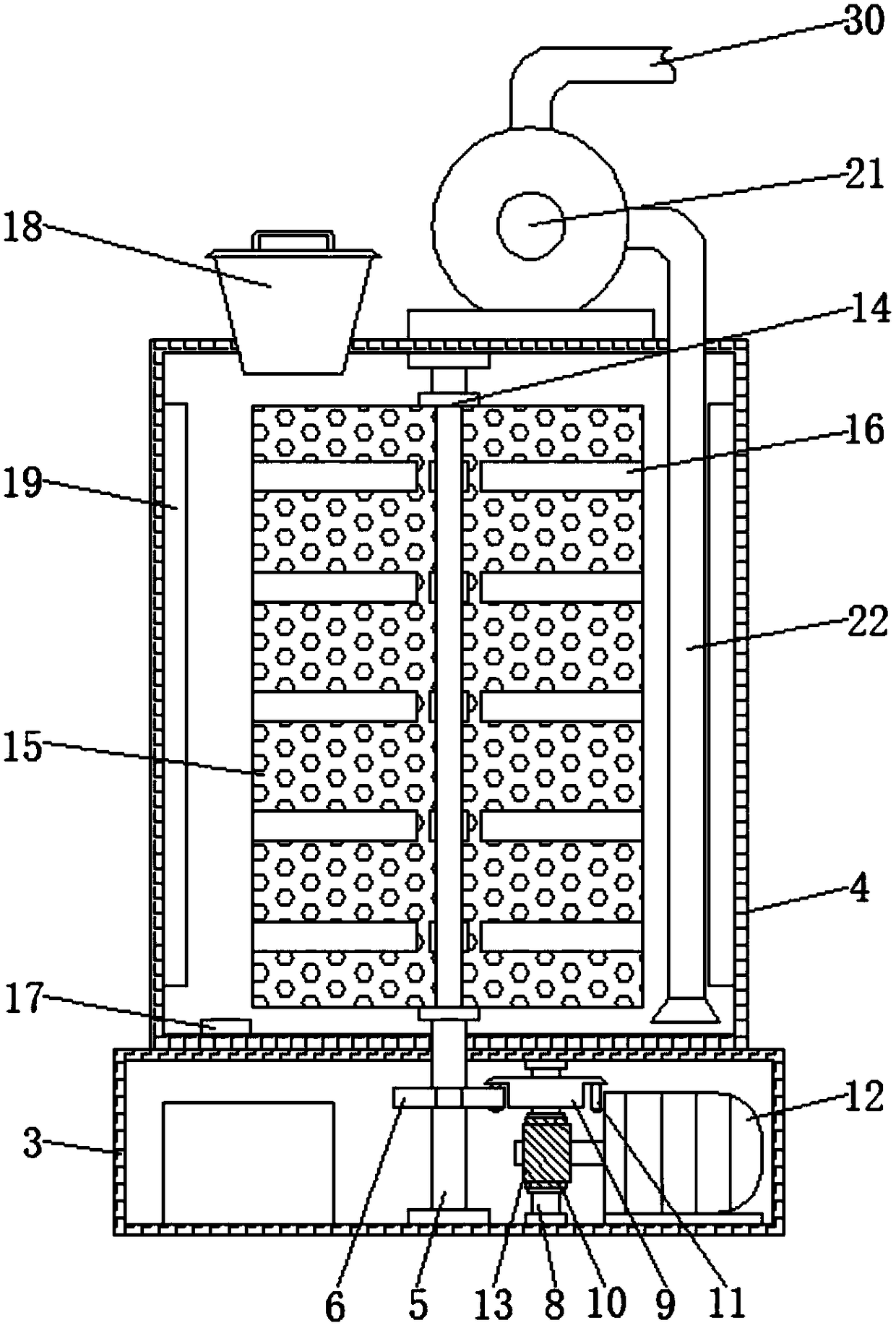

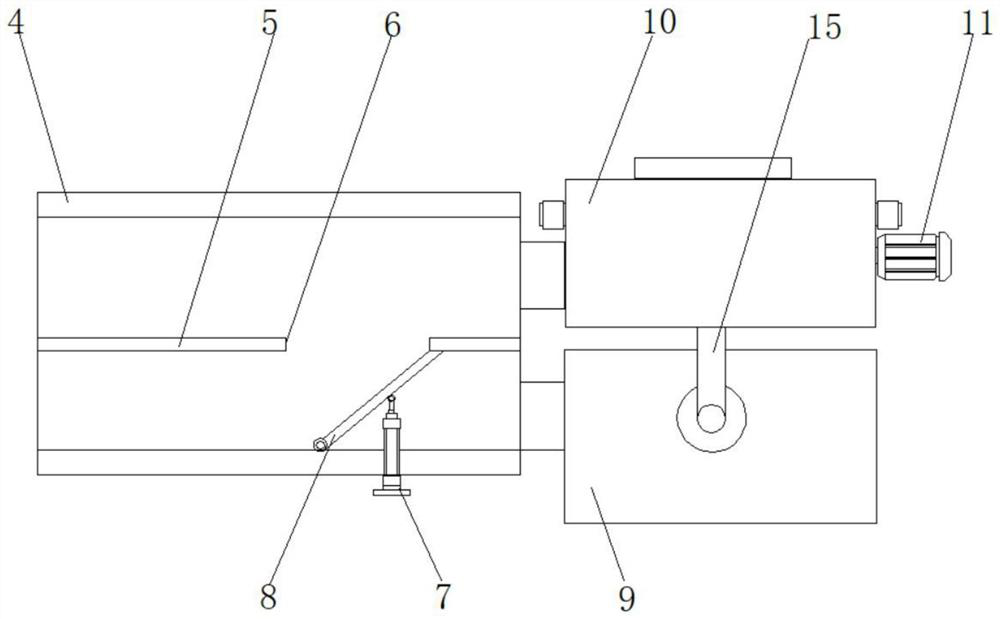

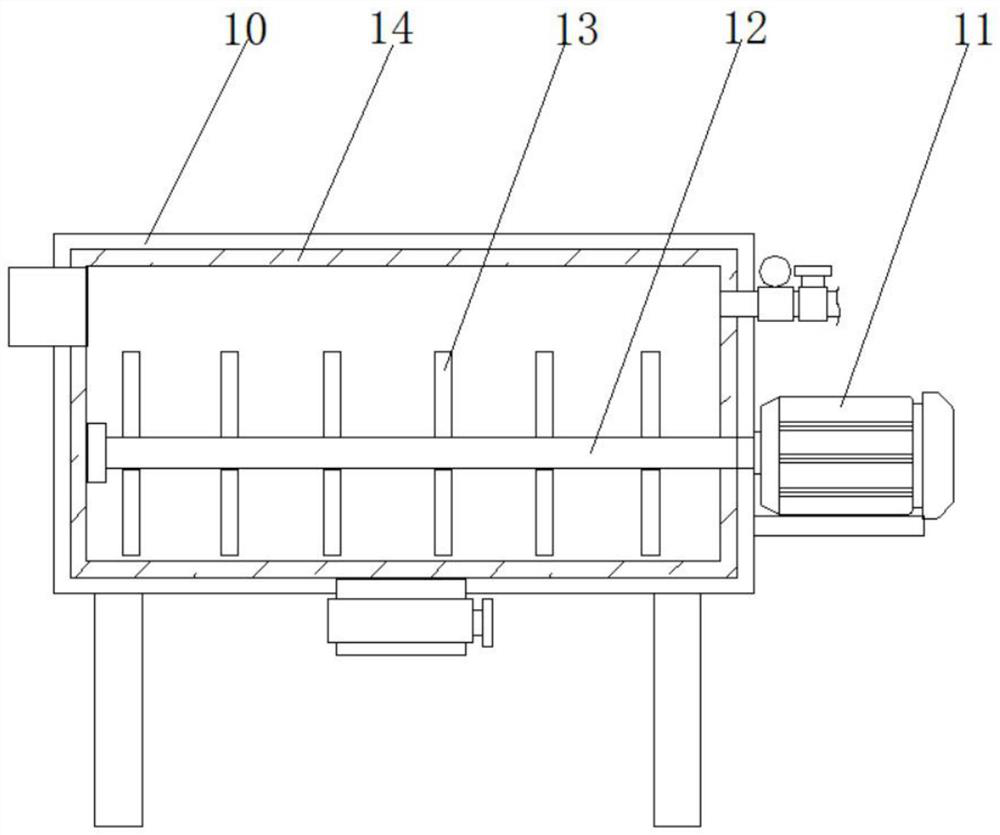

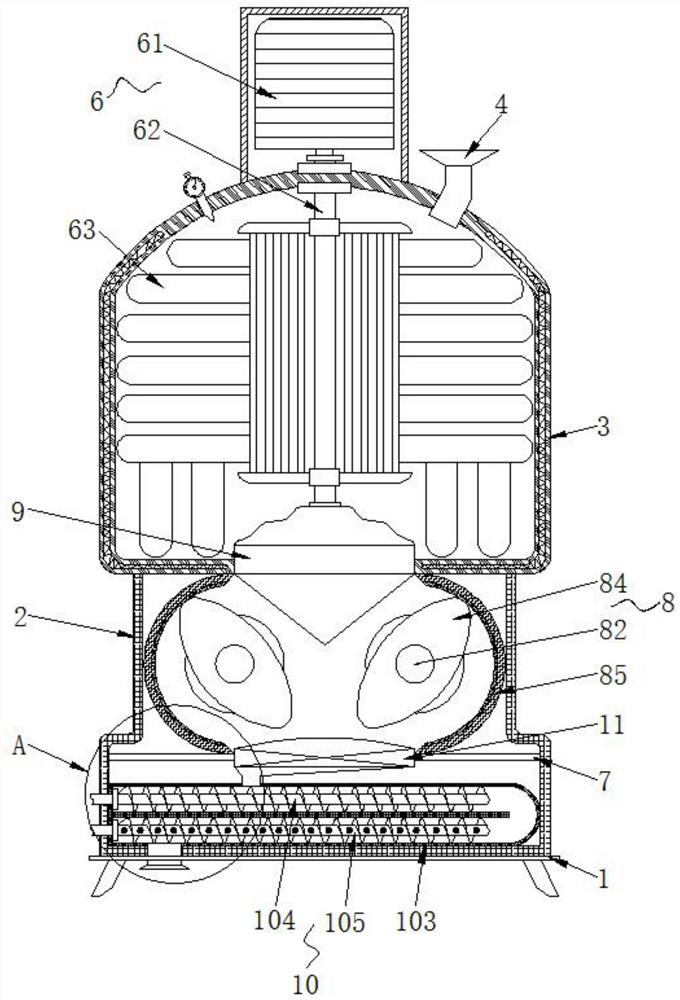

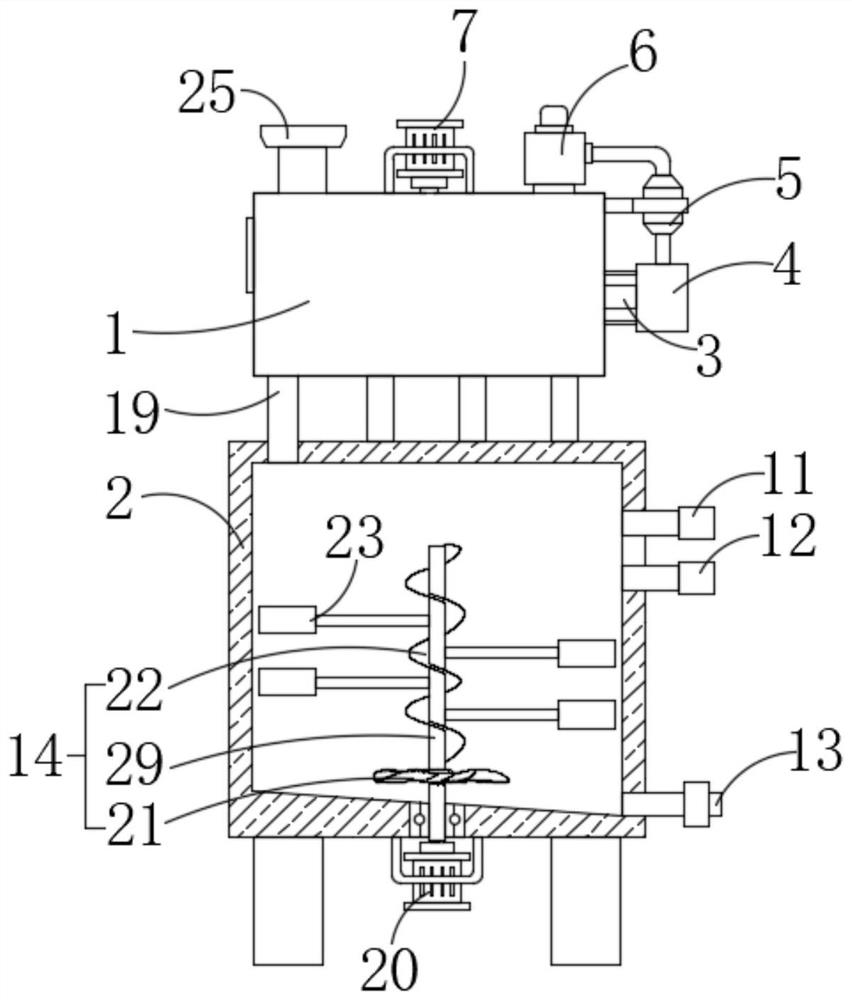

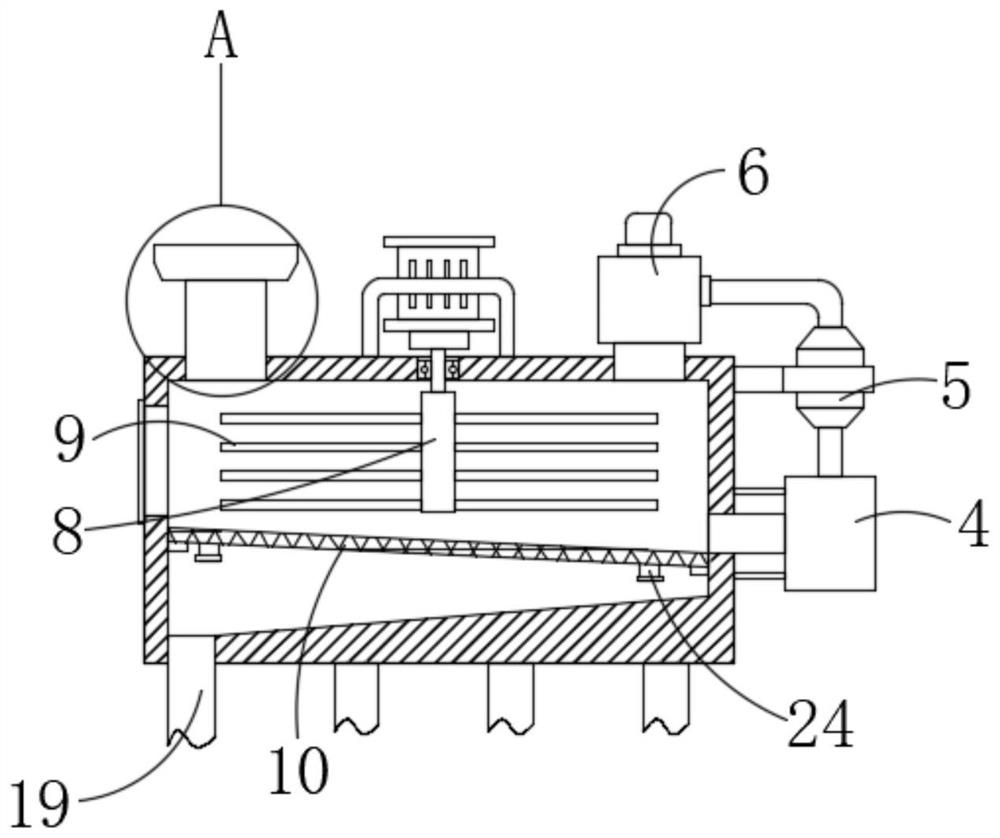

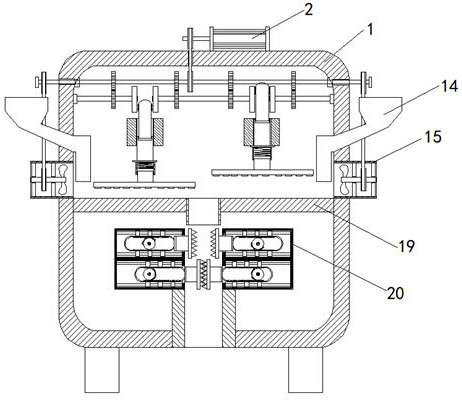

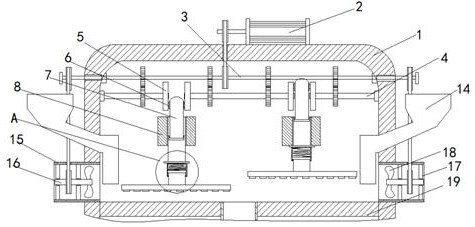

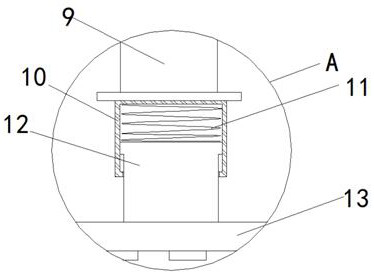

Crushing, stirring and lifting device for construction

InactiveCN107127038ASimple and reasonable designEasy to operatePackagingGrain treatmentsQuality assuranceBuilding material

The invention discloses a crushing and stirring lifting device for building construction, which comprises a bottom frame, a shock-absorbing layer and a base. A second crushing box is provided, the lower end of the second crushing box is provided with a feeding channel, the lower end of the feeding channel is provided with a first conveying cylinder, the right end of the first conveying cylinder is provided with a conveying port, and the lower right end of the conveying port is provided with a second Two delivery cylinders. This device realizes double crushing and mixing of building materials, ensures the quality of material crushing and mixing, and realizes the lifting of materials from low to high, which brings great convenience to construction and can greatly reduce the labor intensity of workers , which is conducive to improving the efficiency of construction. The shock absorbing mechanism and the shock absorbing layer have a good shock absorbing and buffering effect, which can reduce the vibration caused by the equipment during operation, protect the device, and prolong the service life of the device. .

Owner:蔡政伟

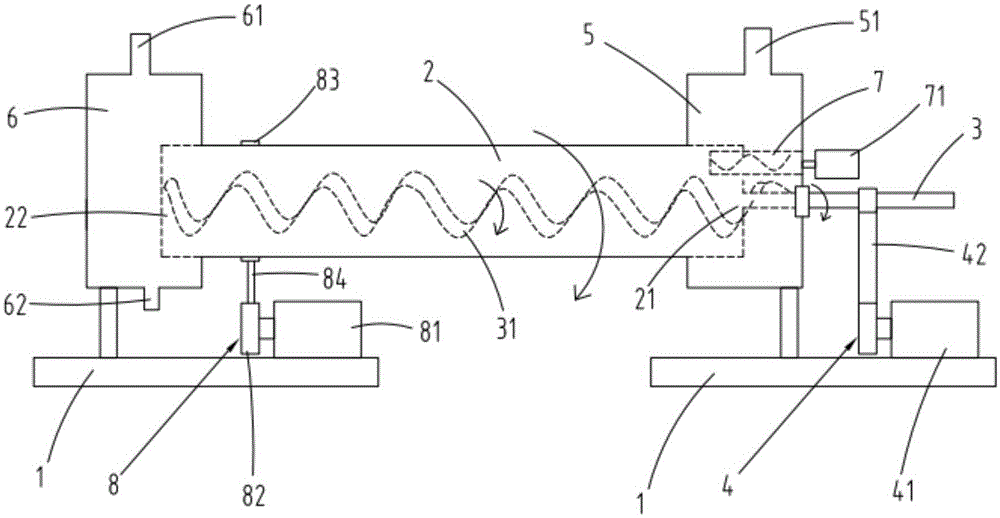

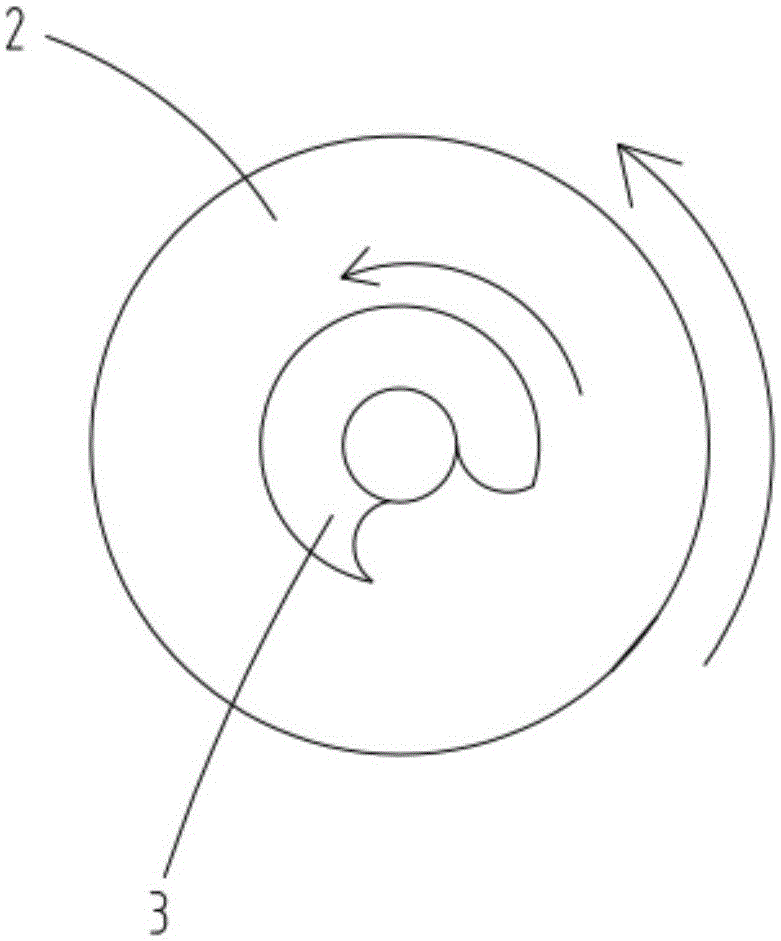

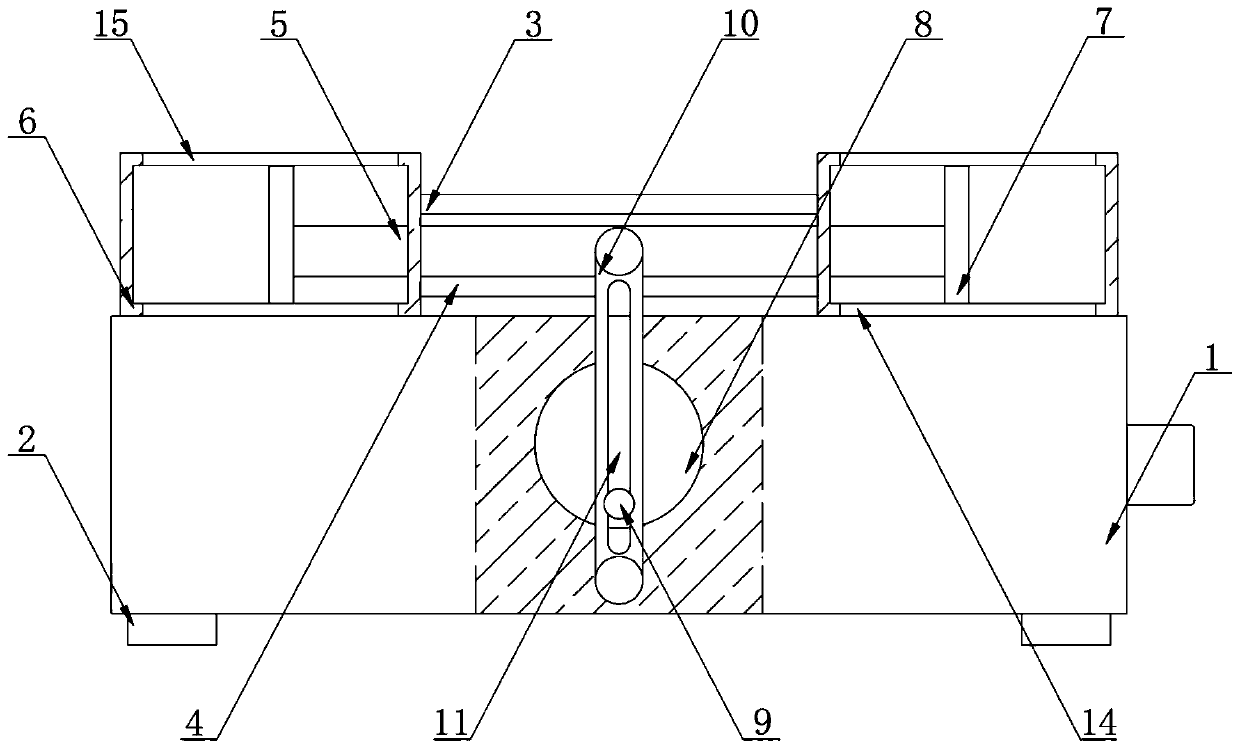

Belt conveyor slippage and fracture detection device

InactiveCN105501886ASolve slippageIncrease the level of automationControl devices for conveyorsMotor controllerControl theory

The invention relates to the technical field of belt transportation, and especially relates to a belt conveyor slippage and fracture detection device. The belt conveyor slippage and fracture detection device comprises a drive roller rotating speed sensor used for detecting the rotating speed of a drive roller; and a driven roller rotating speed sensor used for detecting the rotating speed of a driven roller. The drive roller rotating speed sensor and the driven roller rotating speed sensor send detected signals to a PLC controller, the output terminal of the PLC controller is connected with a motor controller, and the motor controller controls and drives a motor to work. The belt conveyor slippage and fracture detection device is advantaged in that the device is simple in structure and convenient to install, and monitoring of belt conveyor slippage and fracture is effectively achieved.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

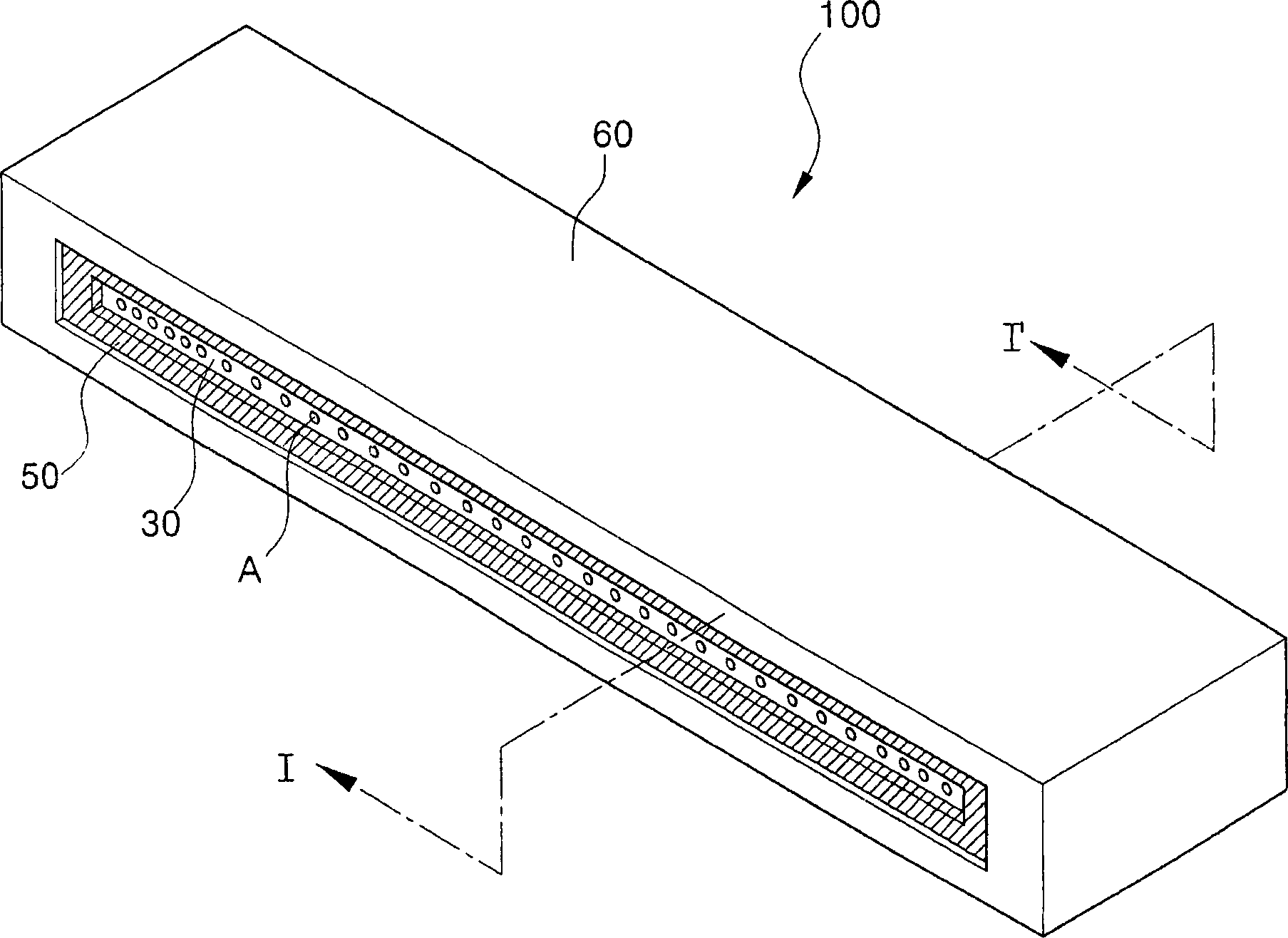

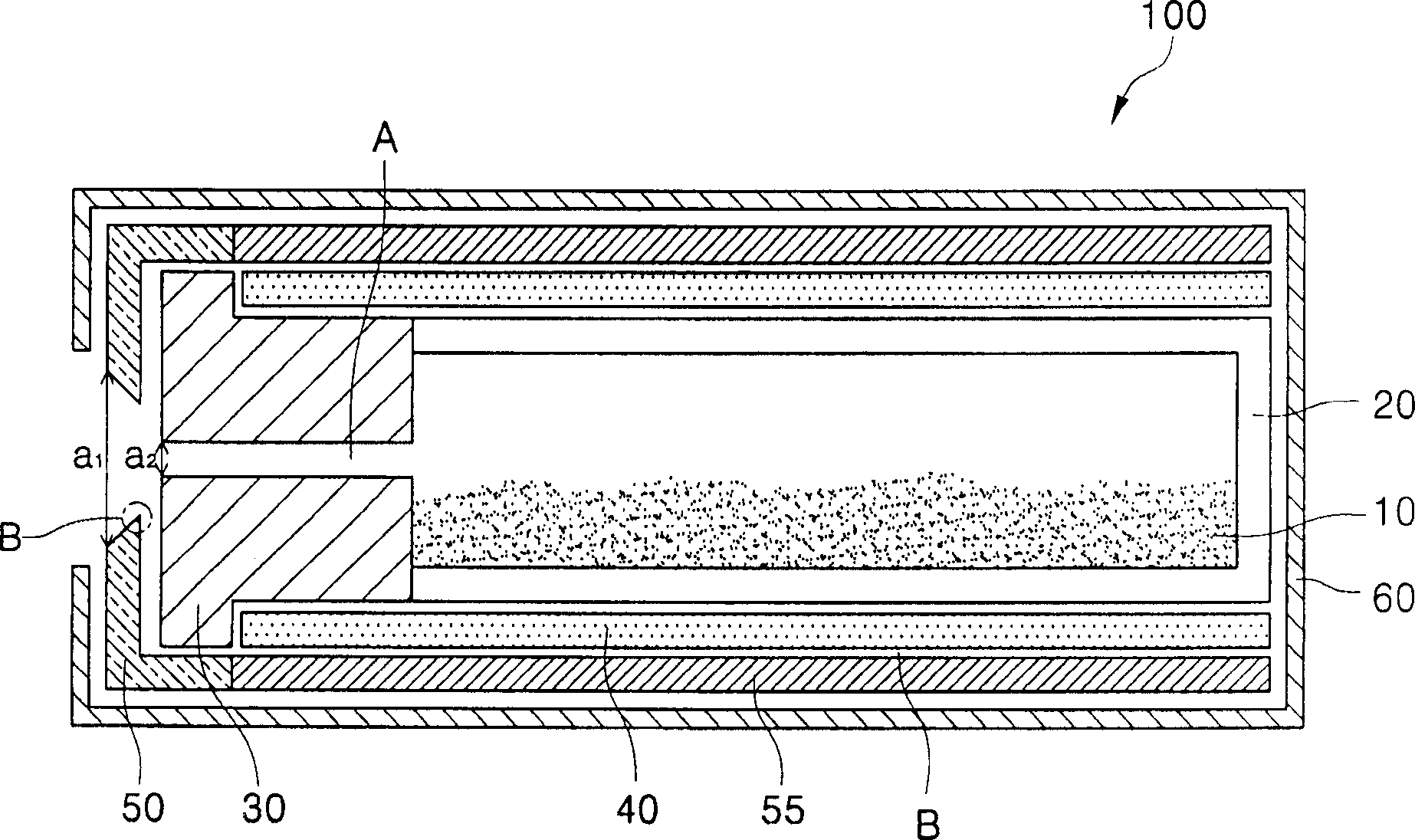

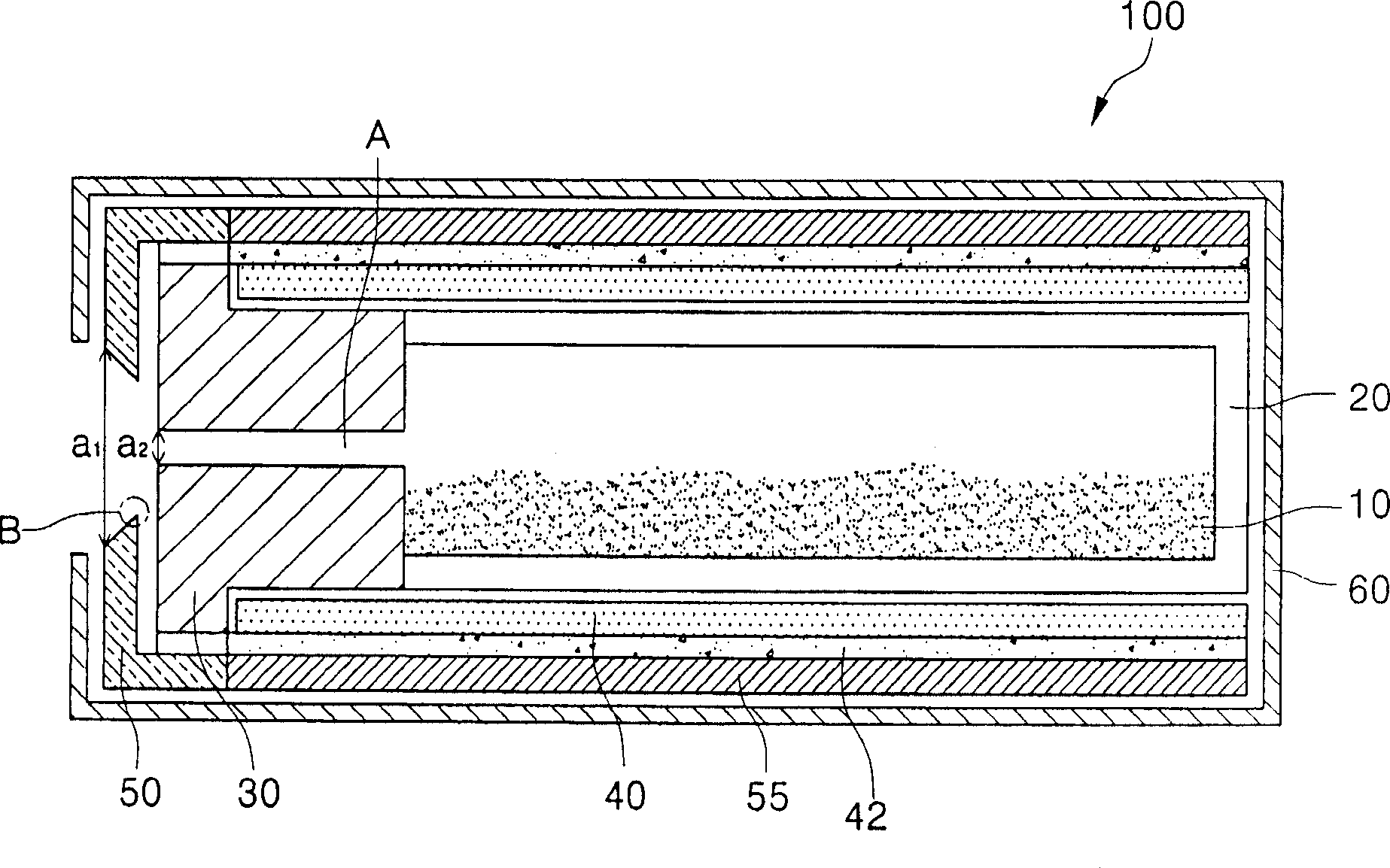

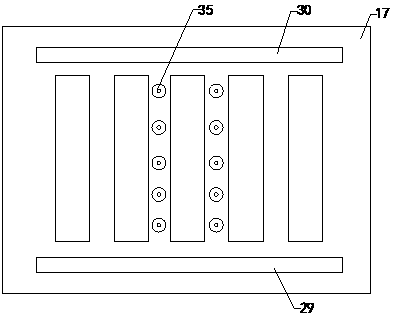

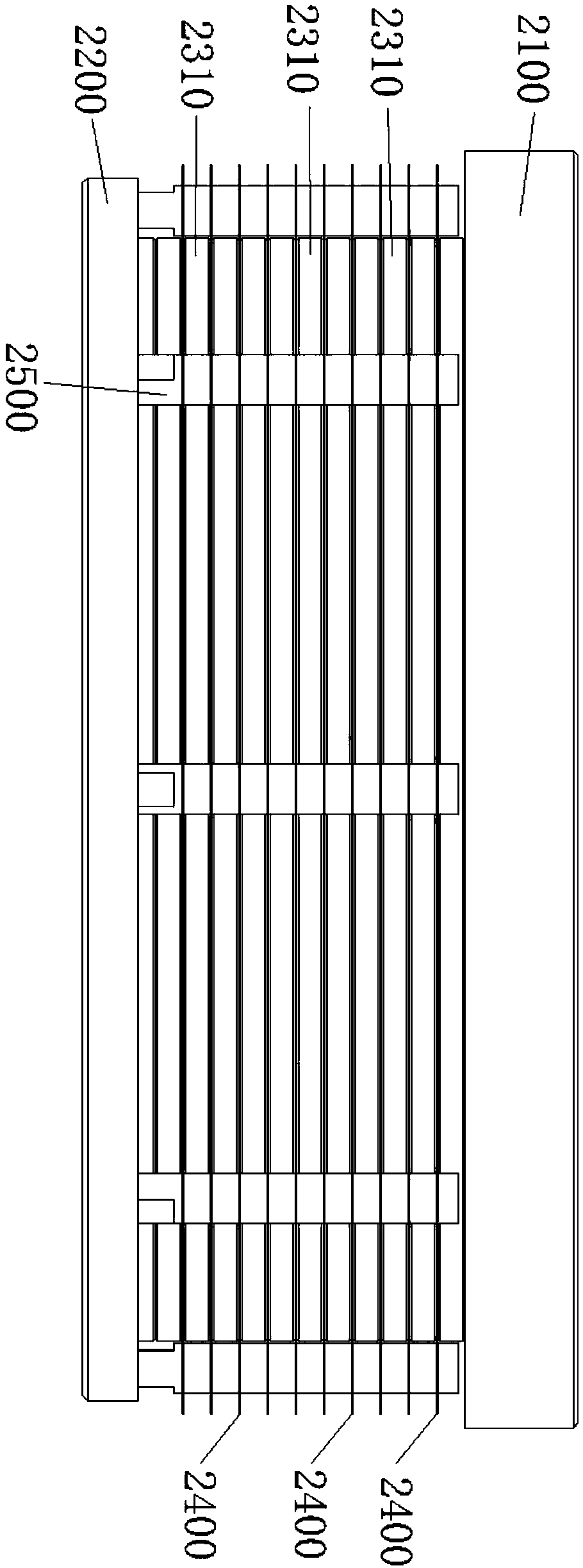

Evaporation source and steam plating device with evaporation source

ActiveCN1782120AAvoid getting lostHigh thermal efficiencyElectrical apparatusElectroluminescent light sourcesProcess engineeringVaporization

The invention provides an evaporation source and an evaporation device equipped with the evaporation source, which can effectively increase the heat of a nozzle by using a reflection plate, thereby preventing evaporation substances from condensing at the nozzle. The evaporation source of the present invention includes: an evaporating substance storage part, which is placed with an evaporating substance and has a partial opening; a nozzle part, which has a part connected to the opening of the evaporating substance storage part, and is used to spray the evaporating substance the opening part; the reflection plate, which surrounds at least a part of the corner of the nozzle part; the casing, which surrounds the vapor deposition substance storage part; the heating part, which is located between the casing and the vapor deposition substance between storage units. The vapor deposition device of the present invention includes the vaporization source. In addition, since the organic matter evaporation source of the present invention improves the material of the organic matter storage part and the nozzle part and attaches the organic matter leakage preventing parts on their surfaces, it improves the thermal conductivity of the nozzle part and the organic matter storage part, and prevents Organic spills.

Owner:SAMSUNG DISPLAY CO LTD

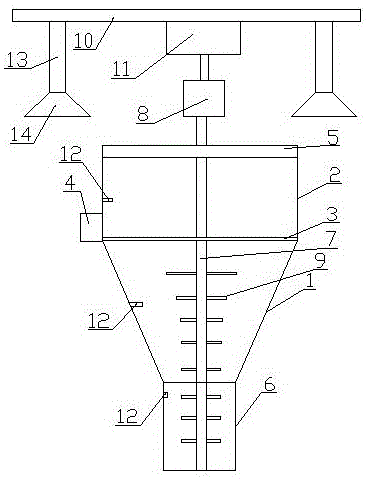

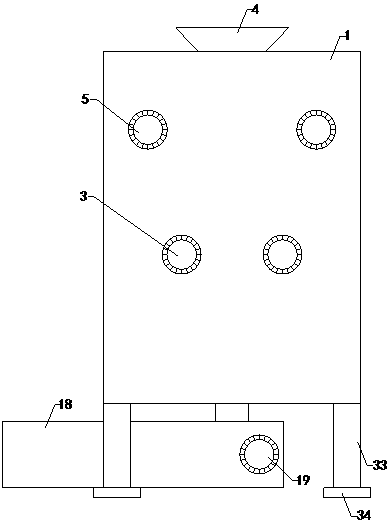

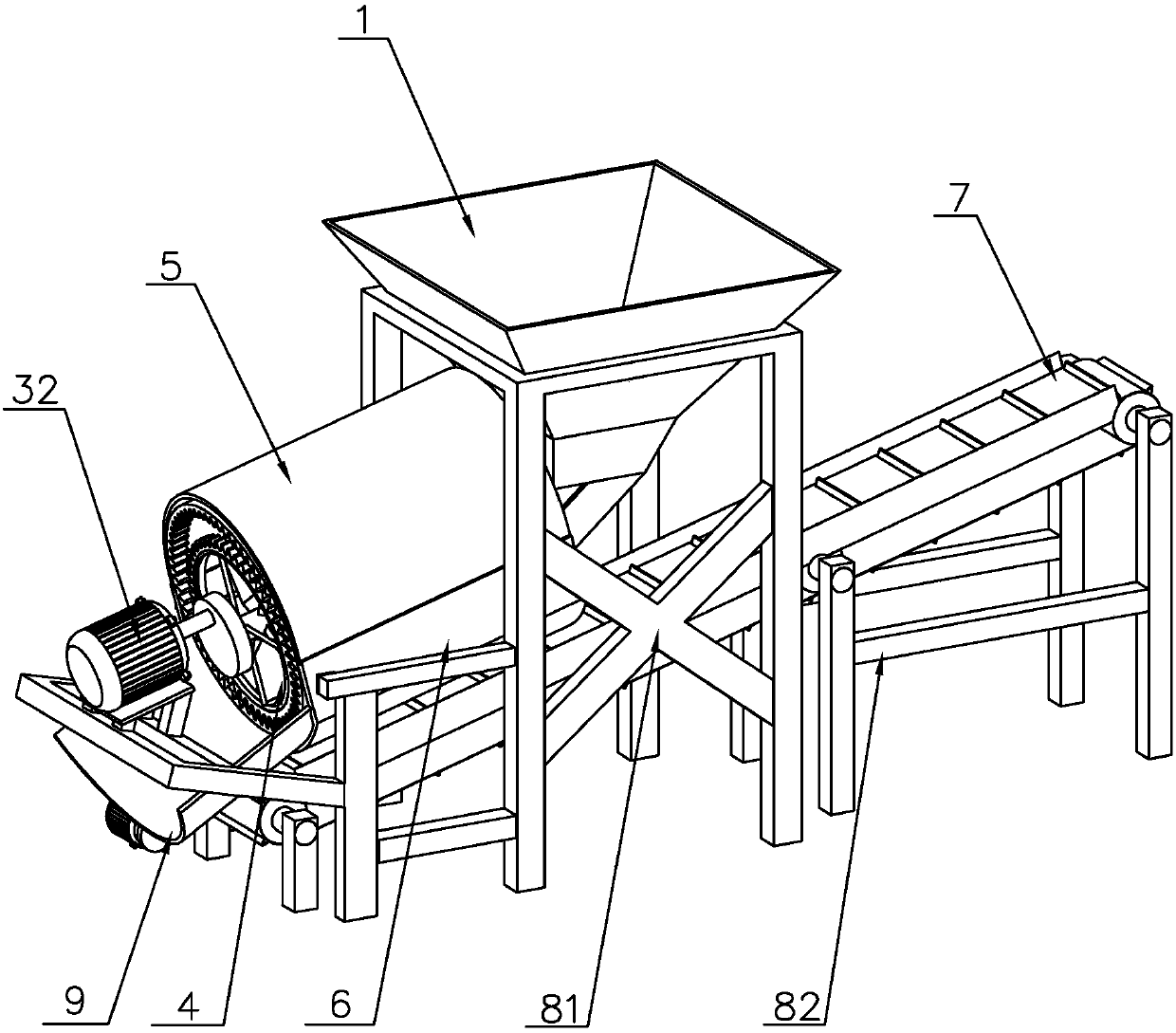

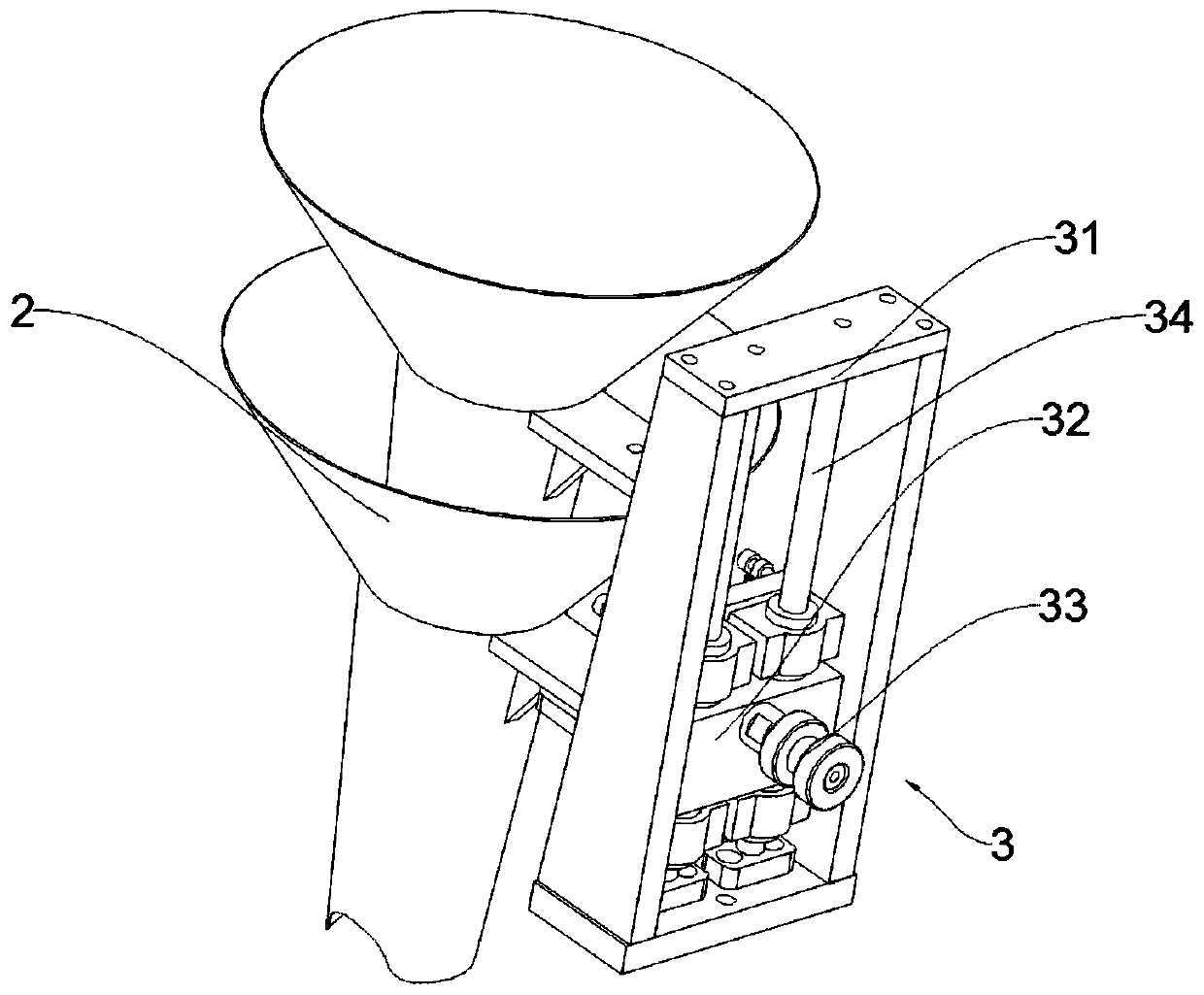

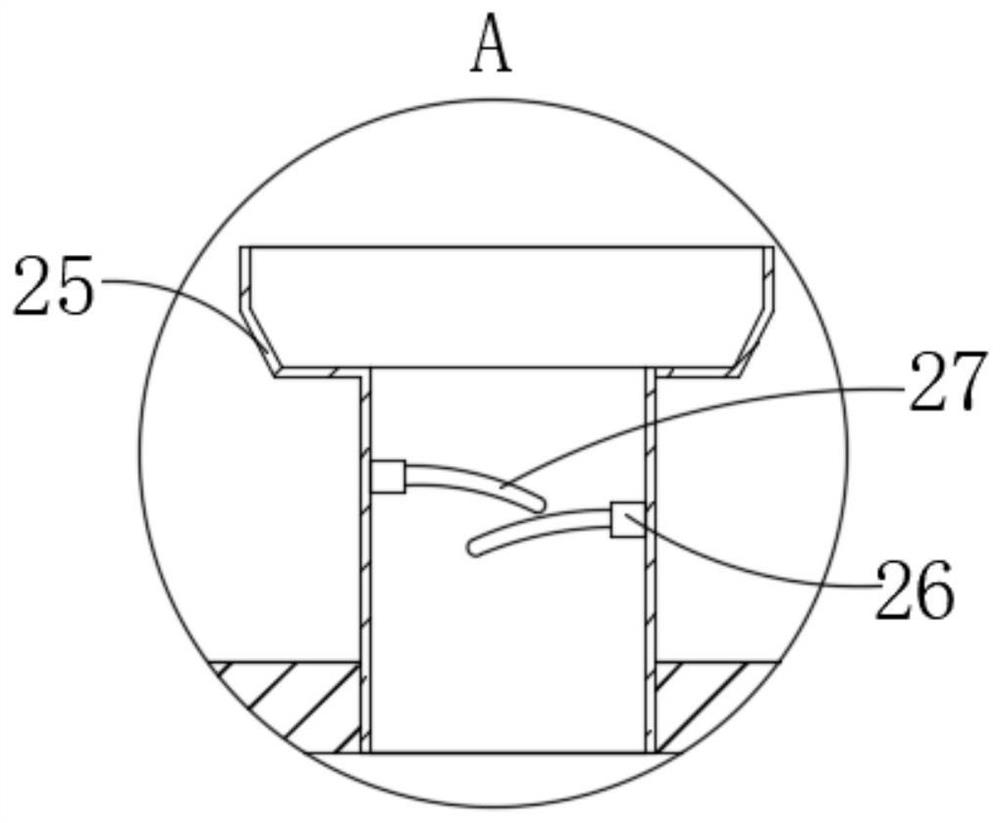

Powder feeding hopper

InactiveCN105151574APrevent blockingSimple structureRotary stirring mixersLarge containersPush pullEngineering

The invention aims to provide a powder feeding hopper. A feeding box is arranged above a feeding hopper body for feeding; a vibration screen is arranged for screening out large particles; a conveying pipe is arranged to convey powder into a machine; a rotating shaft is arranged to stir the powder in the feeding hopper body and the conveying pipe and can further move vertically through a push-pull air cylinder to rapidly eliminate the situation of material blocking; and in addition, a powder concentration sensor is arranged to sense dust concentration so as to control the rotating shaft to rotate and move vertically, and thus high intelligence is realized. The powder feeding hopper is simple in structure and convenient to operate, can well feed materials smoothly and is applicable to production.

Owner:WUHU JITUO RUBBER TECH

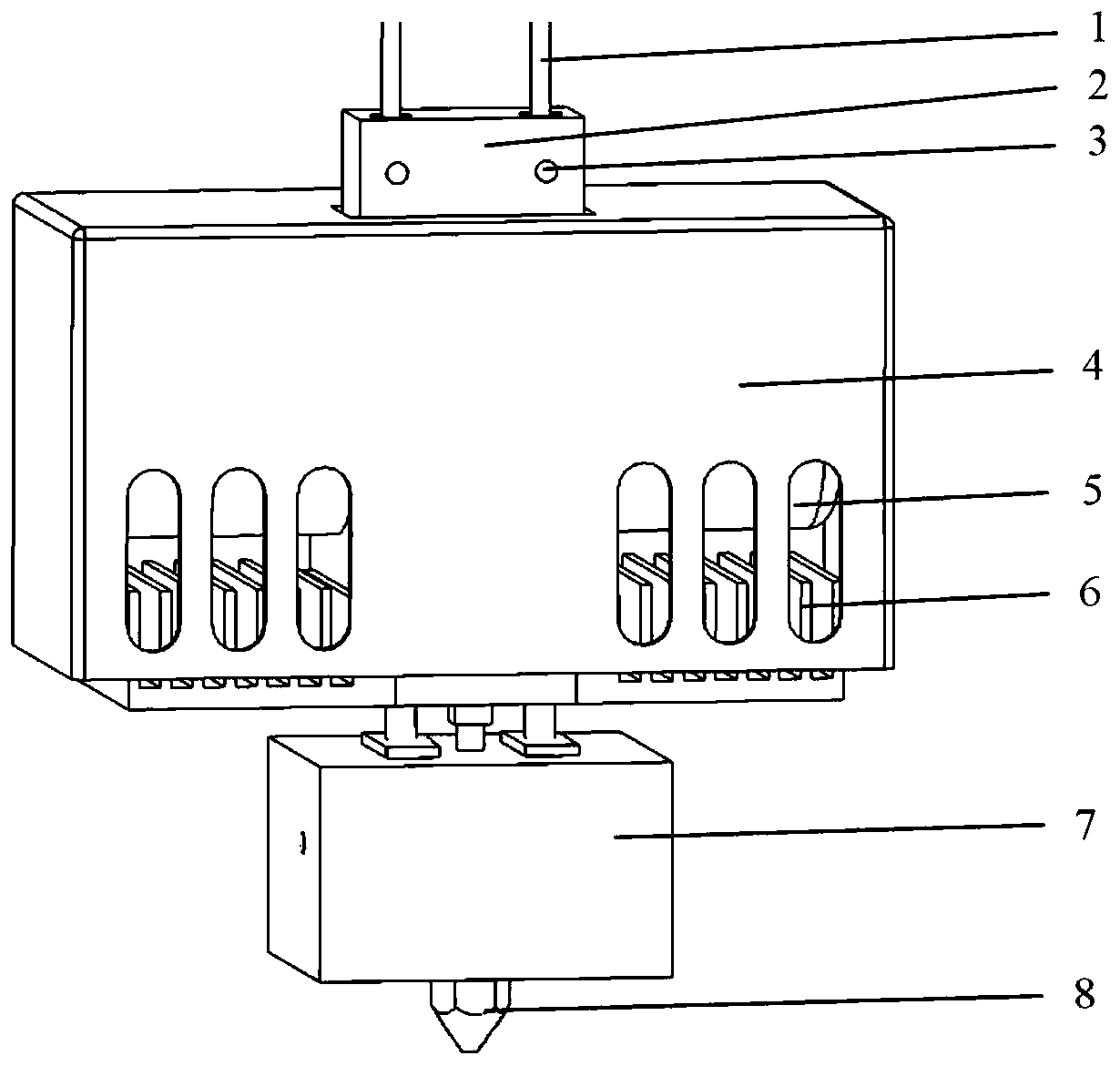

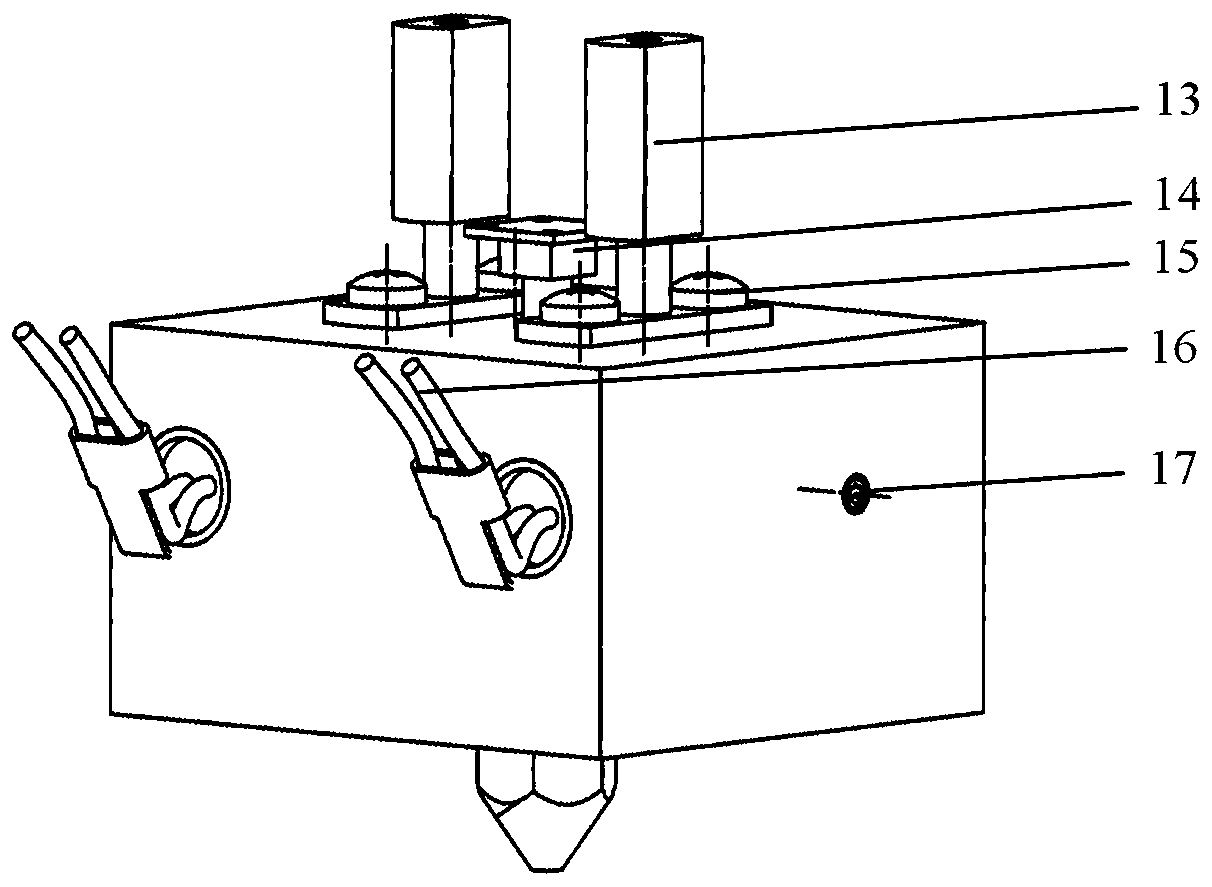

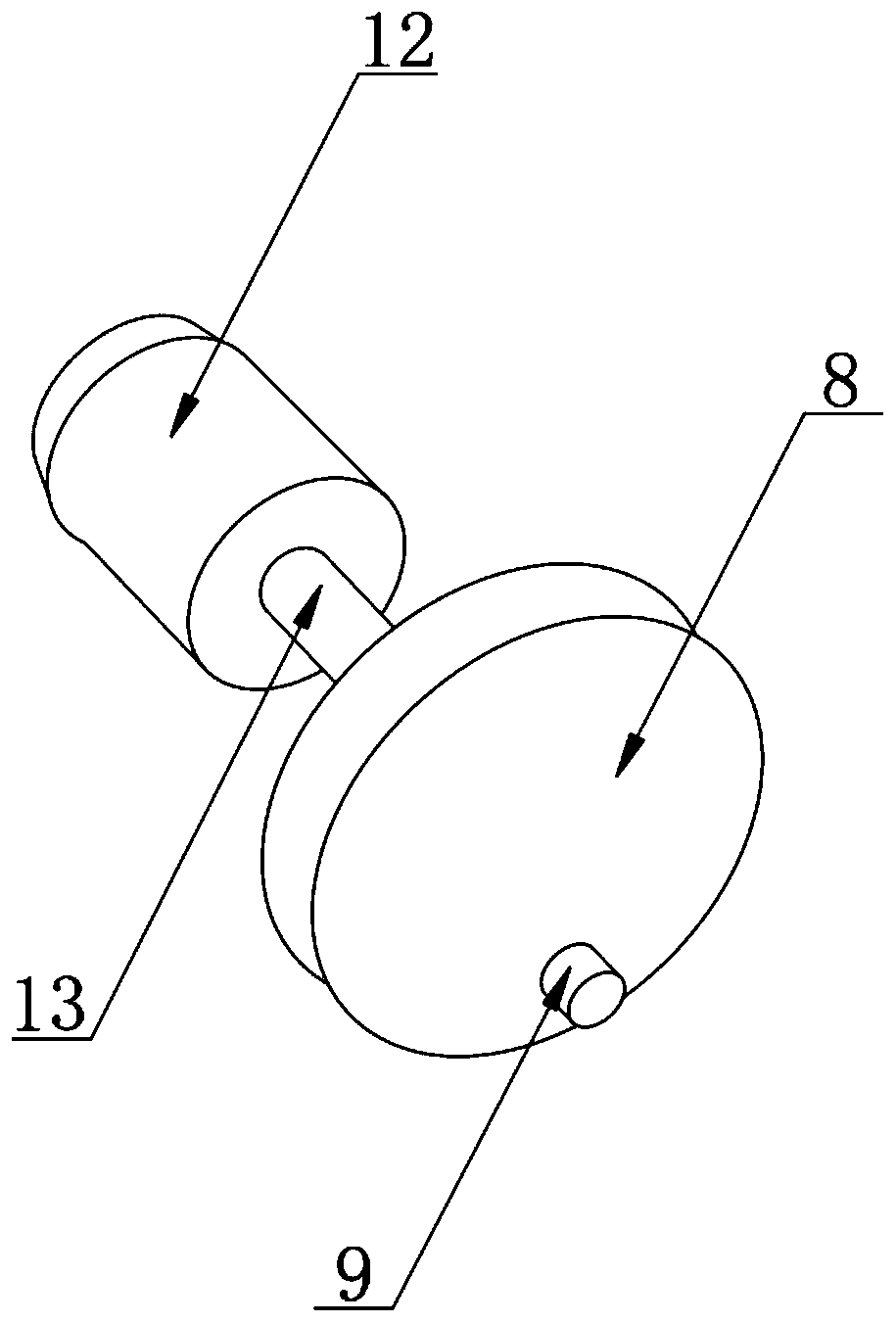

Color mixing 3D printing nozzle device based on FDM technology and discharging method thereof

InactiveCN110435145AIncrease profitEven color mixingManufacturing heating elements3D object support structuresYarnColor printing

The invention discloses a color mixing 3D printing nozzle device based on an FDM technology and a discharging method thereof. Color mixing printing can realize the color of a product and has more advantages compared with single-color printing. The color mixing 3D printing nozzle device based on the FDM technology comprises a feeding mechanism and a mixing heating mechanism. The feeding mechanism comprises a feeding shell, a feeding guide block and a feeding driving assembly. The feeding driving assembly comprises a feeding motor, a driving conveying wheel, an extruding conveying wheel, an extruding sliding block and an extruding spring. The mixing heating mechanism comprises a heating mixing block, a heating guide pipe, a color mixing stirrer, a nozzle, a cooling fin and a heating wire. The color mixing stirrer comprises a connecting shaft, a stirring fan and a stirring motor. According to the two-inlet-one-outlet type color mixing nozzle device, two thermoplastic wire yarns with different colors can be sent to a color mixing cavity of the heating mixing block for color mixing by controlling the mixing proportion of different color wire yarns or setting the change trend of the mixing proportion.

Owner:HANGZHOU DIANZI UNIV

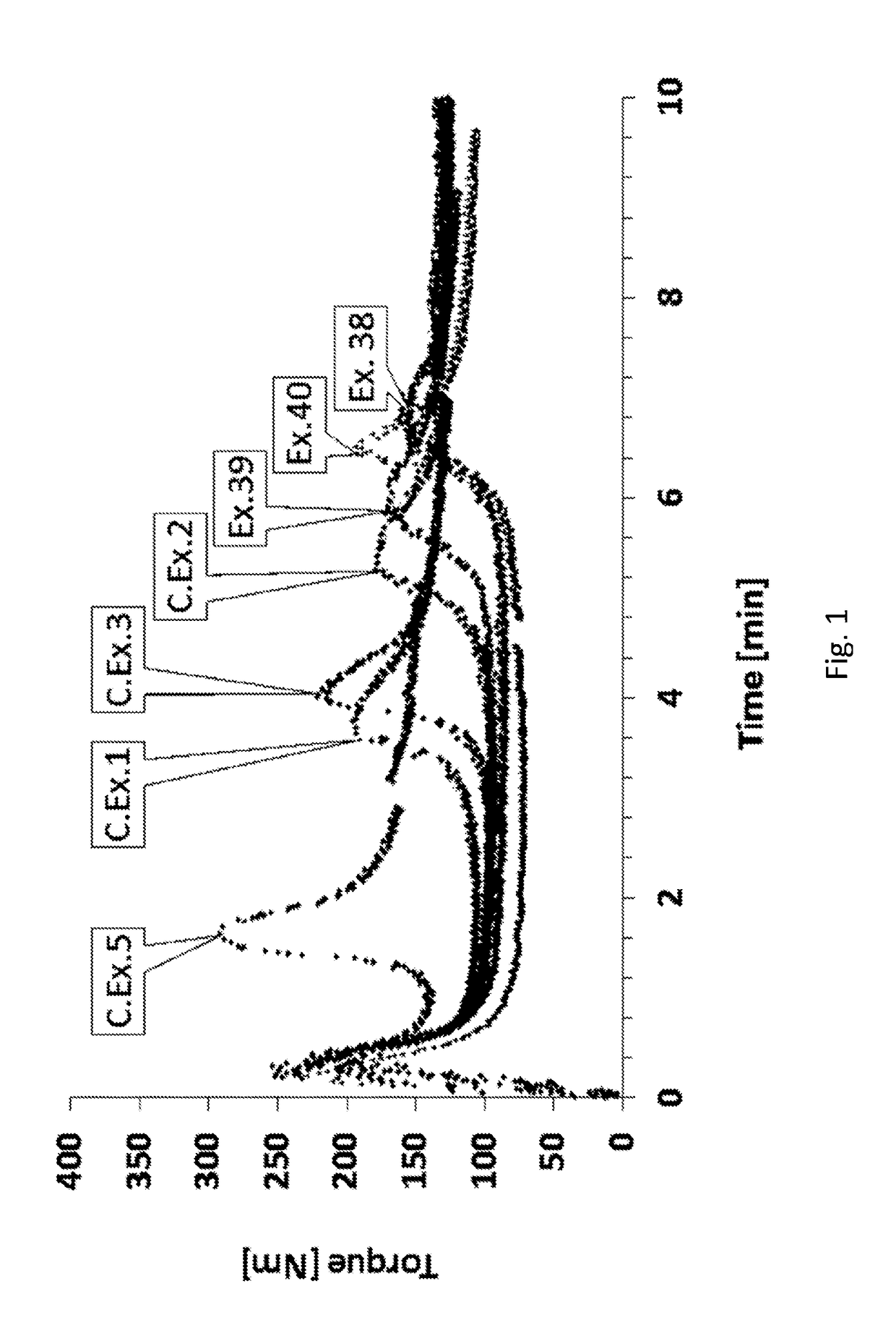

Use of a Sulphur or Phosphorous-Containing Polymer as a Processing Aid in a Polyvinyl Chloride Polymer Composition

The present invention relates to use of a sulphur or phosphorous-containing polymer as a processing aid in a polyvinyl chloride polymer composition.

Owner:SYNTHOMER UK

Road waste disposal area waste residue treatment device

PendingCN109847830ADamage reductionImprove practicalityUsing liquid separation agentGrain treatmentsSlagScrap

The invention relates to the technical field of solid waste treatment accessory devices, in particular to a road waste disposal area waste residue treatment device. The road waste disposal area wasteresidue treatment device can break large waste, damage to a smashing roller can be reduced, raised dust caused during waste slag guide-out operation can be treated, the pollution to the construction environment and nearby air environment can be avoided, practicability reliability is improved, meanwhile, blockage generated by waste slag in a work cavity can be effectively avoided, construction proceed is ensured, the device comprises a smashing box, two sets of smashing rollers, two driving motors, a loading hopper, a discharging opening, two first motors, a left breaking plate, a right breaking plate, four sets of left guide columns, four sets of left guide sleeves, four sets of right guide columns, four sets of right guide sleeves, a left driving rod, a right driving rod, a driving shaftand a rotating disc; the right end of the left breaking plate and the left end of the right breaking plate are provided with multiple sets of breaking teeth, and a grid plate, a conveying box, a conveying motor, an atomizing pump, a conveying device, an atomizing head, a communication pipe, a discharging pipe, a left guide conveying plate and a right guide conveying plate are further included.

Owner:山西省交通环境保护中心站(有限公司)

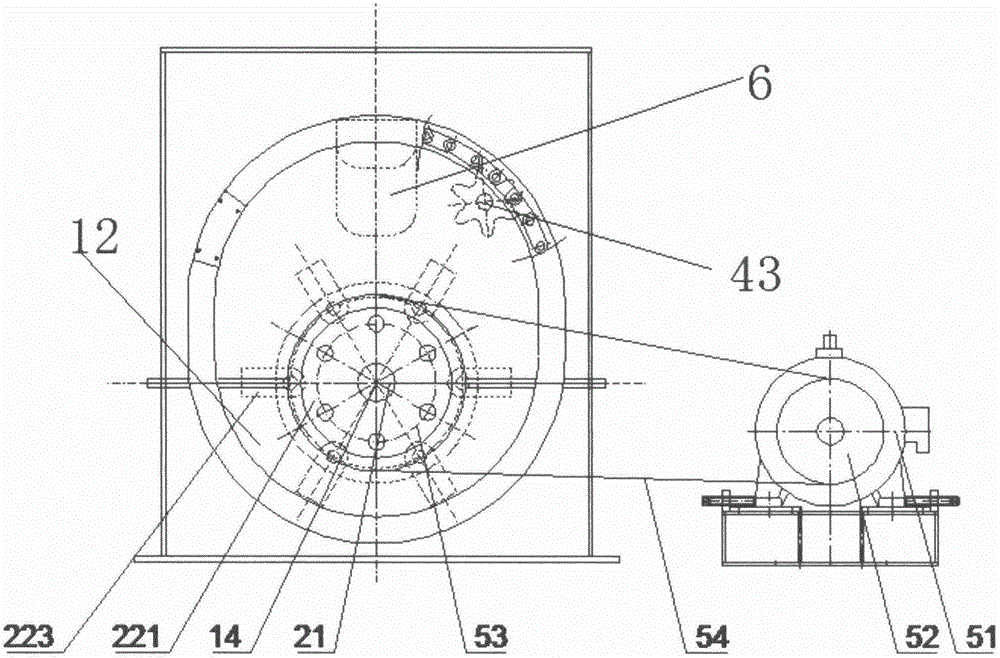

Roller sand screening machine for building

The invention discloses a drum sand screening machine for construction, which comprises a hopper, a turning arm, a motor I, a motor II, a motor III, a drum, a baffle I, a baffle II, a transmission device, Frame, transmission device frame, baffle IV, chain drive, gear III, gear IV, eccentric wheel; motor I is installed on the side below the hopper, and a turning arm is installed on the side of motor I, and motor I is installed on the bottom of the hopper On the outer wall, the motor I is connected with the turning arm to drive the turning arm to rotate in the hopper. The invention avoids the material blocking in the hopper, ensures the working efficiency of the drum sand screening machine, and prevents the materials moving with the drum from spilling outwards, reduces the manual workload in the later stage, and changes the drum The original motion trajectory realizes better separation of materials and increases the working efficiency of the drum sand screening machine.

Owner:邱善晓

Screen strip rotation hammer type crusher

The invention discloses a screen strip rotation hammer type crusher. The screen strip rotation hammer type crusher comprises a machine shell, a heavy hammer device, a screen strip device, a first drive device and a second drive device. The screen strip device comprises a screen strip assembly. The screen strip assembly is of an annular or U-shaped structure formed by multiple screen strips arranged in parallel. The screen strip assembly wraps the outer portion of the heavy hammer device. The first drive device and the screen strip assembly are connected to drive the screen strip assembly to rotate. In the screen strip rotation hammer type crusher, when sticky materials with the high water content are encountered and the materials are beaten to screen strips, some materials can be bonded to the surfaces of the screen strips, due to rotation of the screen strips, the materials bonded to the screen strips can disengage during screen strip moving or can be beaten away by materials when the angles of the screen strips change, finally the screen strips rotate to extrusion cavities and are extruded and ground through hammer heads to be cleaned thoroughly, and therefore material accumulation can be effectively avoided, and the blockage situation is eradicated.

Owner:陈爱广

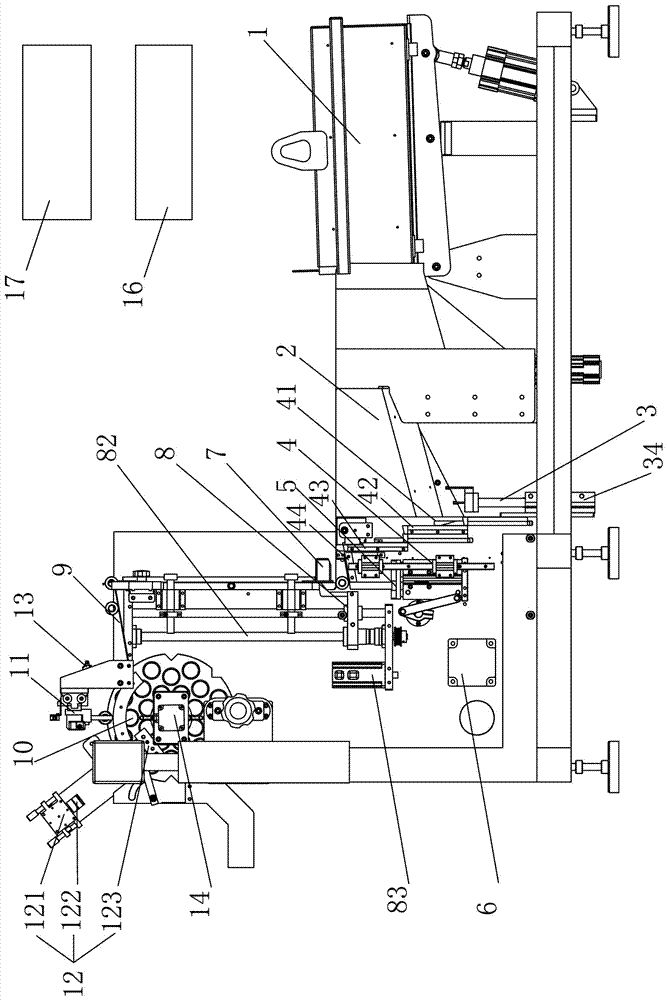

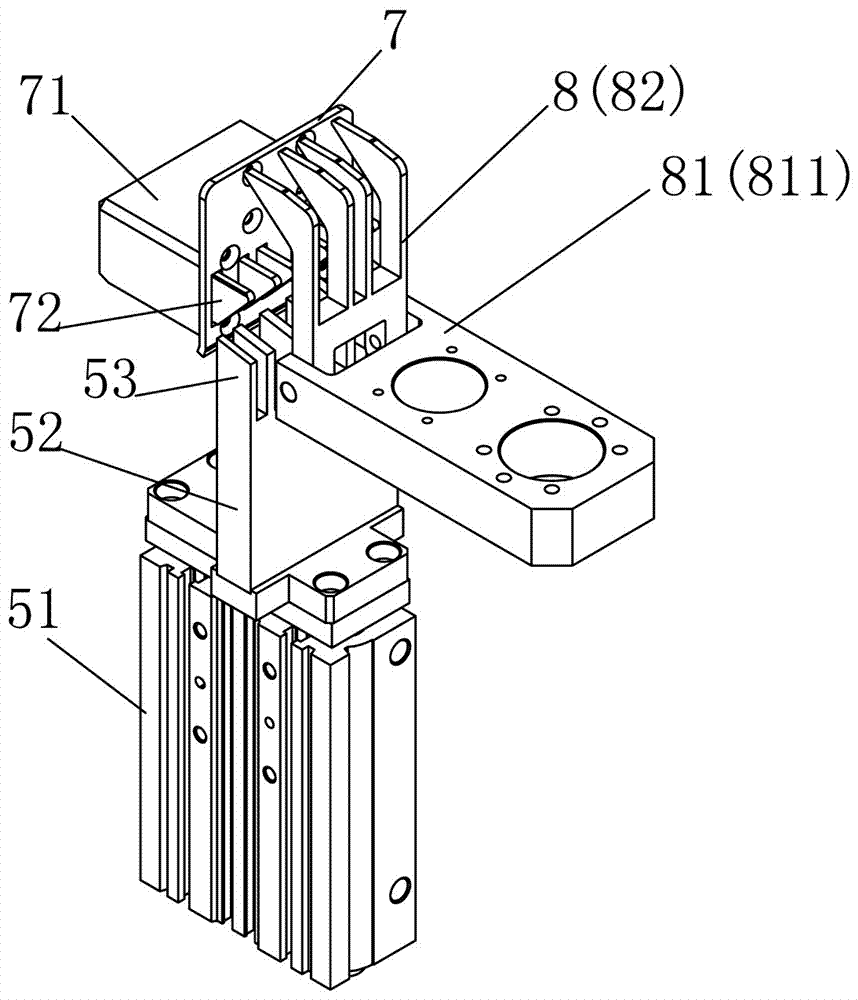

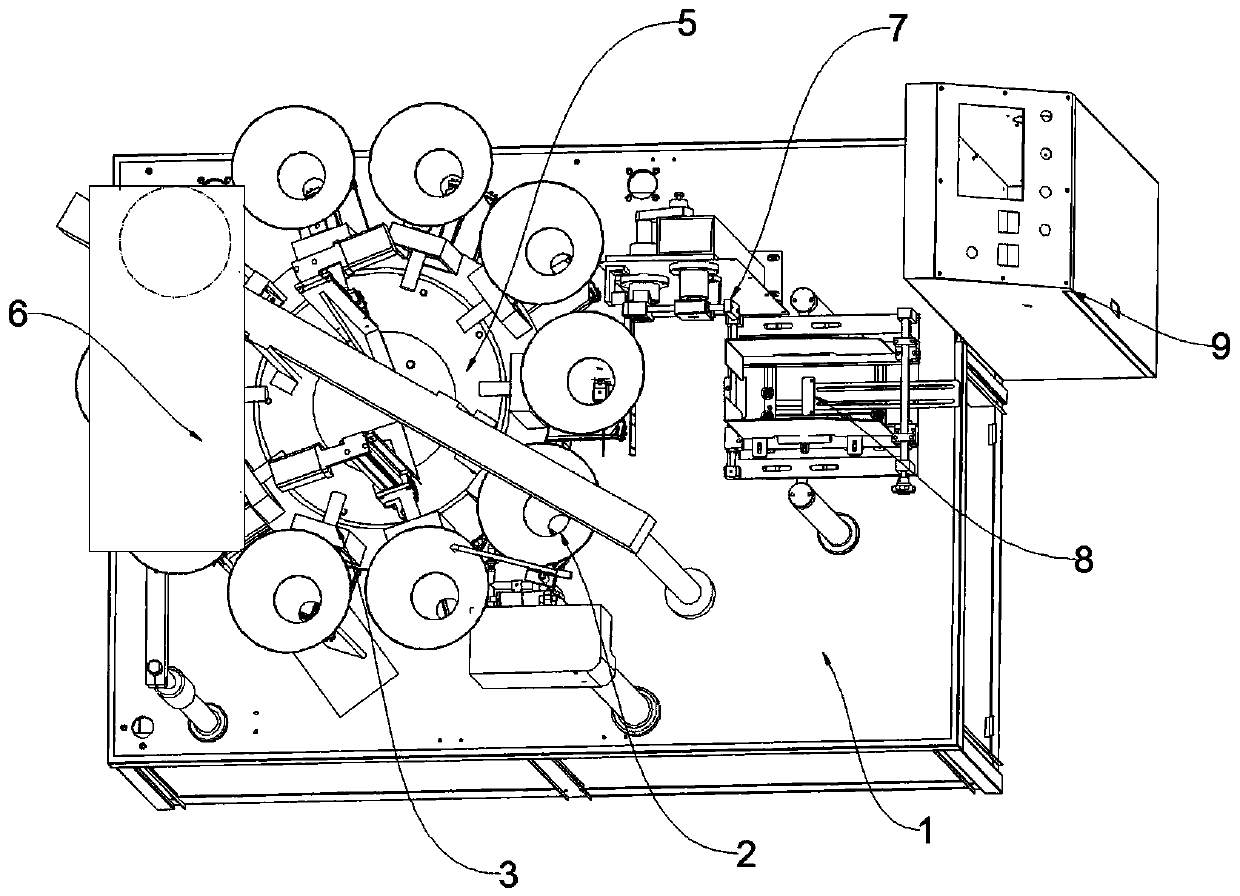

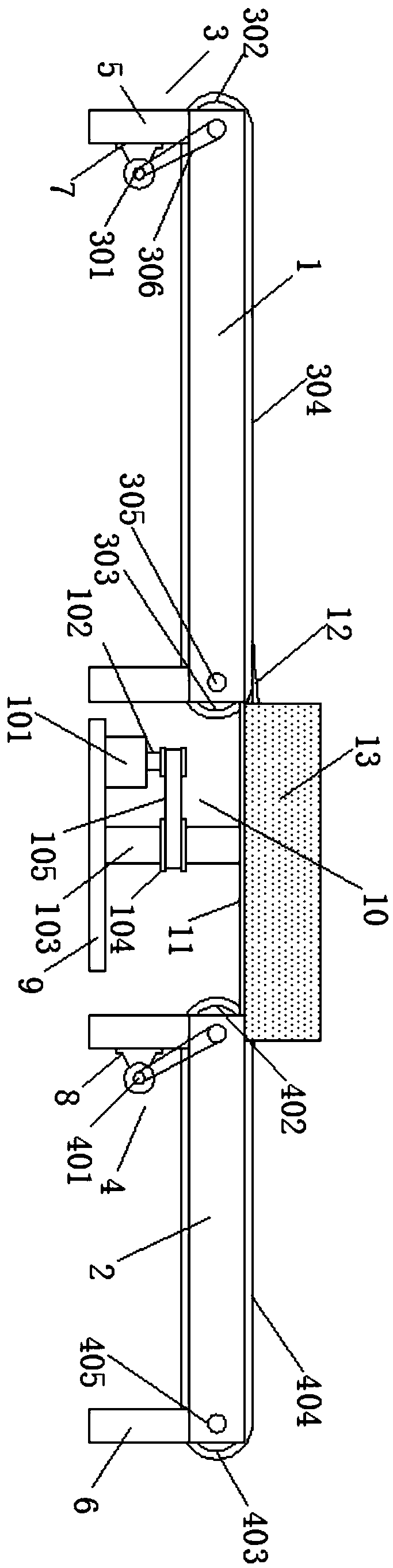

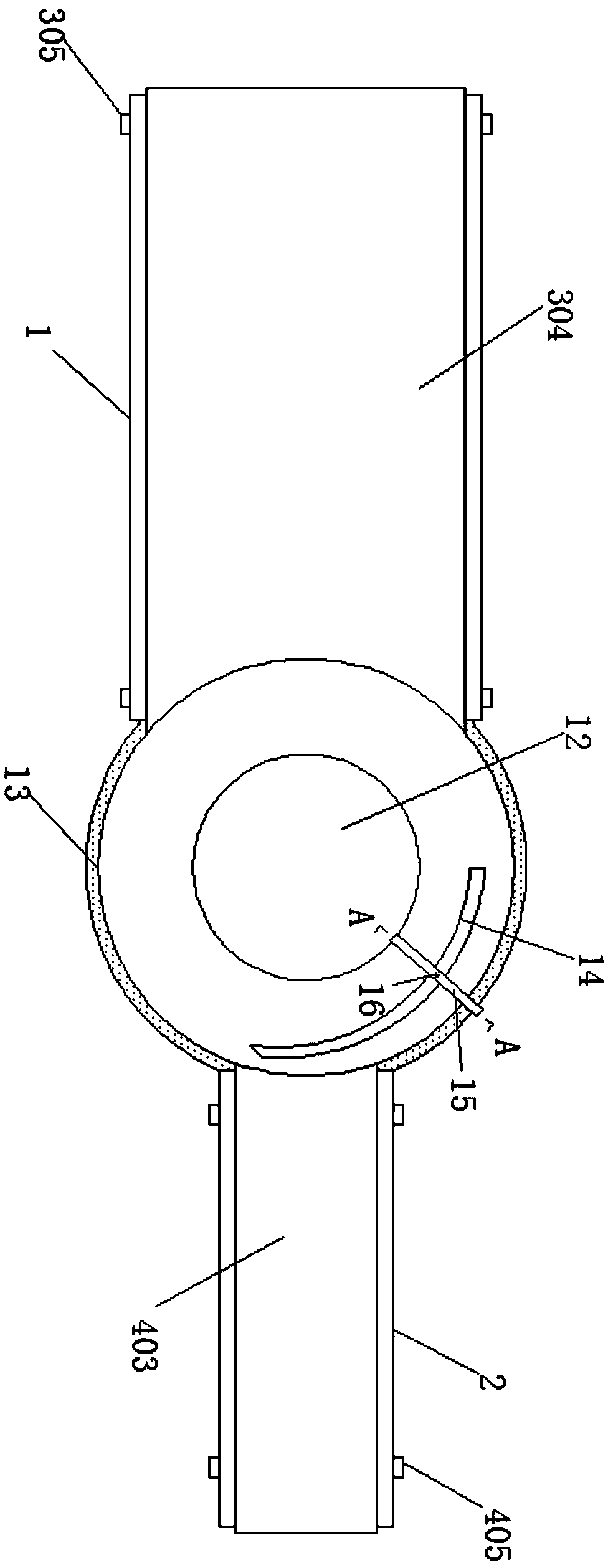

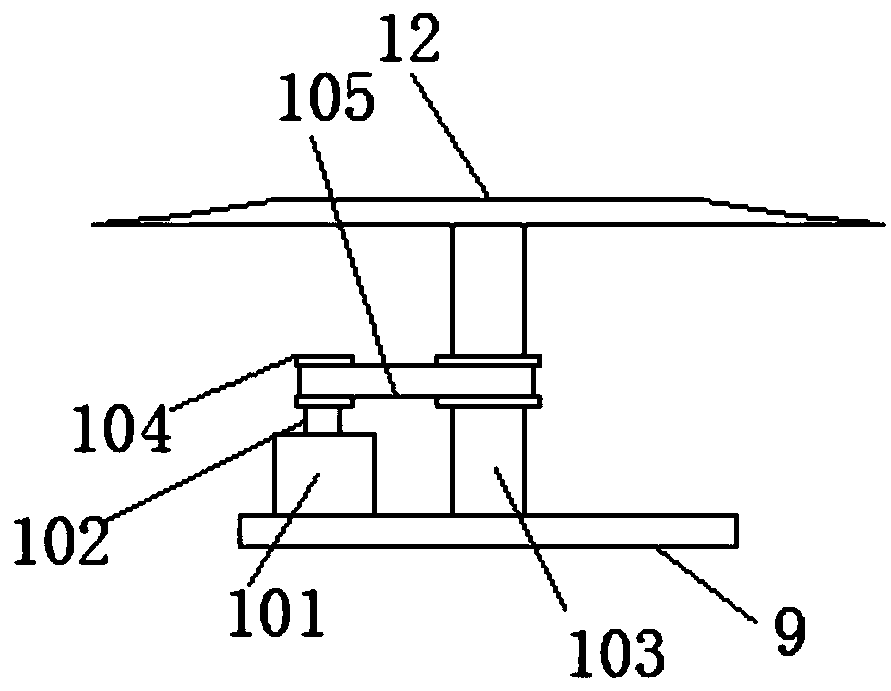

Industrial digital production on-line quality intelligent detection and sorting device

The invention discloses an industrial digital production on-line quality intelligent detection and sorting device. The industrial digital production on-line quality intelligent detection and sorting device comprises a pre guide device, a multi-stage push plate feeding device, a jacking device, a ball screw rod lifting feeding device with a self-resetting isolation lifting function, an indexing rotary table, a grating ruler measurement device located on the preset position of the indexing rotary table, and an optical image appearance detection and recognition device; and the pre guide device, the multi-stage push plate feeding device, the jacking device, the ball screw rod lifting feeding device, the indexing rotary table, the grating ruler measurement device, and the optical image appearance detection and recognition device are arranged orderly. The pre guide device guides messy pin shaft type products and ensures the movement direction to be suitable for the multi-stage push plate feeding device driven by a stepping motor, the pin shaft type products sent by the push plate feeding device is in the induction of a photoelectric sensor, and materials are periodically sent to the ball screw rod lifting feeding device through the jacking device; and the ball screw rod lifting feeding device sends the materials to the grating ruler measurement device of the indexing rotary table and the optical image appearance detection and recognition device to detect and analyze, and an on-line quality analysis and detection system completes the intelligent detection and analysis of the pin shaft type products according to the measurement and the identification data obtained.

Owner:长沙麦睛科技股份有限公司

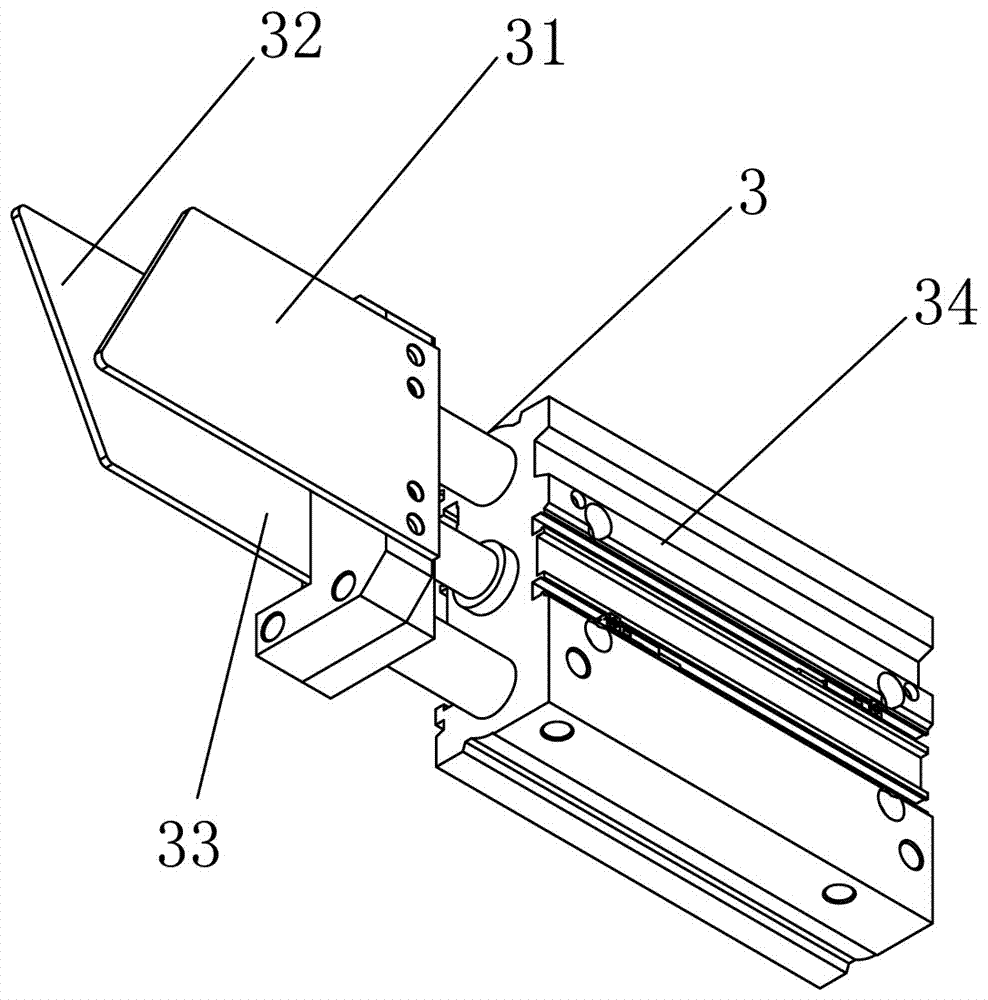

Feeding device

InactiveCN103482260AImprove stabilityImprove reliabilityLarge containersEngineeringMechanical engineering

The invention discloses a feeding device. The feeding device comprises a hopper and a feeding slot arranged at the discharging port of the hopper, a turning board and a driving device of the turning board, wherein the turning board and the driving device of the turning board are arranged on one side of the inclined board of the hopper and at the discharging port of the hopper. The turning board is hinged to the inclined board. According to the feeding device, by arranging the turning board on the inclined board of the hopper, when sliding down inside the hopper, bars can be turned over and settled by the turning board, so that the bars can drop inside the feeding slot smoothly, the problem that bar blocking occurs at the outlet of the feeding slot can be avoided and the stability and reliability of hopper feeding can be improved, and further tool processing precision can be enhanced.

Owner:SHENZHEN JINZHOU PRECISION TECH

Pulverizer

The invention discloses a pulverizer which comprises a rack. The rack is movably provided with a spindle driven by a revolution power device; the spindle is sleeved with two revolution disks; a plurality of grinding devices are arranged between the two revolution disks and are peripherally and uniformly distributed; the spindle is sleeved with a material divider communicated with the feed ends of the grinding devices; the material divider is communicated with a feed hopper arranged on the rack; the rack is provided with a driving gear driven by a rotation power device; the discharge end of each grinding device is provided with a driven gear meshed with the driving gear; each grinding device comprises a grinding cylinder body; the side of each grinding cylinder body, which is close to the revolution power device, is provided with a feeding device; the end part of each feeding device is inserted in the corresponding revolution disk and is communicated with the material divider; the other side of each grinding cylinder body is provided with a discharge device; and the discharge devices on the grinding cylinder bodies on the spindle are sleeved with two discharge cover plates; and discharge bins are arranged outside the discharge cover plates on the rack. The invention provides the pulverizer with high working efficiency and low energy consumption.

Owner:JIANGSU PUGE MACHINERY

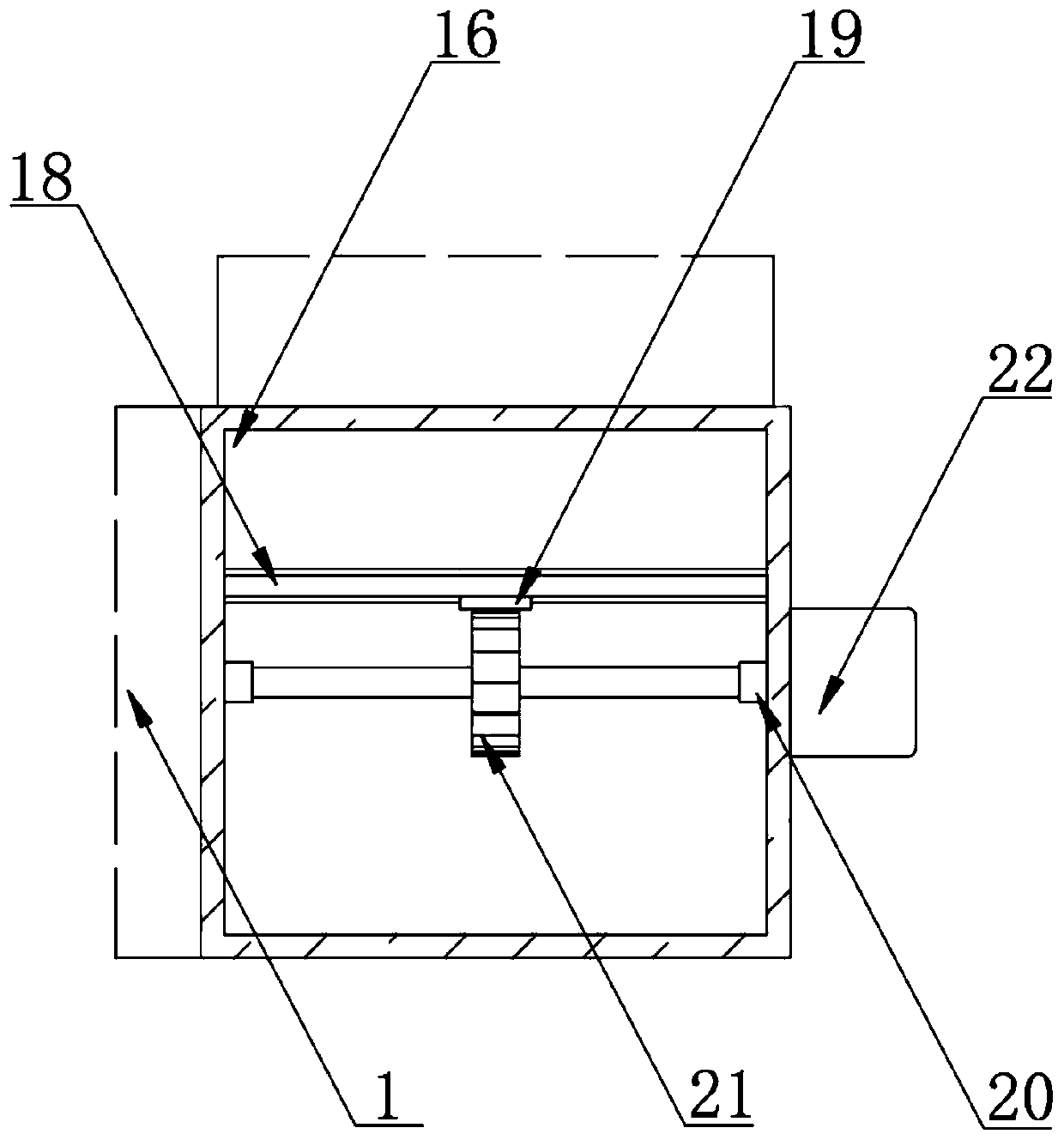

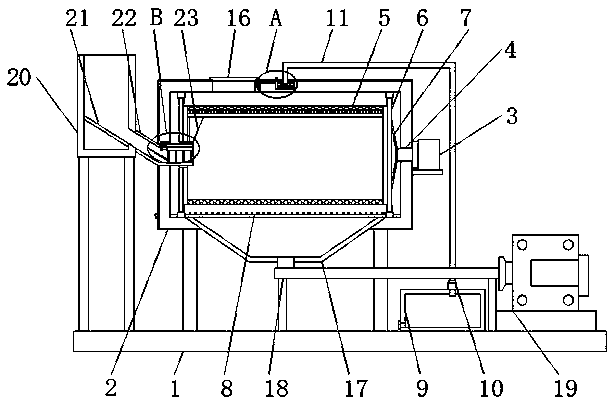

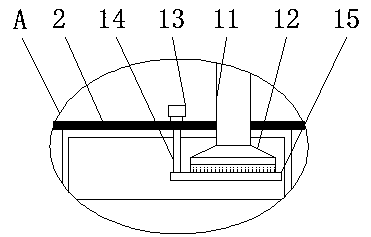

3D printer with quick heating and anti-blocking functions

InactiveCN108357091AFast central heatingEasy to useManufacturing heating elementsManufacturing recyclingRotational axisEngineering

The invention discloses a 3D printer with quick heating and anti-blocking functions and relates to the technical field of 3D printing equipment The 3D printer comprises a baseplate, wherein a machinecase is fixedly connected with the top of the baseplate; a transmission case is fixedly connected with the top of the baseplate and positioned on one side of the machine case; a heating case is fixedly connected with the top of the transmission case; a rotating shaft is rotationally connected with the bottom of the inner wall of the transmission case; and the top end of the rotating shaft sequentially penetrates through the transmission case and the heating case as well as extends into the heating tank. By adoption of the 3D printer with the quick heating and anti-blocking functions, a raw material can be quickly heated and molten in a centralized manner, and then the molten raw material can be pumped into a printing head for printing; when people have no need to use the 3D printer, a material pump can be enabled to perform reverse operation; and accordingly, a molten liquid remaining inside the printing head and a heat preservation hose can be pumped back to the heating case, and thecircumstance that the printing head is blocked can be well avoided.

Owner:武汉华成知识产权代理服务有限责任公司

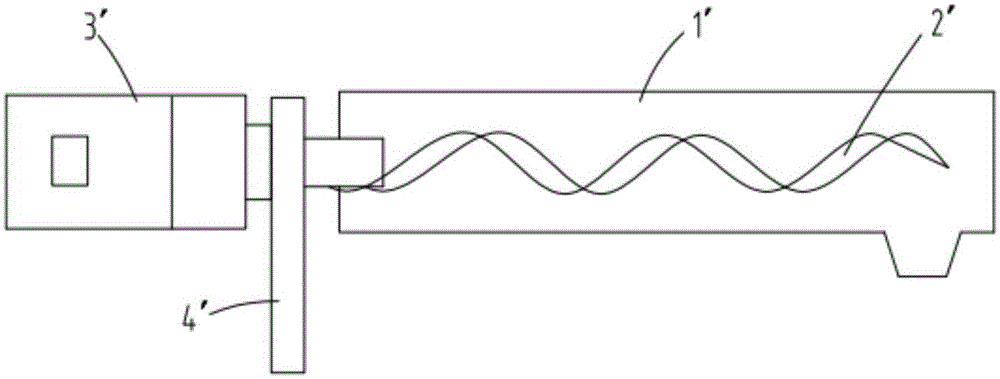

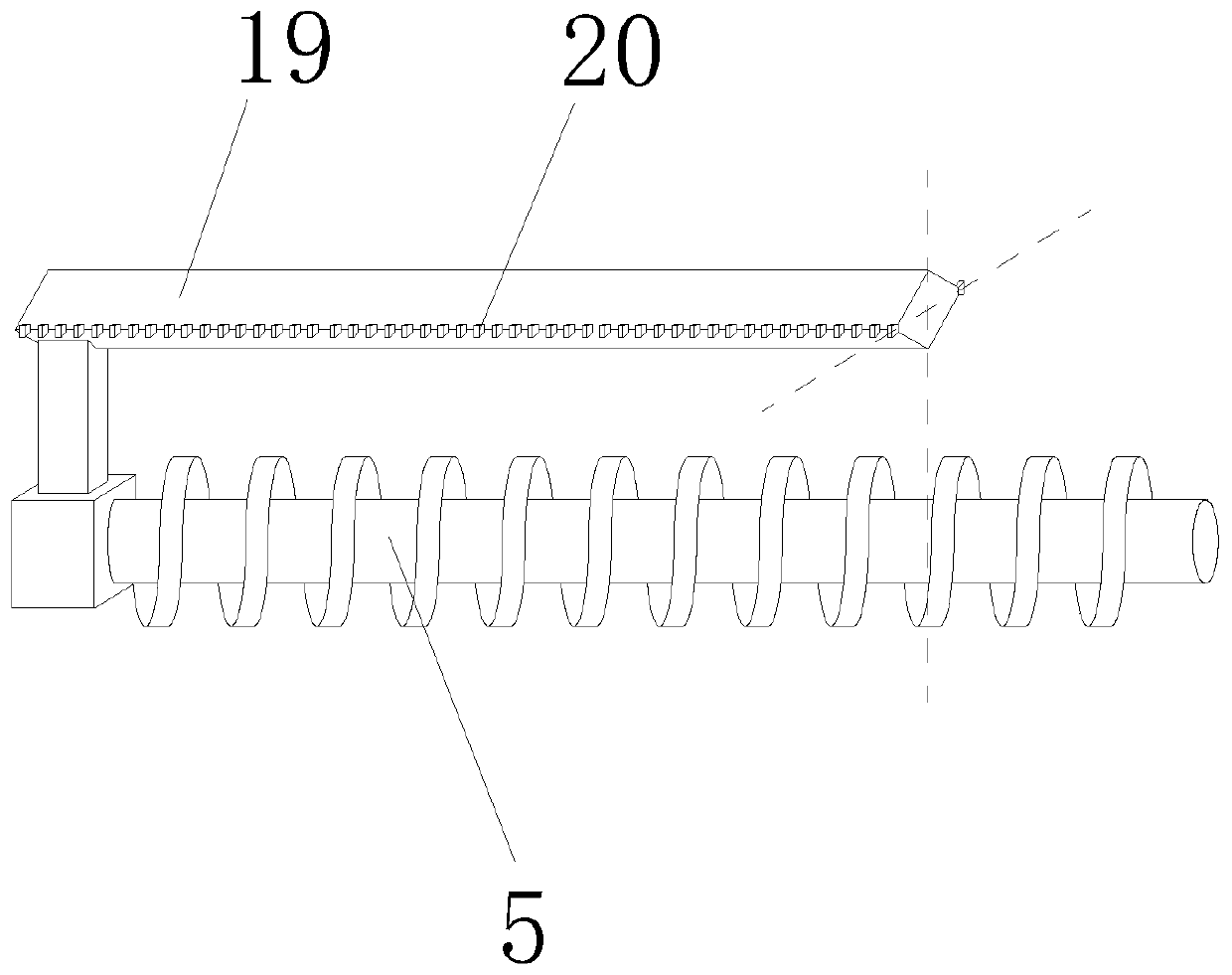

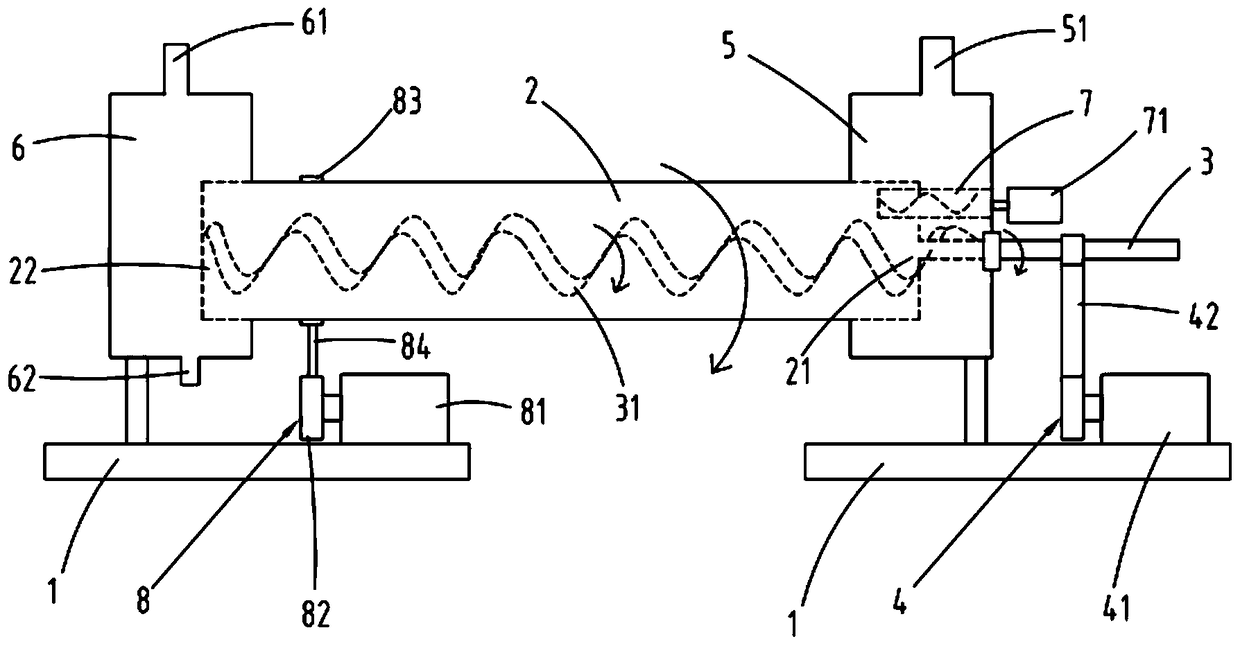

Self-cleaning coke hang prevention mechanism

ActiveCN105112075AAvoid wear and tearPrevent blockingBiofuelsSpecial form destructive distillationEngineeringScrew conveyor

The invention relates to a self-cleaning coke hang prevention mechanism. The self-cleaning coke hang prevention mechanism comprises a support, a charring cylinder, a shaftless screw, a driving apparatus, a feed inlet tank and a feed outlet tank, wherein the feed inlet tank and the feed outlet tank are mounted on the support; the shaftless screw is transversely arranged in the charring cylinder, one end of the shaftless screw is connected with the driving apparatus, and the other end of the shaftless screw floats in the charring cylinder; the charring cylinder is in rotary sealing connection with the feed inlet tank and the feed outlet tank, and the feed inlet end and the feed outlet end of the charring cylinder respectively extend into the inside of the feed inlet tank and the feed outlet tank. A feed inlet is formed in the upper part of the feed inlet, and a screw conveyor mechanism is arranged below the feed inlet; a fume outlet is formed in the top of the feed outlet tank, and a feed outlet is formed in the bottom; a transmission apparatus is further arranged on the support, and the transmission apparatus drives the charring cylinder to rotate. According to the mechanism provided by the invention, the transmission apparatus drives the charring cylinder to rotate to a certain angle; by means of extrusion and friction with the inner wall of the charring wall in the material pushing process, hanging coke accumulated on the inner wall of the charring cylinder is automatically removed, so that the occurrence of material blocking is prevented, and long-term wear for local area of the charring cylinder is avoided.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

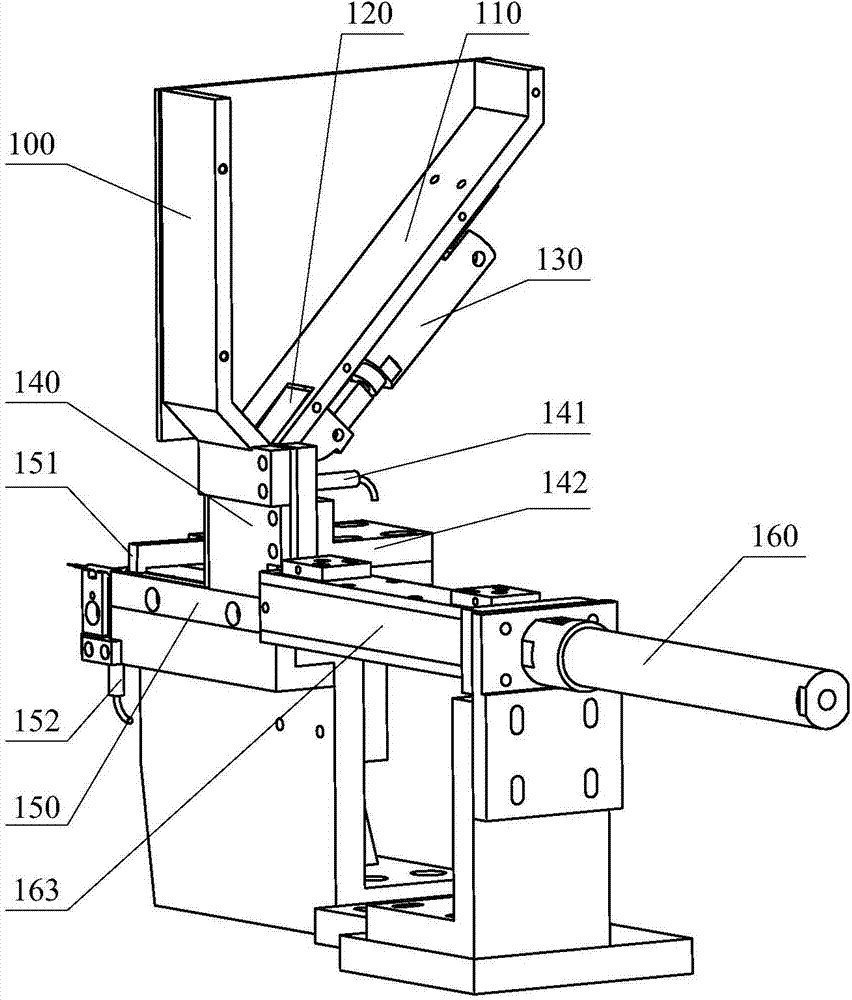

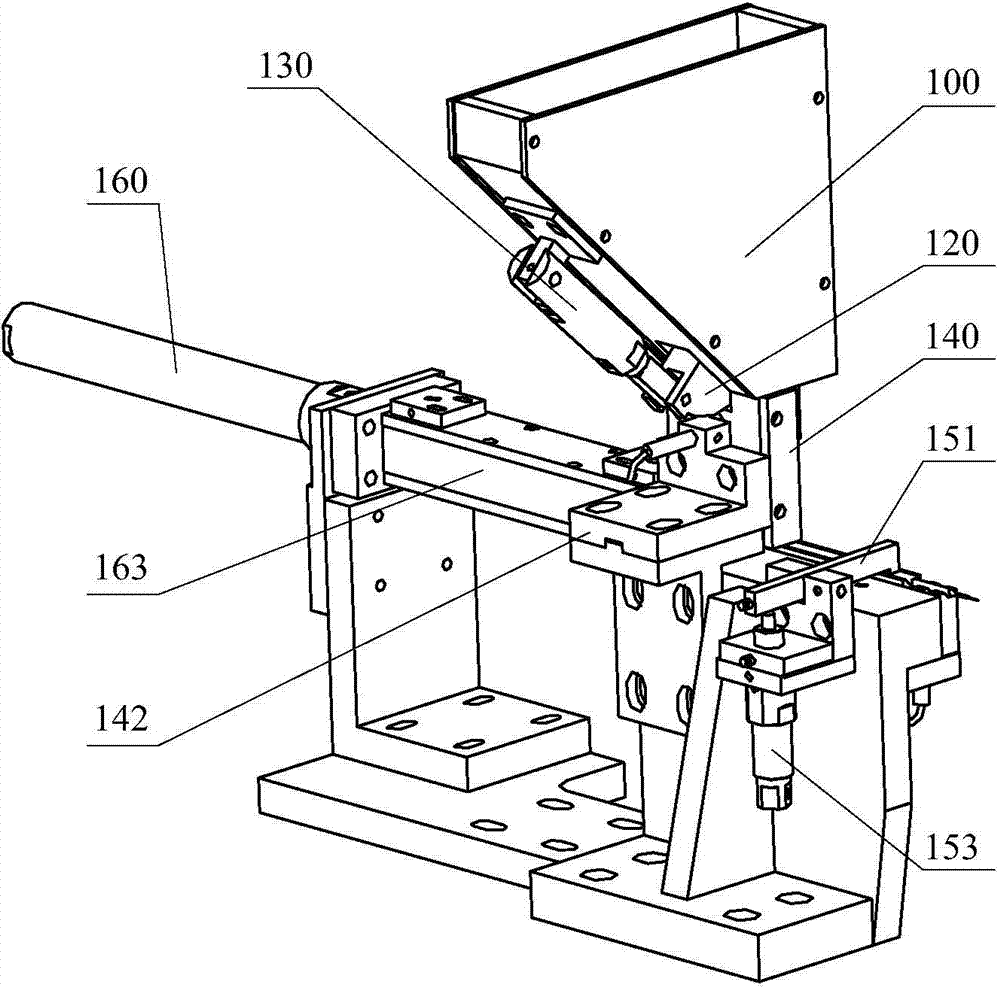

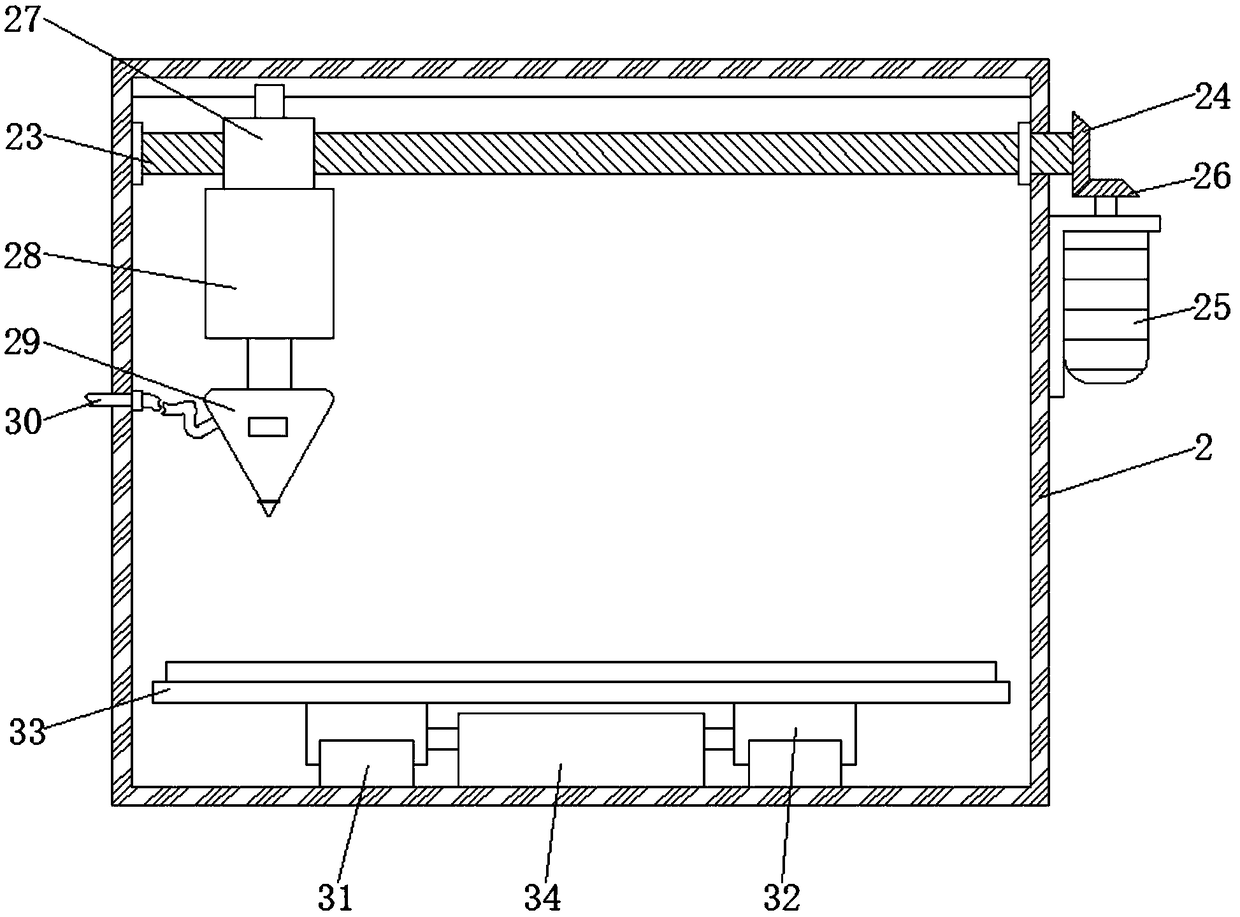

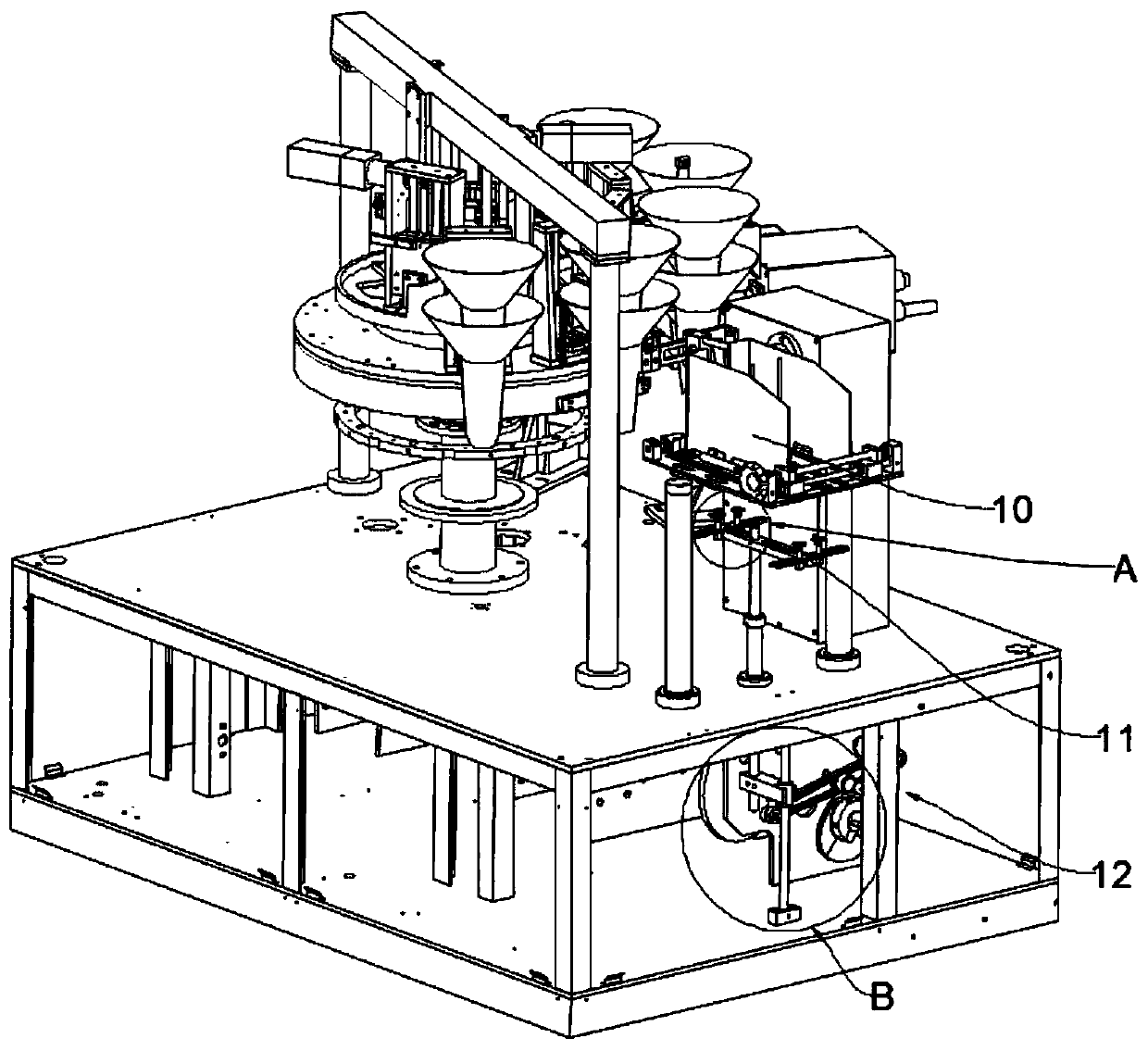

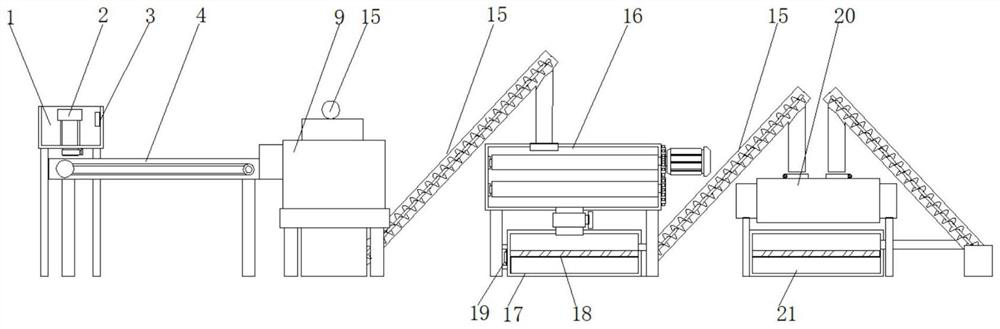

Food packaging method and equipment

InactiveCN111252281AAvoid blockingPrevent blockingSolid materialPackaging foodstuffsElectric machinerySlide plate

The invention discloses a food packaging method. The food packaging method includes the steps that packaging bags are clamped through a fixture, the packaging bags are loaded with materials through afunnel of a material falling station; the loaded packaging bags are subjected to material poking through a material poking mechanism, the material poking mechanism includes a frame body, a telescopicrod and a material poking head, the telescopic rod is fixedly installed on the frame body, the telescopic rod drives the material poking head to move up and down, and the material poking head extendsinto the packaging bags after penetrating through the funnel; while the materials are poked, the packaging bags are subjected to material vibrating through a material vibrating mechanism, the materialvibrating mechanism includes a housing with a cavity, a motor is fixedly arranged inside the cavity of the housing, a cam is fixedly installed on the shaft part of the motor, the cam is in contact with a sliding plate, the sliding plate is in sliding connection with the inner wall of the cavity of the housing, a slide bar is vertically arranged on the upper surface of the sliding plate, and a material receiving plate is fixedly arranged at the top of the slide bar; and openings of the loaded packaging bags are sealed. The functions are various, and the situation of material blockage of the packaging bags does not occur during material filling, so that the yield of packaged food is improved.

Owner:安徽溜溜梅研究院有限公司

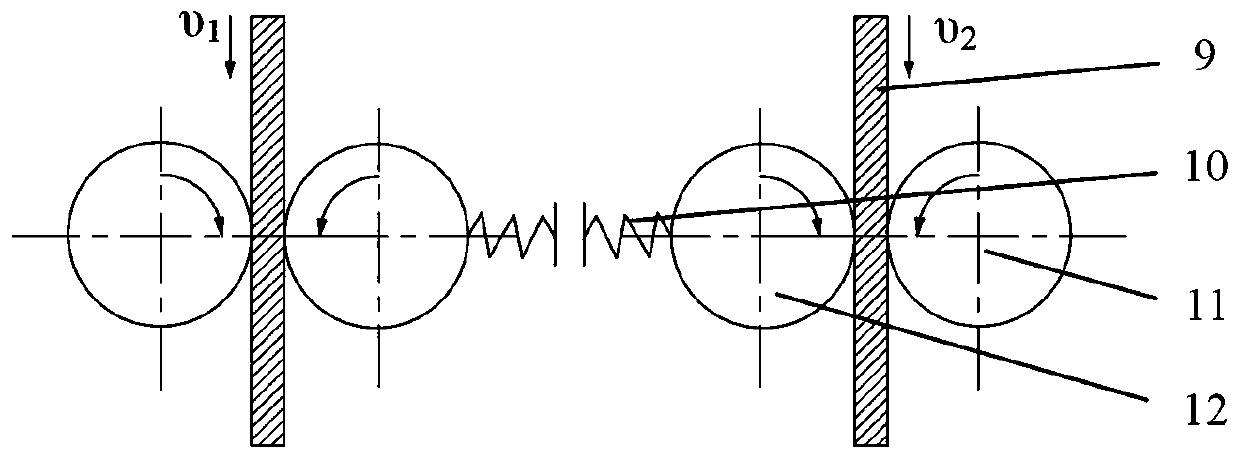

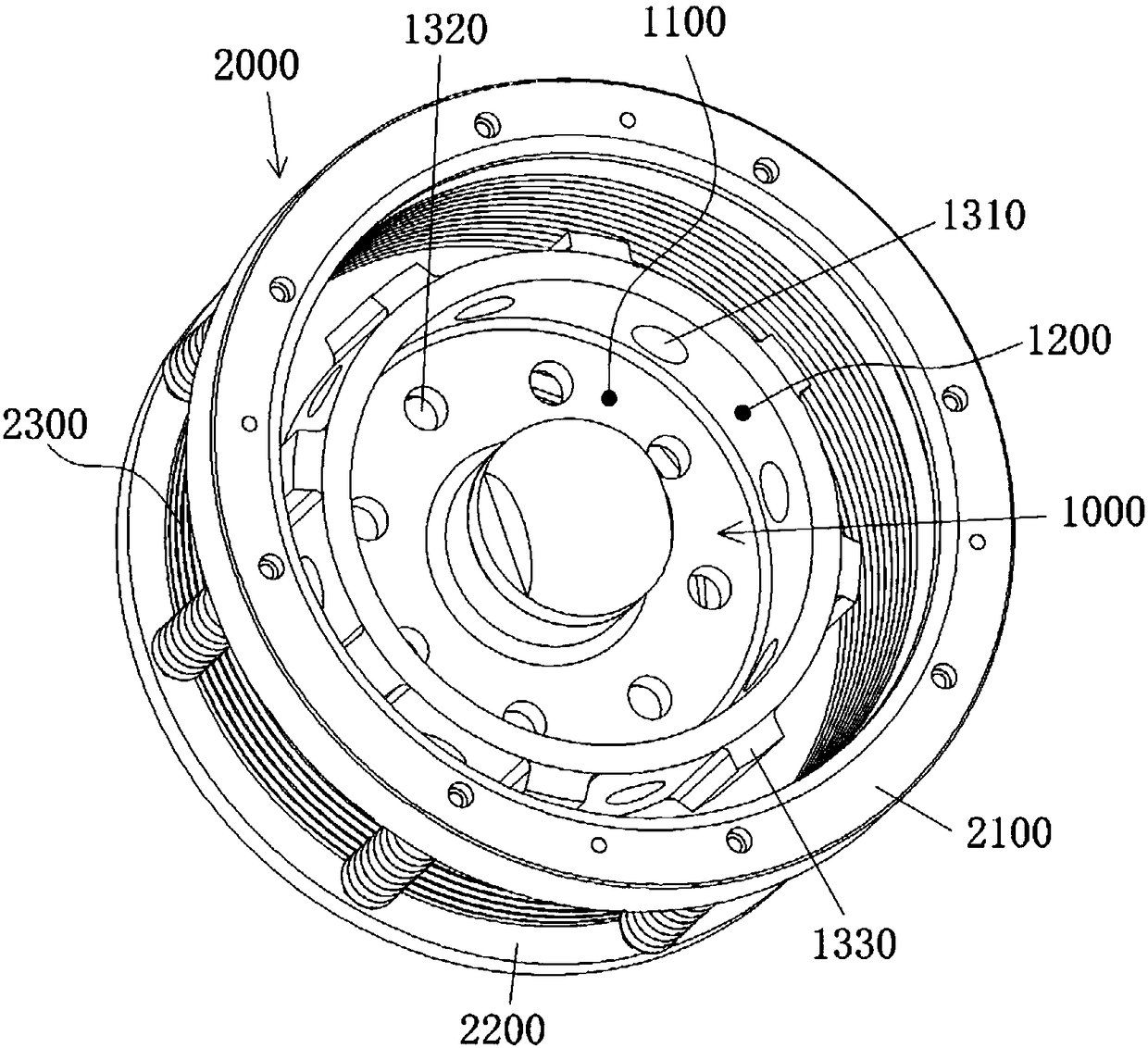

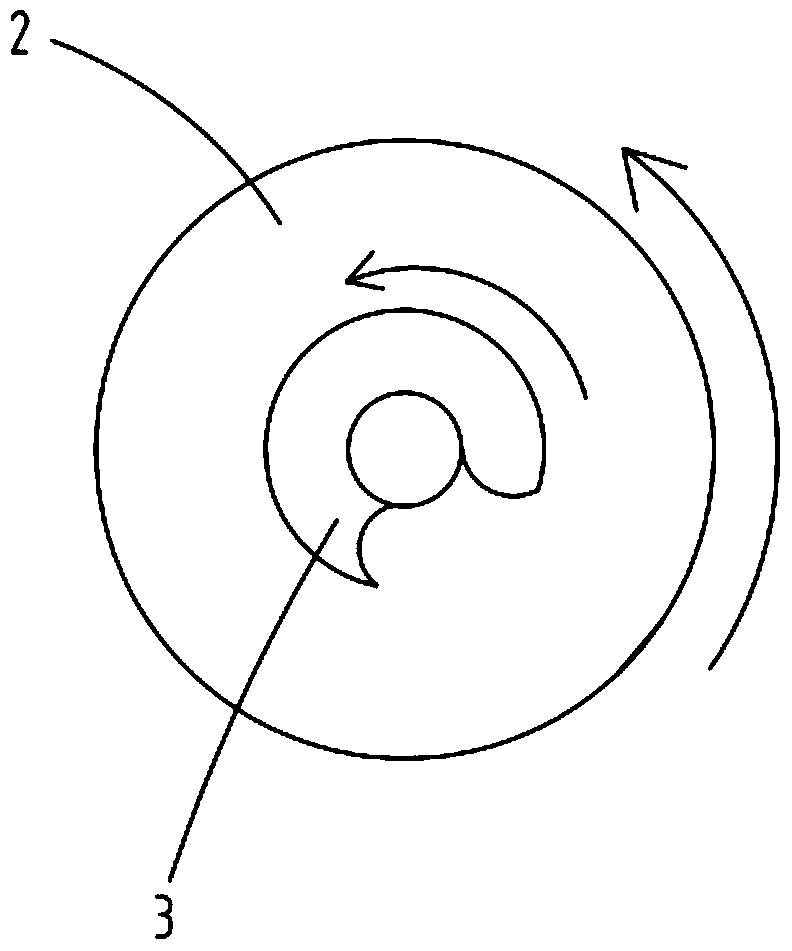

Grinding separating device and sand mill

The invention discloses a grinding separating device and a sand mill. The grinding separating device comprises a grinding disc and a separating assembly, wherein the separating assembly comprises a first mounting seat, a second mounting seat and a separating part; the first mounting seat and the second mounting seat are in parallel and are fixedly connected; the separating part consists of a plurality of separating rings with collinear axes, and the separating rings are all located between the first mounting seat and the second mounting seat; the separating rings are of equidistant distribution, and discharging gaps are formed among adjacent separating rings and can only enable finished products to pass through; the grinding disc is located in the separating part and is fixed onto a rotating shaft; a rotation axis of the grinding disc is collinear with those of the separating rings. According to the grinding separating device, the grinding efficiency is high, the obtained finished granules are uniform, and the condition of material plugging does not occur.

Owner:ZHAOQING GELANG AUTOMATION SCI & TECH

Garbage treatment equipment and garbage treatment system

PendingCN111495931AImplement classificationImprove processing efficiencySievingScreeningComputer hardwareElectric machinery

The invention discloses garbage treatment equipment and a garbage treatment system. The garbage treatment equipment comprises a workbench, wherein seat legs are fixedly connected to the two sides of the bottom of the workbench, a top seat is fixedly connected to the top of the workbench, a sliding groove is formed inside the top seat in a penetrating mode, a sliding plate is slidably connected tothe inner surface of the sliding groove, and garbage storage boxes are fixedly connected to the two sides of the top of the workbench. The invention relates to the technical field of garbage treatment. According to the garbage treatment equipment and the garbage treatment system, a first driving motor is arranged to drive a rotating shaft to rotate, a rotating rod rotates to drive the sliding plate to move left and right in a reciprocating mode through a rotating disc, a convex column and a through groove, garbage is extruded in a reciprocating mode through cooperation with an extruding plate,oil stains in the garbage are effectively discharged and collected, the problem that the environment is influenced, and resources are wasted due to direct garbage treatment is solved, the structure is easy in operation and low in cost, and the efficiency of the garbage treatment is greatly improved.

Owner:HUZHOU ZHONGZHOU ENERGY SAVING TECH

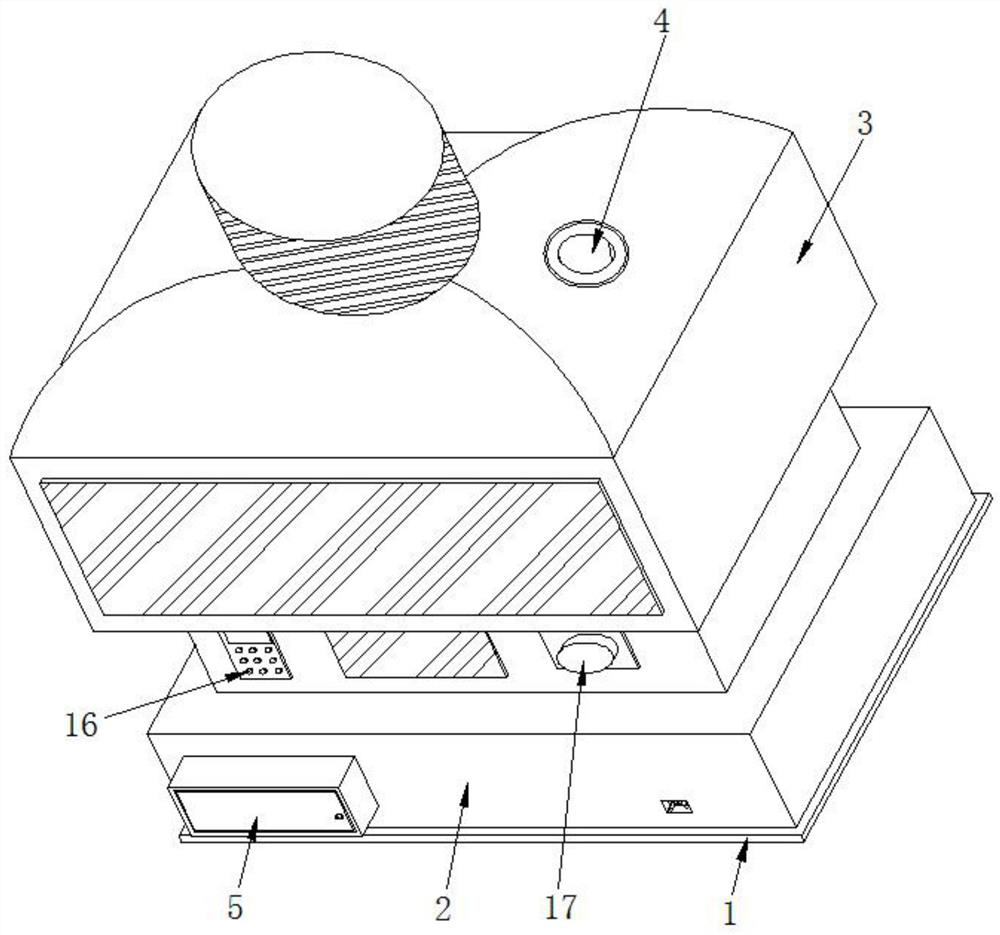

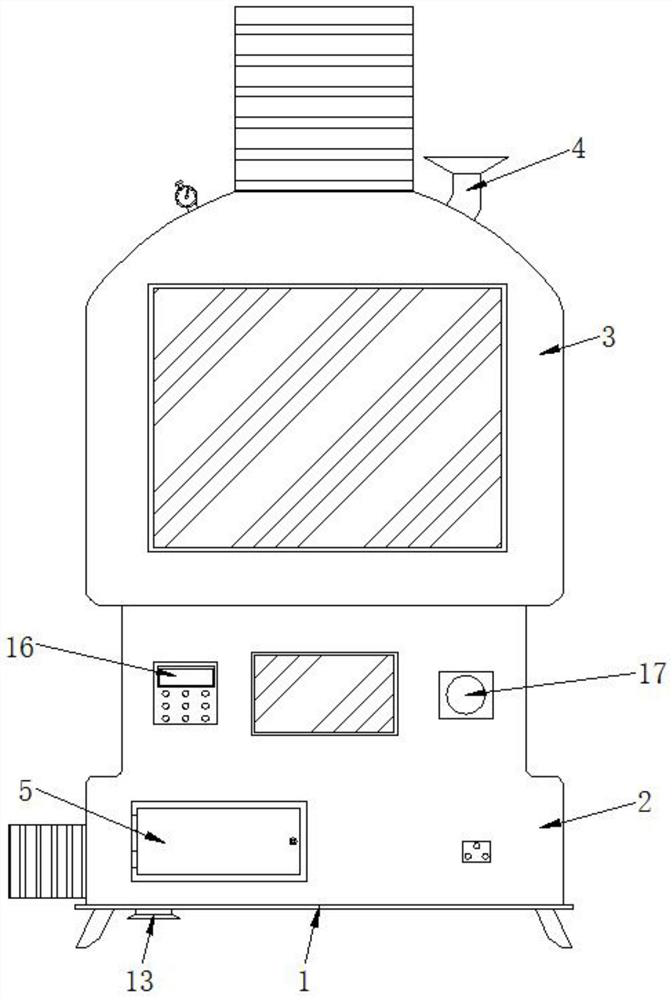

Novel rotary drum type domestic waste drying incineration device

PendingCN111288450AAvoid cloggingPrevent blockingDispersed particle filtrationTransportation and packagingElectric machineProcess engineering

The invention discloses a novel rotary drum type domestic waste drying incineration device. The novel rotary drum type domestic waste drying incineration device comprises an installation bottom frame,a driving motor, a motor and a waste storage box; a holding furnace is fixed to the upper portion of the installation bottom frame, the driving motor is installed on the right side surface of the holding furnace, the inner side of the holding furnace is connected with a combustion box, and the bottom end of the holding furnace is provided with a natural pipe in a penetrating mode; the motor is located on the left side of a gas pipe; a maintenance cover is installed at the top end of the holding furnace, and the bottom end of the holding furnace is connected with a residue box; a belt conveyoris arranged below the residue box; the waste storage box is located on the left side of the holding furnace; and a discharging pipe is welded to the right end of a base plate; and a pounding mechanism is installed in the discharging pipe. According to the novel rotary drum type domestic waste drying incineration device, by rotating the combustion box, the rotation incineration temperature is equalized, the disposal time is short, energy is saved, reduction is obvious, a filter net is avoided being blocked, and the situation that the material blockage occurs to the discharging pipe is prevented.

Owner:四川茂源环保设备制造有限公司

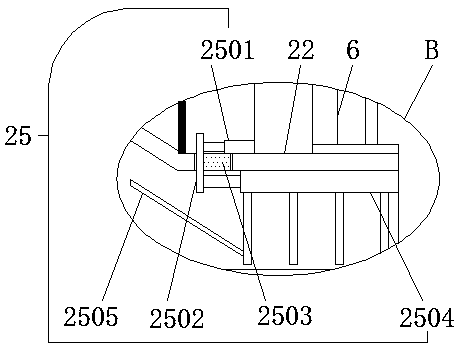

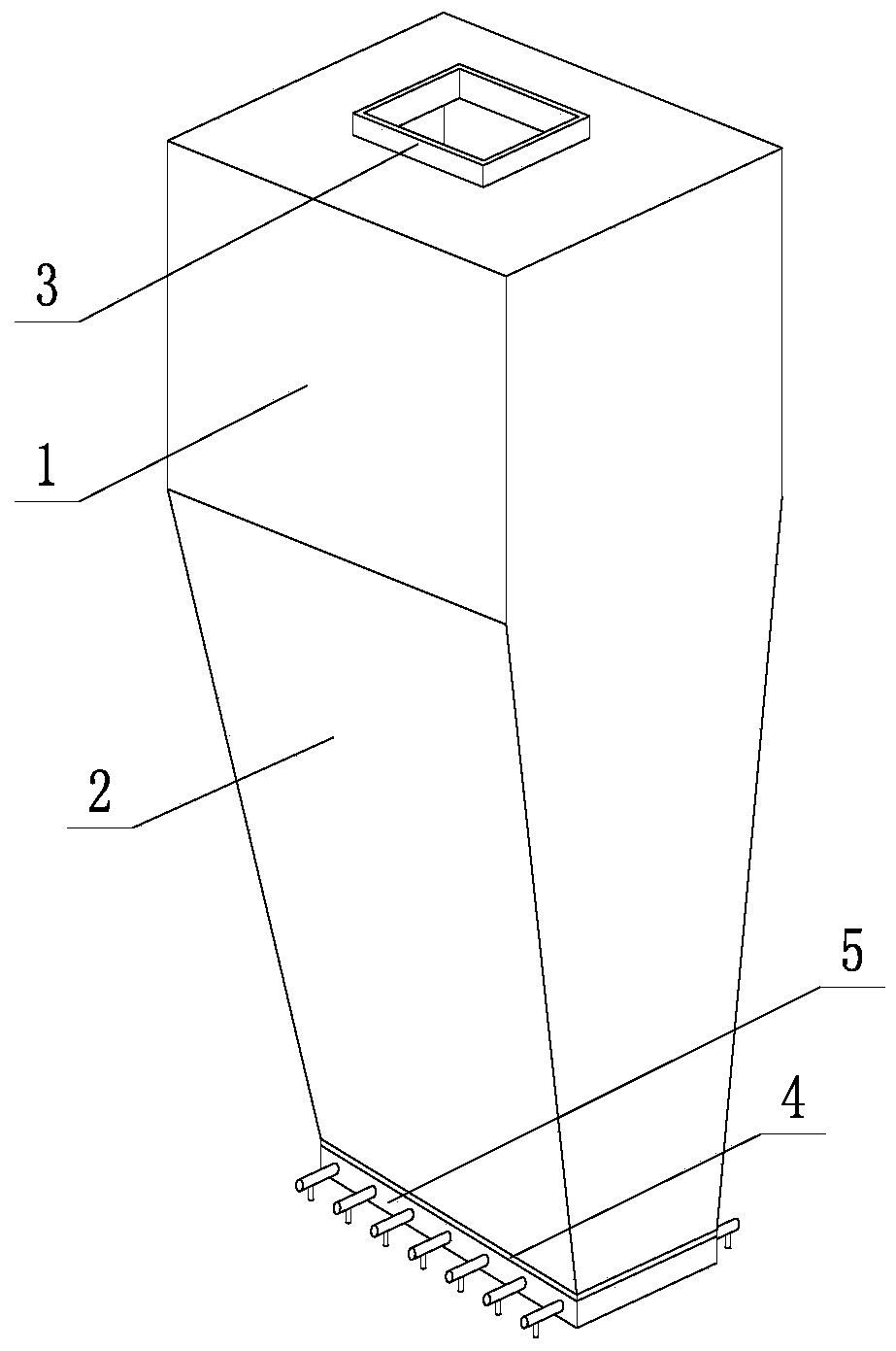

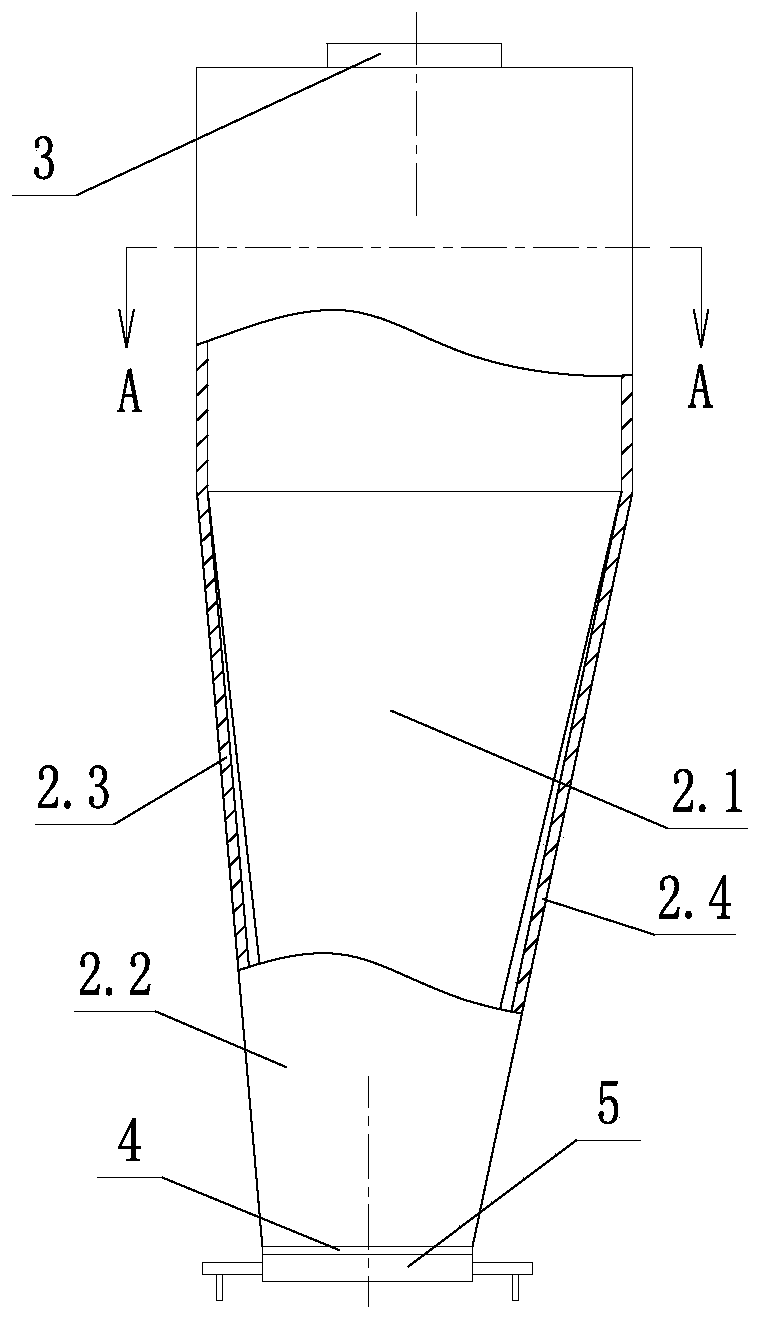

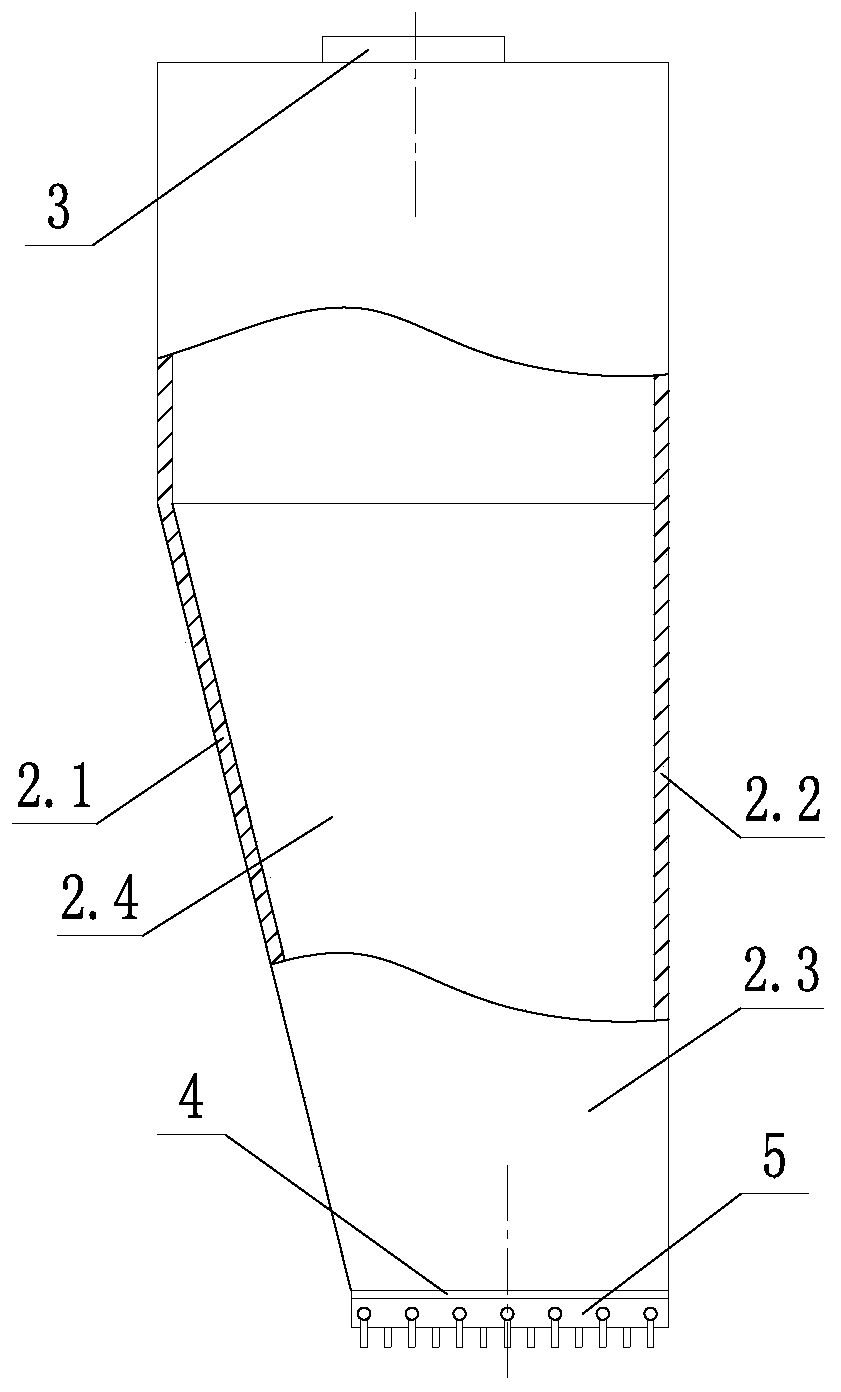

Anti-blocking type lightly-calcined magnesium oxide powder feeding buffering bin

PendingCN110182478AReasonable warehouse structure designIncrease productivityLarge containersWall materialMaterials science

The invention discloses an anti-blocking type lightly-calcined magnesium oxide powder feeding buffering bin. A bin body is vertically arranged, is of a two-section type structure and comprises a bin body straight section and a bin body tapered section, the bin body straight section is located on the upper portion, the bin body tapered section is located on the lower portion, the top end of the binbody straight section is provided with a mineral powder feeding port, the bottom end of the bin body tapered section is provided with a mineral powder discharging port, and a bar valve is installed at the mineral powder discharging port; anti-sticking material lining plates are laid on the inner surfaces of the bin walls of the bin body straight section and the bin body tapered section and made of polytetrafluoroethylene plates or surface-polished stainless steel plates; the section of the bin body straight section is in a rectangular shape, and the inclination angles of the bin walls of thefour faces of the bin body straight section are each 0 degree; the section of the bin body tapered section is in a trapezoidal shape, the bin walls of the bin body tapered section adopt large inclination angle design, and the inclination angles of the bin walls of the four faces of the bin body tapered section are different; and the axis of the mineral powder feeding port and the axis of the mineral powder discharging port are eccentrically arranged. According to the anti-blocking type lightly-calcined magnesium oxide powder feeding buffering bin, the problems of bin wall material sticking andbin wall material blocking are solved, the problems of powder bin pressing and nonuniform discharging are solved, a calcinator can stably run, and the production efficiency of lightly-calcined magnesium oxide is improved.

Owner:SHENYANG XINBO IND TECH

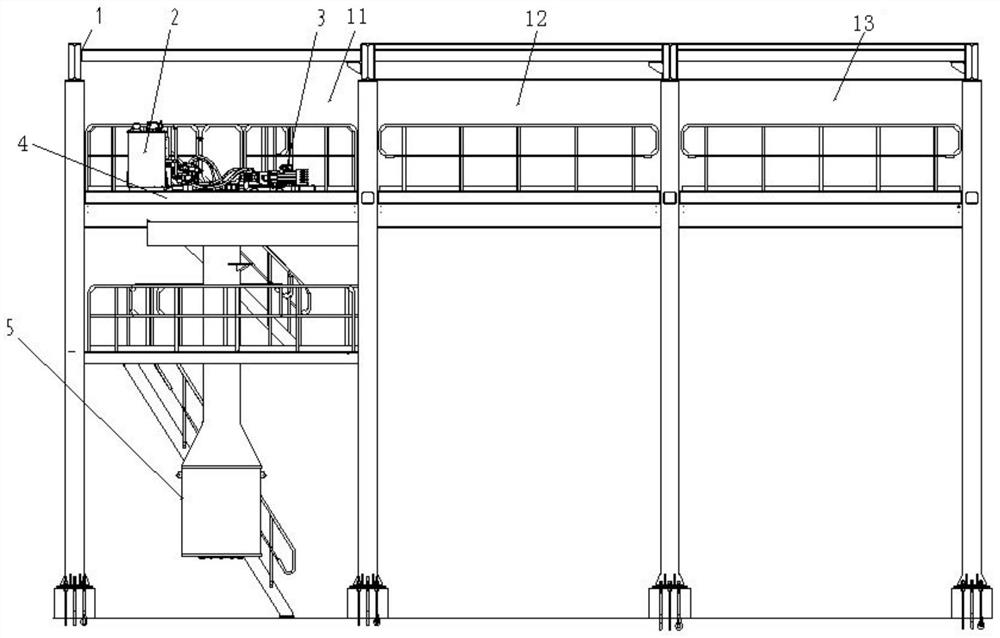

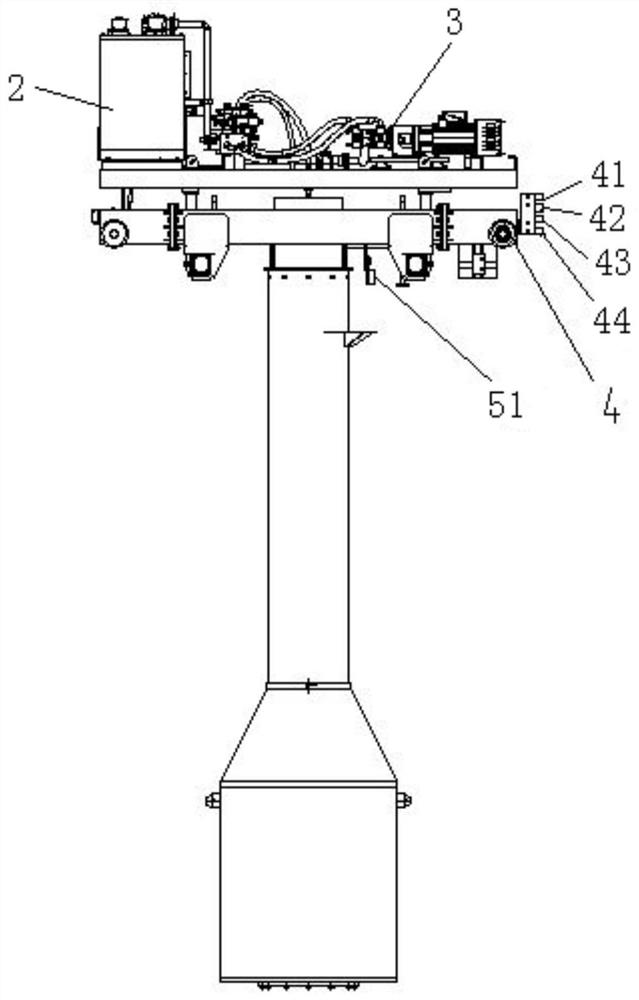

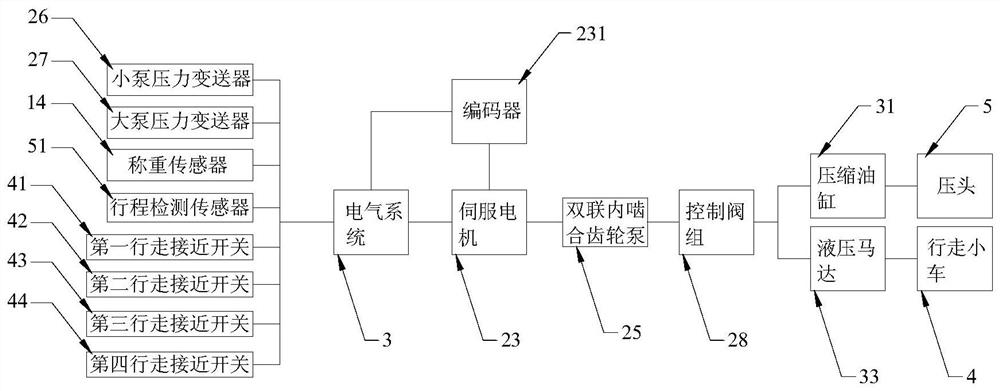

trash compactor

ActiveCN110482084BReduce output torqueReduce operating costsRefuse transferringLoading/unloadingGear pumpLow speed

The invention discloses a garbage compactor. The garbage compactor of the present invention adopts a combination of double pumps combined with servo volume speed regulation to drive the pressure head to perform garbage compression operations and drive the walking trolley to travel. When the pressure head performs compression operations and the walking trolley moves, the hydraulic system does not have variable throttling Energy consumption; the motor responds quickly, and it can sleep without turning during standby loading, and the system has no energy consumption; it adopts double-connected internal gear pumps, which have lower noise and smaller flow pulsation; when the load is heavy or light, the double pumps flow together at low pressure and high speed Operation, the small pump runs at high pressure and low speed when pressing garbage into the tank, which can reduce the output torque of the motor compared with the single pump system, reduce the operating cost of the motor, and generate less heat, no need to install a radiator, and reduce the compactor Low manufacturing cost; when the trolley is moving, the small pump of the double-internal gear pump is loaded separately, and the motor outputs a low speed, so as to obtain a stable small flow rate, and the walking speed of the trolley has good repeat stability.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

Burdening and blank making device for porous checker brick and manufacturing method of the brick

PendingCN111875348AReduced chance of cracking and deformationImproved thermal conductivity and thermal insulationPhotography auxillary processesHeat storage plantsCoal ganguePerlite

The invention discloses a burdening and blank making device and a manufacturing method for a porous checker brick, and relates to the field of production of porous checker bricks. The brick comprisesthe following components in parts by mass: 35-55 parts of shale; 20-30 parts of coal gangue; 10-15 parts of clay; 13-20 parts of fly ash; 5-8 parts of silica; 3-5 parts of aluminum oxide; 2-6 parts ofmodified copper; 2.5-2.9 parts of graphite powder; 2.5-3 parts of calcium silicate; and 2-4 parts of perlite. The shale, the coal gangue, the clay, the fly ash, the silicon dioxide, the aluminum oxide, the modified copper, the graphite powder, the calcium silicate and the perlite are arranged, so that the cracking and deformation probability of the checker brick is greatly reduced by adding the aluminum oxide, the modified copper and metal elements into traditional ingredients of the checker brick; the graphite powder, the calcium silicate and the perlite are added into the raw material formula, so that the heat-conducting property and the heat-insulating property of the checker brick are greatly improved, the heat-conducting effect of the checker brick is good, and the heat-insulating time is prolonged.

Owner:长兴宏伟耐火材料厂

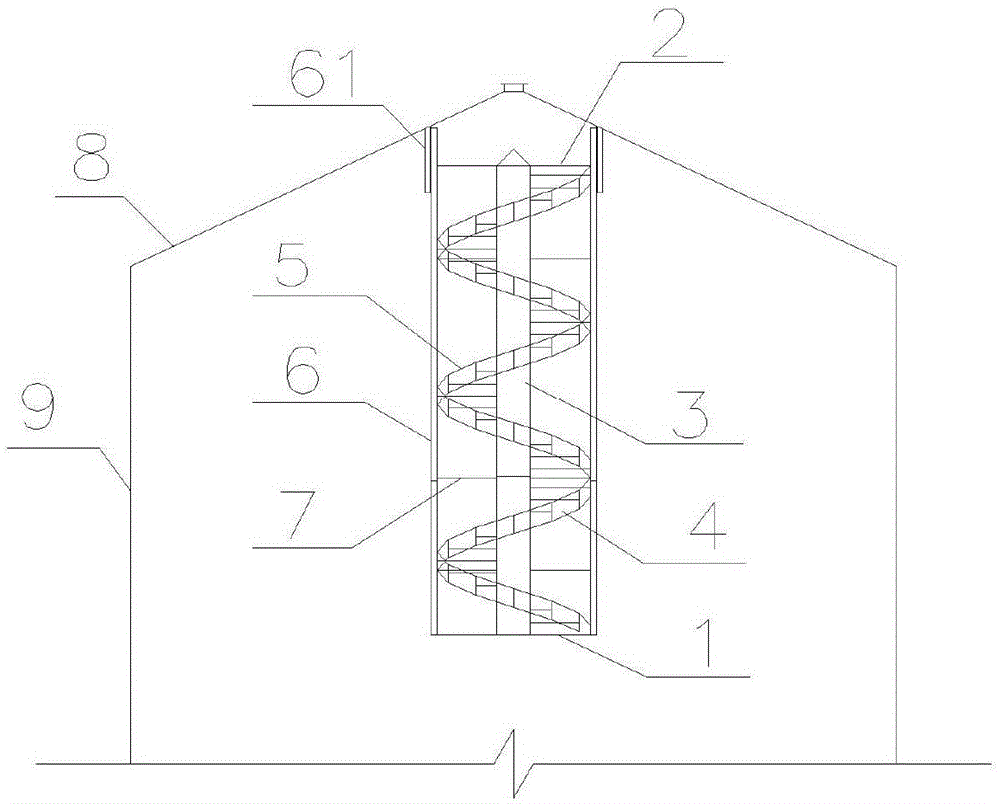

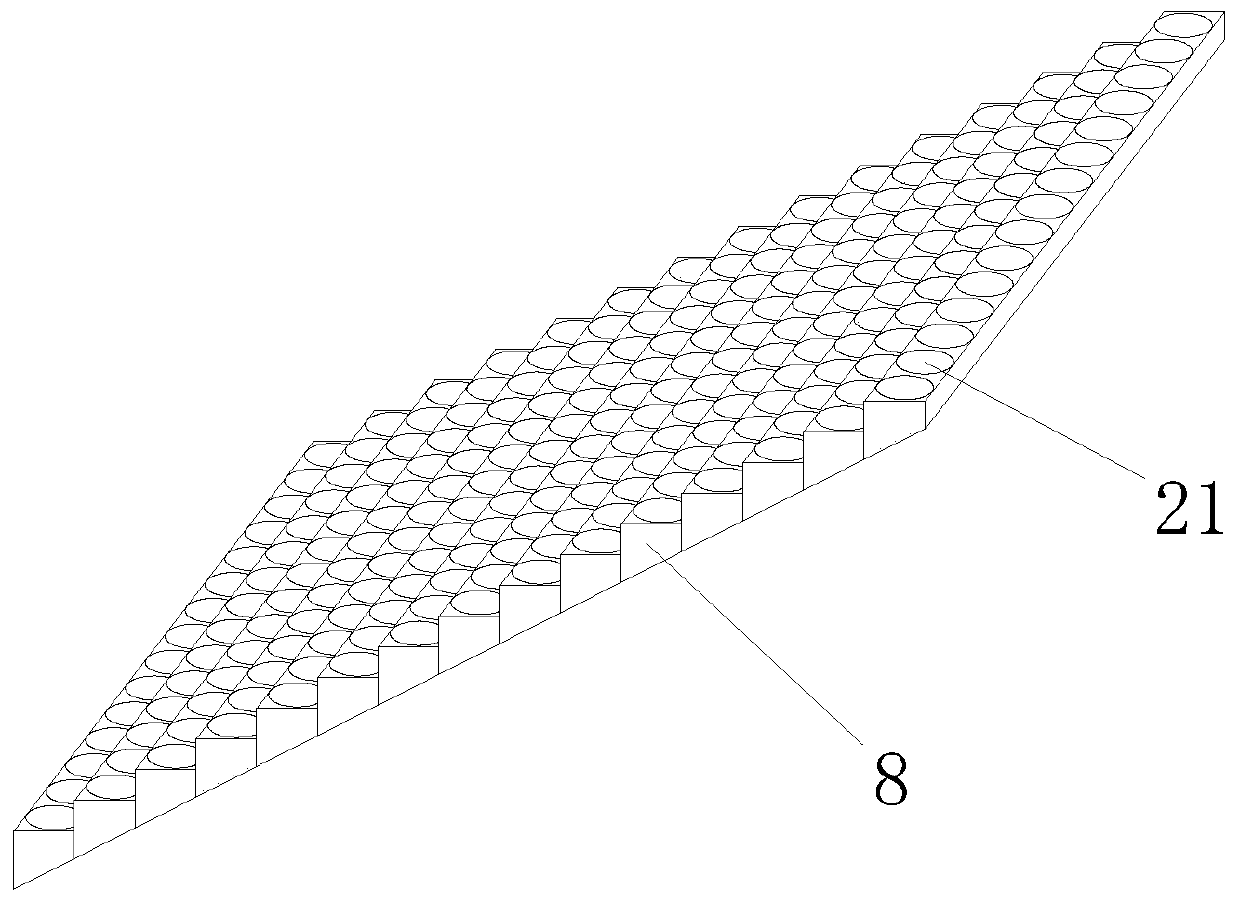

Steel plate bin with coiled stacked discharging device

The invention discloses a steel plate bin with a coiled stacked discharging device. The steel plate bin comprises a lower support which is horizontally arranged on a silo bottom foundation of a silo, and an upper support connected with the silo top of the silo. A supporting shaft arranged in the center position of the lower support vertically extends to the center position of the upper support. Stepped conveying plates are spirally arranged on the supporting shaft at intervals from top to bottom. The conveying plates incline downwards from top to bottom in the spiral direction. A baffle is arranged at the outer edge of each conveying plate. The coiled stacked discharging device can effectively decrease the descending speed of materials, so that blocking of materials is avoided; and the structure is simple, no power is needed, low carbon and energy saving are achieved, and the effect is remarkable.

Owner:JIANGSU HENGXIN SILO EQUIP CO LTD

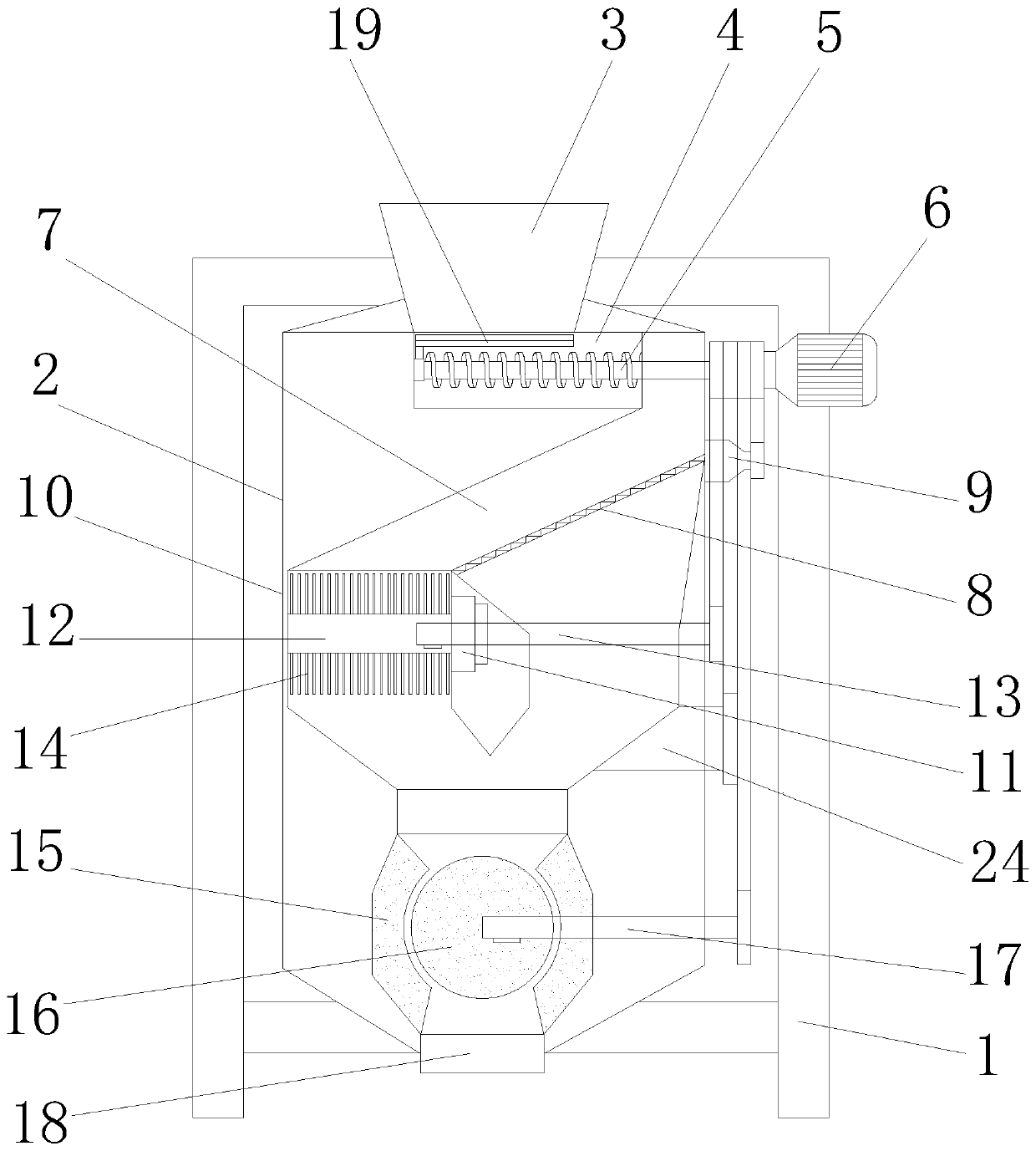

A layered organic fertilizer mixing and pulverizing machine

The invention discloses a layered-type organic fertilizer stirring pulverizer. The layered-type organic fertilizer stirring pulverizer comprises a machine frame and a shell arranged on the machine frame. The shell is internally provided with a feeding device, a screening device arranged below the feeding device, a cutting device arranged below the screening device and a grinding device arranged below the cutting device. The layered-type organic fertilizer stirring pulverizer has the advantages that the layered-type structure is adopted, organic fertilizer is subjected to stirring, quantitative feeding, sorting, cutting and grinding successively, and the processed organic fertilizer is uniform in size and good in quality; meanwhile, the fertilizer which greatly differs from one another in specification is not ground at the same time, the steps of sorting and cutting at first and then uniform grinding are executed, an air draft aided flowing mechanism is adopted, and the condition of material blocking is avoided; and only one motor is required in the whole device to serve as a driving mechanism, the overall structure is made simpler and more reasonable, and energy is saved.

Owner:安徽铸星机械制造有限公司

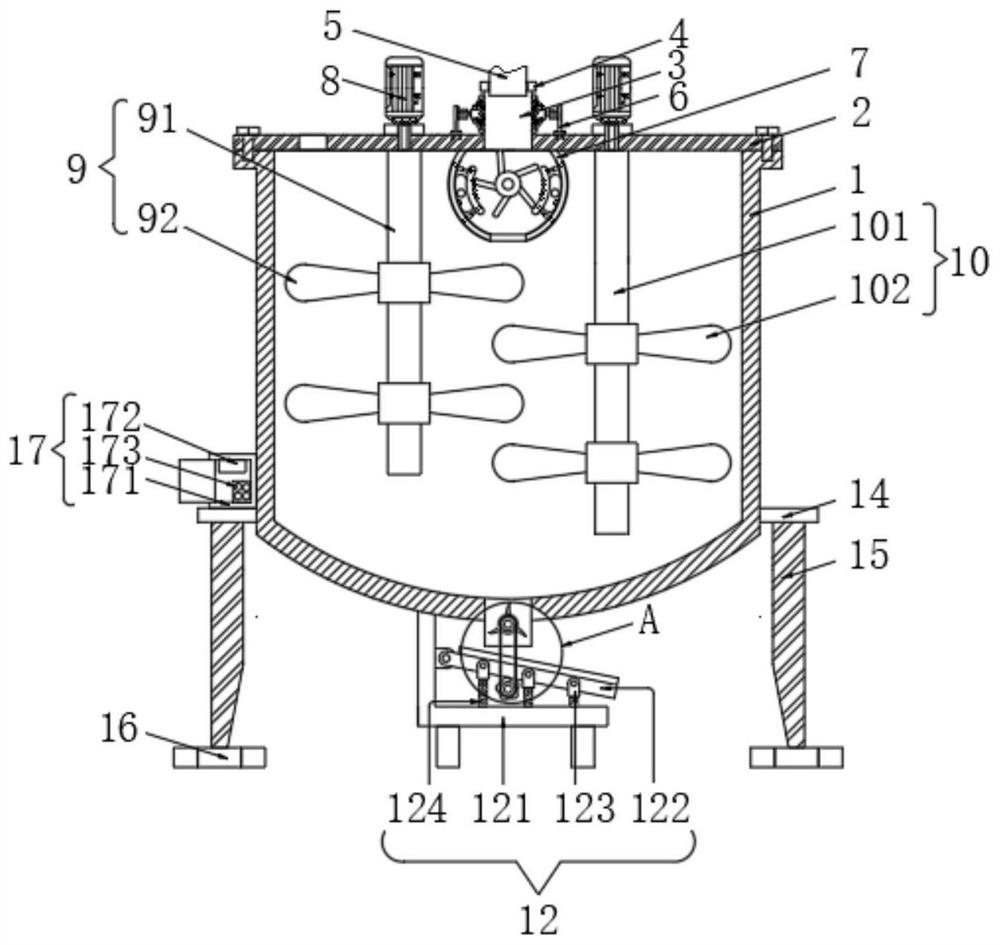

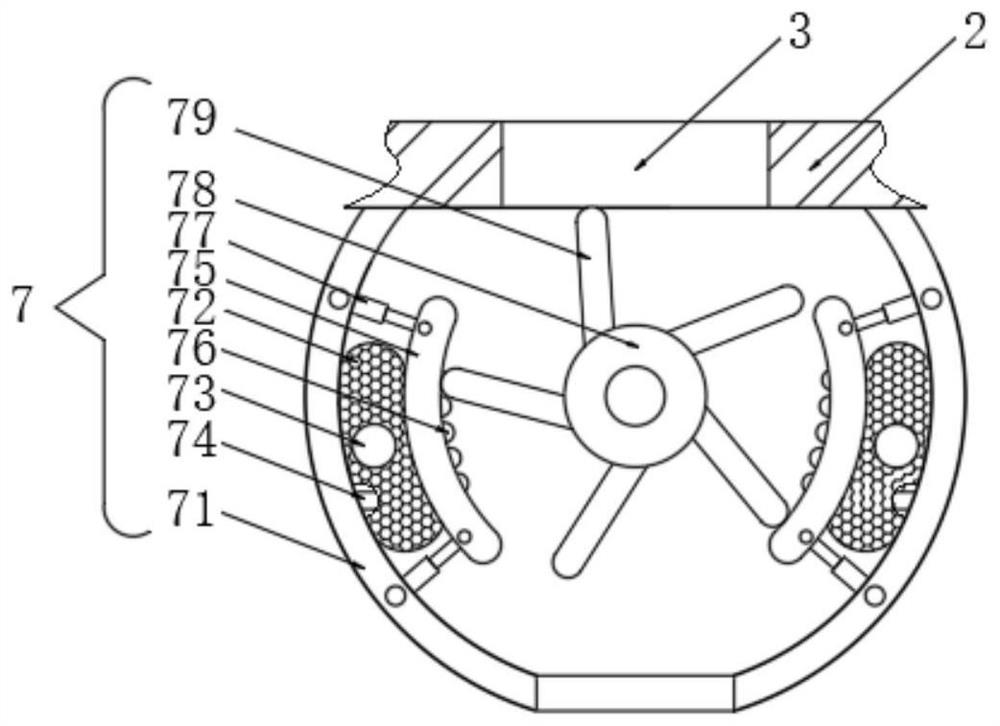

Mixing kettle for engineering polymer material production

The invention discloses a mixing kettle for engineering polymer material production. The mixing kettle comprises a bottom plate, a lower tank body mounted on the bottom plate and an upper tank body mounted at the top of the lower tank body, wherein a feeding nozzle is fixedly mounted at the top of the upper tank body, an electric control box is mounted on the front side of the lower tank body, a dispersing mechanism is arranged in the upper tank body, and a partition board is fixedly mounted in the lower tank body. The invention relates to the technical field of polymer material mixing equipment. According to the mixing kettle for engineering polymer material production, intermittent small material extrusion, shearing and mixing can be performed while a mixed material is sufficiently dispersed, the use range of the mixing kettle is greatly expanded, and the mixed and dispersed material can be uniformly ground by designing a fine grinding mechanism in the mixing kettle, so that the compactness of the mixed polymer material is greatly enhanced, the granularity of the mixed material is uniform, and the product quality of the formed polymer material is guaranteed.

Owner:山东颐工材料科技股份有限公司

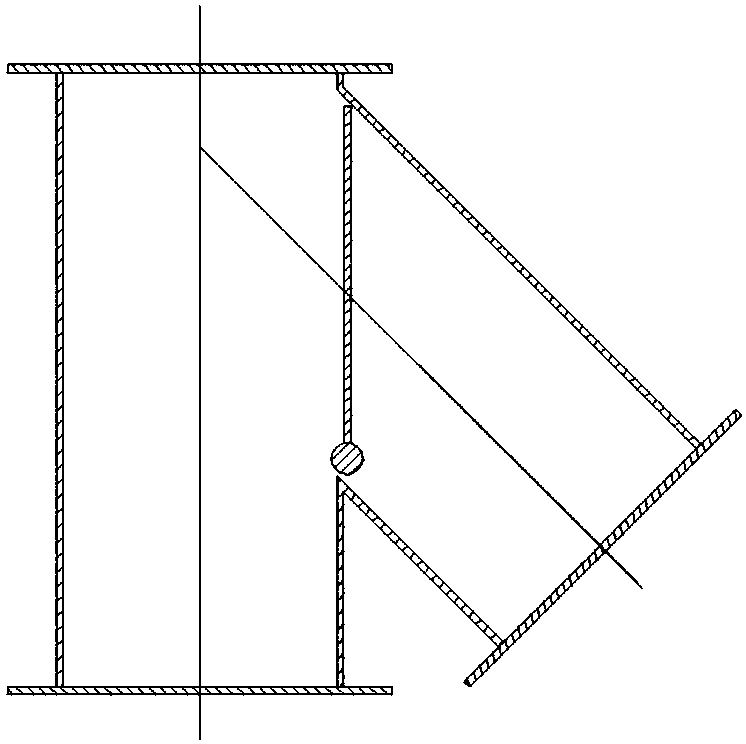

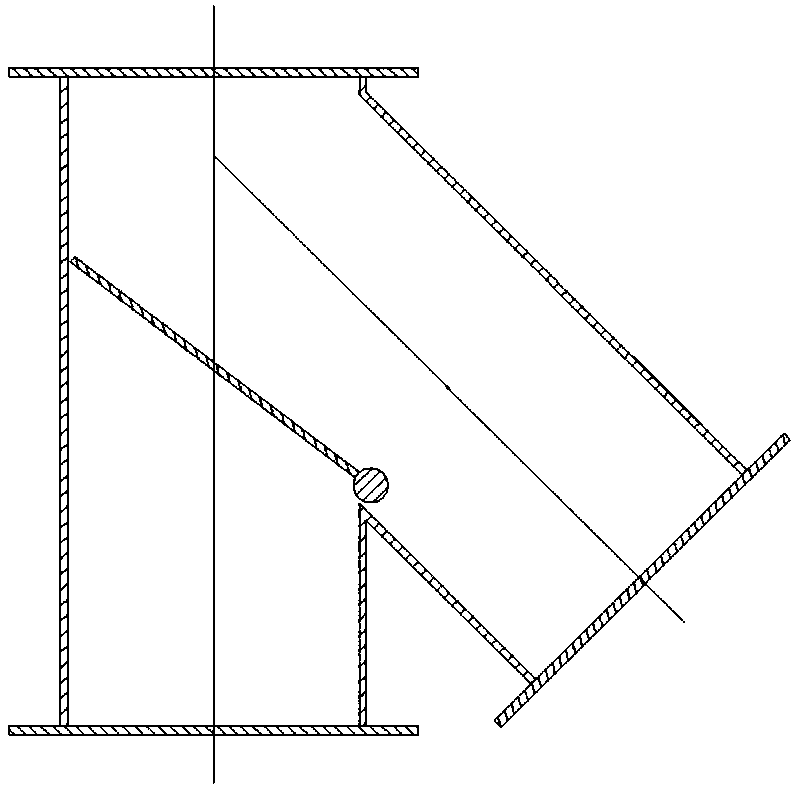

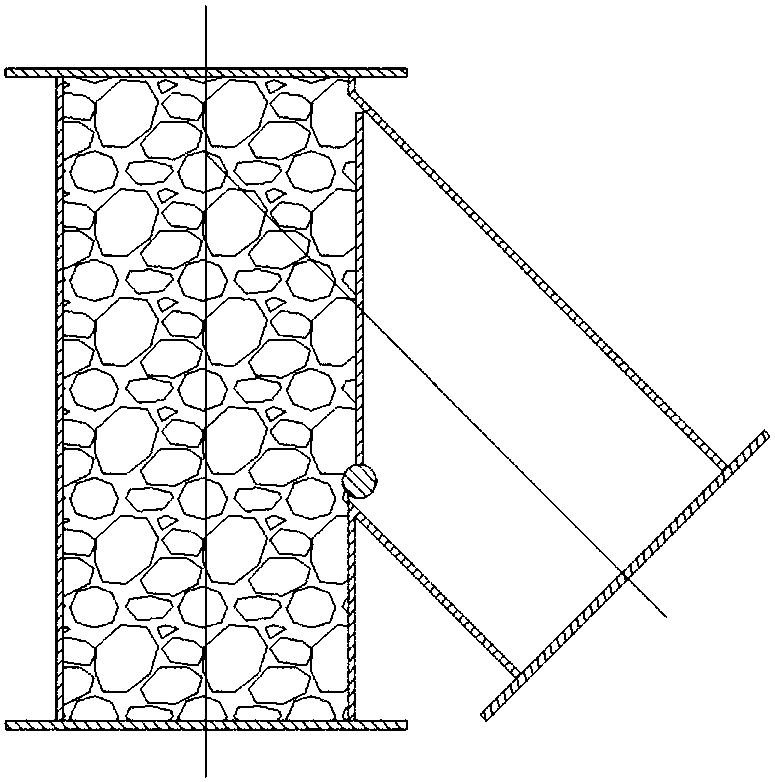

Three-way reverser

PendingCN108799552ASolve the problem of easy jammingSolve the problem of blockageMultiple way valvesValve housingsEngineeringMechanical engineering

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Adding and stirring device for desulfurization gypsum improver

ActiveCN111745817BAvoid compromising accuracyRealize the function of pre-mixingDischarging apparatusLarge containersProcess engineeringMaterials processing

The invention discloses a desulfurization gypsum modifier adding and stirring device in the technical field of material processing. There is a water inlet, the middle part of the tank cover is fixedly connected with a feeding port, the top of the feeding port is movably connected with a cover body, the middle part of the cover body runs through a feeding pipe, and the outer wall of the feeding pipe and the cover body are connected. A sealing ring is filled between the two sides of the feed port, and anti-residue components are movably connected to both sides of the feed port. When the guide rod rotates, due to the elastic telescopic cylinder, the guide rod can squeeze the pressure plate, thereby making the pressure plate squeeze water. So that the water in the water bag is sprayed out through the nozzle, so that the sprayed water can be combined with the desulfurized gypsum to become a block, thus effectively avoiding a part of the raw materials floating in the mixing tank, which takes a period of time to fall. It affects the efficiency of subsequent mixing with water.

Owner:平顶山中悦环保科技有限公司

Raw material treatment device for rumen bypass nicotinic acid coating and treatment method

PendingCN113877806AAvoid blockingGuaranteed screening effectSievingScreeningAcidum NicotinicumEngineering

The invention discloses a raw material treatment device for rumen bypass nicotinic acid coating. The raw material treatment device comprises a raw material screening box and a mixing box, wherein the raw material screening box is fixedly installed at the upper end of the mixing box through a stand column, a material returning opening is formed in the raw material screening box, a material returning box is fixedly connected to the side wall of the raw material screening box through a connecting column, the material returning opening communicates with the interior of the material returning box, a pneumatic conveyor is fixedly installed on the portion, located at the upper end of the material returning box, of the side wall of the raw material screening box, the feeding end of the pneumatic conveyor communicates with the interior of the material returning box through a connecting pipe, a smashing mechanism is fixedly installed at the upper end of the raw material screening box, the discharging end of the pneumatic conveyor communicates with the smashing mechanism through a connecting pipe, and the discharging end of the smashing mechanism communicates with the interior of the raw material screening box. According to the raw material treatment device for the rumen bypass nicotinic acid coating and the treatment method, nicotinic acid raw materials are screened through the raw material screening box, the first driving motor is adopted to drive a crushing rod to scatter the caked nicotinic acid raw materials during screening, and the screening effect of the nicotinic acid raw materials is ensured.

Owner:INNER MONGOLIA AUTONOMOUS REGION ACAD OF AGRI & ANIMAL HUSBANDRY SCI +1

Conveying and guiding device for machining

The invention discloses a conveying and guiding device for machining. The conveying and guiding device comprises a first rack, a base and a second rack, all of which are sequentially arranged from left to right. A first supporting leg and a second supporting leg are mounted at the bottom of the first rack and the bottom of the second rack correspondingly. A first conveying device and a second conveying device are mounted on the first rack. A rotating device comprises a third motor, an output shaft, a main shaft and belt wheels. A protection clamp ring is arranged on the outer side of a rotating disc and is fixedly connected to the first rack and the second rack through supports. An arc frame is arranged at the position, located on one side of the top of the rotating disc, of the inner sideof the protection clamp ring. The protection clamp ring and the arc frame are connected through a guide rod. The arc frame is in sliding connection to the guide rod through a sliding block. Conveyedcomponents continue to be cyclically guided on the rotating disc, the situation of material blocking is avoided, labor force is relieved, adjustment is convenient, and adaptability is higher.

Owner:张丁午

Injection molding pre-machining device for preparing HAC-ECM porous orientation support

InactiveCN112643925AEasy to heat and softenPrevent blockingElectric machineryInjection molding process

The invention discloses an injection molding pre-machining device for preparing an HAC-ECM porous orientation support, and relates to the technical field of support production. The injection molding pre-machining device comprises a machining box, a first motor is fixedly installed on the outer wall of the top end of the machining box, and the output end of the motor is fixedly sleeved with an output shaft. The output shaft of the motor is in transmission connection with a transmission rod through a belt, the transmission rod is in transmission connection with a first rotating rod through a gear, and the two ends of the first rotating rod are rotatably connected with the inner wall of the machining box through bearings. The outer walls of the two sides of the first rotating rod are fixedly sleeved with rotating discs, the other sides of the rotating discs are fixedly sleeved with connecting rods, and the outer walls of the connecting rods are movably connected with moving rods. According to the injection molding pre-machining device, particles on the upper surfaces of sliding blocks are extruded through extrusion plates, the plastic particles are crushed, and the plastic particles can be conveniently heated and softened in the subsequent injection molding process.

Owner:朱元康

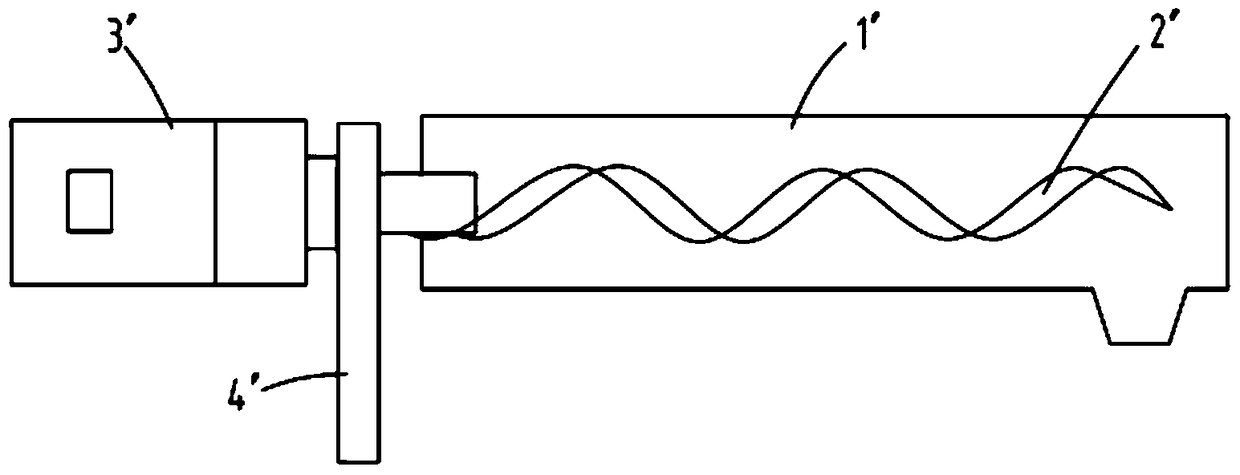

A self-cleaning anti-coking mechanism

ActiveCN105112075BAvoid wear and tearPrevent blockingBiofuelsSpecial form destructive distillationEngineeringScrew conveyor

The invention relates to a self-cleaning coke hang prevention mechanism. The self-cleaning coke hang prevention mechanism comprises a support, a charring cylinder, a shaftless screw, a driving apparatus, a feed inlet tank and a feed outlet tank, wherein the feed inlet tank and the feed outlet tank are mounted on the support; the shaftless screw is transversely arranged in the charring cylinder, one end of the shaftless screw is connected with the driving apparatus, and the other end of the shaftless screw floats in the charring cylinder; the charring cylinder is in rotary sealing connection with the feed inlet tank and the feed outlet tank, and the feed inlet end and the feed outlet end of the charring cylinder respectively extend into the inside of the feed inlet tank and the feed outlet tank. A feed inlet is formed in the upper part of the feed inlet, and a screw conveyor mechanism is arranged below the feed inlet; a fume outlet is formed in the top of the feed outlet tank, and a feed outlet is formed in the bottom; a transmission apparatus is further arranged on the support, and the transmission apparatus drives the charring cylinder to rotate. According to the mechanism provided by the invention, the transmission apparatus drives the charring cylinder to rotate to a certain angle; by means of extrusion and friction with the inner wall of the charring wall in the material pushing process, hanging coke accumulated on the inner wall of the charring cylinder is automatically removed, so that the occurrence of material blocking is prevented, and long-term wear for local area of the charring cylinder is avoided.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com