Roller sand screening machine for building

A technology for construction and sand screening machines, which is applied in the fields of screening, mechanical equipment, solid separation, etc., can solve the problems of waste, incomplete separation, and increase manual workload, so as to ensure work efficiency, reduce workload, and increase work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

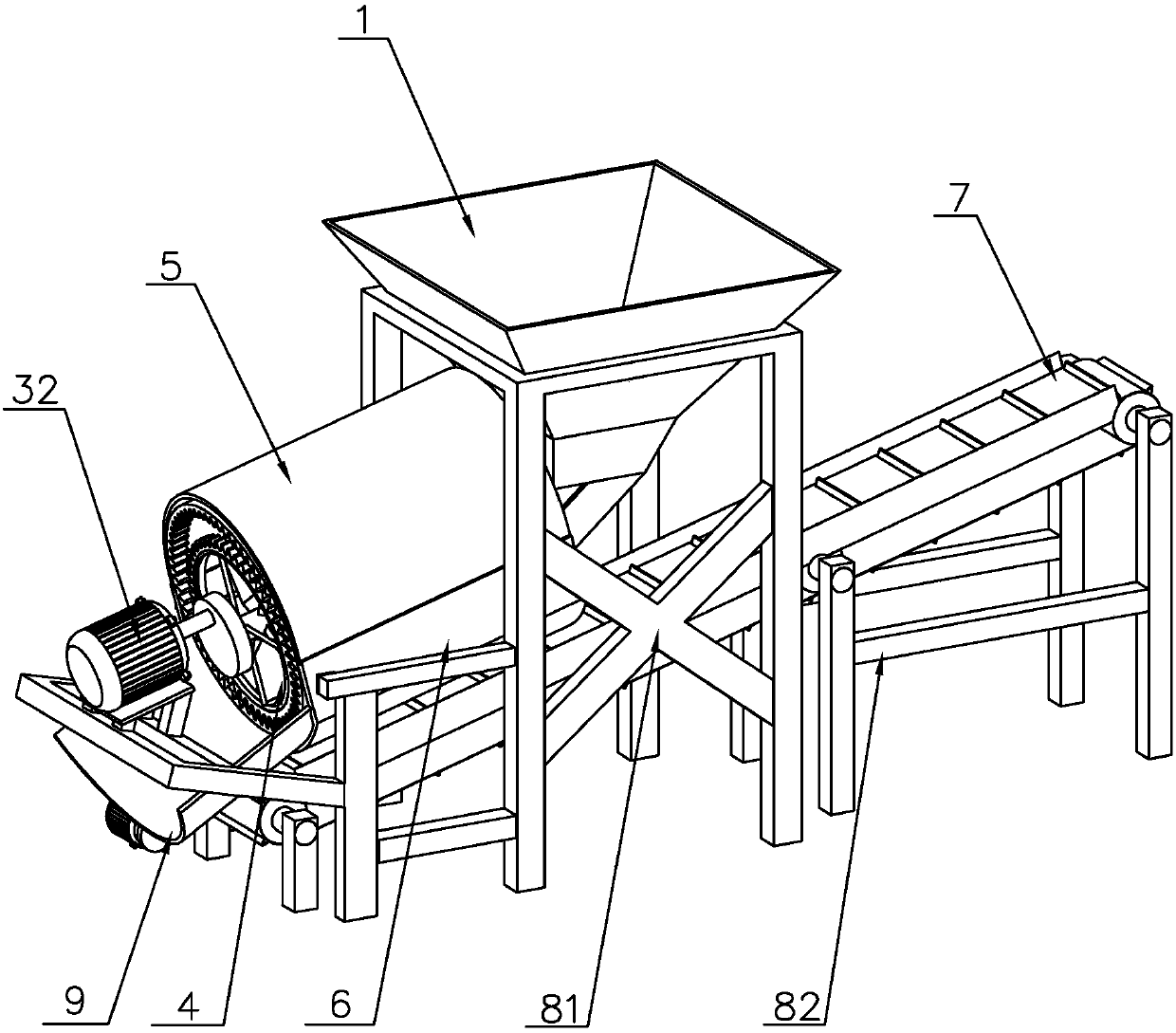

[0025] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-8 , to further specifically describe the technical solution of the present invention.

[0026] A drum sand screening machine for construction, including a hopper 1, an overturning arm 2, a motor I31, a motor II32, a motor III33, a drum 4, a baffle I5, a baffle II6, a transmission device 7, a frame 81, and a transmission device frame 82 , chain drive 10, gear III 11, gear IV 12, eccentric wheel 13; the side below the hopper 1 is provided with a motor I31, and the side of the motor I31 is provided with a turning arm 2, and the motor I31 is installed on the outer wall below the hopper 1, and the motor Ⅰ31 is connected with the turning arm 2 to drive the turning arm 2 to rotate in the hopper 1, which avoids the material blocking in the hopper 1 and ensures the working efficiency of the drum sand screening machine; the lower side of the hopper 1 is equipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com