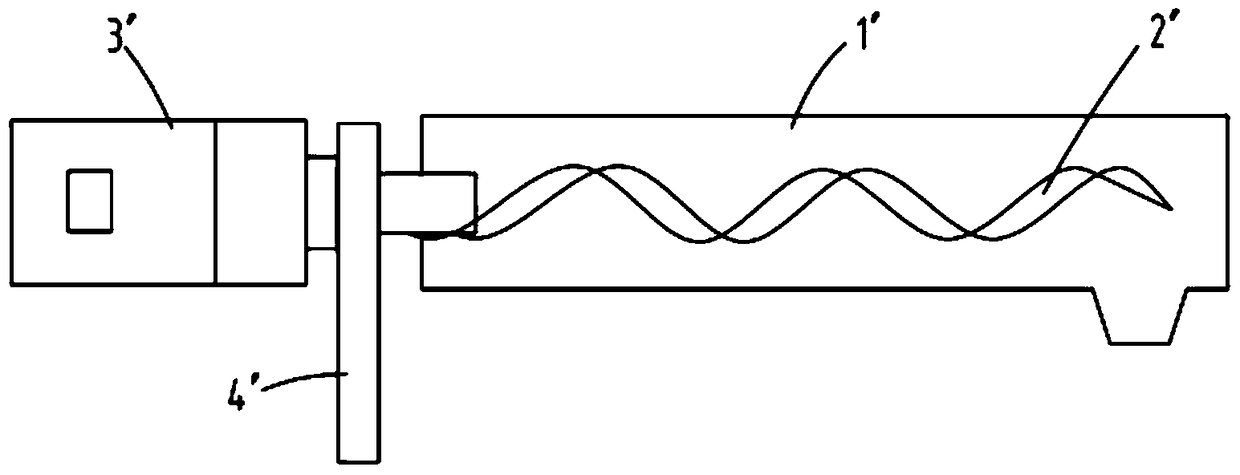

A self-cleaning anti-coking mechanism

An anti-hanging and self-cleaning technology, which is applied in coke ovens, special forms of dry distillation, petroleum industry, etc., can solve problems such as material blockage, achieve the effects of reducing production costs, avoiding downtime for cleaning, and continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

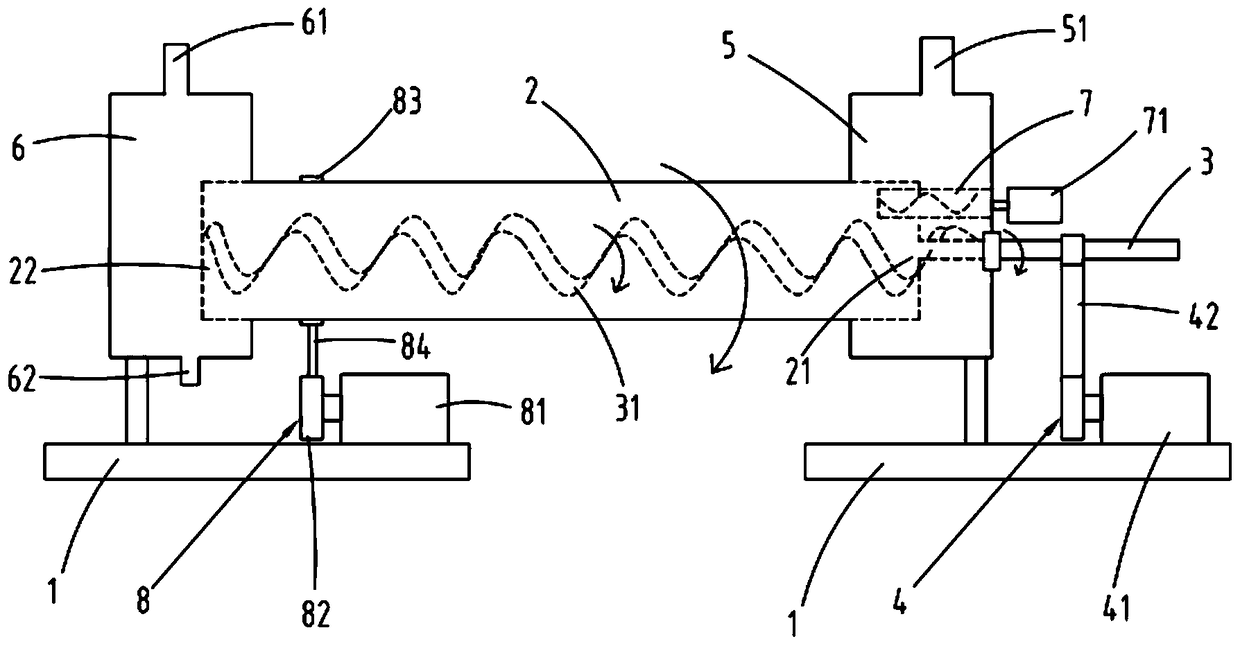

[0029] Such as figure 2 As shown, a self-cleaning anti-coking mechanism includes a bracket 1, a carbonization cylinder 2, a shaftless screw 3, a driving device 4, a feed bin 5 and a discharge bin 6, and the feed bin 5 and the discharge bin 6 are installed on On the bracket 1, and respectively arranged at both ends of the carbonization cylinder 2, the upper part of the feed bin 5 is provided with a feed port 51, the top of the discharge bin 6 is provided with a flue gas outlet 61, and the bottom is provided with a connection with the inside of the carbonization cylinder 2. The discharge port 62 of the shaftless screw 3 is horizontally arranged in the carbonization cylinder 2, and the shaftless screw 3 is provided with a screw blade 31 along the axial direction, and the screw blade 31 is driven to rotate by the driving device 4. In order to avoid the shaftless screw 3 due to heat expansion Stuck in the direction of deformation, one end of the shaftless screw 3 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com