Evaporation source and steam plating device with evaporation source

An evaporation source and evaporation technology, which is applied in vacuum evaporation coating, lighting devices, electroluminescent light sources, etc., can solve the problems of increased production costs, prevent internal pollution, improve heat dissipation, and prevent interruption or interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

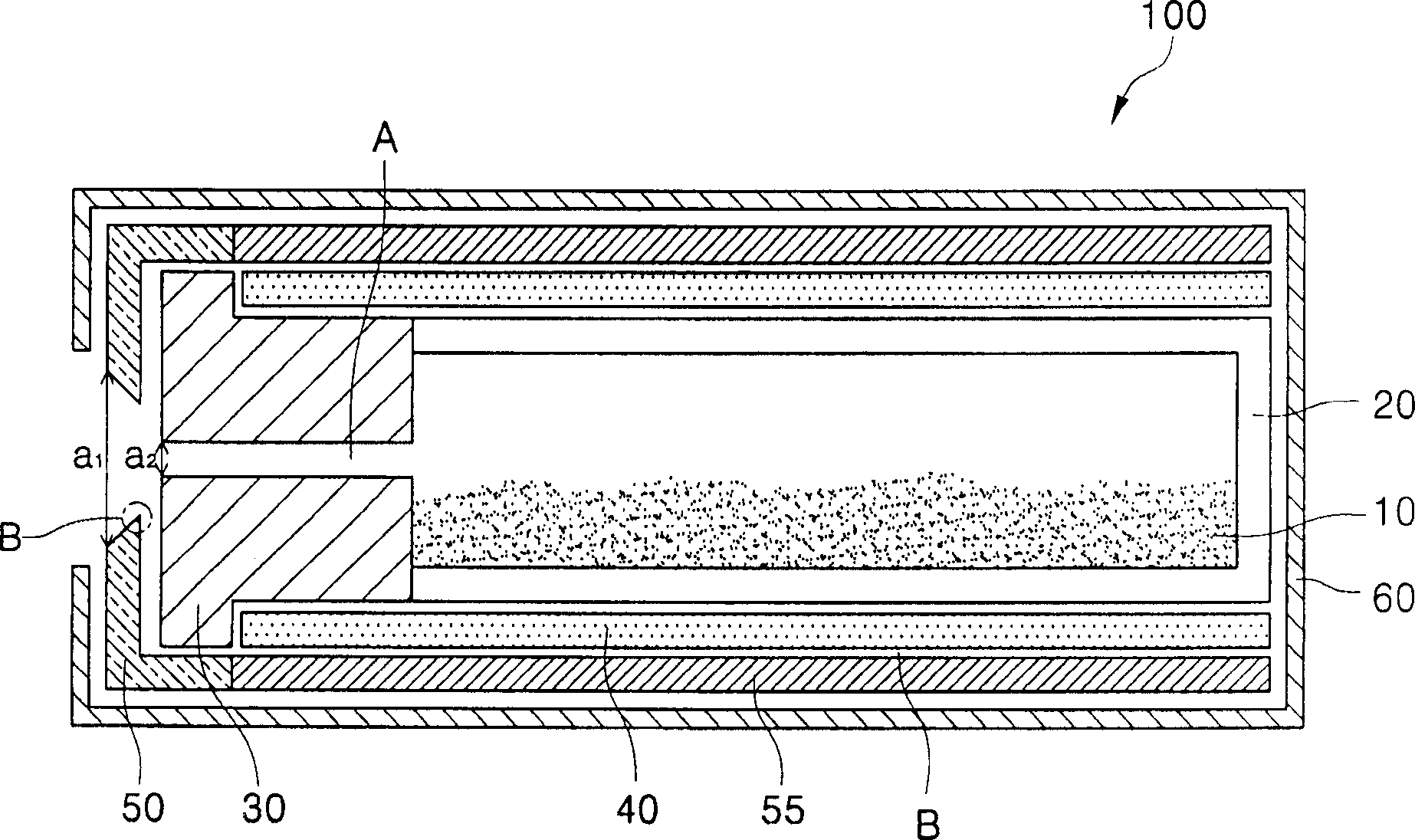

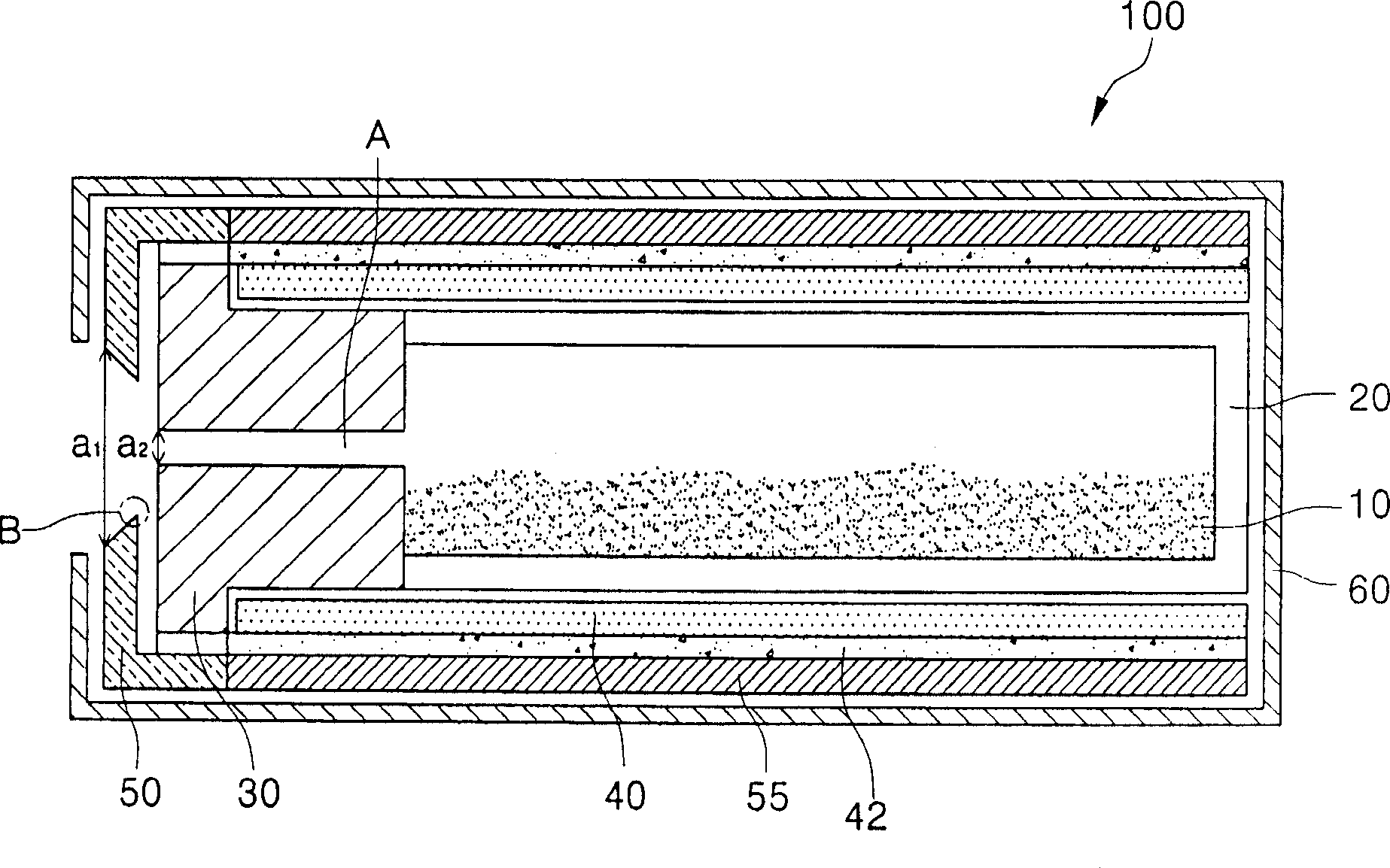

[0072] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The following embodiments are presented as examples in order to fully convey the idea of the present invention to those skilled in the art. Therefore, the present invention is not limited to the following embodiments, and various modifications are possible. The lengths and thicknesses of layers and regions in the drawings may be exaggerated for clarity. The same reference signs in this specification denote the same structural elements.

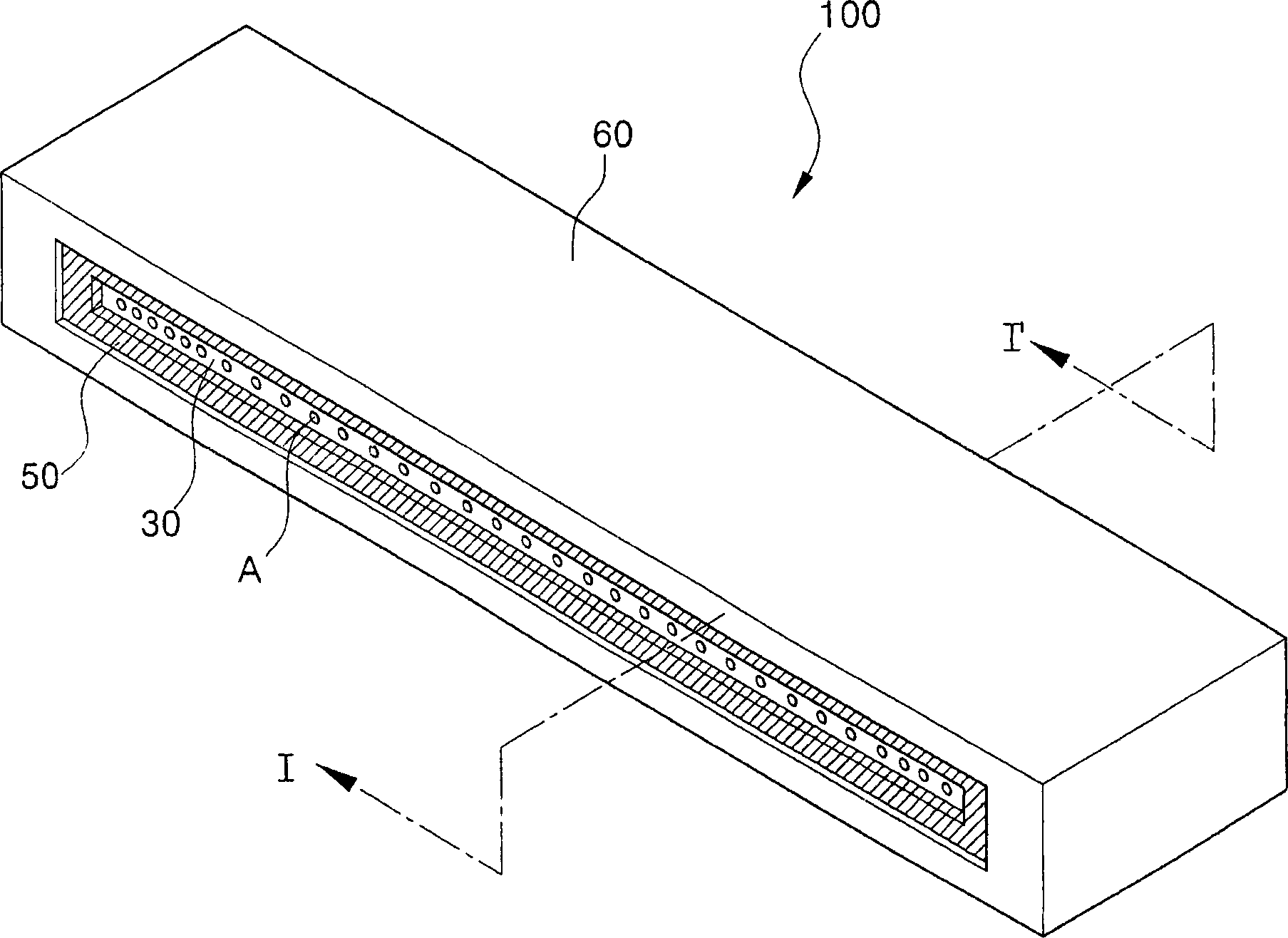

[0073] figure 1 It is a perspective view showing the evaporation source of the first embodiment of the present invention.

[0074] Referring to the drawings, the evaporation source 100 constitutes an evaporation substance storage part, which is placed with evaporation substances and partially opened. Furthermore, a nozzle portion 30 having an opening A for spraying the vapor deposition substance is provided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com