Feeding device

A technology of feeding device and driving device, applied in the field of machining, can solve the problems of affecting the efficiency of tool processing, prone to inclination, and prone to errors and jamming of bars, so as to improve stability and reliability, avoid material blocking, improve The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

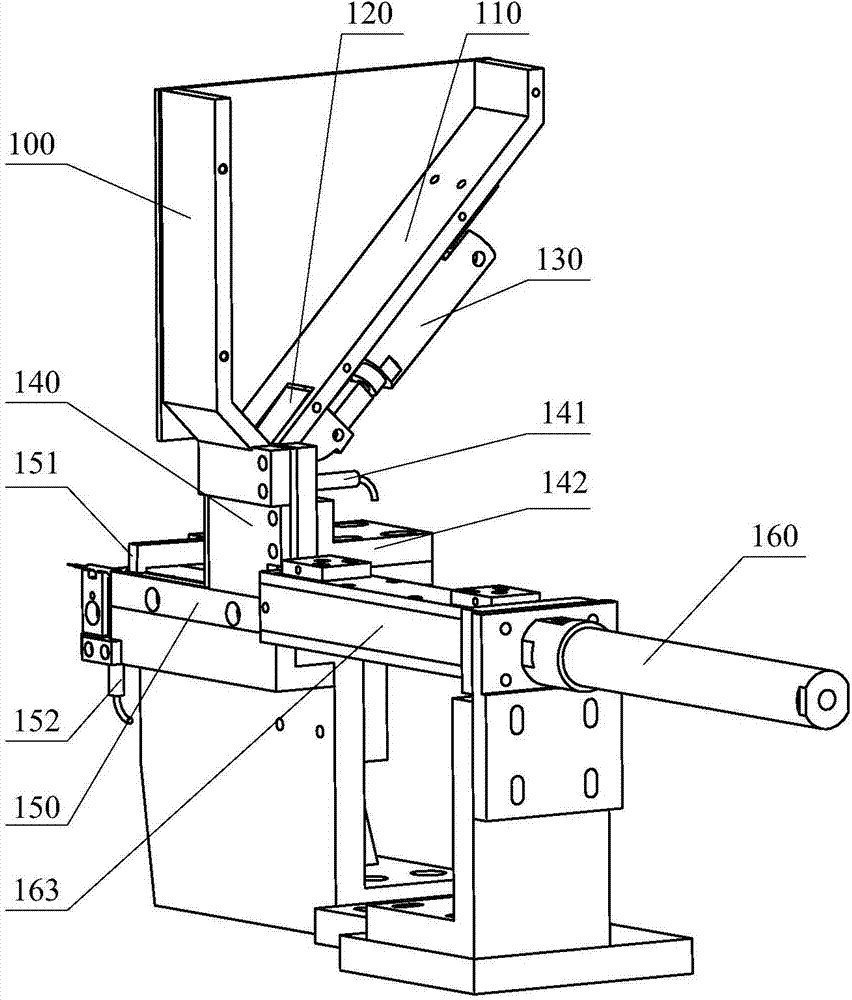

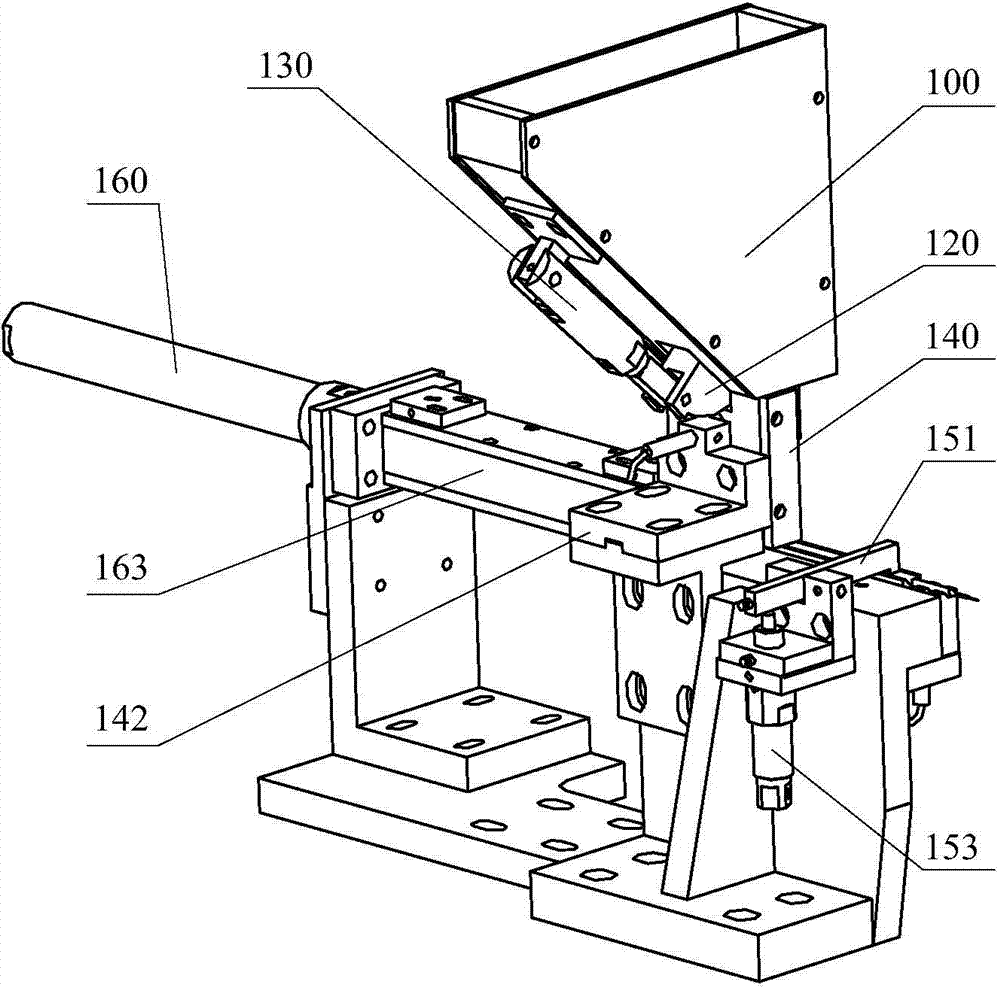

[0020] like figure 1 and figure 2 As shown, the present embodiment provides a feeding device, including: a hopper 100 and a lower chute 140 arranged at the outlet of the hopper 100, on the side of the inclined plate 110 of the hopper 100, at the outlet, and a There is a material turning plate 120 and its driving device 130 , the material turning plate 120 is hinged on the inclined plate 110 . Since the turning plate 120 is set on the inclined plate 110 of the hopper 100, when the bar material slides down in the hopper 100, the bar material is flipped and sorted through the material turning plate 120, so that the bar material can smoothly fall into the trough 140 , thereby avoiding the situation that the bar material is blocked at the notch of the feeding chute 140, improving the stability and reliability of feeding in the hopper 100, and fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com