Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

105results about How to "Orderly operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

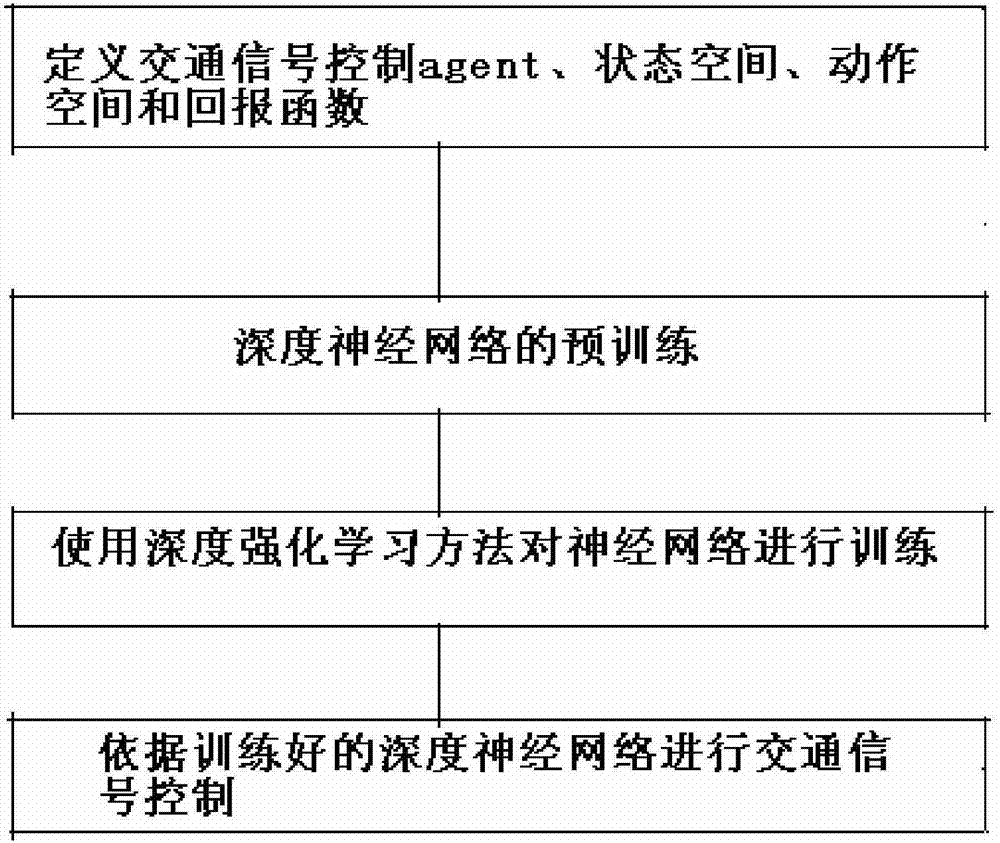

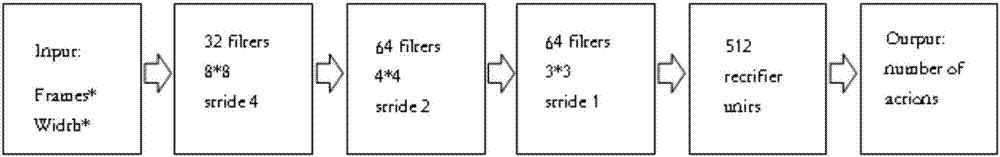

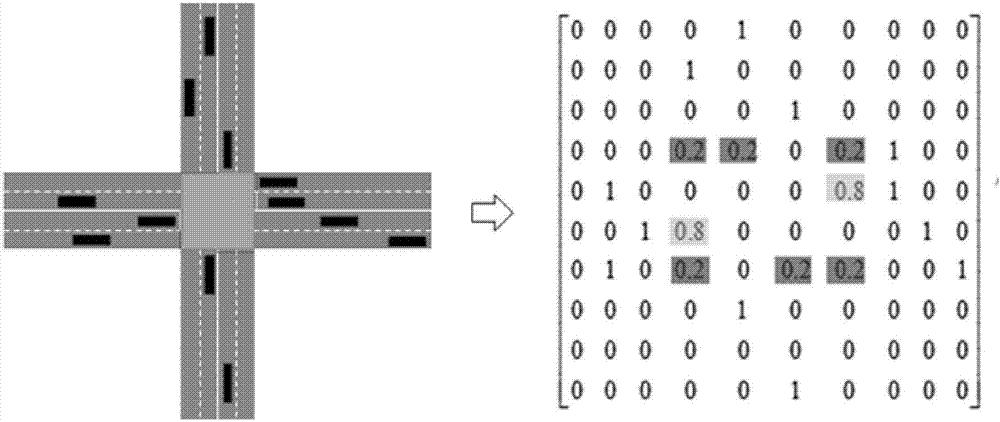

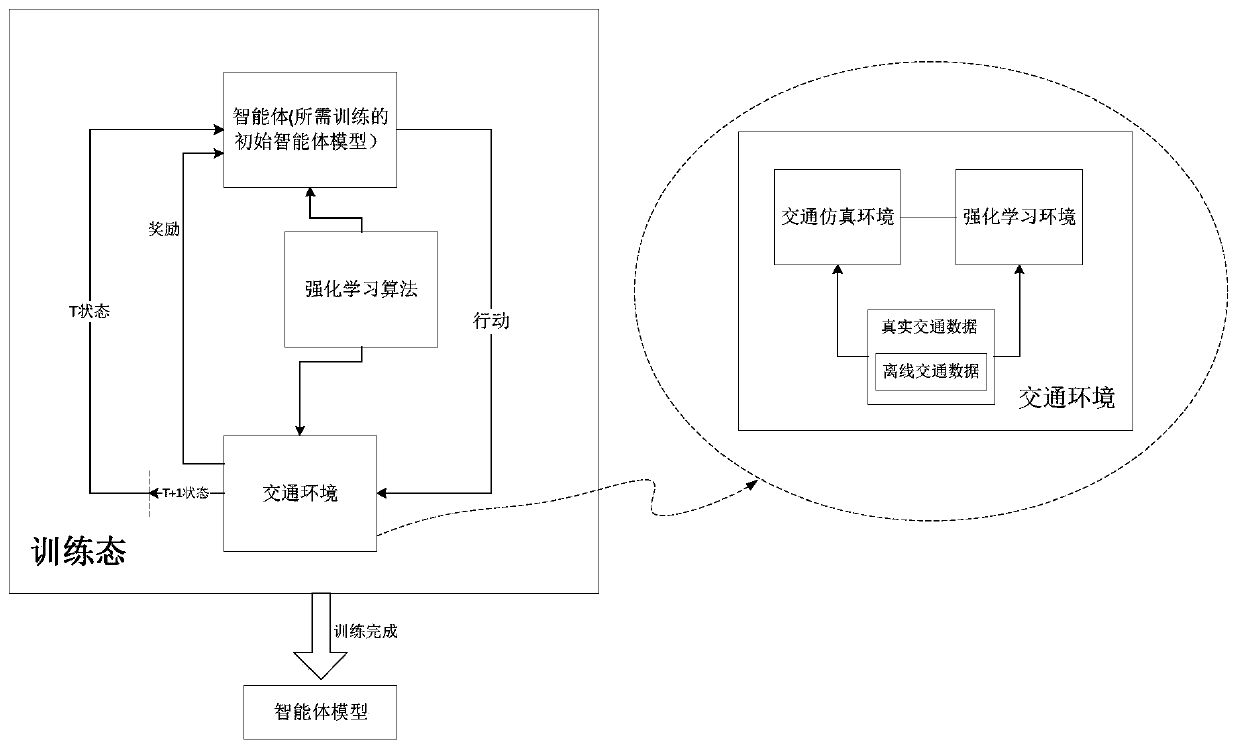

Traffic signal self-adaptive control method based on deep reinforcement learning

InactiveCN106910351ARealize precise perceptionSolve the problem of inaccurate perception of traffic statusControlling traffic signalsNeural architecturesTraffic signalReturn function

The invention relates to the technical field of traffic control and artificial intelligence and provides a traffic signal self-adaptive control method based on deep reinforcement learning. The method includes the following steps that 1, a traffic signal control agent, a state space S, a motion space A and a return function r are defined; 2, a deep neutral network is pre-trained; 3, the neutral network is trained through a deep reinforcement learning method; 4, traffic signal control is carried out according to the trained deep neutral network. By preprocessing traffic data acquired by magnetic induction, video, an RFID, vehicle internet and the like, low-layer expression of the traffic state containing vehicle position information is obtained; then the traffic state is perceived through a multilayer perceptron of deep learning, and high-layer abstract features of the current traffic state are obtained; on the basis, a proper timing plan is selected according to the high-layer abstract features of the current traffic state through the decision making capacity of reinforcement learning, self-adaptive control of traffic signals is achieved, the vehicle travel time is shortened accordingly, and safe, smooth, orderly and efficient operation of traffic is guaranteed.

Owner:DALIAN UNIV OF TECH

Signal lamp control method, and related equipment and system

PendingCN110114806ARealize intelligent controlImprove congestionControlling traffic signalsDetection of traffic movementSimulationComputer science

A signal control method comprises following steps: through database, obtaining historical traffic state data of an intersection; through a training module, based on the historical traffic state data,carrying out intensive learning to obtain a signal lamp training model; and through a model library, storing the signal lamp training model, wherein the signal lamp training model comprises mapping relationship between the traffic state data and a control strategy, which indicates the light-on rule of the signal lamps of the intersection. The signal lamp training model is used to output the control strategy of the signal lamps of the intersection based on the real-time traffic state data.

Owner:HUAWEI CLOUD COMPUTING TECH CO LTD

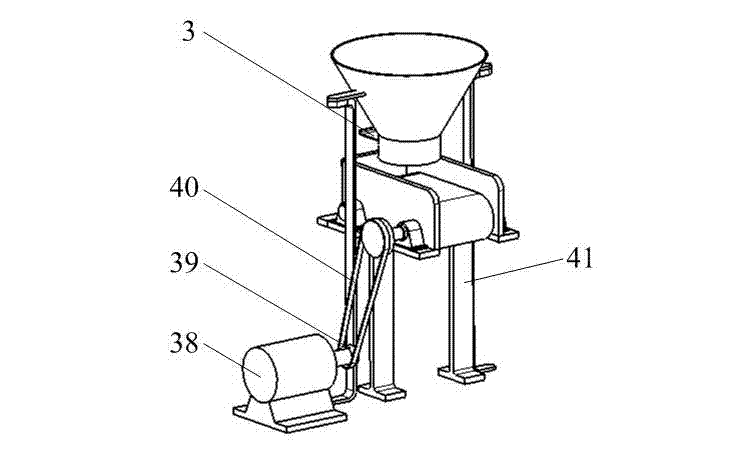

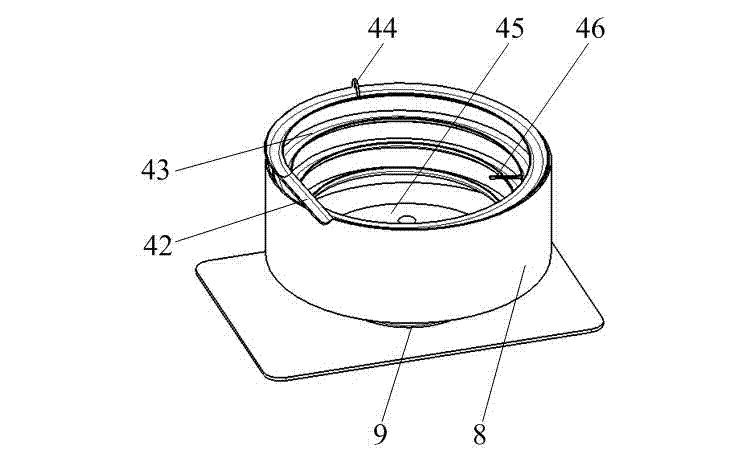

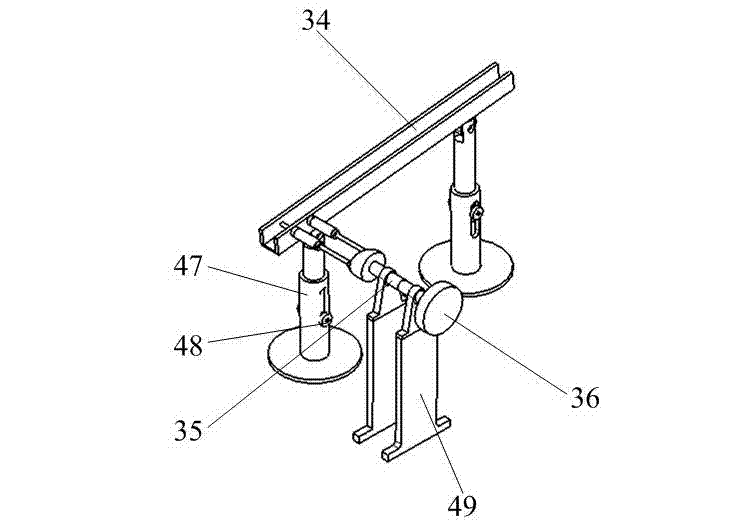

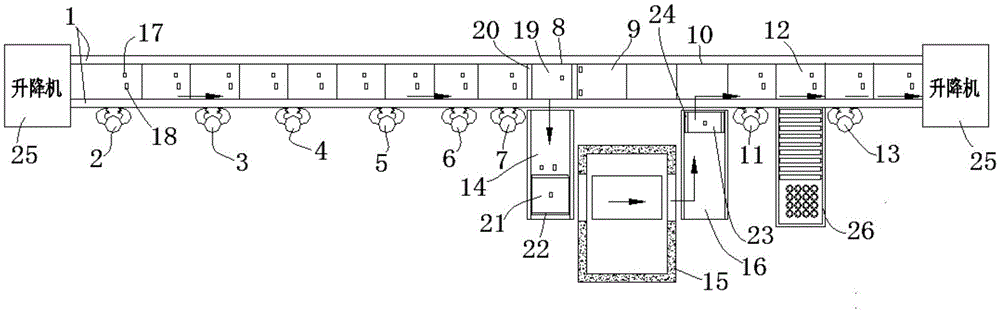

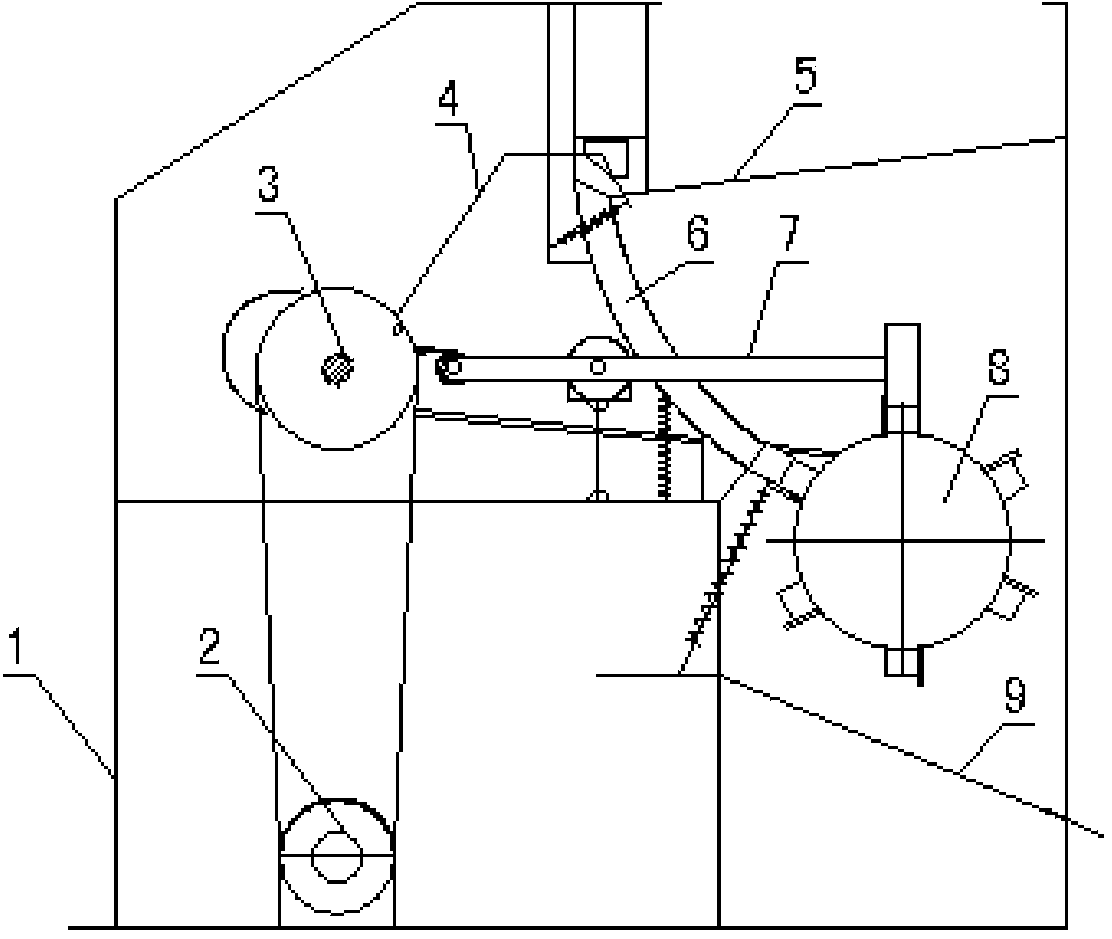

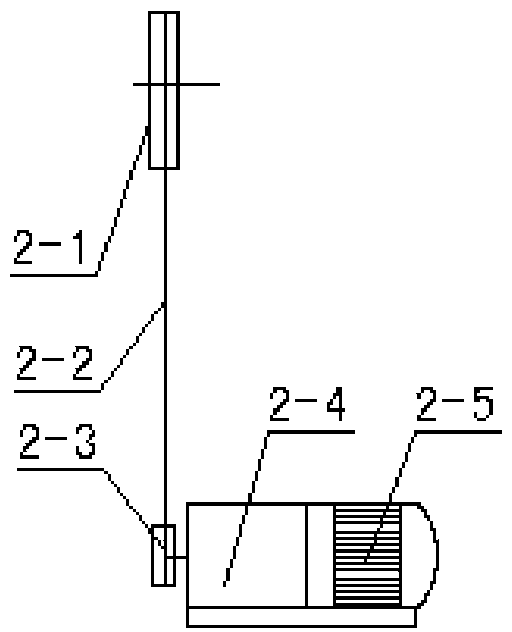

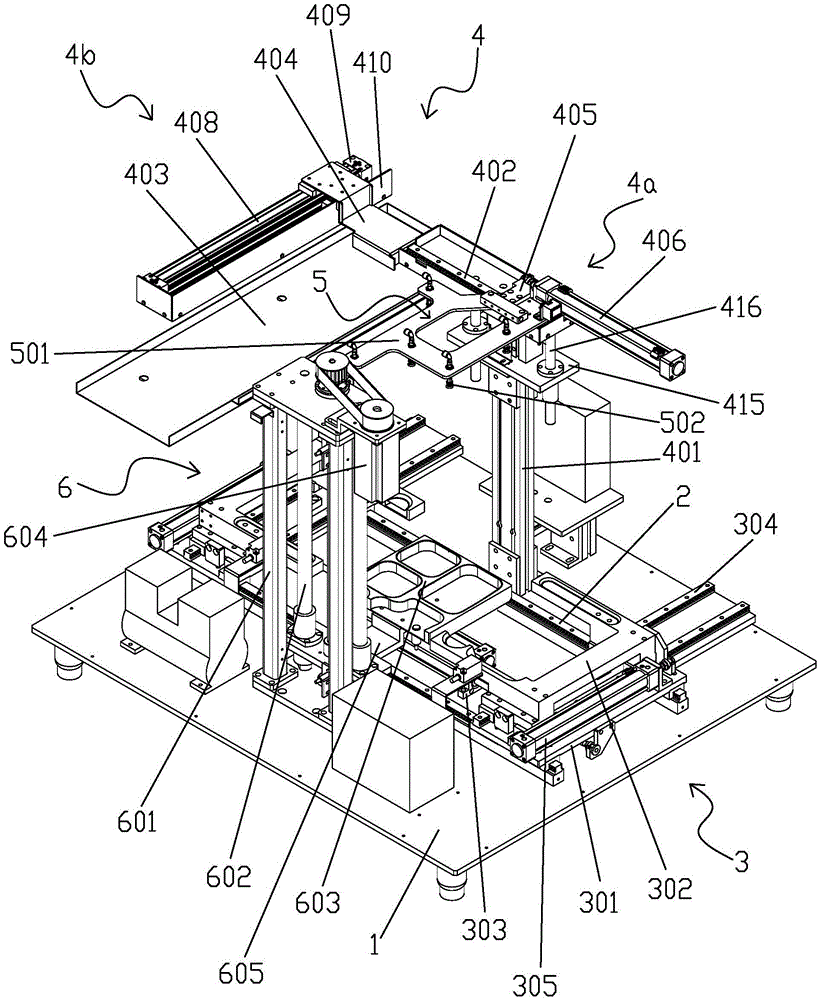

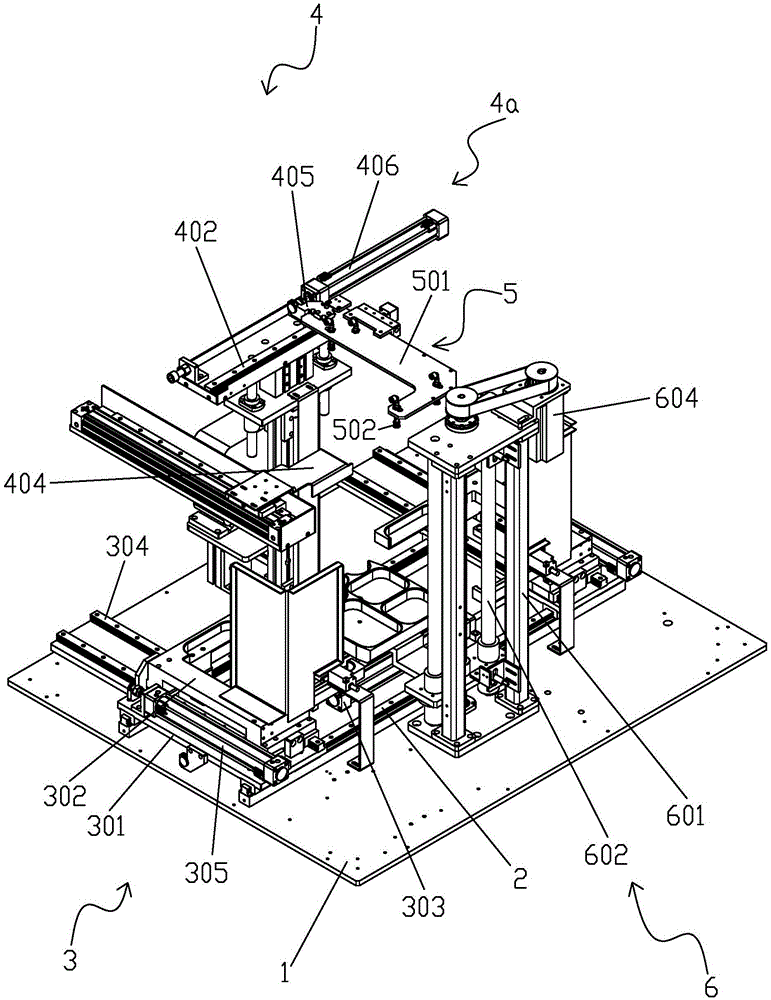

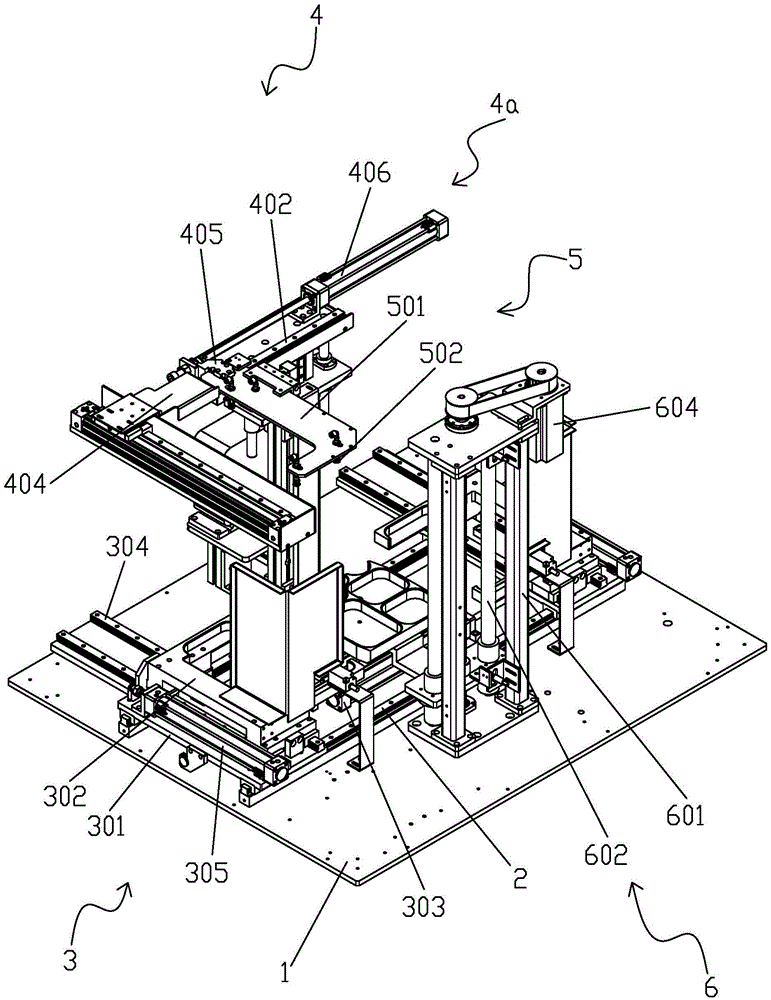

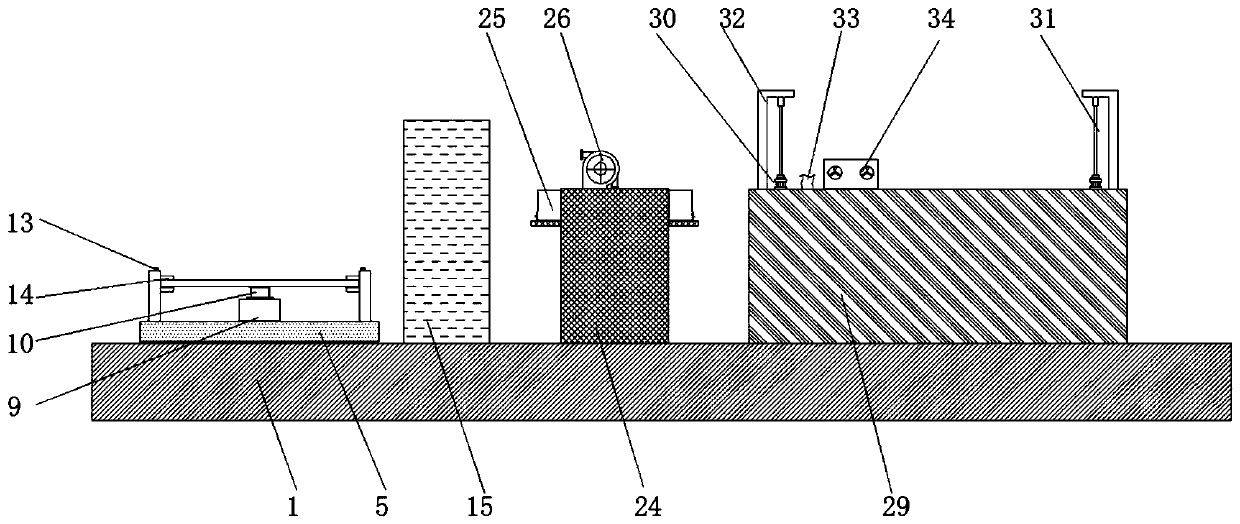

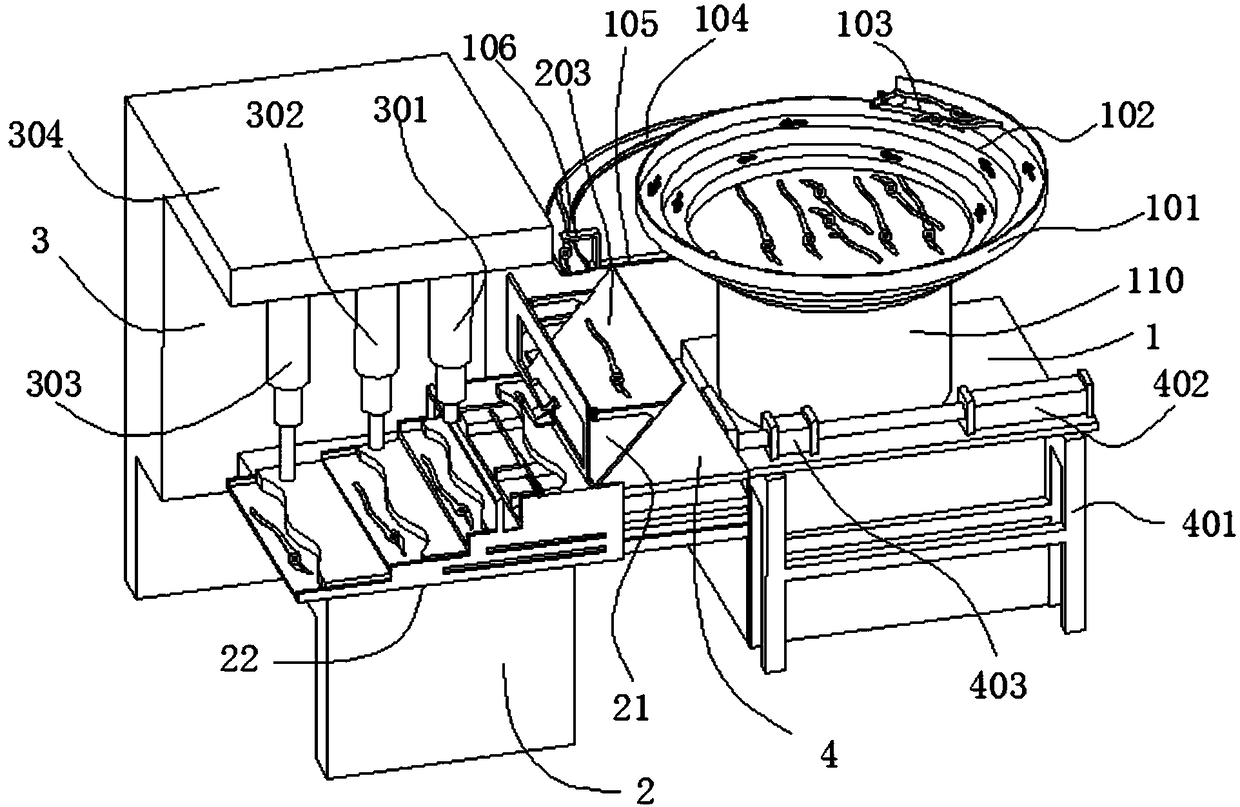

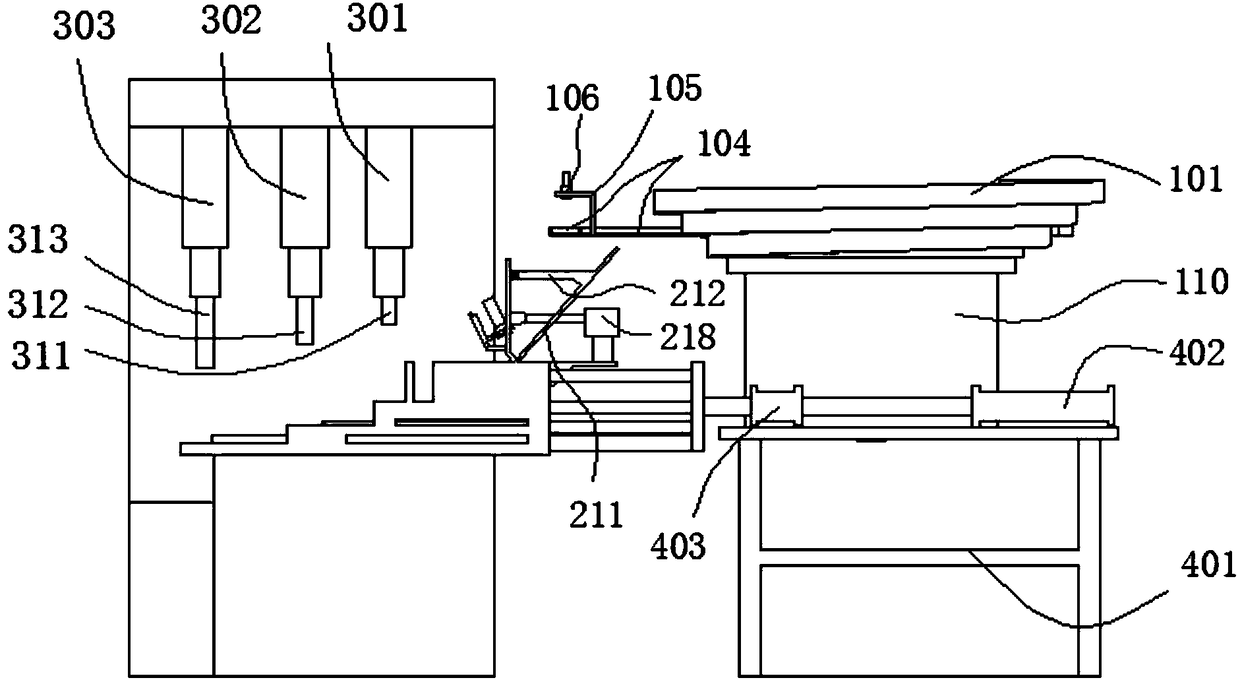

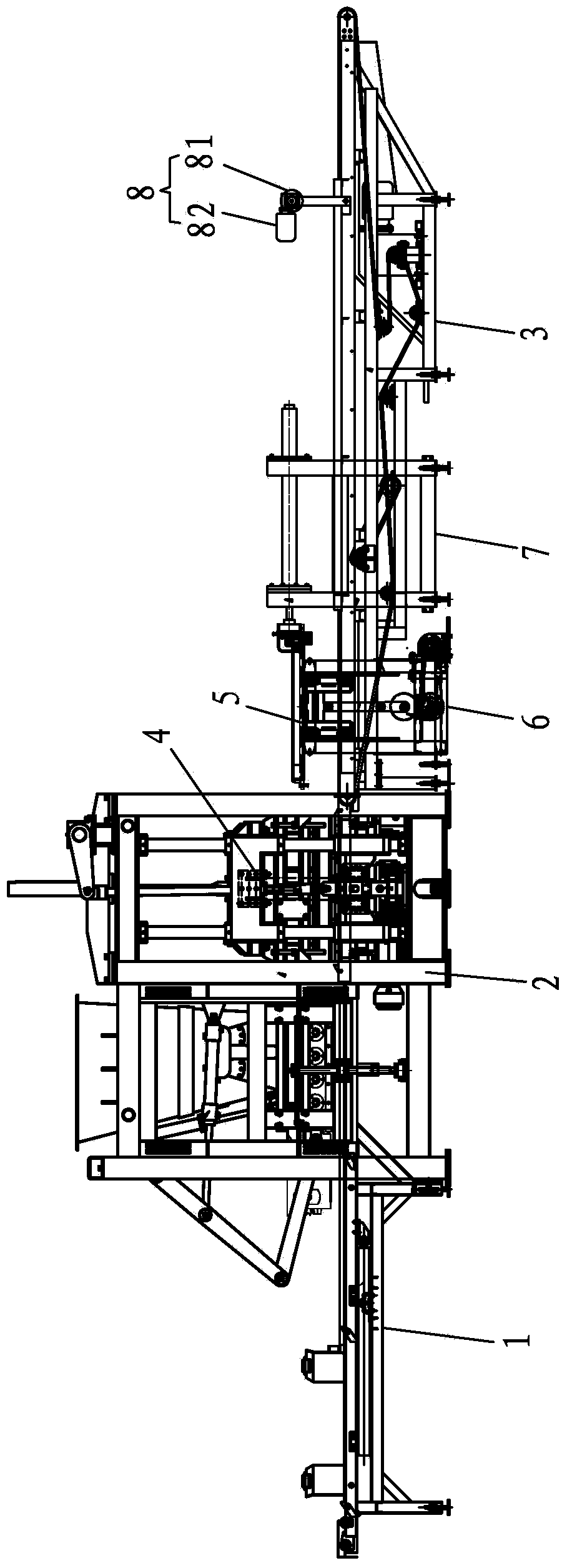

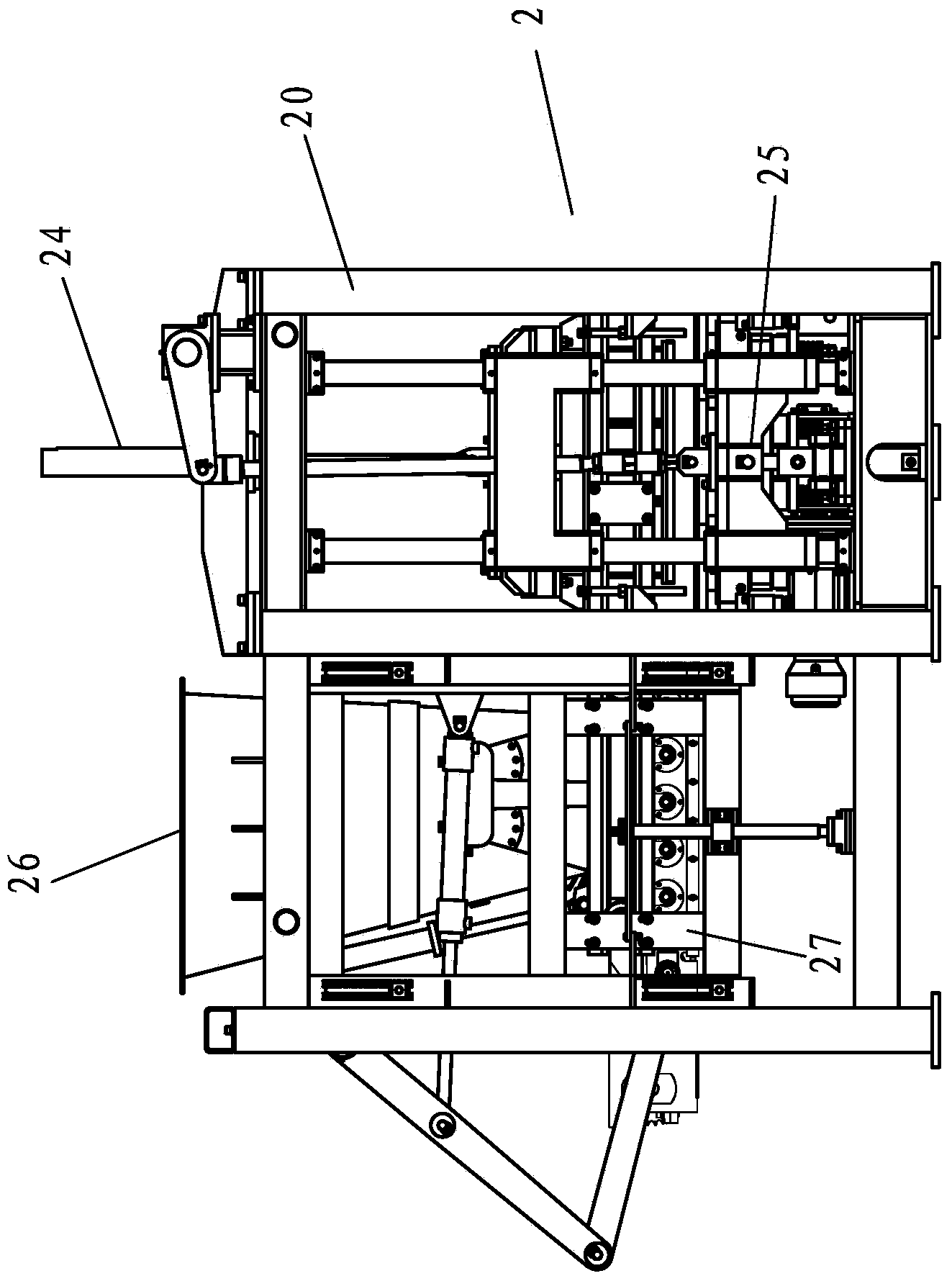

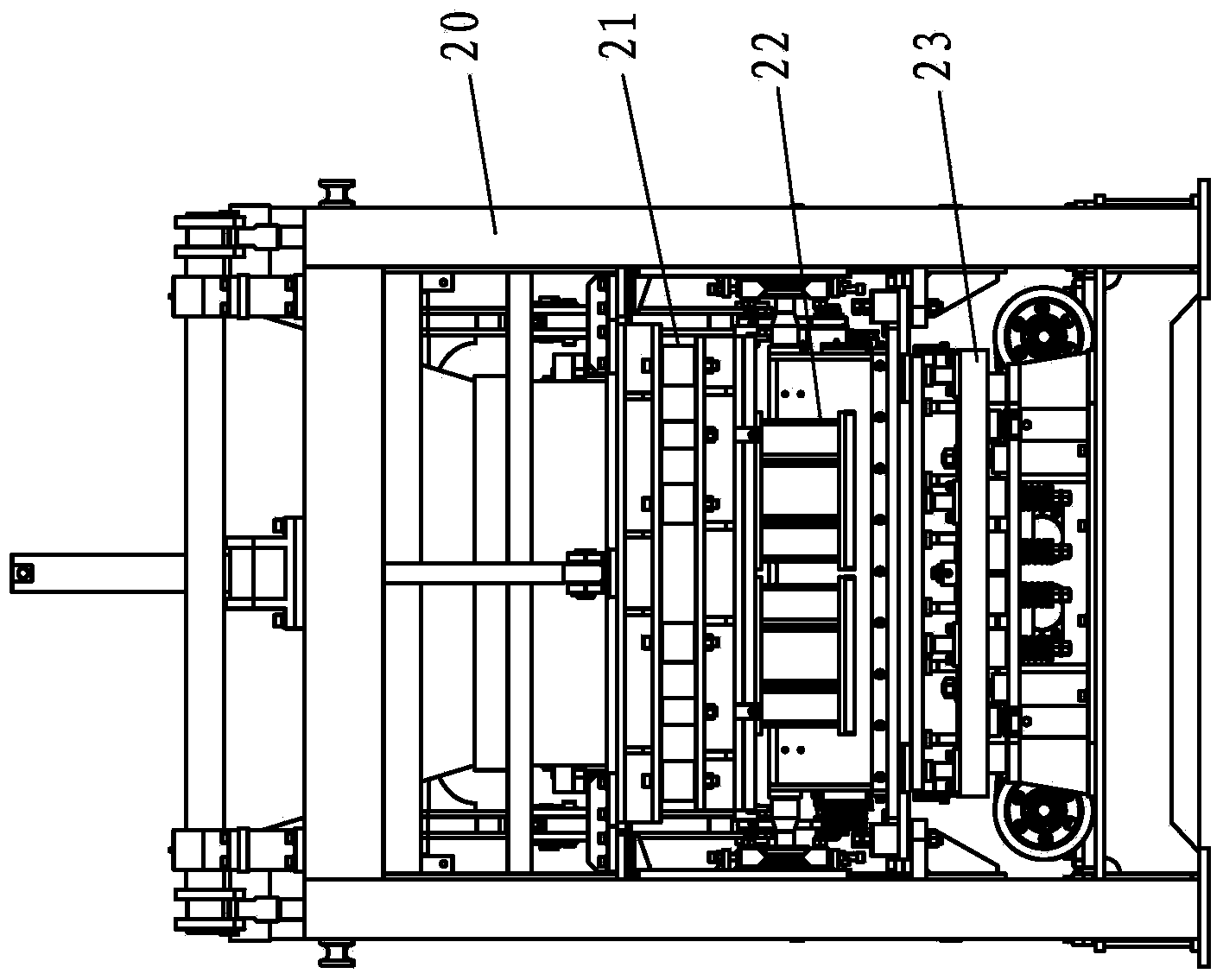

Walnut feeding, conveying, isolating and shelling all-in-one machine

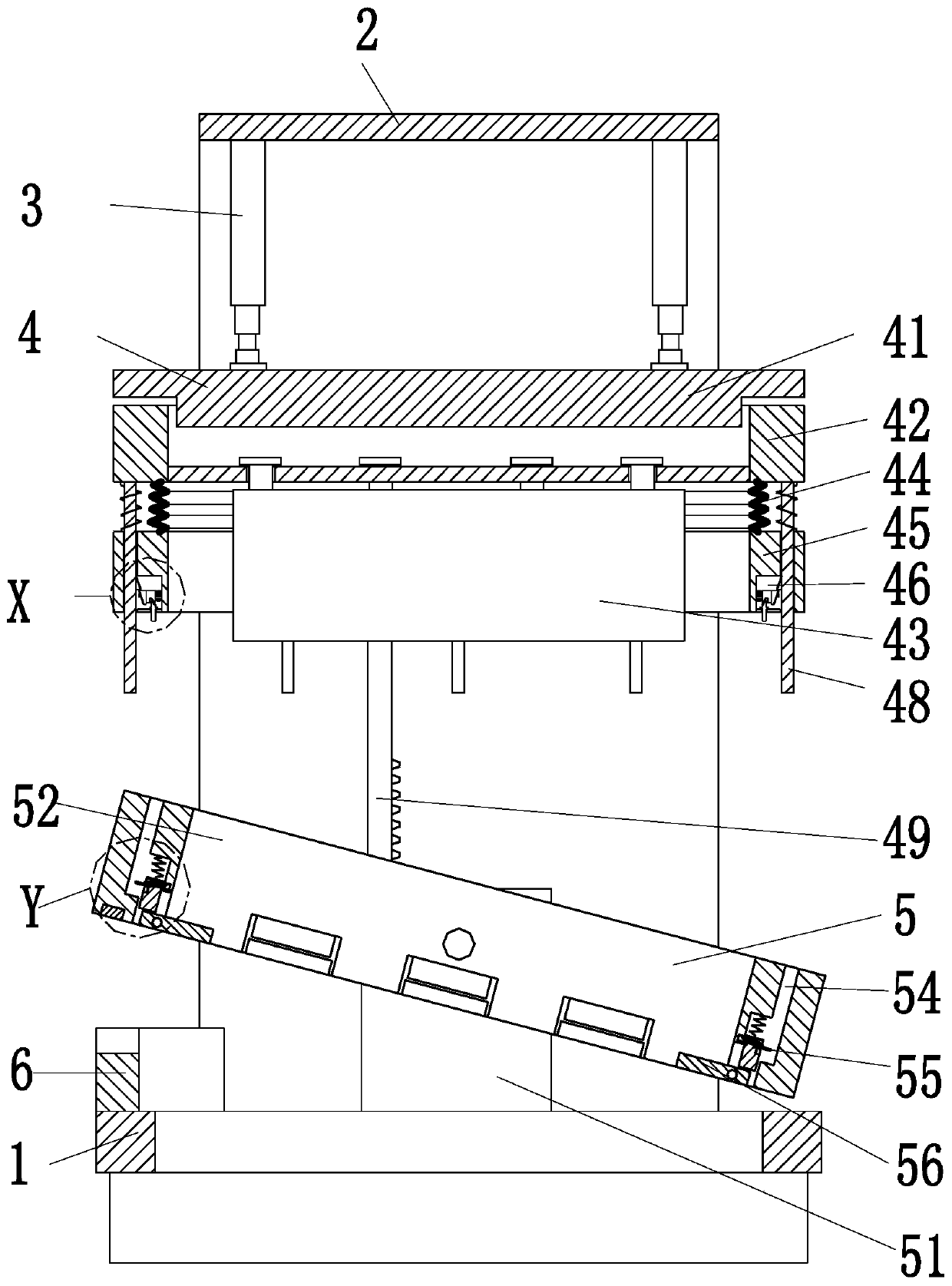

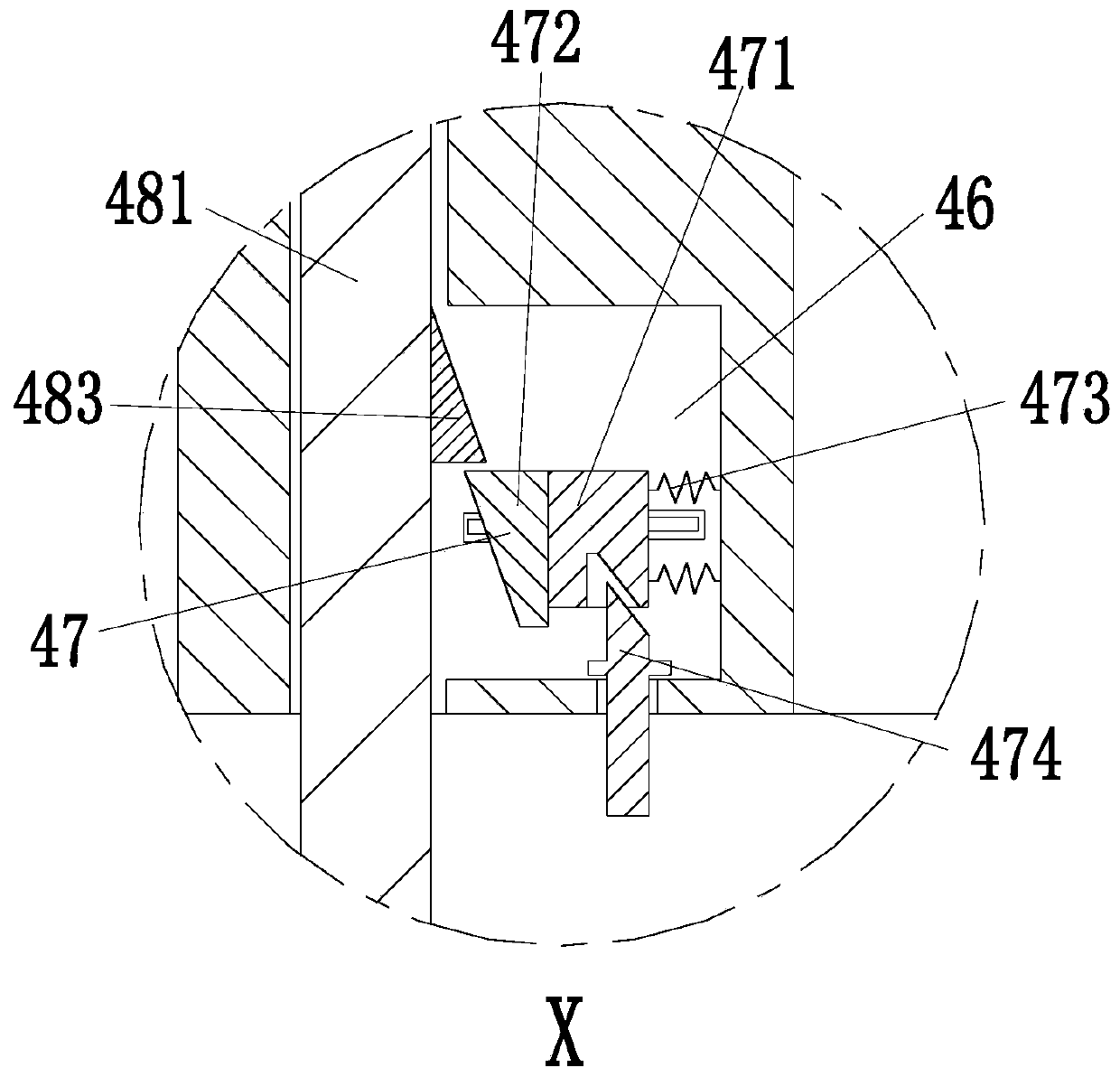

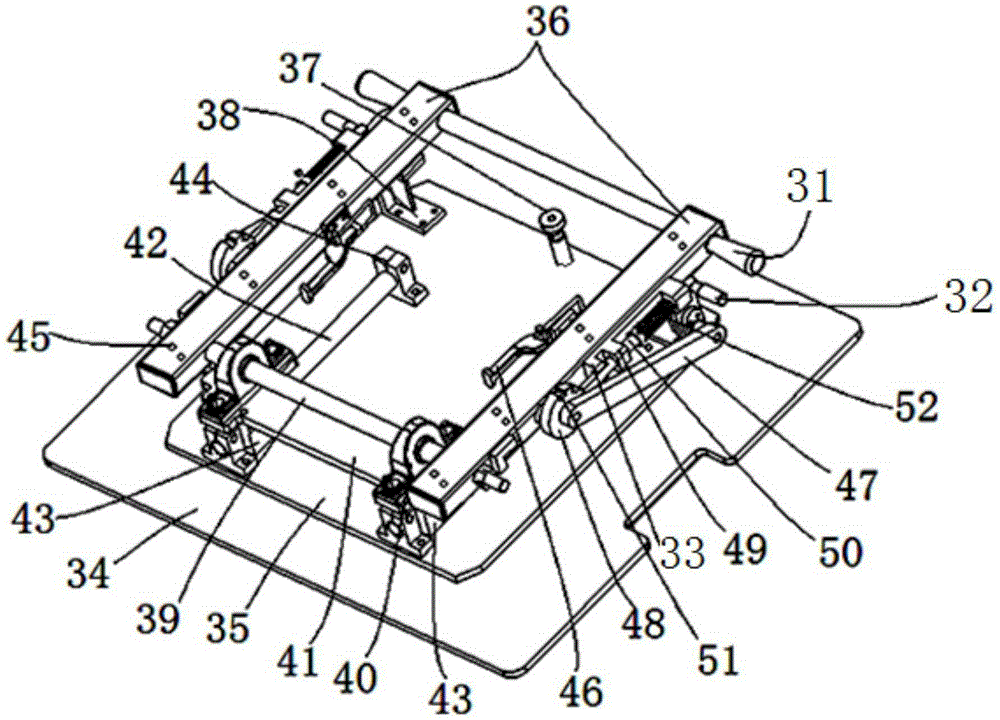

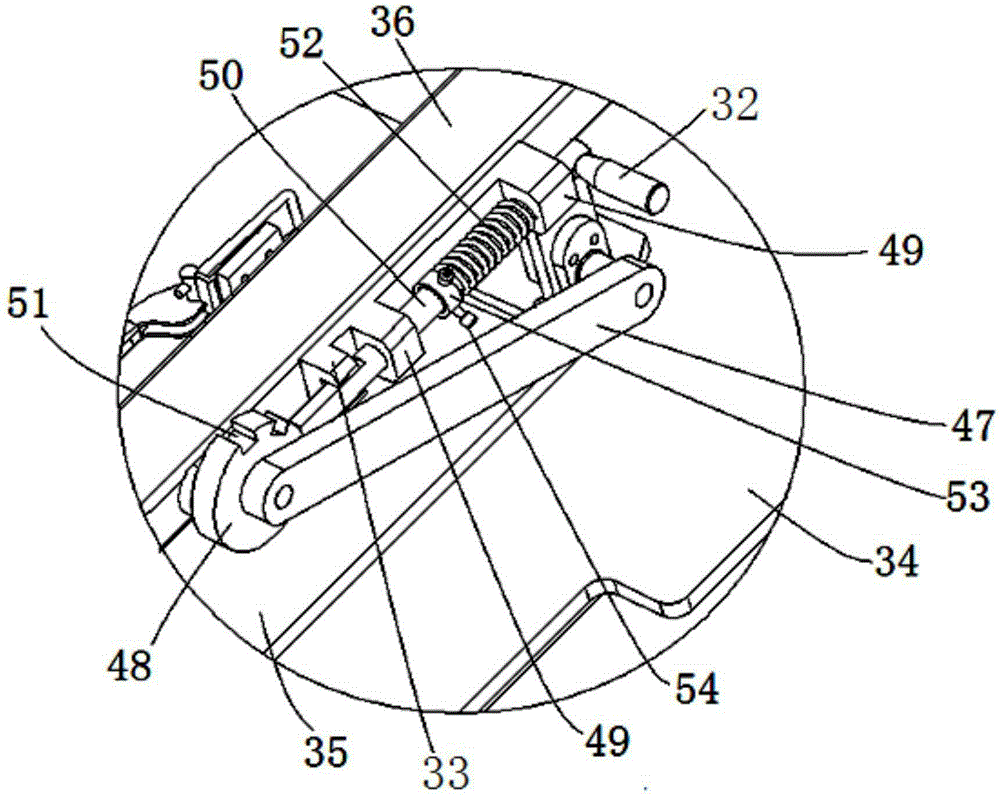

The invention discloses a walnut feeding, conveying, isolating and shelling all-in-one machine which consists of a main machine seat, a feeding and conveying device, a vibrating and conveying device, an isolating device, a shelling device and a power transmission. The feeding and conveying device, the vibrating and conveying device, the isolating device, the shelling device and the power transmission are mounted on the main machine seat. Compared with the prior art, the walnut feeding, conveying, isolating and shelling all-in-one machine has the following advantages that an integrated design method integrating feeding, conveying, isolating and shelling is adopted, and mechanization, automation and integration degrees of the total machine are high; walnuts are supplied by the aid of a conveying belt, a vibrating disc, an isolating device and a conveying disc, so that supplying speed is flexible and adjustable, labor cost is effectively reduced, and processing efficiency is improved; and the linear reciprocating latch type isolating device and the cylindrical cam indexing type conveying disc are adopted, so that coordinated, orderly and efficient running is realized in a walnut shelling process, and the walnut feeding, conveying, isolating and shelling all-in-one machine is applicable to industrialized, standard and large-scale production. In addition, a work mode is reliable, shelling efficiency is high, and accordingly the walnut feeding, conveying, isolating and shelling all-in-one machine is popularized and applied conveniently.

Owner:SHANDONG UNIV OF TECH

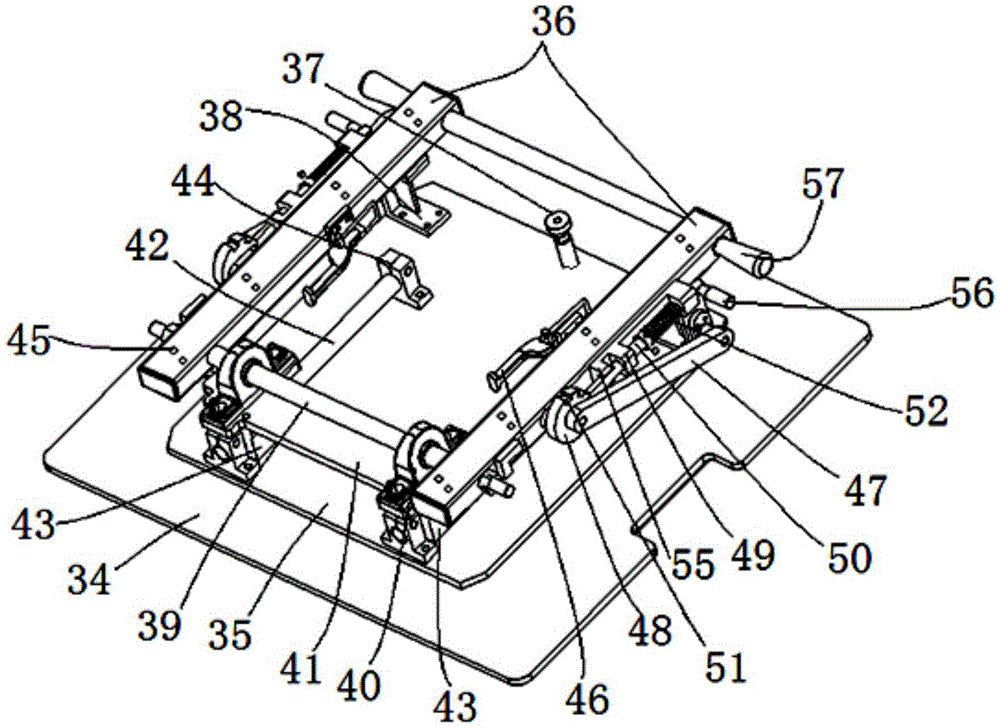

Automatic assembly line for automobile seats and assembly method

ActiveCN105537928AGuaranteed assembly qualityReduce labor intensityAssembly machinesVehicle componentsProduction lineNoise detection

The invention discloses an automatic assembly line for automobile seats and an assembly method. The automatic assembly line comprises a work table and conveying chains arranged on the two sides of the work table, and the work table is sequentially provided with a sliding rail set assembly station, a cushion set assembly station, a backrest set assembly station, a protection plate and safety belt buckle assembly station, a headrest assembly station, a wire arranging station, a first transferring station, a transitioning station, a second transferring station, an appearance function detection station, a repair station and a packaging station; a noise detection conveying work table located the side led to a sound insulation testing chamber is arranged on the side part of the first transferring station, and a noise detection outputting work table led to the second transferring station is arranged on the other side of the sound insulation testing chamber. According to the automatic assembly line, the labor intensity is lowered, the work efficiency is improved, the operation is orderly, errors and neglected assembly occur hardly, and the assembly quality of the seats can be guaranteed.

Owner:WUHU RUITAI AUTO PARTS

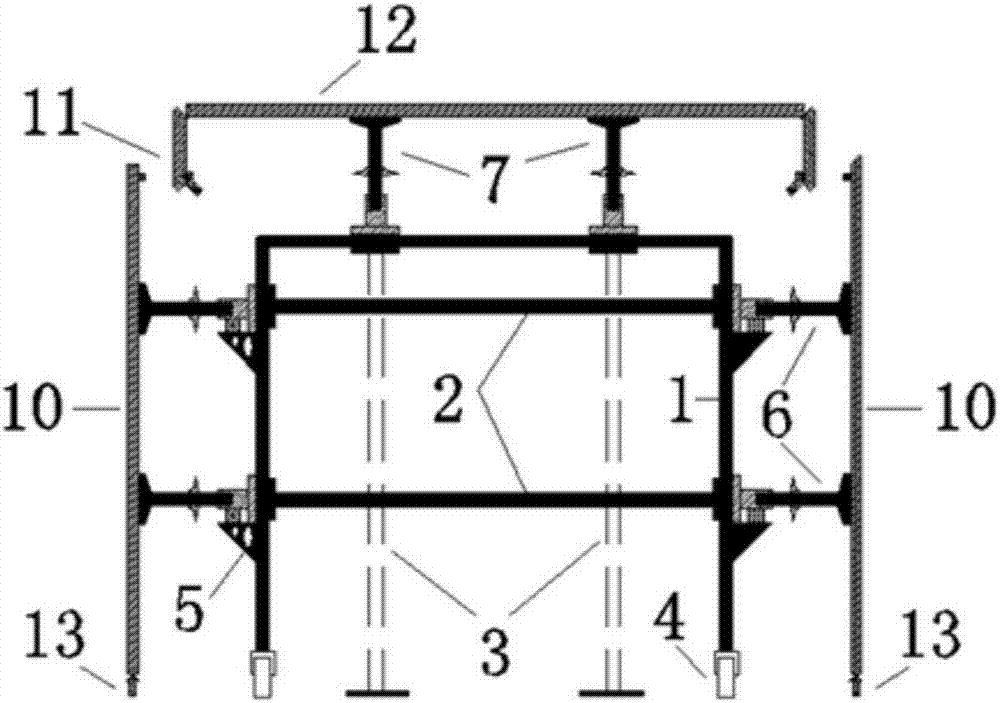

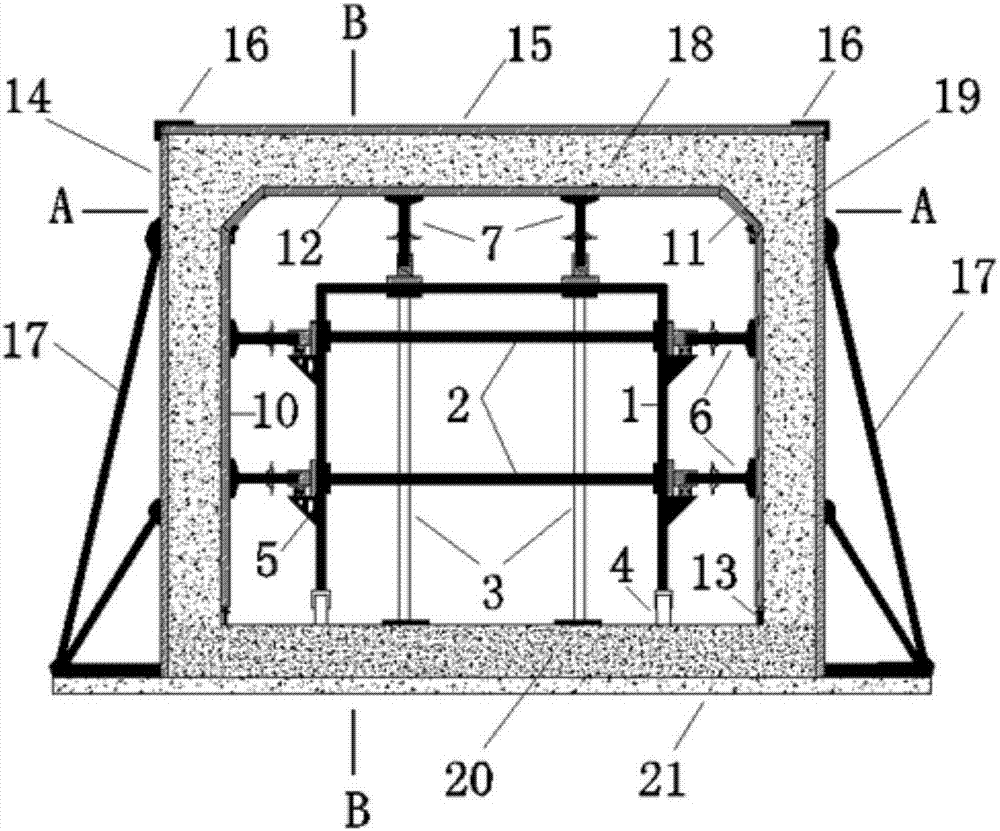

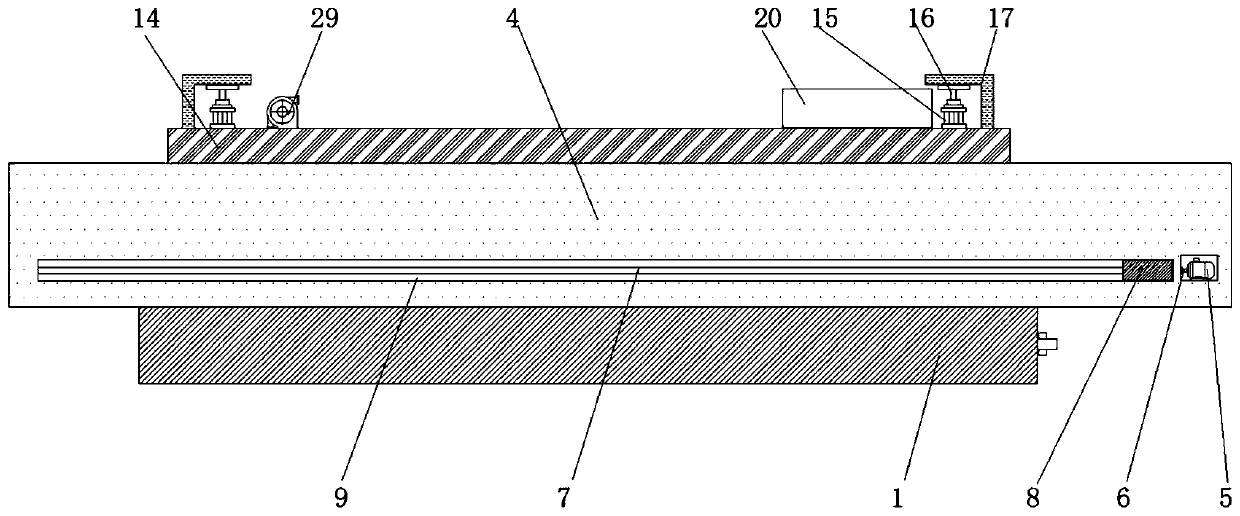

Utility tunnel integral formwork and using method thereof

ActiveCN107119715AImprove construction qualityImprove waterproof performanceArtificial islandsUnderwater structuresSupporting systemEconomic benefits

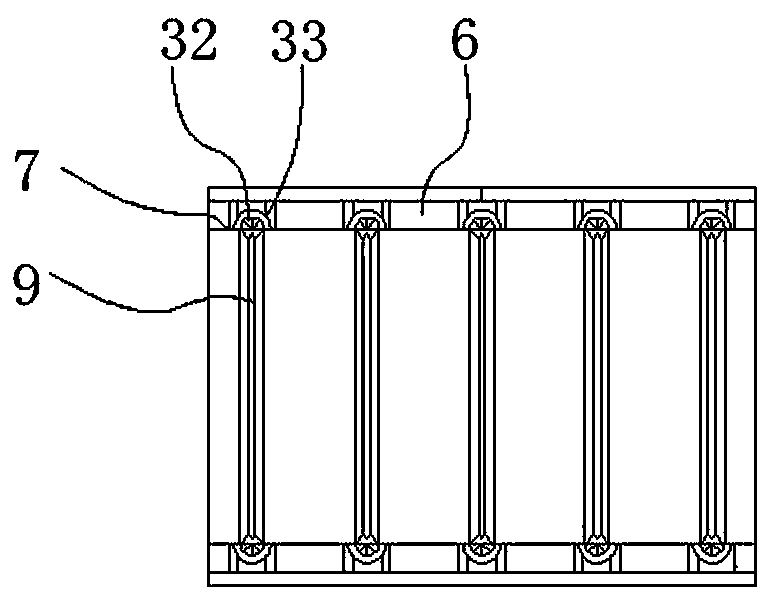

The invention discloses a utility tunnel integral formwork and a using method thereof. The utility tunnel integral formwork comprises an inner formwork body and an outer formwork body. The inner formwork body comprises an inner supporting frame, wheels, tripods, transverse adjustable jacks, vertical adjustable jacks, inner formwork vertical plates, an inner formwork top plate, inner formwork corner plates and universal wheels. The outer formwork body comprises outer formwork vertical plates, an outer formwork top plate, buckles and inclined struts. According to the utility tunnel integral formwork capable of moving integrally, a traditional supporting system composed of a plurality of anchor rods and a plurality of wooden plates is effectively optimized, the supporting procedures are simplified, the construction efficiency is improved, the construction quality of a utility tunnel can be improved, and the surface waterproofing performance of the utility tunnel can also be optimized. The inner formwork body can move integrally to the next construction section for direct supporting. The construction method is easy and convenient to implement, ordered and high in construction efficiency, does not need much labor or time, and can bring great economic benefits.

Owner:NORTHEASTERN UNIV

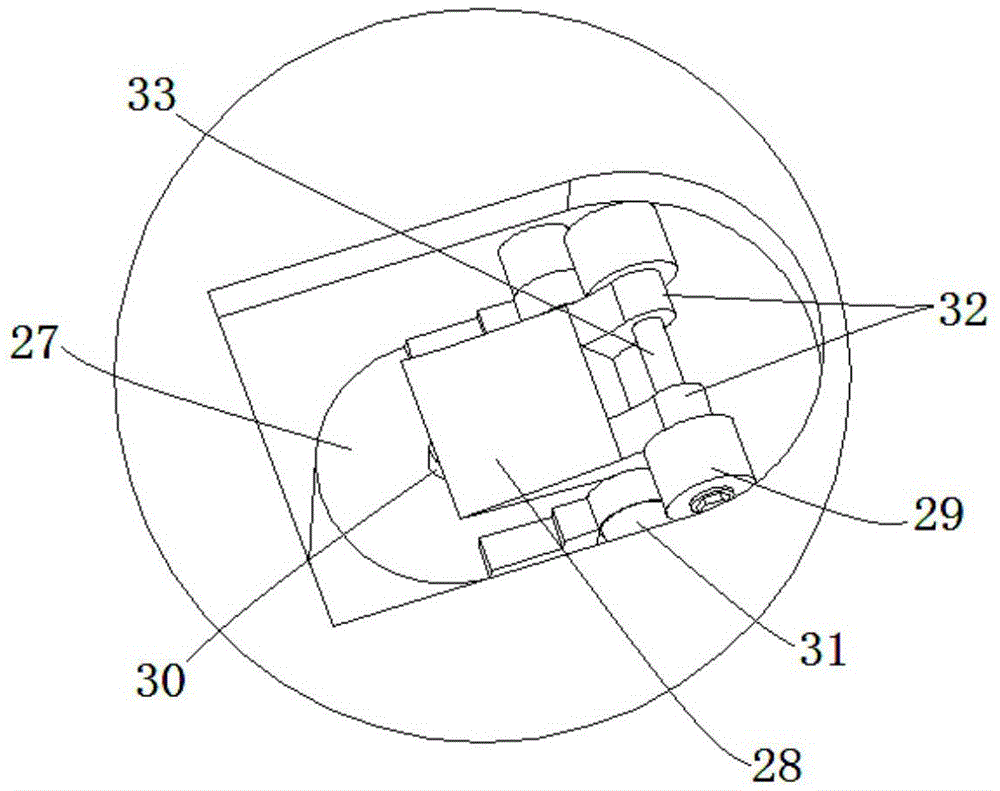

Pecan hulling machine

The invention discloses a pecan hulling machine. The pecan hulling machine comprises a machine frame, wherein the machine frame is provided with a feed device, a hulling device, a discharge device and a power transmission device, wherein the feed device comprises a feed hopper and a feed pipe; the hulling device comprises a feed cylinder and a beating rod assembly; a plurality of outwards convex hammer bases are evenly arranged on the circumference of the feed cylinder; a plurality of small concave pits are formed in the inwards concave surfaces of the hammer bases; the beating rod assembly comprises a beating rod idler wheel, a beating rod, a beating rod bearing base, a beating rod hammer and a beating rod spring; the front end and the rear end of the beating rod are provided with the beating rod hammer and the beating rod idler wheel respectively; the middle of the beating rod is hinged to the beating rod bearing base to form a lever fulcrum; the upper end of the beating rod spring is connected to the beating rod; the lower end of the beating rod spring is fixed to the machine frame; the beating rod is driven through a cam mechanism to vertically swing; the cam mechanism comprises a cam and a flat board; the flat board is arranged at the opposite end of the convex surface of the cam. The pecan hulling machine has the advantages that granules of hulled pecans are full and low in degree of breakage, the level of integration and degree of automation are high, the hulling efficiency is high, and cost is low.

Owner:丁孝德

Automatic wood-working mechanical device

InactiveCN106965267AReduce stepsImprove work efficiencyEdge grinding machinesStationary drilling machinesEngineeringMechanical devices

The invention relates to the field of wood-working mechanical devices, in particular to an automatic wood-working mechanical device. The automatic wood-working mechanical device comprises a rack table face and further comprises a supplying mechanism, a feeding mechanism, slotting mechanisms, a drilling mechanism and unloading mechanisms which are arranged on the rack table face; the automatic wood-working mechanical device further comprises smoothing mechanisms arranged on the rack table face; the supplying mechanism comprises a guide rail, a supplying bracket sliding along the guide rail and a supplying air cylinder connected with the supplying bracket; and the feeding mechanism is arranged on one side of the front end of the guide rail, the smoothing mechanisms, the unloading mechanisms and the slotting mechanisms are sequentially arranged on the two sides of the middle portion of the guide rail, and the drilling mechanism is arranged in front of the tail end of the guide rail. By means of the automatic wood-working mechanical device, wood materials can be subject to the smoothing, drilling and slotting processes automatically.

Owner:WUHAN UNIV OF SCI & TECH

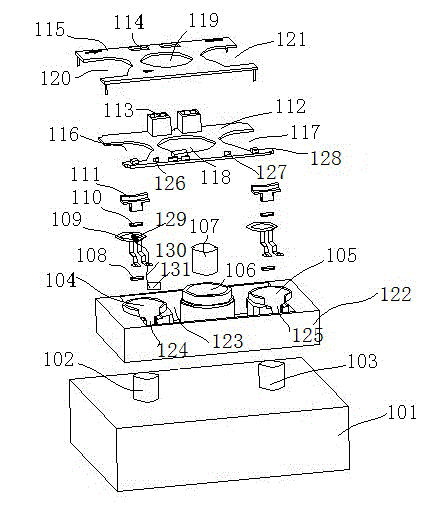

Full-automatic intelligent meal separating machine

The invention discloses a full-automatic intelligent meal separating machine which comprises a base. The full-automatic intelligent meal separating machine is characterized in that a sliding rail is arranged on the base and provided with a plate input conveying device; the plate input conveying device can slide on the sliding rail, store dinner plates and convey the dinner plates into the meal separating machine; and the base is provided with a plate output conveying device, and the plate output conveying device can transfer and convey the dinner plates to the position below a meal separating opening of the meal separating machine through the plate input conveying device and push out the dinner plates after meal separating. The full-automatic intelligent meal separating machine aims at overcoming the defects in the prior art, is simple in structure, can automatically carry out meal separating and meal delivering, saves meal fetching time, increase efficiency, and is safer and more sanitary.

Owner:DEA GENERAL AVIATION HLDG CO LTD

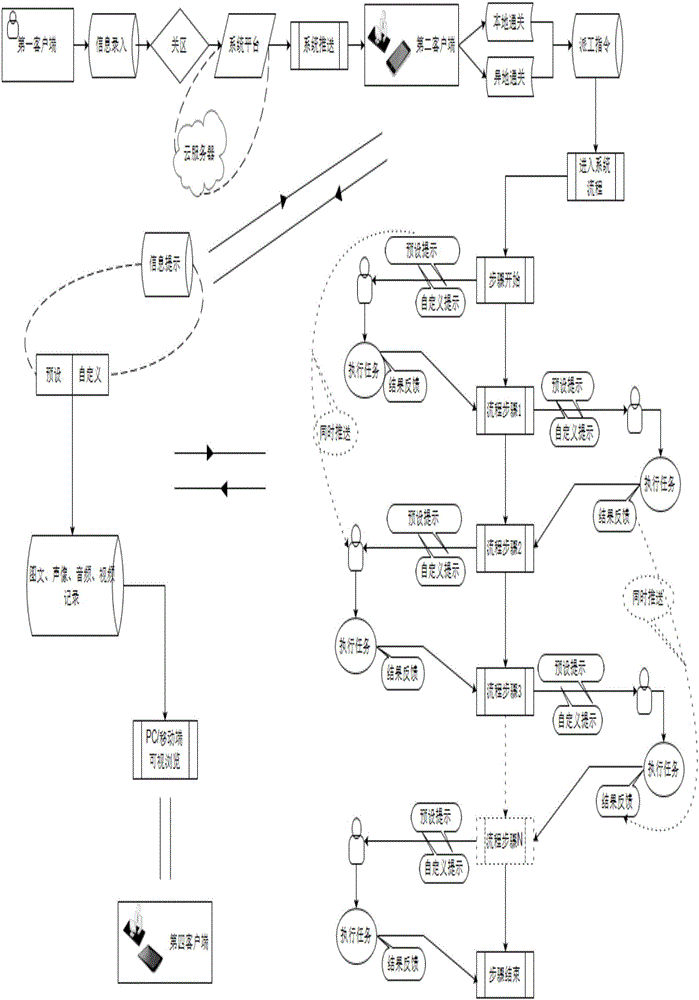

International trade logistics processing system and method with immediate prompting function

InactiveCN106845903AImprove operational efficiencyReduce management costsTransmissionLogisticsLogistics managementSoftware system

The invention discloses a foreign trade logistics processing system and method with an instant prompt function, which provides a generally applicable stylized and standardized foreign trade logistics operation and tracking service software system for foreign trade, freight forwarding, customs brokers and other industries, and is especially suitable for different places The logistics service is especially in line with the strategy of "Regional Communication" and "Electronic Port" that the country is implementing. Through the data interaction between multiple data interaction clients and the cloud server, the system realizes the information synchronization of multiple data interaction clients at different points, so that business managers, operators and customers can understand the logistics process in the first time and make decisions. Corresponding processing; through online job dispatch and business management, work instructions and business processes are clarified, which greatly saves enterprise management costs; this system realizes the real-time connection between online and offline, making business operations more timely, smooth, efficient and efficient. Orderly, improve the operating efficiency of the enterprise, and save the labor cost and time cost of the enterprise at the same time.

Owner:天津联兴科技技术有限公司

Stamping, grinding and coating integrated device for manufacturing carbon fiber automobile engine hood

PendingCN110900218AImprove stabilityEasy to handleEdge grinding machinesShaping toolsFiberCarbon fibers

The invention discloses a stamping, grinding and coating integrated device for manufacturing a carbon fiber automobile engine hood. The device comprises a base and a fixed die. First hydraulic cylinders are fixed to the left side and the right side of the lower end face of a sliding block, a second support is arranged on the right side of a first support, air suction pipelines and an air outflow pipeline are arranged on the inner sides of dust collectors and the bottom of an air outflow pump correspondingly, a third support is arranged on the right side of the second support, the upper sides of second hydraulic cylinders are connected with baffles through second hydraulic rods, a spraying machine, an air exhaust pump and an electric heating plate are arranged between the baffles, and the spraying machine and the electric heating plate are arranged on the left sides and the right sides of the air suction pipelines correspondingly. According to the stamping, grinding and coating integrated device for manufacturing the carbon fiber automobile engine hood, as stamping and grinding are completed, chips generated in the stamping and grinding processes can be scattered under the effect ofair exhausted by the air outflow pipeline, then the scattered chips can be absorbed away in time through the air suction pipelines, and therefore the purpose of removing the chips is achieved.

Owner:江苏东科复合材料有限公司

Rapid beef slitting device

ActiveCN109676657AEasy to processImprove cleanupMetal working apparatusMeat shaping/cuttingEngineeringMachining

The invention discloses a rapid beef slitting device, and relates to the technical field of food processing. The device comprises a supporting mechanism and a conveying mechanism, a driving mechanismis arranged in the middle end of the top of the supporting mechanism, the conveying mechanism is arranged at the bottom of the supporting mechanism, the supporting mechanism is fixedly connected withthe driving mechanism through a screw, and the front face of the driving mechanism is provided with a hydraulic air cylinder. The device has the beneficial effects that according to the rapid beef slitting device, through slitting blades and a mounting sliding block, a worker refers to numerical value on a graduation ruler in advance and marks the needed slitting interval numerical value on the front face of the slitting mechanism through a corresponding marking tool, through the manual control sliding method, each slitting blade is sequentially drawn to be adjusted to the corresponding slitting interval segment point through the mounting sliding block, and through changing of the interval numerical value of each slitting blade in the sliding adjusting process, the device can convenientlyachieve cutting machining of beef needing different slitting intervals.

Owner:济南高投能源发展有限公司

Manufacturing process for mold base

The invention discloses a manufacturing process for a mold base. The manufacturing process comprises the following steps of: manufacturing all mold plates in the mold base by carrying out a series ofsteps including cutting, rough milling, primary roughing, secondary roughing, chamfering, surface grinding, rough frame machining, fine frame machining, perforation, carburization, quenching, fine milling and polishing on steel plates; and connecting and assembling the mold plates by virtue of pin rods and screws to form the mold base, wherein by utilizing carburization, active carbon atoms decomposed from a carburizing medium permeate into the surface layer of each steel plate so that the surface strength of each steel plate in quenching is improved; after the steel plates are cut, the surfaces and sawing surfaces of the steel plates are inspected; qualified steel plates are selected to be subjected to subsequent machining, and thus the strength of the steel plates is improved. The manufacturing process disclosed by the invention adopts closely-arranged procedures, realizes orderly operation, improves the production efficiency, improves the quality of the mold base and prolongs the service life of the mold base.

Owner:昆山普恩斯模具有限公司

Linkage type stamping die

InactiveCN111531034AAvoid stress injuriesEnsure safetyShaping toolsShaping safety devicesStampingHand parts

The invention relates to a linkage type stamping die. The linkage type stamping die comprises a base, an L-shaped frame, a stamping cylinder, an upper die, a lower die and an abutting ring, wherein the L-shaped frame is installed at the rear end of the base, the upper end of the L-shaped frame is connected with the upper die through the stamping cylinder, the lower die is installed in the middle of the base, the upper die and the lower die are vertically arranged, and the abutting ring is installed at the left end of the base. The linkage type stamping die can solve the problems that a lower die and a base of an existing stamping die are always fixedly connected, a flange plate needs to be operated from right above when the flange plate is manually placed or taken out, at the moment, the hand of a person is completely positioned between an upper die and the lower die, the descending time interval of the upper die is the same, and when the flange plate is placed or taken out by the person for a long time and the hand is not timely pulled, the falling upper die can easily cause damage to the hand part which is difficult to recover.

Owner:汪煜

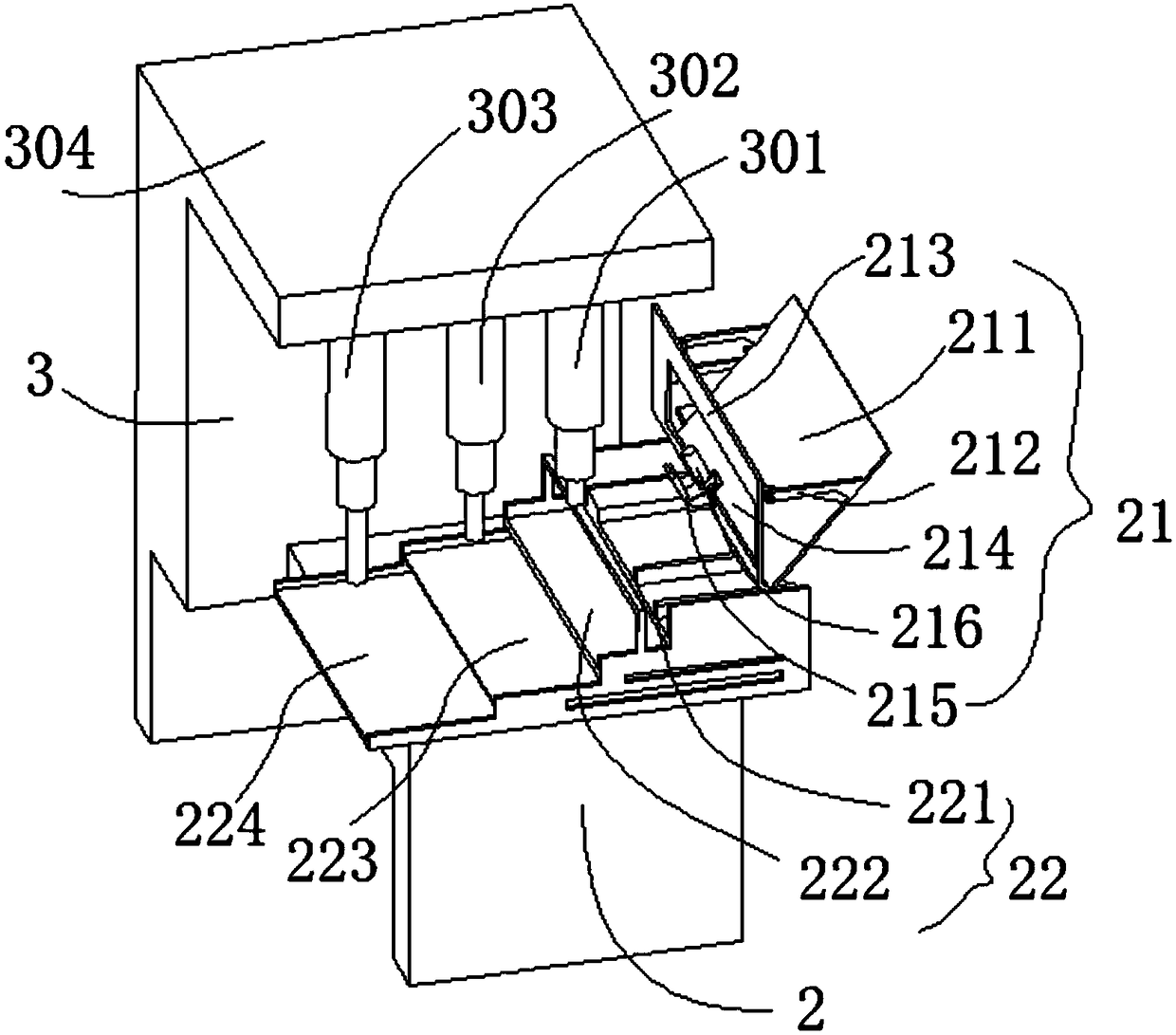

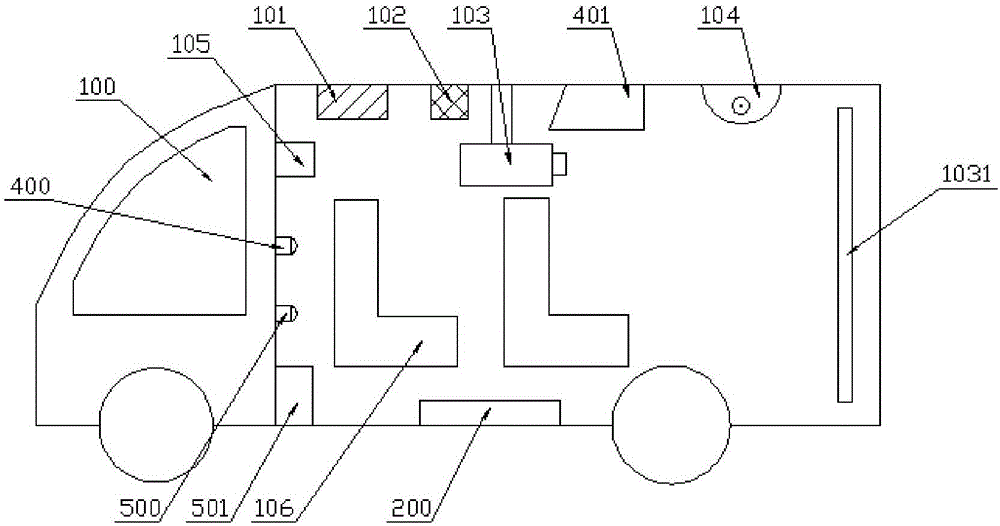

Sorting trolley

PendingCN107774579AOrderly operationReduce error rateGripping headsSortingEngineeringIntelligent control

The invention relates to a sorting trolley. The sorting trolley comprises a trolley body (3), wherein a mechanical arm (2) is arranged on the trolley body (3), a negative pressure device (1) is arranged on the mechanical arm (2), the trolley body is also provided with a camera shooting identification system, an image transmission module, an industrial control computer, a signal receiver and a tablet computer. The sorting trolley also relates to a mobile device thereof, and the mobile device comprises a roller conveyor belt and a wheel (6). The sorting trolley provided by the invention has thecharacteristics of intelligent control, ordered operation, prescription correctness checking, real-time checking on prescription and medicinal materials, real-time monitoring, low medicine sorting error rate, low labor intensity and high sorting efficiency.

Owner:SINOPHARM GRP DEZHONG (FOSHAN) PHARM CO LTD +1

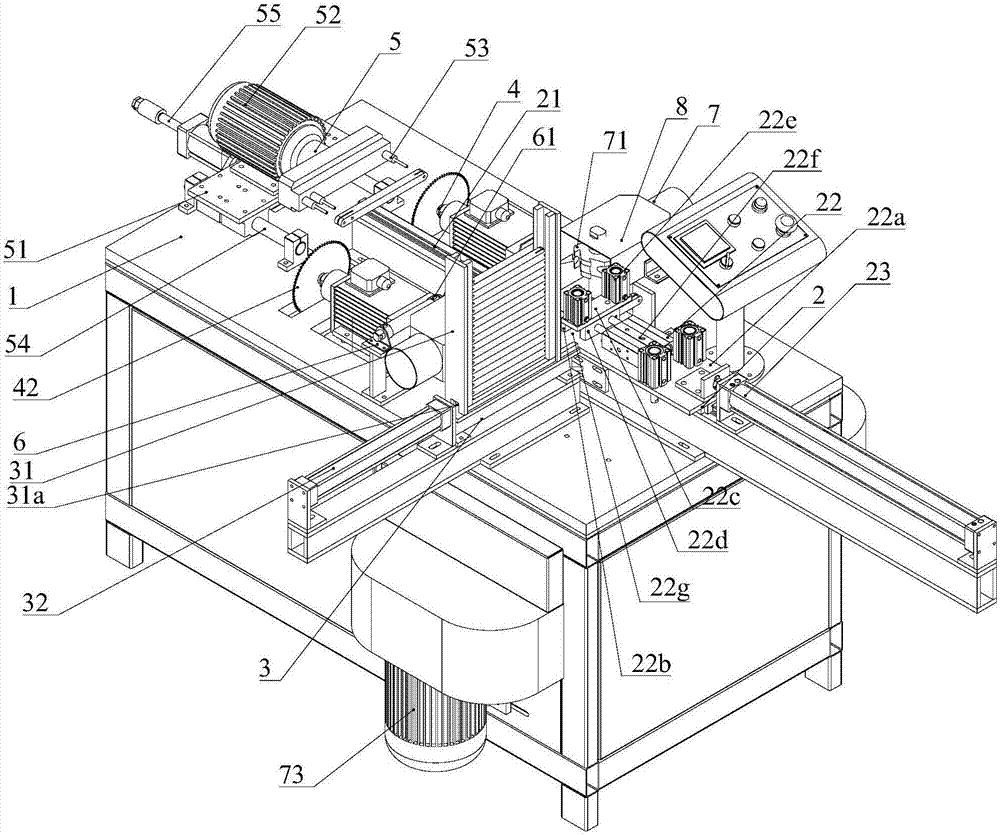

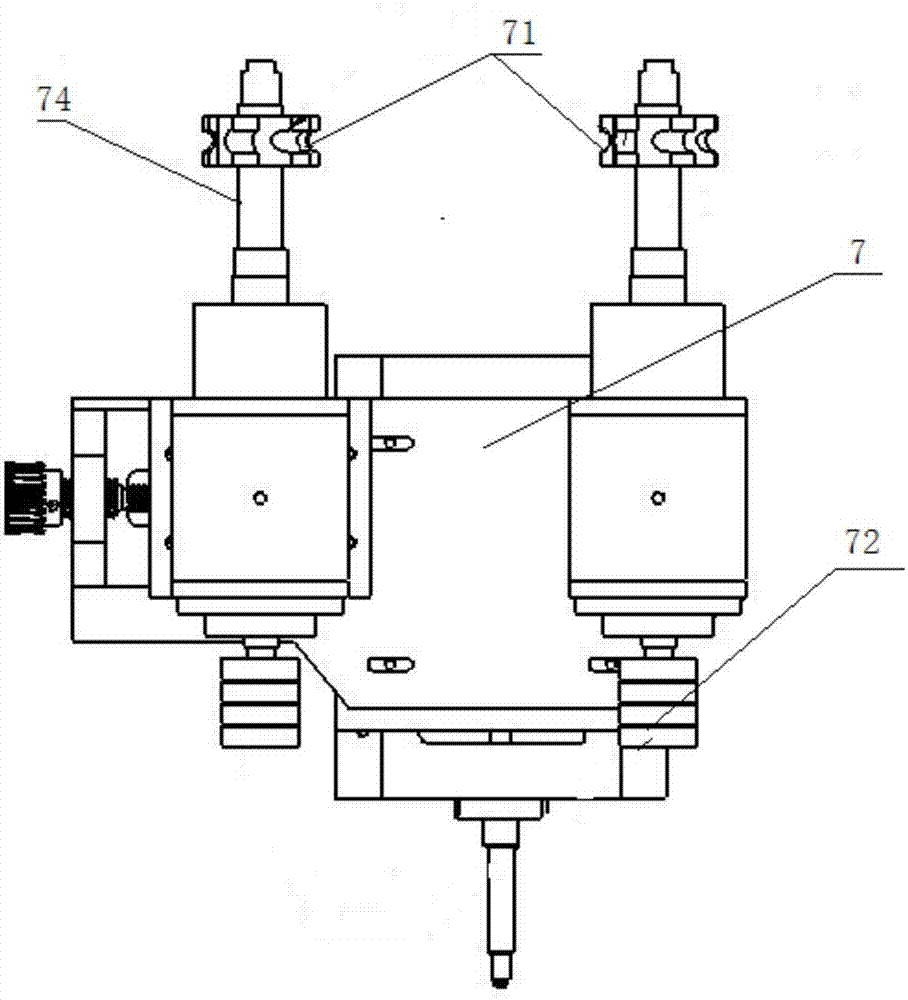

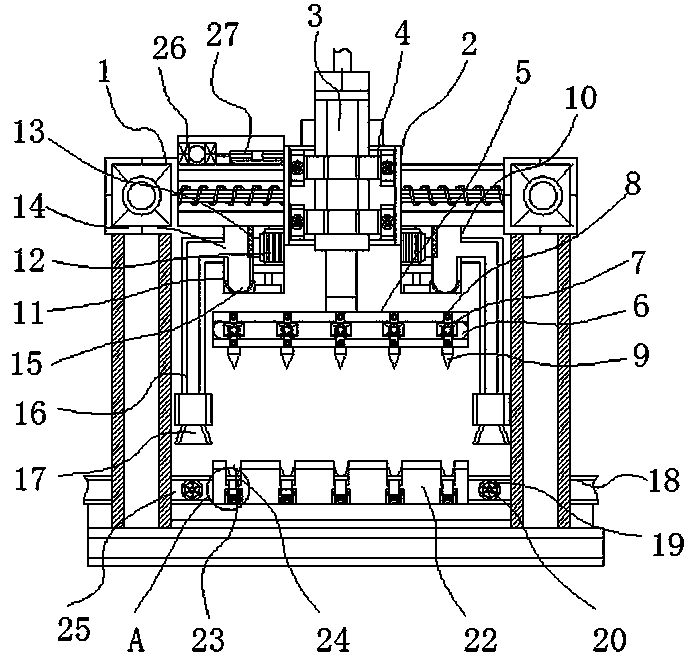

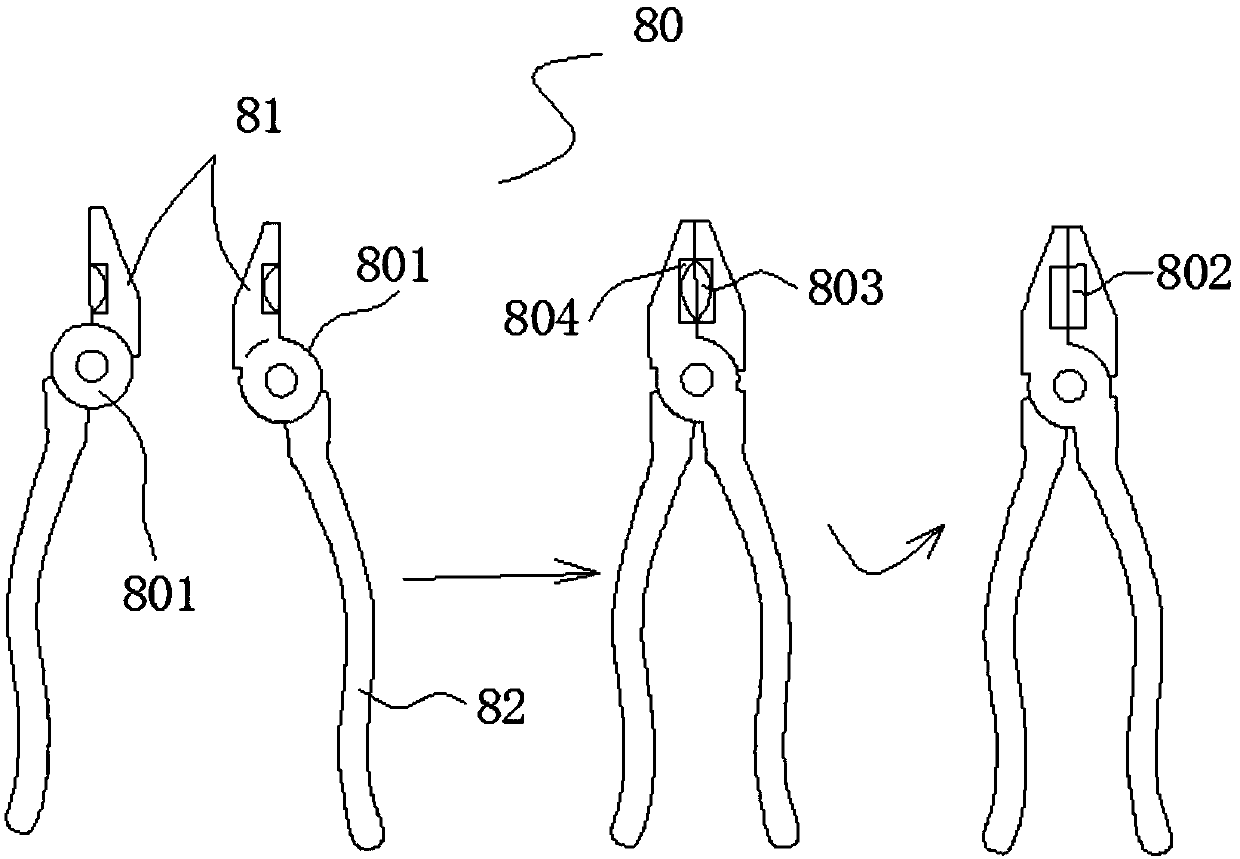

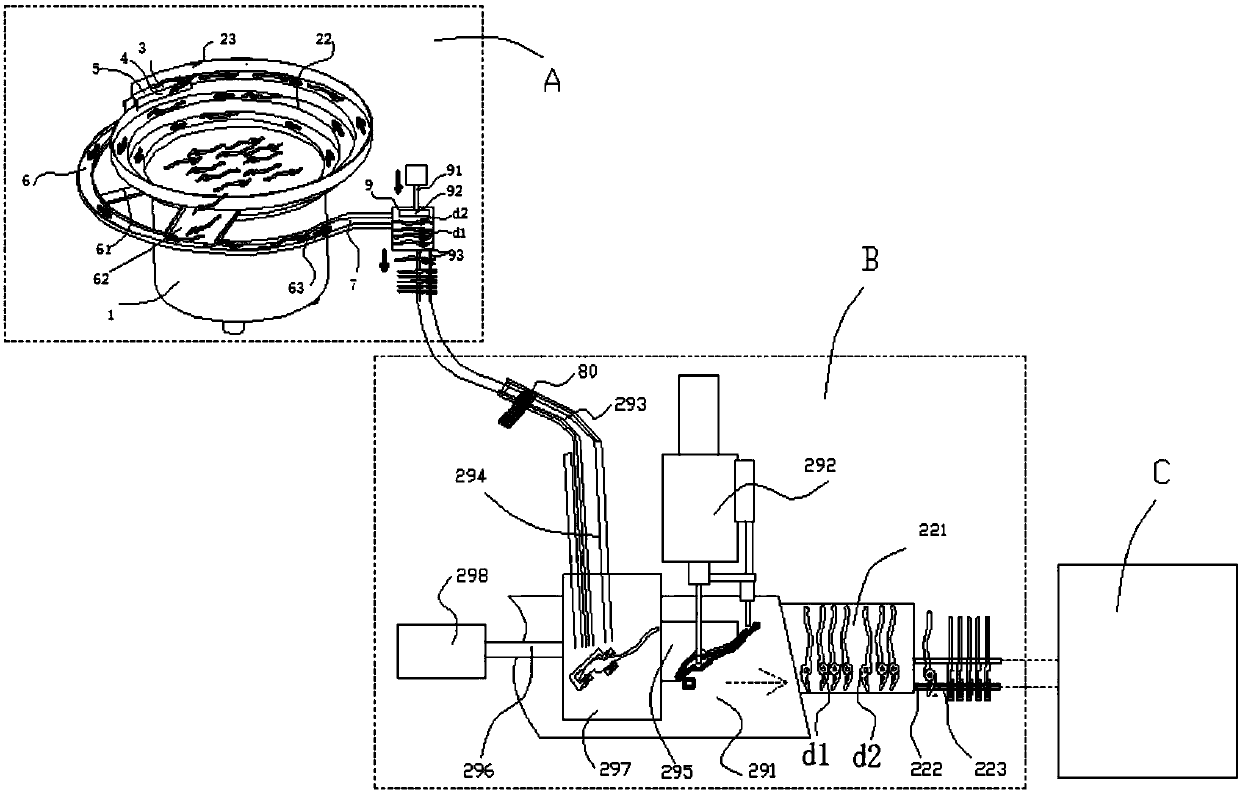

Full-automatic drilling and grinding processing production center of tong heads

ActiveCN107598578AEasy to placeReduce processing stepsOther manufacturing equipments/toolsMetal working apparatusEconomic benefitsEngineering

The invention discloses a full-automatic drilling and grinding processing production center of tong heads. The full-automatic drilling and grinding processing production center comprises a material falling assembly at the most front end and further comprises a drilling assembly and an automatic grinding disc assembly which are sequentially connected with the material falling assembly; and the material falling assembly and the drilling assembly are smoothly transitioned through a feeding groove. Automatic collection of tong bodies is achieved through a spiral vibration disc in the material falling assembly and a gravity free return technique, and then automatic positioning drilling is conducted; and after secondary gravity free return, the tong bodies automatically enter a grinding disc toenable the peripheries of the tong heads to be ground. According to the full-automatic drilling and grinding processing production center of the tong heads, through the self-weight characteristic andthe gravity effect of tongs, the tong bodies are orderly put conveniently, the processing procedures are reduced, and technological support is provided for efficient production; and automatic orderingand discharging, automatic drilling and automatic tong head grinding are achieved, automatic processing production is facilitated, the labor efficiency is improved, the labor intensity is relieved, and the economic benefit is increased.

Owner:湖南精专自动化技术有限公司

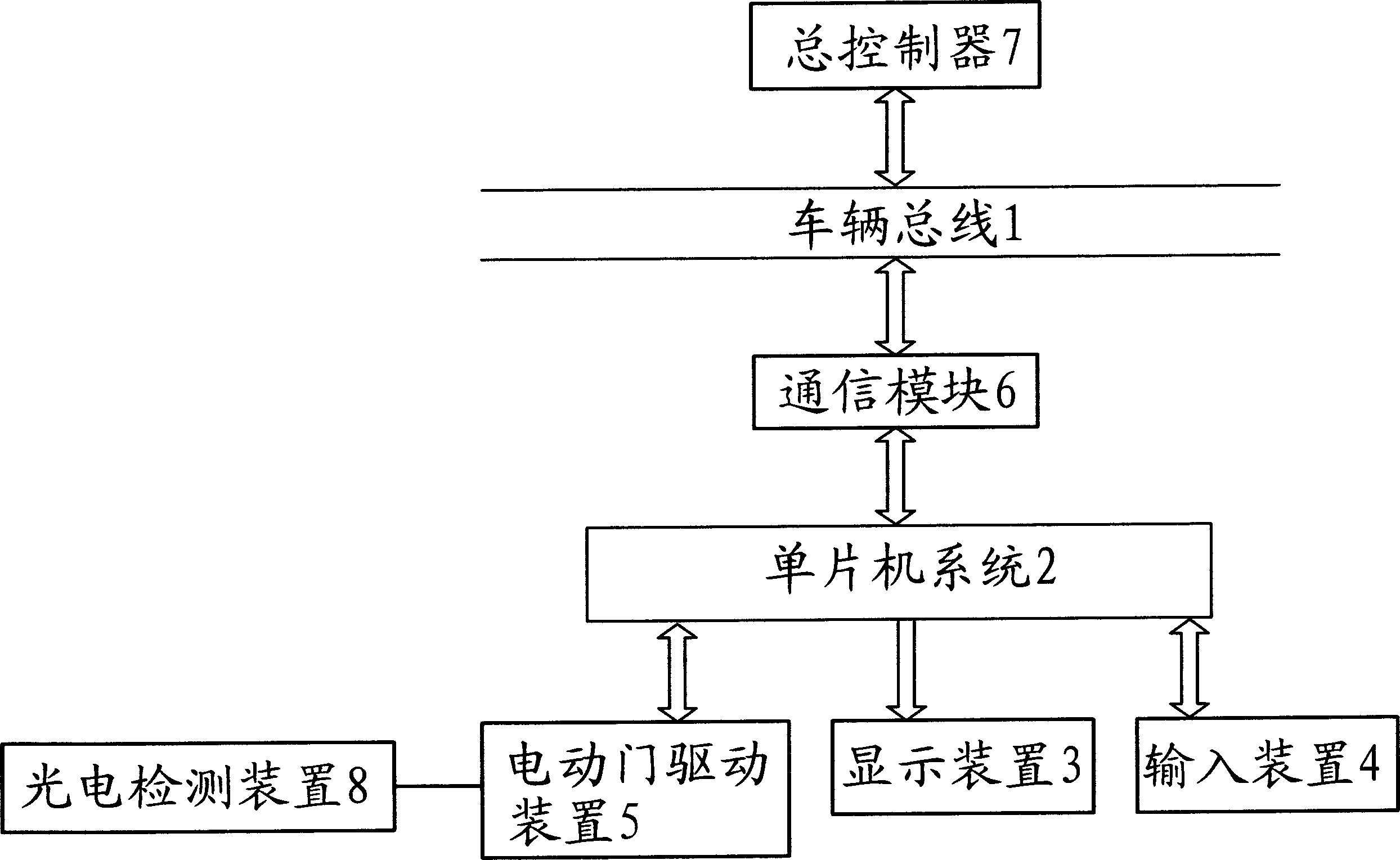

Control sub system for carriages in overhead subminiature rail train

The control sub system includes following parts: vehicle bus; several single chip systems corresponding to each carriage connected to vehicle bus; each single chip system connected to display device corresponding to each carriage; input unit in use for inputting control signal for corresponding carriage; each single chip connected to motor-driven door drive, which is connected to electromotor of controlling open and close of carriage door. Through communication module, vehicle bus carries out information exchange with each single chip system respectively. Comparing with prior art, the invention solves issues of high price of equipment, high operating cost, unstable signal transmission, and longer time delay. Advantages of the control sub system are: reasonable design, easy of implementation, stable signal transmission and safety.

Owner:杨宗林

Automatic discharging and continuous drilling and milling machine tool for pliers body

PendingCN108058053AConvenient automatic discharge and placementReduce processing stepsMetal working apparatusBoring/drilling machinesEngineeringMachine tool

The invention discloses an automatic discharging and continuous drilling and milling machine tool for a pliers body. The machine tool comprises a feeding assembly and a discharging assembly, wherein the feeding assembly is used for automatic feeding, and the discharging assembly is connected to the tail end of the feeding assembly; the discharging assembly is connected to a machining assembly, andthe machining assembly is provided with a pushing assembly in a matched mode; the feeding assembly comprises a feeding base and a vibration table on the base; a spiral surrounding type feeding disc is fixed to the vibration table; a surrounding type ascending spiral layer is arranged on the inner side surface of the spiral surrounding type feeding disc; a falling port is formed in the tail end ofthe highest position of the spiral ascending spiral layer; a feeding groove is formed in the lower part of the falling port; and a discharging detector is arranged at the tail end of the feeding groove. The automatic discharging and continuous drilling and milling machine tool for the pliers body has the advantages that the pliers body can be conveniently automatically discharged and placed for machining, the machining working procedures can be reduced, technical support can be provided for efficient production, automatic machining and feeding can be facilitated, the speed can be increased, the effect can be improved, and the machining cost can be lowered.

Owner:湖南精专自动化技术有限公司

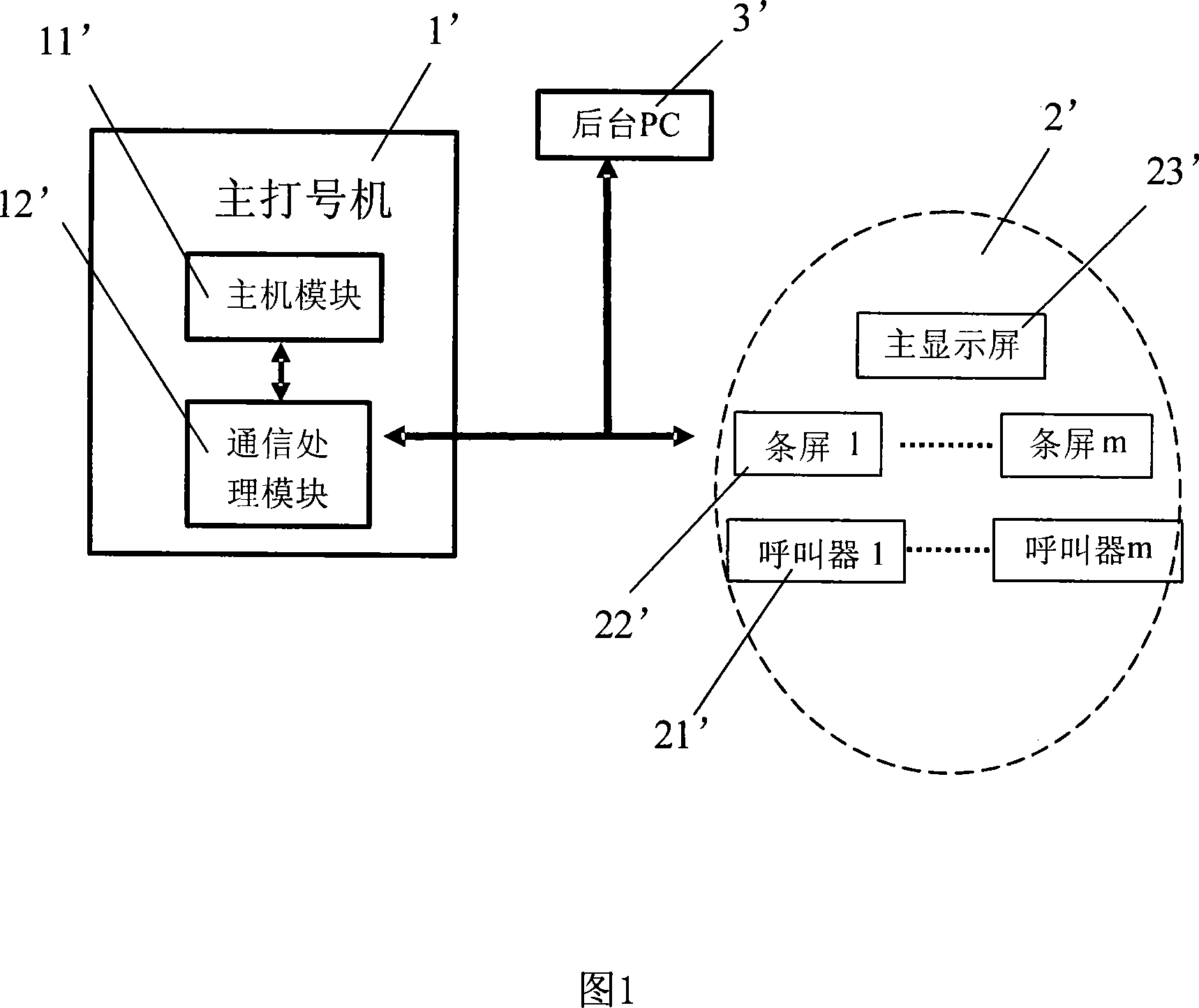

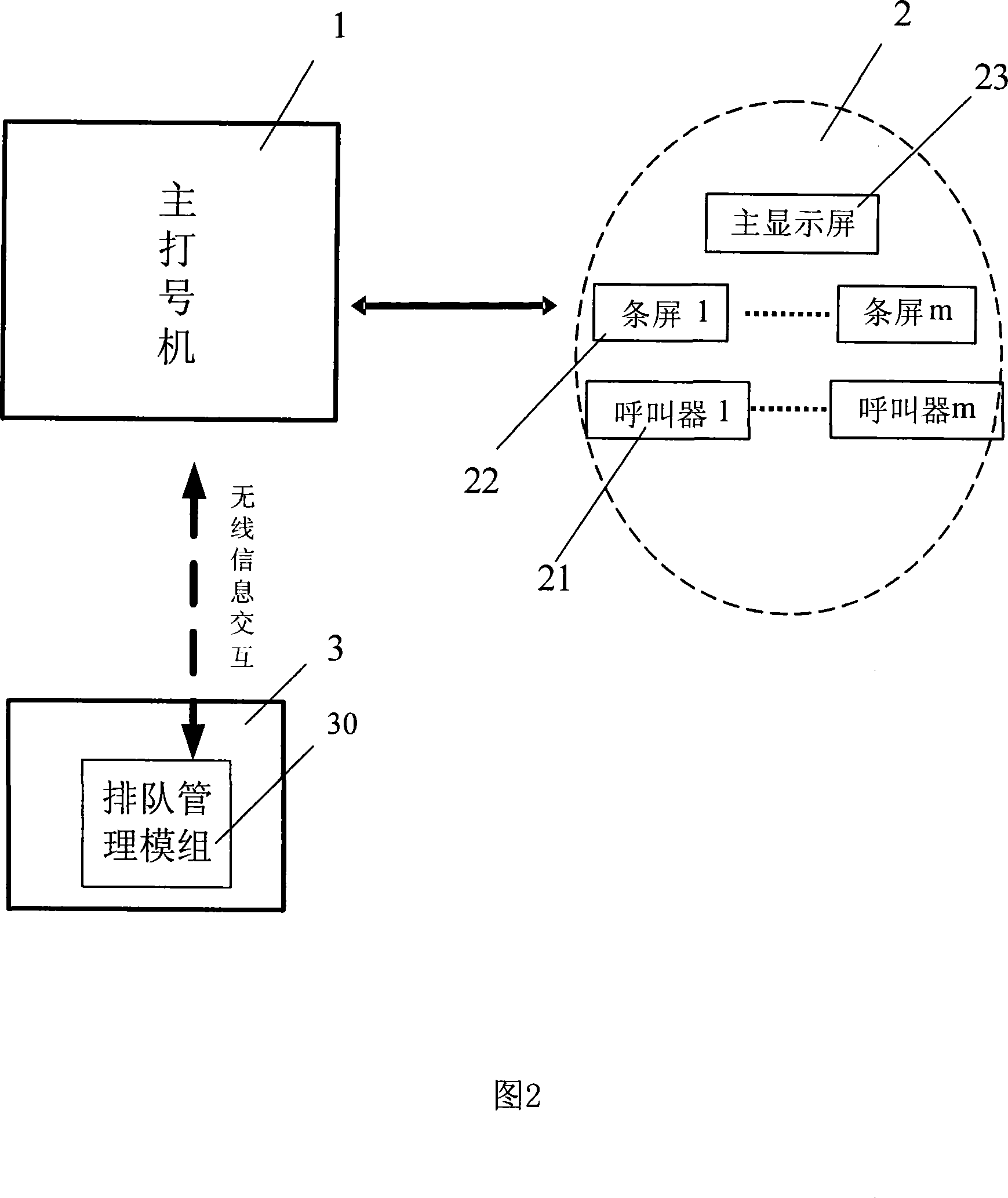

Flexible intelligent queuing management method and system

InactiveCN101110137AEasy to moveMake the most of your flexibilityChecking apparatusRelevant informationHand held devices

A maneuvering intelligent queuing management method and system related to control are provided, which comprises a main number printing machine and a calling and display group. The calling and display group comprises at least a calling device. The invention is characterized in that: it also comprises at least a portable device that is composed of a queuing management module; the queuing management module interacts with the main printing machine via wireless information, so as to complete the configuration, service and monitor of the queuing system. The method of the invention is: A) the portable device sends command or data to the main number printing machine; B) the main number printing machine completes corresponding operation according to the command or data, or; A) the main number printing machine sends command or data to the portable device and the latter displays relevant information; the main number printing machine returns a TCP / IP data package containing processing result to the portable device. Therefore, the invention has excellent flexibility, high efficiency, excellent practicality and maneuverability.

Owner:武汉市奥拓智能科技有限公司

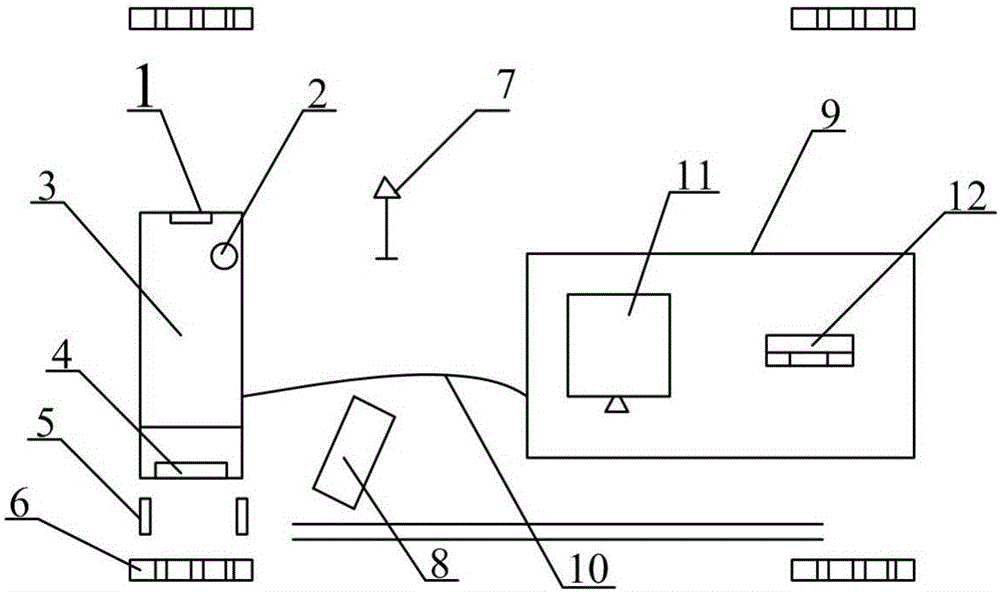

Multi-agent regional logistics distribution system and control scheduling method thereof

InactiveCN105976297AReduce consumptionIndicates that the device is in good conditionLogisticsSignal lightLogistic process

The invention discloses a multi-agent regional logistics distribution system and a control scheduling method thereof. The system is composed of an entrance, a signal light, a loadometer, a label, induction coils, railings, a signal base station, an identification device, a main control body, a wire, a computer and a printer. A supply demand value is extracted timely; when the stock value is too low or the existing supply value is too high and thus a stockout phenomenon may occur, an alarm module carries out alarming, so that the operation of the logistics system becomes ordered. Processing is carried out on an object by the loadometer at the entrance; label processing is carried out; networking data transmission is carried out on the computer; the signal base station is used for guaranteeing information transmission; the printer prints a necessary logistics voucher; and then positioning real-time monitoring is carried out on the logistic process. An intelligent scanning unit scans book information; a main control unit extracts the existing object number information and the existing number information in stock; if the object is likely to be in a stock-out situation, the alarm module carries out alarming and thus a logistic center is warned to pay attention to replenishing of the object. Therefore, a stock-out phenomenon is avoided.

Owner:GUANGDONG COMM POLYTECHNIC

Carbon fiber automobile engine hood machining integrated device

PendingCN111085480APlace stableOrderly operationDrying gas arrangementsPretreated surfacesElectric machineryAutomotive engineering

The invention discloses a carbon fiber automobile engine hood machining integrated device. The device comprises a base, a dust collector, a third motor and an air pump; a baffle penetrates through a top plate and is connected to the base in a clamped mode; the dust collector is arranged on the right side of a second hydraulic cylinder on the left side, a cleaning roller is arranged on the lower side of the dust collector, a third hydraulic cylinder is arranged on the right sides of dust collecting pipelines, and an electric heating plate is arranged on the right side of the third hydraulic cylinder; the air pump is arranged on the left side of a first hydraulic cylinder on the right side, and an air outlet pipeline is arranged on the lower side of the air pump; and water spraying pipelinespenetrates through the lower end face of the top plate. According to the carbon fiber automobile engine hood machining integrated device, a carbon fiber automobile engine hood continuously moves rightwards, the cleaning roller rotates clockwise so as to sweep away dust on the surface of the carbon fiber automobile engine hood, and at the moment, the dust collecting pipelines can suck away the scattered dust in time, so that the dust removal purpose is achieved, and the situation that the dust remains on the surface of the carbon fiber automobile engine hood to affect the spraying quality is avoided.

Owner:江苏东科复合材料有限公司

Intelligent process for lead-acid storage battery

ActiveCN105261718AImprove insulation safetyWon't fall offCell lids/coversElectric connector introductionEngineeringL&D process

Owner:BAODING YUXIN ELECTRICAL TECH

Special protective clothing for offshore operations

PendingCN108158078AImprove the working environment at seaImprove work efficiencyProtective garmentButtocksSufficient time

The invention discloses special protective clothing for offshore operations. According to the special protective clothing, graphene heating sheets are arranged on liners corresponding to the positionsof the chest, the back, the feet of one-piece clothing, protective air bags are arranged at the neck part, the chest part, the hip part and the crotch part of an interlayer, symmetric protective fansare arranged at the positions corresponding to buttocks, and the clothing is made of an aerogel material; heating of related parts of a human body is conducted by using the graphene heating sheets, cold on the sea in winter is overcome and the sense of cooling is brought by ventilation and temperature reduction performed by the protective fans in summer, so that the environment of offshore operations is improved, each operation is performed orderly, and the operation efficiency is significantly improved; emergency protection can be achieved when offshore emergency events suddenly occur, so that the danger of drowning after offshore operators fall in the sea accidentally is effectively reduced, and sufficient time for salvage is gained. The clothing has the advantages of being novel and unique in inventive concept, compact and reasonable in structural design, stable and reliable in safety performance, integrated in multi-functional protection, simple and convenient to operate and use,suitable for offshore operation application and the like.

Owner:吉林省荣发服装服饰有限公司

Rapid dewatering and curing method for sludge

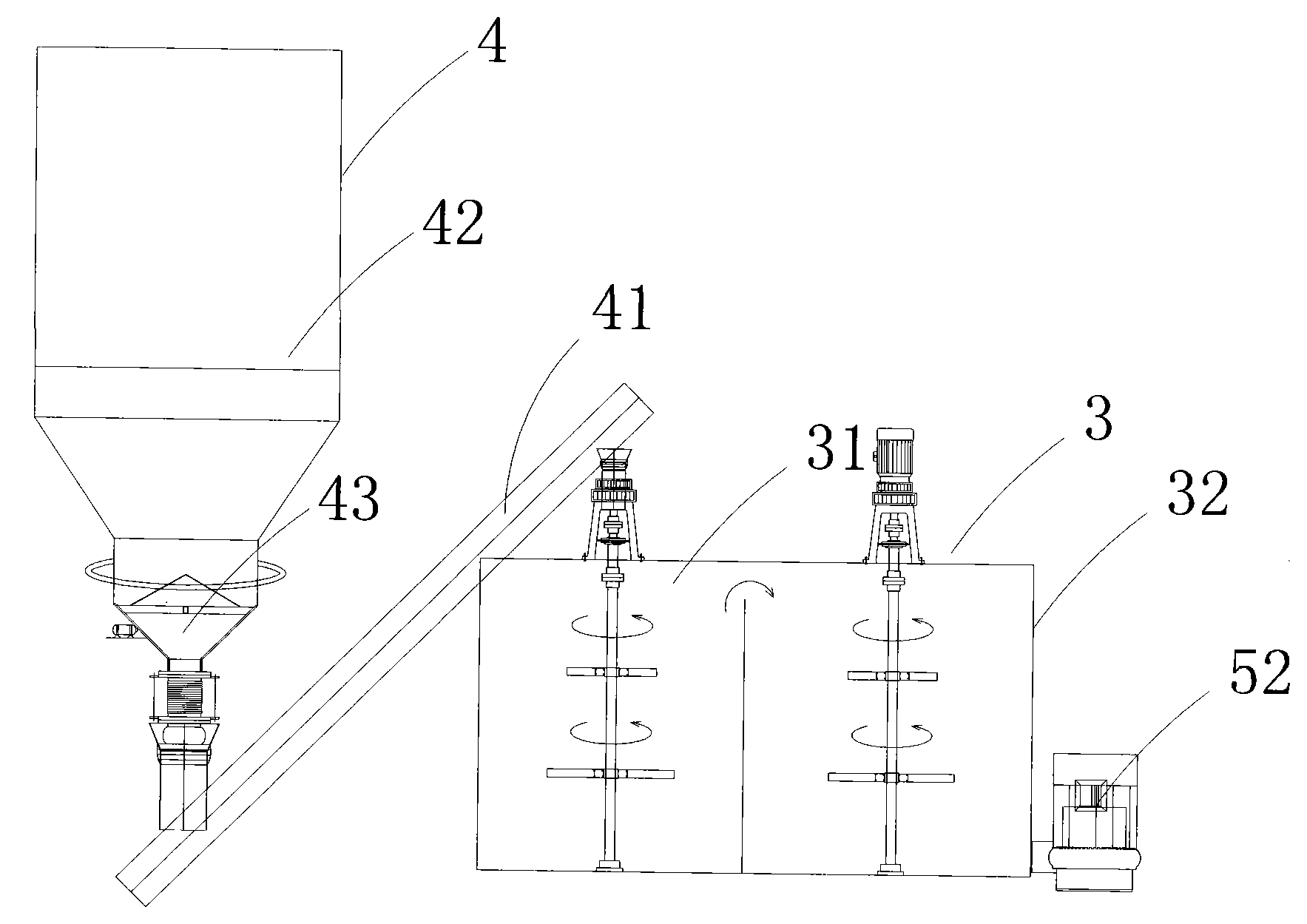

ActiveCN103979777AStir wellOrderly operationSludge treatment by de-watering/drying/thickeningSludgeEngineering

The invention relates to a rapid dewatering and curing method for sludge. The method is as below: slurry sucked by a slurry pump is output to a pipeline, has flow rate measured, and flows into a coagulant mixing device, and the measurement results are sent to a control device; the control device, according to the preset coagulant addition rate, determines the rotation speed of a screw conveying unit of the coagulant mixing device, and adds the coagulant to the coagulant mixing device according to the speed of the rotation speed; a second flow measuring element and a concentration measuring element measure the flow rate and concentration of slurry in the pipeline; the control device based on the measured flow rate and concentration data adds the coagulant and clean water into a three-box overflow type stirring box for stirring according to preset dewatering agent concentration; and the dewatering agent mixing device is output according to the preset dewatering agent addition amount, and mixed with slurry in the mixing device on the pipeline. According to the invention, the sludge is treated with coagulant and dewatering agent, so as to output to slurry met the requirements.

Owner:浙江省围海建设集团股份有限公司

Multifunctional tool cart

The invention discloses a multifunctional tool cart comprising a cart body, a tool storage table arranged on an upper tier of the cart body, an upper storage table for ground wires, a lower storage table for ground wires; the upper storage table is arranged in the middle of the cart body; the lower storage table is arranged on the lower portion of the cart body. A safety tool storage box is arranged on the tool storage table and comprises a plurality of storage cells. The front of the safety tool storage box is provided with a cylinder. The uppermost portion of the cart body is provided with a push handle. A partition is disposed at the center of the upper storage table; an outer retainer is hinged to one side of the partition. A pin is disposed between the outer retainer of each of the upper and lower storage tables and the cart body. The parts, corresponding to the lower storage table, of the tool storage table are provided with collecting racks used for storing long tools. The multifunctional tool cart is convenient to use; the three storage tables allow the tools to be placed in advance and missing to be avoided; pushing the cart to the site by one operator is required only; abrasion of the tools caused by random placement is avoided; central placement of the tools allows more standardized and order operation.

Owner:STATE GRID CORP OF CHINA +1

Assembly line for automobile seats

ActiveCN105345469AGuaranteed assembly qualityReduce labor intensityAssembly machinesVehicle componentsEngineeringAssembly line

The invention discloses an assembly line for automobile seats. The assembly line comprises a working table and conveying chains arranged on two sides of the working table; a sliding rail set assembly station, a seat cushion set assembly station, a backrest set assembly station, a guard plate and safety belt lock catch assembly station, a headrest assembly station, a harness sorting station, a first switch-over station, a transition station, a second switch-over station, an appearance and function detection station, a repair station and a packing station are sequentially arranged on the working table; the side part of the first switch-over station is provided with a sound insulation detection conveying working table which is located on one side of a sound insulation detection chamber; the other side of the sound insulation detection chamber is provided with a sound insulation detection output working table which leads to the second switch-over station; and the assembly line further comprises an assembly base which is arranged on the conveying chains and can realize conveying for each station of seat assembly. By adopting the assembly line for the automobile seats disclosed by the invention, the labor intensity is lowered; the working efficiency is improved; and the operation is ordered, error or neglected assembly do not easily happen, so that the assembly quality of the seats can be ensured.

Owner:WUHU RUITAI AUTO PARTS

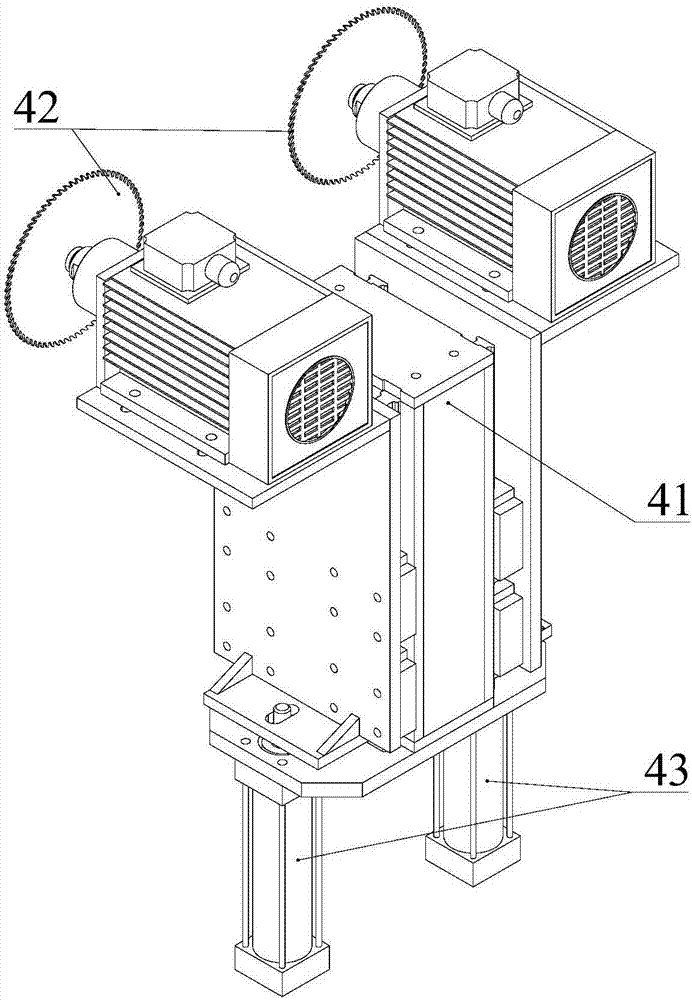

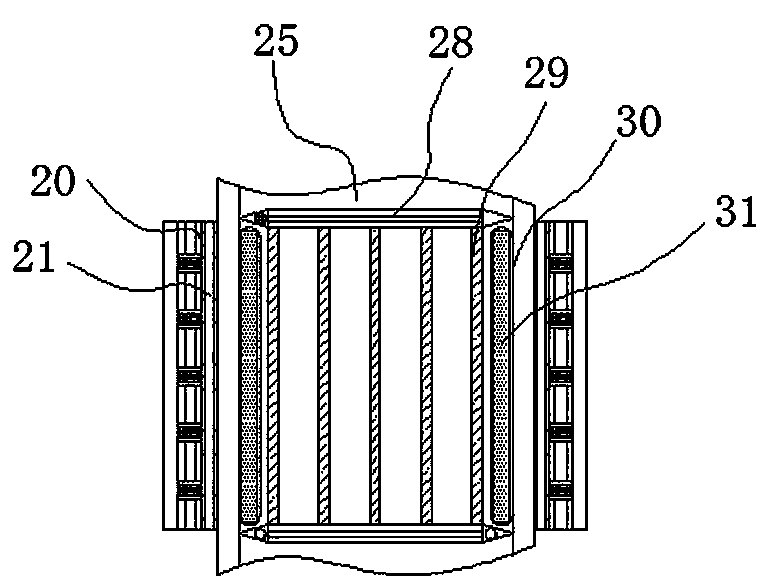

Yarn joining device for station of textile machine for manufacturing cross-wound bobbins

ActiveCN107777472ALimited space requirementsPrecisely scheduled rotationFilament handlingYarnEngineering

The invention relates to a yarn joining device (10) used for a station (2) of a textile machine (1) for manufacturing cross-wound bobbins. The yarn joining device has an air distribution body (18) equipped with joint holes (19, 23) used for compressed air pipelines (26, 27), an accommodating hole (30) used for a holding and opening pipe (17) and a yarn joining prism (34), the yarn joining prism has a yarn joining channel (35) to which compressed air can be applied, and a plurality of yarn processing mechanisms, particularly yarn cutting mechanisms (36A, 36B), yarn clamping mechanisms (37A, 37B) and a yarn inlet device (38) are arranged at a distance from the yarn joining prism (34), and can be controlled through driving devices. The invention provides that at least two rotatably mounted control members (41, 42) capable of receiving action each through an independent driving device (39, 40) in a limited manner are arranged on the air distribution body (18), and by virtue of the controlmembers, the yarn processing mechanisms, particularly the yarn cutting mechanisms (36A, 36B), the yarn clamping mechanisms (37A, 37B) and / or the yarn inlet device (38) can be controlled according to the need.

Owner:SAURER GERMANY GMBH & CO KG

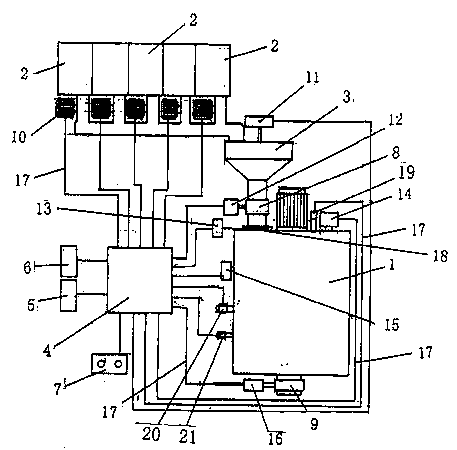

Digital-controlled slasher mixing vessel

ActiveCN103882645ASolve many problems of unstable sizing qualityDesign scienceTextile treatment machine arrangementsMicrocomputerMicrocontroller

A digital-controlled slasher mixing vessel comprises a vessel body of the mixing vessel and is characterized in the the vessel body is provided with a weighing hopper used for material feeding, the weighing hopper is connected to a plurality of material feeding boxes through conveying pipes; the entire digital-controlled slasher mixing vessel comprises the vessel body, the material feeding boxes and the weighing hopper; the digital-controlled slasher mixing vessel is further provided with a plurality of sensors and actuating valves are connected to a single-chip microcomputer; procedures of loading material, feeding water, mixing and discharging slurry are adjusted and controlled through a microcomputer automatically. Since the sensors are connected with the microcomputer through a single-chip microcomputer adjusting program, during usage, the whole procedures of loading material, weighing, feeding material, mixing and discharging slurry are adjusted and controlled through set programs by the single-chip microcomputer automatically. The digital-controlled slasher mixing vessel has the advantages that design is scientific, operation is simple, the whole procedures are accurate and reliable, product quality can be improved, and production cost can be reduced.

Owner:XIANGYANG XINZHENG TEXTILE

Commercial vehicle and commercial vehicle integrated system

PendingCN106740534AImprove office efficiencyConvenient for officeAir-treating devicesBelt control systemsTransceiverCommercial vehicle

The invention relates to the technical field of commercial vehicles, in particular to a commercial vehicle and a commercial vehicle integrated system. The commercial vehicle comprises a vehicle body, a processor, a signal transceiver, a vehicle projector, a signal collection unit and a WIFI launcher; seats are arranged in the vehicle body facing the vehicle projector; the processor is used for controlling equipment in the vehicle body to from an integrated system, and confusion is prevented from occurring through control of the processor; the WIFI launcher is arranged in the vehicle body to supply a wireless network to a user, and the office efficiency is improved; the signal collection unit faces the seats and can collect image information and sound information of the user and transmit the information into the processor when working; the information is sent by the signal transceiver after being processed by the processor and is transmitted to a switchboard; and the signal transceiver transmits the user information collected by the signal collection unit to the switchboard, and the user in the vehicle body can carry out visual conference with the long-distance user, so that the office efficiency of the user is improved.

Owner:HENAN POLYTECHNIC

Special-shaped brick manufacturing device and method

ActiveCN104015245AReliable demoulding operationImprove yieldDischarging arrangementMouldsMechanical engineeringBrick

The invention discloses a special-shaped brick manufacturing device and method. The special-shaped brick manufacturing device comprises a building block forming machine, a plate conveying machine, a composite conveyor, a pressing die connecting body device, a forming bottom plate, a bottom plate lifting device and a plate taking component arranged on the composite conveyor. During brick manufacturing, a die frame is arranged on the forming bottom plate in an overlapping mode, a cavity is formed, building block forming is carried out, the pressing die connecting body device is matched with the plate taking component, the forming bottom plate is sent out, a supporting plate bears formed bricks obtained by demoulding, and at last, the supporting plate and the bricks are sent out. The device is simple in structure, process operation is easy, efficiency is high, the finished product rate is high, and the innovative device and method are provided for manufacturing of special-shaped bricks.

Owner:FUJIAN QUNFENG MACHINERY

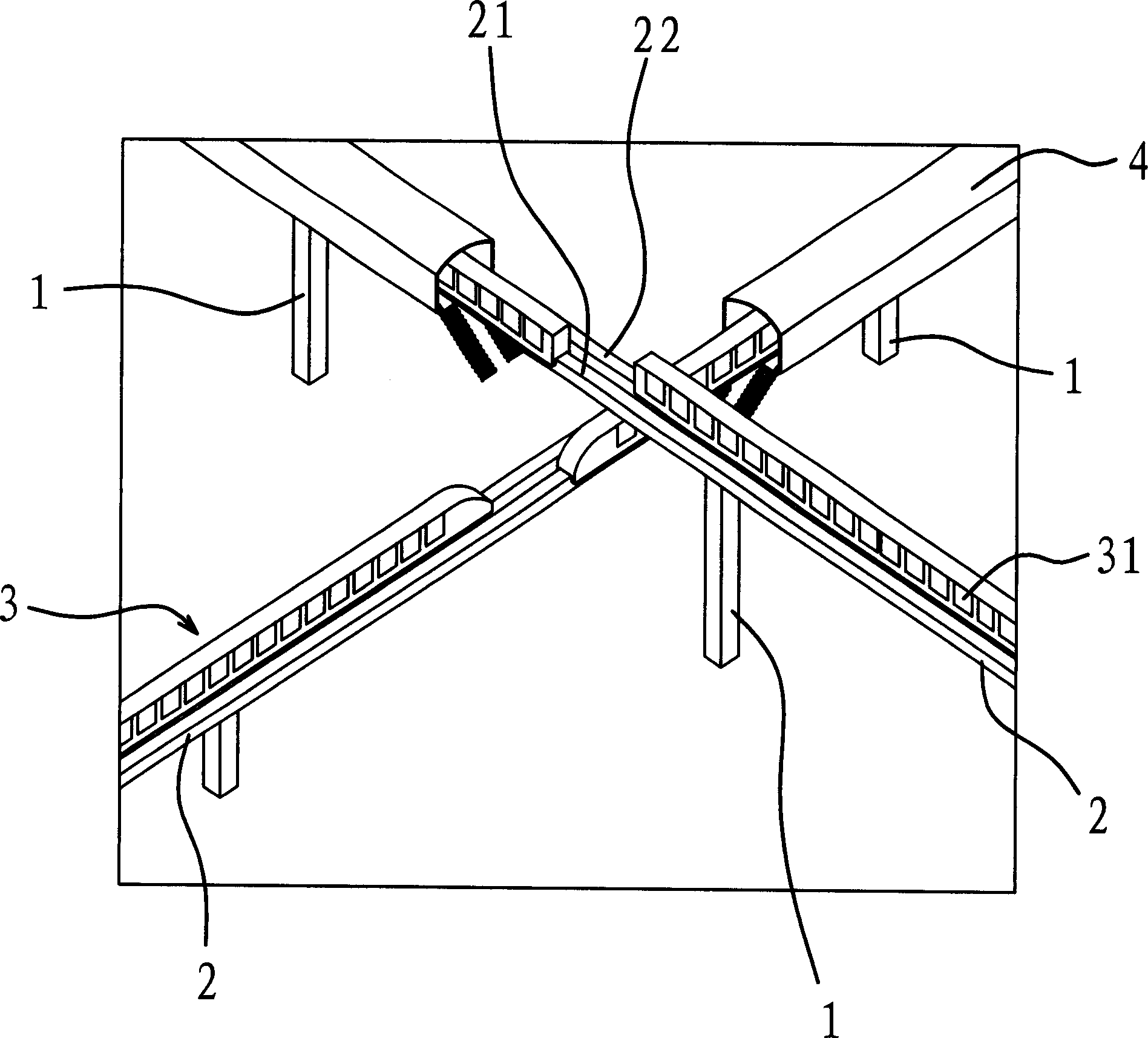

Single person carriage elevated track train traffic system

InactiveCN1803506AReasonable designSimple structureRailway componentsRailway stationControl systemSimulation

The invention discloses a high-rack orbital train traffic system of individual wagon, which comprises the following parts: column, elevated orbit on the column, individual wagon train on the orbit and station, wherein the total control system of wagon is set in the individual wagon train, which controls wagon subsystem to display kinds of information; the station contains station tag system, which connects the total control system of wagon through central control system of control center. The invention improves the traffic system intelligent degree, which expands the transportation space.

Owner:杨宗林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com