Walnut feeding, conveying, isolating and shelling all-in-one machine

An all-in-one machine and material separation technology, which is applied in the field of shell breaking machine, walnut feeding, conveying, material separation, and walnut shell breaking machine. The integration of production and shell breaking machine, weak integration performance, low degree of mechanization and automation, etc., can achieve the effect of reducing the cost of manual intervention, flexible and adjustable feeding speed, and high degree of automation and integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

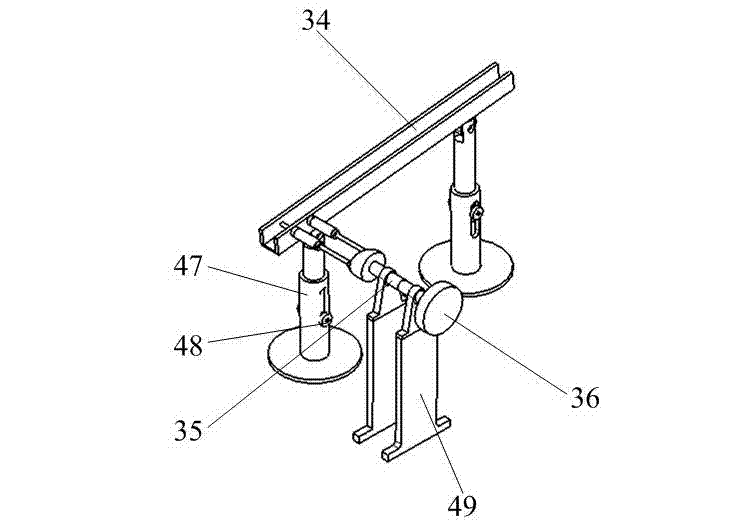

[0031] refer to figure 1 , The main base 11 of the present embodiment is equipped with a feeding conveying device, a vibrating feeding device, a material spacer, a shell breaking device and a power transmission device.

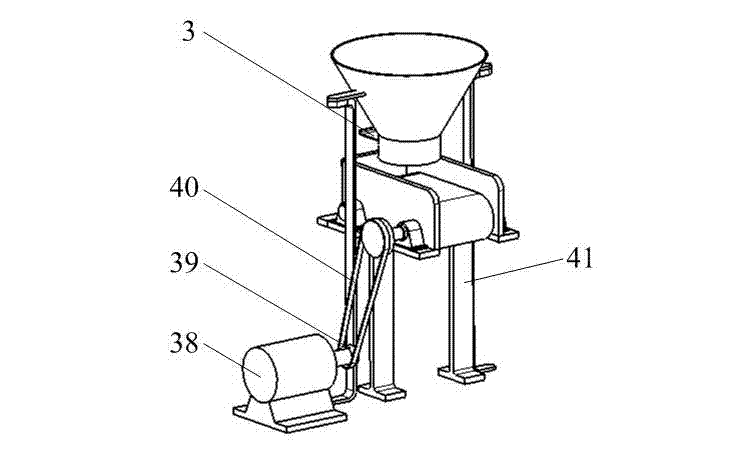

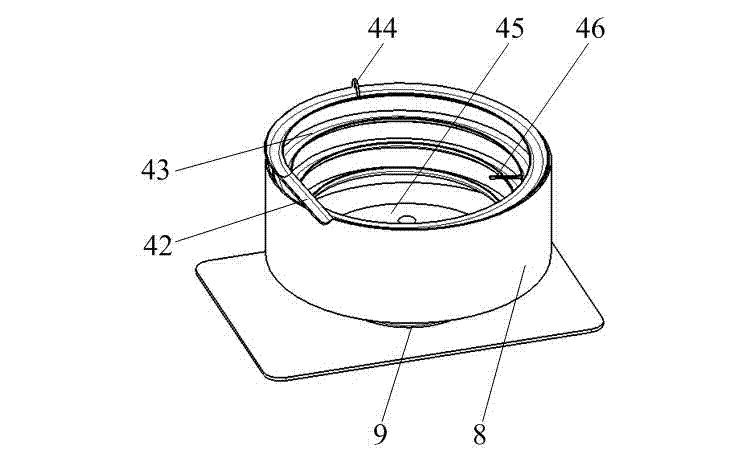

[0032] refer to figure 1 and figure 2 , The feeding transmission device of this embodiment includes a feeding hopper 2, a feeding hopper support 1, a conveyor belt 4, a transmission baffle 5, a transmission support 6, a transmission spindle 7 and a conveyor belt bracket 41. The feeding hopper 2 is equipped with a feeding adjustment plate 3, which can flexibly adjust the amount of material feeding. The feeding hopper 2 is suspended above the main base 11 through the feeding hopper bracket 1, and is located below the feeding hopper 2 and has a conveyor belt with a transmission baffle 5 4 is driven by the transmission main shaft 7, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com