Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Optimize cutting process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

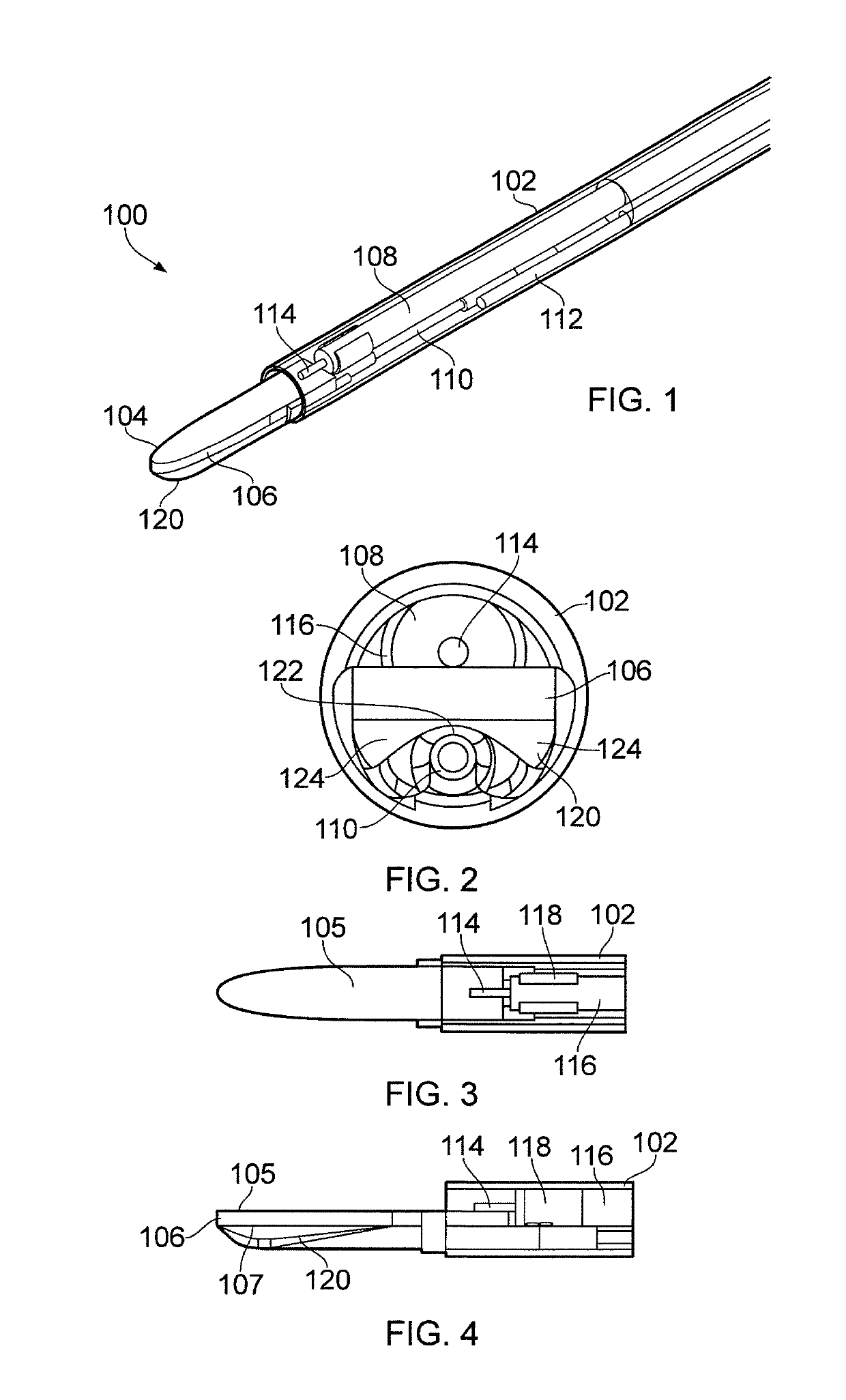

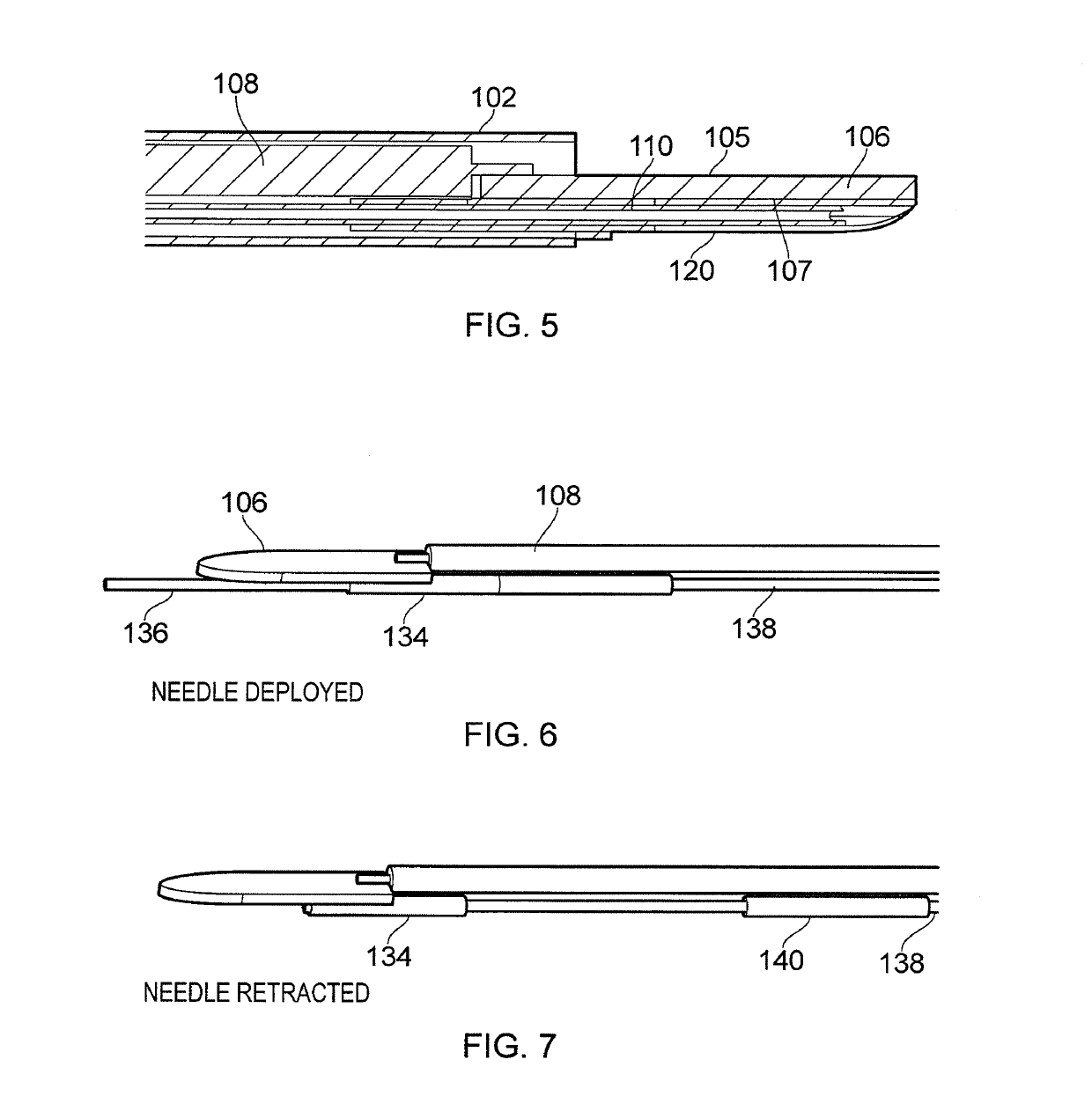

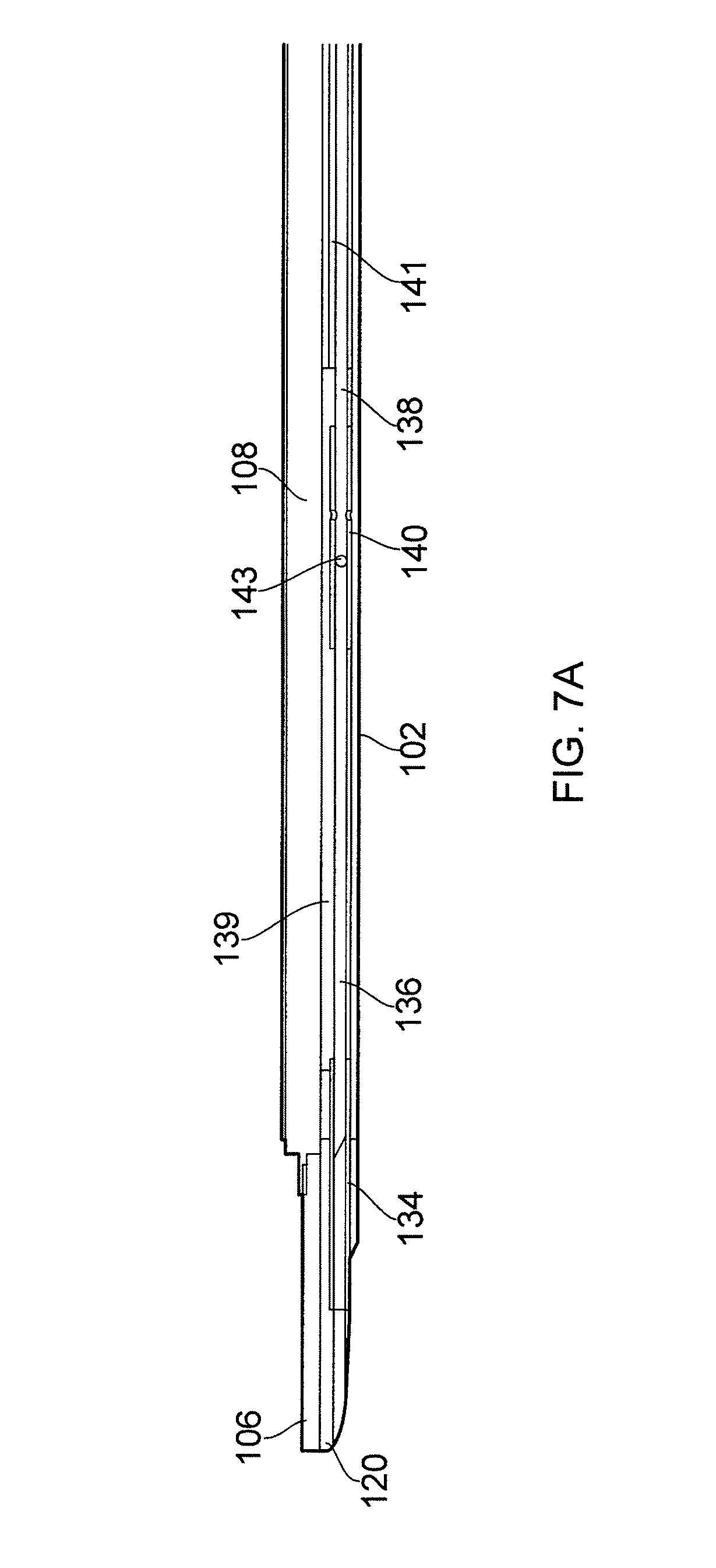

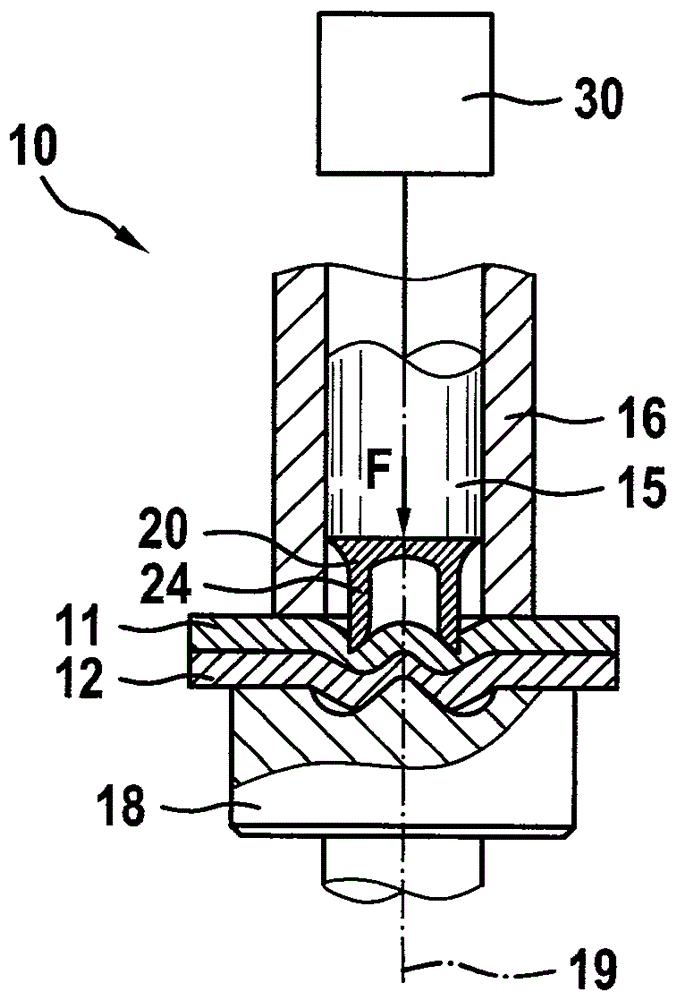

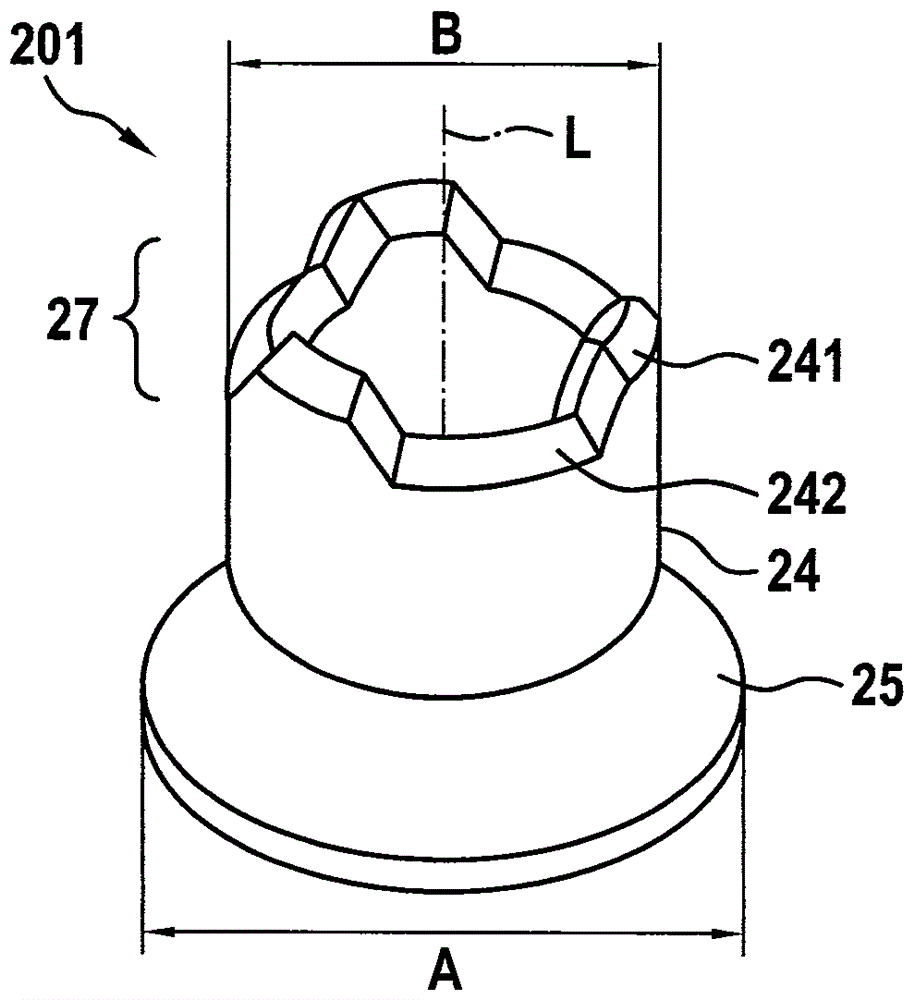

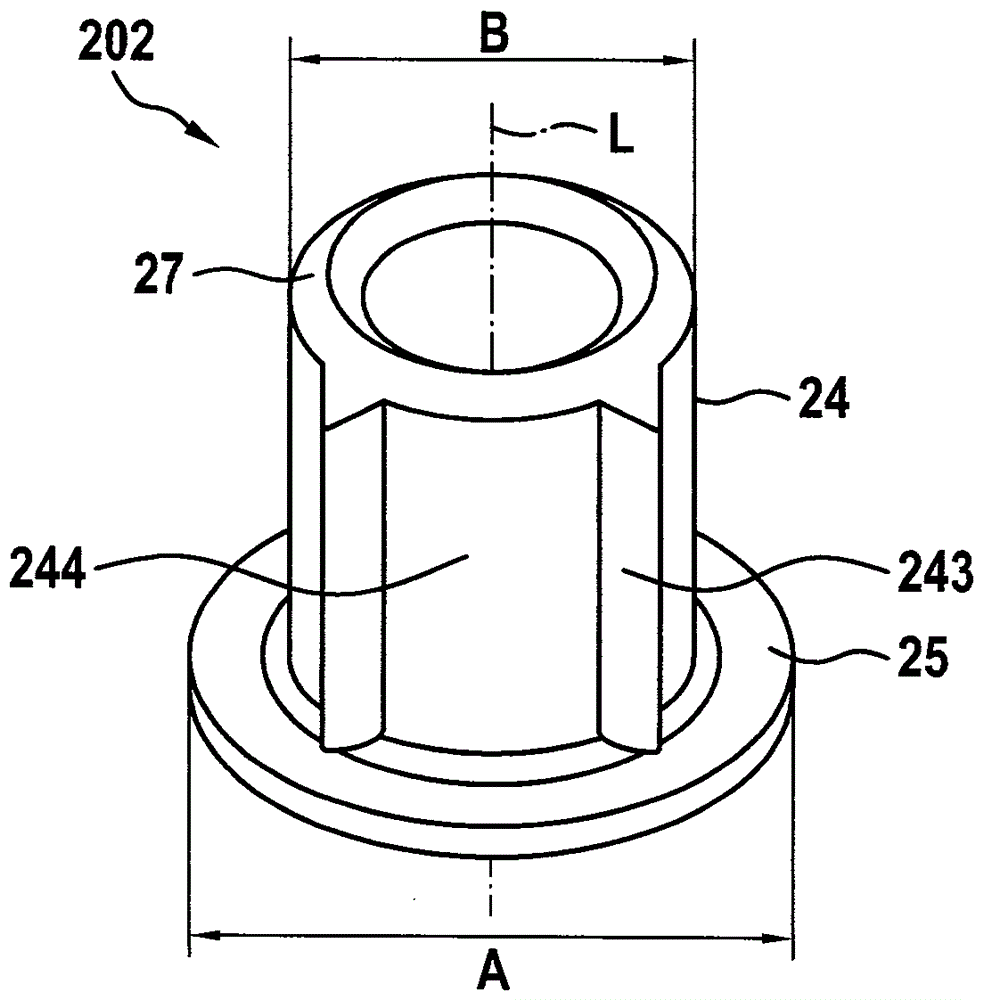

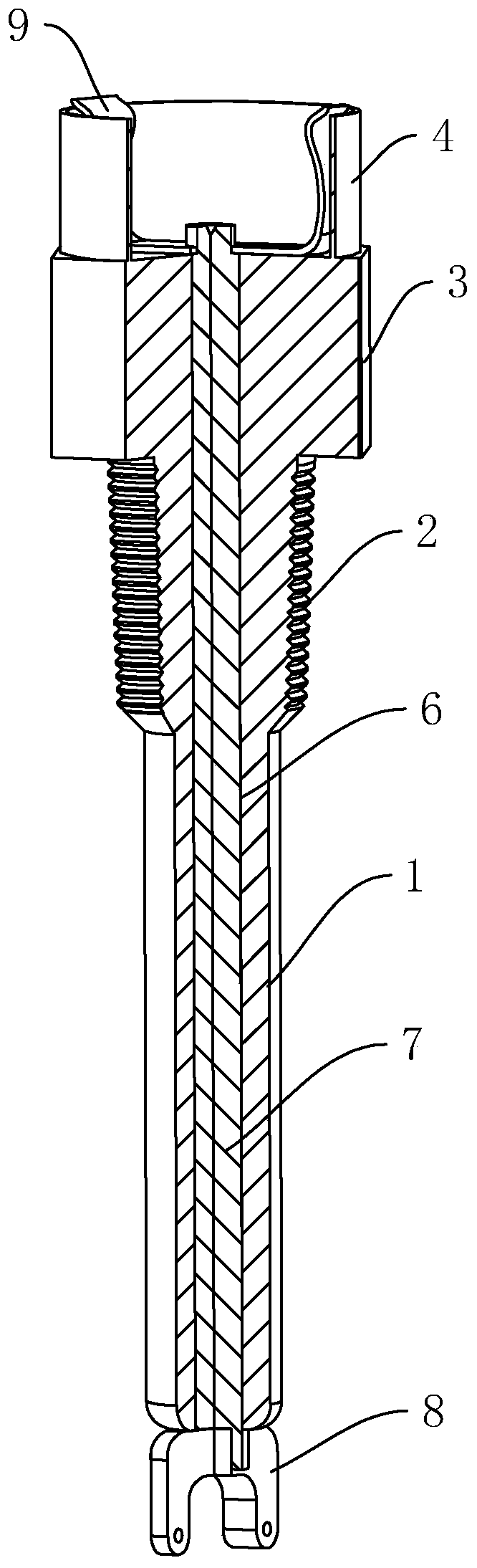

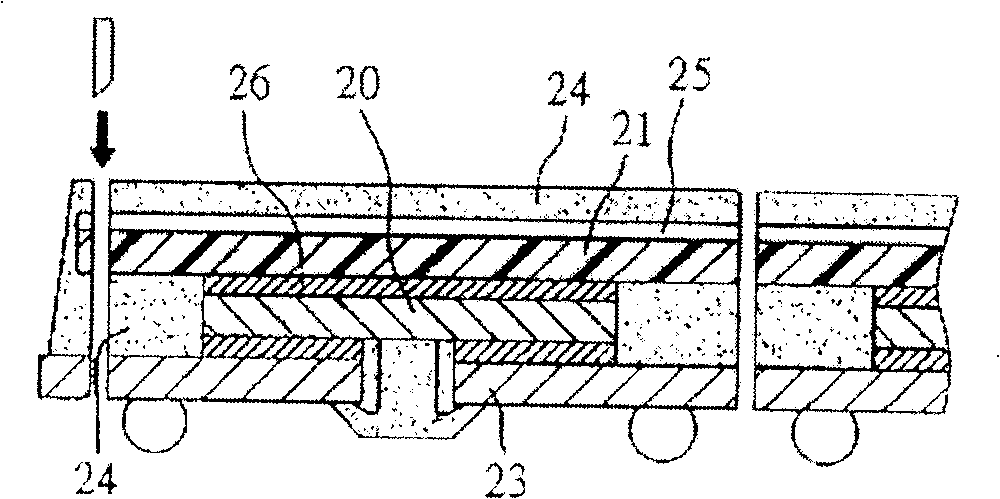

Electrosurgical resection instrument

ActiveUS20150196353A1Reduce riskProtective structureDiagnosticsSurgical instruments for heatingVeinBowel perforations

An electrosurgical resection instrument for applying to biological tissue radiofrequency electromagnetic energy has a protective hull comprising a shaped piece of dielectric material mounted to cover an underside of an instrument tip of the instrument. The protective hull acts as a shield to protect tissue that may lie under the instrument tip from damage during treatment. The instrument may be particularly useful in procedures performed in a gastrointestinal tract, where bowel perforation is a concern, or in the pancreas, where damage to the portal vein or the pancreatic duct may occur when a tumour or other abnormality is being resected, dissected or removed.

Owner:CREO MEDICAL LTD

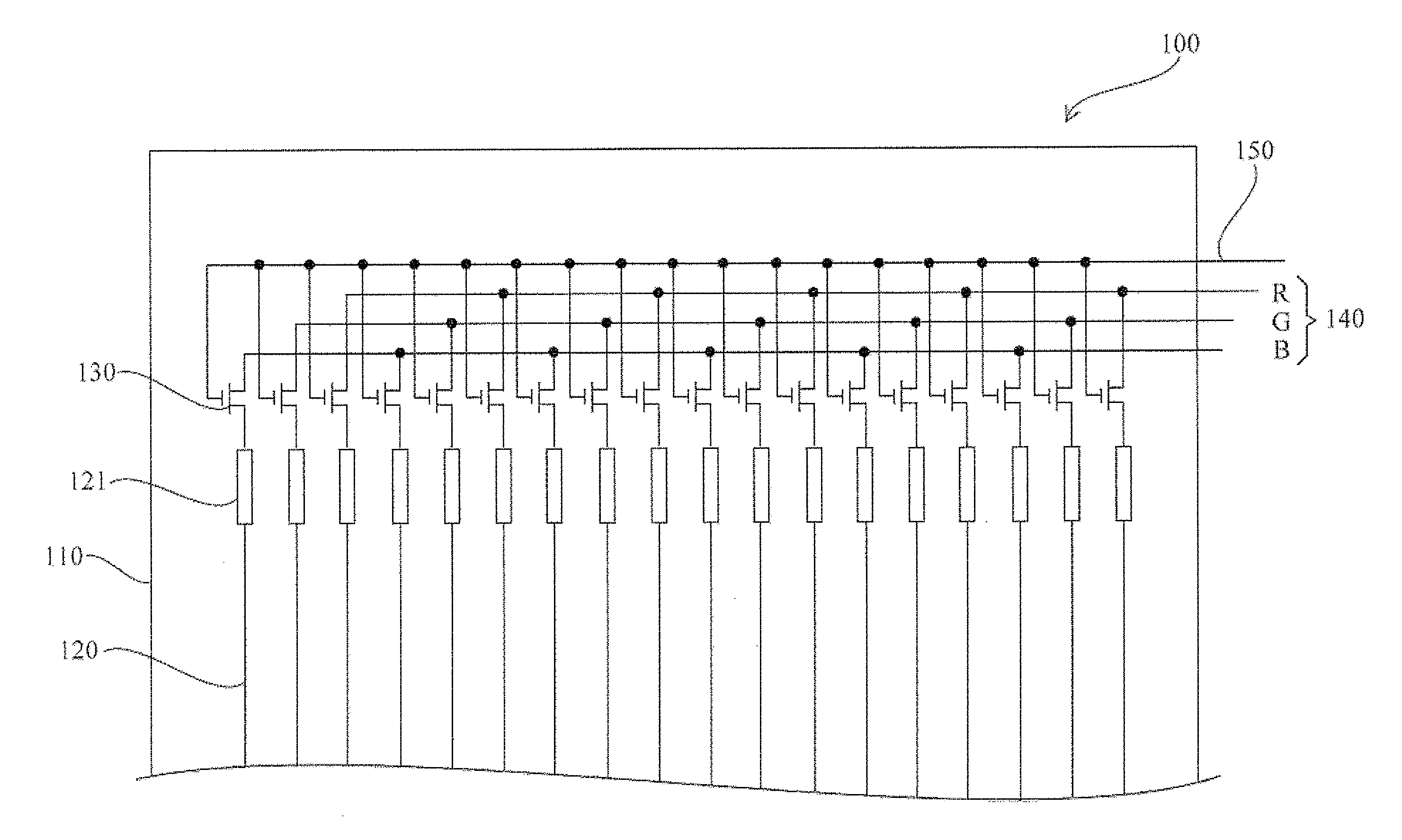

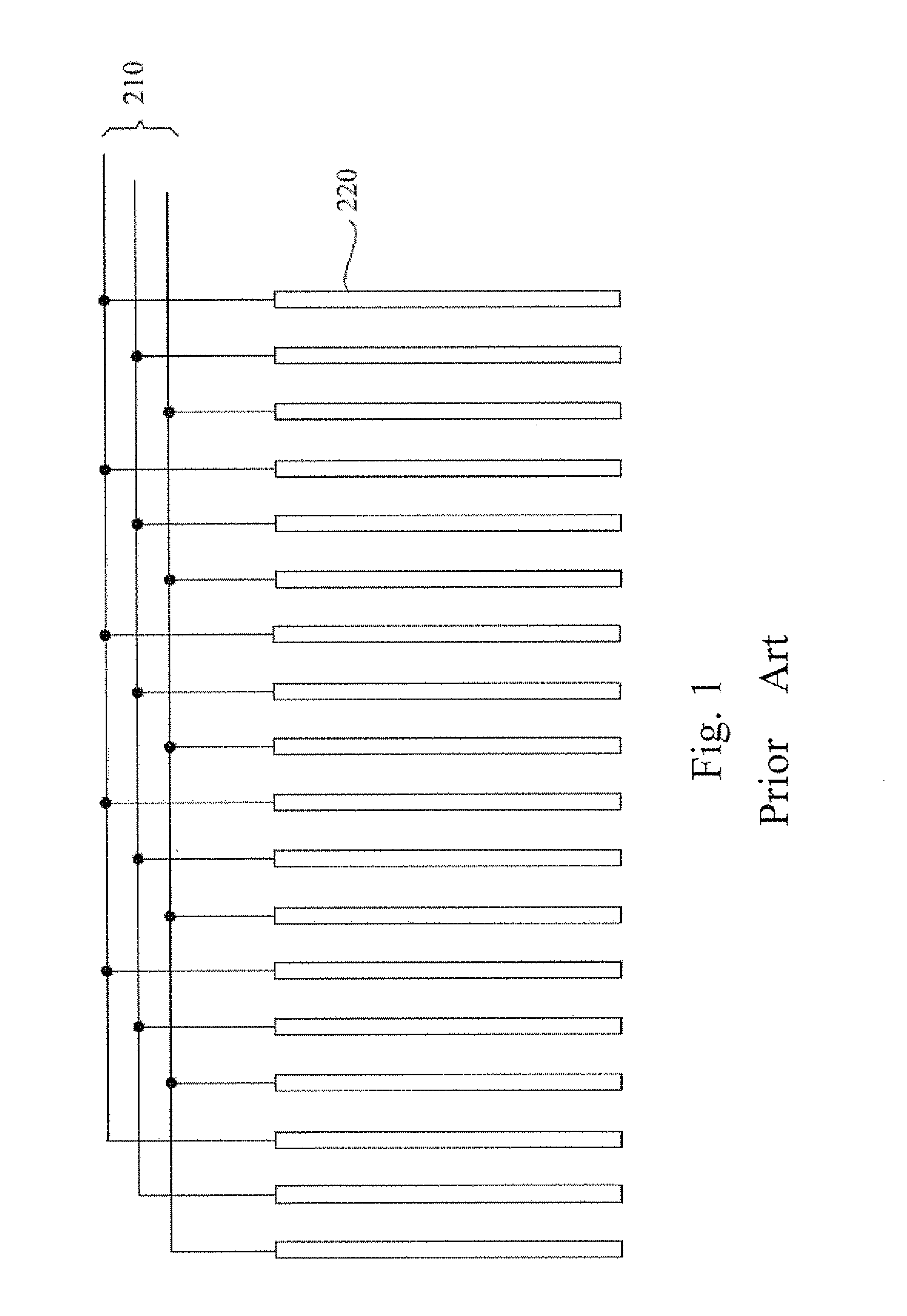

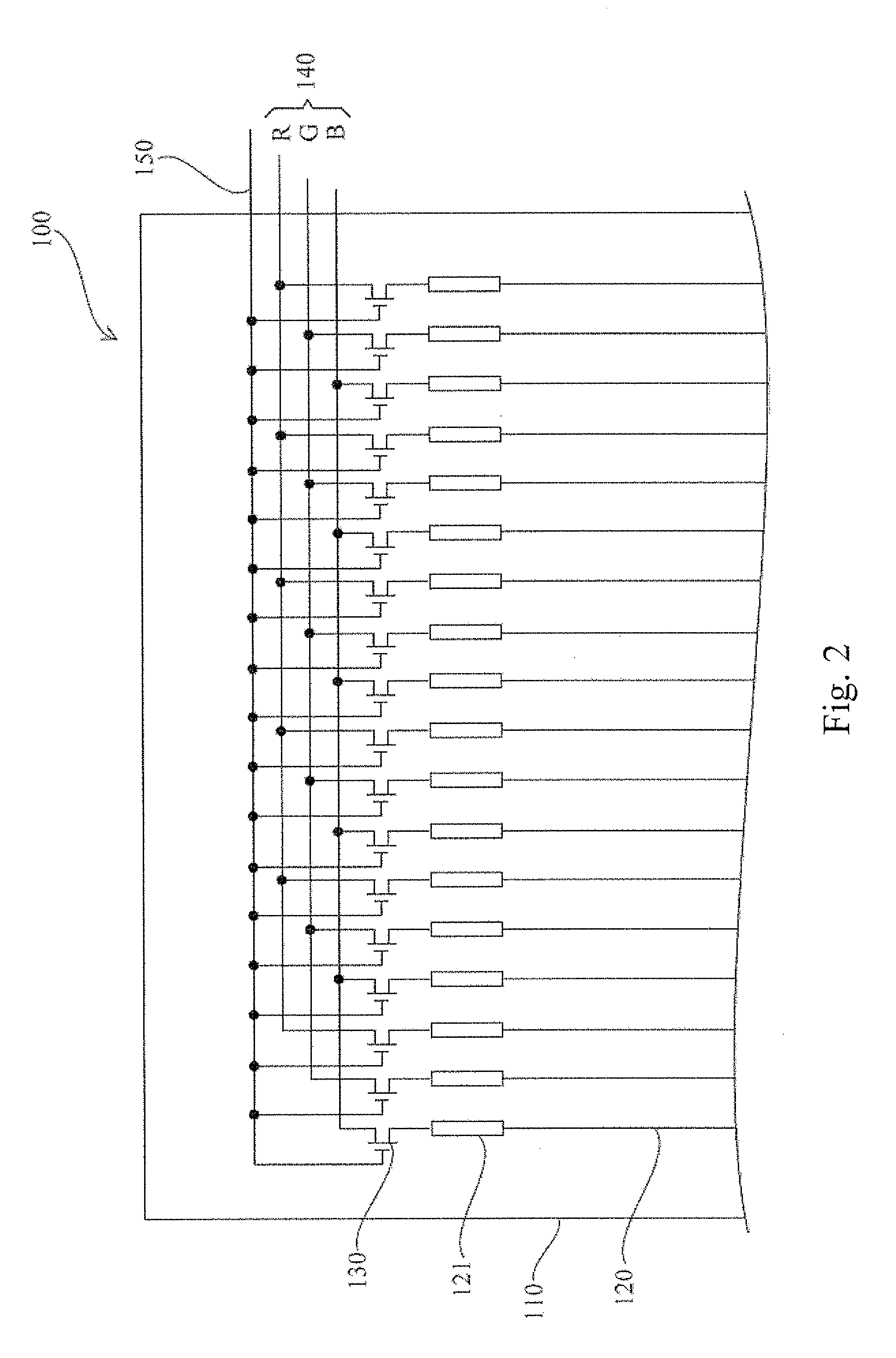

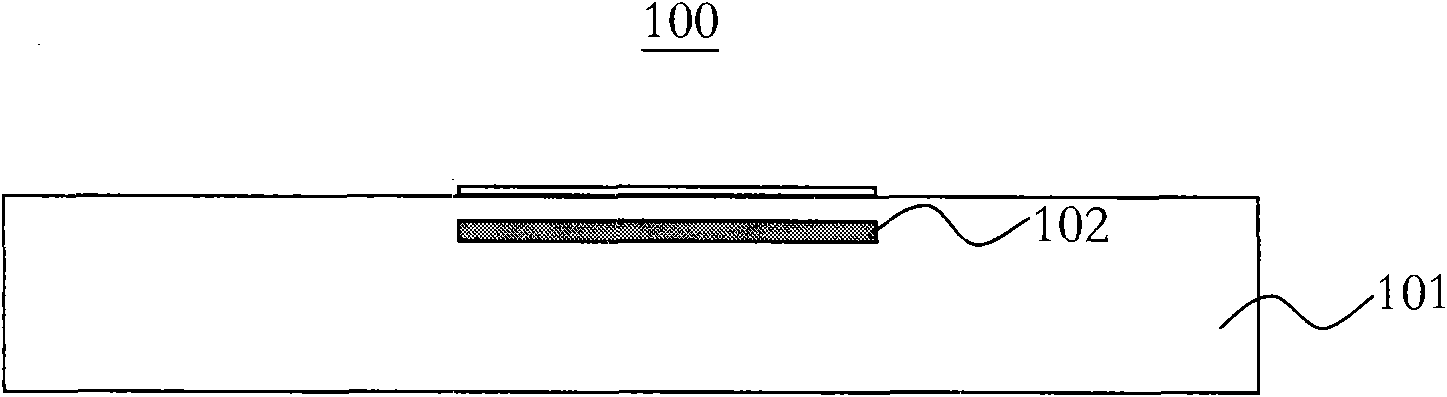

Liquid crystal display panel

InactiveUS20150077681A1Reduce processing timeIncrease capacityStatic indicating devicesNon-linear opticsLiquid-crystal displayControl line

The present invention provides a liquid crystal display (LCD) panel. The LCD panel comprises a substrate, signal lines, test switches, at least one test line and a control line. The test switches are connected between the signal lines and the test line, and the at least one test line is configured to input test signals to the test switches, and the control line is configured to turn on the test switches. In the present invention, the test line is not required to be cut off by a laser, thereby improving a production capacity and a process yield of the LCD panel.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

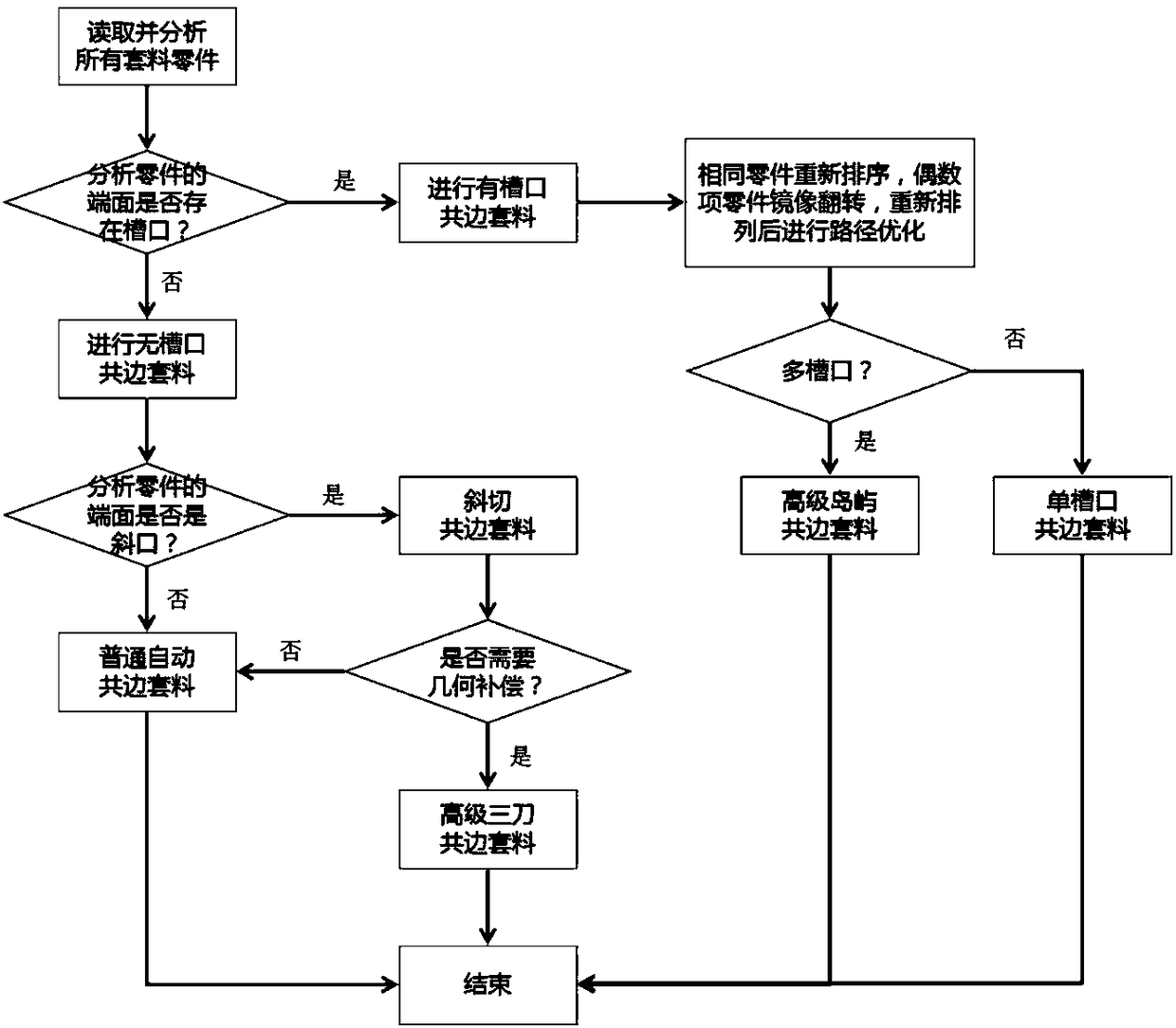

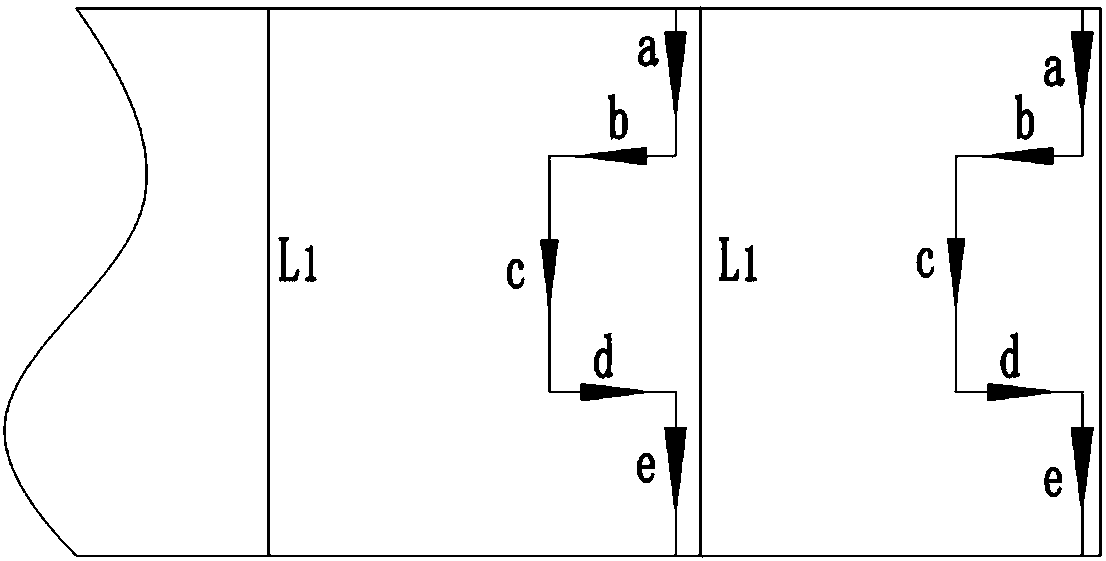

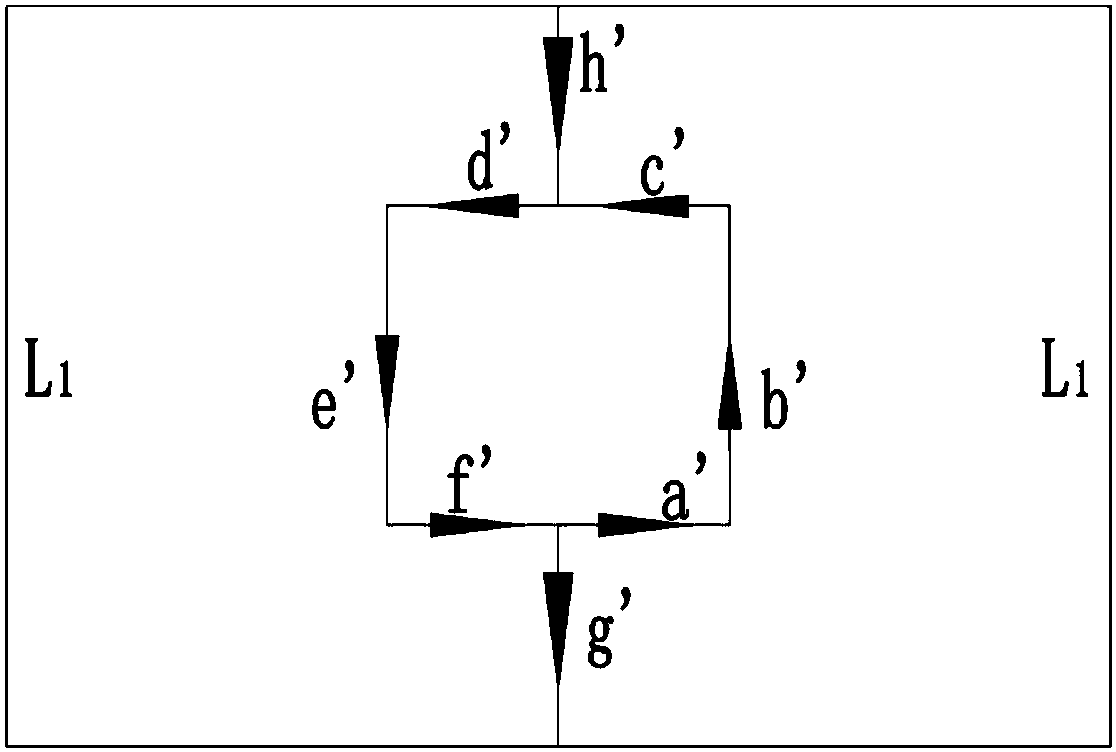

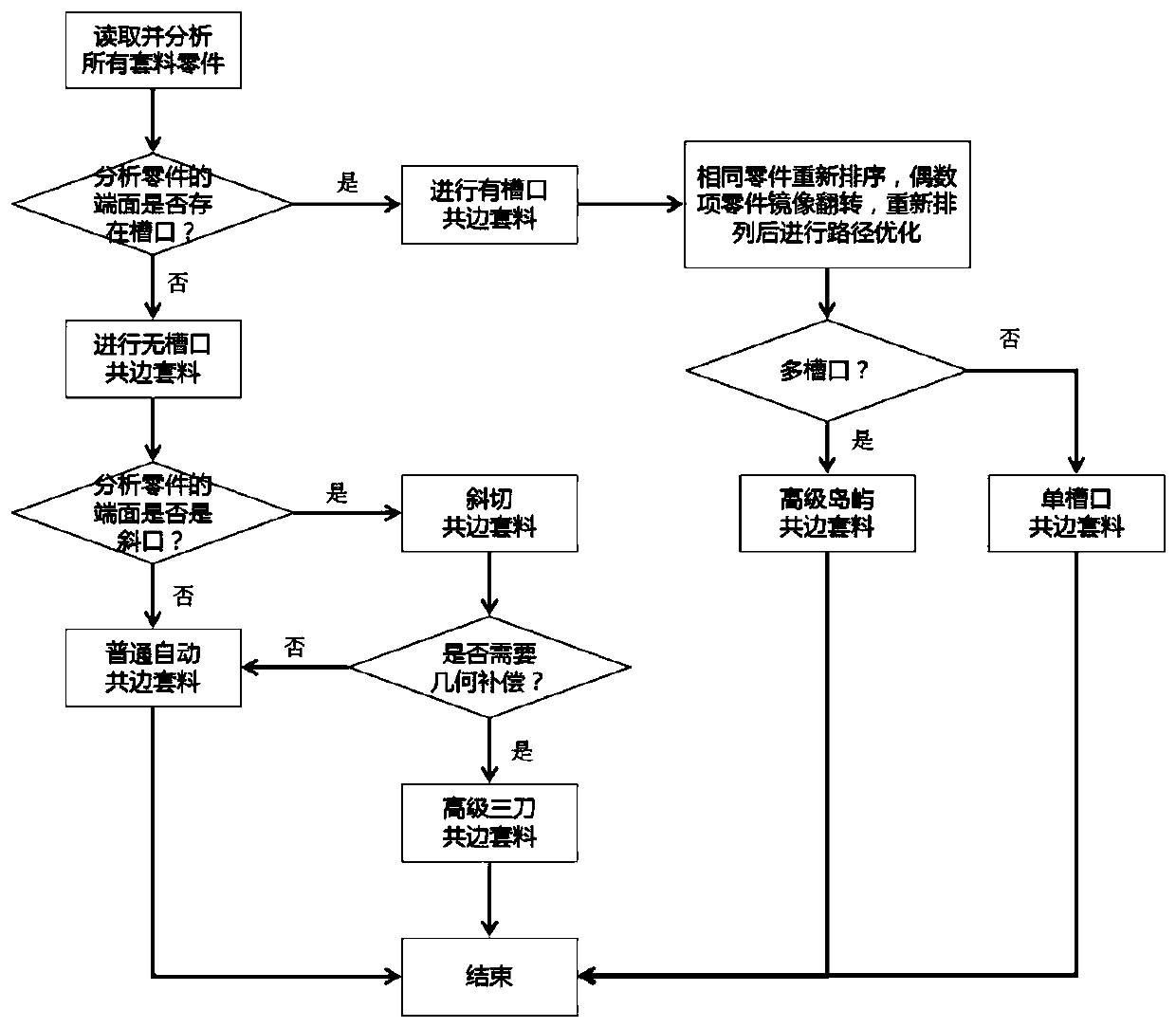

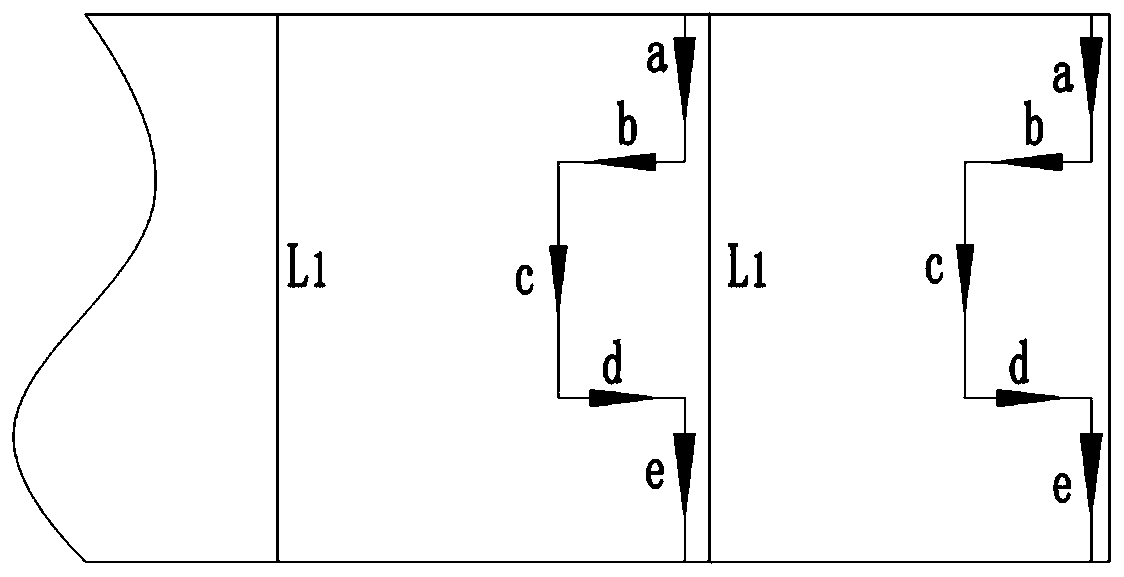

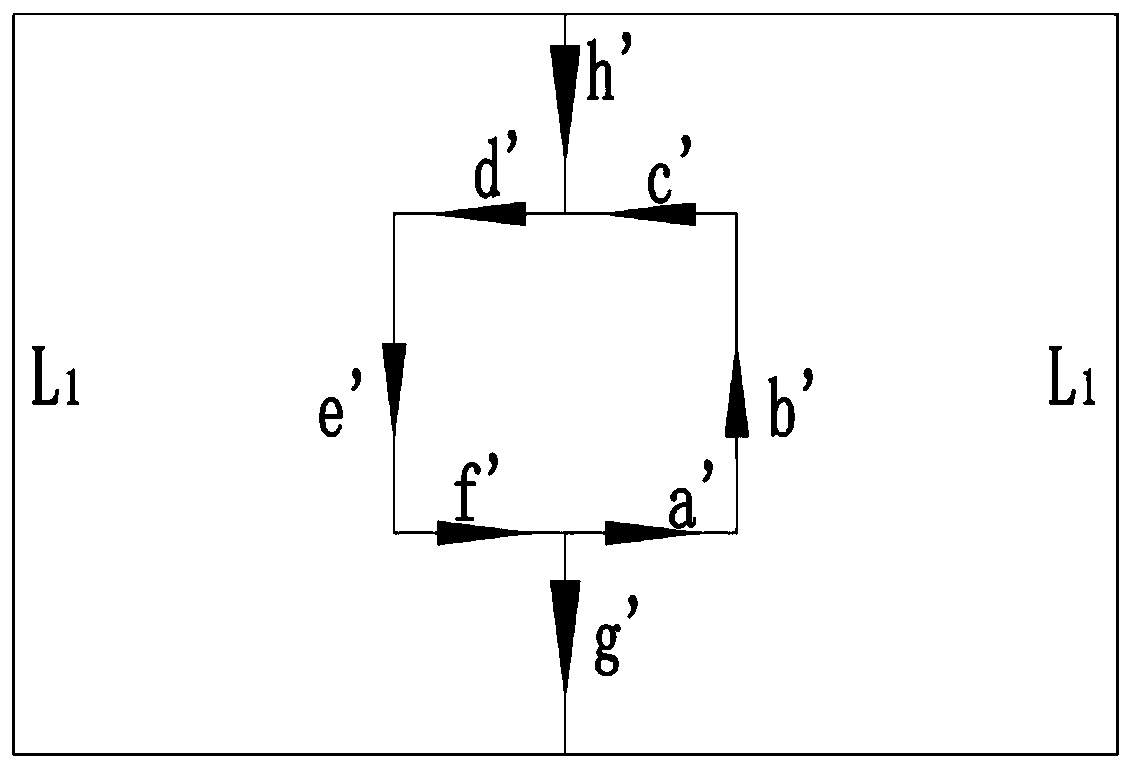

Material sleeve path optimization method applied to common edge cutting of pipe parts

ActiveCN108465944AReduce cutting costsImprove processing efficiencyForecastingLaser beam welding apparatusProduct gasEngineering

The invention provides a material sleeve path optimization method applied to common edge cutting of pipe parts. On the premise that machine tool equipment, the pipe raw material and machined parts arenot changed, the cutting path is optimized, so that the purpose that the raw material of the pipe is saved, the energy consumption of the laser is reduced, the gas consumption is assisted, and the total movement path of the machine tool is reduced is achieved, and meanwhile, the method has positive significance for improving the cross section quality of part products and prolonging the service life of equipment.

Owner:FOSHAN HONGSHI LASER TECH

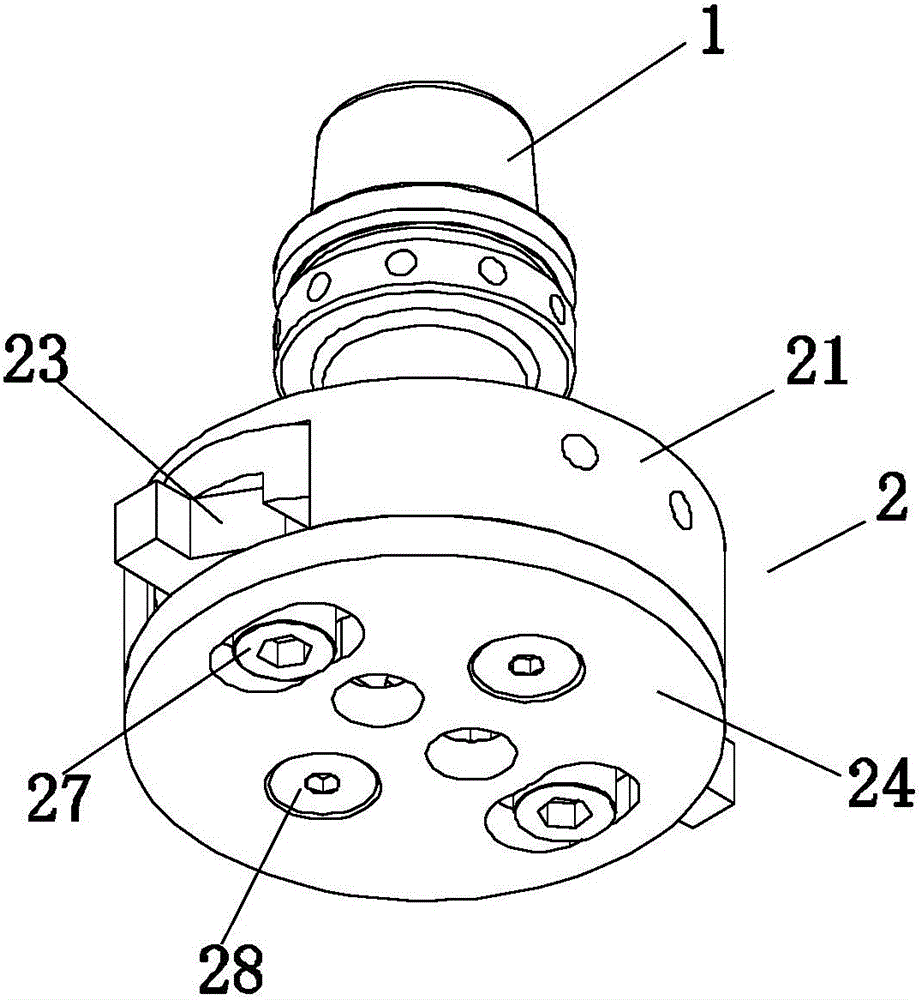

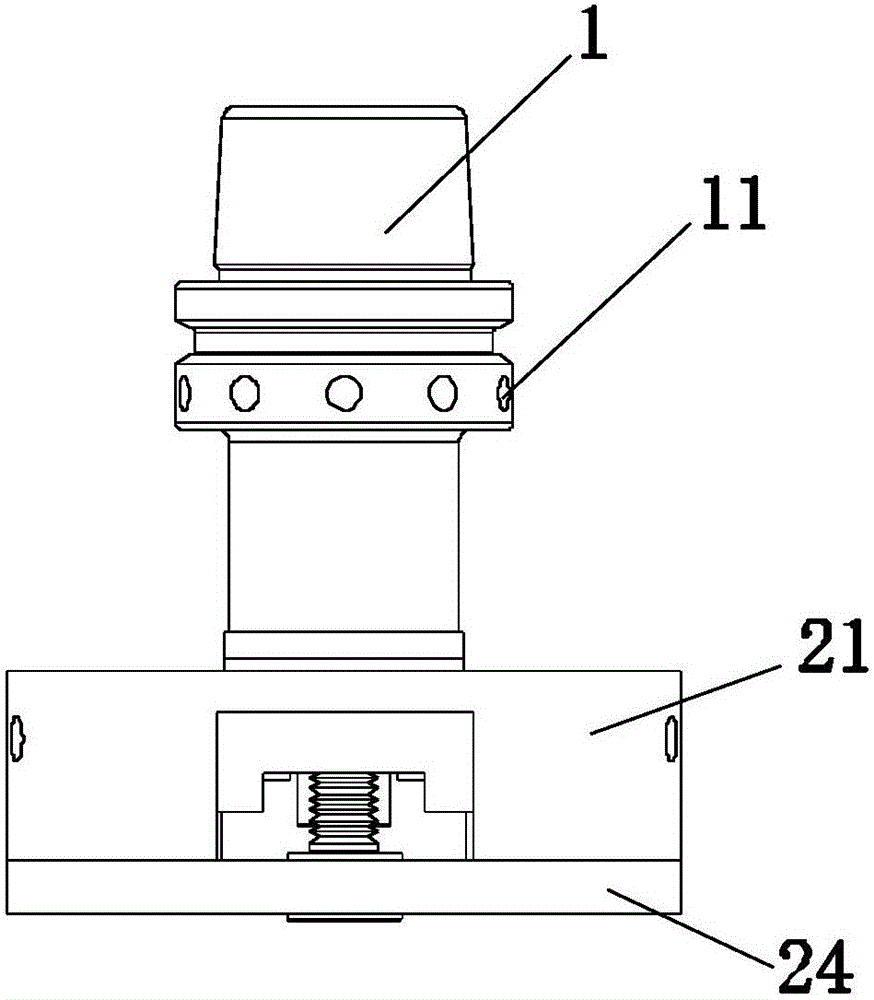

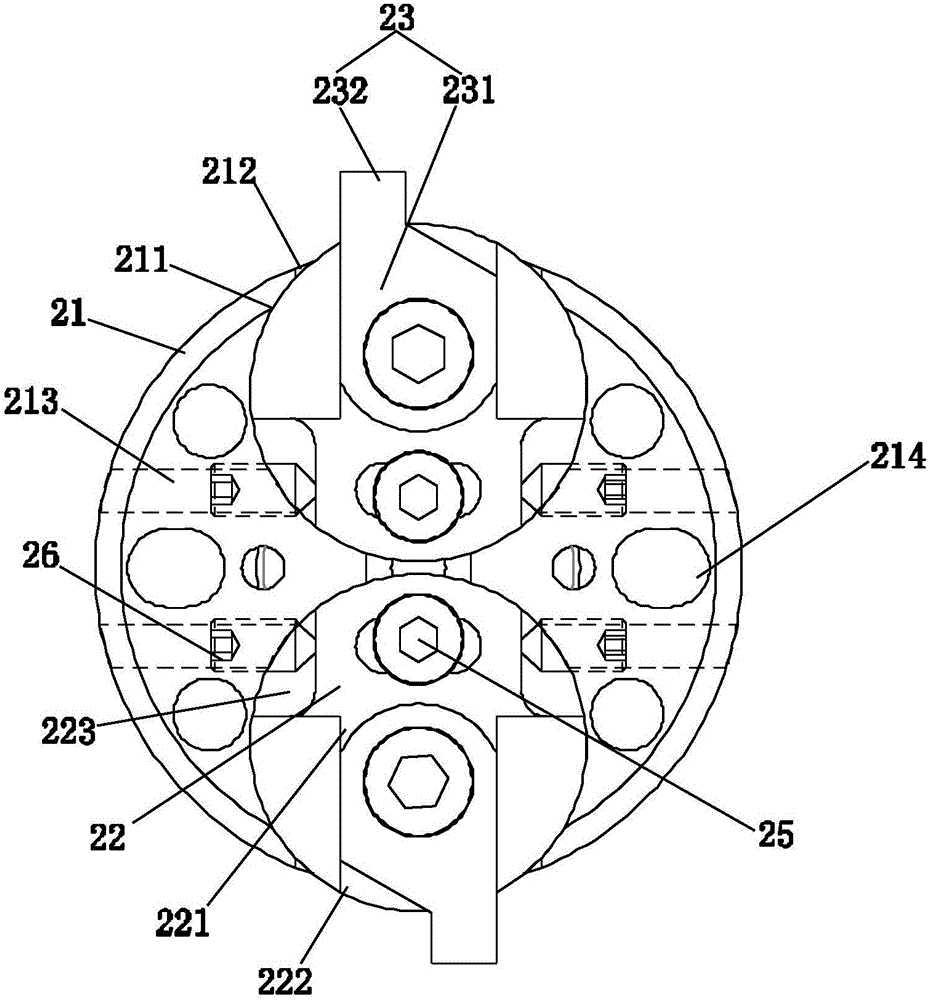

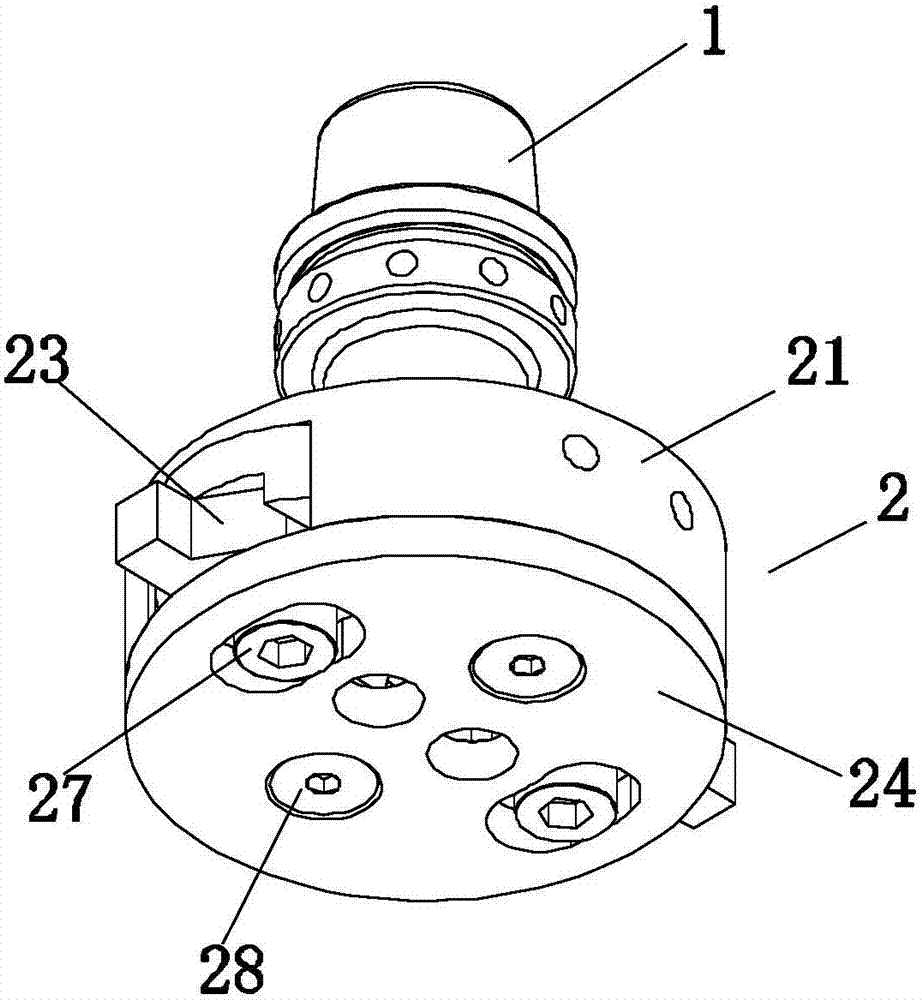

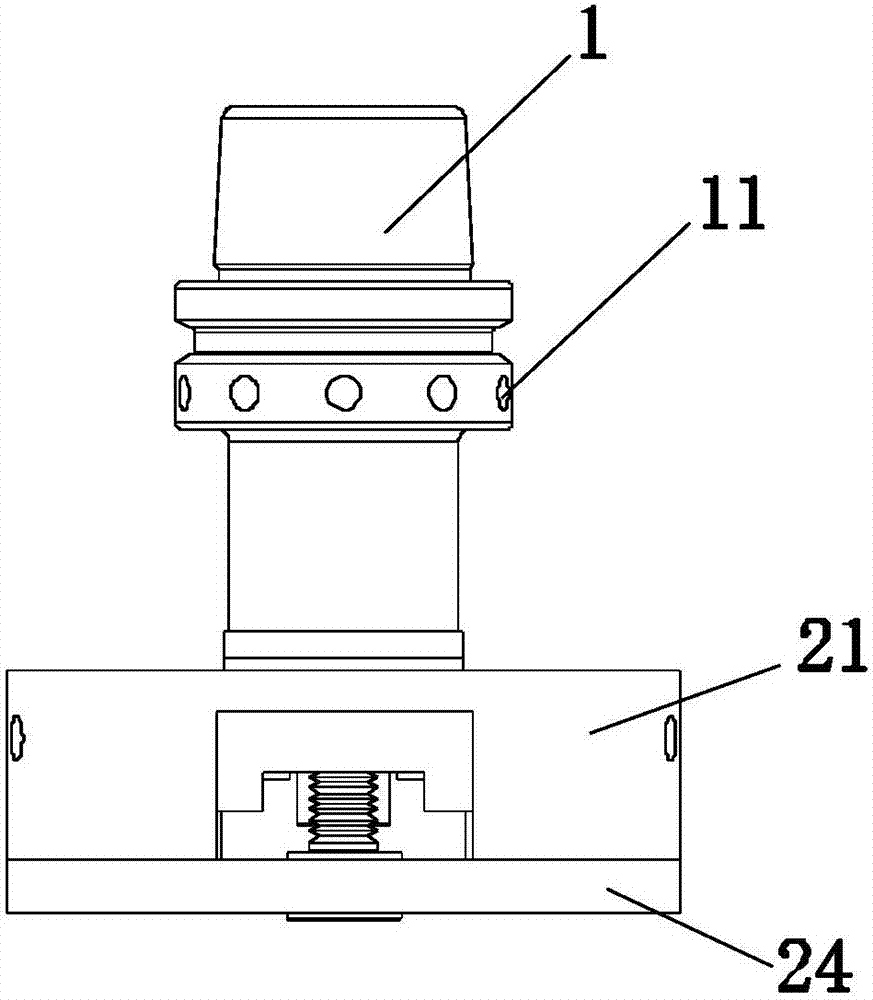

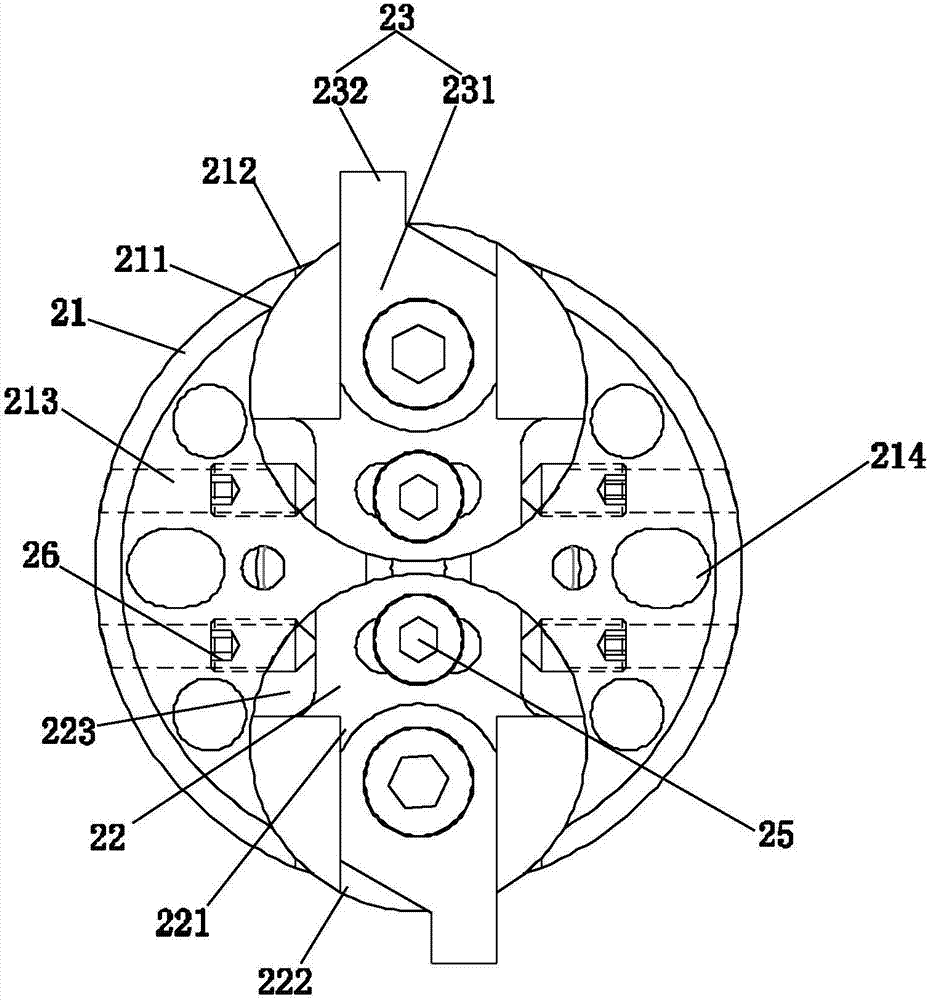

Highlight face milling cutterhead and highlight face milling cutter

ActiveCN105772820AImprove the knife patternGood highlight effectMilling cuttersMilling cutterEngineering

The invention discloses a highlight face milling cutterhead. The highlight face milling cutterhead comprises a face milling cutterhead body, two rotating plates, two milling cutters and a cover plate. Two circular grooves are symmetrically distributed in the end face of the face milling cutterhead body. Each rotating plate is installed in one circular groove and provided with a milling cutter installation groove. Each milling cutter comprises a milling cutter handle and a milling cutter head arranged at one end of the milling cutter handle. The milling cutter handles of the milling cutters are fixedly installed in the milling cutter installation grooves. The milling cutter head of each milling cutter sequentially penetrates a second notch and a first notch and extends outwards, wherein the second notch and the first notch correspond to the milling cutter head. The cover plate is fixedly connected with the end face of the face milling cutterhead body. The invention further discloses a highlight face milling cutter. By means of the highlight face milling cutterhead and the highlight face milling cutter, the highlight effect of products can be improved, the mirror surface effect that Ra is smaller than or equal to 25 nm is achieved, and cutter patterns are eliminated; and an upper chamfer and a lower chamfer can be machined at the same time, the machining efficiency is improved, the balance performance of the whole cutterhead can be effectively ensured, and the subsequent balancing difficulty is lowered.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

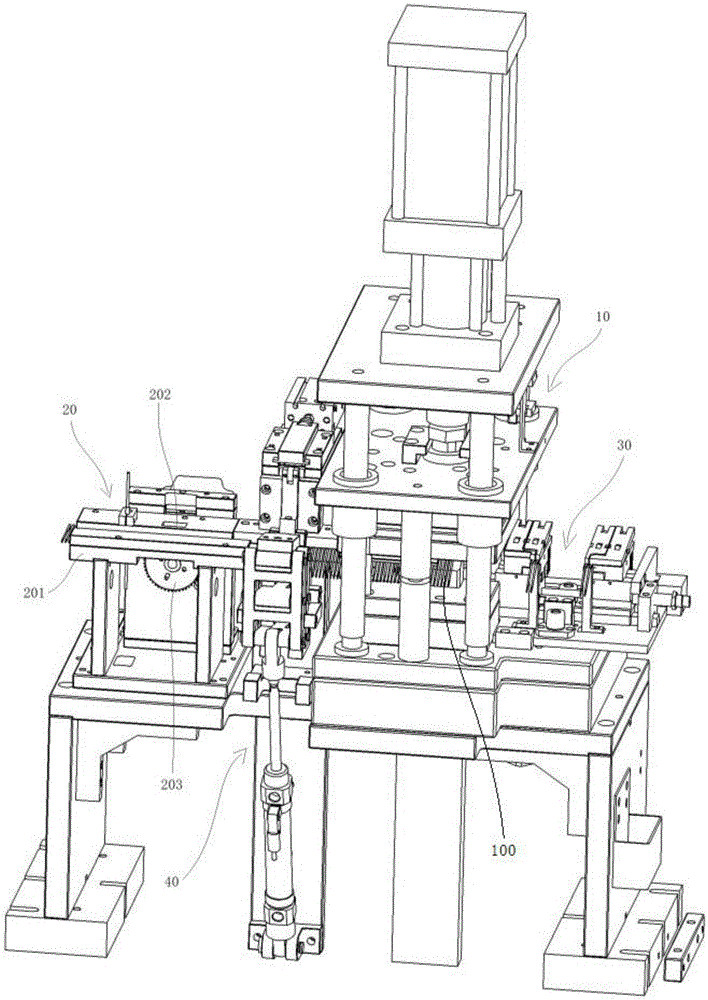

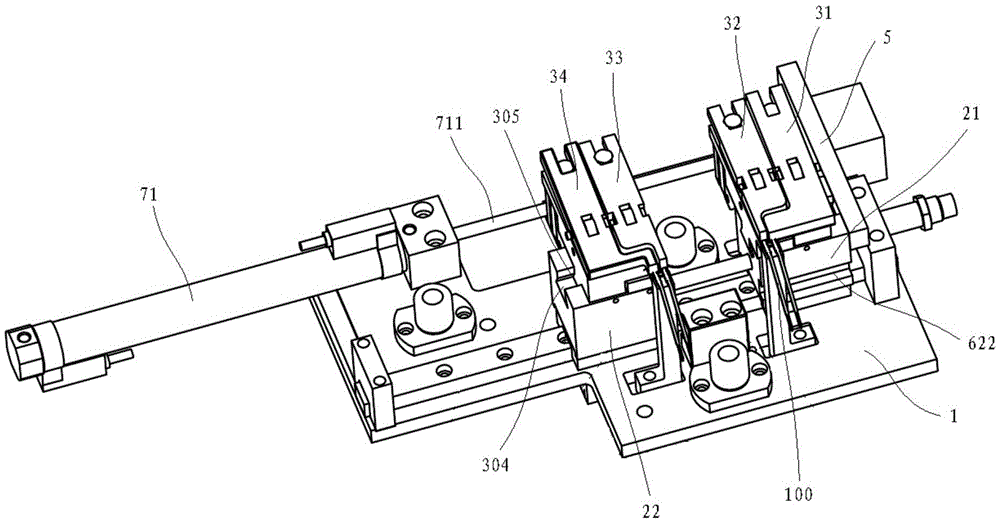

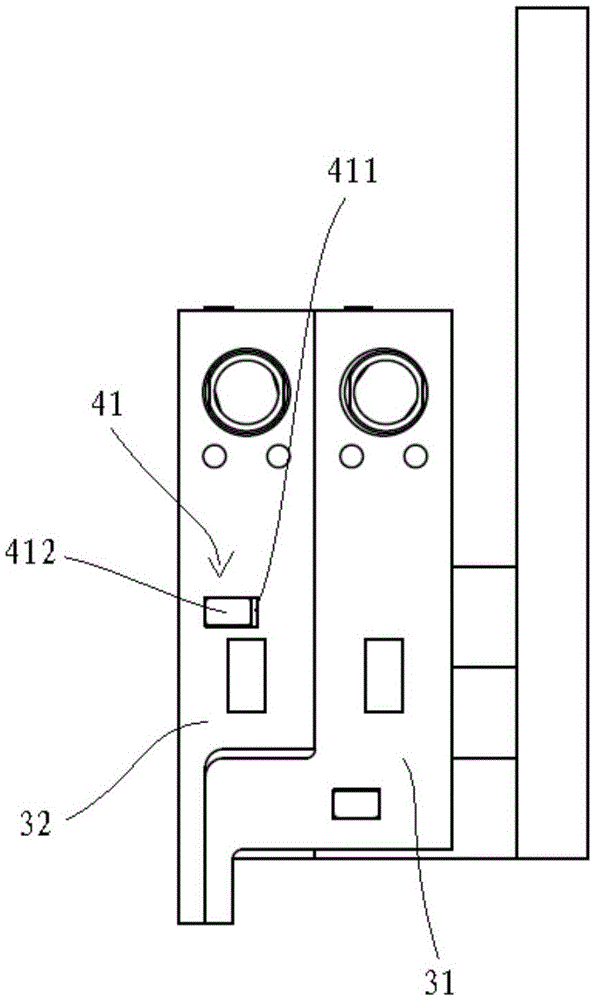

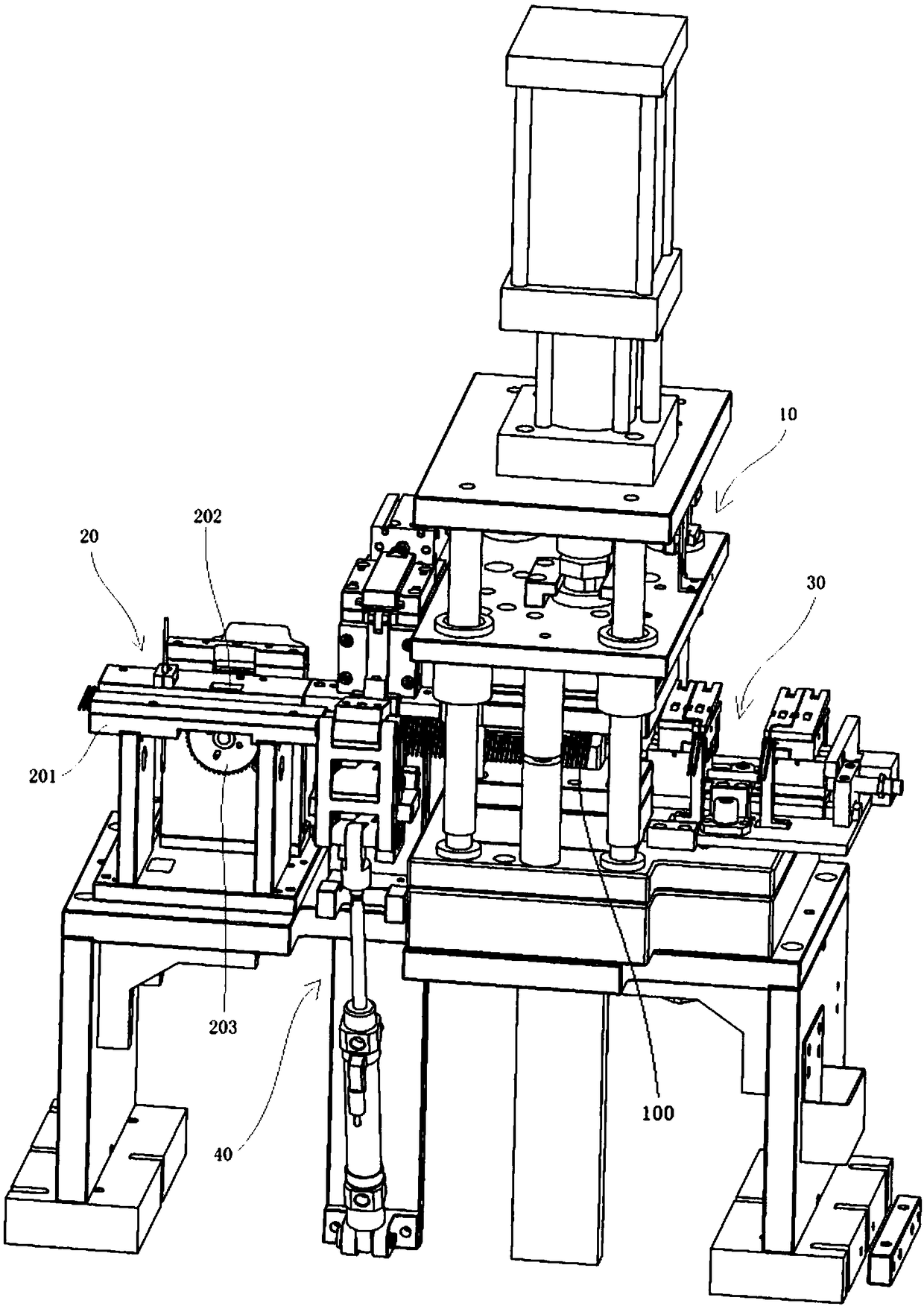

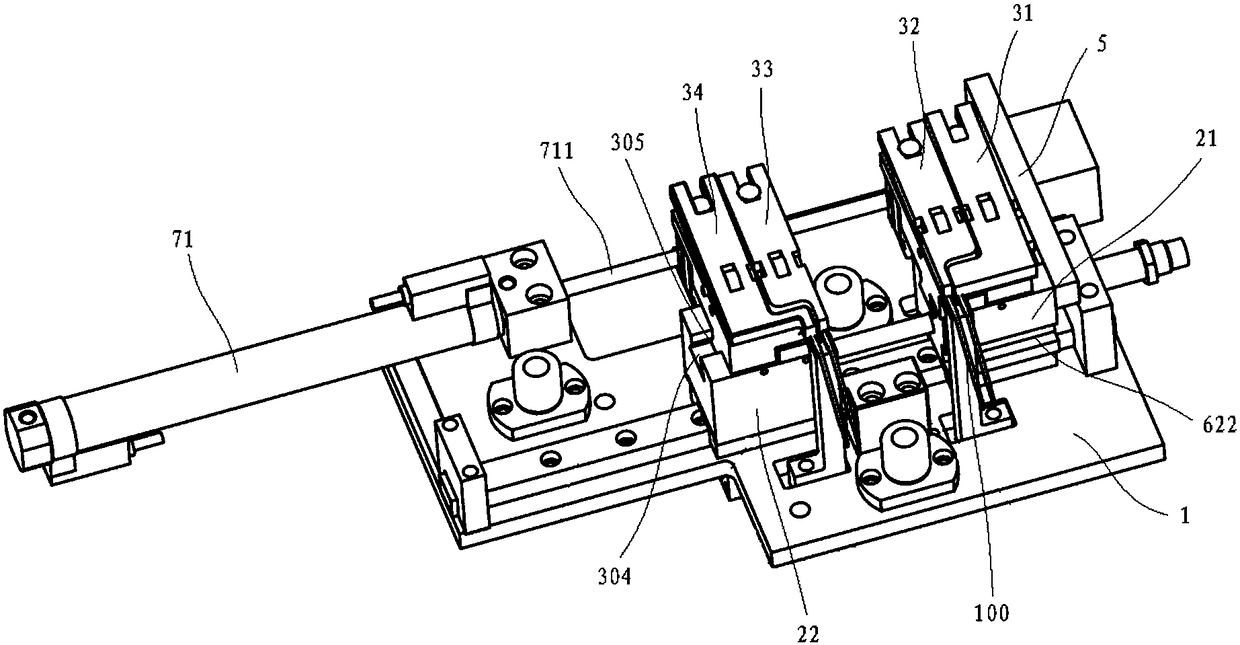

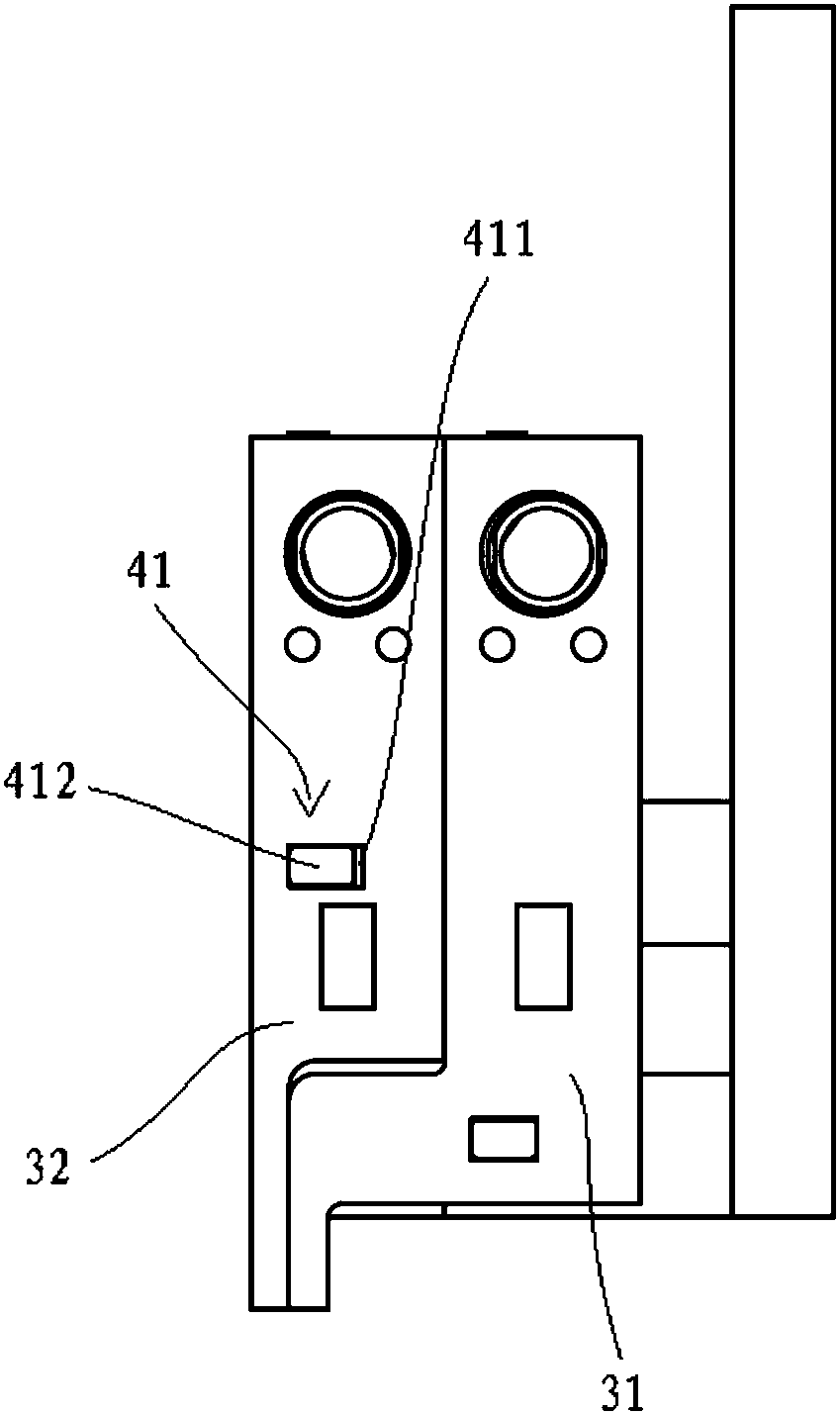

Cropping working station for PIN material strap

ActiveCN105598524AFully automatedIncrease productivityShearing machinesShearing machine accessoriesEngineeringAutomation

The invention provides a cropping working station for a PIN material strap. The cropping working station comprises a cropping mechanism cropping the PIN material strap into separated PINs, a feeding mechanism feeding the PIN material strap to the cropping mechanism, and a PIN distributing mechanism. The PIN distributing mechanism is used for clamping a set number of PINs from the cropping mechanism and distributing the clamped PINs so as to enable the PINs to be distributed according to preset intervals. According to the cropping working station for the PIN material strap, the PIN material strap can be cropped into the separated PINs, the set number of PINs can be distributed so that the PINs can be distributed according to the preset intervals, full automation of the PIN cropping and distributing technology can be achieved, production efficiency is high, the interval accuracy of the PINs is high, and manpower cost is reduced.

Owner:CWB AUTOMOTIVE ELECTRONICS

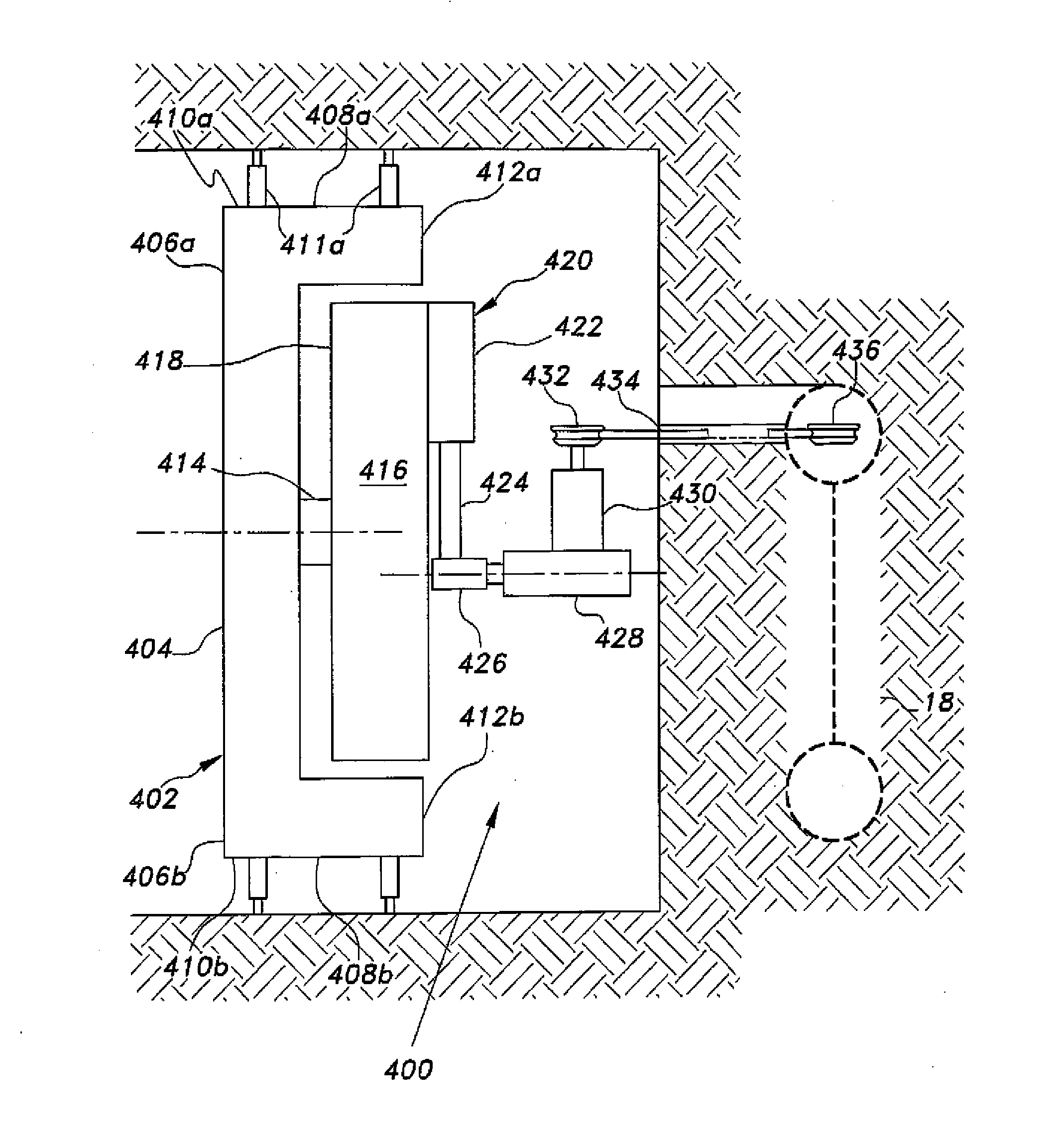

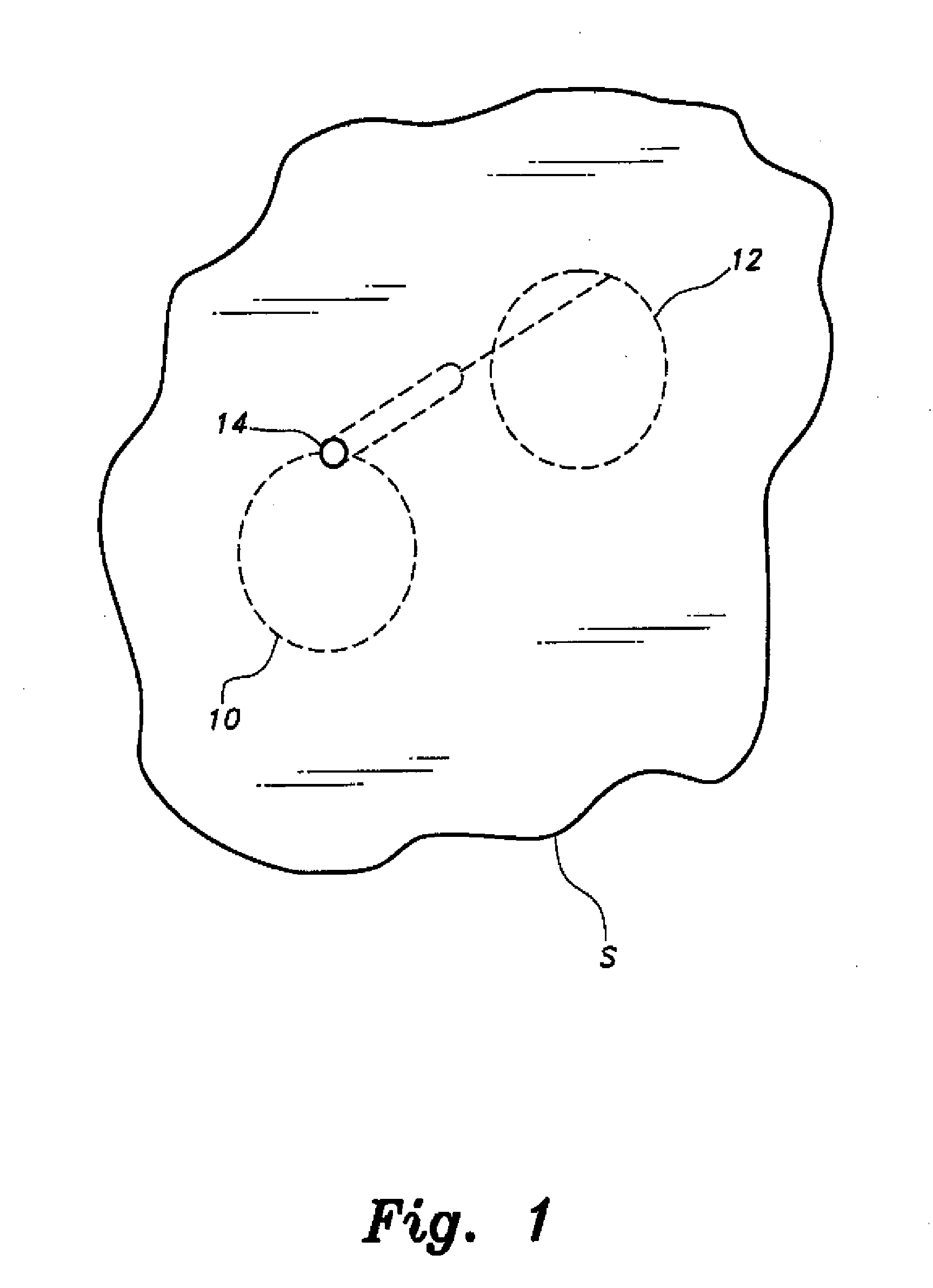

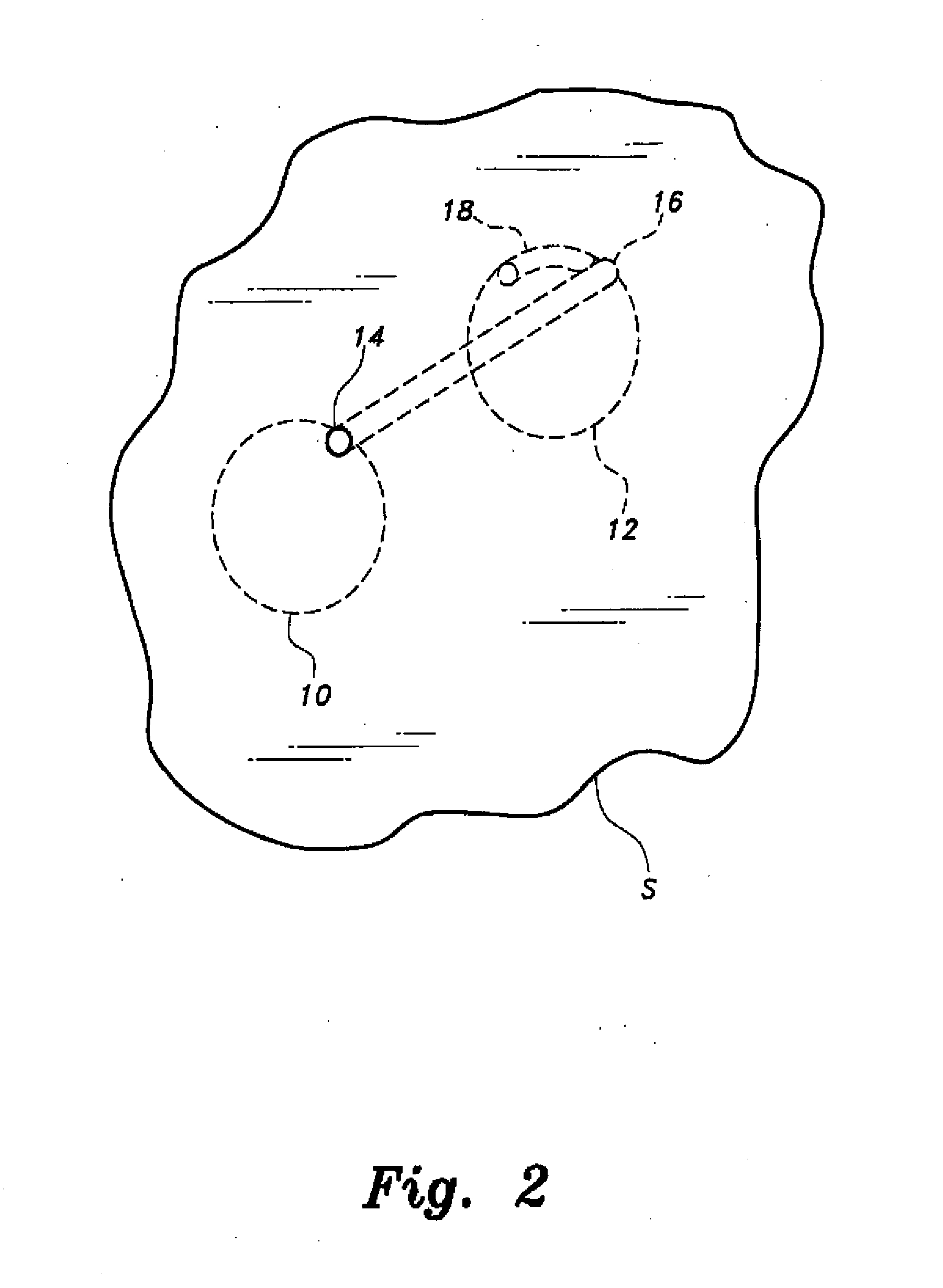

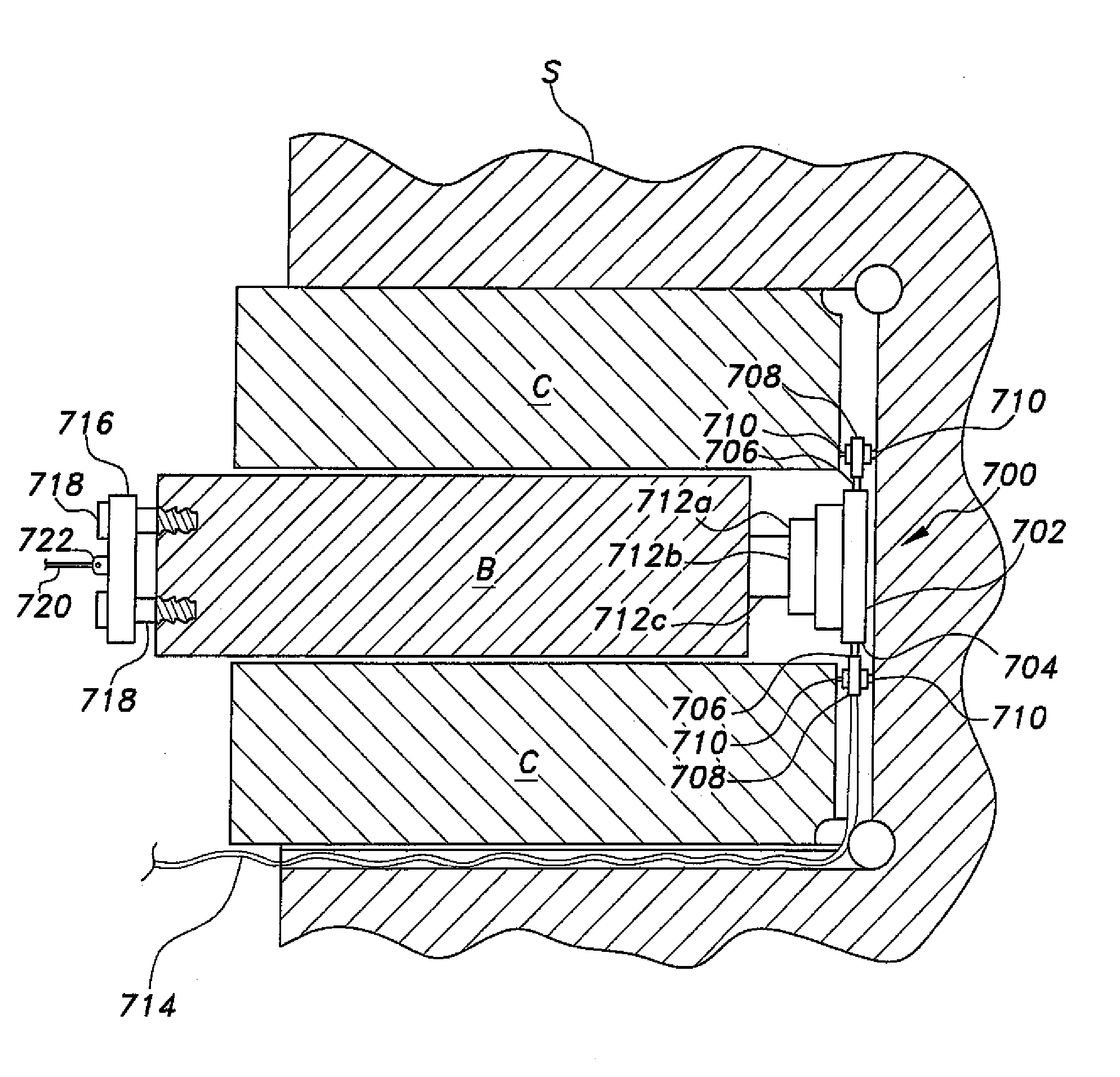

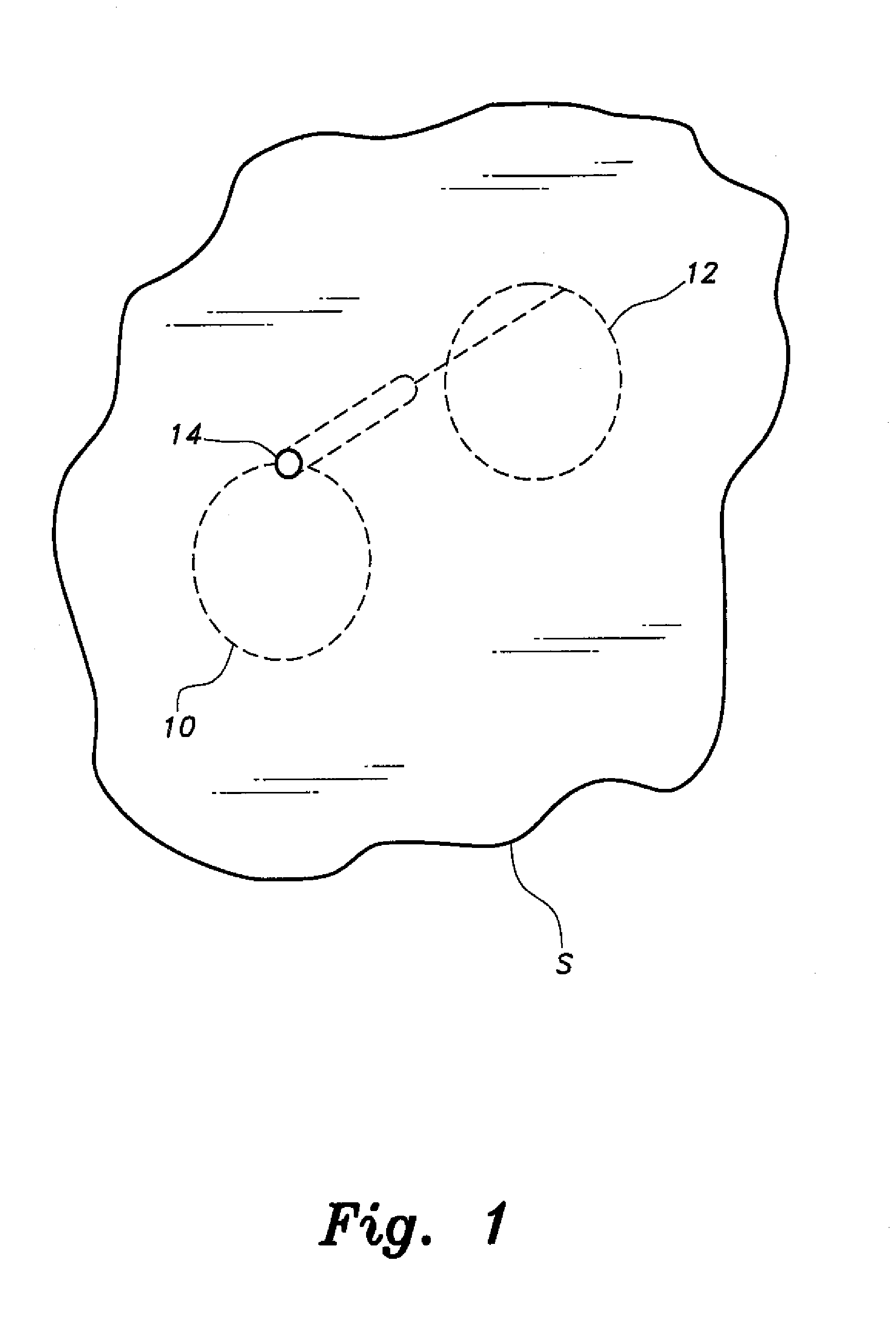

Method for wire saw excavation

InactiveUS20150174789A1Reduces time and effort and expenseOptimize cutting processMetal sawing devicesDisloding machinesClosed loopWire saw

The method for wire saw excavation provides a significant savings in time, effort, and expense in the cutting of a core of material from a solid substrate such as rock or concrete. A single downhole is formed, and a robotic excavator then forms a continuous, closed loop base passage at the distal end of the downhole to define the periphery of the core to be cut. When the base passage has been completed, the robotic excavator is removed and two subsurface guide pulleys are placed in the bottom of the downhole. A wire saw is passed from a first surface pulley around the first and second subsurface pulleys and back to a second surface pulley. The surface pulleys are advanced along the predetermined periphery of the core at the same rate as the subsurface pulleys, so that the saw simultaneously cuts the periphery and the bottom of the core.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

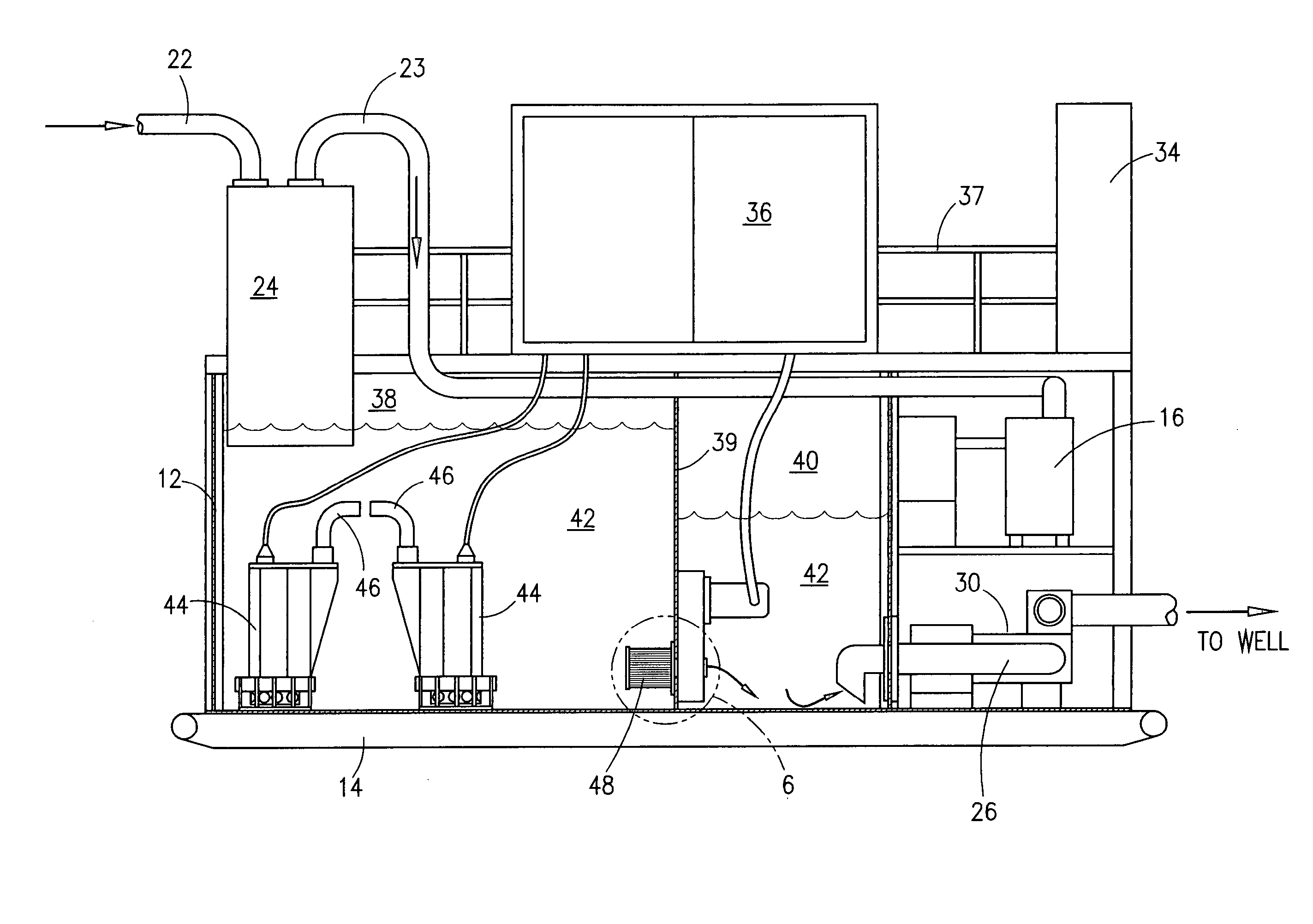

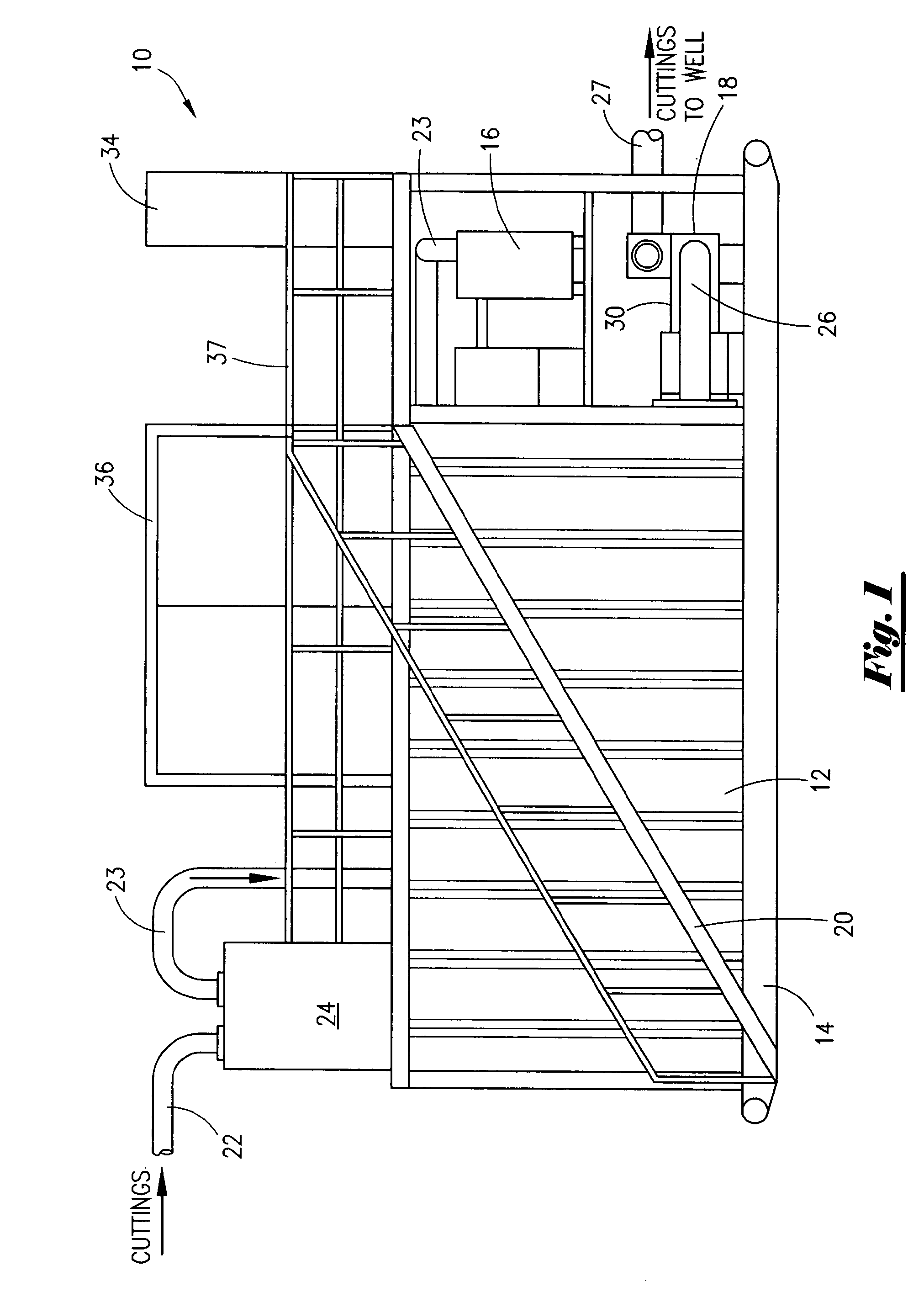

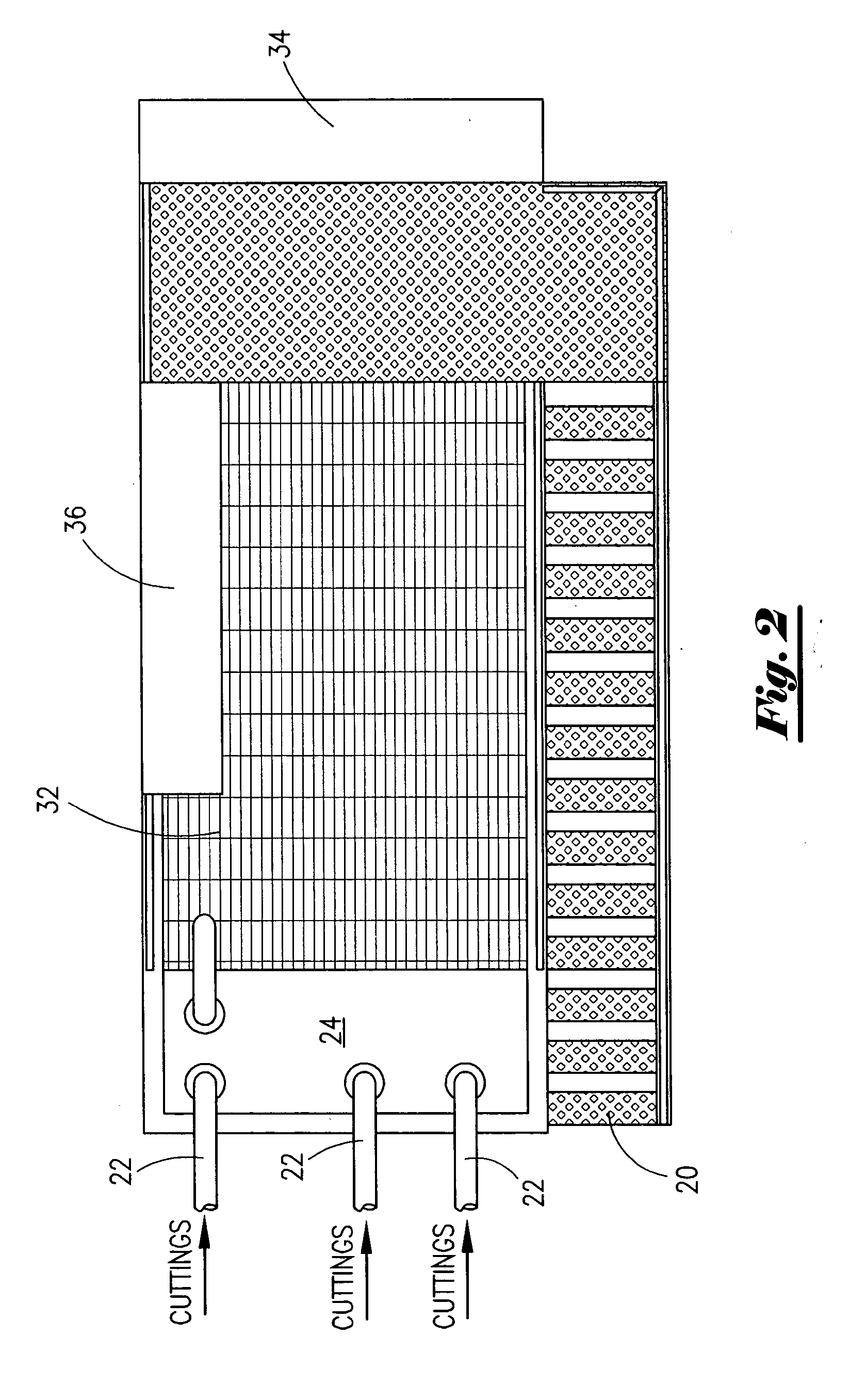

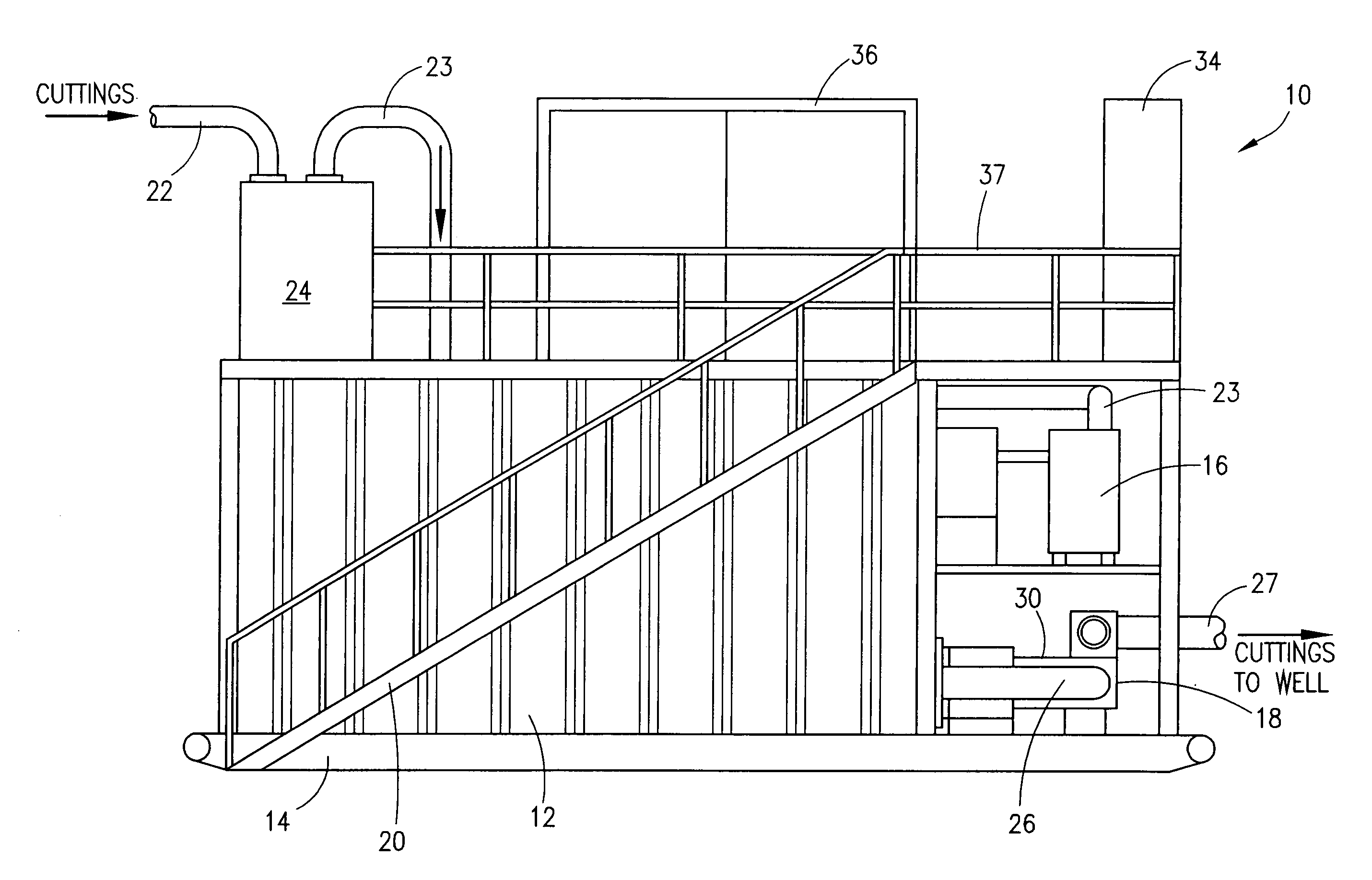

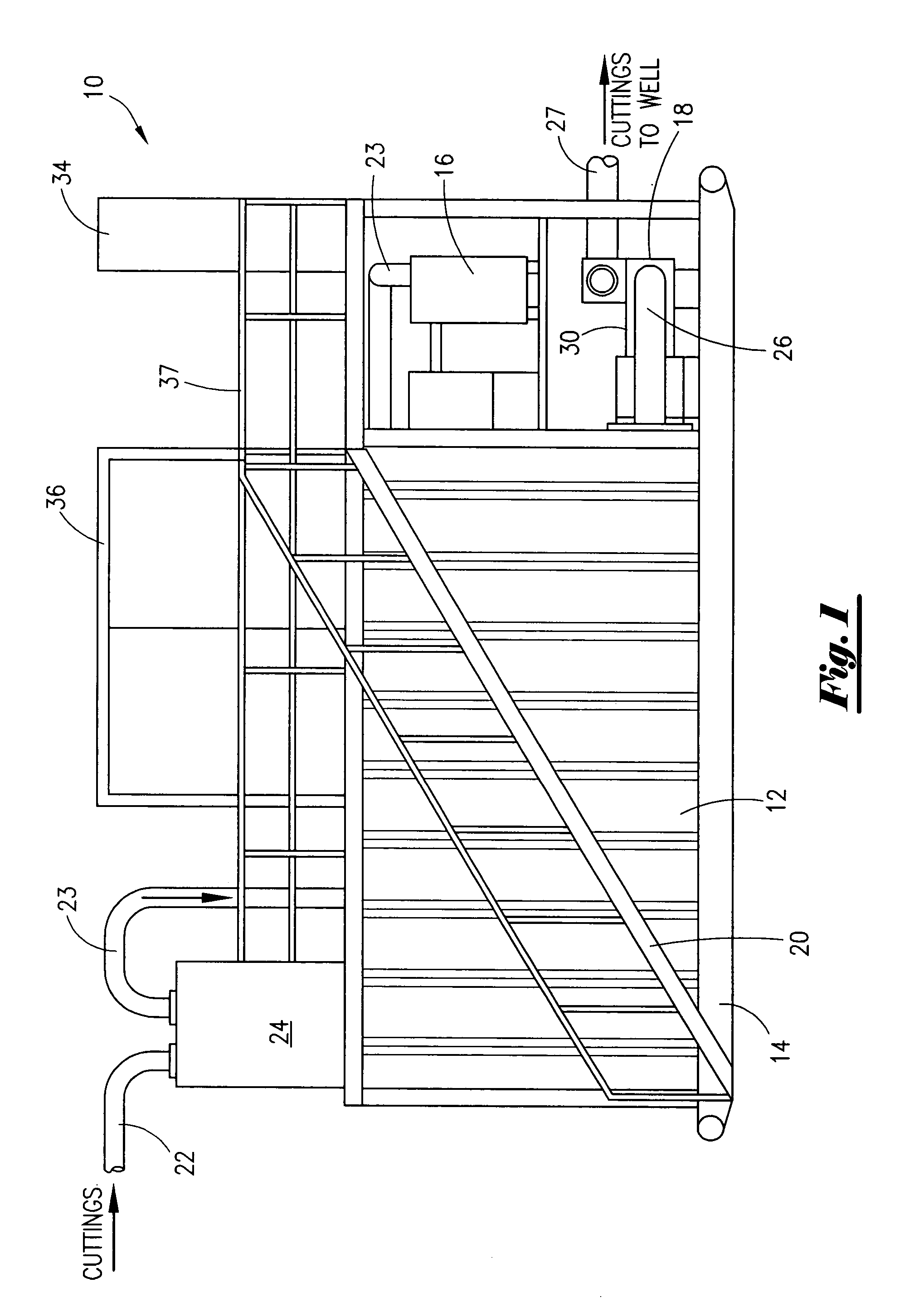

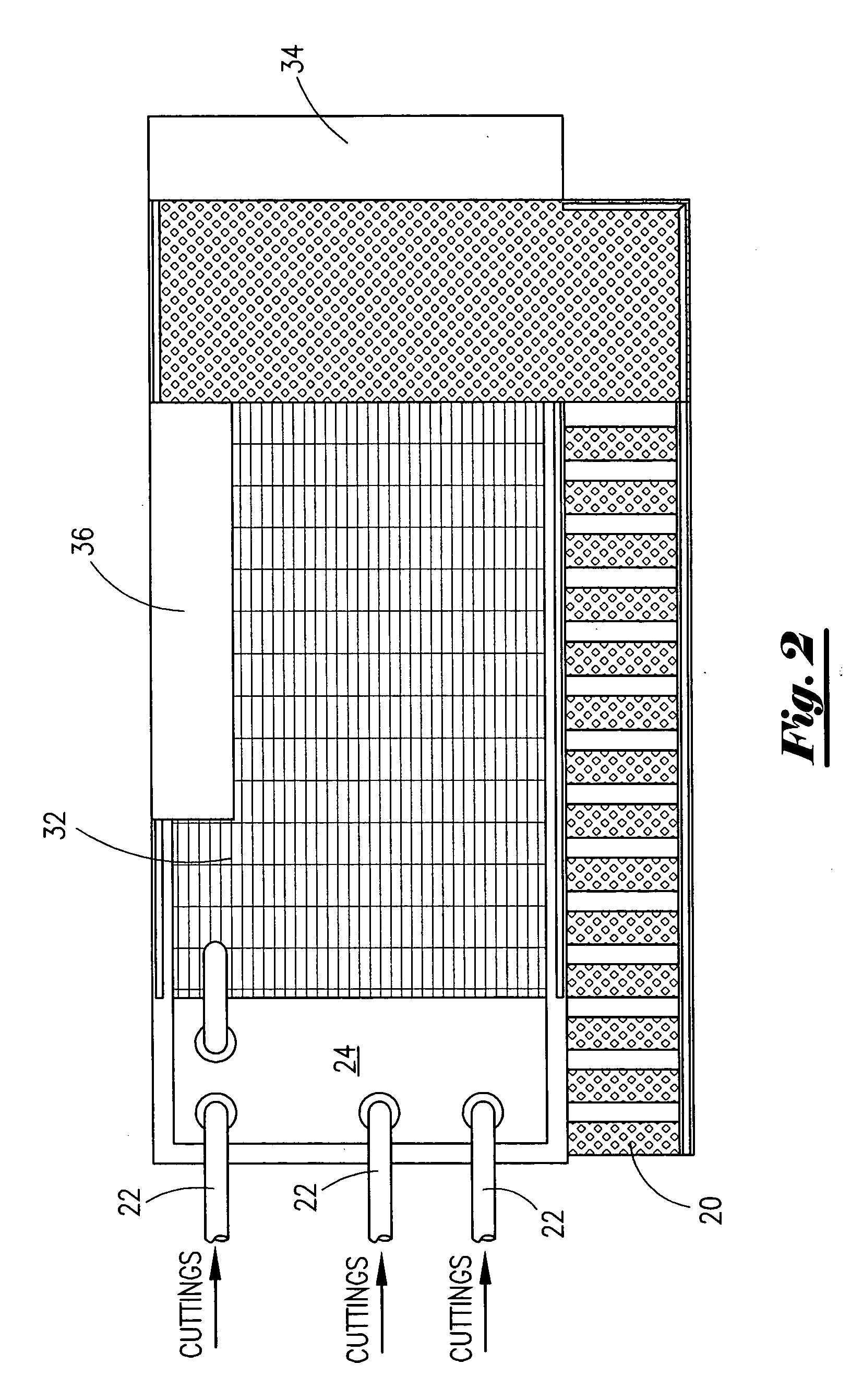

Method and Apparatus for Processing and Injecting Drill Cuttings

InactiveUS20090200083A1Eliminating expensive and complicated cutting transfer systemExtensive circulating and holding systemsWater cleaningDrilling rodsTransfer systemCollection system

An improved cuttings system located adjacent a drilling rig's shale shaker system utilizing a vacuum collection / gravity fed processing system, thereby eliminating expensive and complicated cuttings transfer systems. The use of a vacuum cuttings collection system combined within a common fluid-filled open tank and submersible grinding pumps eliminate the need for extensive circulating and holding systems. Cuttings are sized and chemically prepared within the same tank and fed directly to an injection pump for discharge to cuttings transport tanks or injected down hole. Other improvements include non-restrictive cuttings sizing, filtering, and an injection pump cuttings relief system.

Owner:REDDOCH SR JEFFREY A

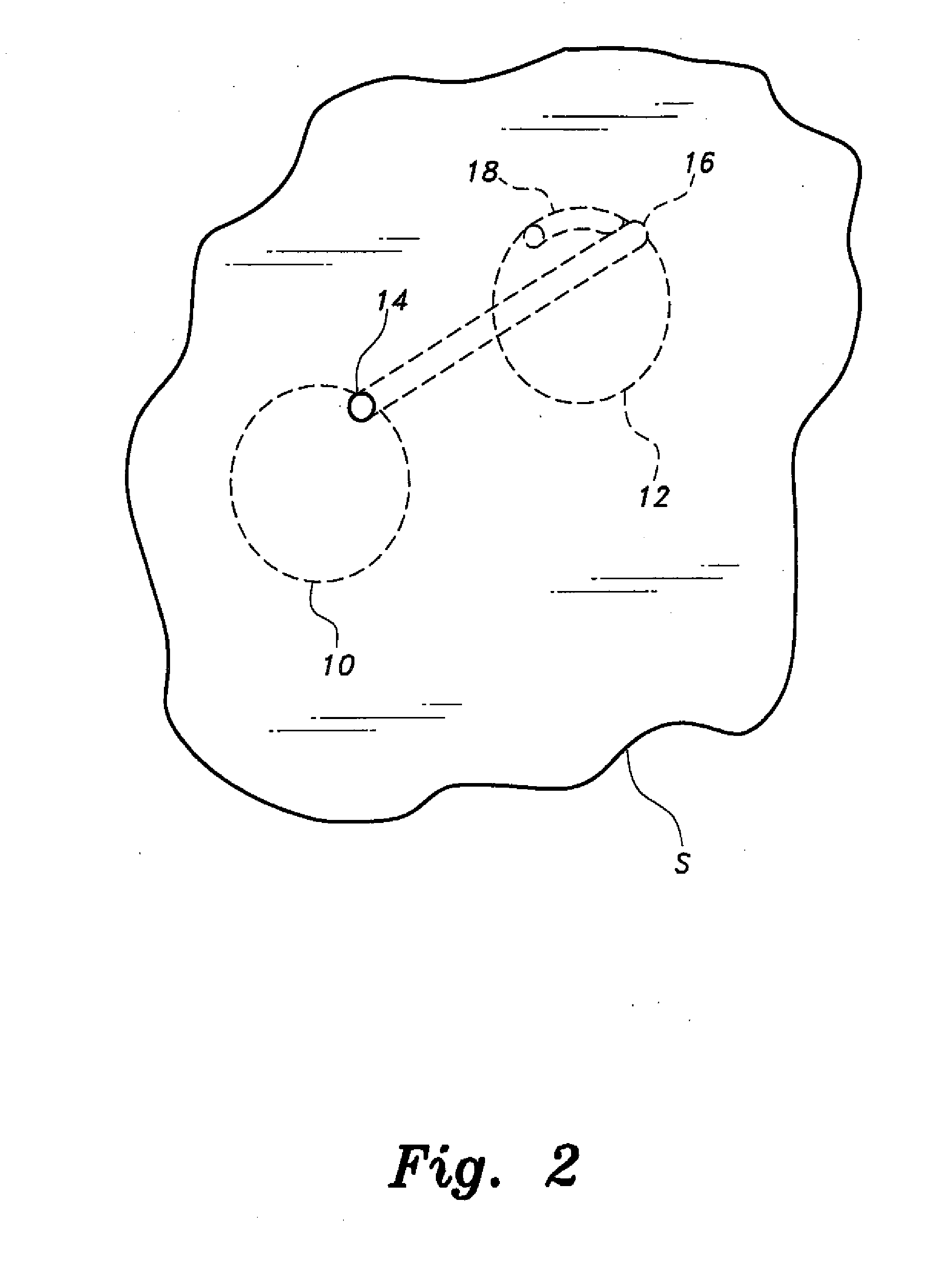

Method for wire saw excavation

ActiveUS20150167460A1Reduces time and effort and expenseOptimize cutting processMetal sawing devicesDisloding machinesEngineeringSolid substrate

The method for wire saw excavation provides a significant savings in time, effort, and expense in the cutting of a core of material from a solid substrate such as rock or concrete. A single downhole is formed, and a robotic excavator then forms a continuous, closed loop base passage at the distal end of the downhole to define the periphery of the core to be cut. When the base passage has been completed, the robotic excavator is removed and two subsurface guide pulleys are placed in the bottom of the downhole. A wire saw is passed from a first surface pulley around the first and second subsurface pulleys and back to a second surface pulley. The surface pulleys are advanced along the predetermined periphery of the core at the same rate as the subsurface pulleys, so that the saw simultaneously cuts the periphery and the bottom of the core.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Method and apparatus for processing and injecting drill cuttings

InactiveUS20070119628A1Reduced space requirementsReduces personnelDrilling rodsFlushingTransfer systemCollection system

An improved cuttings system located adjacent a drilling rig's shale shaker system utilizing a vacuum collection / gravity fed processing system, thereby eliminating expensive and complicated cuttings transfer systems. The use of a vacuum cuttings collection system combined within a common fluid-filled open tank and submersible grinding pumps eliminate the need for extensive circulating and holding systems. Cuttings are sized and chemically prepared within the same tank and fed directly to an injection pump for discharge to cuttings transport tanks or injected down hole. Other improvements include non-restrictive cuttings sizing, filtering, and an injection pump cuttings relief system.

Owner:REDDOCH SR JEFFREY A

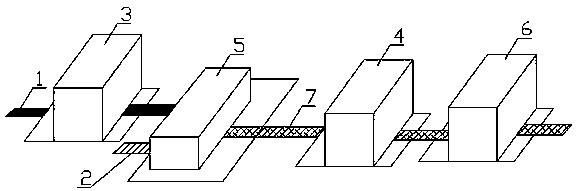

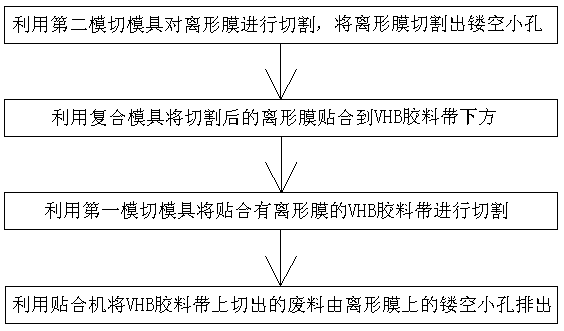

Hollow waste discharging device and waste discharging method of VHB (Very High Bond) rubber compound

PendingCN108127726AOptimize cutting processGuarantee product qualityMetal working apparatusEngineeringMaterial resources

The invention provides a hollow waste discharging device and waste discharging method of a VHB (Very High Bond) rubber compound. The hollow waste discharging device comprises a first die-cutting mould, a second die-cutting mould, a composite mould and an adhering machine, wherein a structure of the second die-cutting mould is identical to that of the first die-cutting mould; and the cross sectionarea of a die-cutting cutter of the first die-cutting mould is less than that of a die-cutting cutter of the second die-cutting mould. According to the hollow waste discharging device and waste discharging method of the VHB rubber compound disclosed by the invention, a separate film is cut by utilizing the second die-cutting mould with the die-cutting cutter having the smaller cross section area,hollow waste discharging holes are cut out on the separate film, a VHB rubber compound tape adhered with the separate film is cut, and scraps of the VHB rubber compound tape is removed from the hollowwaste discharging holes by utilizing the adhering machine in an adhering manner, so that clean adhesion removal on the scraps can be ensured, and the phenomenon that a cutting outline of the VHB rubber cannot be extruded by the scraps also can be ensured so as to further ensure that occurrence of unqualified products can be avoided; and therefore, the production quality is ensured, manpower and material resources also can be reduced, and the production cost is controlled.

Owner:郑州领胜科技有限公司

Electrosurgical resection instrument

ActiveUS10251697B2Optimize cutting processDiagnosticsSurgical instruments for heatingVeinBowel perforations

An electrosurgical resection instrument for applying to biological tissue radiofrequency electromagnetic energy has a protective hull comprising a shaped piece of dielectric material mounted to cover an underside of an instrument tip of the instrument. The protective hull acts as a shield to protect tissue that may lie under the instrument tip from damage during treatment. The instrument may be particularly useful in procedures performed in a gastrointestinal tract, where bowel perforation is a concern, or in the pancreas, where damage to the portal vein or the pancreatic duct may occur when a tumor or other abnormality is being resected, dissected or removed.

Owner:CREO MEDICAL LTD

High-precision aluminum profile water cutting machine

InactiveCN106346082AReduce surface roughnessOptimize cutting processPulp and paper industryWater cut

The invention discloses a high-precision aluminum profile water cutting machine, which includes a steel frame tripod, a conveyor belt, a fixed bracket, a water cutting machine bracket, a baffle, a cutting length scale and a water cutting machine. Motor, a controller is installed on one side of the motor, a conveyor belt is installed on the top of the steel frame tripod, and the conveyor belt is connected to the motor through a synchronous belt, a fixed bracket is installed on one side of the steel frame tripod, and a water jet machine bracket is installed on the side of the fixed bracket , the top of the water cutting machine support is provided with a baffle, the water cutting machine support is provided with a cutting length scale, and the top of the water cutting machine support is provided with a water cutting machine. In the process of the user using the present invention, the cutting plane of the water cutting machine is smooth and free of burrs, and fixing plates are installed on both sides of the cutting aluminum profile, which can fix the aluminum profile very stably. The length scale can quickly identify the cutting length, and the whole design is reasonable and easy to use and the cutting effect is good.

Owner:大冶市万和铝业有限责任公司

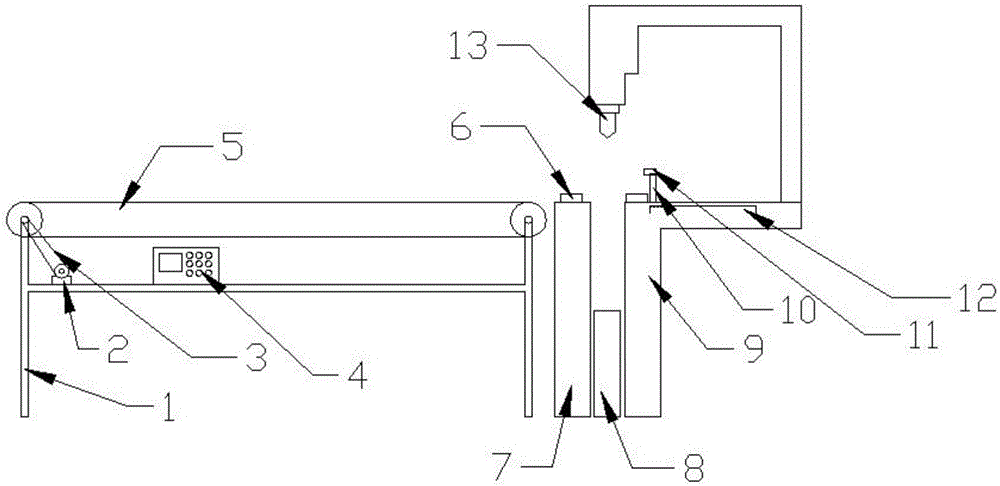

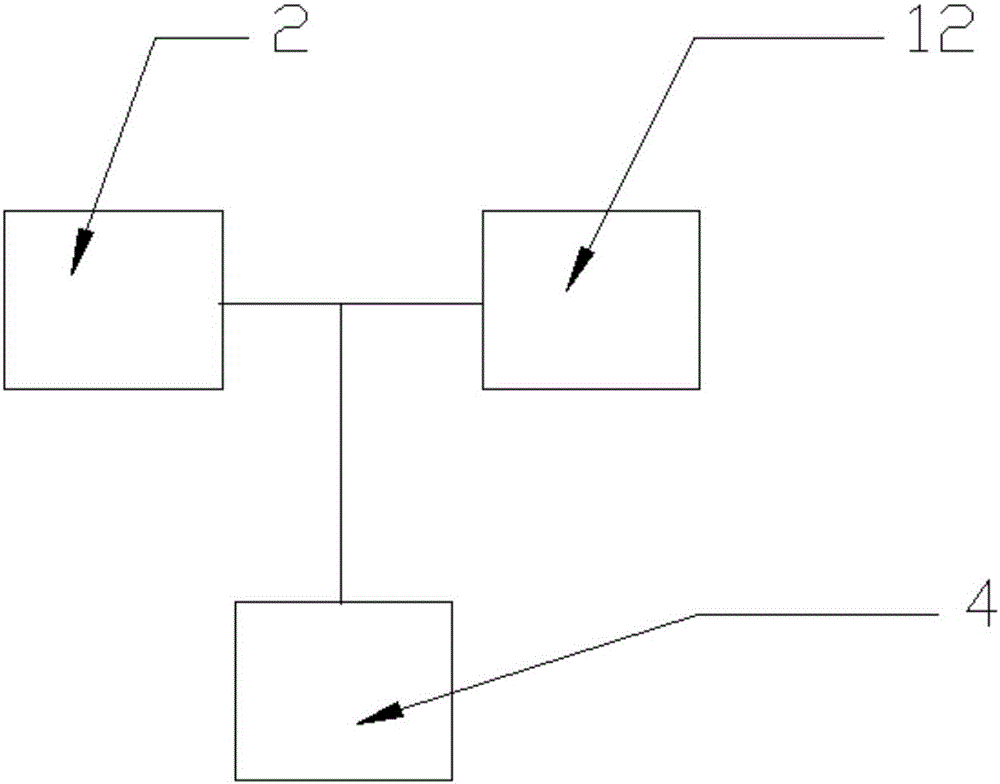

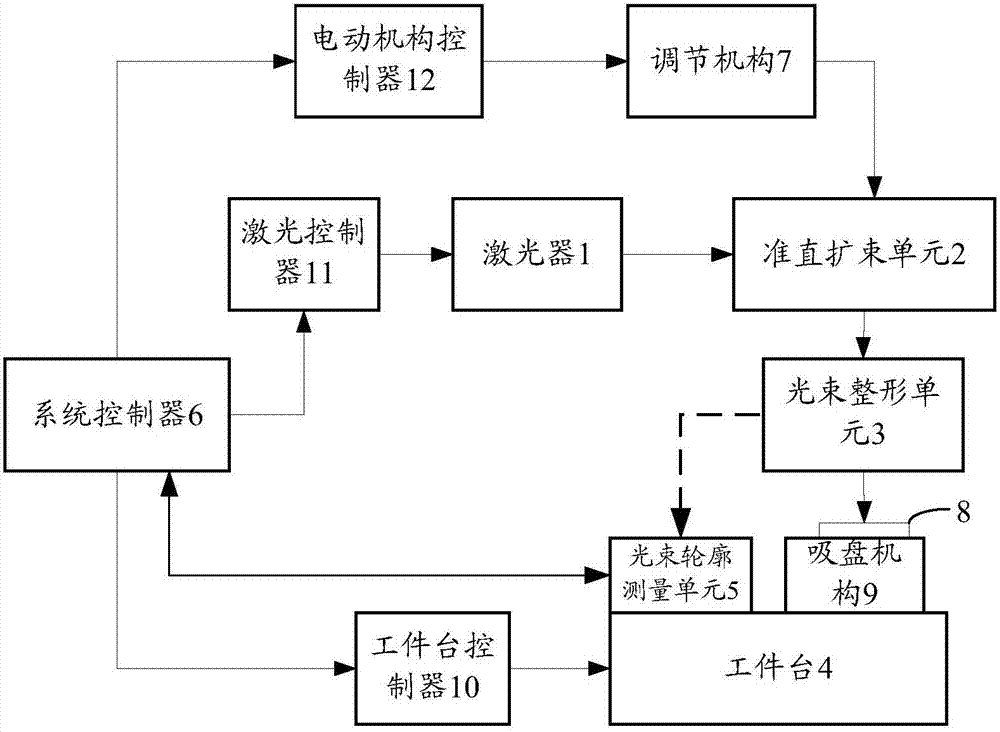

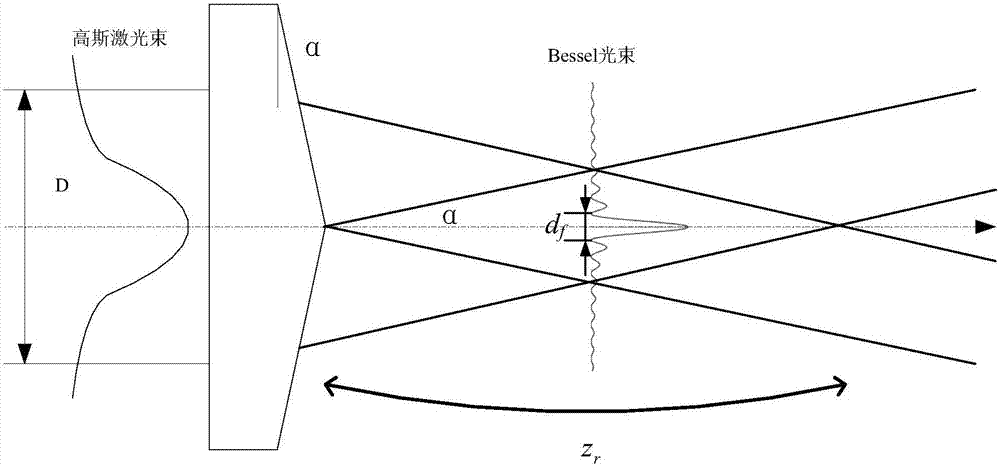

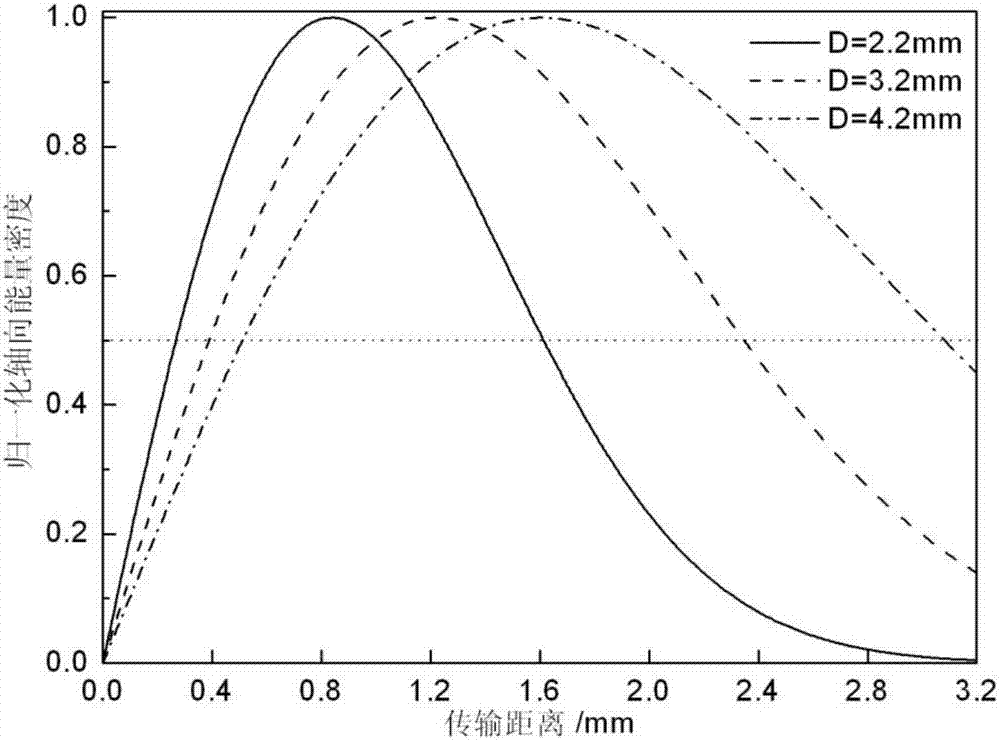

Laser cutting device and method

InactiveCN107876971AImprove processing efficiencyOptimize cutting processLaser beam welding apparatusLight beamMagnification

The invention discloses a laser cutting device and method. The device comprises a system controller and a laser device, a collimation and beam expanding unit, a laser beam shaping unit and a workbench. A suction cup mechanism and a laser beam outline measuring unit. The vertical height of the test surface of the laser beam outline measuring unit is equal to that of the surface of the suction cup mechanism. The collimation and beam expanding unit comprises a magnification continuous adjustable shotgroup. The system controller receives laser beam energy intensity fed back by the laser beam outline measuring unit and adjusts the magnification of the shotgroup according to the thickness of a to-be-cut object. Through the laser beam outline measuring unit, detection of vertical Bessel laser beam three-dimensional energy intensity is achieved, detected data are uploaded to the system controller, the system controller controls an adjusting mechanism to adjust the incident laser beam diameterof the laser beam shaping unit according to the detected data and the thickness of the to-be-cut object, length control over cutting acting laser beams is achieved, laser energy is fully utilized, andthe machining efficiency is improved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Indoor air conditioner and fin production method

PendingCN112283794ASolve the problem that the safety distance of pipe hole cutting cannot be metAddress process complexityLighting and heating apparatusAir conditioning systemsProcess engineeringIndoor air

The invention discloses an indoor air conditioner and a fin production method. The indoor air conditioner is internally provided with a heat exchanger, and the heat exchanger comprises a plurality ofheat exchange tubes and a heat dissipation device. The heat dissipation device comprises a plurality of parallel fins, in the fin production process, fin machining adopts a beveling machining method,and the beveling machining method comprises the two procedures of pre-punching and beveling. According to the indoor air conditioner and the fin production method, the fins are cut through one set ofcutters, the problem that an existing beveling process cannot meet the requirement for the pipe hole cutting safety distance is solved, and the problems that two sets of cutters are adopted for special-shaped cutting, the process is complex and the cost is high are also solved.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

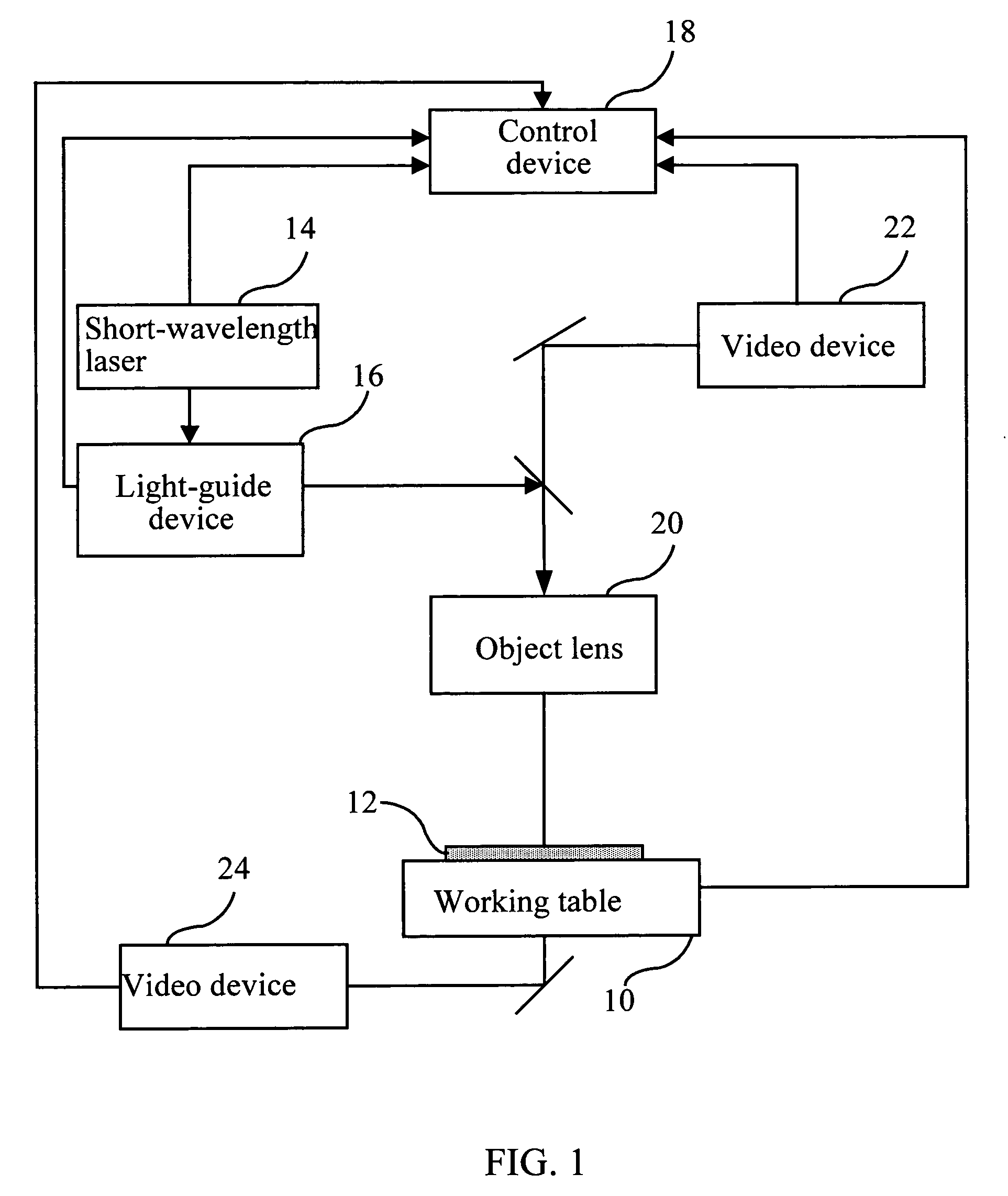

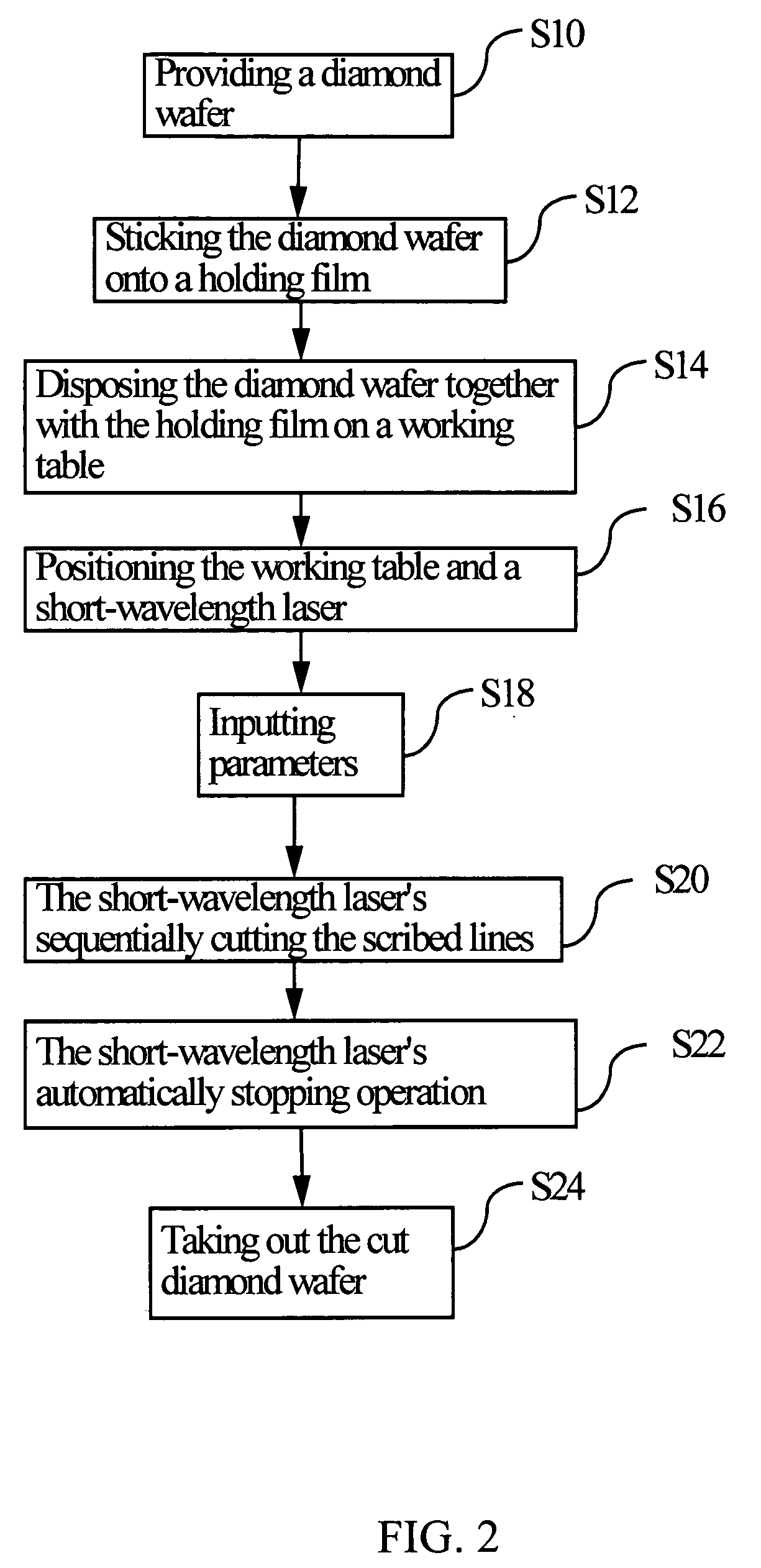

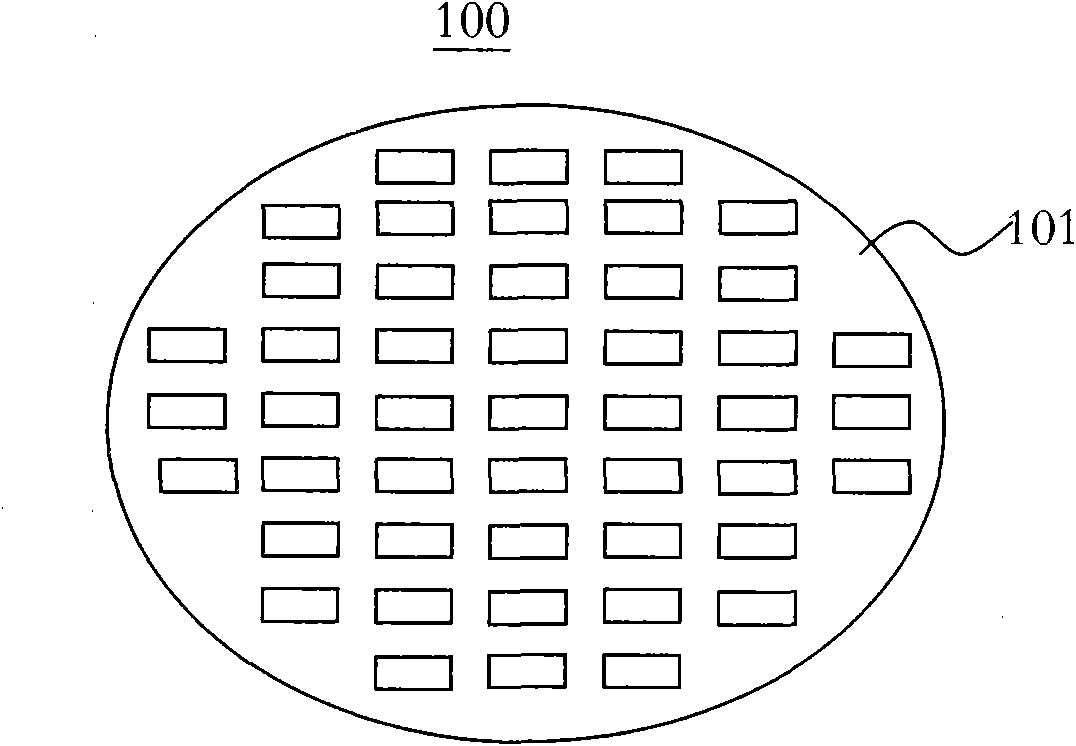

Short-wavelength laser dicing apparatus for a diamond wafer and dicing method thereof

InactiveUS20060128120A1Easily and rapidly cutOptimize cutting processSemiconductor/solid-state device manufacturingFine working devicesHigh energyHigh energy photon

The present invention discloses a short-wavelength laser dicing apparatus for a diamond wafer and a dicing method thereof, wherein a diamond wafer is disposed on a working table; the diamond wafer has multiple scribed lines; a control device is used to position the working table and a short-wavelength laser so that the short-wavelength laser can sequentially cut the scribed lines and the diamond wafer can be separated into multiple discrete chips or dice. The present invention utilizes the high-energy photons of a short-wavelength laser to enable a diamond wafer to be easily cut and can accelerate the cutting process.

Owner:CLEAVAGE ENTERPRISE

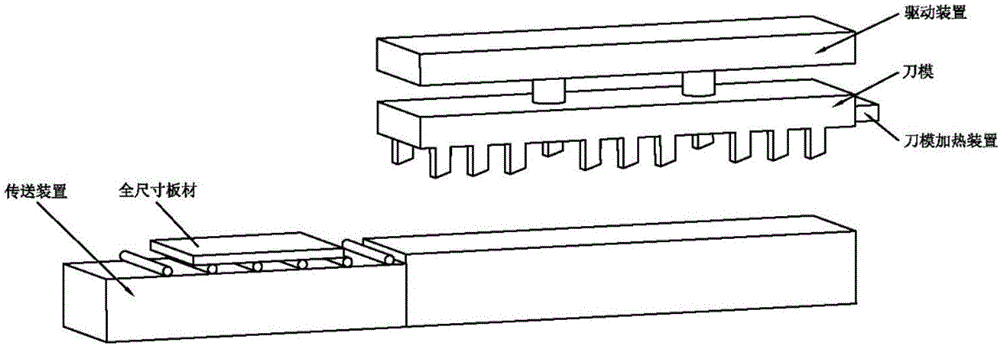

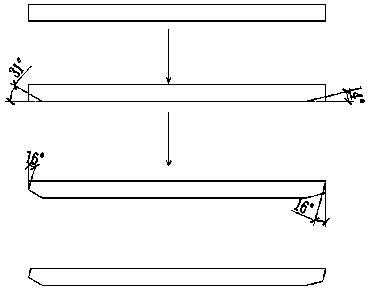

Diffusion plate cropping process

InactiveCN106239621AOptimize cutting processEliminate the polishing and molding process stepsMetal working apparatusMechanical engineeringEngineering

The invention discloses a diffusion plate cropping process. A cropping device is used for cropping a full-size diffusion plate, and mainly comprises a cutting die, a cutting die heating device and a driving mechanism, wherein the driving mechanism is used for driving the cropping and resetting of the cutting die. The cropping process mainly comprises a mounting step, a heating step, a conveying step, a cropping step, a taking-out step and a resetting step, wherein in the heating step, the cutting die heating device is utilized to heat the cutting die to 50 to 150 DEG C, heat preservation is performed, and the heated cutting die is utilized to crop the full-size diffusion plate. The diffusion plate cropping process has the beneficial effects that the cropping process is free from processing steps such as polishing and broken filament removal, and the defects that the diffusion plate cropping process is long in procedure and low in cleanness are overcome.

Owner:DONGGUAN XINJU OPTRONICS INC

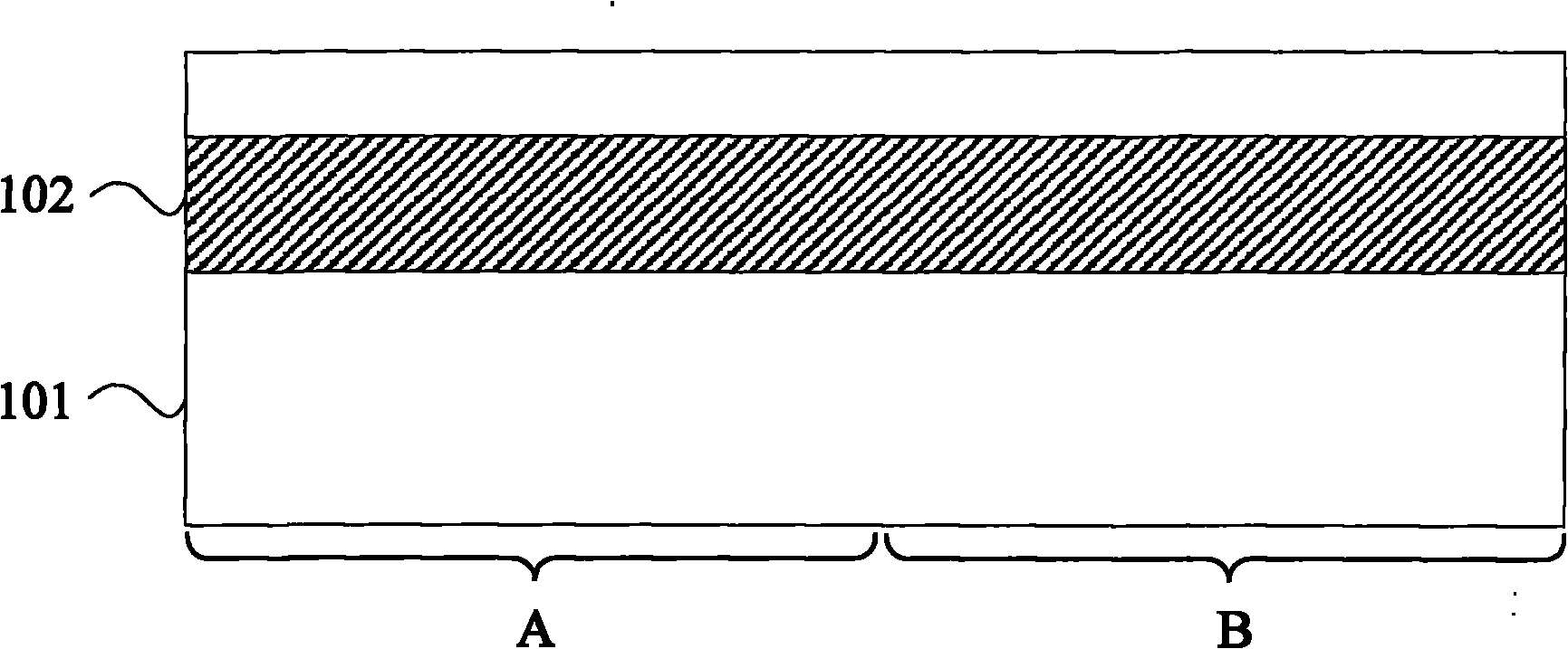

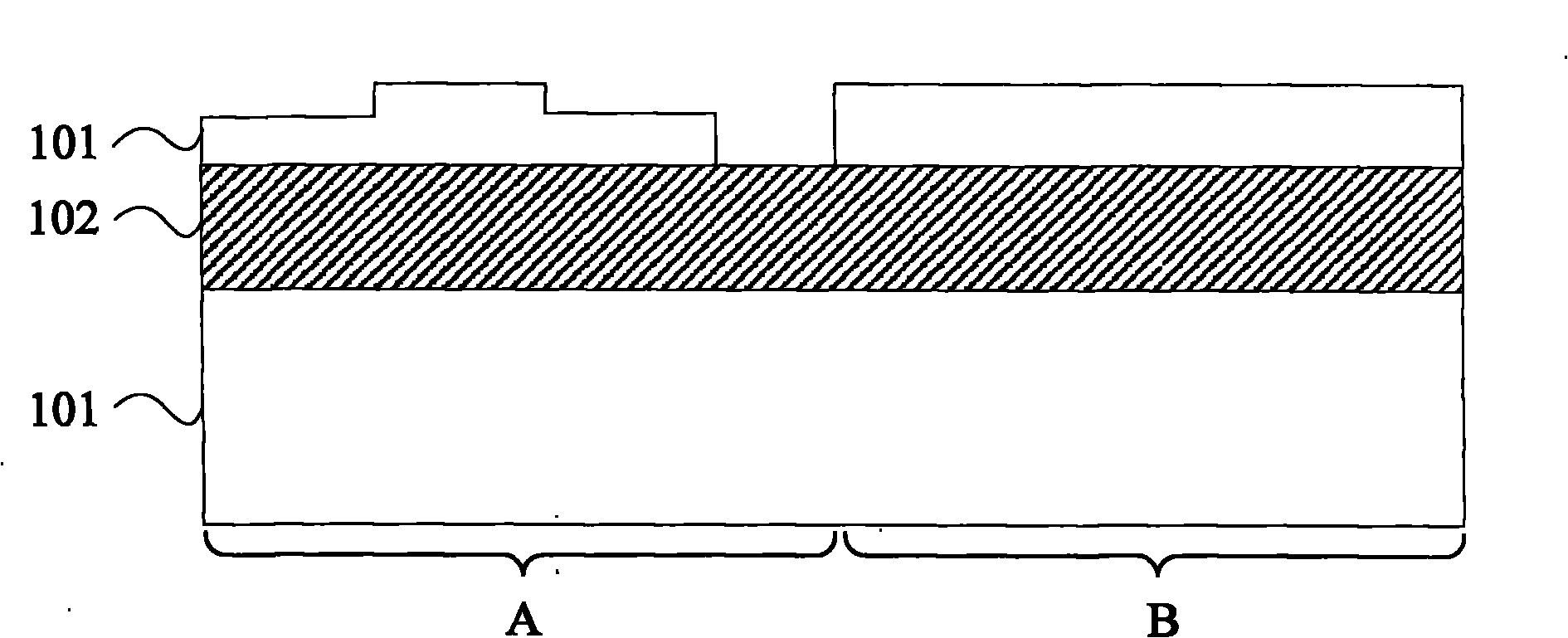

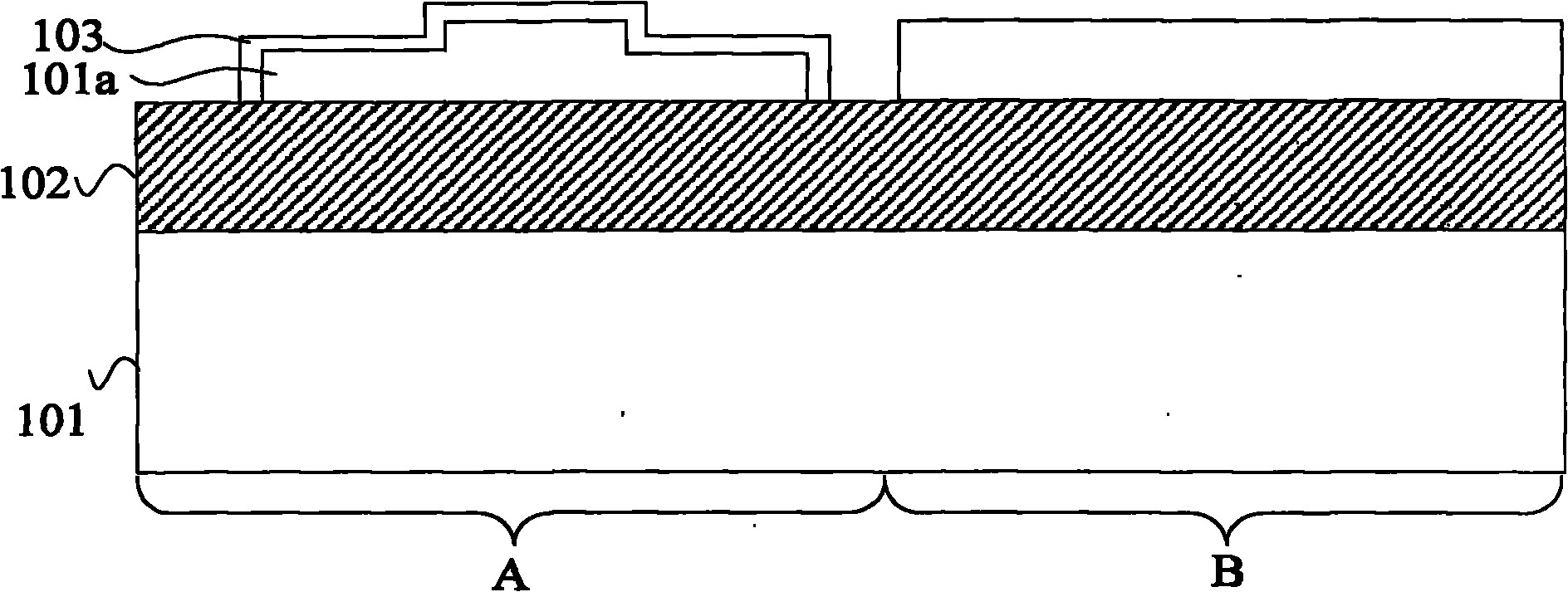

Semiconductor device and manufacturing method thereof

InactiveCN102097432ARealize integrationAvoid Undercut DefectsSolid-state devicesSemiconductor/solid-state device manufacturingEtchingOxide

The invention provides a semiconductor device, comprising a semiconductor substrate having an optical device area and an electrical device area, a light guide layer formed by etching the optical device area, a first oxide layer formed in the semiconductor substrate below the light guide layer, and a third oxide layer covering the surface of the light guide layer. The invention further provides a manufacturing method of the semiconductor device, which comprises the steps of: providing the semiconductor substrate, wherein the semiconductor substrate comprises the optical device area and the electrical device area; etching the optical device area to form the light guide layer; then forming a second oxide layer on the surface of the light guide layer and removing the second oxide layer by means of wet etching; forming the third oxide layer covering the surface of the light guide layer; and finally, injecting oxygen ions into the semiconductor substrate in order to form the first oxide layer in the semiconductor substrate below the light guide layer. According to the semiconductor device and the manufacturing method thereof, light leakage of the semiconductor device can be avoided, and more convenience can be brought to the integration of an optical device base plate and an electrical device base plate on the same semiconductor device.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

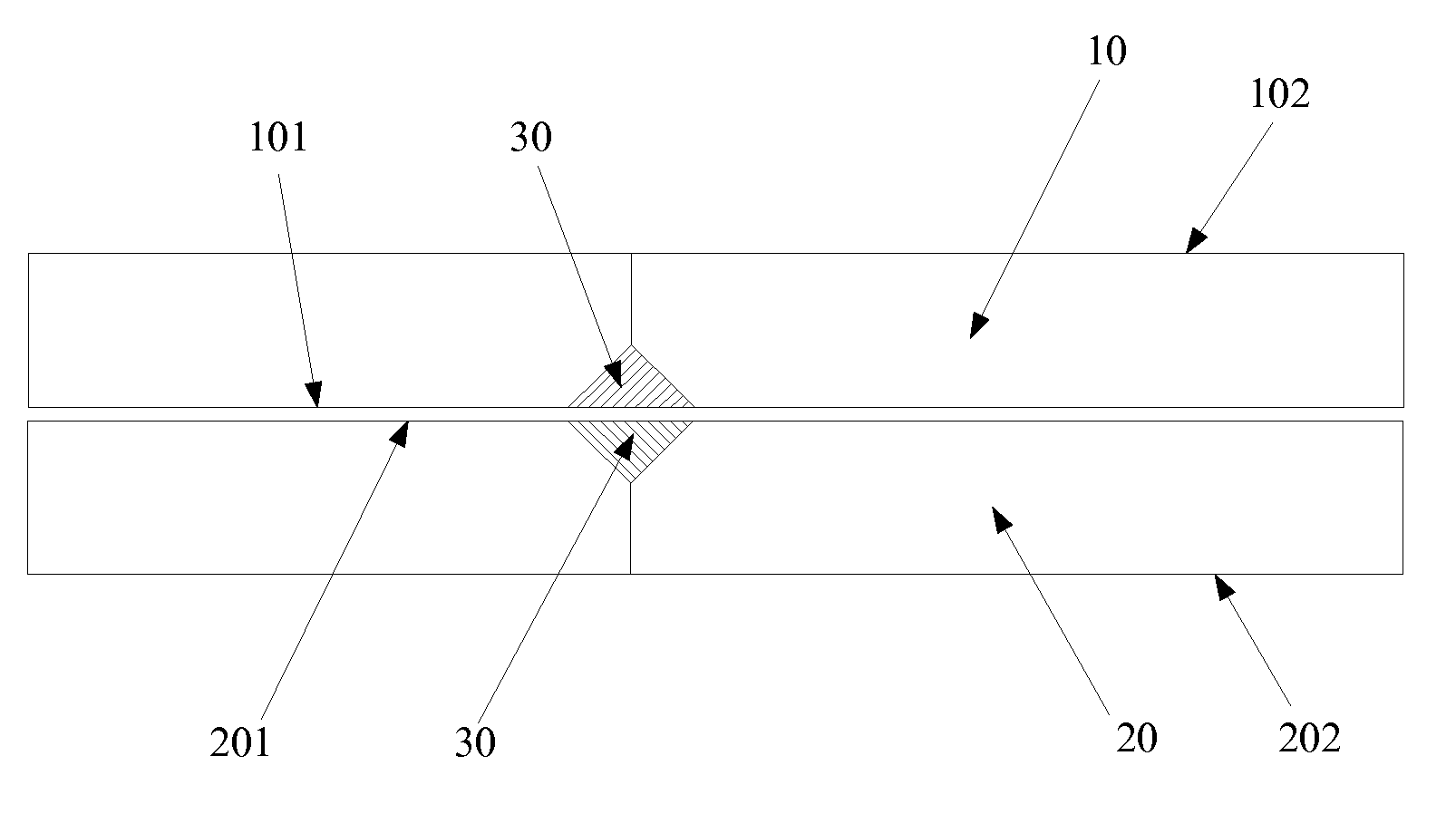

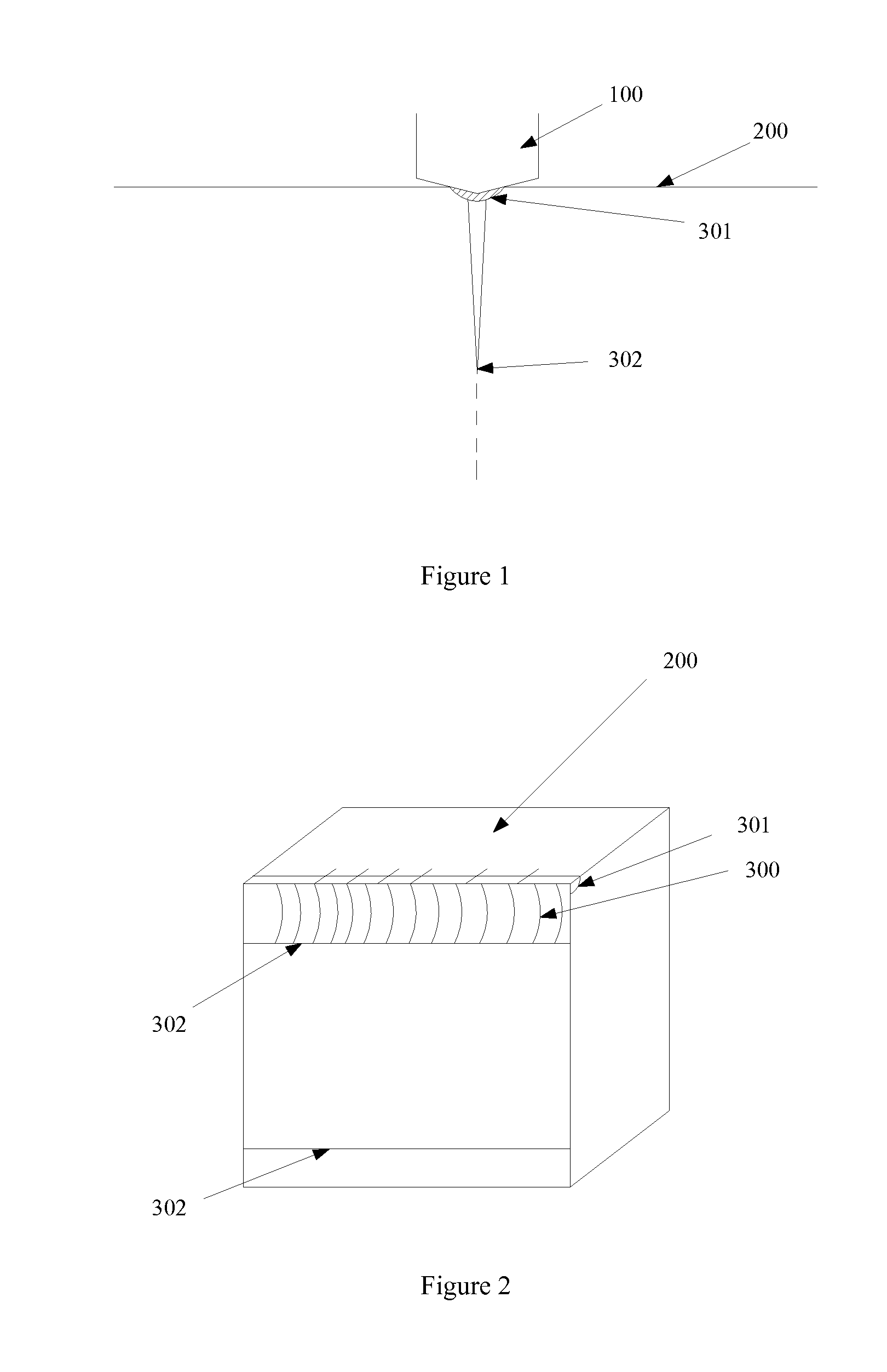

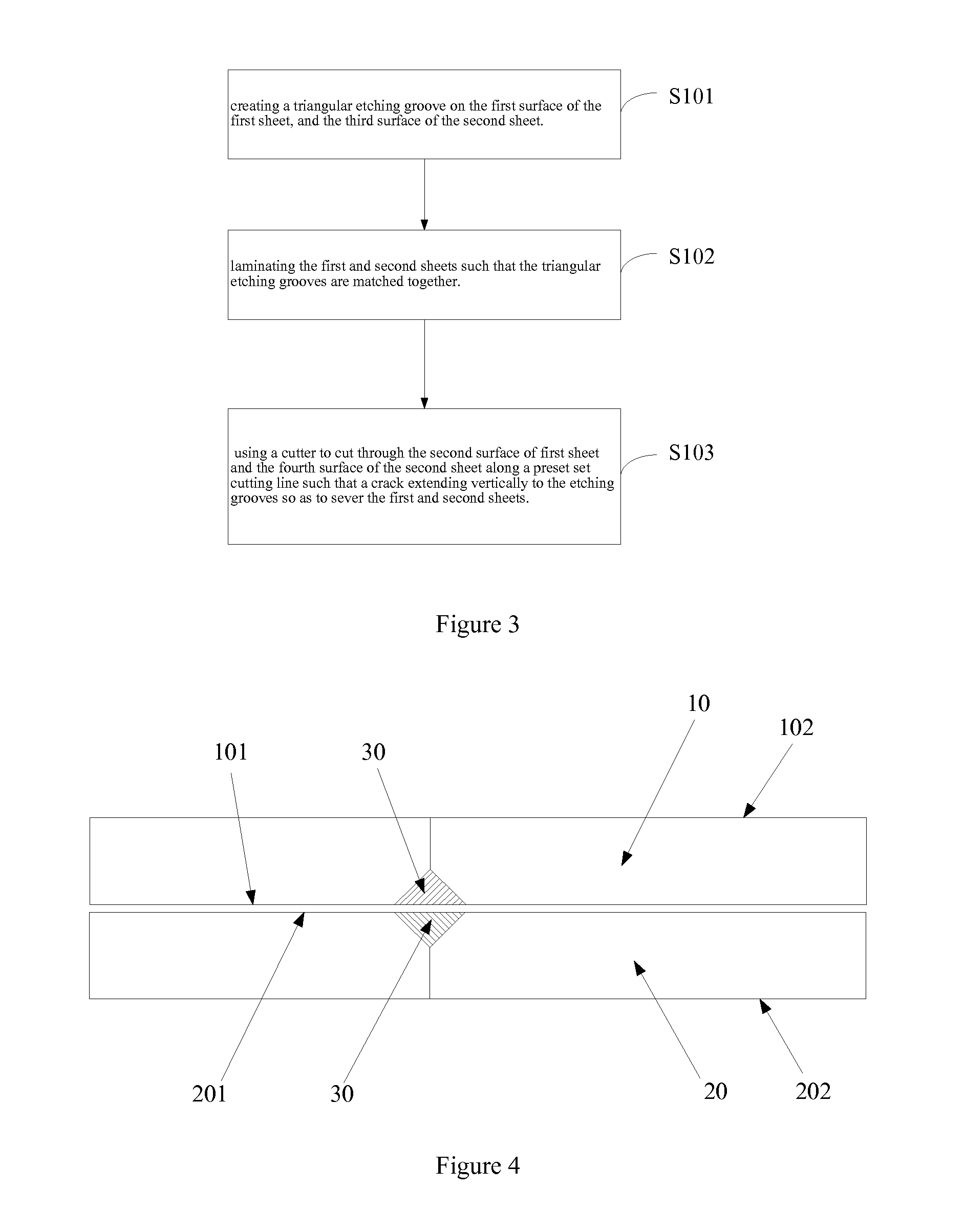

Substrate and Method for Cutting the Substrate

InactiveUS20140110867A1Cutting speed of substrateReduce gradientSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

The present invention discloses a method for cutting a substrate. The method includes the steps of 1) creating a etching groove in the first surface of the first sheet and the third surface of the second sheet; 2) laminating the first and second sheets with the etching grooves aligned with each other; and 3) using a cutter to cut through the second surface of first sheet and the fourth surface of the second sheet along a preset set cutting line such that a crack extending vertically to the etching grooves so as to sever the first and second sheets. The present invention further discloses a substrate. By way of the foregoing, the taper and gradient along the cutting edge can be reduced.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

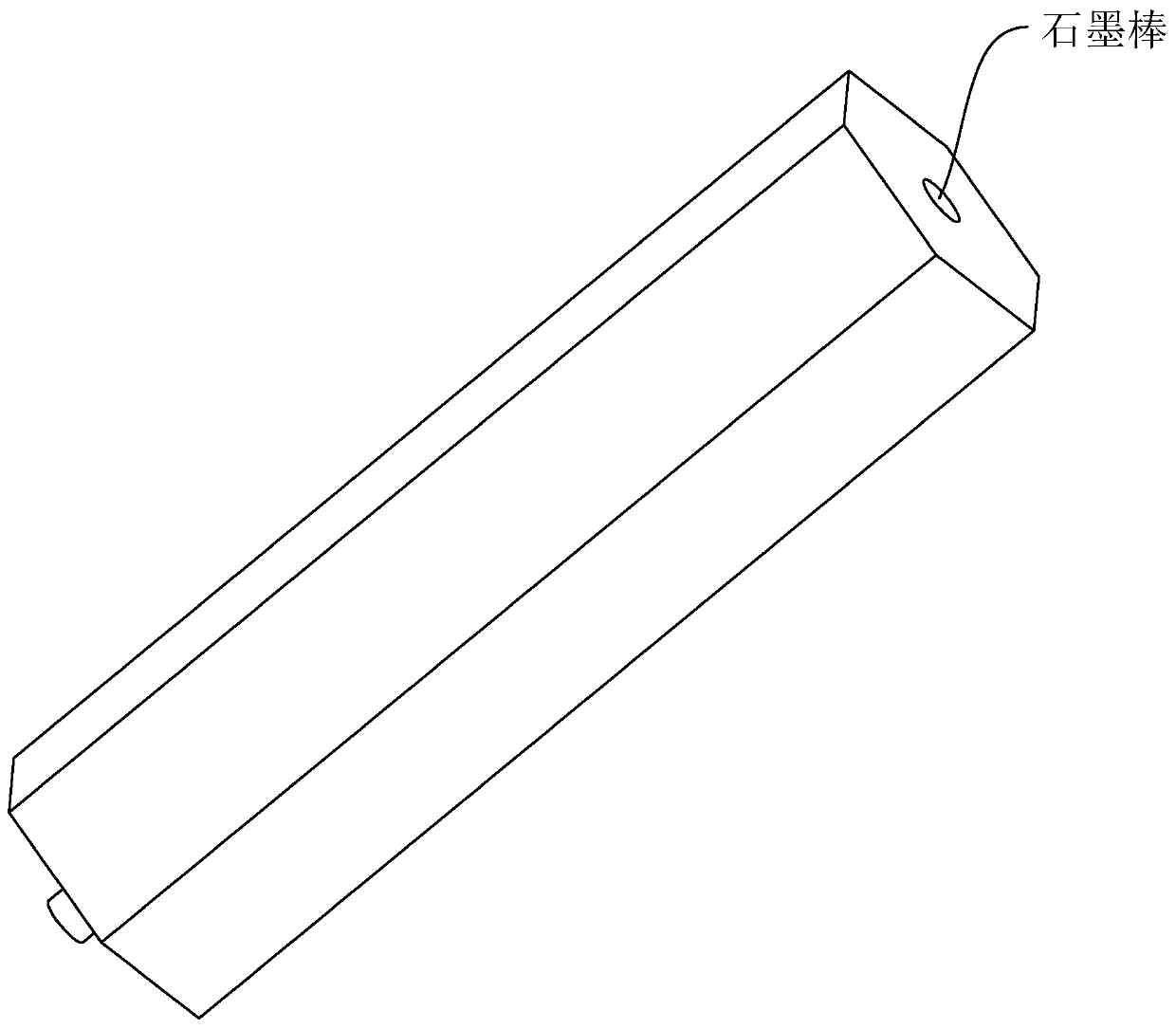

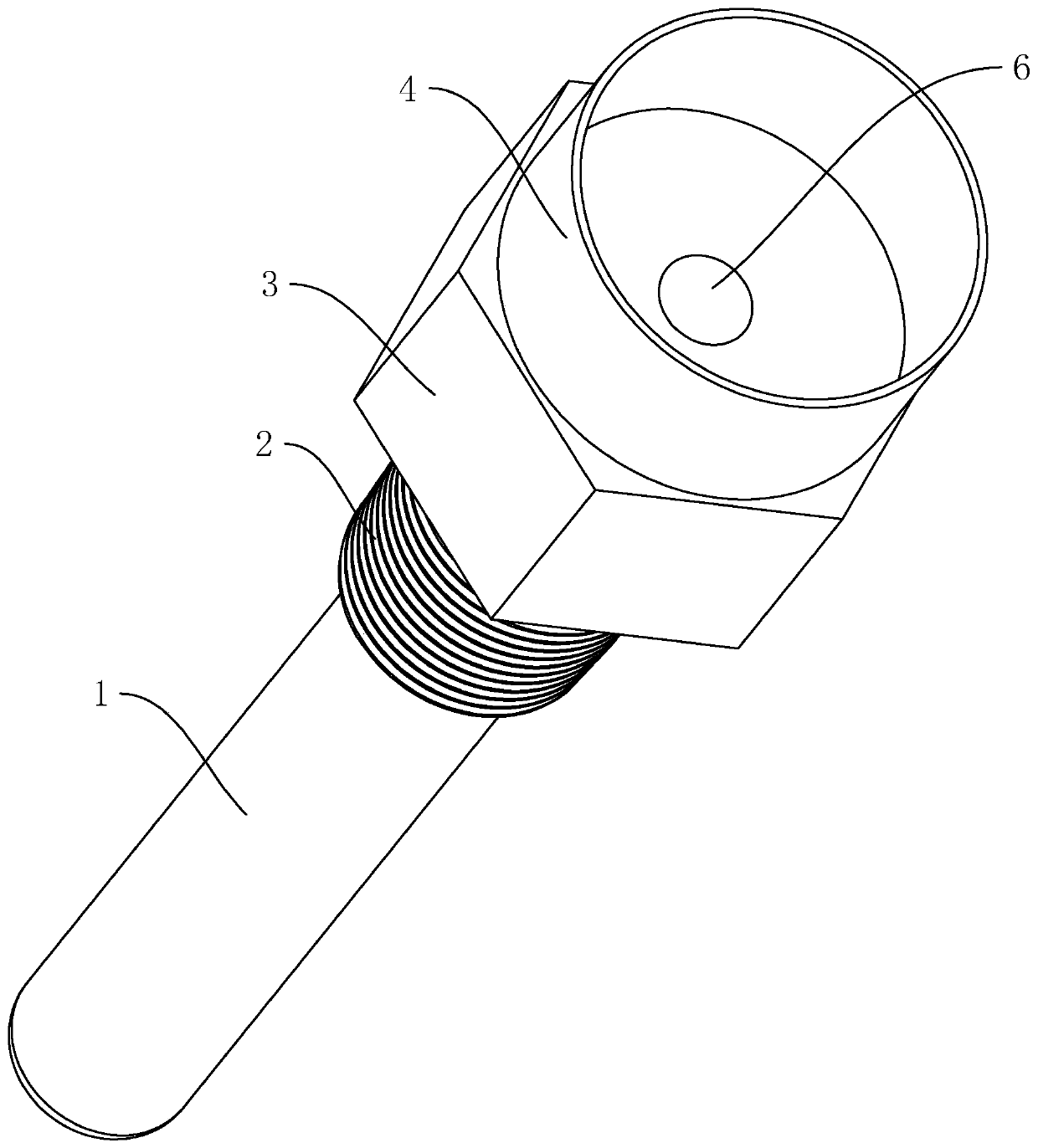

Method for producing conductive screw

The invention discloses a method for producing a conductive screw rod, and relates to the conductive screw rod with the purpose of solving the great hidden danger of cutter breakage during deep hole machining. According to the technical scheme, the method for producing the conductive screw rod is characterized by comprising the following specific steps of A, casting, B, rough machining, C, drilling and D, assembly, wherein in the step A, 1, raw materials, namely, molten metal and a graphite rod are provided, 2, equipment, namely a casting press and a mould are provided, and 3, a working flow is as follows: after the graphite rod is vertically fixed in the mould, molten metal is injected into the mould, and the mould is pressurized by the press, so that a blank is formed under pressure; and in the step C, 1, equipment, namely, a drilling machine is provided, and 2, a working flow is as follows: a drill bit of the drilling machine is aligned with the graphite rod, and the graphite rod is pulverized and drilled away from a roughing material so that the roughing material with a deep hole is formed. According to the method for producing the conductive screw, the deep hole is formed by drilling the graphite rod with the drilling machine, and since the hardness of the graphite rod is far lower than that of a casting piece, the problem of the cutter breakage is effectively prevented.

Owner:嘉兴柯宇机械有限公司

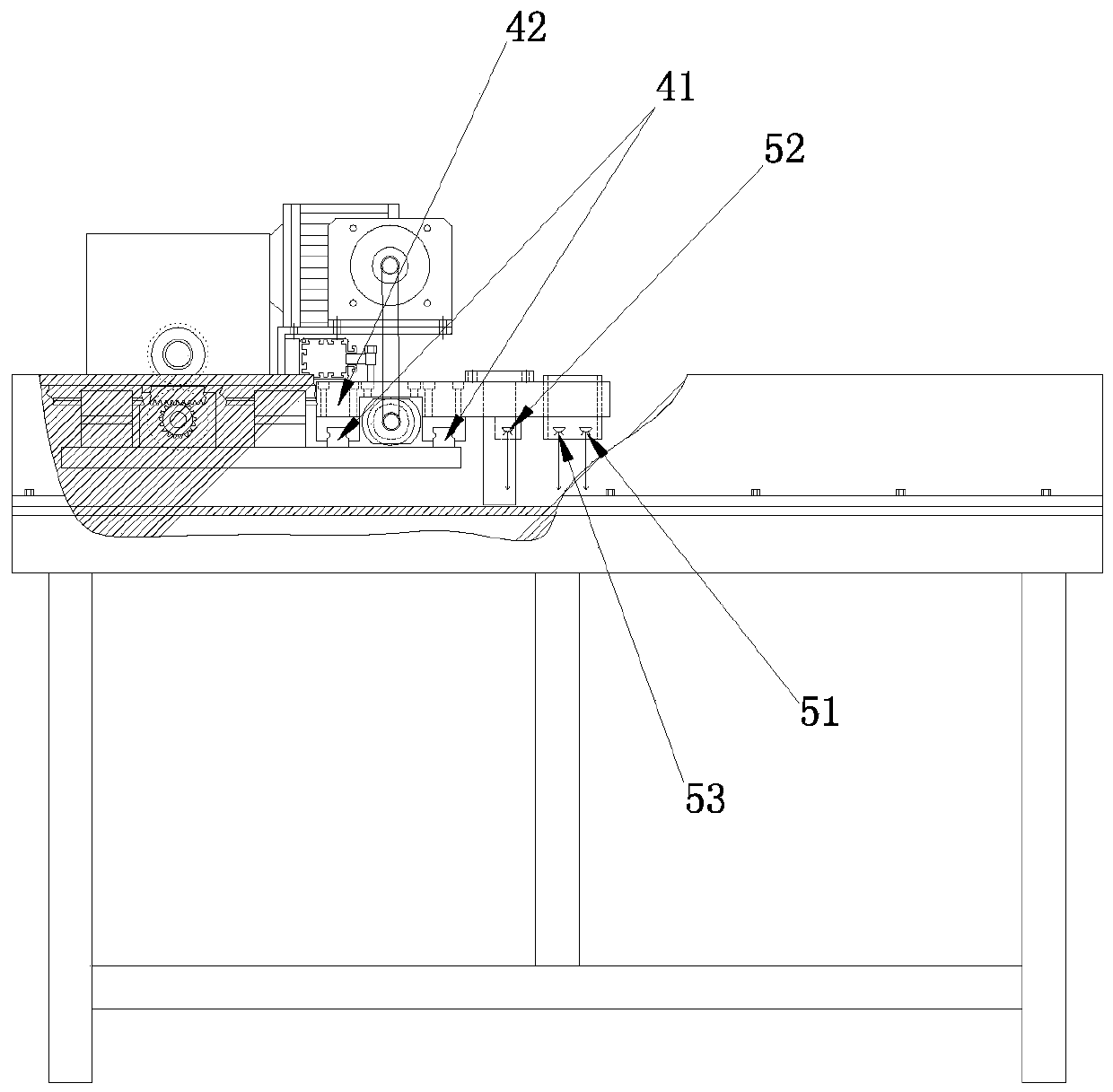

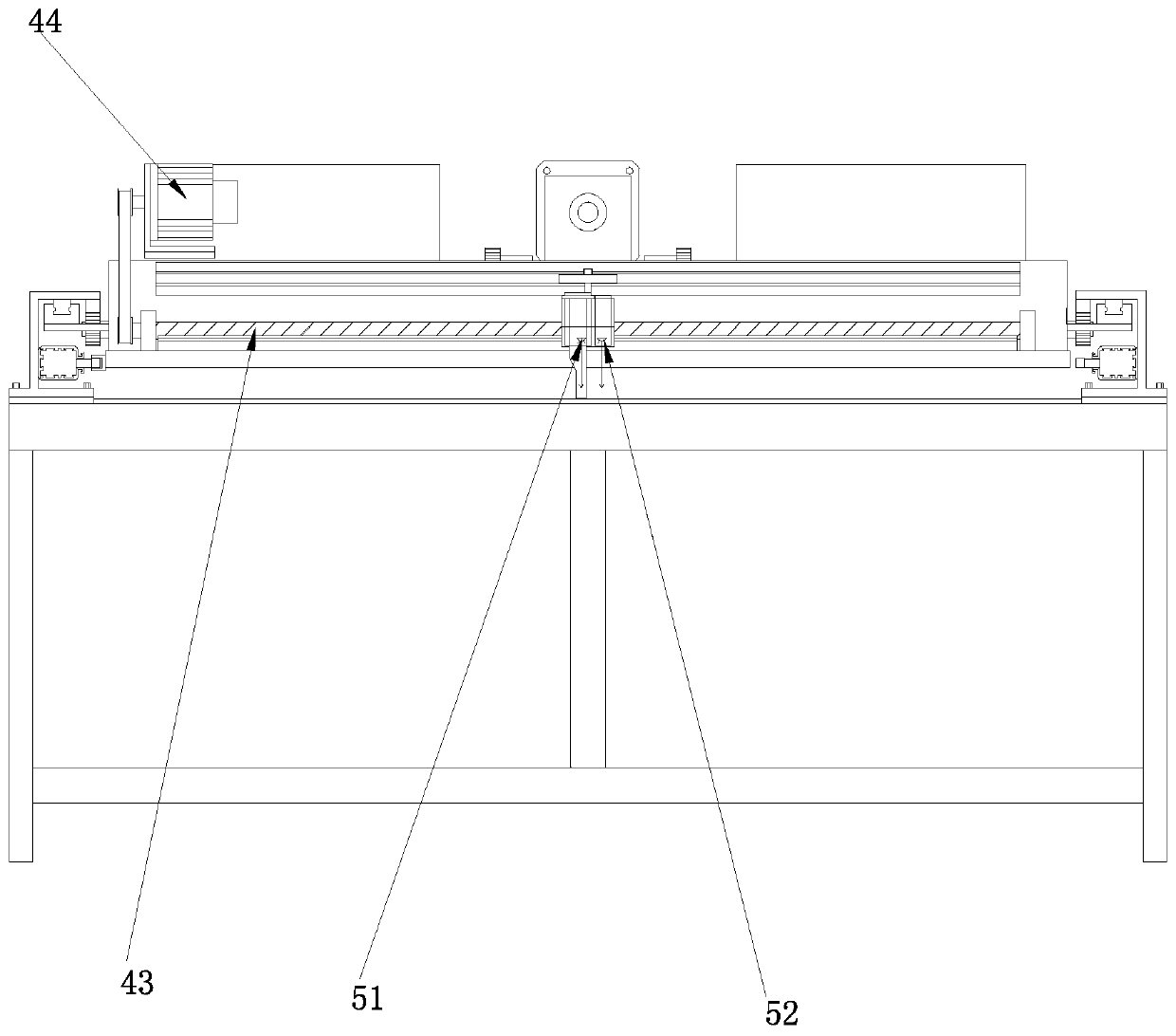

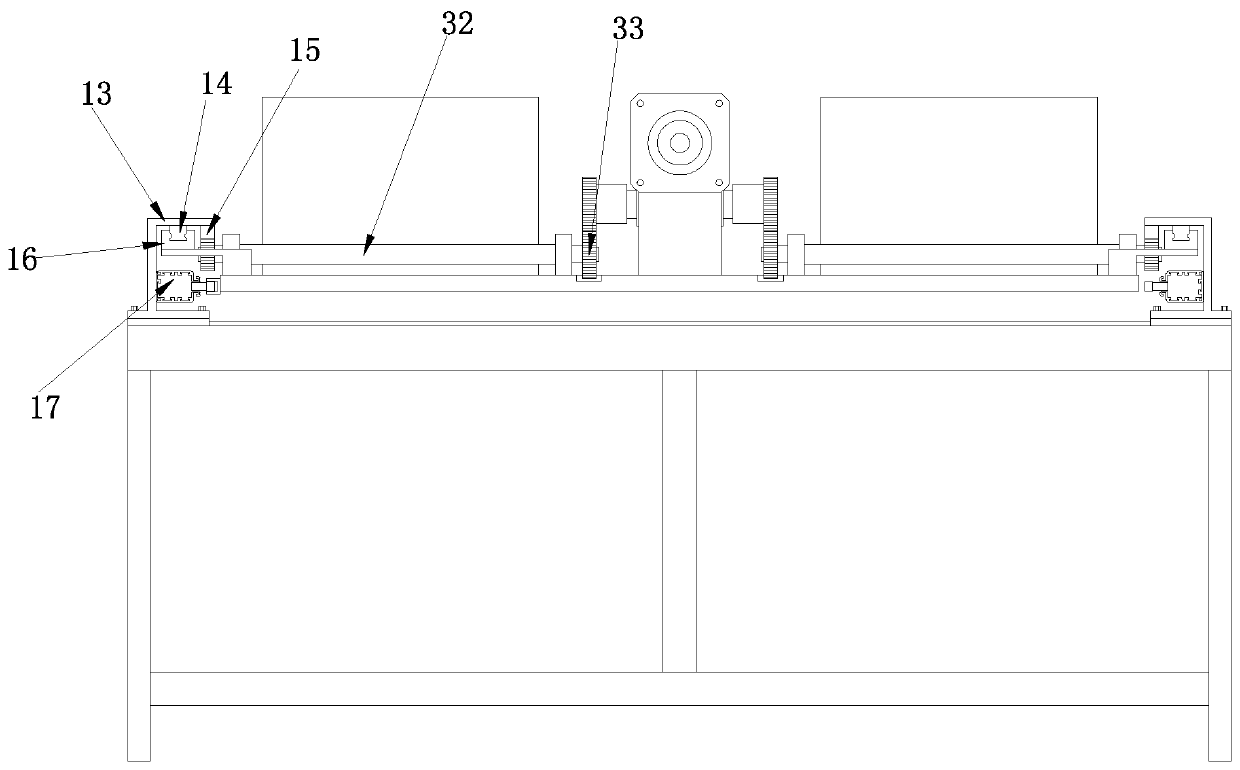

Continuous production line of finger joint boards

PendingCN110293611AEasy to operateAvoid deviationWood veneer joiningAdhesive application devicesAgricultural engineeringContinuous production

The invention discloses a continuous production line of finger joint boards, and belongs to the technical field of finger joint board production. The production line comprises a swing platform, wherein a pressing device is arranged on the swing platform; the swing platform is in butt joint with a feeding end of a high-frequency press; a cutting device is in butt joint with a discharging end of thehigh-frequency press; the pressing device comprises a longitudinal moving device, a transverse moving device, an ejector rod, a first sensing device, a second sensing device and a third sensing device; the longitudinal moving device, the transverse moving device, the ejector rod, the first sensing device, the second sensing device and the third sensing device are arranged on the swing platform; the two sides of the swing platform are each provided with a side pressing plate correspondingly; at least one side pressing plate is in transmission connection with a first telescopic driving part; acutting device comprises a first frame, a cutting saw mechanism, a second frame, a finger joint board transmission mechanism and a slicing saw mechanism; a discharge end of the finger joint board transmission mechanism is provided with a fourth sensing device; a feeding end of the finger joint board transmission mechanism is in butt joint with the discharging end of the high-frequency press; and the feeding end of the finger joint board transmission mechanism is provided with a fifth sensing device. The production line is simple in operation and applicable to mass production of the finger joint boards; and both time and efforts are saved when the finger joint boards are cut, and the cutting precision is high.

Owner:陈彦

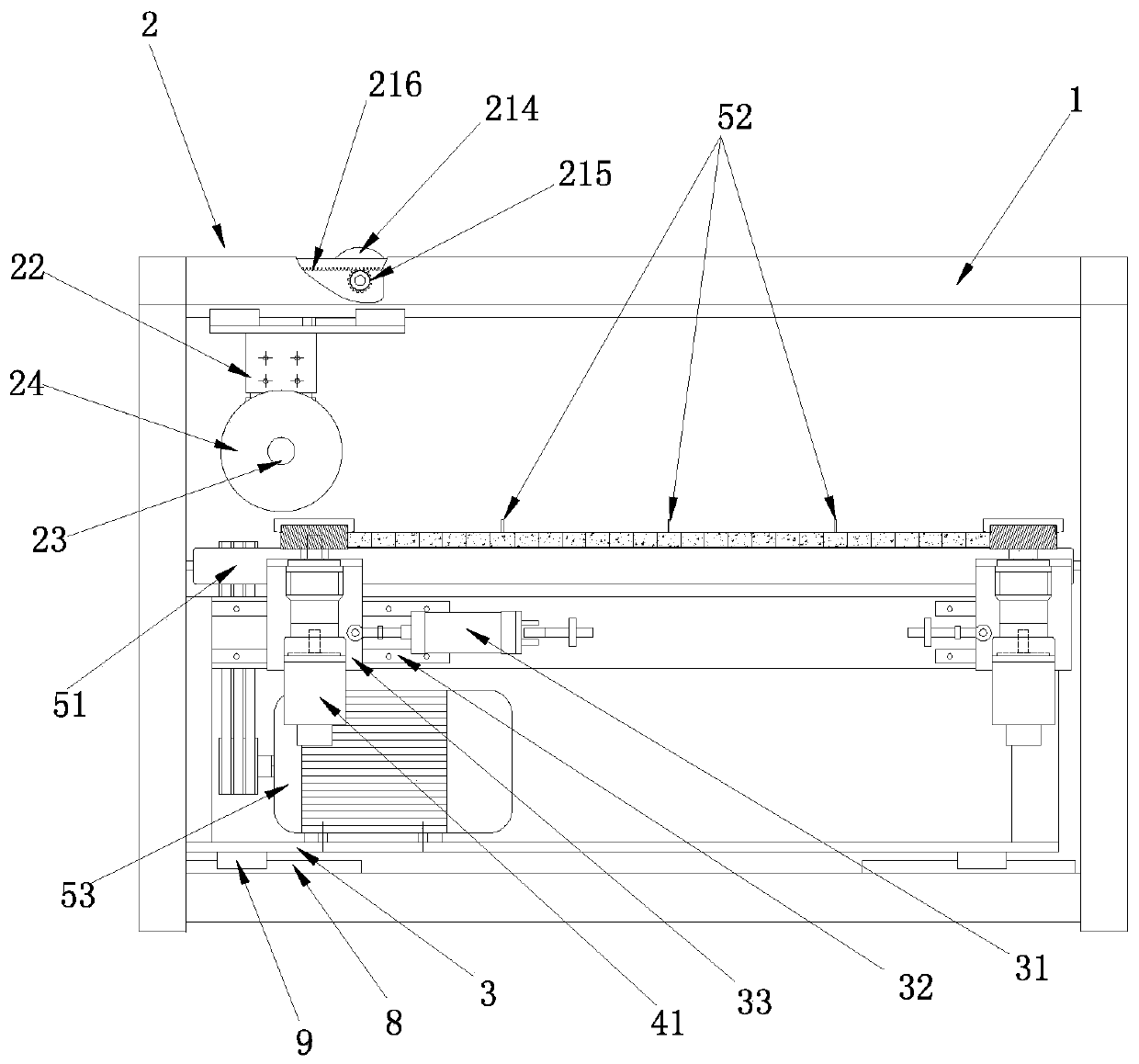

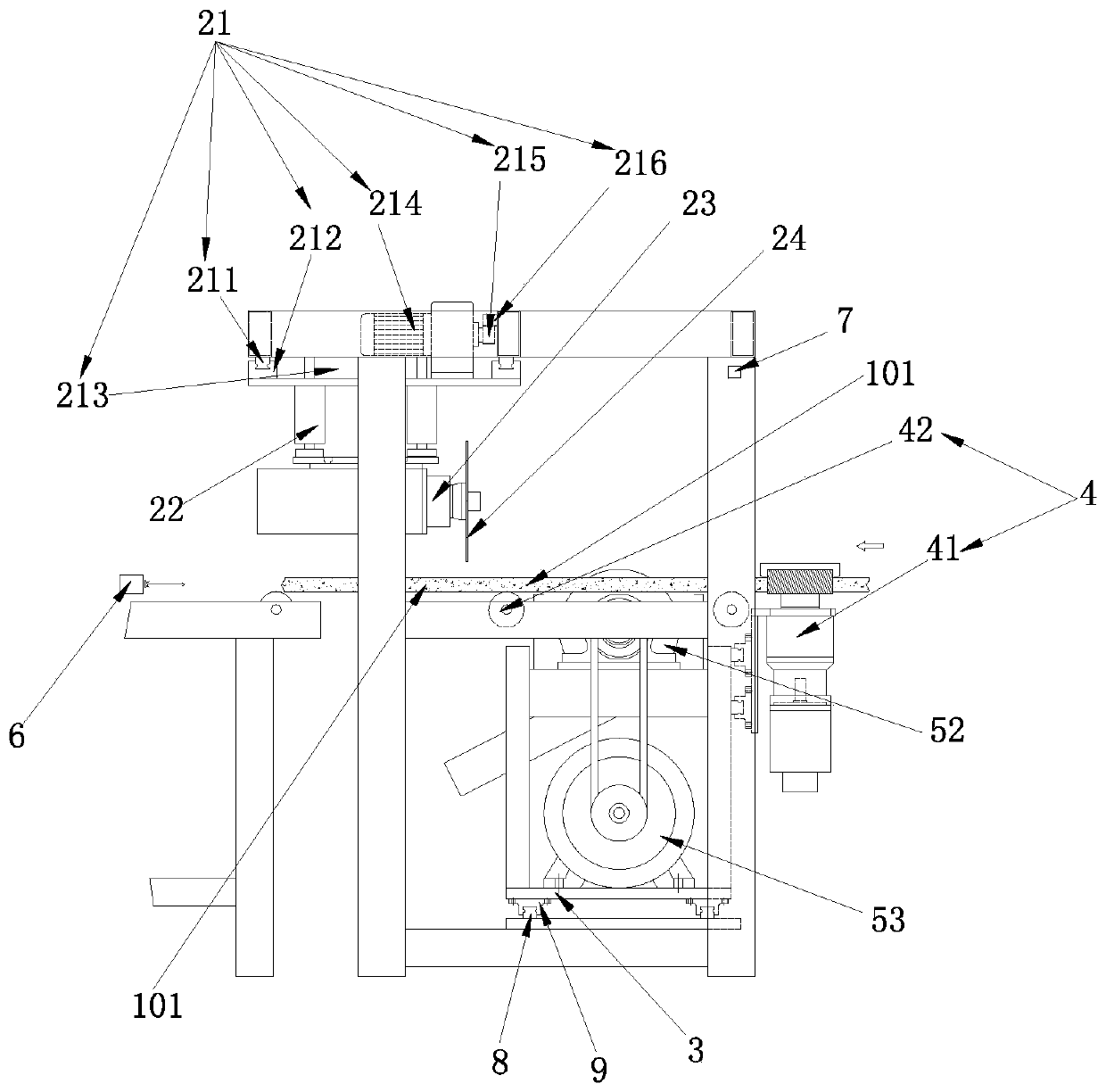

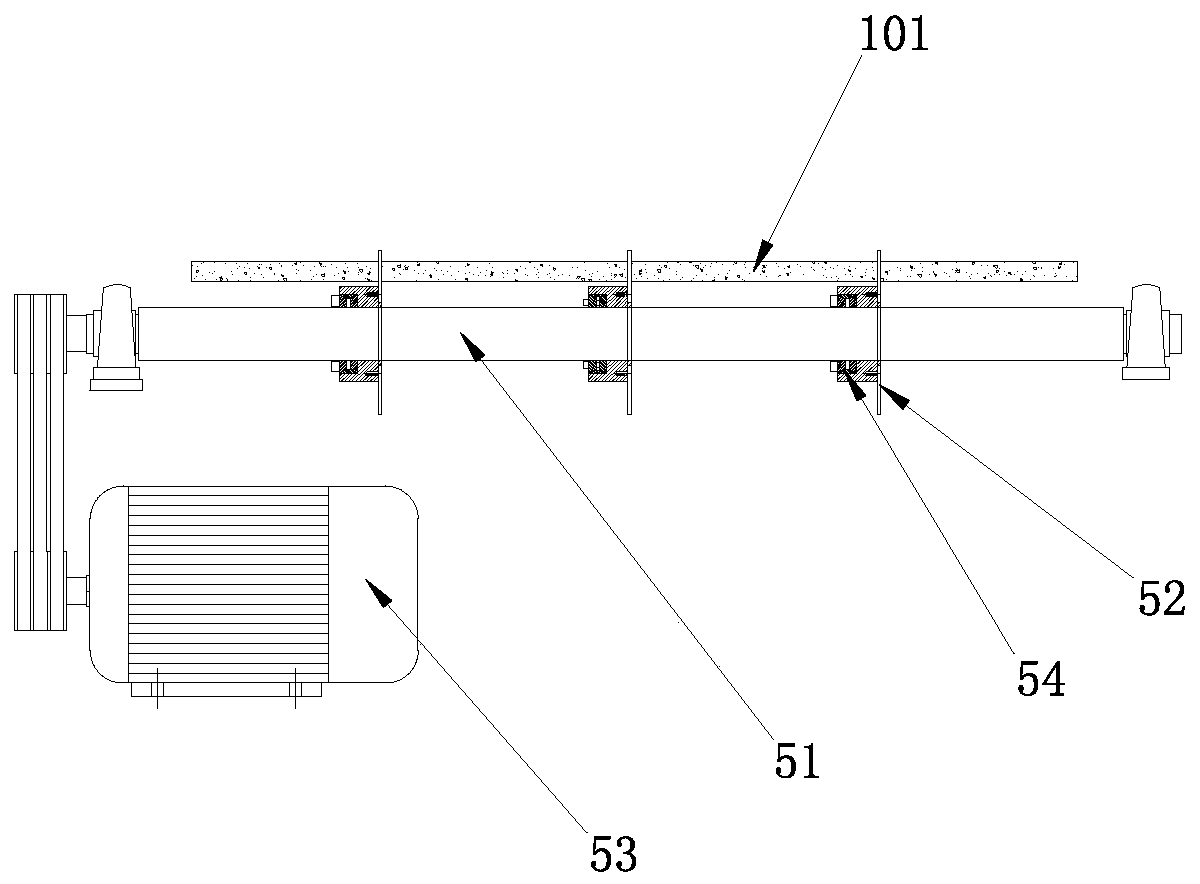

Wedge joint board cutting device

PendingCN110293604APrevent deviationHigh precisionFeeding devicesCircular sawsControl systemEngineering

The invention discloses a wedge joint board cutting device comprising a first machine frame. The first machine frame is provided with a cut-off saw mechanism. A second machine frame is arranged belowthe cut-off saw mechanism in a sliding manner. The second machine frame is provided with a wedge joint board conveying mechanism and a slicing saw mechanism. The sliding direction of the second machine frame is perpendicular to the conveying direction of the wedge joint board. The discharging end of the wedge joint board conveying mechanism is provided with a first sensing device. The feeding endof the wedge joint board conveying mechanism is provided with a second sensing device. The cut-off saw mechanism, the wedge joint board conveying mechanism, the slicing saw mechanism, the first sensing device and the second sensing device are electrically connected with the control system. When a wedge joint board is cut, time and effort are saved, and the cutting precision is high. The wedge joint board cutting device is applied to the technical field of wedge joint board production.

Owner:陈彦

Wafer structure and manufacturing method thereof

InactiveCN101958317ASimple manufacturing processOptimize cutting processSolid-state devicesSemiconductor/solid-state device manufacturingOxygen ionsEngineering

The invention provides a wafer structure comprising a semiconductor substrate embedded with a plurality of buried oxide layers, wherein the buried oxide layers are breadthwise generated in the semiconductor substrate at intervals. The invention also provides a manufacturing method of the wafer structure, comprising: injecting oxygen ions in the surface of a wafer; generating the buried oxide layers in a semiconductor substrate required to be oxidized; forming the base plate of an electrical appliance by the semiconductor substrate which is not embedded into the buried oxide layers; and forming the base plate of an optical device by the semiconductor substrate which is positioned above the buried oxide layers. The wafer is provided with the base plate capable of manufacturing the electrical appliances, and is integrated with the base plate for manufacturing the optical device so as to realize the integration of integrated optoelectronic elements.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

A high-gloss surface milling cutter disc and a high-gloss surface milling tool

ActiveCN105772820BImprove the knife patternGood highlight effectMilling cuttersTool bitMilling cutter

The invention discloses a high-gloss face milling cutter disc, which comprises a face milling cutter disc body, two rotating discs, two milling cutters and a cover plate; two circular grooves are symmetrically distributed on the end surface of the face milling cutter disc body ; each rotating disk is installed in a circular groove; each rotating disk is provided with a milling cutter installation groove; both milling cutters include a milling cutter handle and a milling cutter head arranged at one end of the milling cutter handle; The milling cutter handles of the milling cutters are respectively fixedly installed in a milling cutter installation groove, and the milling cutter heads of each milling cutter pass through the corresponding second gap and the first gap to protrude outwards; the cover plate and the face milling The end face of the cutter head body is fixedly connected. The invention also discloses a high-gloss face milling tool. The invention can improve the high-gloss effect of the product, achieve the mirror surface effect Ra≤25nm, and eliminate the knife lines; and can process the upper and lower chamfered surfaces at the same time, improve the processing efficiency, and can effectively ensure the overall balance of the cutter head, reducing the follow-up The difficulty of balancing.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

Cutting station for pin tape

ActiveCN105598524BFully automatedIncrease productivityShearing machinesShearing machine accessoriesPins needlesEngineering

The invention provides a cropping working station for a PIN material strap. The cropping working station comprises a cropping mechanism cropping the PIN material strap into separated PINs, a feeding mechanism feeding the PIN material strap to the cropping mechanism, and a PIN distributing mechanism. The PIN distributing mechanism is used for clamping a set number of PINs from the cropping mechanism and distributing the clamped PINs so as to enable the PINs to be distributed according to preset intervals. According to the cropping working station for the PIN material strap, the PIN material strap can be cropped into the separated PINs, the set number of PINs can be distributed so that the PINs can be distributed according to the preset intervals, full automation of the PIN cropping and distributing technology can be achieved, production efficiency is high, the interval accuracy of the PINs is high, and manpower cost is reduced.

Owner:CWB AUTOMOTIVE ELECTRONICS

A Nesting Path Optimization Method Applied to Co-edge Cutting of Pipe Parts

ActiveCN108465944BReduce cutting costsHigh practical valueForecastingNumerical controlMachine partsErbium lasers

The invention provides a material sleeve path optimization method applied to common edge cutting of pipe parts. On the premise that machine tool equipment, the pipe raw material and machined parts arenot changed, the cutting path is optimized, so that the purpose that the raw material of the pipe is saved, the energy consumption of the laser is reduced, the gas consumption is assisted, and the total movement path of the machine tool is reduced is achieved, and meanwhile, the method has positive significance for improving the cross section quality of part products and prolonging the service life of equipment.

Owner:FOSHAN HONGSHI LASER TECH CO LTD

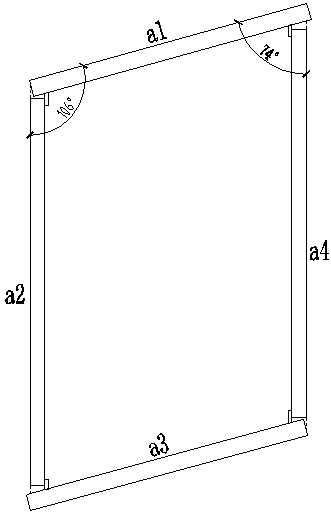

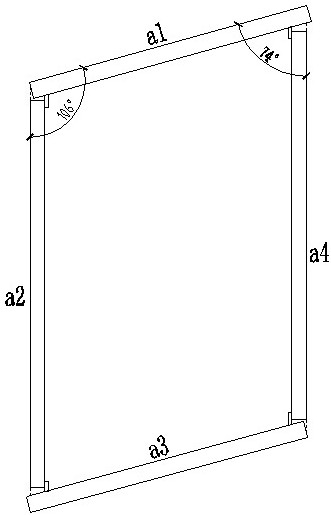

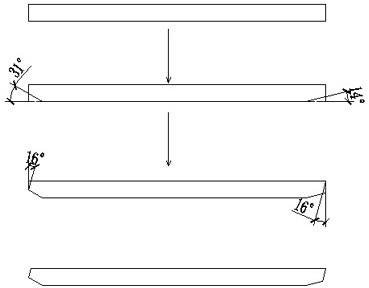

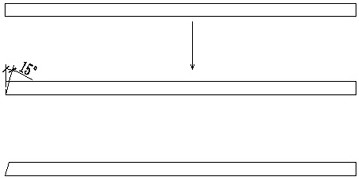

Special-shaped box type steel component groove fabrication method

ActiveCN111571057AEasy to manufactureOptimize cutting processWelding apparatusStructural engineeringMechanical engineering

The invention provides a special-shaped box type steel component groove fabrication method. The special-shaped box type steel component groove fabrication method is realized through the following steps that step1, lofting is performed according to a special-shaped box type section size graph; step2, an angle in the special-shaped box section is taken as the reference point to select and confirm cover plates and ventral plates; step3, under the premise that blunt edges are larger than or equal to 5 mm, the cover plates are cut separately, and the sum of groove angles of cut plate blocks being spliced together is guaranteed to be 30 degrees; step4, one-time natural bevel cutting is performed on the other ends of the cover plates, included angles among the plate blocks are compensated by cutting the ventral plates, and the sum of groove angles of the cut plate blocks being spliced together is guaranteed to be 30 degrees; step5, all the angles are judged according to the step2, the step3 and the step4, and the groove cutting angle, size and direction are measured and labelled on the plate blocks; and step6, groove cutting is performed through a semi-automatic cutting machine. By meansof adoption of the special-shaped box type steel component groove fabrication method, the cutting times of the cover plates are reduced, a cutting process is simplified, and resource waste is reduced.

Owner:CHINA 22MCC GROUP CORP

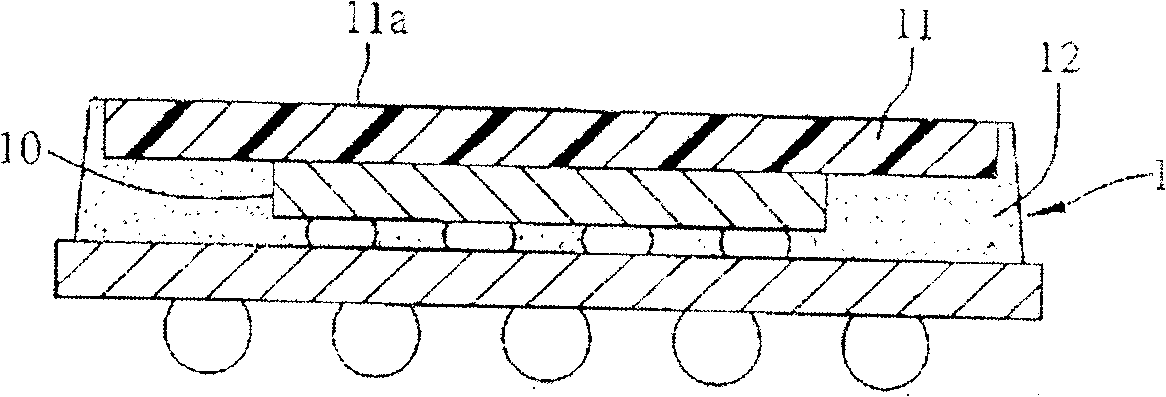

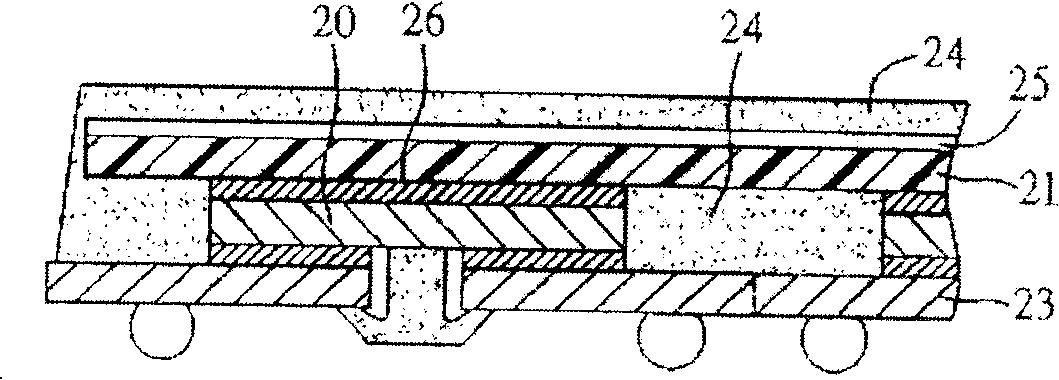

Heat radiation type packaging structure and its making method

InactiveCN100446200CNot easy to produce burrsReduce wear and tearSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureThin layer

A heat-dissipating package structure and its manufacturing method. The package structure includes: a chip carrier, a semiconductor chip, a heat sink, and an encapsulant; it connects and electrically connects at least one semiconductor chip to the chip carrier, and connects the heat sink to the After the chip is mounted, the encapsulation and molding process is carried out, and the cutting process is performed along the periphery of the package component to reveal the side of the heat sink, and remove the encapsulant on the thin metal layer of the heat sink to expose the thin metal layer of the heat sink , the heat generated during operation is dissipated by the thin metal layer of the heat sink and the heat conduction through hole; the present invention avoids the problem of burrs and tool wear caused by cutting heat sinks with singling tools, and can also reduce the cutting cost in the singling process. Moreover, when the heat sink is integrated into the semiconductor structure, it will not cause chip cracks and glue overflow problems during the molding process, thereby improving the yield of finished products.

Owner:SILICONWARE PRECISION IND CO LTD

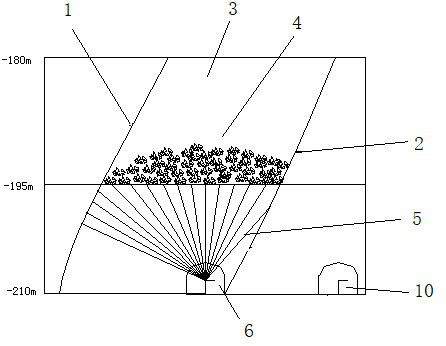

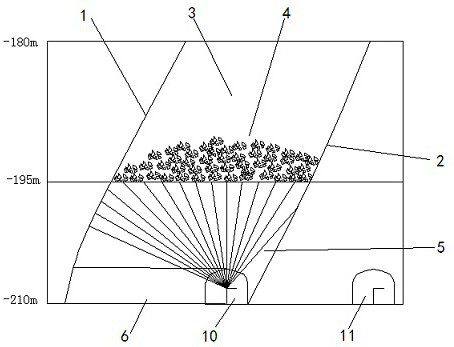

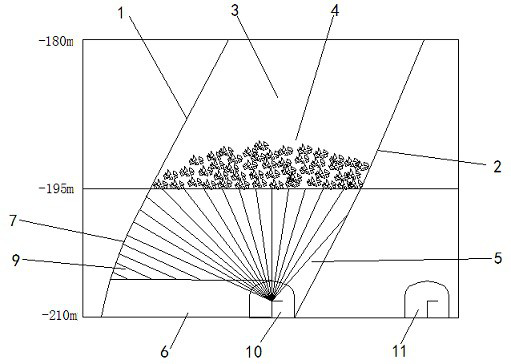

Application of blasting groove broaching method in underground stope of metal mine

PendingCN114812313AOptimize cutting processImprove ore preparation efficiencyUnderground miningBlastingMining engineeringStructural engineering

The invention discloses application of a blasting groove broaching method in an underground stope of a metal mine, belongs to the technical field of mining engineering methods, and is used for cutting and groove broaching in the underground stope of the metal mine. According to the technical scheme, firstly, more than or equal to two rows of fan-shaped deep blast holes are formed in the position of a cutting groove of a stope; the length of the cutting roadway is larger than or equal to the designed length of the cutting groove; then, top falling with the height gradually reduced is carried out on the cutting roadway from inside to outside in the side hole direction of the fan-shaped deep hole blast hole, and a protection layer larger than or equal to 500 mm is reserved between a top falling area and the fan-shaped deep hole blast hole; and finally, the cutting gate way and the roof falling area serve as free faces of groove broaching blasting, the fan-shaped deep blast holes are gradually blasted, and a cutting groove is formed. The method is the first creation of metal mine chamber cutting engineering, the construction period is greatly smaller than that of a cutting gate way and cutting well groove broaching method, the working procedures are optimized, the construction cost is reduced, and the safety coefficient and the chamber ore preparation efficiency are improved.

Owner:HEBEI IRON & STEEL GRP MINING

Groove making method of special-shaped box-shaped steel member

ActiveCN111571057BEasy to manufactureOptimize cutting processWelding apparatusSlope angleSemi automatic

The invention provides a method for manufacturing the groove of a special-shaped box-shaped steel member, which is realized by the following steps: step 1: setting out according to the dimension drawing of the special-shaped box-shaped section; step 2: taking a corner on the section of the special-shaped box as a reference point, and selecting a cover Plate and web; Step 3: On the premise that the blunt edge is greater than or equal to 5mm, cut the cover plate separately, and ensure that the sum of the bevel angles of the cut plates is 30 degrees; Step 4: For the cover plate At the other end, a natural slope cutting is performed, and the angle between the plates is compensated by the cutting web to ensure that the sum of the bevel angles of the cut plates is 30°; Step 5: According to the above steps 2 to 4, each Determine the angle, measure the angle, size, and direction of the cutting groove, and mark it on the plate; Step 6: Use a semi-automatic cutting machine to cut the groove. By adopting the above method, the cutting times of the cover plate is reduced, the cutting process is simplified, and the waste of resources is reduced.

Owner:CHINA 22MCC GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com