Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Meet material quality requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

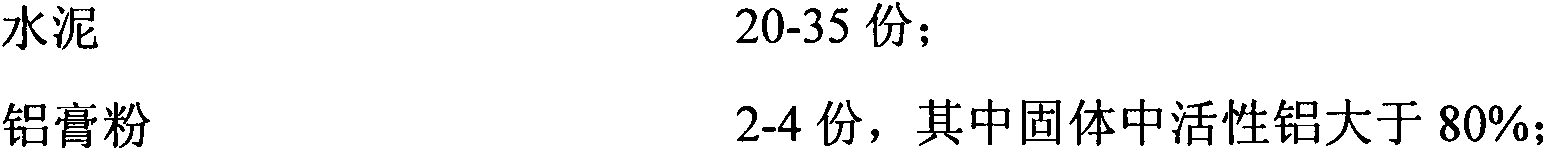

Method for producing air entrapping building block by utilizing red mud

InactiveCN101648402ALight weightHigh strengthSolid waste managementCeramic shaping apparatusNatural resourceRed mud

The invention provides a method for producing an air entrapping building block by utilizing red mud, comprising the following steps: mixing the following raw materials (dry basis) by weight part: 50-70 parts of red mud, 5-10 parts of calcium oxide and 20-40 parts of active gelled material; adding water according to 85-100 percent of the dry basis mass of the mixture, adding aluminium powder according to 0.04-0.06 percent of the dry basis mass of the mixture and adding an auxiliary agent according to 0.5-0.8 percent of the dry basis mass of the mixture; mixing to prepare a sizing agent; and finally obtaining the air entrapping building block through foaming, standing and steam curing. The air entrapping building block has the advantages of stable physical properties, light weight, good heat-insulation property, high waste use ratio, simple process, low cost, environmental protection, natural resource saving and the like, and can be used as non-load bearing partitions of urban high-risebuildings and as heat-insulation building blocks of low-temperature warehouses, heat-insulation warehouses and cold storage warehouses of industrial equipment.

Owner:KUNMING UNIV OF SCI & TECH

Cullet-doped aerated block production method

The invention discloses a cullet-doped aerated block production method. The method comprises the following steps: 1) respectively crushing river sand and ardealite, and preparing 12 to 19 parts of river sand and 3 to 5 parts of ardealite in parts by mass; and 2) preparing 60 to 70 parts of phosphorus slag, 0.02 to 0.03 part of powdered aluminum, 0.5 to 2 parts of methyl cellulose, 2 to 5 parts of re-dispersible polymer powder, 5 to 6 parts of cement, and 10 to 15 parts of quick lime in parts by mass, mixing and finely grinding the crushed river sand, the crushed ardealite and the phosphorus slag, and mixing with the powdered aluminum, the methyl cellulose, the re-dispersible polymer powder, the cement and the quick lime; and foaming and performing autoclaved curing. The method has the advantages that use amount of cullet is large, energy saving and environmental-friendliness effects are achieved, the problem of environmental pollution caused by cullet accumulation treatment is relieved, and a new raw material of hollow bricks is provided.

Owner:安徽中龙建材科技有限公司

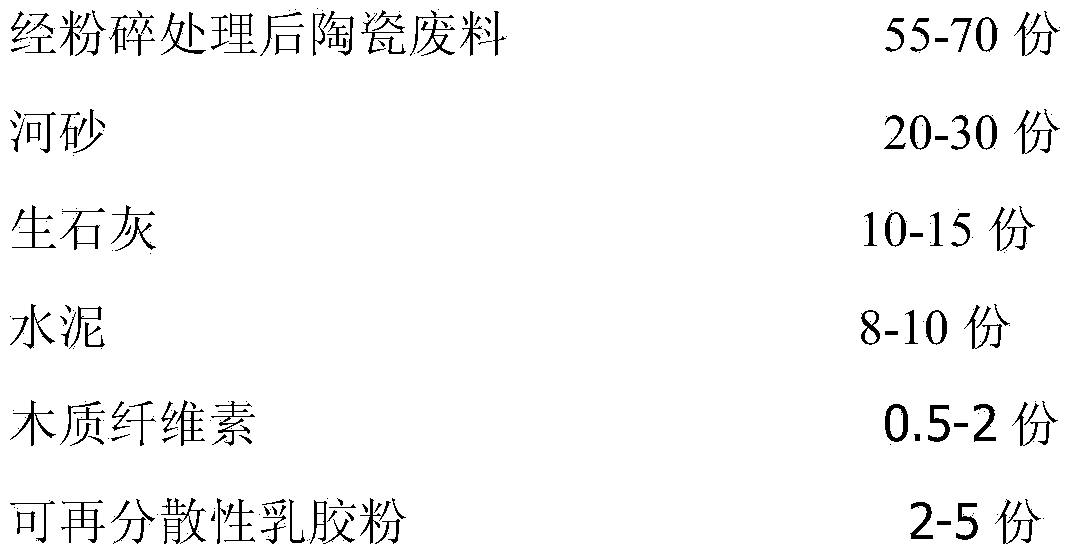

Method for preparing aerated bricks by utilizing ceramic waste

The invention discloses a method for preparing aerated bricks by utilizing ceramic waste, and the method comprises following steps of (1) mixing raw materials according to the following dry basis in parts by weight: ceramic waste after being ground, quicklime, cement and the like; (2) placing water according to 85 to 95 percent of the mass of the mixed raw material dry base in step (1), placing waste aluminum powder according to 0.01 to 0.03 percent of the mass of the mixed raw material dry base, placing plaster according to 9 to 11 percent of the mass of quicklime, and placing peregal which is 1 to 4 percent of the mass of aluminum powder; and (3) the slurry after being stirred in step (2) is foamed for 30 to 40 minutes under the temperature of 60 to 80 DEG C. Due to the adoption of the method, the consumption of ceramic waste is vast, energy conservation and environmental protection can be realized, the environmental pollution problem caused by the stacking treatment of the ceramic waste can be alleviated, and simultaneously new raw material source can be supplied for the hollow bricks.

Owner:安徽中龙建材科技有限公司

Method for producing fireproof heat-preservation board

The invention discloses a method for producing a fireproof heat-preservation board. The method comprises the following step: 1) performing steam pre-expansion on 5 to 8 parts by weight of expandable polystyrene master batch particles, uniformly mixing prepared flame retardant slurry and the pre-expanded polystyrene particles according to the weight ratio of 1: (2-4), fully mixing the mixture, 5 to 8 parts by weight of enteromorpha fibers, 25 to 35 parts by weight of water glass and 12 to 15 parts by weight of expanded perlite, and putting the mixture in a ball mill to be finely grinded, wherein the granularity of the mixture is controlled to be 5 to 10 mm. According to the method, a large amount of iron tailings are used, energy is saved, the environment is protected, the problem of environmental pollution caused by the stockpiling treatment of the iron tailings is mitigated, and meanwhile, a novel raw material is provided for a hollow brick.

Owner:山东盛都节能科技有限公司

Preparation method of high-strength building thermal insulation board

InactiveCN104386952ALight weightHigh strengthSolid waste managementMagnetic separatorLow magnetic field

The invention discloses a preparation method of a high-strength building thermal insulation board. The preparation method comprises the following steps of 1, treating 12-15 parts of fly ash, carrying out magnetic separation by a magnetic separator to obtain fly ash with low magnetic field intensity, and carrying out superfine grinding on the fly ash subjected to magnetic separation to obtain power of 1200 meshes, and 2, mixing the fly ash subjected to magnetic separation, 10-12 parts of stove ash, 6-8 parts of phosphogypsum, 12-14 parts of volcanic rock fibers, 28-30 parts of water and 5-7 parts of hydroxyethyl cellulose to obtain anti-cracking slurry. The preparation method has a large water-quenched slag use amount, saves energy, is environmentally friendly, relieves water-quenched slag stacking storage-caused environmental pollution and provides a novel raw material for a hollow brick.

Owner:罗瑛

Production method for insulating brick used for high temperature furnace

The invention discloses a production method for an insulating brick used for a high temperature furnace. The method comprises the following steps: 1) mixing raw materials consisting of, on a dry basis, 55 to 65 parts by mass of powder modified fly ash, 6 to 10 parts by mass of quicklime and 20 to 35 parts by mass of cement; 2) before fine grinding, weighing 60 to 70 parts by mass of inorganic garbage and 2 to 3.5 parts by mass of aluminum powder, uniformly mixing crushed cement, dihydrate gypsum and phosphorus slag with inorganic garbage and aluminum powder and then carrying out fine grinding; and 3) putting a crushed ceramic waste material and a dry material obtained after fine grinding into a stirring apparatus, adding water and carrying out full mixing. According to the invention, the usage amount of inorganic garbage is great, energy conservation and environmental protection are realized, the problem of environmental pollution caused by stockpiling treatment of inorganic garbage is alleviated, and a novel raw material is provided for a hollow brick.

Owner:HEFEI RISINE HEATEK

Method for producing aerated building block by using doping blast furnace slag

The invention discloses a method for producing an aerated building block by using doping blast furnace slag. The method comprises the following steps: 1) mixing and crushing fly ash, dihydrate gypsum and blast furnace slag and weighing, by mass, 12 to 19 parts of fly ash, 2 to 3 parts of dihydrate gypsum and 20 to 30 parts of blast furnace slag; 2) before fine grinding, weighing 10 to 15 parts by mass of vanadium slag and 1 to 2.5 parts by mass of aluminum powder, uniformly mixing crushed fly ash, dihydrate gypsum and blast furnace slag with vanadium slag and aluminum powder and then carrying out fine grinding; and 3) crushing broken stone granules and taking 12 to 25 parts by mass of the crushed broken stone granules.

Owner:HEFEI RISINE HEATEK

A method of using red mud to produce aerated blocks

InactiveCN101648402BEasy to useLight weightSolid waste managementCeramic shaping apparatusNatural resourceRed mud

The invention provides a method for producing an air entrapping building block by utilizing red mud, comprising the following steps: mixing the following raw materials (dry basis) by weight part: 50-70 parts of red mud, 5-10 parts of calcium oxide and 20-40 parts of active gelled material; adding water according to 85-100 percent of the dry basis mass of the mixture, adding aluminium powder according to 0.04-0.06 percent of the dry basis mass of the mixture and adding an auxiliary agent according to 0.5-0.8 percent of the dry basis mass of the mixture; mixing to prepare a sizing agent; and finally obtaining the air entrapping building block through foaming, standing and steam curing. The air entrapping building block has the advantages of stable physical properties, light weight, good heat-insulation property, high waste use ratio, simple process, low cost, environmental protection, natural resource saving and the like, and can be used as non-load bearing partitions of urban high-risebuildings and as heat-insulation building blocks of low-temperature warehouses, heat-insulation warehouses and cold storage warehouses of industrial equipment.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method for steel-making slag-doped aerated hollow brick

The invention discloses a preparation method for a steel-making slag-doped aerated hollow brick. The method is characterized by comprising the following steps: 1) mixing raw materials consisting of, on a dry basis, 35 to 45 parts by mass of modified fly ash, 6 to 10 parts by mass of hemihydrate gypsum, 20 to 35 parts by mass of cement and 10 to 12 parts of carbide slag; 2) before fine grinding, weighing 60 to 70 parts by mass of inorganic garbage and 2 to 3.5 parts by mass of aluminum powder, uniformly mixing crushed fly ash, cement, hemihydrate gypsum and carbide slag with inorganic garbage and aluminum powder and then carrying out fine grinding; and 3) putting a crushed ceramic waste material and a dry material obtained after fine grinding into a stirring apparatus, adding water and carrying out full mixing. According to the invention, the usage amount of the inorganic garbage is great, energy conservation and environmental protection are realized, the problem of environmental pollution caused by stockpiling treatment of inorganic garbage is alleviated, and a novel raw material is provided for a hollow brick.

Owner:HEFEI RISINE HEATEK

Method capable of utilizing blast-furnace slag to produce aerated hollow brick

The invention discloses a method capable of utilizing blast-furnace slag to produce an aerated hollow brick. The method comprises the following steps: 1), taking 5-10 parts of mixing cement, 1-3 parts of gypsum and 12-35 parts of phosphorus slag to be mixed and crushed according to the mass part; and 2), before fine milling, as mass percent, taking 50-70 parts of blast-furnace slag and 1-3 parts of aluminite powder according to the mass part, uniformly mixing the two with the three crushed materials in the step 1, and then carrying out fine milling. According to the invention, a larger amount of blast-furnace slag can be used to achieve the purposes of energy conservation and environment protection and relieve the environment pollution caused by processing the blast-furnace slag pile, and a novel material source is provided for the hollow bricks.

Owner:安徽中龙建材科技有限公司

Method for producing aerated building block used for oxidation furnace by using doping iron ore tailings

The invention discloses a method for producing an aerated building block used for an oxidation furnace by using doping iron ore tailings. The method comprises the following steps: 1) mixing and crushing fly ash, anhydrite and iron ore tailings and weighing, by mass, 12 to 19 parts of fly ash, 2 to 3 parts of anhydrite and 20 to 30 parts of iron ore tailings; 2) before fine grinding, weighing 10 to 15 parts by mass of phosphorus slag and 1 to 2.5 parts by mass of aluminum powder, uniformly mixing crushed fly ash, anhydrite and iron ore tailings with phosphorus slag and aluminum powder and then carrying out fine grinding; and 3) crushing brick slag and taking 12 to 25 parts by mass of the crushed brick slag. According to the invention, the usage amount of iron ore tailings is great, energy conservation and environmental protection are realized, the problem of environmental pollution caused by stockpiling treatment of iron ore tailings is alleviated, and a novel raw material is provided for a hollow brick.

Owner:HEFEI RISINE HEATEK

Method for producing aerated hollow brick used for pre-oxidation furnace by using inorganic garbage

The invention discloses a method for producing an aerated hollow brick used for a pre-oxidation furnace by using inorganic garbage. The method comprises the following steps: 1) mixing cement, dihydrate gypsum and phosphorus slag, then carrying out crushing and weighing, by mass, 5 to 10 parts of cement, 1 to 3 parts of dihydrate gypsum and 12 to 33 parts of phosphorus slag; and 2) before fine grinding, weighing 60 to 70 parts by mass of inorganic garbage and 2 to 3.5 parts by mass of aluminum powder, uniformly mixing the crushed cement, dihydrate gypsum and phosphorus slag with the inorganic garbage and the aluminum powder and then carrying out fine grinding, wherein after the crushed cement, dihydrate gypsum and phosphorus slag are uniformly mixed with the inorganic garbage and the aluminum powder, fine grinding is carried out until a particle size is less than 20 mm. According to the invention, the usage amount of the inorganic garbage is great, energy conservation and environmental protection are realized, the problem of environmental pollution caused by stockpiling treatment of inorganic garbage is alleviated, and a novel raw material is provided for a hollow brick.

Owner:HEFEI RISINE HEATEK

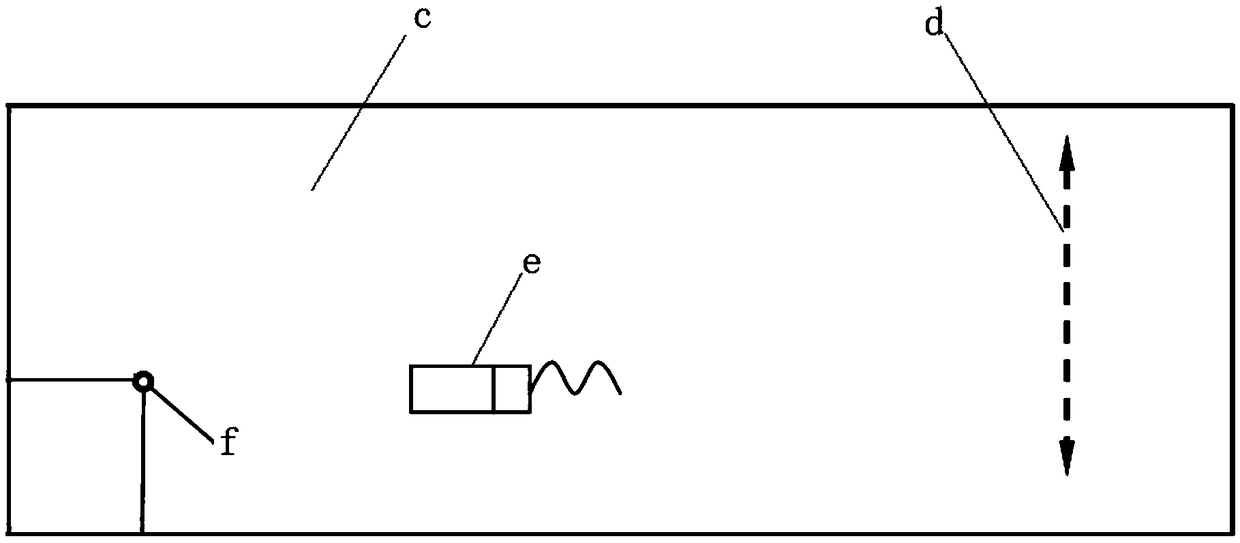

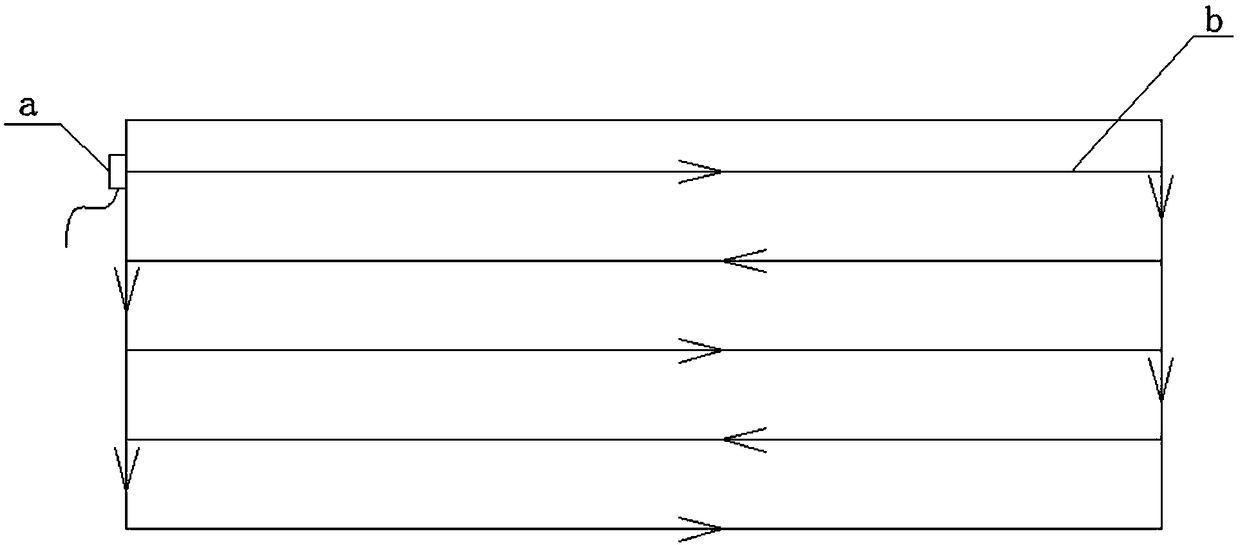

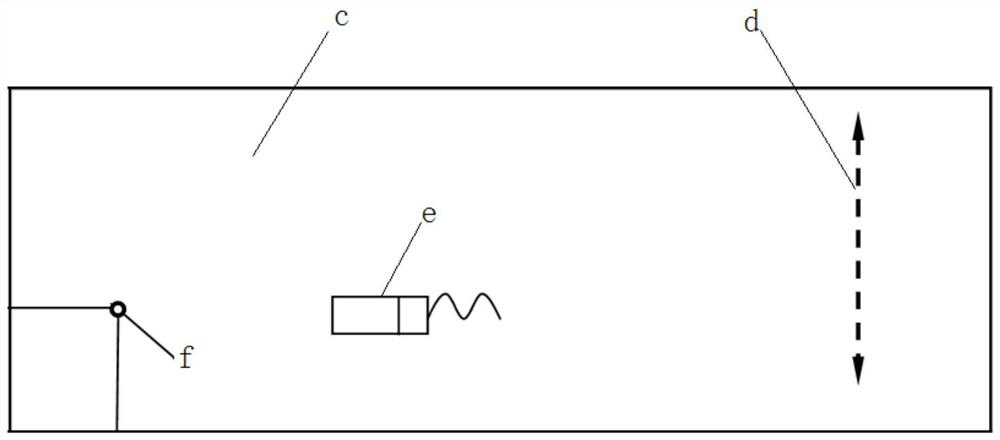

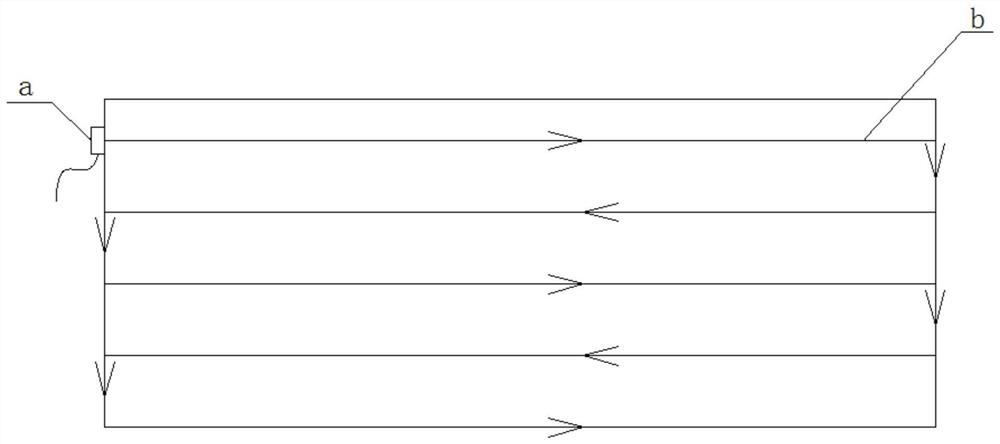

A Lamb wave contact type flaw detection method for a 2XXX type aluminum alloy sheet

ActiveCN108918669AReliable detectionEnsure application qualityAnalysing solids using sonic/ultrasonic/infrasonic wavesContact typeMaterials science

The invention relates to a flaw detection method for an aluminum alloy sheet, particularly a Lamb wave contact type flaw detection method for a 2XXX type aluminum alloy sheet. The method is provided to solve a problem that tissue inclusion, layering and other metallurgical flaws in aluminum alloy plates having a size less than 6 mm cannot be detected by the prior art. The method includes selectingtwo angle-variable ultrasonic wave probes, manufacturing a contrast test piece, determining reference sensitivity through a detection angle difference between the two angle-variable ultrasonic wave probes, setting the maximum scanning interval and a scanning path, setting a scanning speed, searching for flaw positions, determining flaw waves, and precisely determining flaw positions through comparison of oil waves with the flaw waves. Flaws of an aluminum alloy sheet having a size less than 6 mm can be accurately and reliably detected through the method, acoustic beams of the probes cover theoverall sheet in a scanning process to ensure no omission of flaws. The method is suitable for flaw detection of a 2XXX type aluminum alloy sheet.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Method capable of utilizing city inorganic waste to produce aerated hollow brick

The invention discloses a method capable of utilizing city inorganic waste to produce an aerated hollow brick. The method comprises the following steps: (1), mixing such materials in dry basis mass as crushed city inorganic waste, lime and coal ash; and (2), according to the step (1), adding water in 85-95 percent of mixed material dry basis, adding waste aluminite powder in 0.04-0.06 percent of mixed material dry basis, gypsum in 9-11 percent lime, and peregal in 1-4 percent of waste aluminite powder. According to the invention, a larger amount of inorganic waste can be used to achieve the purposes of energy conservation and environment protection and relieve the environment pollution caused by processing the inorganic waste piles, and a novel material source is provided for the hollow bricks.

Owner:安徽中龙建材科技有限公司

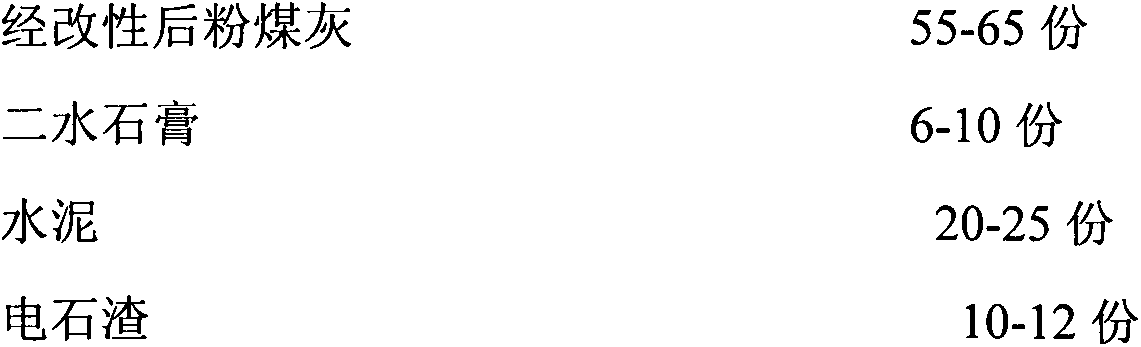

Method for producing aerated building block by using doping carbide slag

The invention discloses a method for producing an aerated building block by using doping carbide slag. The method comprises the following steps: 1) mixing raw materials consisting of, on a dry basis, 55 to 65 parts by mass of modified fly ash, 6 to 10 parts by mass of dihydrate gypsum, 20 to 35 parts by mass of cement and 10 to 12 parts of carbide slag; 2) before fine grinding, weighing 60 to 70 parts by mass of inorganic garbage and 2 to 3.5 parts by mass of aluminum powder, uniformly mixing crushed fly ash, cement, dihydrate gypsum and carbide slag with inorganic garbage and aluminum powder and then carrying out fine grinding; and 3) putting a crushed ceramic waste material and a dry material obtained after fine grinding into a stirring apparatus, adding water and carrying out full mixing. According to the invention, the usage amount of the inorganic garbage is great, energy conservation and environmental protection are realized, the problem of environmental pollution caused by stockpiling treatment of inorganic garbage is alleviated, and a novel raw material is provided for a hollow brick.

Owner:HEFEI RISINE HEATEK

Method for producing aerated building block used for high temperature furnace by using doping water-quenched slag

The invention discloses a method for producing an aerated building block used for a high temperature furnace by using doping water-quenched slag. The method comprises the following steps: 1) mixing and crushing stove ash and phosphogypsum and weighing, by mass, 12 to 19 parts of stove ash and 1 to 3 parts of phosphogypsum; 2) before fine grinding, weighing 60 to 70 parts by mass of phosphorus slag and 1 to 2.5 parts by mass of aluminum powder, uniformly mixing crushed stove ash and phosphogypsum with phosphorus slag and aluminum powder and then carrying out fine grinding, wherein after crushed stove ash and phosphogypsum are uniformly mixed with phosphorus slag and aluminum powder, fine grinding is carried out until a particle size is less than 18 mm; 3) crushing water-quenched slag and taking 10 to 20 parts by mass of the crushed water-quenched slag. According to the invention, the usage amount of water-quenched slag is great, energy conservation and environmental protection are realized, the problem of environmental pollution caused by stockpiling treatment of water-quenched slag is alleviated, and a novel raw material is provided for a hollow brick.

Owner:HEFEI RISINE HEATEK

Method for preparing art painting carrier from ramie

InactiveCN112659805AExtended retention timeGood ink and water absorptionSingeingHeating/cooling textile fabricsProduction lineProcess engineering

The invention discloses a method for preparing an art painting carrier from ramie, which is used for preparing the art painting carrier of more than 1 m from ramie on the basis of the existing production line and comprises the following operation steps: determining the type of the art carrier, pretreating ramie, preparing gray cloth, performing finish treatment, boiling off at high temperature, drying the gray cloth and shaping the gray cloth. The quality required by'three fixations' of various art painting carriers is realized. The pen ink rendering effect and the technical parameters can be regulated and controlled, and the problems that an existing art painting carrier product is prone to local deviation in the production process, and therefore color fixing, nature determining and shaping of the product are not easy are expected to be optimized.

Owner:王少农

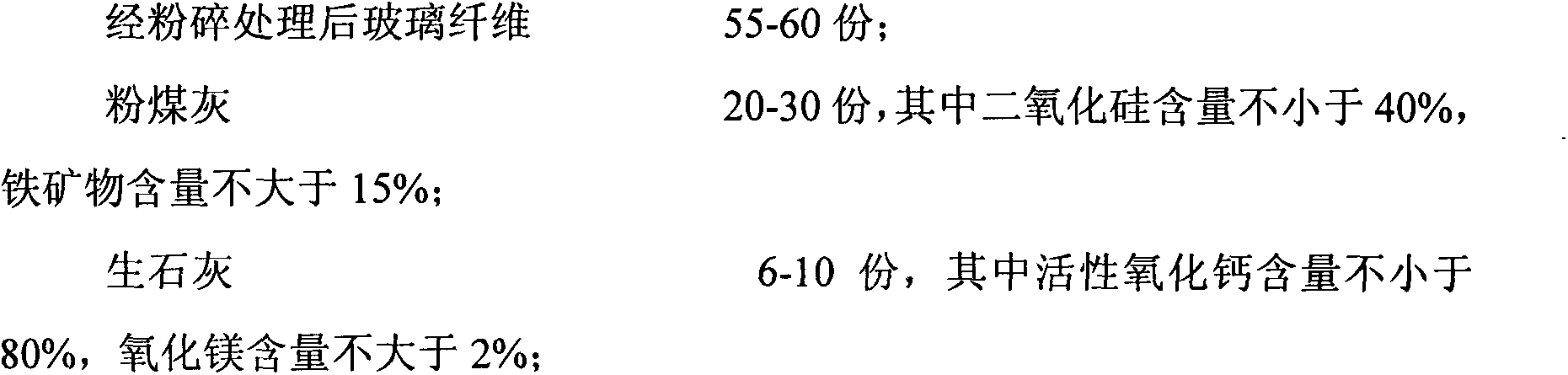

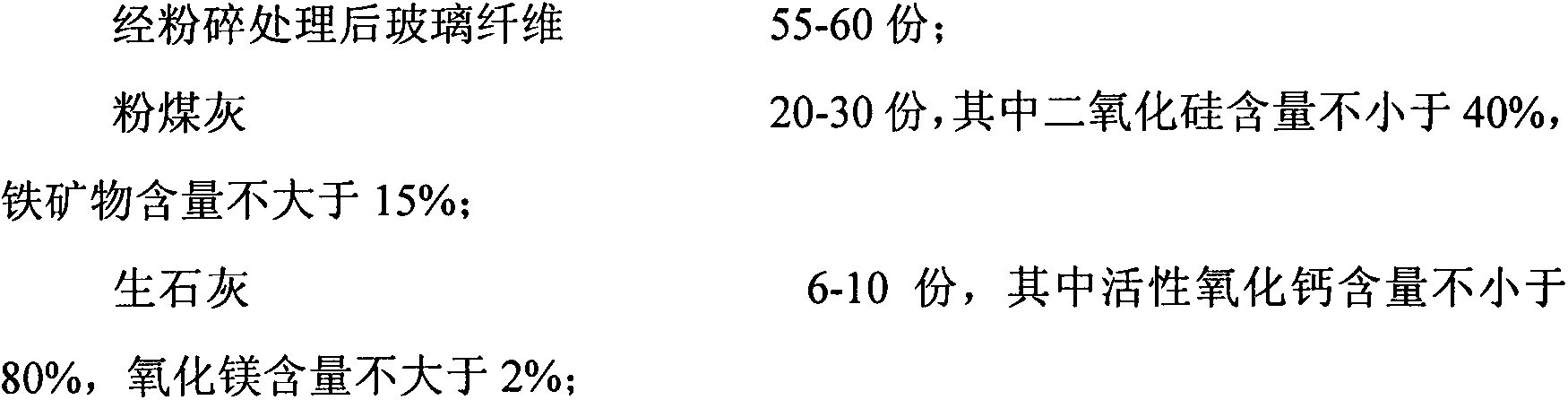

Method for producing insulating brick used for oxidation furnace by using glass fiber

The invention discloses a method for producing an insulating brick used for an oxidation furnace by using a glass fiber. The method comprises the following steps: (1) mixing raw materials consisting of, on a dry basis, 55 to 60 parts by mass of a crushed glass fiber, 20 to 30 parts by mass of fly ash and 6 to 10 parts by mass of quicklime, wherein the fly ash has silica content of no less than 40% and iron mineral content of no greater than 15% and the quicklime has active calcium oxide content of no less than 80% and magnesium oxide content of no greater than 2%; (2) mixing the above-mentioned raw materials with stirring so as to obtain slurry and subjecting the slurry to foaming at 60 to 80 DEG C for 30 to 40 min; (3) subjecting foamed slurry prepared in the step (2) to steam curing at normal pressure so as to obtain a green body and cutting the green body to corresponding sizes; and (4) subjecting the green body prepared in the step (3) to steam curing at a pressure of 0.8 to 0.9 Mpa for 18 to 22 h and sprinkling a soap surfactant on the green body every 0.6 h during steam curing so as to obtain a finished insulating brick product used for the oxidation furnace. According to the invention, the usage amount of an attapulgite waste material is great, energy conservation and environmental protection are realized, the problem of environmental pollution caused by stockpiling treatment of attapulgite waste materials is alleviated, and a novel raw material is provided for a hollow brick.

Owner:HEFEI RISINE HEATEK

Method for preparing aerated bricks by utilizing ceramic waste

The invention discloses a method for preparing aerated bricks by utilizing ceramic waste, and the method comprises following steps of (1) mixing raw materials according to the following dry basis in parts by weight: ceramic waste after being ground, quicklime, cement and the like; (2) placing water according to 85 to 95 percent of the mass of the mixed raw material dry base in step (1), placing waste aluminum powder according to 0.01 to 0.03 percent of the mass of the mixed raw material dry base, placing plaster according to 9 to 11 percent of the mass of quicklime, and placing peregal which is 1 to 4 percent of the mass of aluminum powder; and (3) the slurry after being stirred in step (2) is foamed for 30 to 40 minutes under the temperature of 60 to 80 DEG C. Due to the adoption of the method, the consumption of ceramic waste is vast, energy conservation and environmental protection can be realized, the environmental pollution problem caused by the stacking treatment of the ceramic waste can be alleviated, and simultaneously new raw material source can be supplied for the hollow bricks.

Owner:安徽中龙建材科技有限公司

Heat-insulation wallboard with low heat transfer coefficient

The invention discloses a heat-insulation wallboard with a low heat transfer coefficient, containing the following materials in parts by weight: 80-120 parts of cement, 30-50 parts of prefabricated expanded perlite, 40-60 parts of styrene-acrylic emulsion, 20-40 parts of poly-acrylonitrile base carbon fiber, 30-40 parts of glass fiber, 8-16 parts of gypsum, 15-20 parts of ultra-high molecular weight polyethylene fiber, 5-10 parts of steel fiber, 2-8 parts of kieselguhr, 15-25 parts of esterified starch, 10-20 parts of coal ash, 8-16 parts of talcum powder, 10-20 parts of calcium carbonate, and5-10 parts of mica powder. The prefabricated expanded perlite is prepared by adopting the following process: uniformly mixing gelatin, expanded perlite and hydrogen peroxide solution, filtering, adjusting the system to be neutral, adding ammonium persulfate and sodium hydrogen sulfite under nitrogen protection and stirring, adding acrylamide and stirring, precipitating, and drying, thus obtainingthe prefabricated expanded perlite.

Owner:安徽臻烁新材料技术有限公司

Method for producing fireproof insulation board

The invention discloses a method for producing a fireproof heat-preservation board. The method comprises the following step: 1) performing steam pre-expansion on 5 to 8 parts by weight of expandable polystyrene master batch particles, uniformly mixing prepared flame retardant slurry and the pre-expanded polystyrene particles according to the weight ratio of 1: (2-4), fully mixing the mixture, 5 to 8 parts by weight of enteromorpha fibers, 25 to 35 parts by weight of water glass and 12 to 15 parts by weight of expanded perlite, and putting the mixture in a ball mill to be finely grinded, wherein the granularity of the mixture is controlled to be 5 to 10 mm. According to the method, a large amount of iron tailings are used, energy is saved, the environment is protected, the problem of environmental pollution caused by the stockpiling treatment of the iron tailings is mitigated, and meanwhile, a novel raw material is provided for a hollow brick.

Owner:山东盛都节能科技有限公司

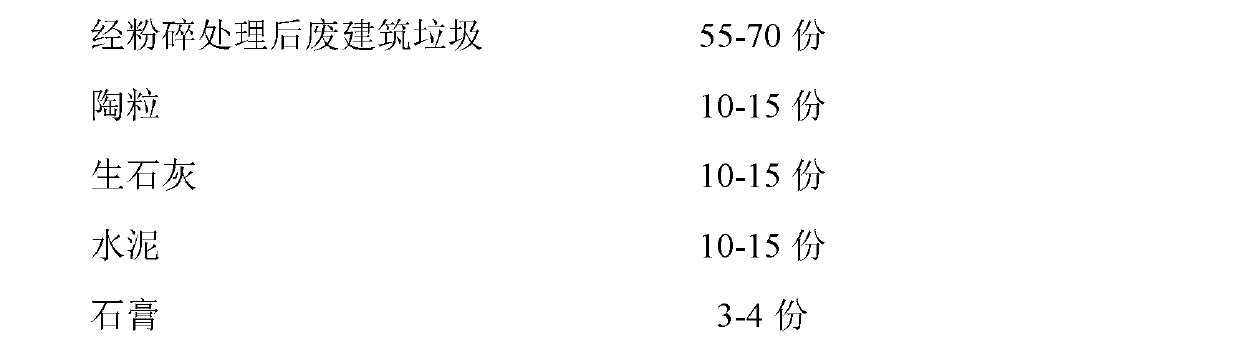

Method for manufacturing aerated hollow bricks by abandoned construction waste

The invention discloses a method for manufacturing aerated hollow bricks by abandoned construction waste. The method includes steps of (1), mixing dry-base raw materials including crushed and treated abandoned construction waste, quicklime, cement and the like according to mass parts; (2), adding water accounting for 85-95% of the mass of the dry-base raw materials mixed in the step (1), adding waste aluminum powder accounting for 0.04-0.06% of the mass of the dry-base mixed raw materials, gypsum accounting for 9-11% of the mass of the quicklime and the like into the dry-base raw materials; (3), mixing the mixture in the step (2) to obtain slurry and then foaming the slurry for 30 to 40 minutes at the temperature ranging from 65 DEG C to 75 DEG C; and (4), performing autoclaved curing for the foamed slurry obtained from the step (3) under constant temperature to obtain a green body and cutting the green body into the aerated hollow bricks with corresponding sizes. Consumption of the abandoned construction waste is high, effects of energy conservation and environmental protection are realized, the problem of environmental pollution caused by stockpiling and disposal of the abandoned construction waste is alleviated, and a new raw material for production of the hollow bricks is provided.

Owner:安徽中龙建材科技有限公司

Method for making external wall thermal insulation board with fluorite slag

ActiveCN104355654BMeet material quality requirementsMeet quality requirementsSolid waste managementCeramicwareSlagBasalt fiber

The invention discloses a method for preparing an external wall heat preservation plate through fluorite slag. The method comprises the following steps: mixing and crushing 14-16 parts by weight of active packing, 5-8 parts by weight of basalt fibers, 20-30 parts by weight of the fluorite slag and 10-15 parts by weight of carbide slag, and before fine grinding, putting 10-12 parts by weight of fly ash and 3-5 parts by weight of modified rubber powder into a ball grinding machine for fine grinding; (2) putting a dry mixture subjected to fine grinding into stirring equipment, adding 22-30 parts by weight of water for full stirring, and adding 5-8 parts by weight of a hydrochloric acid solution with the concentration being 18-20 percent. By adopting an inorganic-organic combined mode, the defects that an existing organic external wall heat preservation material is combustible, an existing inorganic external wall heat preservation material is high in ratio and high in heat conduction coefficient, and the maintenance middle stage is long, energy consumption is high and the heat preservation effect is poor in a construction or manufacturing process are overcome.

Owner:DALIAN DEETOP ENVIRONMENTAL TECH CO LTD

Method for preparing high-strength heat-preservation wallboard

InactiveCN108585664AReduce pollutionMeet material quality requirementsConstruction materialFlexural strengthNitrogen gas

The invention discloses a method for preparing a high-strength heat-preservation wallboard. The method comprises the following steps that xanthan gum, expanded perlite and a hydrogen peroxide aqueoussolution are uniformly mixed and filtered, a system is adjusted to be neutral, ammonium persulfate and sodium bisulfite are added and stirred under the protection of nitrogen, acrylamide is added andstirred, and precipitating and drying are conducted to obtain a prefabricated material; cement, the prefabricated material, a polyurethane emulsion, nylon fibers, coal gangue and glutinous rice flourare stirred, pressed, shaken and then pressed, and then steam maintenance and natural airing are conducted to obtain the high-strength heat-preservation wallboard, wherein the weight ratio of the cement, the prefabricated material, the polyurethane emulsion, the nylon fibers, the coal gangue and the glutinous rice flour is (50-100):(20-40):(20-40):(10-20):(15-23):(2-10). The obtained heat-preservation wallboard has high compressive strength and flexural strength, low heat transfer coefficient and excellent heat preservation performance.

Owner:安徽臻烁新材料技术有限公司

A kind of preparation method of external wall insulation board containing steel tailings

ActiveCN104326761BIncrease dosageLight weightSolid waste managementCeramicwareGranularityThermal insulation

The invention discloses a preparation method for an exterior-wall thermal-insulation board containing steel tailings. The method comprises the following steps: 1) putting steel tailings in a ball mill, crushing to have the granularity of 2-3 mm, then mixing with 10-12 parts of calcium carbide slurry, 8-10 parts of cobs and 3-5 parts of potash feldspar to obtain a mixture, and adding water accounting for 35-55% by mass of the mixture and plaster accounting for 0.5-0.9% by mass of the mixture, so as to prepare a slurry; and 2) standing the stirred slurry at 58 DEG C, and controlling the standing foaming time to be 2 h and the standing exterior temperature to be 18 DEG C. The prepared exterior-wall thermal-insulation board is a novel building exterior-wall thermal-insulation material, by using the material, the thermal insulation performance of the thermal-insulation mortar is obviously improved, the bonding performance between a thermal-insulation material and boundary mortar is enhanced, and the usage cost is reduced.

Owner:铜陵鑫隆钢结构有限公司

Method capable of utilizing city inorganic waste to produce aerated hollow brick

The invention discloses a method capable of utilizing city inorganic waste to produce an aerated hollow brick. The method comprises the following steps: (1), mixing such materials in dry basis mass as crushed city inorganic waste, lime and coal ash; and (2), according to the step (1), adding water in 85-95 percent of mixed material dry basis, adding waste aluminite powder in 0.04-0.06 percent of mixed material dry basis, gypsum in 9-11 percent lime, and peregal in 1-4 percent of waste aluminite powder. According to the invention, a larger amount of inorganic waste can be used to achieve the purposes of energy conservation and environment protection and relieve the environment pollution caused by processing the inorganic waste piles, and a novel material source is provided for the hollow bricks.

Owner:安徽中龙建材科技有限公司

Preparation method of high-strength building insulation board

The invention discloses a preparation method of a high-strength building thermal insulation board. The preparation method comprises the following steps of 1, treating 12-15 parts of fly ash, carrying out magnetic separation by a magnetic separator to obtain fly ash with low magnetic field intensity, and carrying out superfine grinding on the fly ash subjected to magnetic separation to obtain power of 1200 meshes, and 2, mixing the fly ash subjected to magnetic separation, 10-12 parts of stove ash, 6-8 parts of phosphogypsum, 12-14 parts of volcanic rock fibers, 28-30 parts of water and 5-7 parts of hydroxyethyl cellulose to obtain anti-cracking slurry. The preparation method has a large water-quenched slag use amount, saves energy, is environmentally friendly, relieves water-quenched slag stacking storage-caused environmental pollution and provides a novel raw material for a hollow brick.

Owner:罗瑛

Method for producing aerated hollow brick by using steel tailings

The invention discloses a method for producing an aerated hollow brick by using steel tailings. The method comprises the following steps: 1) mixing cement, dihydrate gypsum and phosphorus slag, then carrying out crushing and weighing, by mass, 5 to 10 parts of cement, 1 to 3 parts of dihydrate gypsum and 10 to 30 parts of phosphorus slag; 2) before fine grinding, weighing 60 to 70 parts by mass of steel tailings and 1 to 2.5 parts by mass of aluminum powder, uniformly mixing the crushed cement, dihydrate gypsum and phosphorus slag with the steel tailings and the aluminum powder and then carrying out fine grinding; and 3) crushing a ceramic waste material and taking 12 to 25 parts by mass of the crushed ceramic waste material. According to the invention, the usage amount of the steel tailings is great, energy conservation and environmental protection are realized, the problem of environmental pollution caused by stockpiling treatment of steel tailings is alleviated, and a novel raw material is provided for a hollow brick.

Owner:HEFEI RISINE HEATEK

A Lamb wave contact flaw detection method for 2××× aluminum alloy sheet

ActiveCN108918669BReliable detectionEnsure application qualityAnalysing solids using sonic/ultrasonic/infrasonic wavesAcousticsMaterials science

The invention relates to a flaw detection method for an aluminum alloy sheet, particularly a Lamb wave contact type flaw detection method for a 2XXX type aluminum alloy sheet. The method is provided to solve a problem that tissue inclusion, layering and other metallurgical flaws in aluminum alloy plates having a size less than 6 mm cannot be detected by the prior art. The method includes selectingtwo angle-variable ultrasonic wave probes, manufacturing a contrast test piece, determining reference sensitivity through a detection angle difference between the two angle-variable ultrasonic wave probes, setting the maximum scanning interval and a scanning path, setting a scanning speed, searching for flaw positions, determining flaw waves, and precisely determining flaw positions through comparison of oil waves with the flaw waves. Flaws of an aluminum alloy sheet having a size less than 6 mm can be accurately and reliably detected through the method, acoustic beams of the probes cover theoverall sheet in a scanning process to ensure no omission of flaws. The method is suitable for flaw detection of a 2XXX type aluminum alloy sheet.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Cullet-doped aerated block production method

The invention discloses a cullet-doped aerated block production method. The method comprises the following steps: 1) respectively crushing river sand and ardealite, and preparing 12 to 19 parts of river sand and 3 to 5 parts of ardealite in parts by mass; and 2) preparing 60 to 70 parts of phosphorus slag, 0.02 to 0.03 part of powdered aluminum, 0.5 to 2 parts of methyl cellulose, 2 to 5 parts of re-dispersible polymer powder, 5 to 6 parts of cement, and 10 to 15 parts of quick lime in parts by mass, mixing and finely grinding the crushed river sand, the crushed ardealite and the phosphorus slag, and mixing with the powdered aluminum, the methyl cellulose, the re-dispersible polymer powder, the cement and the quick lime; and foaming and performing autoclaved curing. The method has the advantages that use amount of cullet is large, energy saving and environmental-friendliness effects are achieved, the problem of environmental pollution caused by cullet accumulation treatment is relieved, and a new raw material of hollow bricks is provided.

Owner:安徽中龙建材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com