Method for preparing aerated bricks by utilizing ceramic waste

A technology of ceramic waste and hollow bricks, which is applied in the direction of ceramic products, applications, household appliances, etc., to achieve the effect of high strength, large usage, and light bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A method for preparing air-entraining hollow bricks by using ceramic waste is carried out according to the following steps:

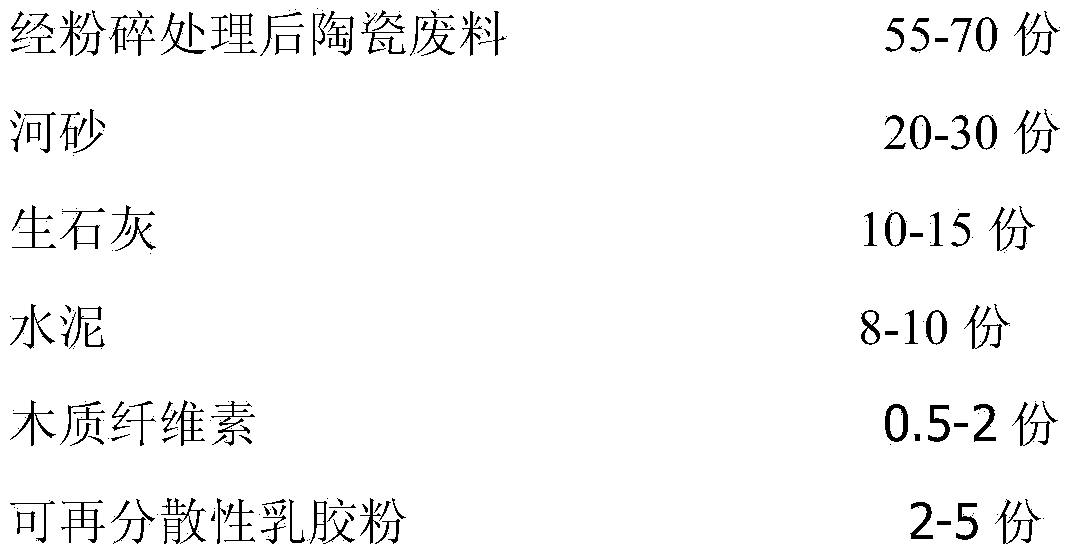

[0025] (1) Mix the raw materials according to the following parts by weight on a dry basis:

[0026] 65 parts of ceramic waste after crushing

[0027] 25 parts of river sand

[0028] Quicklime 10 parts

[0029] Cement 8 parts

[0030] 1.5 parts of lignocellulose

[0031] Redispersible latex powder 4 parts

[0032] (2) According to the above steps (1) add water to 85% of the dry basis of the mixed raw materials, add waste aluminum powder to 0.02% of the dry basis of the mixed raw materials, add methyl cellulose ether to 0.3%, and add epoxy linseed oil to 2% , add gypsum to 20% of the mass of quicklime, add Pingping to 14% of the weight of aluminum powder;

[0033] (3) Put the slurry stirred in the above step (2) at a temperature of 60-80°C, and foam for 30-40 minutes;

[0034] (4) The foaming slurry in the above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com