Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Meet loading needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

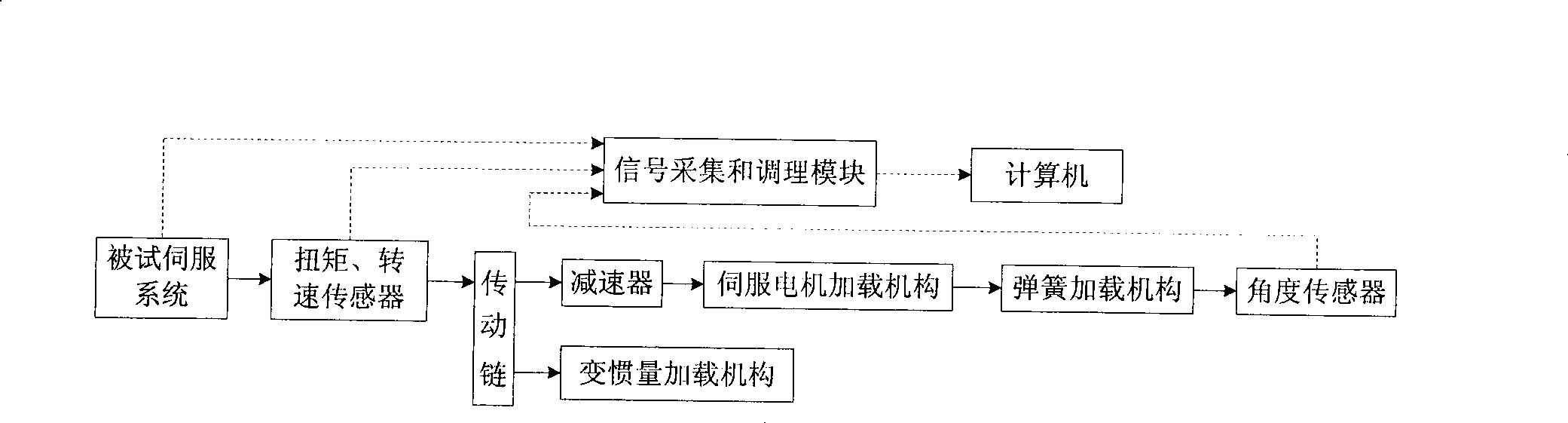

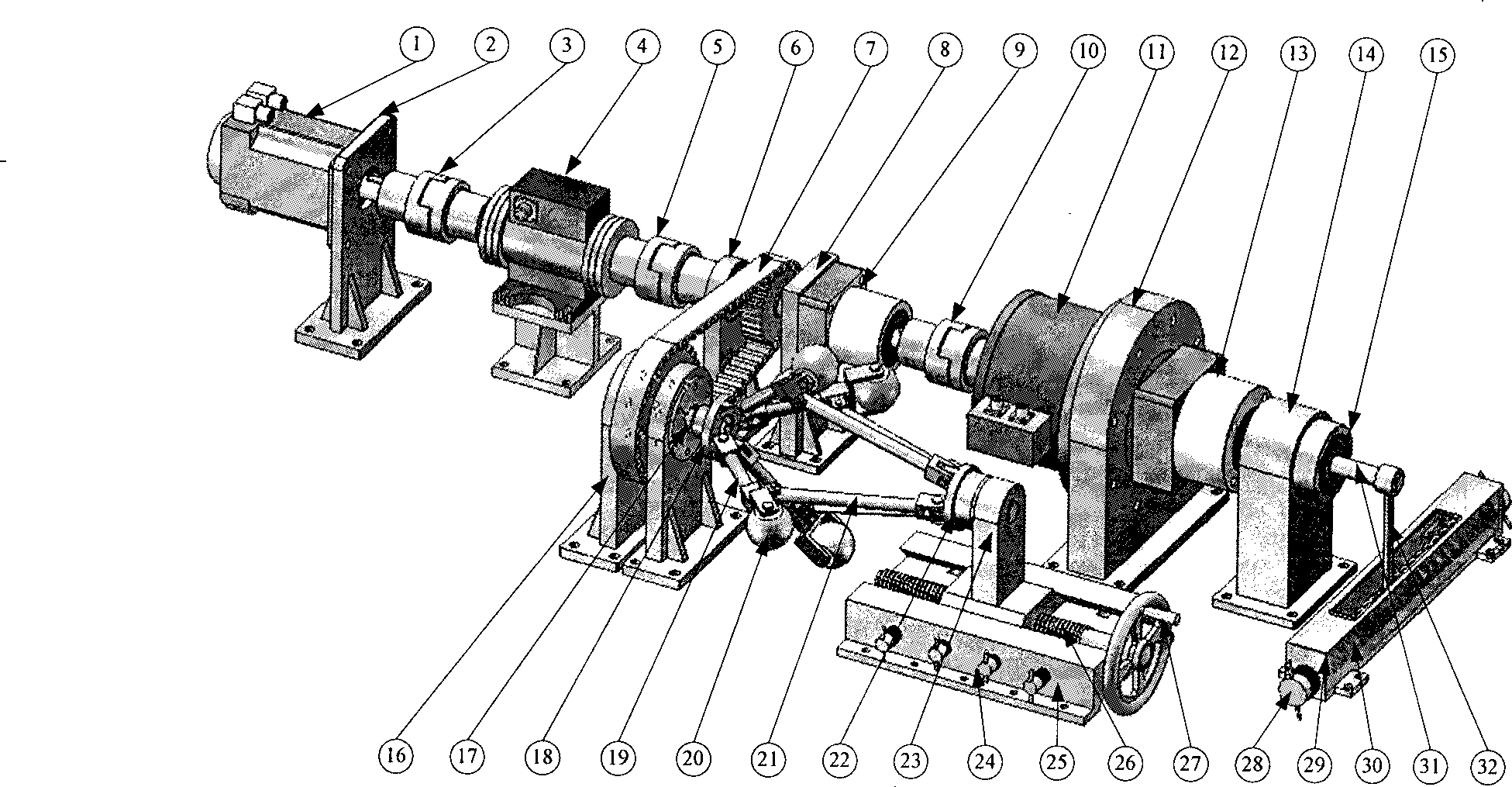

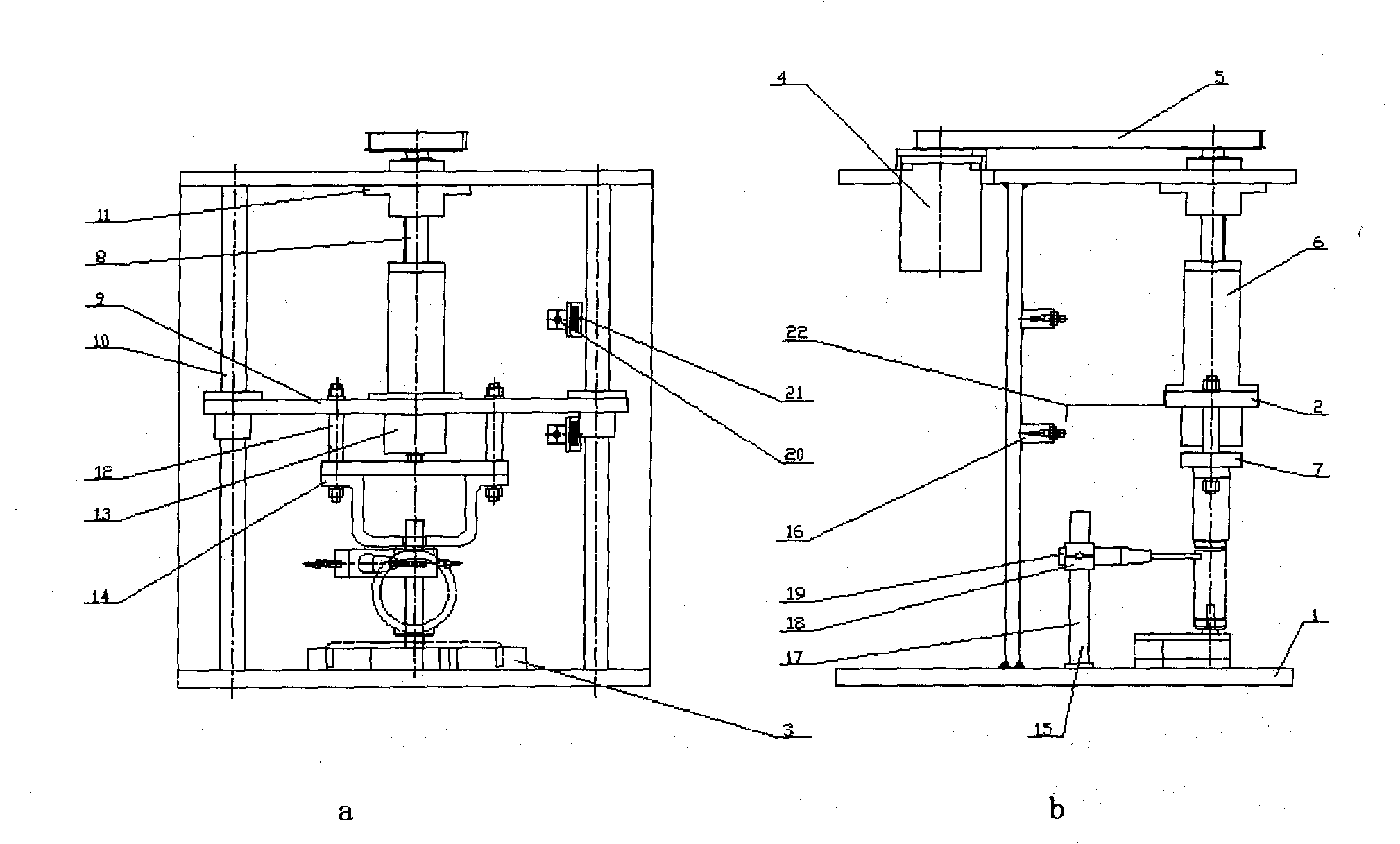

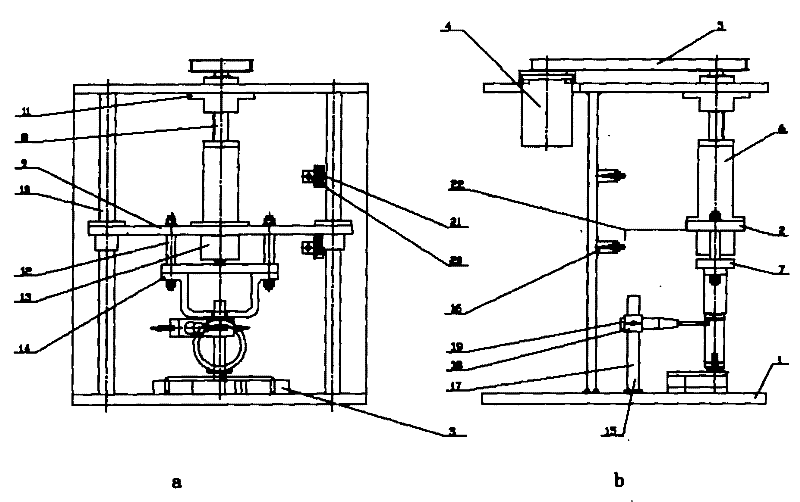

Complex load behavior simulation and performance test apparatus for servo system

InactiveCN101477174AOvercome the shortcomings of a single loading methodMeet loading needsDynamo-electric machine testingTime changesTest fixture

The invention relates to a load stimulation device of a servo system and a performance testing device of the servo system and belongs to the field of detection technology and automation technology. The devices integrate three modes of inertia loading, servo motor loading and spring loading, can realize independent loading of three loading modes, two combination loading or simultaneous loading, and can stimulate various loading conditions, such as inertia load, elastic loading, unbalanced load, impact load, time change load and the combination of various loads. Acquired signals of a tested servo system, a torsion rotational speed sensor and an angle sensor are sent to a computer for processing so as to realize the static and dynamic performance test under different loading conditions.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

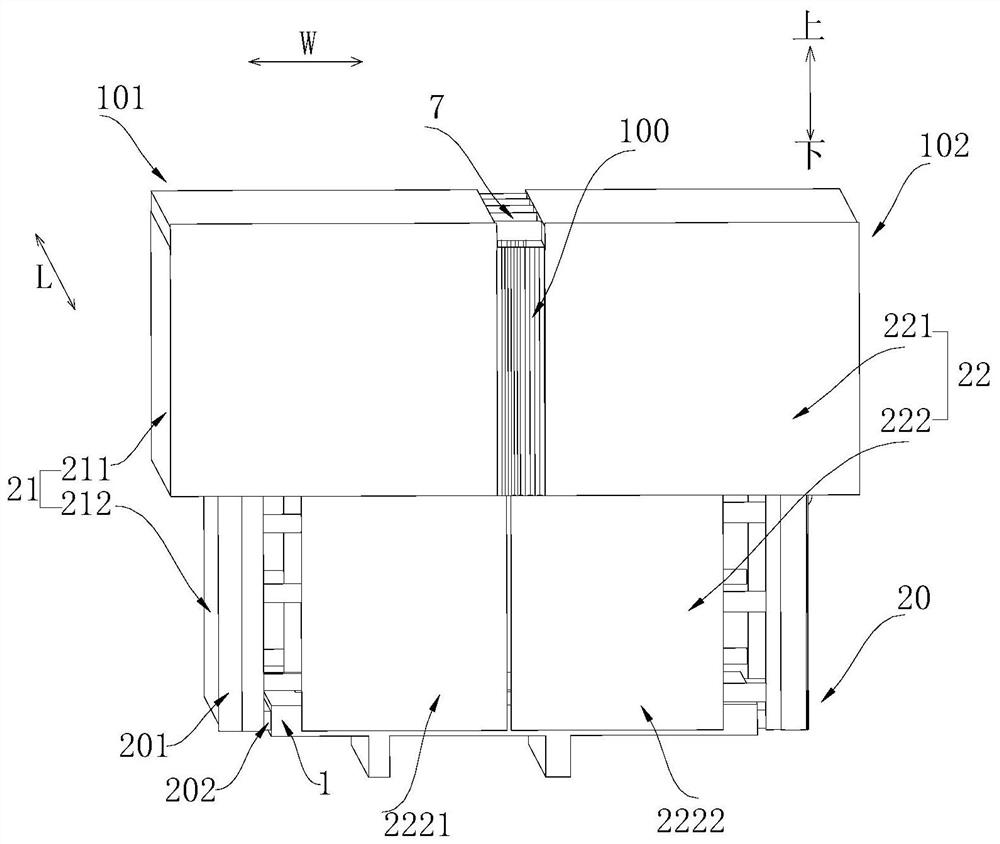

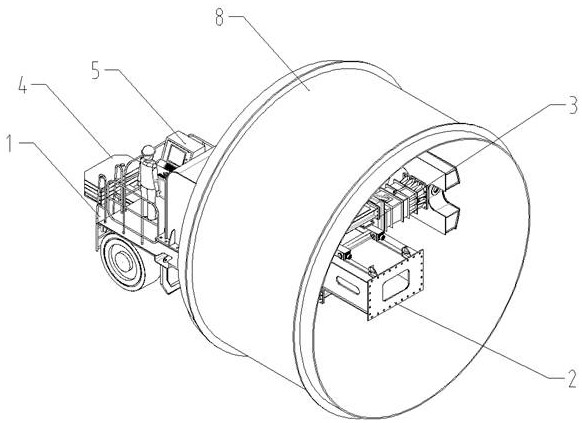

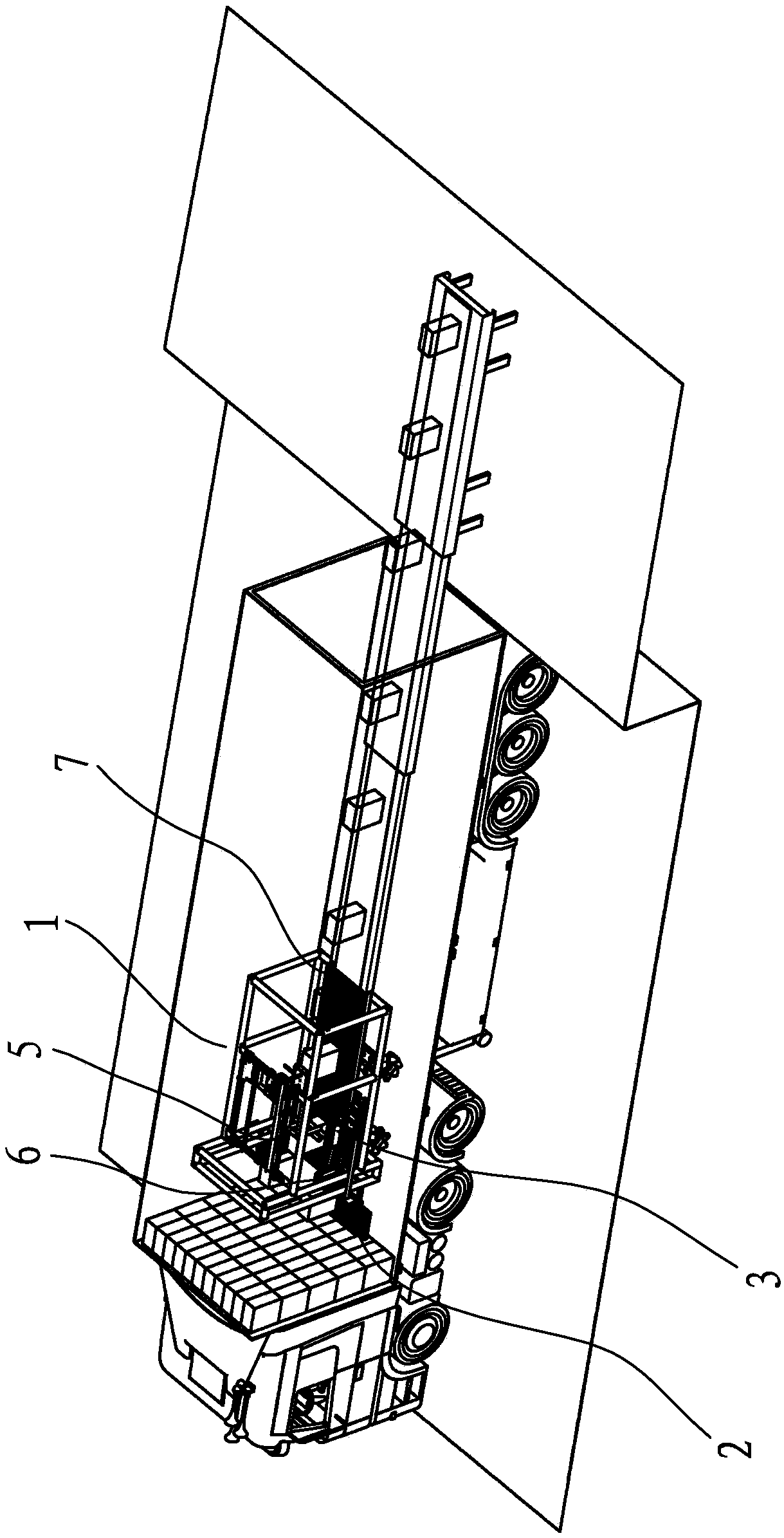

Full-automatic car loader

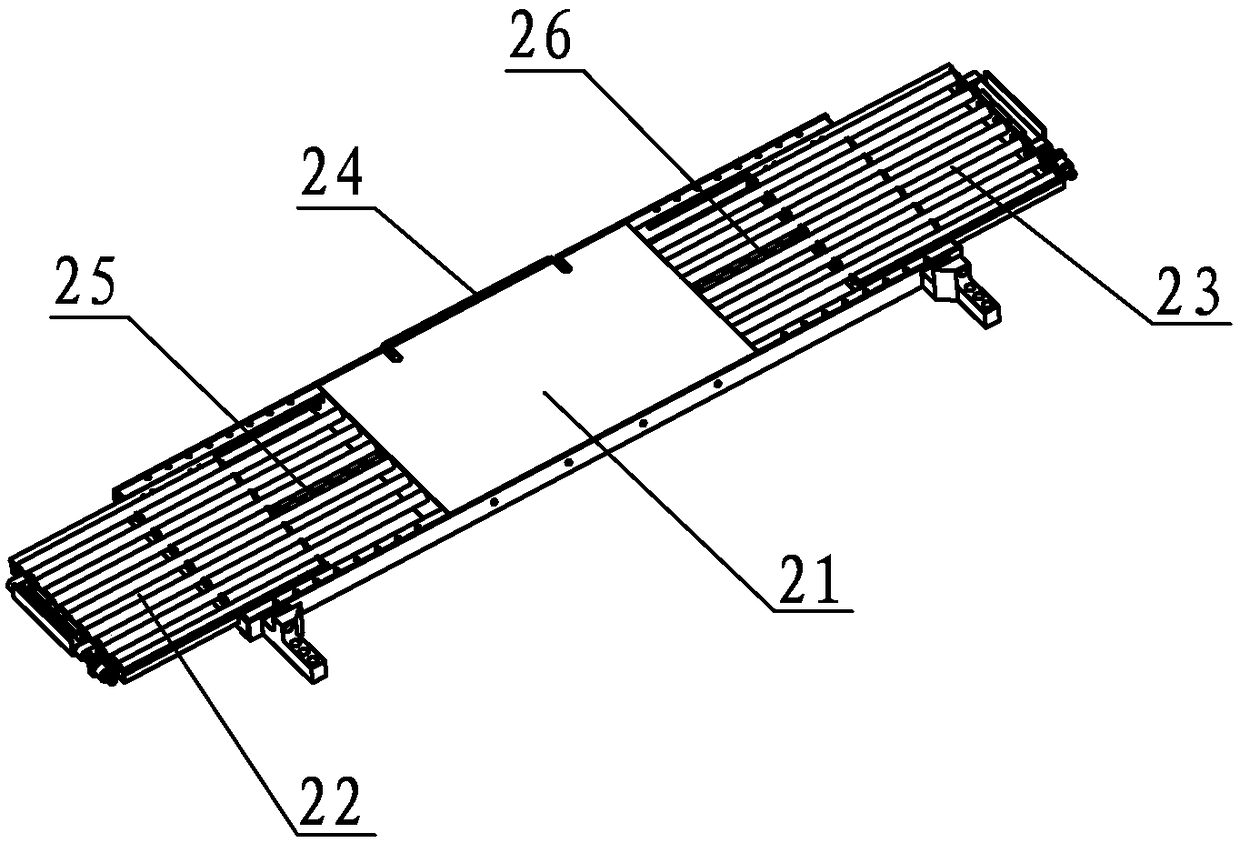

The invention relates to a full-automatic car loader. The full-automatic car loader comprises a wheel-type walking frame, a supporting board mechanism, a leading-in mechanism, a lifting mechanism, a case pushing mechanism, a case allocating mechanism, a conveying mechanism and a layer pushing mechanism; a distance detection unit is arranged on the wheel-type walking frame and can position the motion trail of the wheel-type walking frame; the supporting board mechanism, the lifting mechanism and the layer pushing mechanism share the same power source; the supporting board mechanism and the layer pushing mechanism are provided with telescoping devices and can be adjusted according to the width of a boxcar so as to adapt to the change of the width of the boxcar; the lifting mechanism adopts two lifting guide rails and can adjust the frame and the height of lifting according to the height of the boxcar so as to adapt to the change of the height of the boxcar; two pairs of horizontal guide rails and driving mechanisms are arranged on the leading-in mechanism, so that the leading-in mechanism moves back and forth and right and left so as to enable targeted materials to move into the supporting board mechanism accurately; and the movement of the lifting mechanism, the case pushing mechanism, the case allocating mechanism, and the layer pushing mechanism is all controlled by a PLC control unit.

Owner:HARBIN BOSHI AUTOMATION

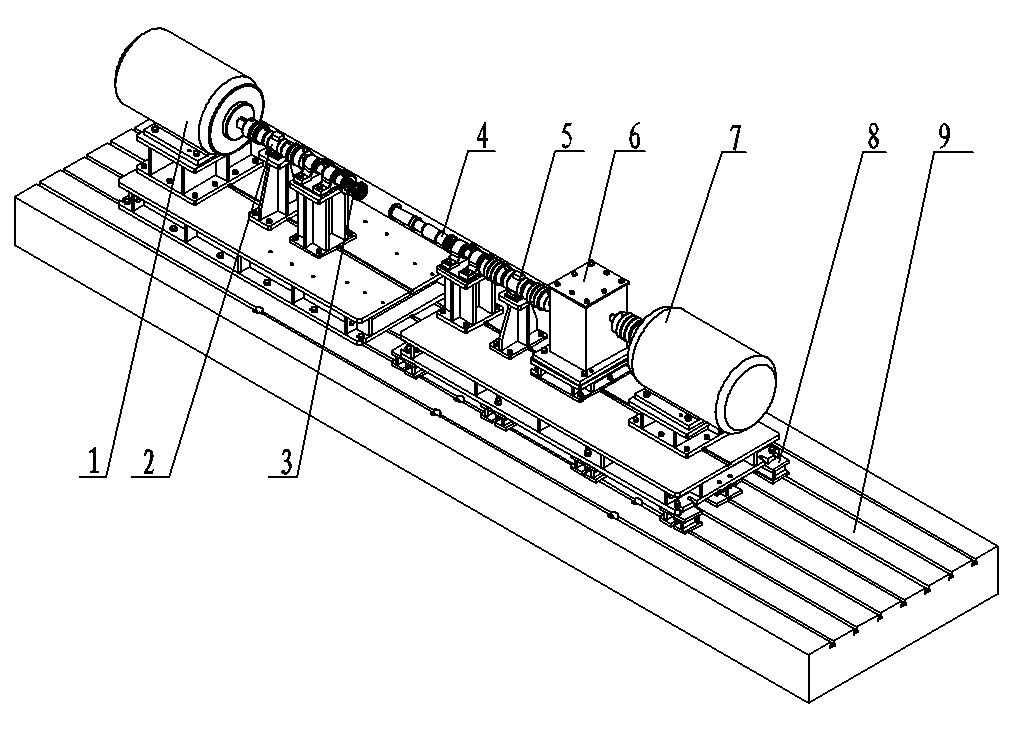

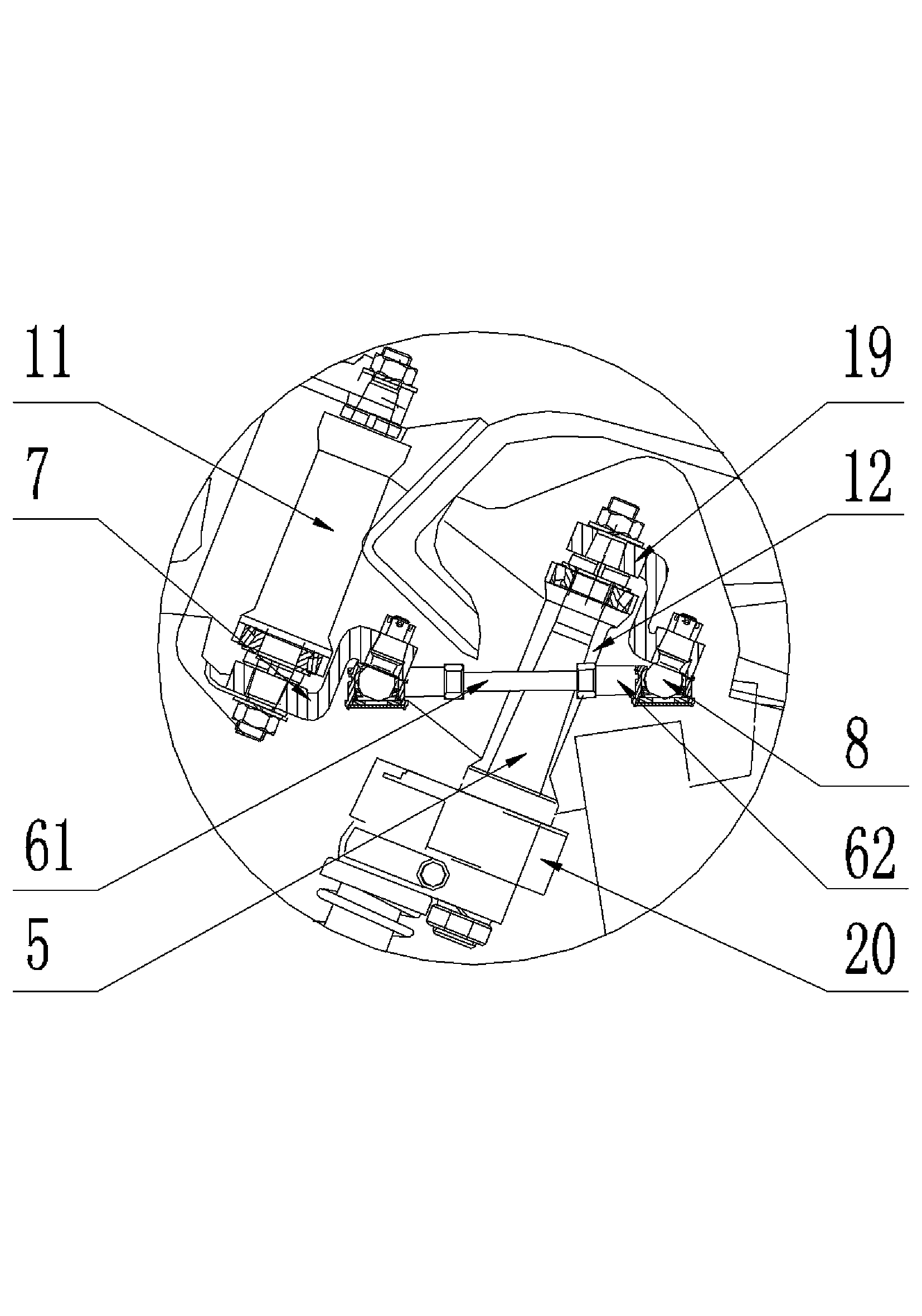

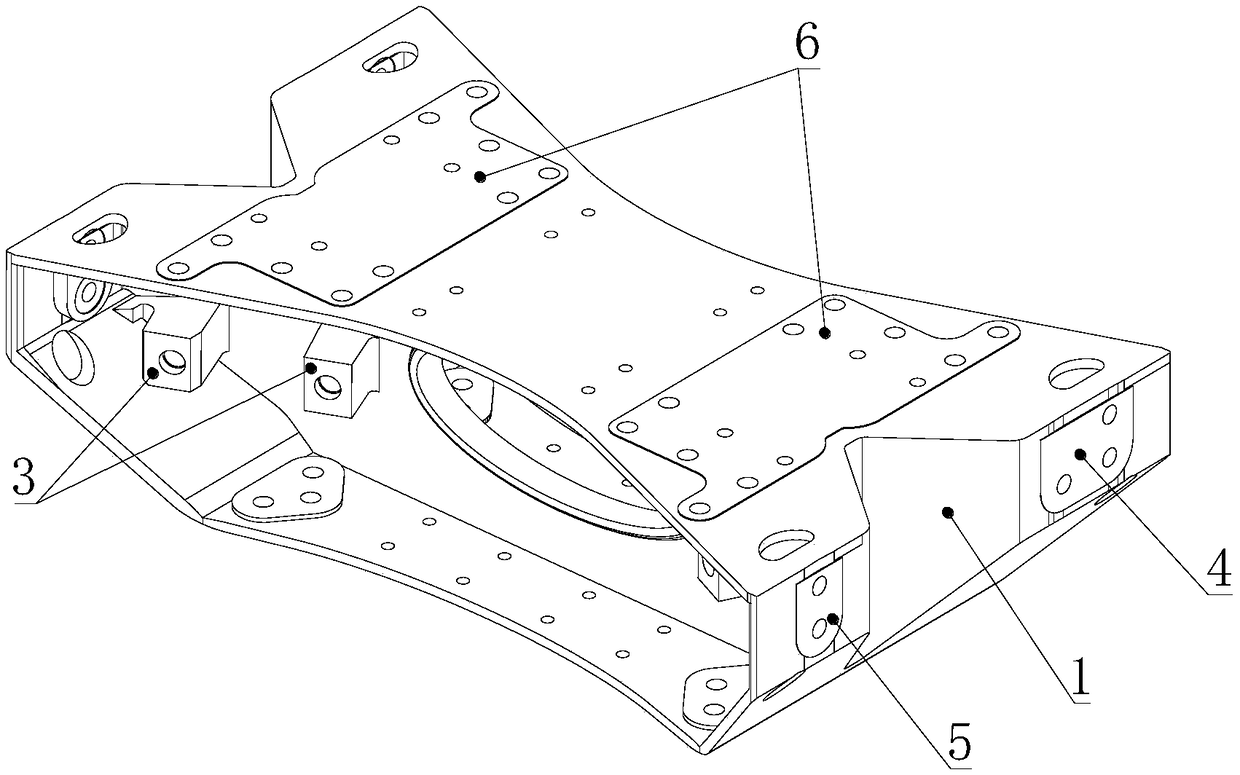

Testing table for testing of forklift transmission part

ActiveCN103018039AMeet driveMeet loading needsMachine gearing/transmission testingModularityStructural engineering

The invention discloses a testing table for testing of a forklift transmission part. The testing table comprises a cast iron base plate, a driving table frame and a load table frame, wherein longitudinal T-shaped installation grooves are evenly distributed on the top surface, the driving table frame and the load table frame are installed and positioned on the cast iron base plate, and the corresponding positions of the driving table frame and the load table frame can be adjusted. The driving table frame comprises a driving transmission chain, a driving support assembly and a driving base plate; and the load table frame comprises a load transmission chain, a load support assembly and a load base plate. The testing table for testing of the forklift transmission part has the advantages of adopting integration and modularizing design, being capable of testing transmission parts different in type and model by combing and tool replacing, and being wide in application range. Modules of the testing table have various functions, can be individually used as a driving power source, and can be individually used as a load loading device or be combined together to meet the requirements of driving and loading of a member to be tested.

Owner:ANHUI HELI CO LTD

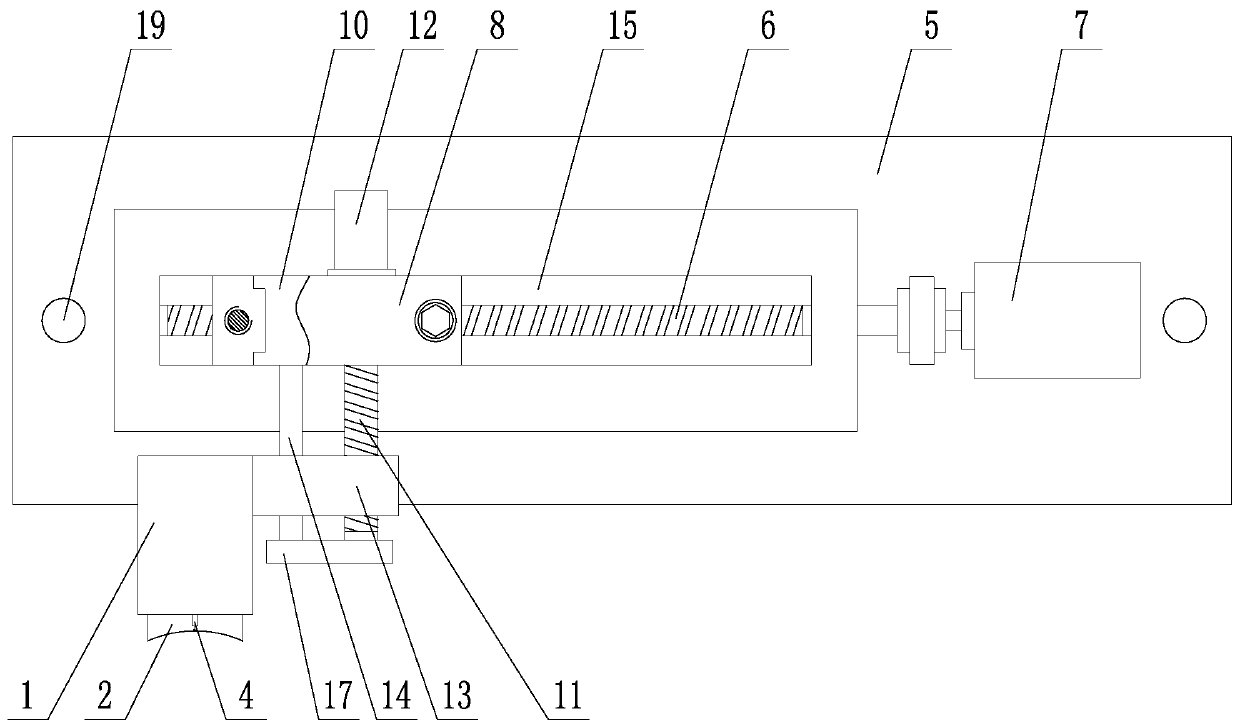

Automatic loading device of stress ring

InactiveCN101793653ARealize automatic loadingMeet loading needsInvestigating abrasion/wear resistanceEngineeringCorrosion

The invention relates to an automatic loading device of a stress ring for a hydrogen sulfide resistant stress corrosion test, belonging to the technical field of mechanical tests. The automatic loading device comprises a stand, a transmission pressurization mechanism and a stress ring positioning board, wherein the stress ring positioning board is horizontally arranged at the bottom of the stand, and the transmission pressurization mechanism is positioned in the stand and is vertically arranged above the stress ring positioning board. The transmission pressurization mechanism comprises a stepping motor, a synchronous belt transmission mechanism, a vertical driving mechanism and a connection pressurization mechanism, wherein the stepping motor is fixedly arranged at the upper part of the stand and is connected with one end of the synchronous belt transmission mechanism; the other end of the synchronous belt transmission mechanism is connected with the vertical driving mechanism; the vertical driving mechanism is rotatablely arranged at the upper part of the stand vertically; and the connection pressurization mechanism is fixedly arranged at the lower end of the vertical driving mechanism and is in contact with the stress ring to be measured. The invention realizes the purpose of loading the load of which the loading force is 0.1-40KN through a compact structure.

Owner:SHANGHAI JIAO TONG UNIV

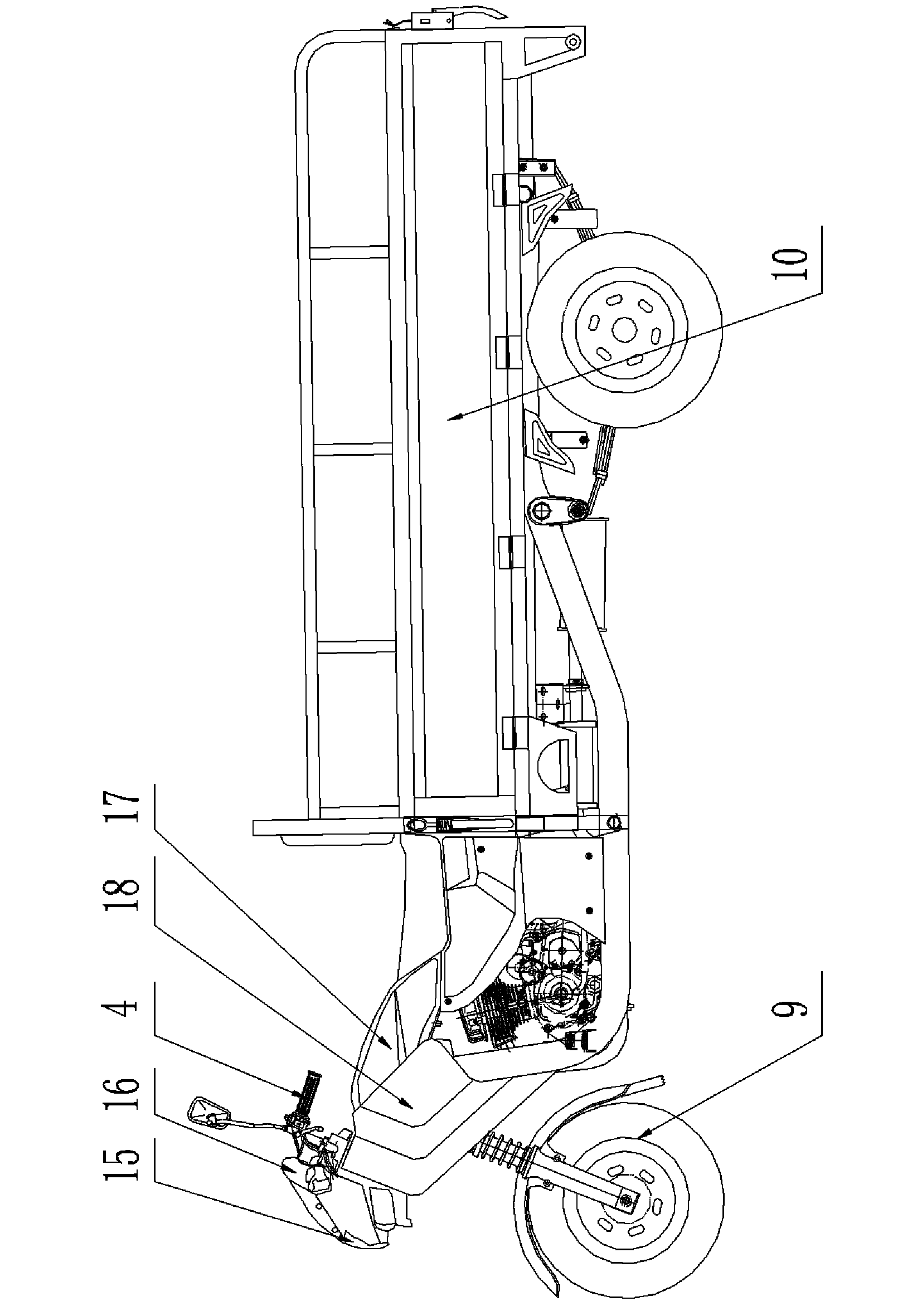

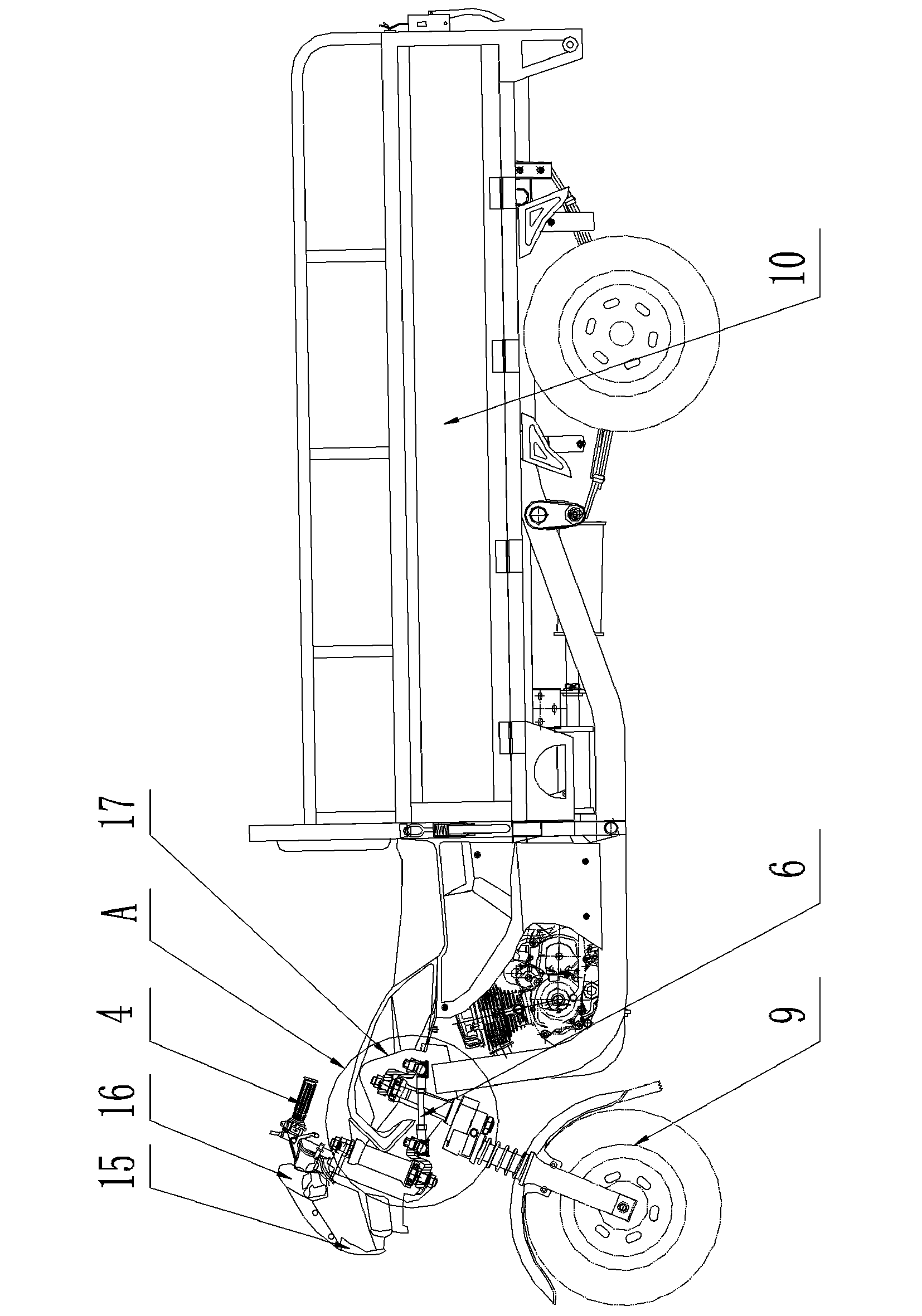

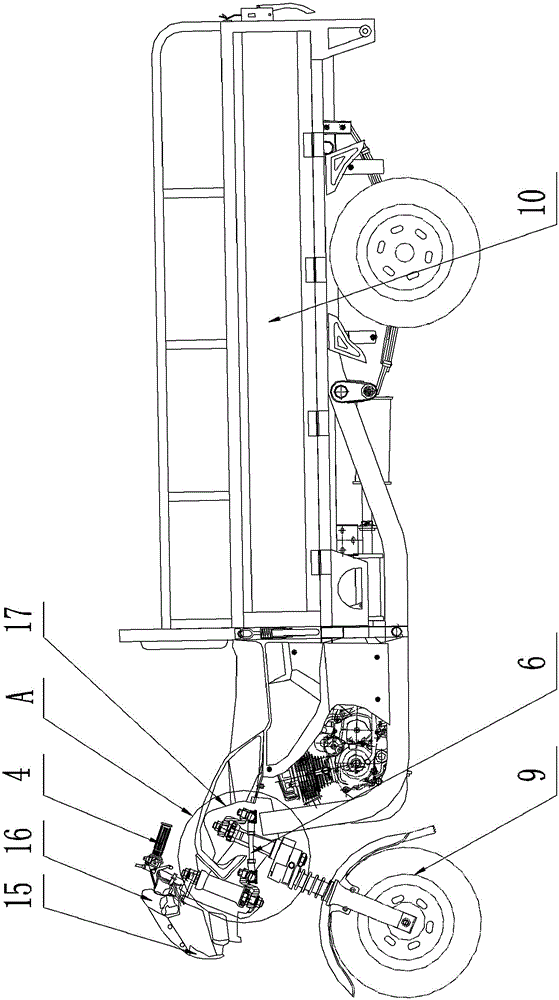

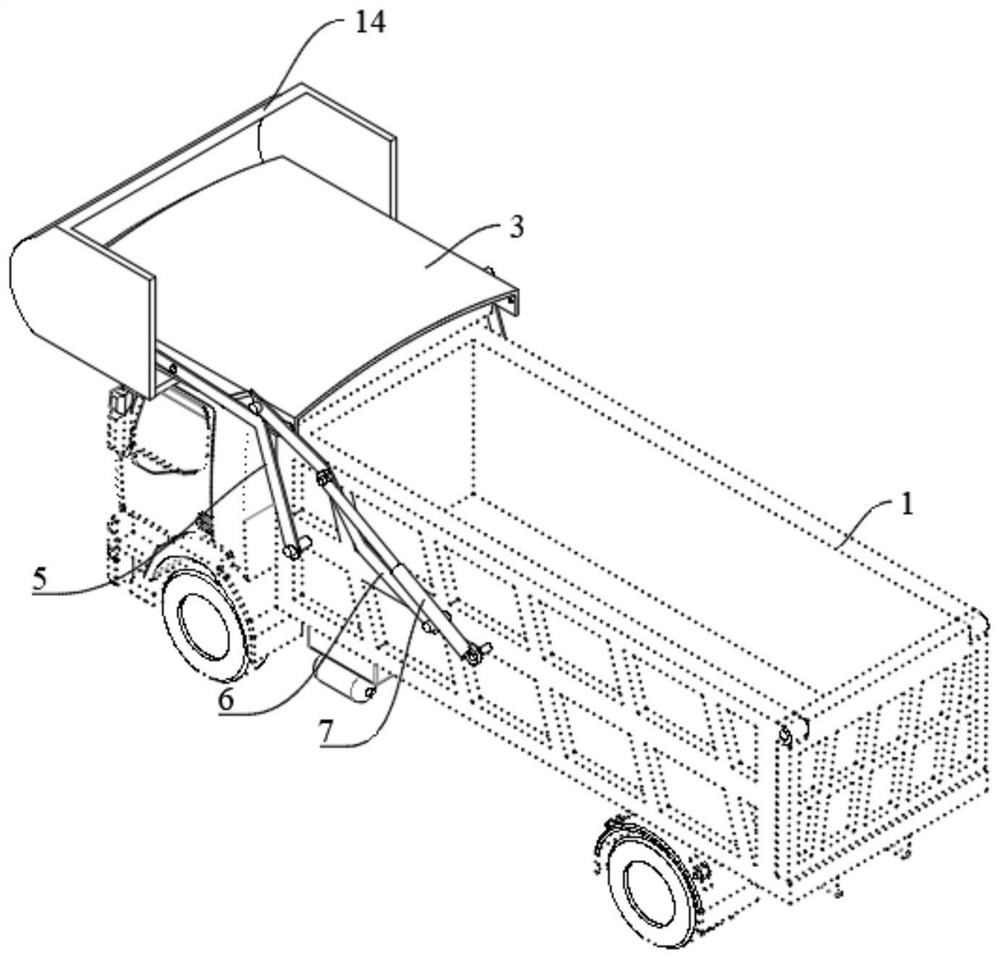

Right three-wheeled motorcycle

ActiveCN103192917AShorten invalid lengthConducive to driving safetyPassenger cyclesChain/belt transmissionVehicle frameControl engineering

The invention discloses a right three-wheeled motorcycle. The right three-wheeled motorcycle comprises a frame with a main beam and a container support beam, wherein a headstock stand pipe for installing a steering post is welded at the front end of the main beam; a handle pipe steering post for installing a handle pipe is rotatably matched in the headstock stand pipe; a handle pipe is arranged at the upper end of the handle pipe steering post; a front fork stand pipe for installing a front fork steering post is welded on the main beam at the back of the headstock stand pipe; a front fork steering post is rotatably matched in the front fork stand pipe; and the handle pipe steering post is connected with the front fork steering post through a linkage device. Compared with a conventional right three-wheeled motorcycle, the front fork steering post of the motorcycle moves backward, so that the invalid length between the front end of a front wheel and the front end of a head lamp of the right three-wheeled motorcycle is shortened; and therefore, a container of the right three-wheeled motorcycle can be lengthened within the specified overall length of the motorcycle, the transportation efficiency can be improved, and the requirements of customers can be met.

Owner:CHONGQING ASTRONAUTIC BASHAN MOTORCYCLE MFG

Railway wagon body

ActiveCN107672612AReduce downswingReduce external inflationRailway transportUnderframesTruckRib cage

The invention discloses a railway wagon body. The railway wagon body is an integral bearing type wagon body formed by combined welding of an underframe, side walls and end walls and of a full-steel welded skeleton-type structure; the underframe is composed of a middle beam, variable section box-type body bolsters, cross beams, I-shaped cross beams, a floor and the like; each side wall is composedof pillow columns, groove-type side columns, T-shaped side columns, transverse belts, side plates and the like; the middle beam serves as a keel; the underframe and the side walls are connected both horizontally and vertically to form a rib of a skeleton; the keel and the rib bear the longitudinal force and the transverse force correspondingly and do not interfere with each other; and the side walls are inclined, the side columns are arranged externally, and the interior of the wagon body is flat and smooth. The railway wagon body is not provided with devices such as stay bars, partition wallsand side column reinforcing seats of a traditional ore open wagon; the underframe and the side walls are subjected to reinforcing design, and therefore, the wagon body can adapt to the requirement ofa high-frequency car dumper for rapid turnover and unloading, and through the smooth inner surface, goods are prevented from adhering and accordingly being stacked when unloaded, the moving speed ofthe goods is high, the complete-unloading rate is high; and the volume is large, so that the requirement of loading the goods with the small specific weight and large viscosity is met.

Owner:CRRC MEISHAN

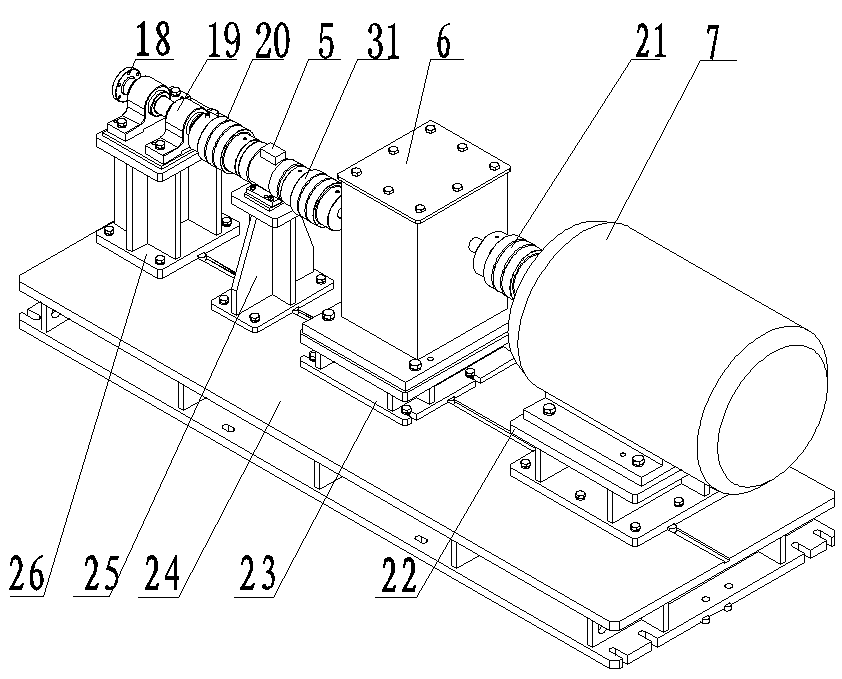

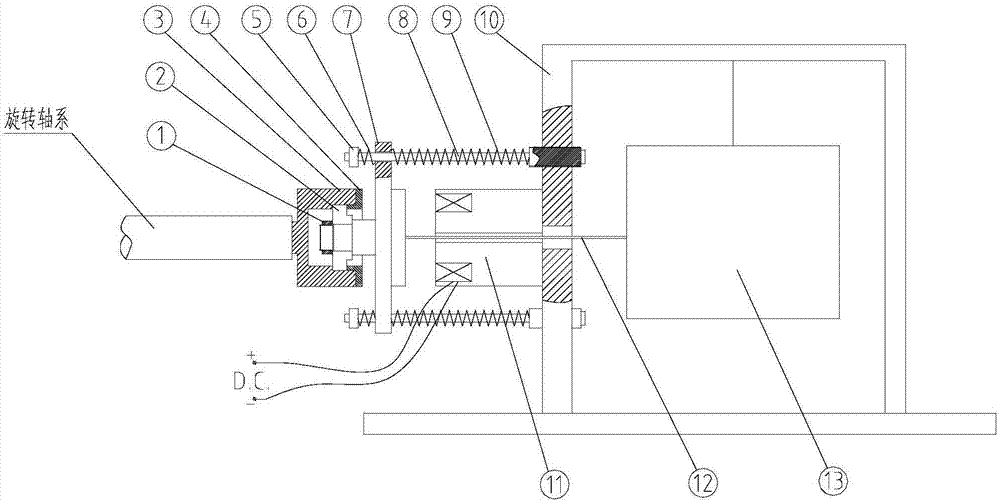

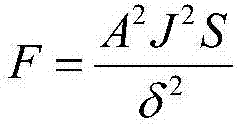

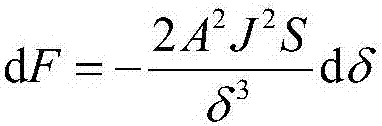

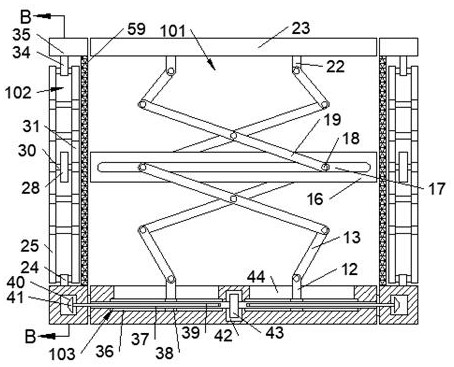

Low-dynamic-stiffness longitudinal loaded excitation device for rotor shaft system

PendingCN107345856AReduce dynamic stiffnessLow vertical loadingMachine gearing/transmission testingVibration testingPhysicsRotational axis

The invention provides a longitudinal loading device with low dynamic stiffness characteristic for a rotor shaft system. The device comprises a servo rotation module, a loading disc, a main spring, an auxiliary spring, a loading screw rod, an electromagnetic suction module, an excitation rod, an electromagnetic vibration exciter and a fixing support, wherein one end of the loading screw rod is fixed on a front panel of the fixing support, and the other end of the loading screw rod runs through the loading disc; the main spring is arranged on the loading screw rod between the fixing support and the loading disc in a sleeving manner; the auxiliary spring is arranged at the tail end of the loading screw rod in a sleeving manner, and is matched with a bolt to compress the loading screw rod and the loading disc; the servo rotation module is arranged at the front end of the loading disc, and is connected with the rotor shaft system; the electromagnetic suction module is arranged on the front panel of the fixing support, and the electromagnetic exciter is rigidly fixed or flexibly suspended on the fixing support; the excitation rod runs through an opening in the front panel of the fixing support and an intermediate hole of the electromagnetic suction module to be fixed at the center of the rear end face of the loading disc. The device can avoid the influence on the longitudinal coherent characteristics of the rotor shaft system caused by a longitudinal loading device.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Special trolley suitable for diversion tunnel large-diameter pressure pipeline

ActiveCN111455945AMeet transportationSolve the problem of quick adjustment and installationWater-power plantsHydro energy generationHydraulic motorHydraulic cylinder

The invention provides a special trolley suitable for a diversion tunnel large-diameter pressure pipeline, and belongs to the technical field of transportation equipment. The trolley is used for solving the problems of difficult transportation and installation of large-diameter pressure pipelines in a tunnel. The trolley comprises a traveling system, a main beam, a support system, a hydraulic system, and an electrical control system, the traveling system comprises a traveling wheel set, a hydraulic motor and a support platform, the left side of the support platform is provided with a counterweight system, the support system comprises a support frame, a support frame traveling mechanism, horizontal support arms and longitudinal support arm, the main beam is fixedly provided with a support frame travelling hydraulic cylinder, the telescopic end of the support frame travelling hydraulic cylinder is fixedly connected with the support frame travelling mechanism, the horizontal support armsare symmetrically distributed on the left and right sides of the support frame, and the longitudinal support arm is vertically arranged above the support arms. The trolley can realize transportation,adjustment, and installation in place of a pressure steel pipe in the tunnel, is suitable for the loading requirements of pipelines of different sizes, is strong in adjustability, and greatly improvesthe construction efficiency and quality.

Owner:SINOHYDRO ENG BUREAU 4 +1

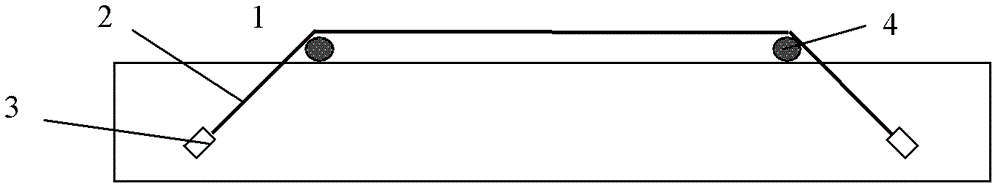

Test apparatus for endurance of flexural member under load-environment coupling

InactiveCN102494945AReduced durabilitySimple structureMaterial strength using tensile/compressive forcesPull forceReinforced concrete

The invention which relates to a test apparatus for mechanical properties of a flexural member under the continuous load action belongs to the civil engineering field, wherein the test apparatus is especially suitable for occasions for testing the endurance of a reinforced concrete flexural member under the environment-load coupling action. The test apparatus comprises the reinforced concrete flexural member, a tension rib, anchoring parts and circular shaft loading rods, the anchoring parts are symmetrically arranged on two ends of the pulling force rib, the circular shaft loading rods are symmetrically arranged on the pulling force rib, and the middle horizontal segment of the pulling force rib is in parallel with the top surface of the reinforced concrete flexural member. The apparatus of the invention, which has the advantages of simple structure, convenient operation, no restriction by the size of the member, no need of pairing or bunching combination, and high strength, can satisfy loading needs of any load ratio.

Owner:ZHEJIANG COLLEGE OF CONSTR

Machining process of heavy truck casting cross beam

The invention provides a machining process of a heavy truck casting cross beam. The machining process comprises the following steps: (S1) top surface machining: positioning grooves on two sides of a casting cross beam, three fixed points on the bottom surface and an auxiliary fixed point are used for positioning to machine an upper reference surface and holes of the casting cross beam; (S2) bottomsurface machining: the casting cross beam is fixed by one surfaces and two pins; and a lower reference surface and hole positions of the casting cross beam are machined; (S3) end surface machining: the casting cross beam is fixed by one surfaces and two pins; two end surfaces of the casting cross beam are machined; and an inclined tabletop is machined; (S4) reverse reaming: one surface and two pins are used for positioning and reverse reaming of holes on the upper reference surface, the lower reference surface and the end surfaces; and (S5) treatment after machining: burrs are cleaned; and high points around the holes are cleaned. The new machining process comprises five procedures, shortens the machining time by 3 times, is fewer in occupied manpower and equipment, and meets the divisional truck loading demands in final assembly scene. The new machining process adopts numerical control equipment, guarantees the machining precision, and guarantees the product quality.

Owner:SINO TRUK JINAN POWER

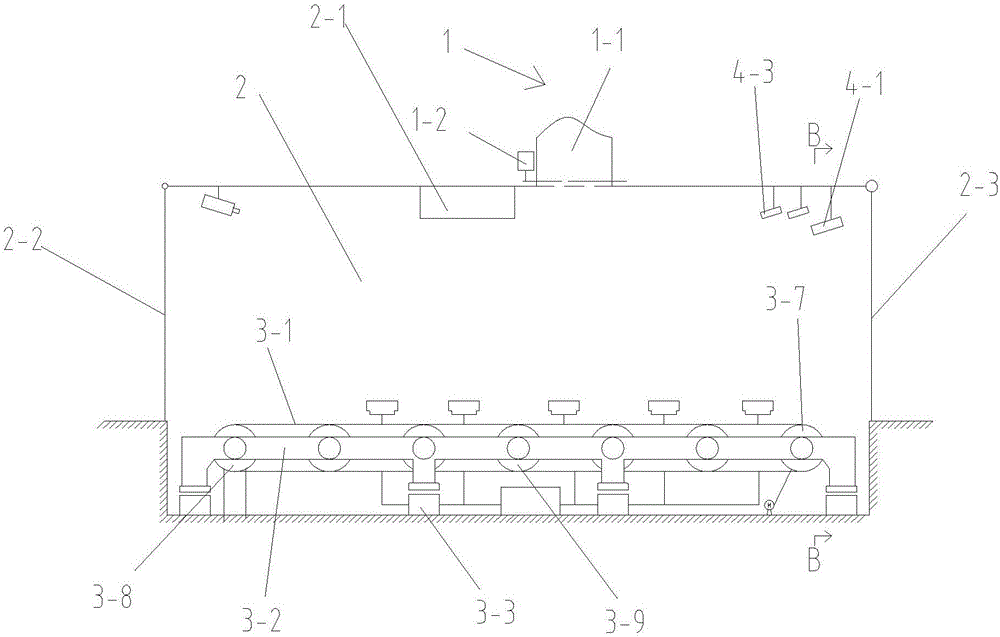

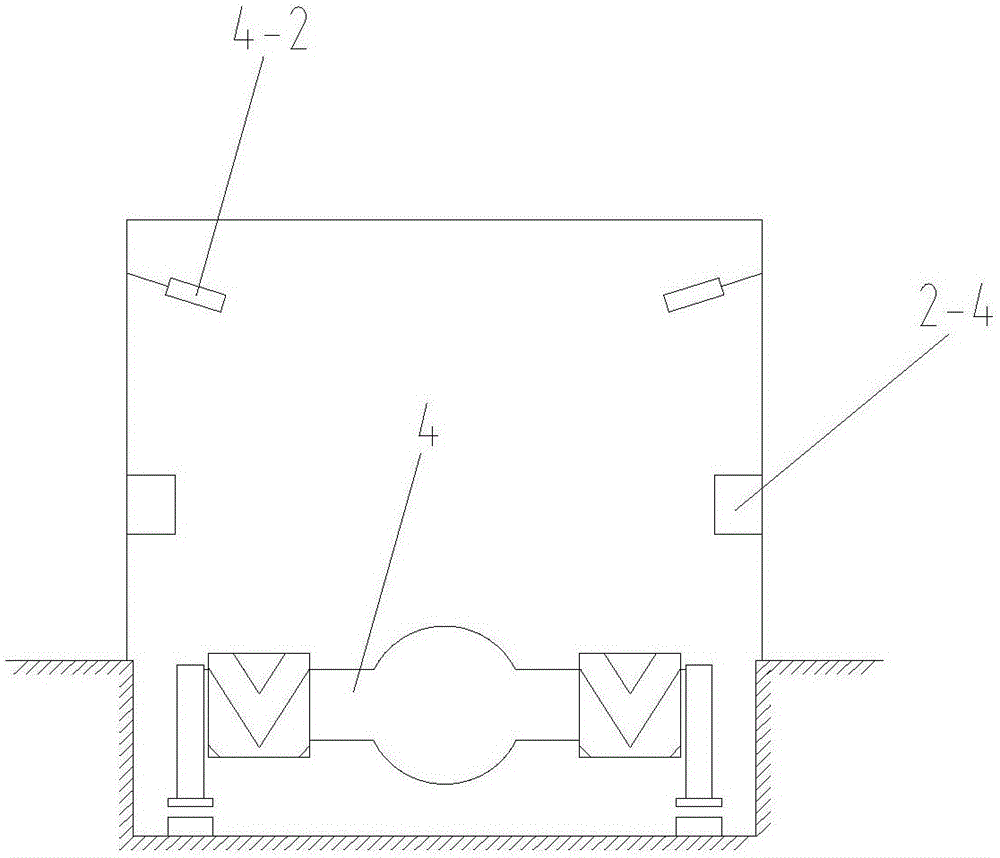

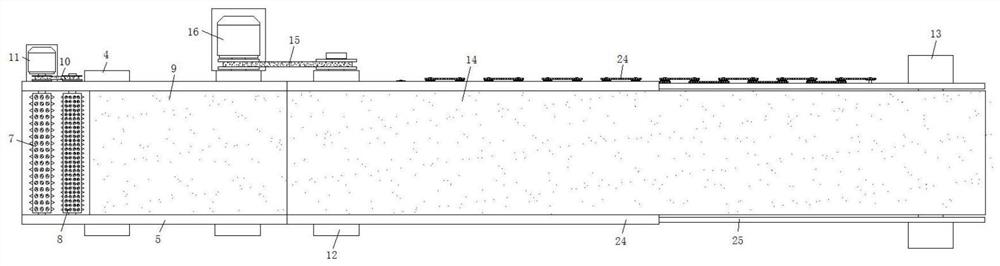

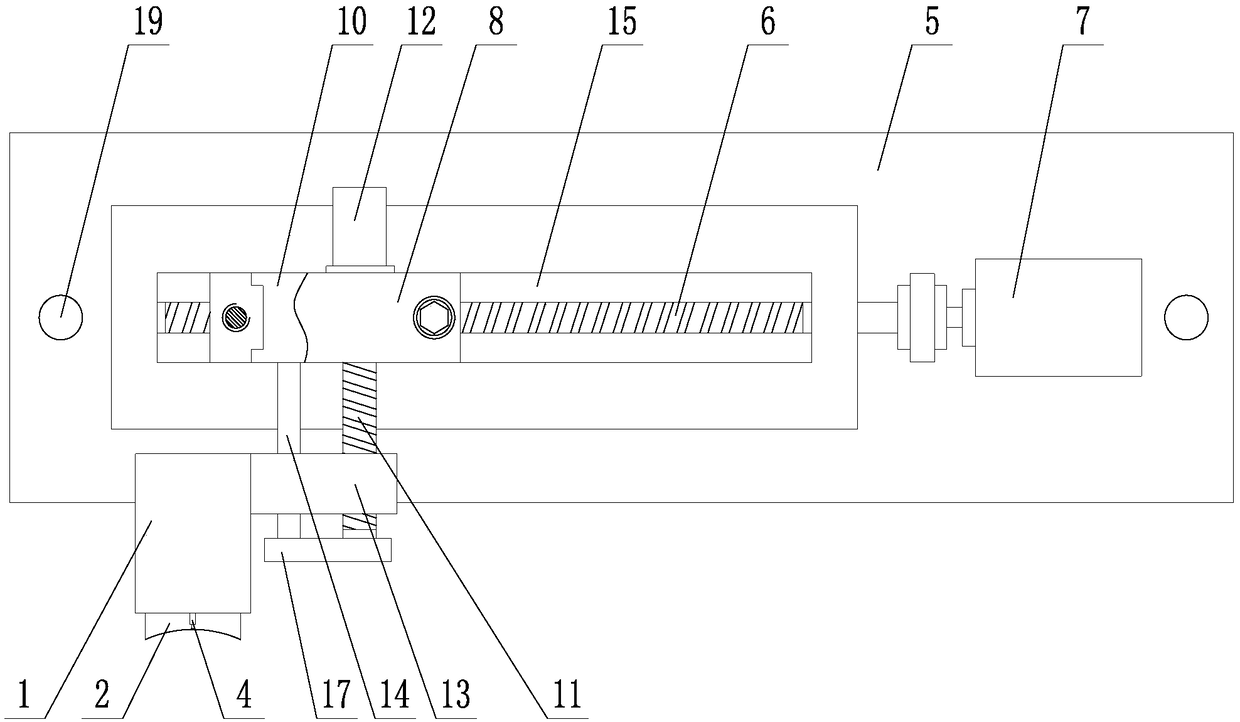

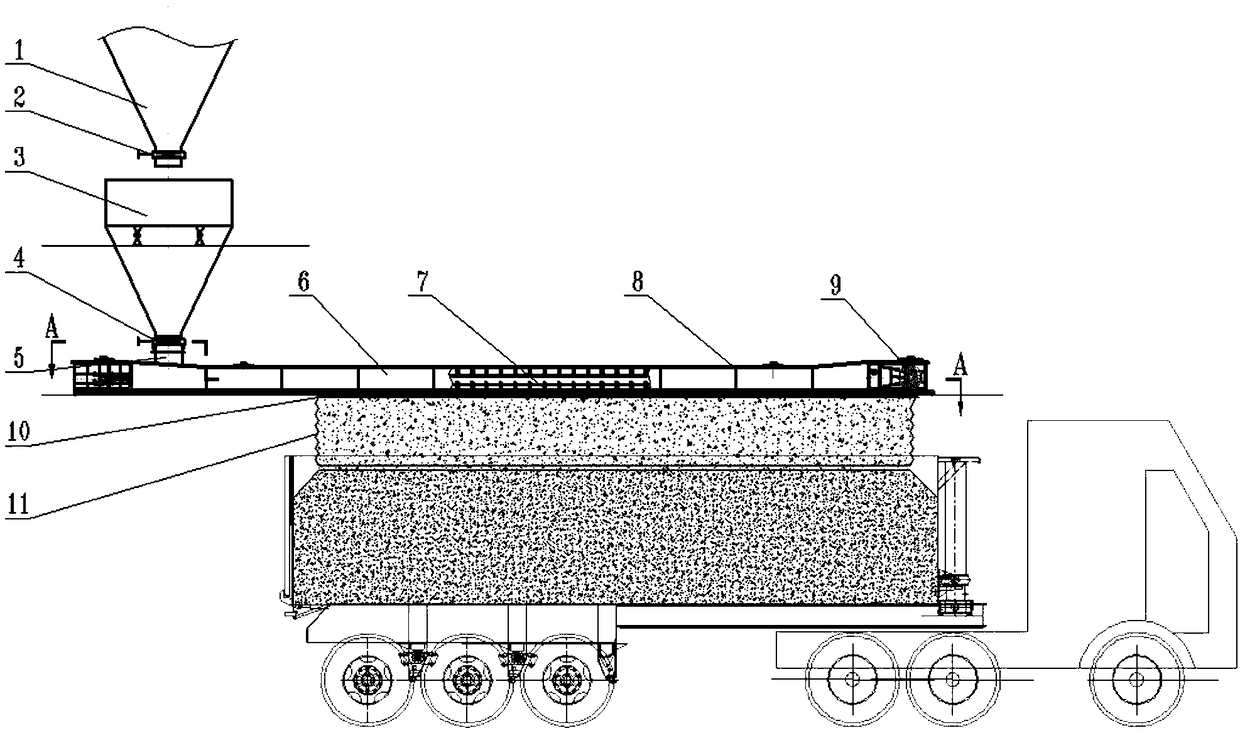

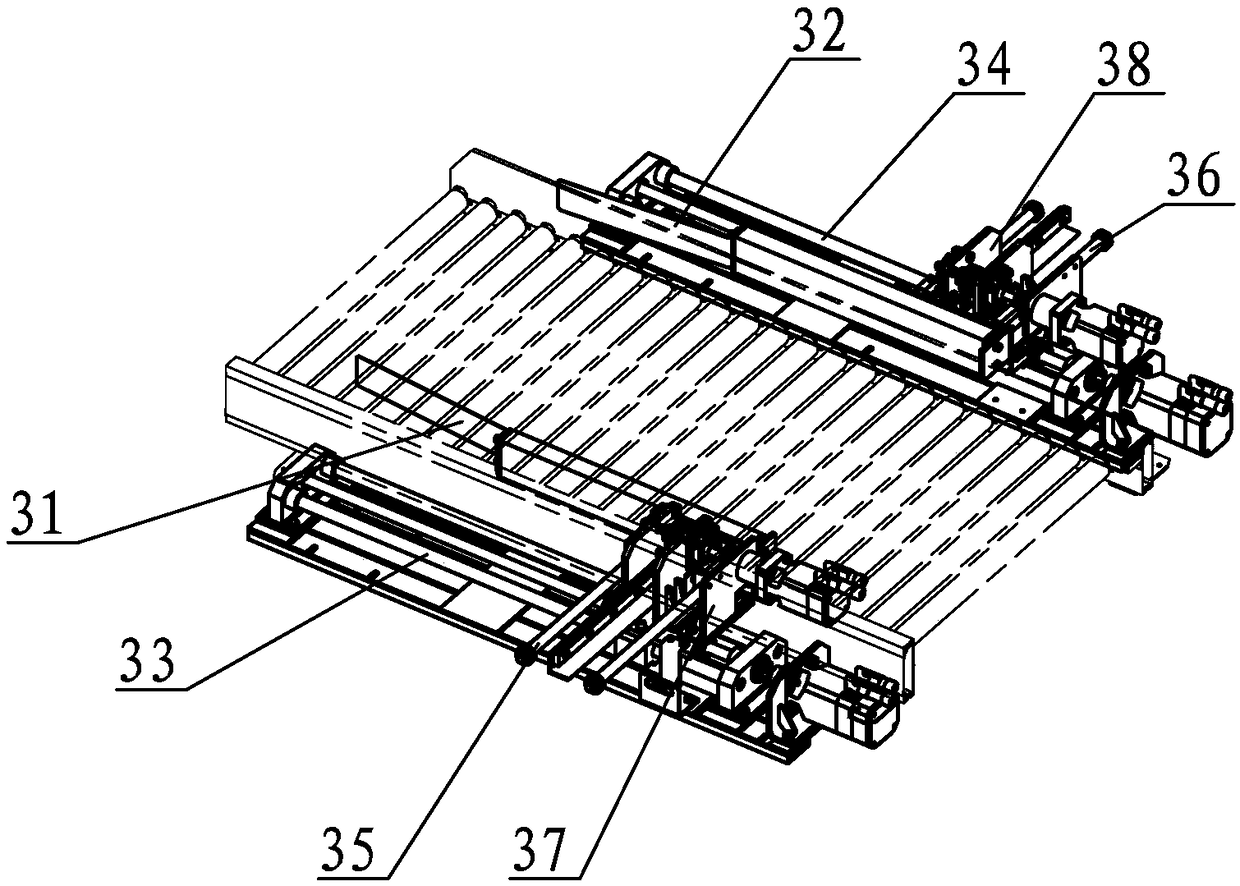

Bituminous mixture loading system based on machine vision and control method

ActiveCN106553990ASimple structureReasonable designLiquid transferring devicesRotary encoderAutomotive engineering

The invention discloses a bituminous mixture loading system based on machine vision and a control method. The system comprises a compartment type loading chamber, a loading door mechanism, a vehicle mobile platform and a machine vision control system. The vehicle mobile platform comprises a track flat plate, a longitudinal beam support, a roller mechanism and a roller driving mechanism. The machine vision control system comprises a control module, an illumination device, a rotating encoder, a pressure sensor, a camera and a photoelectric sensor. The control method comprises the first step of preparation work before loading of a bituminous mixture, the second step of setting of loading parameters of the bituminous mixture, the third step of rapid flat laying and loading, the fourth step of accurate flat laying and loading and the fifth step of unloading of a loading vehicle and scattered material recovery. According to the bituminous mixture loading system, design is reasonable, operation is easy and convenient, the using effect is good, the bituminous mixture loading process is controlled in real time, automatic flat laying type loading is achieved for the bituminous mixture, loading separation of the bituminous mixture is effectively reduced, and environmental pollution is reduced.

Owner:CHANGAN UNIV

A ZWY type mine crawler excavator loader multifunctional conveying device

ActiveCN111994645BMeet loading needsCompact structureConveyorsLoading/unloadingMining engineeringExcavator

Owner:HEFEI UNIV +1

Vehicle container and vehicle

ActiveCN114074720AVersatility and convenienceMeet loading needsLoading-carrying vehicle superstructuresAutomotive engineeringMechanical engineering

Owner:BEIQI FOTON MOTOR CO LTD

Detachable car roof for railway gondola car

InactiveCN104085409AIncrease volumeIncrease carrying capacityRailway transportAxle-box lubricationEngineeringWall plate

The invention relates to a detachable car roof for a railway gondola car. The detachable car roof is characterized in that the detachable car roof comprises two car roof side beams which are equal to upper side beams on the two side walls of the general gondola car in length and two car roof end beams which are equal to the two upper end beams on the two side walls of the general gondola car in length and are connected to the two ends of the two car roof side beams in a fastening mode, a plurality of arched car roof bent beams which are connected between the two car roof side beams in a fastening mode and parallel to each other, a car arched roof plate connected to the inner sides of the car roof bent beams on a fastening mode, two end wall plates connected to the car roof end beams and the car roof bent beams at the two ends in a fastening and a plurality of connecting bases connected to the upper end beams of the two end walls and the upper side beams of the two side walls of the general gondola car at equal intervals in a fastening mode. The detachable car roof has the advantages of being high in strength and rigidity and convenient and fast to use, capable of eliminating the impact on the car roof in the goods transporting process and replacing a boxcar to transport goods which should be protected against the rain water and achieving the functions of both the gondola car and the boxcar. The detachable car roof can be widely applied to general railway gondola cars.

Owner:CRRC BEIJING ERQI VEHICLE CO LTD

Piezoelectric ceramic-based high-precision electric spindle loading mechanism

ActiveCN109443725AHigh loading accuracyImprove loading efficiencyMachine part testingElectricityEngineering

A piezoelectric ceramic-based high-precision electric spindle loading mechanism comprises a loading component and an adjusting component, the loading component is arranged on the adjusting component,the loading component comprises counter force supporting cylinders, a plurality of stress loading cylinders and a plurality of piezoelectric ceramics; each stress loading cylinder is externally sleeved with the counter force supporting cylinder, and each stress loading cylinder has an axial movement degree of freedom in the counter force supporting cylinder; each piezoelectric ceramic is connectedbetween the inner surface of the bottom of the counter force supporting cylinder and the outer surface of the bottom of the stress loading cylinder; the cylinder opening of each stress loading cylinder adopts an arc surface structure, the radian of the cylinder opening of the stress loading cylinder is the same as the radian of the outer surface of an electric spindle to be tested, the pluralityof piezoelectric ceramics are arranged between the inner surface of the bottom of the counter force supporting cylinder and the outer surface of the bottom of the stress loading cylinder, a stress sensor is arranged on the cylinder opening of the counter force supporting cylinder, the stress sensor is in contact fit with the outer surface of the electric spindle to be tested, and the radians of the cylinder openings of the plurality of stress loading cylinders are different.

Owner:SHENYANG JIANZHU UNIVERSITY

Loading device and loading method

PendingCN109230636AUniform unloadingAvoid unbalanced loadConveyorsLoading/unloadingEngineeringMechanical equipment

The invention belongs to the field of mechanical equipment, and mainly relates to a loading device and a loading method. The loading device comprises a scraper for carrying materials, a cloth mouth for unloading the materials is formed in the scraper, the cloth mouth has a cloth curve, the extending direction of the cloth curve intersects with the extending direction of the scraper, the method cannot only achieve uniform loading of the materials during loading of the materials through a loading vehicle, prevent eccentric load, but also no longer dependent on a driver of the loading vehicle tofrequently drive the loading vehicle for loading, and the loading device does not need to be moved.

Owner:CISDI ENG CO LTD

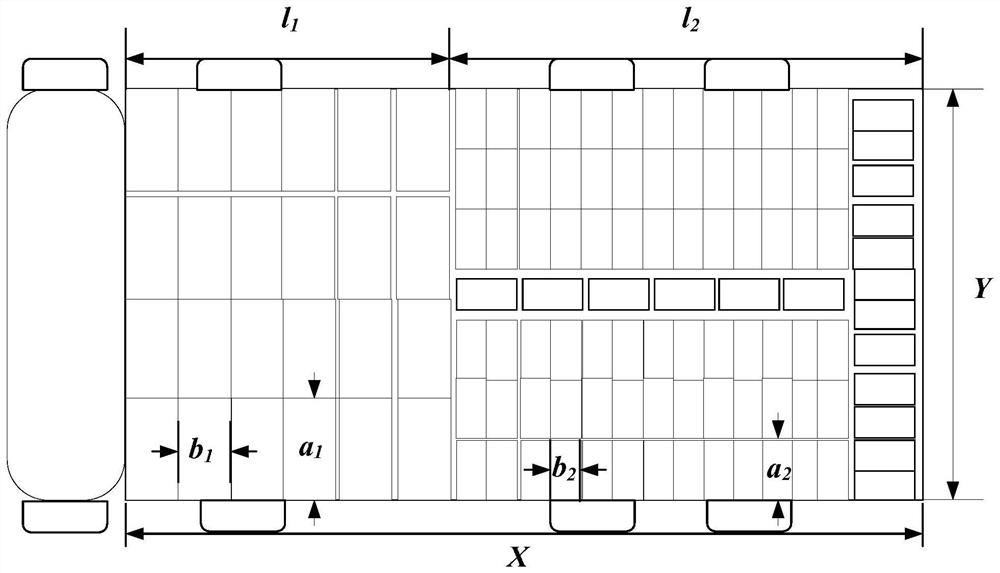

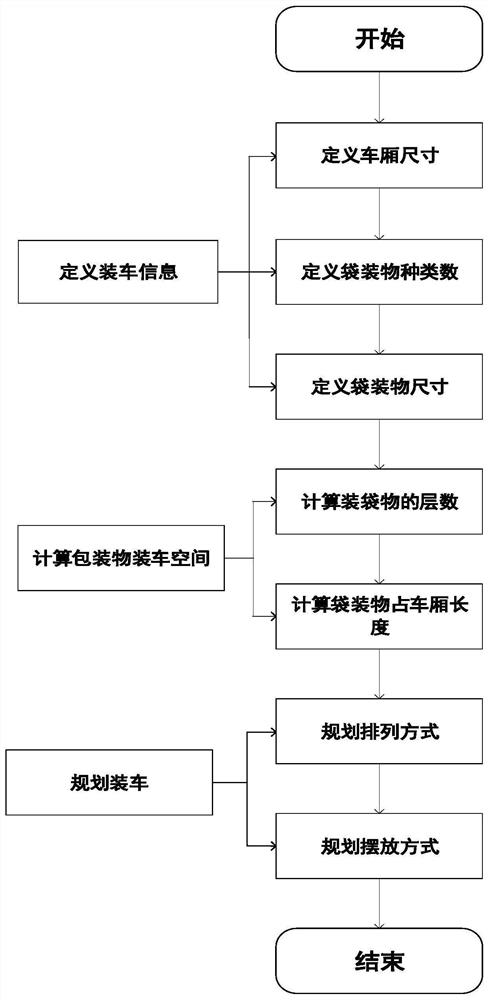

A Palletizing Planning Method for Bags Facing Fully Automatic Loading

ActiveCN111483815BMeet loading needsEasy to transportConveyorsControl devices for conveyorsControl engineeringCarriage

The invention discloses a method for planning palletizing of bagged goods oriented to full-automatic loading, which belongs to the field of automatic loading planning of goods. The system includes: an input module, a storage module, a calculation module and a display module. The input module is connected with the calculation module and the storage module, and the calculation module is connected with the display module. The method used is: determine the information required for loading, calculate the number of layers of bags of each specification in the compartment, put the bags of each specification horizontally in the same area, and calculate the length of the compartment area; place the bags according to the actual situation The heights are arranged horizontally from front to back, and finally, the remaining space in the horizontal and vertical directions is rationally planned and utilized to ensure stable loading. The system and method can provide a reasonable, accurate and safe planning scheme for palletizing in the compartment for single or mixed packing of bags of any model and any specification, and improve the efficiency of automatic loading. It can meet the user's loading requirements for different quantities of any bag type, and the loading and palletizing is more standardized and reasonable, which is conducive to cargo transportation and subsequent unloading.

Owner:NORTHEASTERN UNIV LIAONING

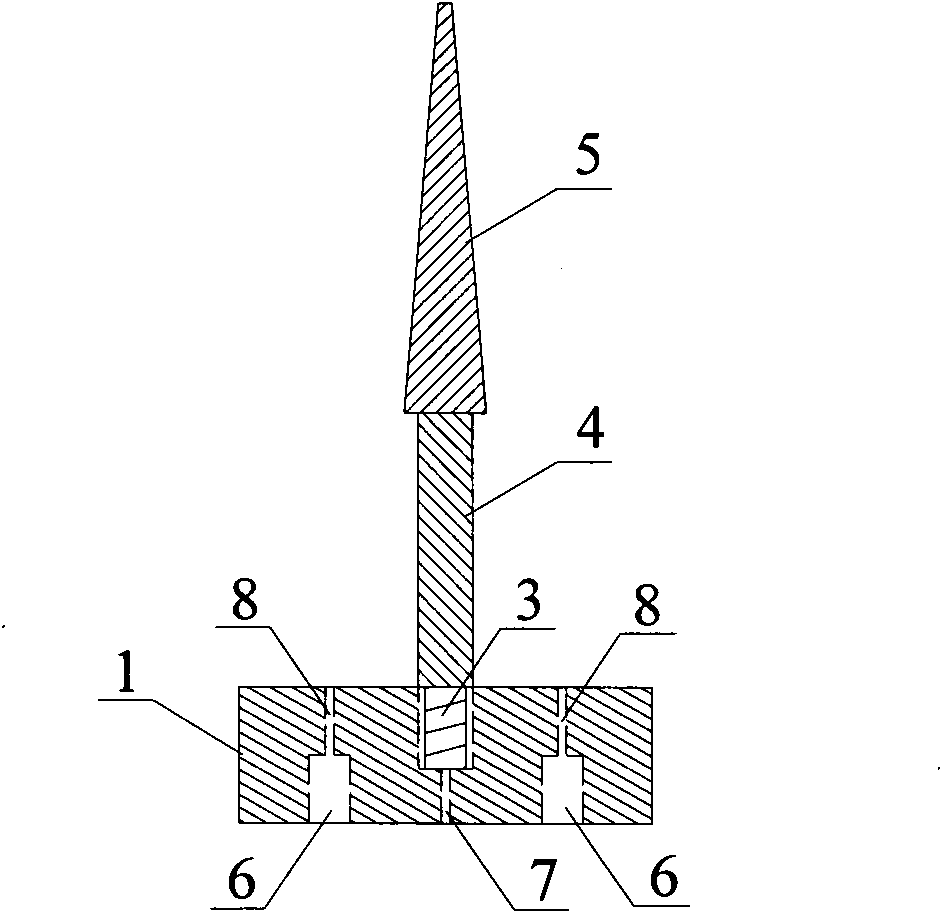

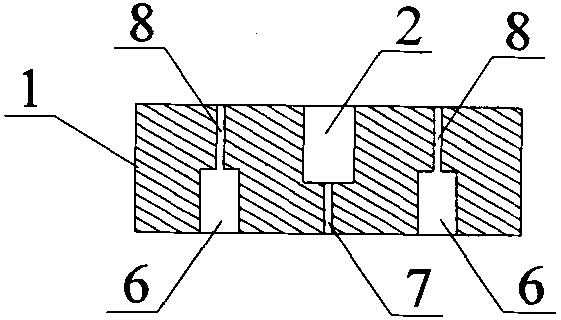

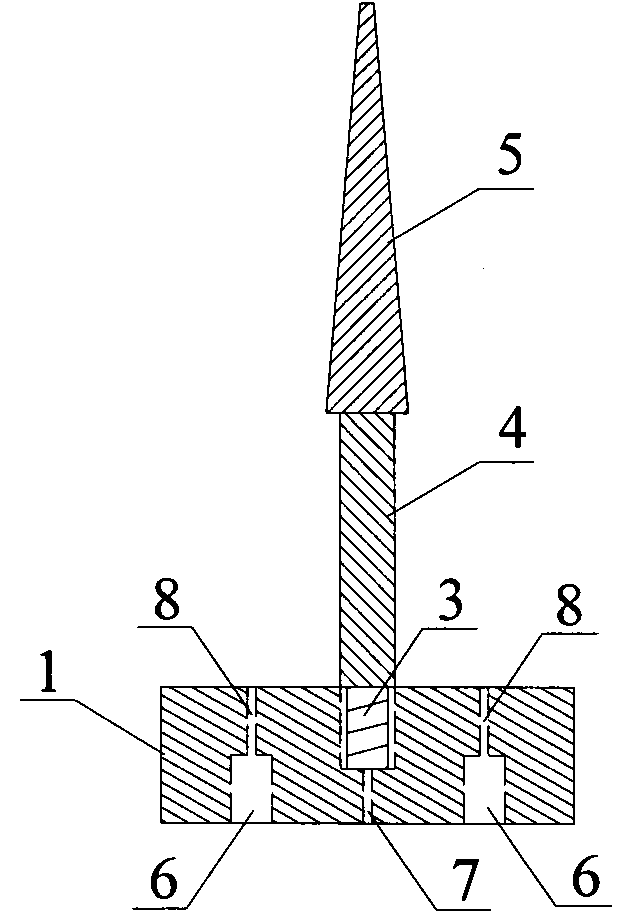

Lower sample loader

InactiveCN101943641BSolve problems encounteredEasy to carryPreparing sample for investigationTest sampleEngineering

The invention discloses a lower sample loader, which is a sample loading device capable of loading a test sample from the lower side of the test sample. The sample loader comprises a base and a bracket, wherein the upper end of the base is provided with inner threaded holes for installing the bracket and the lower end of the base is provided with positioning holes for fixing the base; the bracketcomprises a fastening end, a support post and a loading end; the fastening end is positioned at the lower end of the support post for fixedly connecting the bracket with the base; and the loading endis positioned at the upper end of the support post for loading samples. The sample loader has the advantages of disassembly capability, portability, positioning capability, convenient use, reliable performance, strong universality and the like, can be widely applied to the lower loading of test samples, provides a useful solution for upgrading the loading way of the test samples in the scientificresearch and experimental teaching, in particular for solving the problem of loading samples by using the conventional hanging sample loading methods in the special locations, and is particularly suitable for loading samples during the dynamic test of degradation performance of medical magnesium alloy.

Owner:SOUTH CHINA UNIV OF TECH

A special trolley suitable for large-diameter pressure pipes in diversion tunnels

ActiveCN111455945BMeet transportationSolve the problem of quick adjustment and installationWater-power plantsHydro energy generationSteel tubeHydraulic pressure

The invention provides a special trolley suitable for large-diameter pressure pipes in water diversion tunnels, belongs to the technical field of transportation equipment, and is used to solve the problem of difficult transportation and installation of large-diameter pressure pipes in tunnels. The trolley includes a walking system, a main beam, a support system, a hydraulic system and an electrical control system. The walking system includes a walking wheel set, a hydraulic motor and a support platform. A counterweight system is provided on the left side of the support platform. The support system includes a support frame, The supporting frame traveling mechanism, the transverse supporting arm and the longitudinal supporting arm, the supporting frame traveling hydraulic cylinder is fixed on the main beam, the telescopic end of the supporting frame traveling hydraulic cylinder is fixedly connected with the supporting traveling mechanism, and the transverse supporting arms are symmetrically distributed on the left and right sides of the supporting frame. On the side, the longitudinal support arm is vertically arranged on the upper part of the support arm. The invention can realize the transportation, adjustment and installation of the pressure steel pipe in the tunnel, is suitable for the loading requirements of pipe fittings of different sizes, has strong adjustability, and greatly improves the construction efficiency and quality.

Owner:SINOHYDRO ENG BUREAU 4 +1

A machine vision-based asphalt mixture loading system and control method

ActiveCN106553990BSimple structureReasonable designLiquid transferring devicesMachine visionControl system

The invention discloses an asphalt mixture loading system and control method based on machine vision. The system includes a van loading room, a material door mechanism, a vehicle moving platform and a machine vision control system. The vehicle moving platform includes a crawler flat plate , a longitudinal beam support, a roller mechanism and a roller driving mechanism, the machine vision control system includes a control module, an illumination device, a rotary encoder and a pressure sensor, as well as a video camera and a photoelectric sensor; the control method includes: step 1, asphalt mixture loading Preparations before the vehicle; Step 2, setting the loading parameters of the asphalt mixture; Step 3, fast flat loading; Step 4, precise flat loading; Step 5, pouring out the loading vehicle and recycling the material. The invention has the advantages of reasonable design, simple operation and good use effect, real-time control of the loading process of the asphalt mixture, realizing automatic flat loading of the asphalt mixture, effectively reducing the loading segregation of the asphalt mixture, and reducing environmental pollution.

Owner:CHANGAN UNIV

three-wheeled motorcycle

ActiveCN103192917BShorten invalid lengthReduce shockPassenger cyclesChain/belt transmissionSteering columnVehicle frame

The invention discloses a right three-wheeled motorcycle. The right three-wheeled motorcycle comprises a frame with a main beam and a container support beam, wherein a headstock stand pipe for installing a steering post is welded at the front end of the main beam; a handle pipe steering post for installing a handle pipe is rotatably matched in the headstock stand pipe; a handle pipe is arranged at the upper end of the handle pipe steering post; a front fork stand pipe for installing a front fork steering post is welded on the main beam at the back of the headstock stand pipe; a front fork steering post is rotatably matched in the front fork stand pipe; and the handle pipe steering post is connected with the front fork steering post through a linkage device. Compared with a conventional right three-wheeled motorcycle, the front fork steering post of the motorcycle moves backward, so that the invalid length between the front end of a front wheel and the front end of a head lamp of the right three-wheeled motorcycle is shortened; and therefore, a container of the right three-wheeled motorcycle can be lengthened within the specified overall length of the motorcycle, the transportation efficiency can be improved, and the requirements of customers can be met.

Owner:CHONGQING ASTRONAUTIC BASHAN MOTORCYCLE MFG

Automatic loading device of stress ring

InactiveCN101793653BRealize the function of stress loadingRealize automatic loadingInvestigating abrasion/wear resistanceEngineeringCorrosion

The invention relates to an automatic loading device of a stress ring for a hydrogen sulfide resistant stress corrosion test, belonging to the technical field of mechanical tests. The automatic loading device comprises a stand, a transmission pressurization mechanism and a stress ring positioning board, wherein the stress ring positioning board is horizontally arranged at the bottom of the stand,and the transmission pressurization mechanism is positioned in the stand and is vertically arranged above the stress ring positioning board. The transmission pressurization mechanism comprises a stepping motor, a synchronous belt transmission mechanism, a vertical driving mechanism and a connection pressurization mechanism, wherein the stepping motor is fixedly arranged at the upper part of the stand and is connected with one end of the synchronous belt transmission mechanism; the other end of the synchronous belt transmission mechanism is connected with the vertical driving mechanism; the vertical driving mechanism is rotatablely arranged at the upper part of the stand vertically; and the connection pressurization mechanism is fixedly arranged at the lower end of the vertical driving mechanism and is in contact with the stress ring to be measured. The invention realizes the purpose of loading the load of which the loading force is 0.1-40KN through a compact structure.

Owner:SHANGHAI JIAOTONG UNIV

Lower sample loader

InactiveCN101943641AEasy to carry and useGuaranteed stabilityPreparing sample for investigationTest sampleEngineering

The invention discloses a lower sample loader, which is a sample loading device capable of loading a test sample from the lower side of the test sample. The sample loader comprises a base and a bracket, wherein the upper end of the base is provided with inner threaded holes for installing the bracket and the lower end of the base is provided with positioning holes for fixing the base; the bracketcomprises a fastening end, a support post and a loading end; the fastening end is positioned at the lower end of the support post for fixedly connecting the bracket with the base; and the loading endis positioned at the upper end of the support post for loading samples. The sample loader has the advantages of disassembly capability, portability, positioning capability, convenient use, reliable performance, strong universality and the like, can be widely applied to the lower loading of test samples, provides a useful solution for upgrading the loading way of the test samples in the scientificresearch and experimental teaching, in particular for solving the problem of loading samples by using the conventional hanging sample loading methods in the special locations, and is particularly suitable for loading samples during the dynamic test of degradation performance of medical magnesium alloy.

Owner:SOUTH CHINA UNIV OF TECH

Test apparatus for endurance of flexural member under load-environment coupling

InactiveCN102494945BSimple structureEasy to operateMaterial strength using tensile/compressive forcesPull forceReinforced concrete

The invention which relates to a test apparatus for mechanical properties of a flexural member under the continuous load action belongs to the civil engineering field, wherein the test apparatus is especially suitable for occasions for testing the endurance of a reinforced concrete flexural member under the environment-load coupling action. The test apparatus comprises the reinforced concrete flexural member, a tension rib, anchoring parts and circular shaft loading rods, the anchoring parts are symmetrically arranged on two ends of the pulling force rib, the circular shaft loading rods are symmetrically arranged on the pulling force rib, and the middle horizontal segment of the pulling force rib is in parallel with the top surface of the reinforced concrete flexural member. The apparatus of the invention, which has the advantages of simple structure, convenient operation, no restriction by the size of the member, no need of pairing or bunching combination, and high strength, can satisfy loading needs of any load ratio.

Owner:ZHEJIANG COLLEGE OF CONSTR

Fault loading device for diesel locomotive

ActiveCN104570880BMeet loading needsEnsure breakProgramme controlComputer controlFailure rateCombustion

The invention discloses an internal combustion locomotive fault loading device. The internal combustion locomotive fault loading device comprises an input circuit, a photoelectric coupler, a power supply voltage, a microprocessor, a locomotive internal power supply, a fault switch and an output circuit, wherein the input circuit is in circuit connection with the photoelectric coupler; the power supply voltage is grounded and connected with the microprocessor through the photoelectric coupler; the rear portion of the microprocessor is grounded and connected with the locomotive internal power supply through a triode; the rear portion of the locomotive internal power supply is connected with the output circuit through a relay and the fault switch. According to the internal combustion locomotive fault loading device, the microprocessor is used as the core, normal operation logic of an LC electric appliance and an LLC electric appliance is controlled according to instructions of a driver controller, and low-current breaking of the LC electric appliance is guaranteed; the loading requirements of the driver controller when a contact finger of the driver controller breaks down are met; the fault loading device is used for controlling the corresponding electric appliances to act in a reasonable mode, so the reliability of operation of a DF4 locomotive is effectively improved, and the locomotive failure rate is lowered.

Owner:CSR CHENGDU

A multi-directional telescopic warehouse trolley

ActiveCN111409991BPrevent dumpingMeet loading needsStorage devicesHand carts with multiple axesStructural engineeringStorage garage

Owner:安徽持家汉家居工艺品有限公司

Automatic covering device for truck roof

The invention belongs to the field of truck transformation, and particularly relates to an automatic covering device for a truck roof. The automatic covering device comprises a front awning, a middleawning and a rear awning which are arranged on a cargo compartment, and further comprises a front supporting arm, a rear supporting arm and a hydraulic cylinder which are connected with the cargo compartment and the middle awning; and the device also includes a front connecting rod, a front driving connecting rod and a front driving rod which are connected with the middle awning and the front awning, and a rear connecting rod, a rear driving rod connecting rod and a rear driving rod which are connected with the middle awning and the rear awning. The front awning, the middle awning and the rearawning are movably connected and foldable through the supporting arms and the connecting rods, and the three awning bodies (the front awning, the middle awning and the rear awning) directly cover thecargo compartment or are folded and placed at the top of a cockpit through rotation of the supporting arms around a shaft. Automatic covering and storing of the truck roof are achieved through a four-connecting-rod mechanism combined structure driven by the hydraulic cylinder; and compared with the prior art, the automatic covering device is simple in structure, transmission of belt wheels, storing ropes and other parts in the middle link is reduced, the fault rate of the device is reduced, and the efficiency of covering and storing the roof is improved.

Owner:王学刚

A High-precision Electric Spindle Loading Mechanism Based on Piezoelectric Ceramics

ActiveCN109443725BHigh loading accuracyImprove loading efficiencyMachine part testingStructural engineeringMechanical engineering

A piezoelectric ceramic-based high-precision electric spindle loading mechanism comprises a loading component and an adjusting component, the loading component is arranged on the adjusting component,the loading component comprises counter force supporting cylinders, a plurality of stress loading cylinders and a plurality of piezoelectric ceramics; each stress loading cylinder is externally sleeved with the counter force supporting cylinder, and each stress loading cylinder has an axial movement degree of freedom in the counter force supporting cylinder; each piezoelectric ceramic is connectedbetween the inner surface of the bottom of the counter force supporting cylinder and the outer surface of the bottom of the stress loading cylinder; the cylinder opening of each stress loading cylinder adopts an arc surface structure, the radian of the cylinder opening of the stress loading cylinder is the same as the radian of the outer surface of an electric spindle to be tested, the pluralityof piezoelectric ceramics are arranged between the inner surface of the bottom of the counter force supporting cylinder and the outer surface of the bottom of the stress loading cylinder, a stress sensor is arranged on the cylinder opening of the counter force supporting cylinder, the stress sensor is in contact fit with the outer surface of the electric spindle to be tested, and the radians of the cylinder openings of the plurality of stress loading cylinders are different.

Owner:SHENYANG JIANZHU UNIVERSITY

Permanent magnet motor rotor punching sheet with high reluctance torque

PendingCN114884242ALarge reluctance torqueImprove mechanical propertiesElectric machinesMagnetic circuit stationary partsElectric machineryTorque density

The invention discloses a permanent magnet motor rotor punching sheet with high reluctance torque, which comprises a rotor punching sheet body and a shaft hole, and comprises first V-shaped magnetic steel grooves which are symmetrically distributed relative to the central line of a d shaft, first, second and third magnetic isolation holes are formed in the two ends of each magnetic steel groove group, the outer side lines, away from the shaft hole, of the first, second and third magnetic isolation holes are located on the same circle, and the inner side lines, close to the shaft hole, of the first, second and third magnetic isolation holes are located on the same straight line; third magnetic isolation bridges are arranged between the first magnetic isolation holes and the first V-shaped magnetic steel grooves at equal intervals, and the intersection points of the side lines, close to the second magnetic isolation holes, of the first magnetic isolation holes and the outer side lines, close to the outer circle of the rotor punching sheet, of the first V-shaped magnetic steel grooves are located on the center lines of the third magnetic isolation bridges. The first, second and third magnetic isolation holes are added, and a large number of magnetic isolation bridges are added, so that the mechanical performance of the rotor during high-speed operation can be improved, the high speed of the motor is facilitated, the torque density of the motor is increased, and the speed regulation performance of the motor is improved.

Owner:河南通宇新源动力有限公司

A fully automatic loading machine

ActiveCN106185375BEfficient and accurate loading operationMeet loading needsLoading/unloadingDistance detectionEngineering

The invention relates to a full-automatic car loader. The full-automatic car loader comprises a wheel-type walking frame, a supporting board mechanism, a leading-in mechanism, a lifting mechanism, a case pushing mechanism, a case allocating mechanism, a conveying mechanism and a layer pushing mechanism; a distance detection unit is arranged on the wheel-type walking frame and can position the motion trail of the wheel-type walking frame; the supporting board mechanism, the lifting mechanism and the layer pushing mechanism share the same power source; the supporting board mechanism and the layer pushing mechanism are provided with telescoping devices and can be adjusted according to the width of a boxcar so as to adapt to the change of the width of the boxcar; the lifting mechanism adopts two lifting guide rails and can adjust the frame and the height of lifting according to the height of the boxcar so as to adapt to the change of the height of the boxcar; two pairs of horizontal guide rails and driving mechanisms are arranged on the leading-in mechanism, so that the leading-in mechanism moves back and forth and right and left so as to enable targeted materials to move into the supporting board mechanism accurately; and the movement of the lifting mechanism, the case pushing mechanism, the case allocating mechanism, and the layer pushing mechanism is all controlled by a PLC control unit.

Owner:HARBIN BOSHI AUTOMATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com