A ZWY type mine crawler excavator loader multifunctional conveying device

A multi-functional conveying and loader technology, applied in the direction of conveyor, loading/unloading, transportation and packaging, etc., can solve the problems of low efficiency and manpower consumption, and achieve the effect of ensuring safety, stable operation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

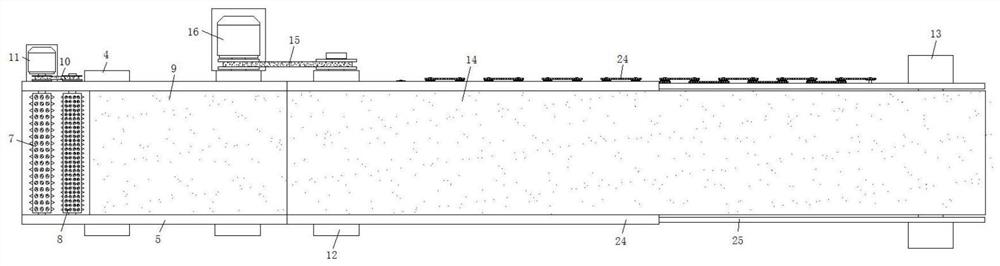

[0030] refer to Figure 1-6 , a ZWY type mining crawler excavator loader multifunctional conveying device, including a loader body 1, the loader body 1 includes a base 101, a drive crawler 102 is installed on the lower end of the base 101, and a driver's cab 103 is fixed on the upper end of the base 101, An excavation mechanism 104 is installed on the front side of the base, and a rolling feeding mechanism 2 and a transmission mechanism 3 are respectively installed on both sides of the rear end of the base 101. The rolling feeding mechanism 2 includes a mounting seat 14, which is fixed by screws A rectangular dish 5 is connected, and the two sides of the rectangular dish 5 are connected through. A rolling block 6 is fixed on the inner bottom of the rectangular dish 5 close to the side of the excavating mechanism 104. The upper end of the rolling block 6 is provided with a rolling roller 7 and a rolling block. Roller two 8, and rolling roller one 7 and rolling roller two 8 are ...

Embodiment 2

[0033] Such as image 3 , 5 As shown in and 6, this embodiment is basically the same as Embodiment 1. Preferably, the top of the mounting seat 2 12 is also rotatably connected to a baffle plate 125, and a rectangular groove is provided in the baffle plate 125, and the inner walls of the rectangular groove all slide The contact connection has a baffle plate two 26.

[0034] In this embodiment, a baffle plate 25 is added on the front and rear sides of the conveyor belt 2 14, and a baffle plate 2 26 is slidably connected to the inside of the baffle plate 25, so as to realize the limit when the ore is transported, and it is very good to avoid Occurrence of falling during ore transportation.

Embodiment 3

[0036] Such as image 3 and 4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, four mounting bases 4 are provided and fixed on the base 101 in a rectangular shape, and the mounting base 4 is located on the side close to the excavating mechanism 104 .

[0037] In this embodiment, four mounting seats 4 are provided to facilitate the installation and fixing of the rectangular dish 5, thereby ensuring more stable conveying of the conveyor belt 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com