Automatic covering device for truck roof

An automatic covering and canopy technology, applied in load covering, motor vehicles, transportation and packaging, etc., can solve the problems of complex structure, slow covering and storage speed, easy damage, etc., and achieve the effect of increasing length and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

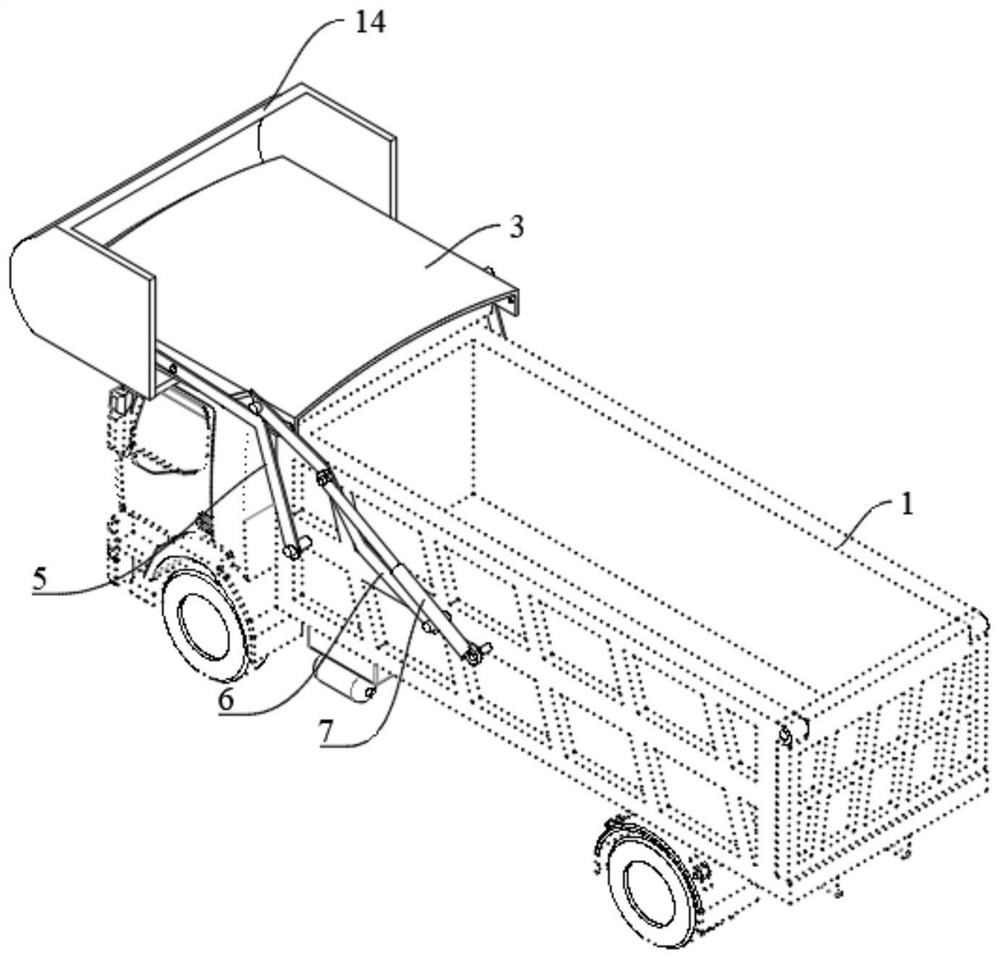

[0030] Such as Figure 1-Figure 7 Shown: an automatic covering device for the roof of a truck, including: a front cover 2, a middle cover 3, and a rear cover 4 arranged on the cargo compartment 1, and a front support arm 5 connecting the cargo compartment 1 and the middle cover 3, and a rear The support arm 6, the hydraulic cylinder 7, also includes the front link 8 connecting the middle tent 3 and the front tent 2, the front drive link 9, the front drive link 10, and also includes the rear link 11 connecting the middle tent 3 and the rear tent 4 , rear driving rod 13 connecting rods, rear driving rod 13; that is, the front tent 2, the middle tent 3, and the rear tent 4 are movably connected and foldable through the support arm and the connecting rod, and the three canopies are directly rotated around the axis by the support arm (Front canopy 2, middle canopy 3, rear canopy 4) are covered on the cargo compartment 1, or folded and placed on the top of the cockpit;

[0031] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com