Bituminous mixture loading system based on machine vision and control method

A kind of asphalt mixture and machine vision technology, applied in the field of asphalt mixture loading system and control based on machine vision, can solve the problem of affecting the homogeneity and service strength of the road surface, the unreliable detection results of the depth of the carriage, and the low control reliability. problems, to achieve the effect of reducing segregation in loading, improving construction quality and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

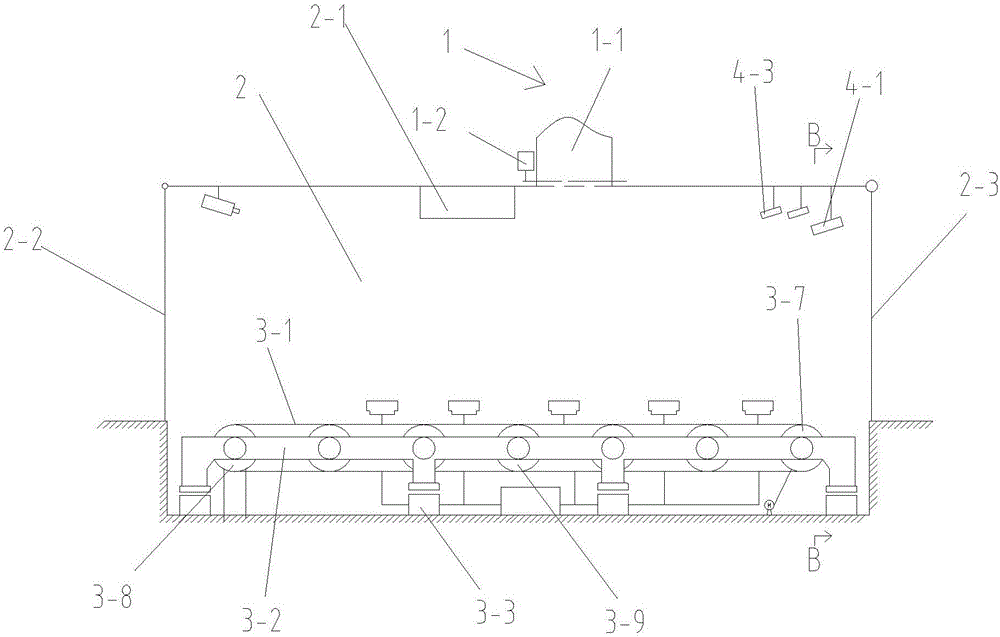

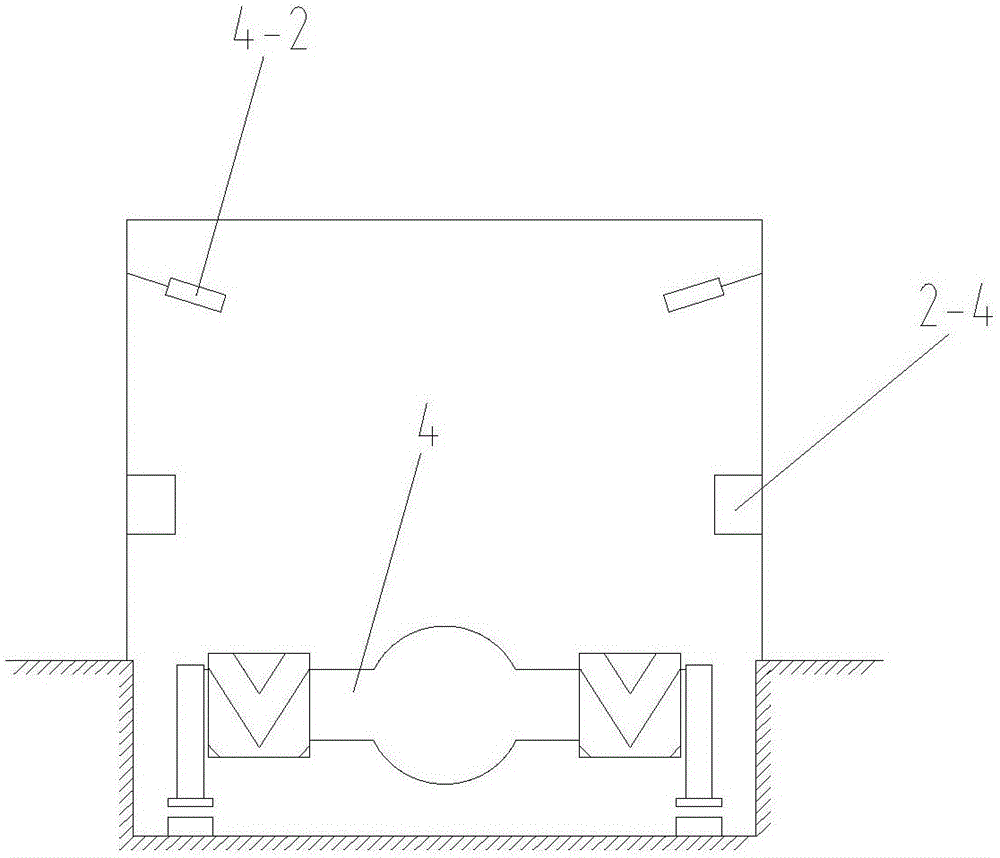

[0054] Such as figure 1 , figure 2 , image 3 and Figure 4 The shown a kind of asphalt mixture loading system based on machine vision includes a box-type loading room 2, a material door mechanism 1 arranged on the top of the box-type loading room 2, a The vehicle mobile platform 3 arranged horizontally and the machine vision control system for controlling the asphalt mixture loading process, the material gate mechanism 1 includes a gate 1-1 for controlling the flow rate of the asphalt mixture and the opening degree of the gate 1-1 A linear displacement sensor 1-2 for real-time detection, the vehicle mobile platform 3 includes a crawler flat 3-1 for the charging vehicle to park, a longitudinal beam support 3-2 arranged at the bottom of the crawler flat 3-1, and a crawler flat 3 -1 The roller mechanism that is connected by transmission and drives the track plate 3-1 to move back and forth in the horizontal direction, and the roller drive mechanism that drives the roller mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com