Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91results about How to "Low control pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

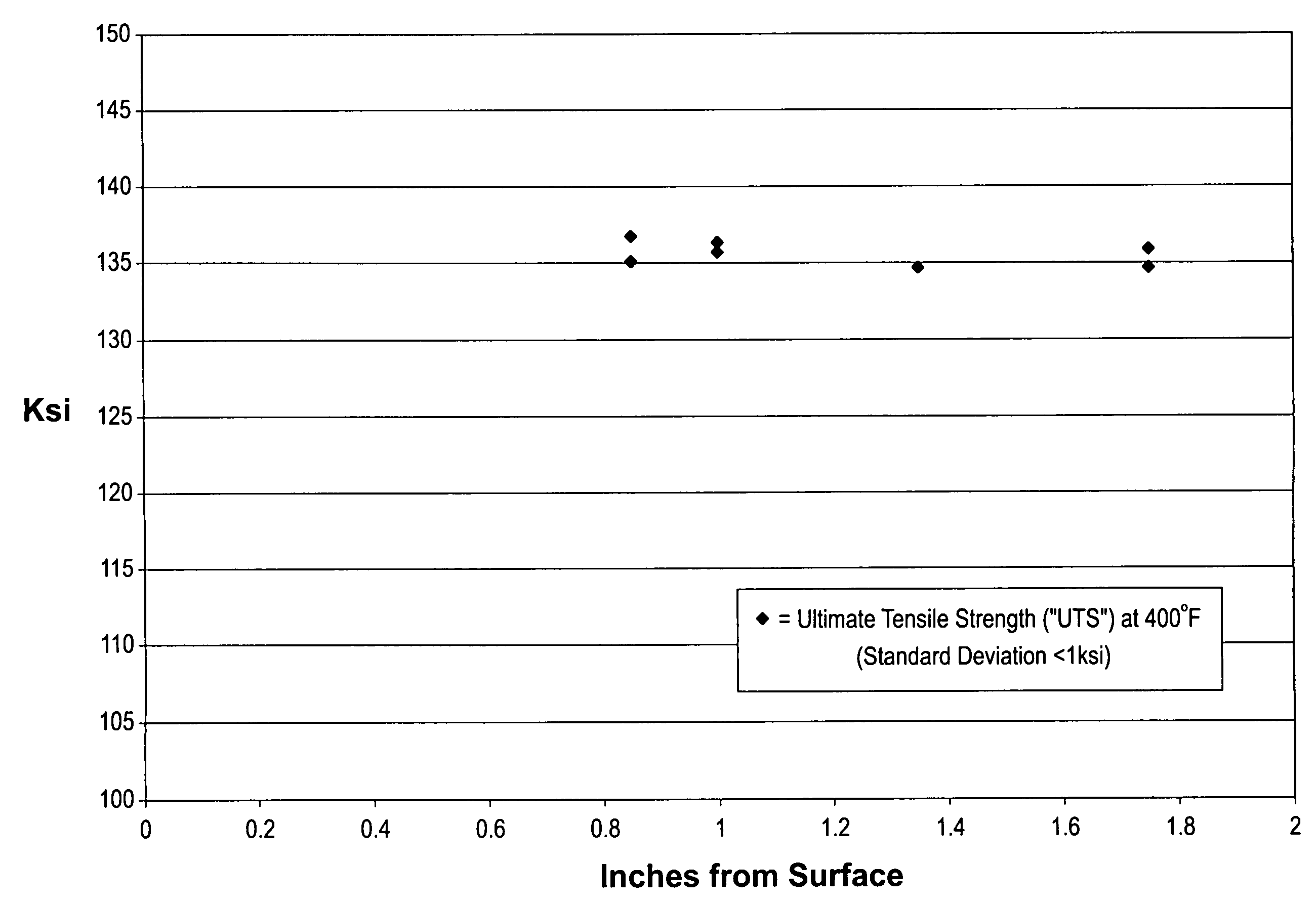

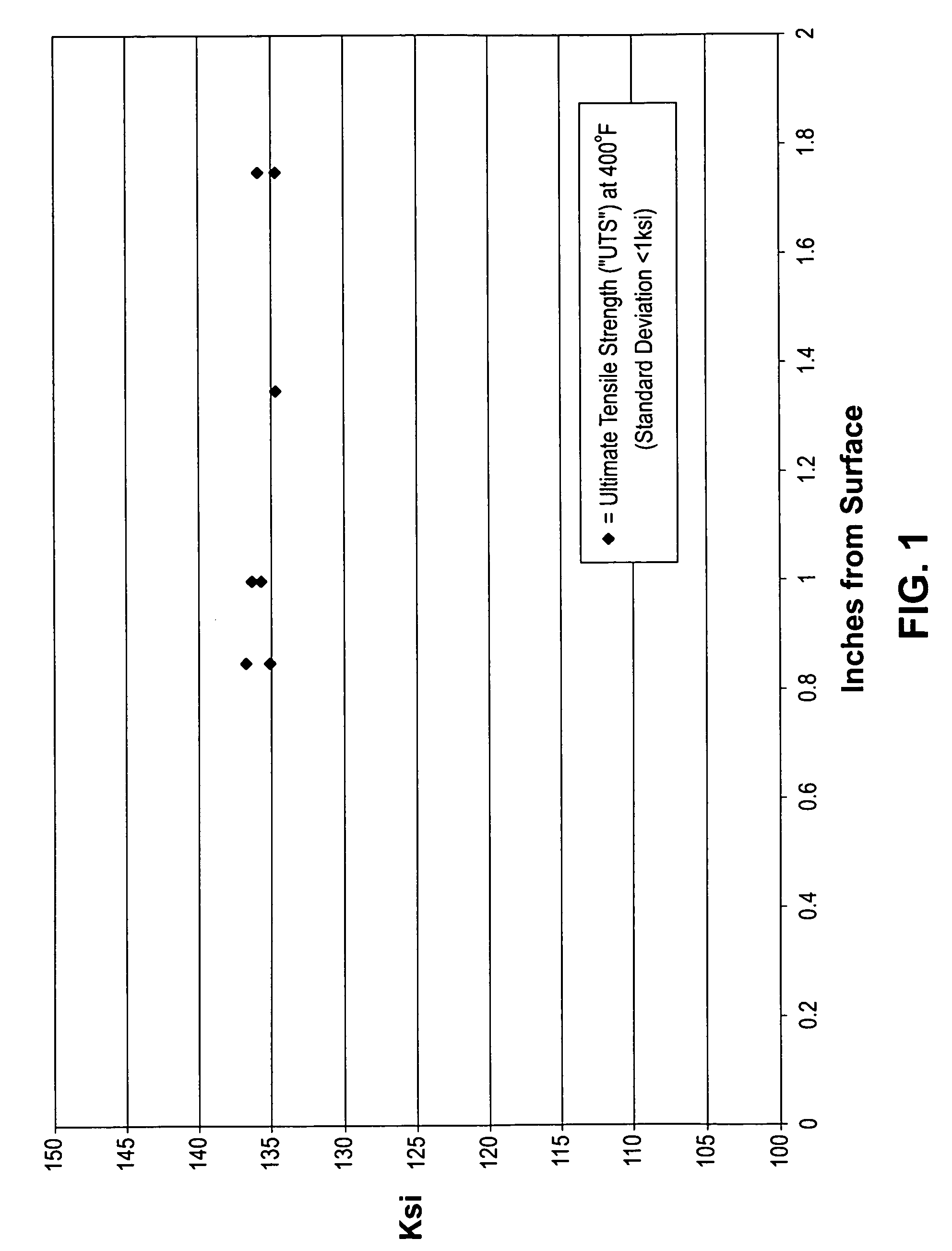

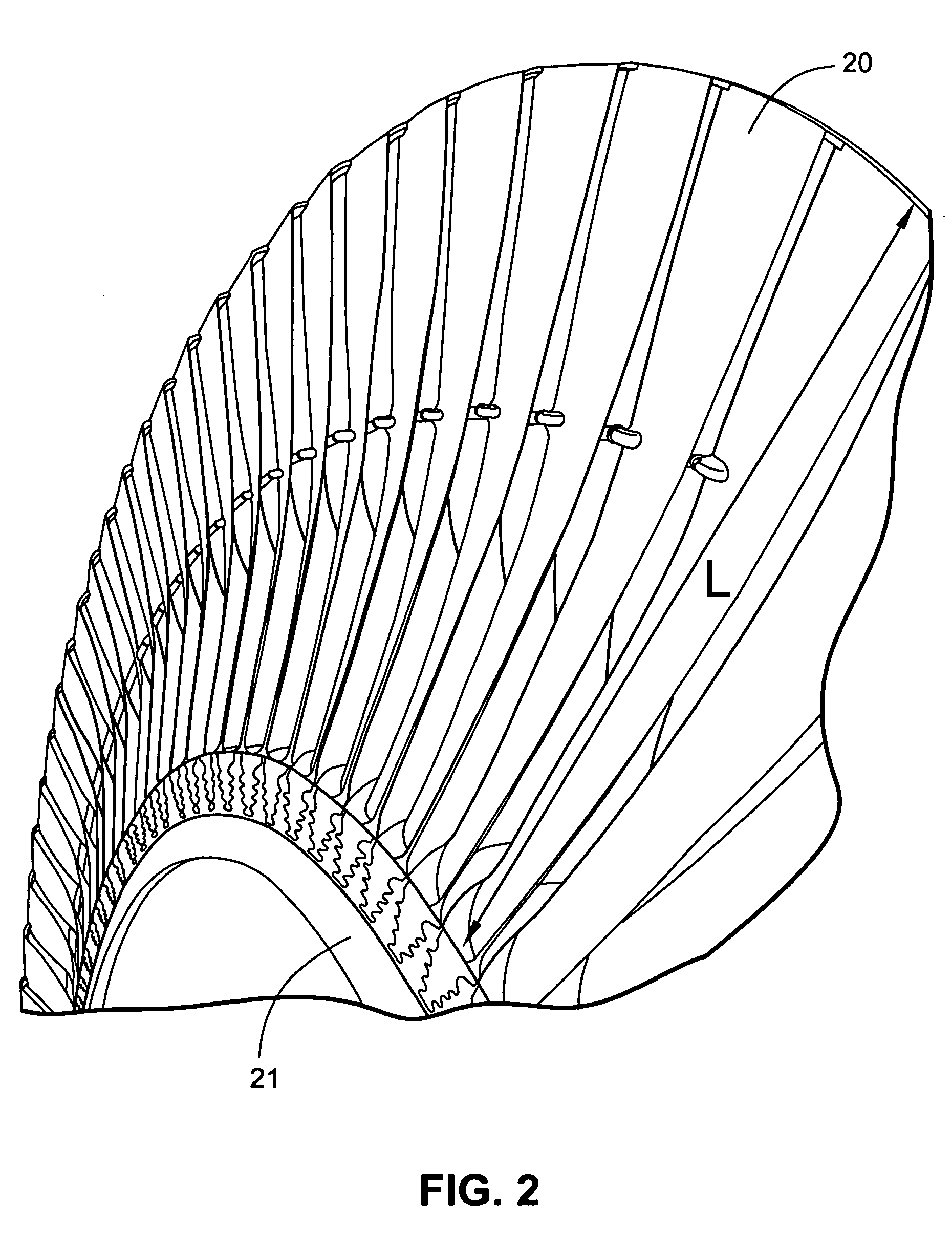

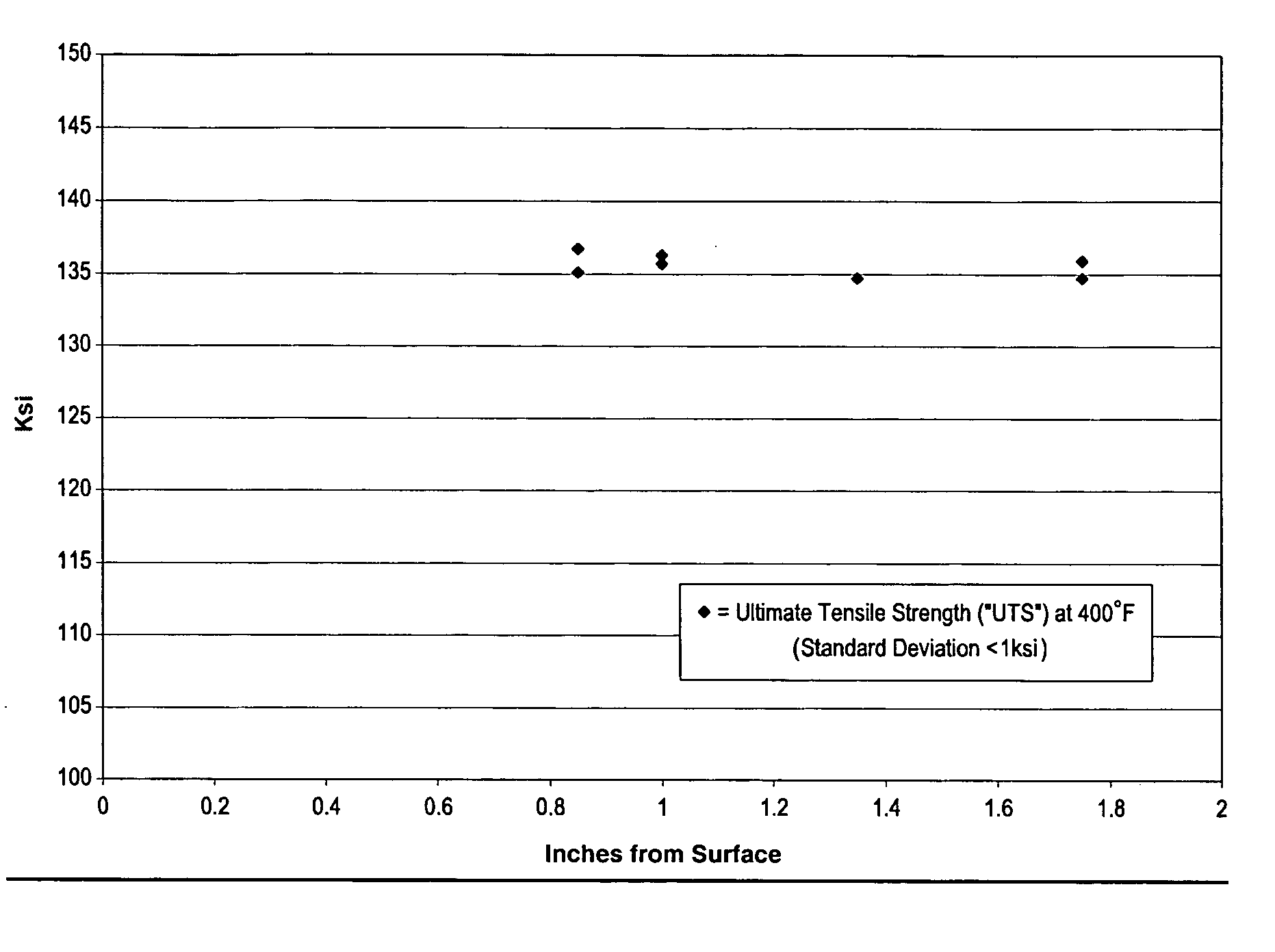

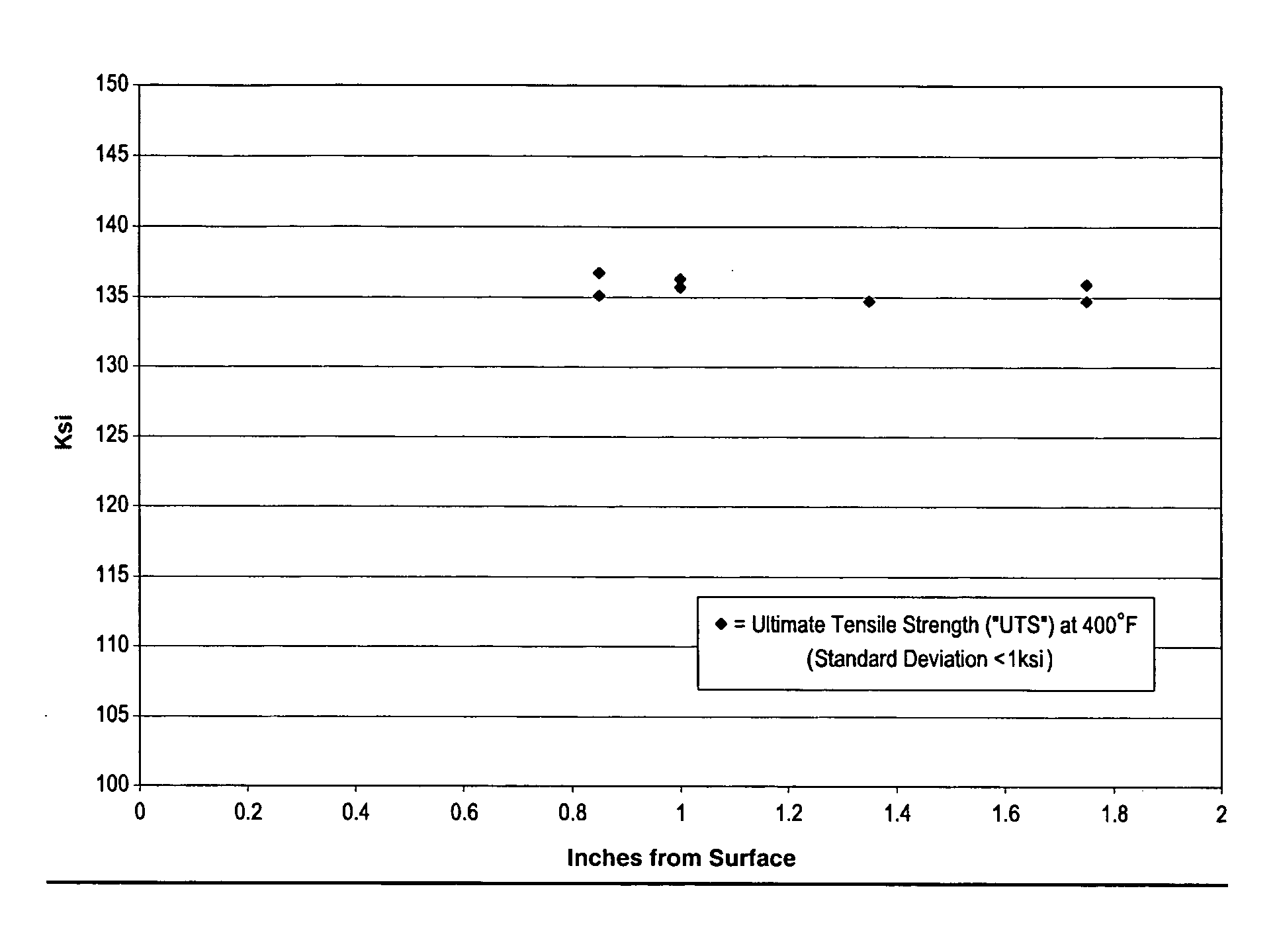

Application of high strength titanium alloys in last stage turbine buckets having longer vane lengths

InactiveUS7195455B2Low control pressureHigh strengthPump componentsReaction enginesStress reliefHeat treated

A new high-strength titanium-based alloy bucket specifically suited for use as the last stage buckets in steam turbine engines having vane lengths of about 40 inches or greater and the method for forming such bucket. Exemplary buckets according to the invention are formed from a titanium-based alloy containing up to about 6.25% aluminum; (b) about to 3.5% vanadium; (c) about 2.25% tin, (d) about 2.25% zirconium, (e) about 1.75% molybdenum, (f) about 2.25% chromium, (g) about 0.7% silicon; and (h) about 2.3% iron, with the balance being titanium. After forming, the bucket can be heat treated to provide stress relief and then machined in a conventional manner.

Owner:GENERAL ELECTRIC CO

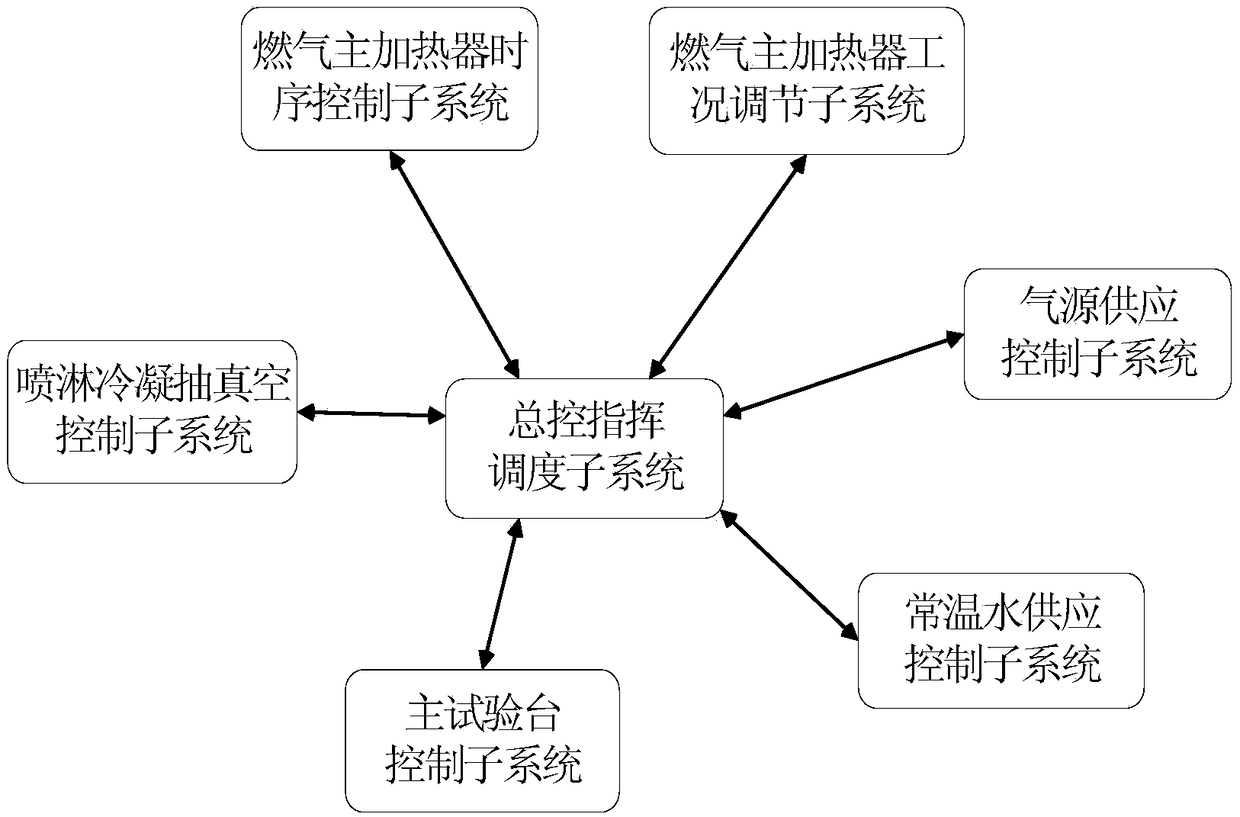

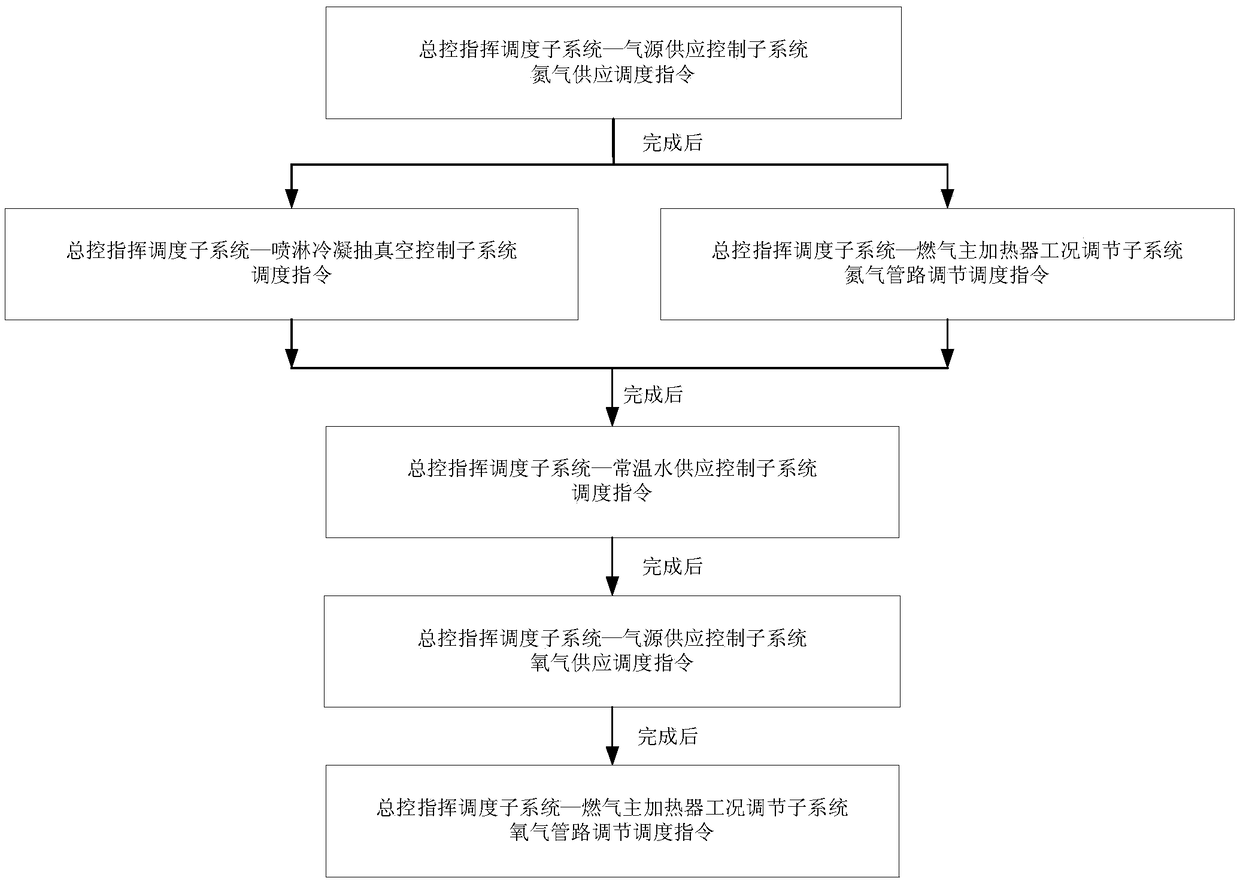

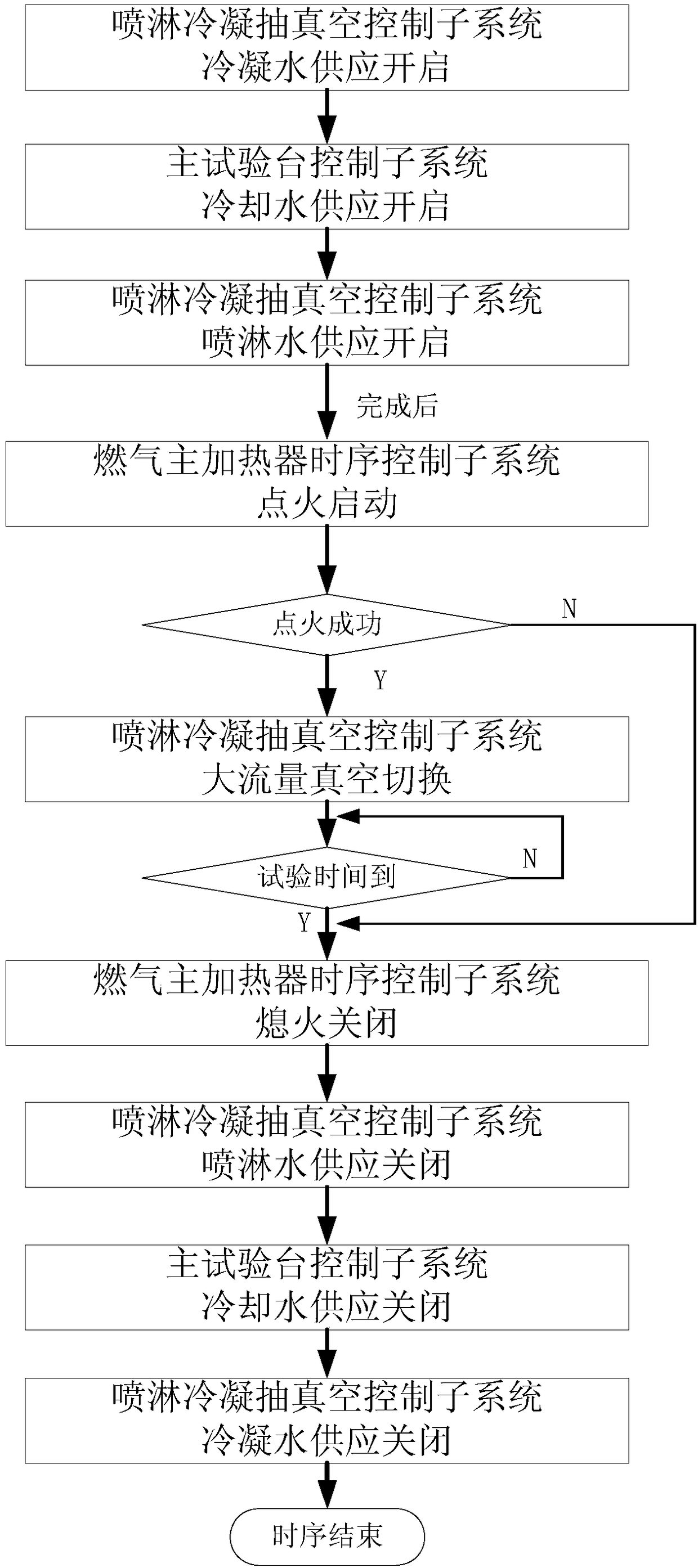

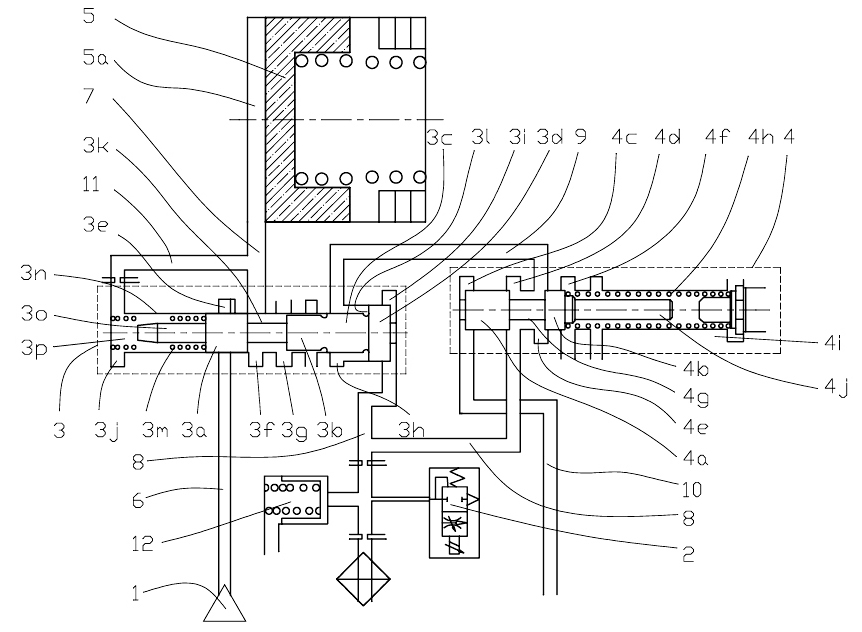

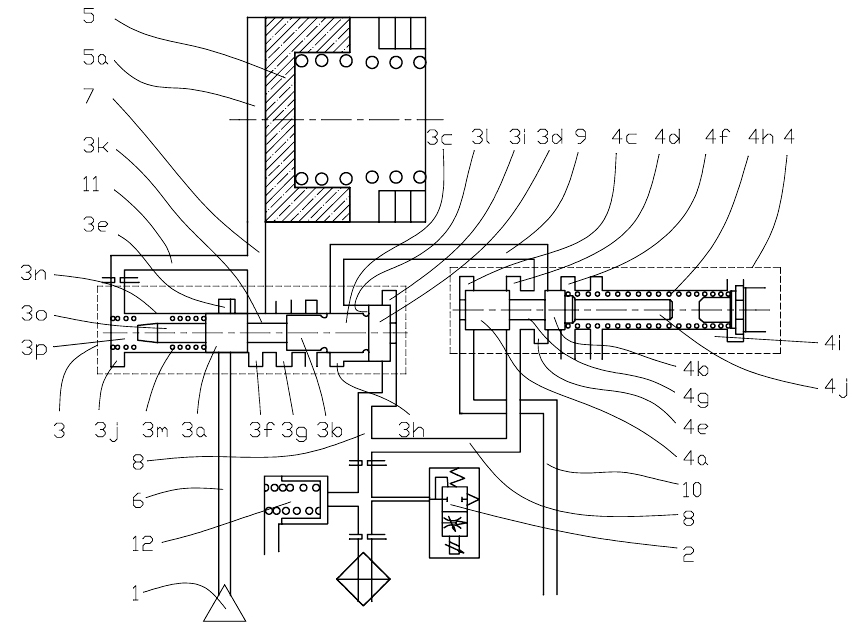

Wind tunnel operation control system based on distributed architecture

ActiveCN108760217ASolve complexitySolve coordination problemsAerodynamic testingSimultaneous control of multiple variablesCombustionThermal insulation

The invention discloses a wind tunnel operation control system based on a distributed architecture, which belongs to the technical field of aerospace ground thermal insulation tests, so as to controleach part in a combustion-gas flow thermal wind tunnel test system to realize thermal examination on a spacecraft thermal protection structure. The distributed control architecture is used, each control subsystem of the wind tunnel has an independent controller, operation control is carried out on a corresponding device, coordination of the whole action is realized through a top-layer master control command and dispatch subsystem, the whole wind tunnel system is ensured to act in a coordinated and orderly mode, software and hardware supports are provided for stable operation of the wind tunnelsystem, and a technical support is provided for condition monitoring and timing control on the equipment.

Owner:BEIJING AEROSPACE INST OF THE LONG MARCH VEHICLE +1

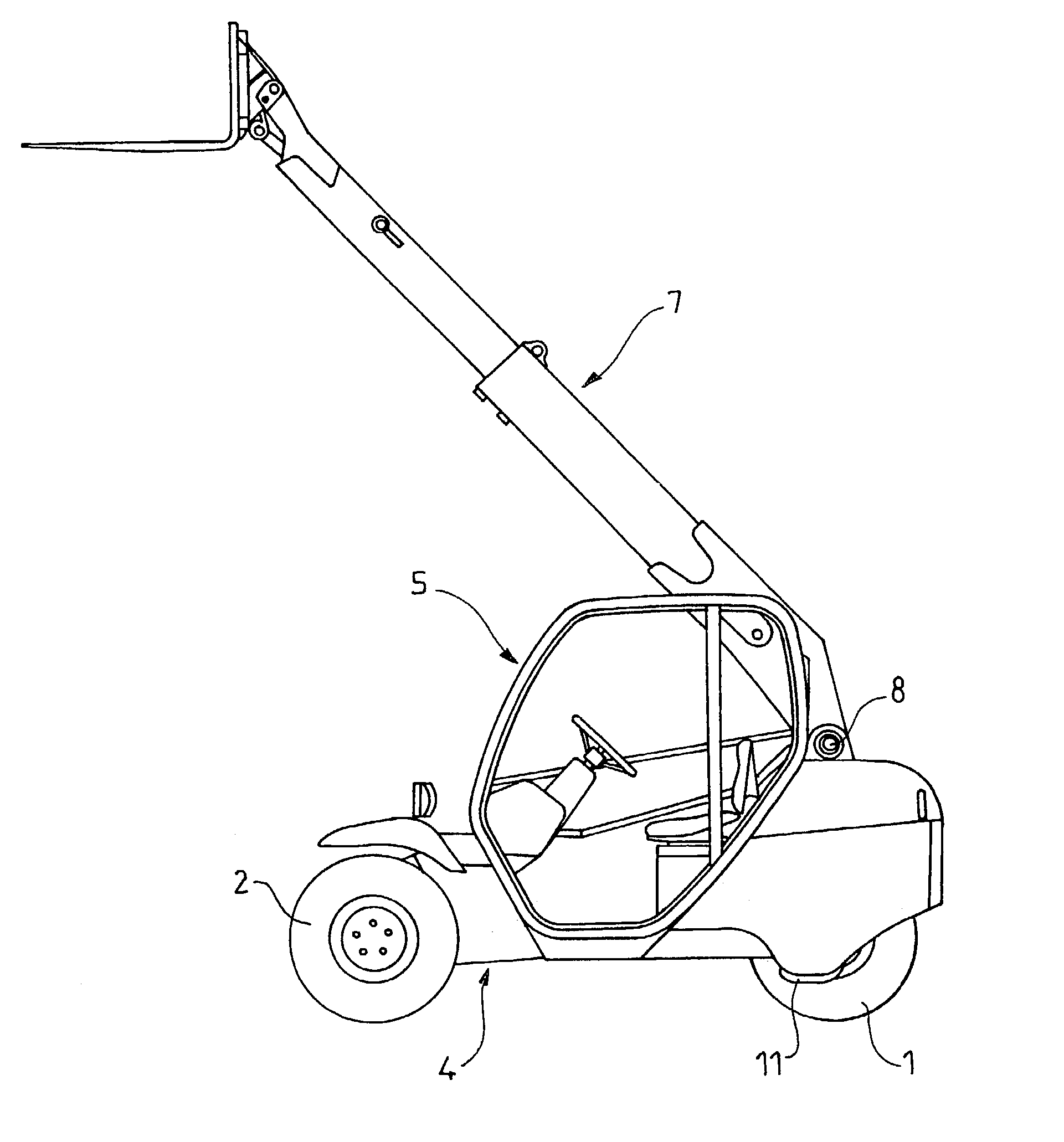

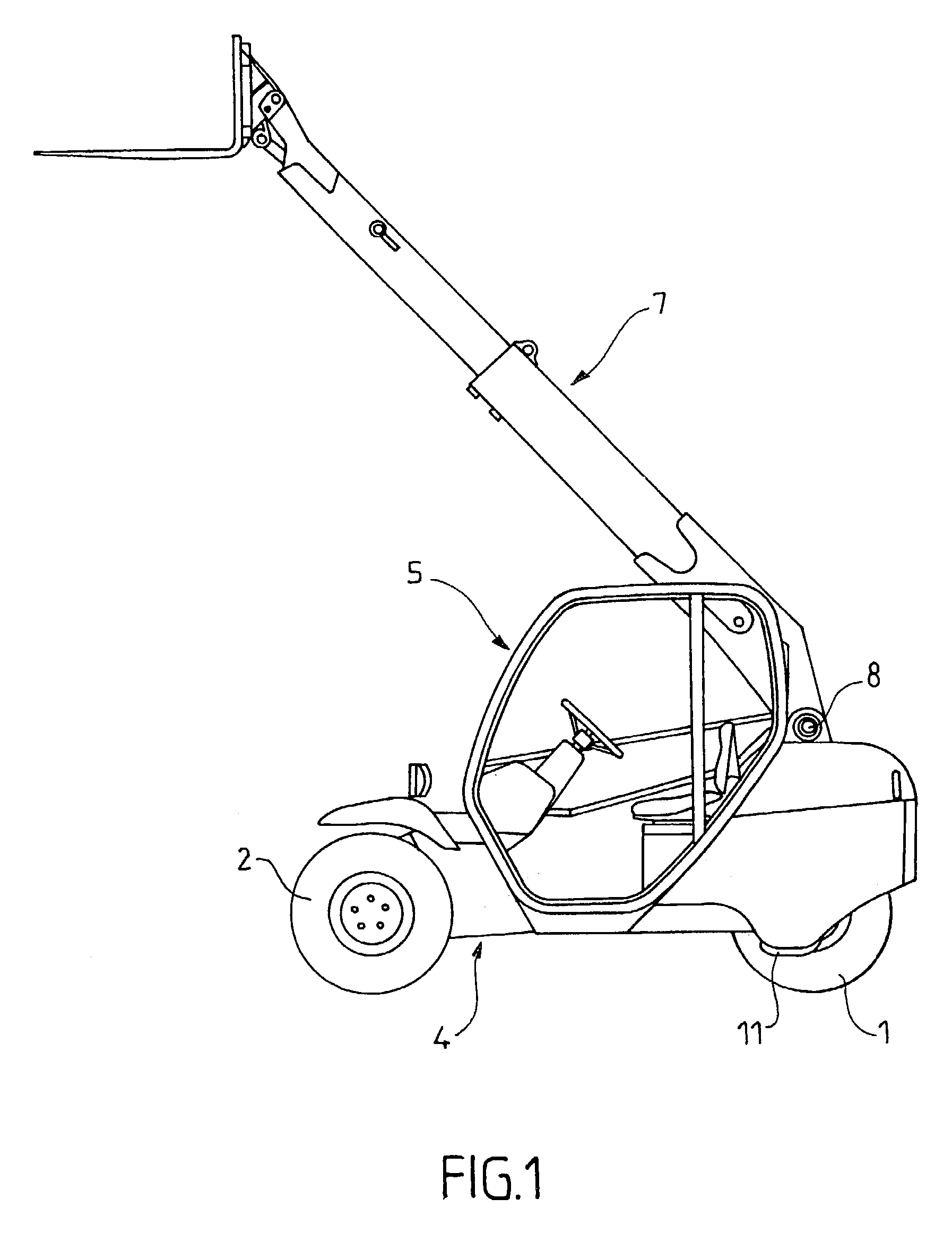

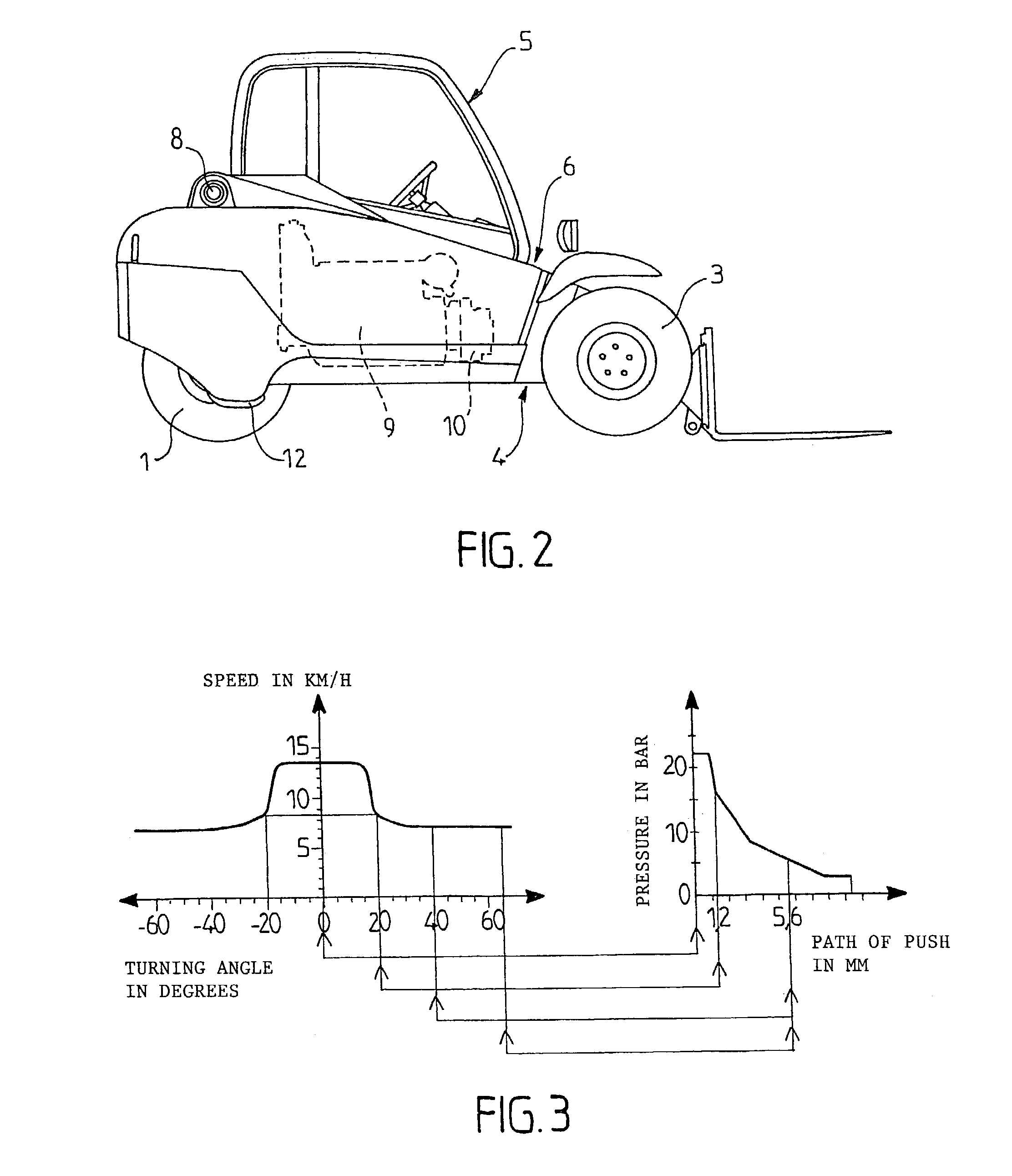

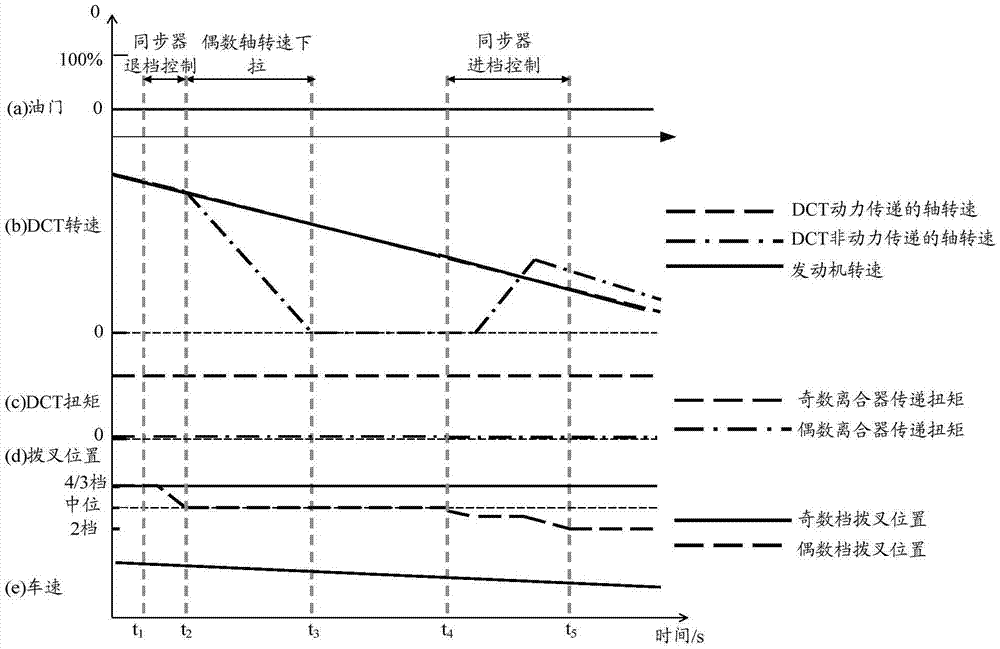

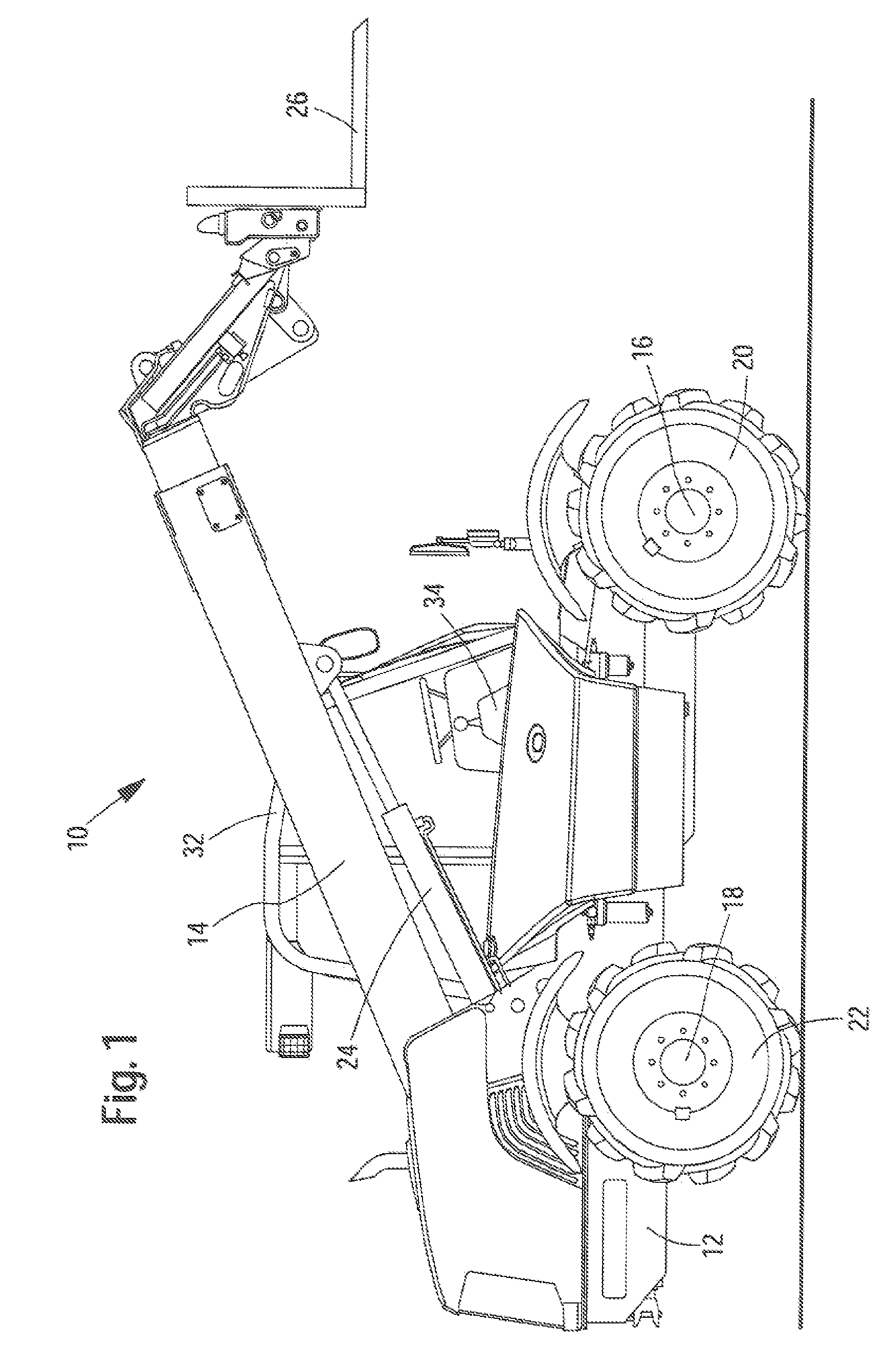

Lift truck with variable range with at least three wheels

InactiveUS7121372B2Simple and economical structureSubstantial lifting heightCyclesElectric devicesTurn angleEngineering

A lift truck with variable range with at least three wheels and a telescopic arm. The lift truck includes a steerable rear wheel and two front wheels, a driver station and a motor propulsion group secured to a chassis. The chassis has a compact configuration and is elongated in the longitudinal direction of advance of the truck, and has safety elements against the risk of loss of lateral stability. The safety elements are adapted to oppose turning over of the truck. The truck also includes a device to limit the maximum speed of advance based on a turning angle of the steerable wheel.

Owner:MANITOU BF SA

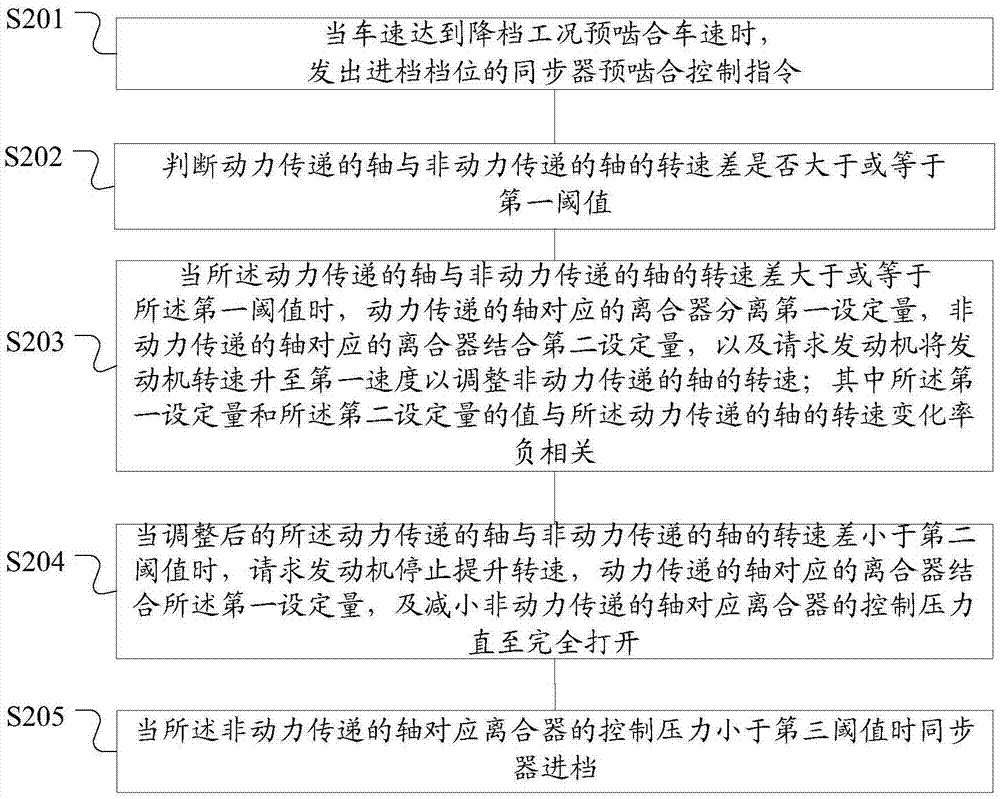

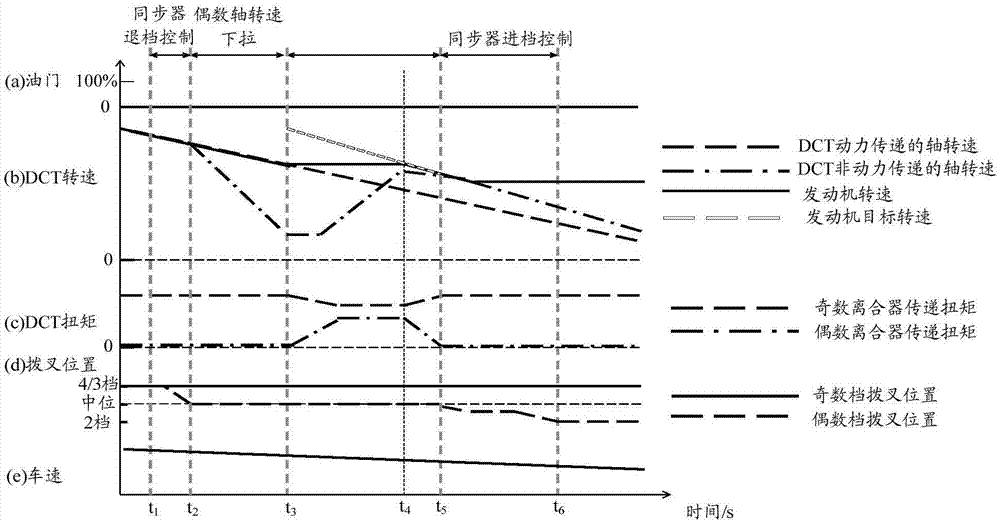

Control method, device and TCU for synchronizer pre-engagement under sliding and downshift working condition

ActiveCN106907477AAvoid different effects of speed synchronization controlLow control pressureClutchesGearing controlControl theoryClutch

The invention discloses a control method, device and TCU for synchronizer pre-engagement under the sliding and downshift working condition. The method comprises the steps that when the rotational speed difference of a power transmission shaft and a non power transmission shaft is larger than or equal to a first threshold value, a clutch corresponding to the power transmission shaft separates from a first set quantity, a clutch corresponding to the non power transmission shaft is combined with a second set quantity, and meanwhile an engine is requested to increase the rotational speed value to the first rotational speed to adjust the rotational speed of the non power transmission shaft, wherein values of the first set quantity and the second set quantity are negatively correlated with the rotational speed change rate of the power transmission shaft; when the adjusted rotational speed difference is smaller than a second threshold value, the engine is requested to stop increasing the rotational speed, the clutch corresponding to the power transmission shaft is combine with the first set quantity, and the control pressure of the clutch corresponding to the non power transmission shaft is reduced till the clutch is fully opened; and when the control pressure of the clutch corresponding to the non power transmission shaft is smaller than a third threshold value, a synchronizer moves up a gear, therefore production of gear moving noise is avoided, and DCT fuel consumption is reduced.

Owner:SAIC MOTOR

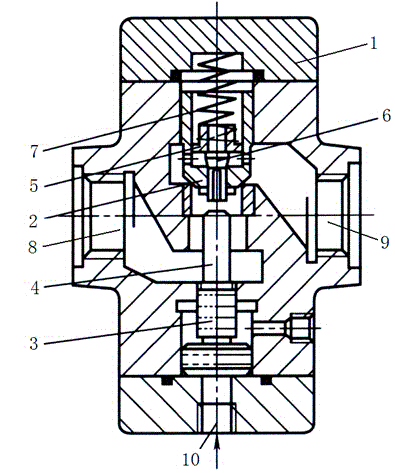

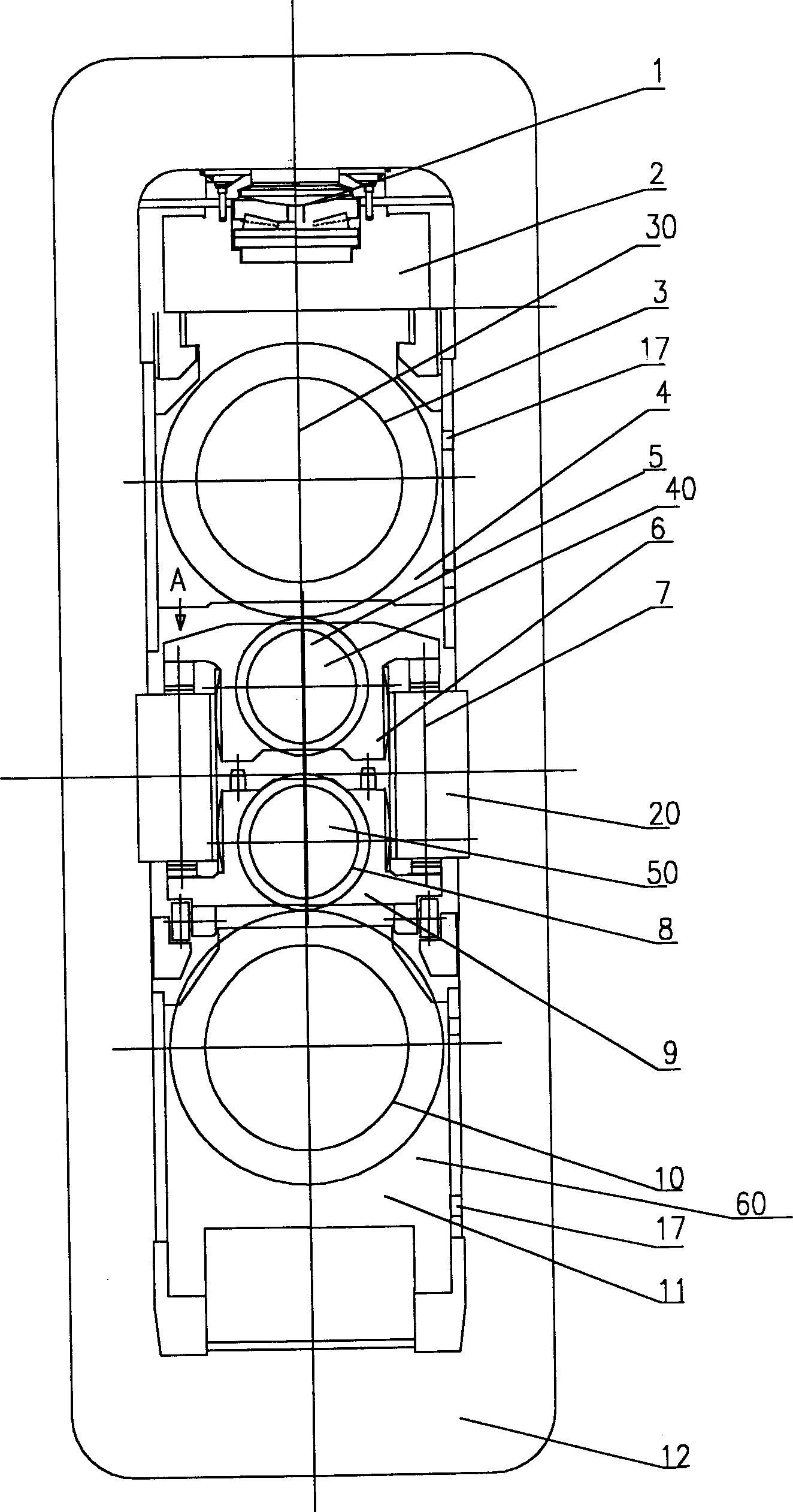

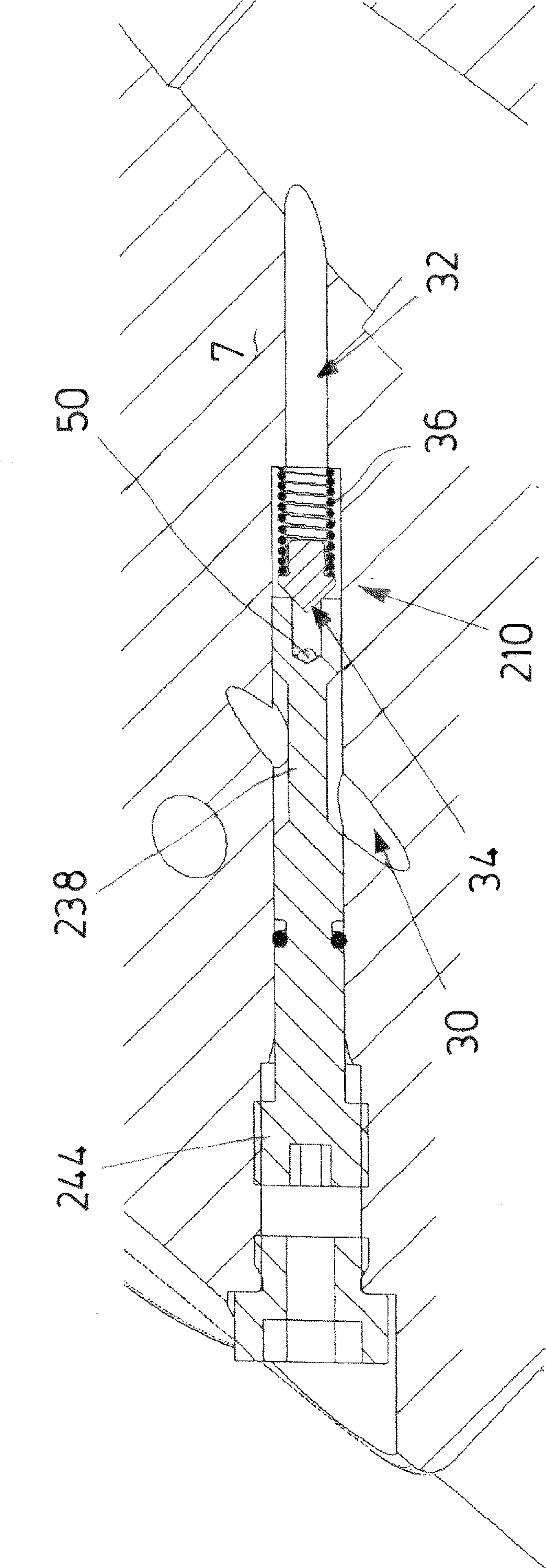

Duplex type hydraulic control one-way valve

InactiveCN104061346ASimple structureSafe and stable useOperating means/releasing devices for valvesCheck valvesEngineeringSmall hole

The invention discloses a duplex type hydraulic control one-way valve, which comprises a valve body and a main valve core and is characterized in that a valve cavity is arranged in the valve body, the main valve core is arranged in the valve cavity, a spring connected with the top of the valve body is arranged inside the main valve core, an axial small hole is formed in the lower end of the main valve core, a radial hole communicated with the axial small hole is formed in the outer circle of the main valve core, the axial small hole is sealed through an unloading valve core push rod, an unloading valve core is arranged at the upper end of the unloading valve core push rod, a control opening is formed in the bottom of the valve body, a piston is arranged in the valve cavity arranged at the upper end of the control opening, a push rod is connected with the upper end of the piston, and the push rod can push the unloading valve core push rod to upwards move. The duplex type hydraulic control one-way valve solves the problems that the one-way valve can only realize the one-way flowing, the stable reverse flowing cannot be realized, the use function is single, in addition, the damage can easily occur, and the service life is short. The provided duplex type hydraulic control one-way valve has the advantages that the structure is simple, the use is convenient, the two-way flowing can be fast and stably realized, in addition, the damage cannot easily occur, and the service life is long.

Owner:SUZHOU HUALAI PHOTOELECTRIC INSTR

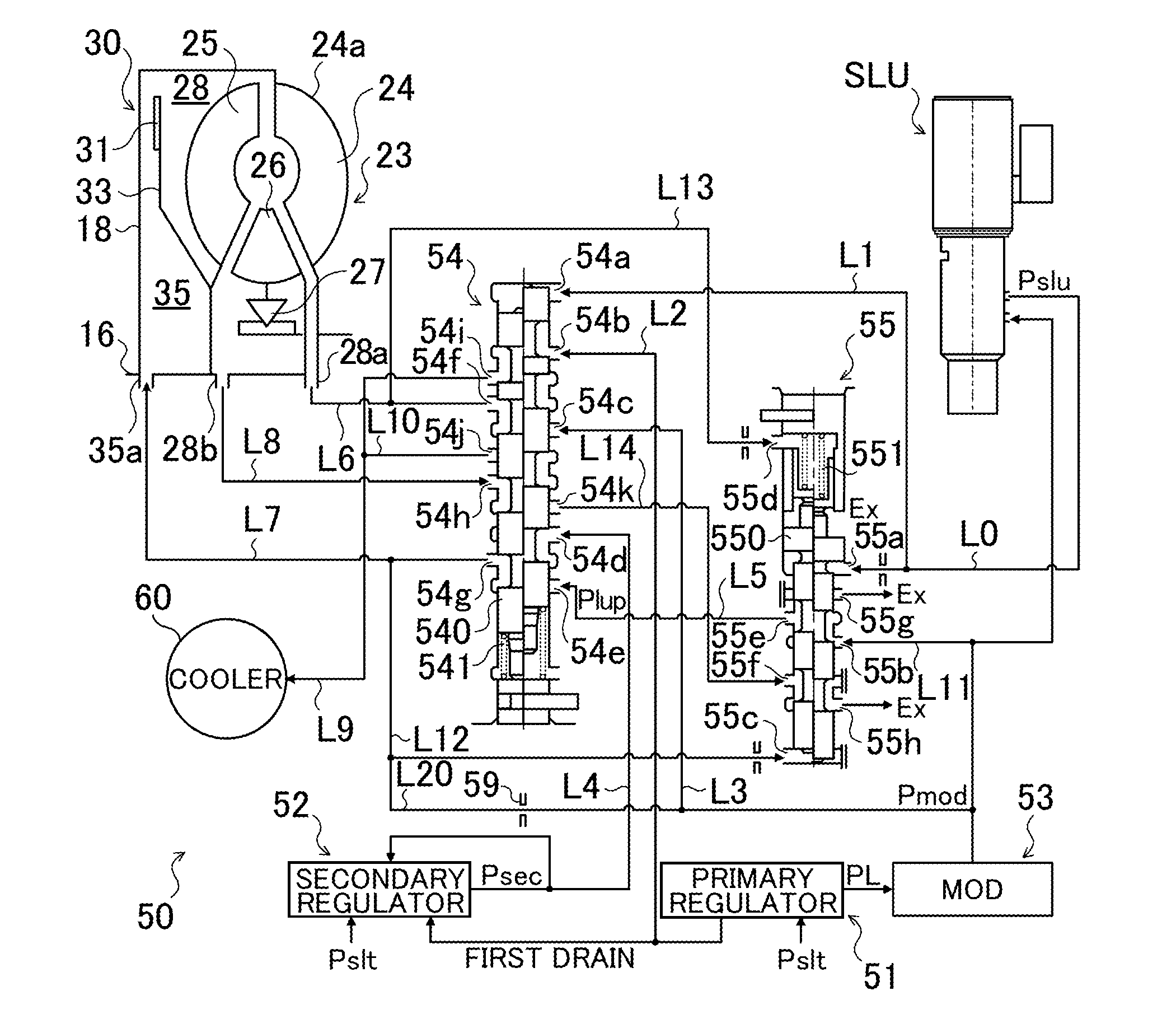

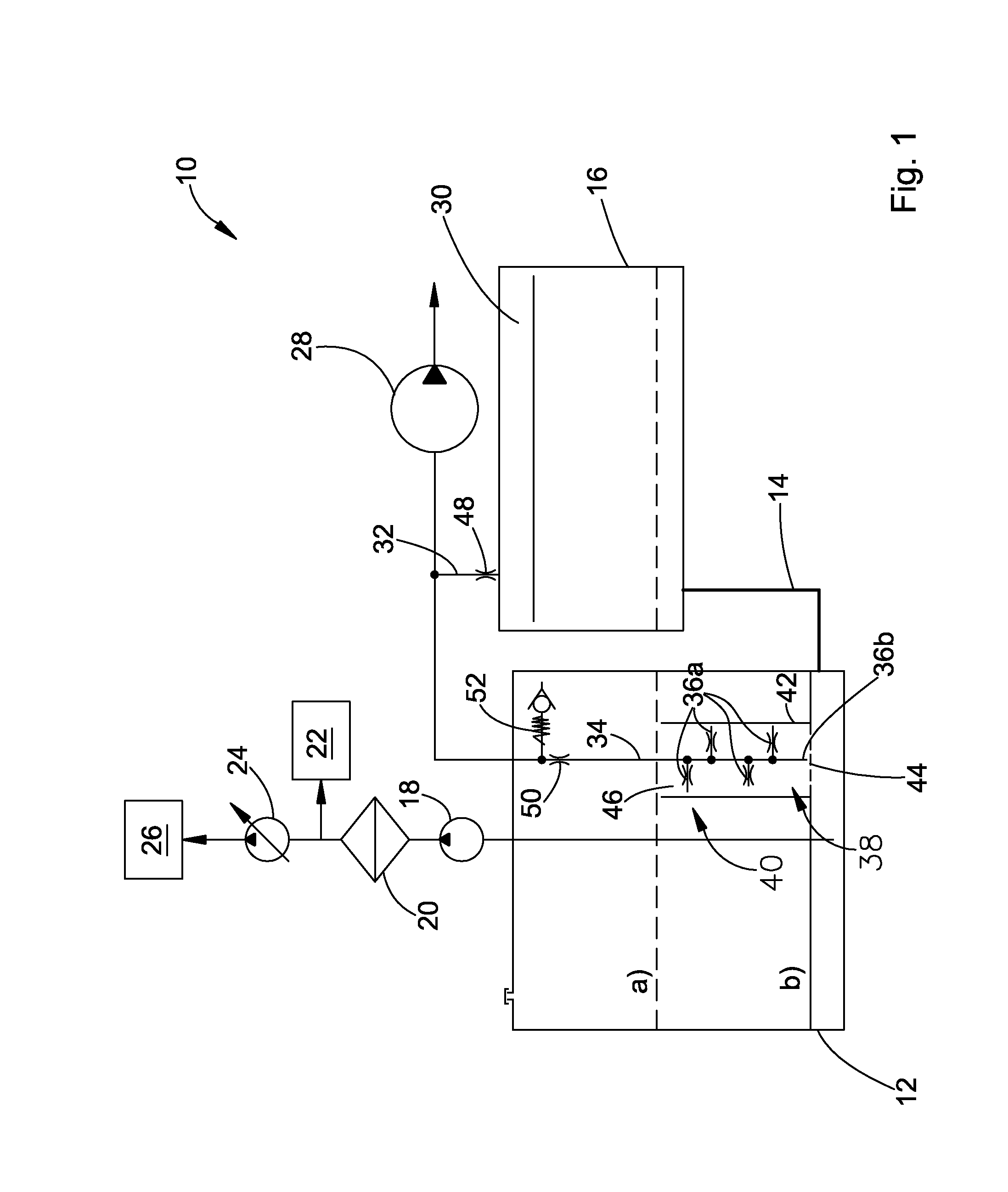

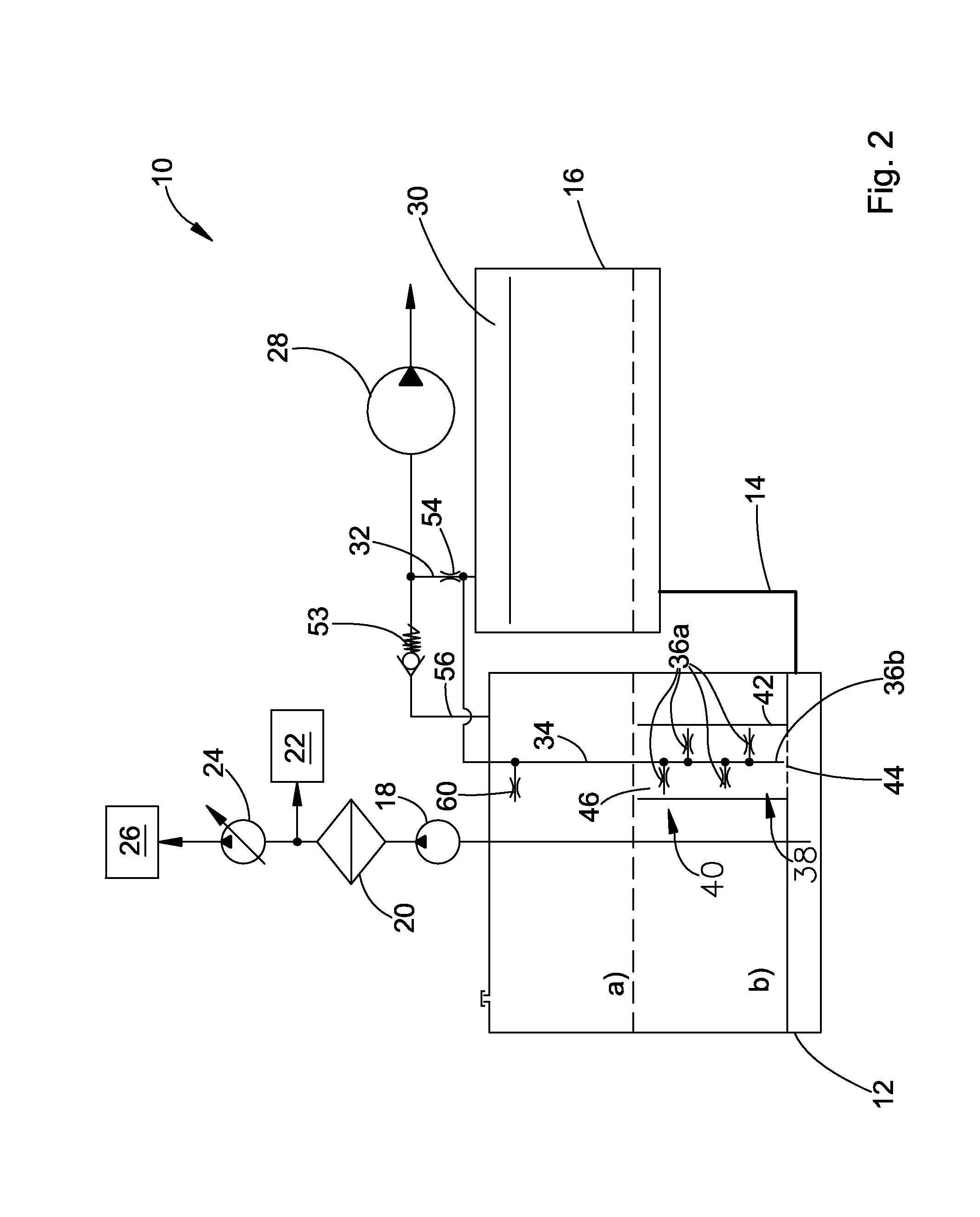

Hydraulic pressure control device

InactiveUS20120000740A1Quick engagementSuppress reduction in hydraulic pressureRotary clutchesFluid actuated clutchesClutch controlDifferential pressure

A hydraulic pressure control device including a first oil passage connected to an engagement side oil chamber defined on one side of a piston included in a clutch, an engagement pressure generating valve generating an engagement pressure supplied to the engagement side oil chamber via the first oil passage; a second oil passage connected to a back-pressure side oil chamber defined on the other side of the piston, and a clutch control pressure generating valve generating a clutch control pressure supplied to the back-pressure side oil chamber via the second oil passage and operates to lower the clutch control pressure as hydraulic pressure supplied as a feedback pressure from the back-pressure-side oil chamber side becomes higher. The hydraulic pressure control device controls a differential pressure between the engagement side oil chamber and the back-pressure side oil chamber, and the first oil passage and the second oil passage are communicated with each other via a bypass oil passage having an orifice in a midway position thereof.

Owner:AISIN AW CO LTD

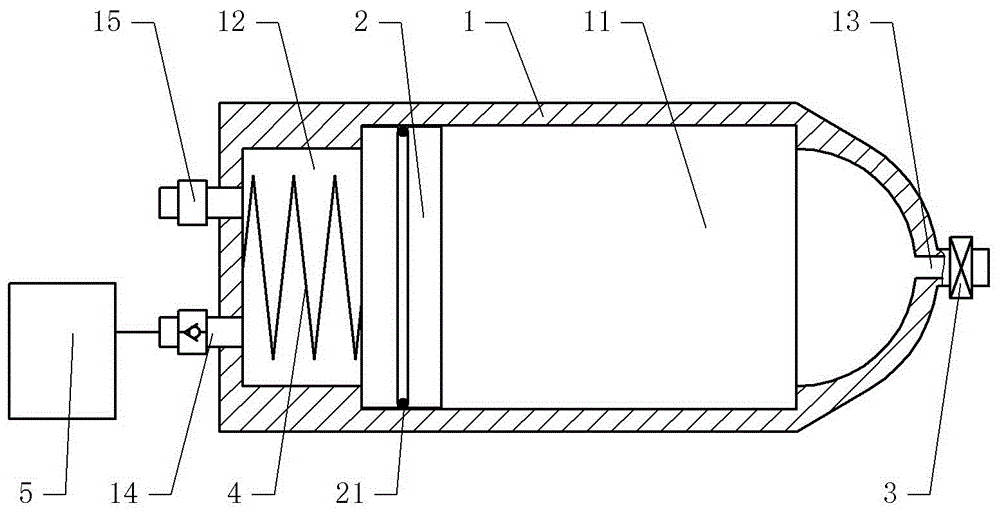

High pressure gas filling process

ActiveCN106382462APrevent leakageForce balanceVessel mounting detailsFluid handledExhaust valveCompressed natural gas

The patient discloses a high pressure gas filling process, and relates to an exhausting device with structural characteristics as features. A gas storage tank is filled with high pressure gas by adopting the high pressure gas filling process. The gas storage tank comprises a tank body and a piston arranged in the tank body. The tank body comprises a head end and a tail end. A gas outlet is formed in the head end of the tank body. An exhaust valve is arranged at the gas outlet. A pressure control valve and a one-way gas inlet are arranged at the tail end of the tank body. The one-way gas inlet is connected with an air compressor. A compressed natural gas bin is arranged between the piston and the head end of the tank body. An air bin is arranged between the piston and the tail end of the tank body. A seal ring is arranged on the piston. The gas storage tank can ensure constant-flow output of gas. During the processes of gas filling, exhausting and storing, the pressure difference between the air bin and the compressed natural gas bin is always not higher than 1 MPa, so that the service life of the seal ring can be prolonged.

Owner:贵州望江气体有限公司

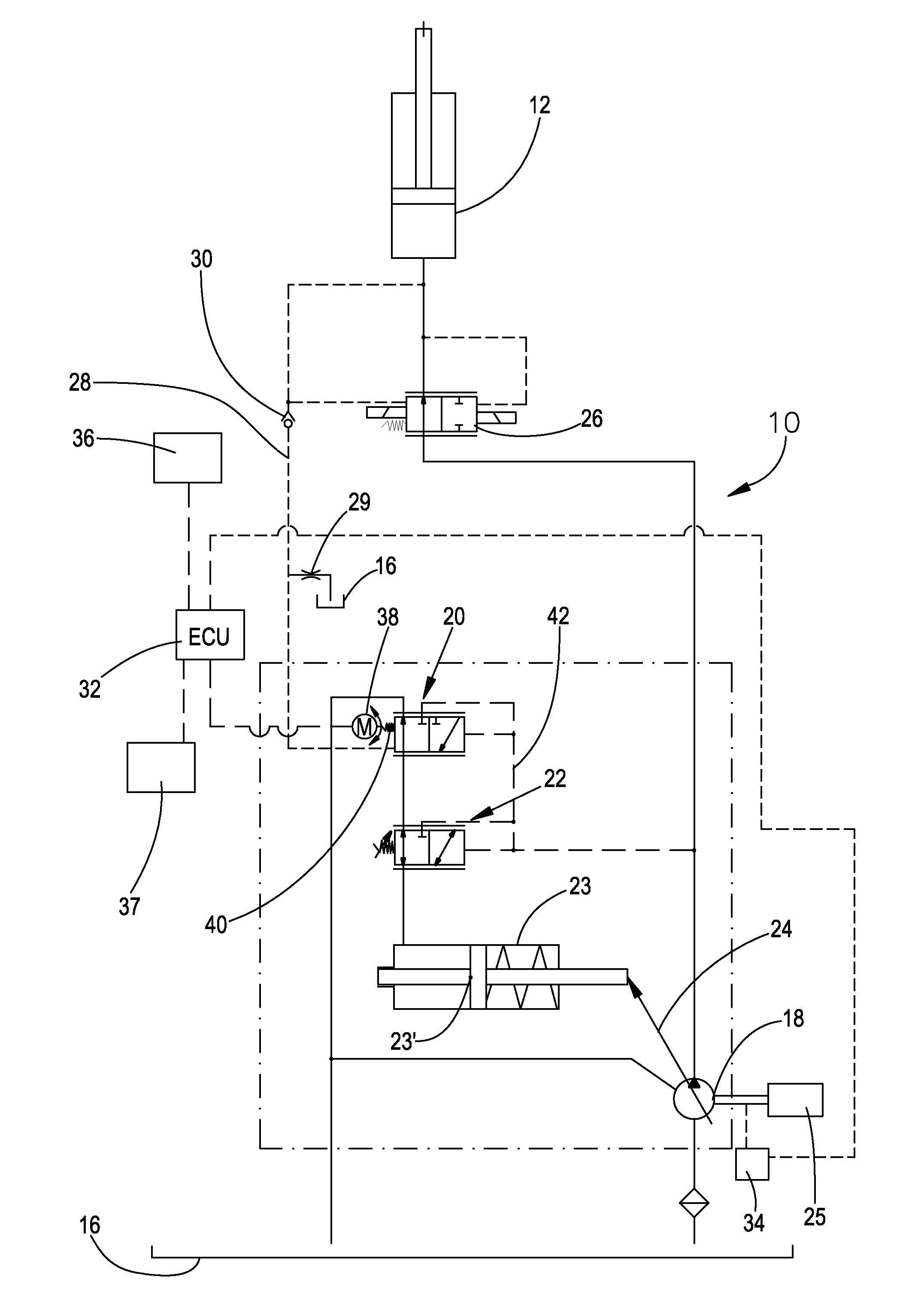

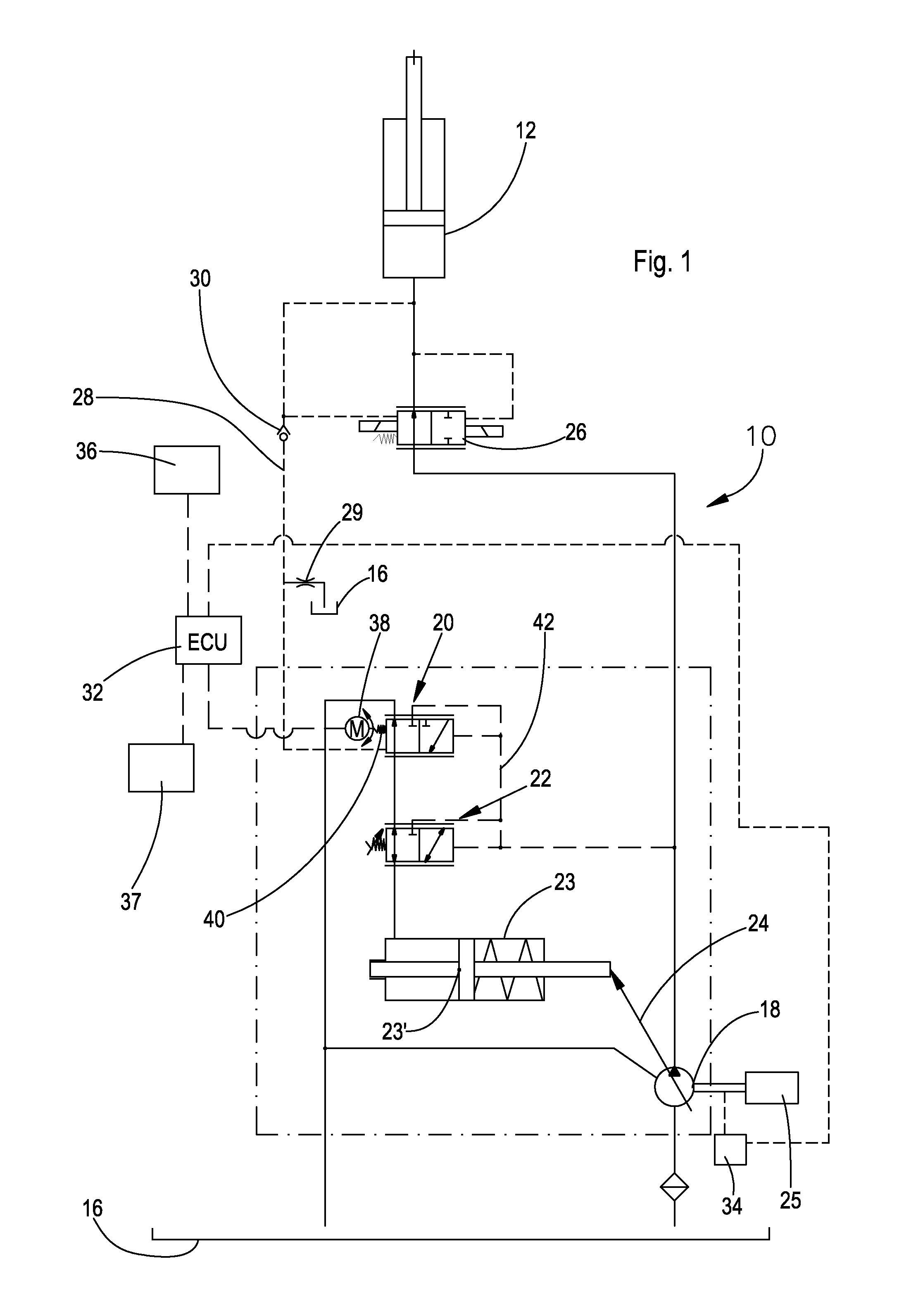

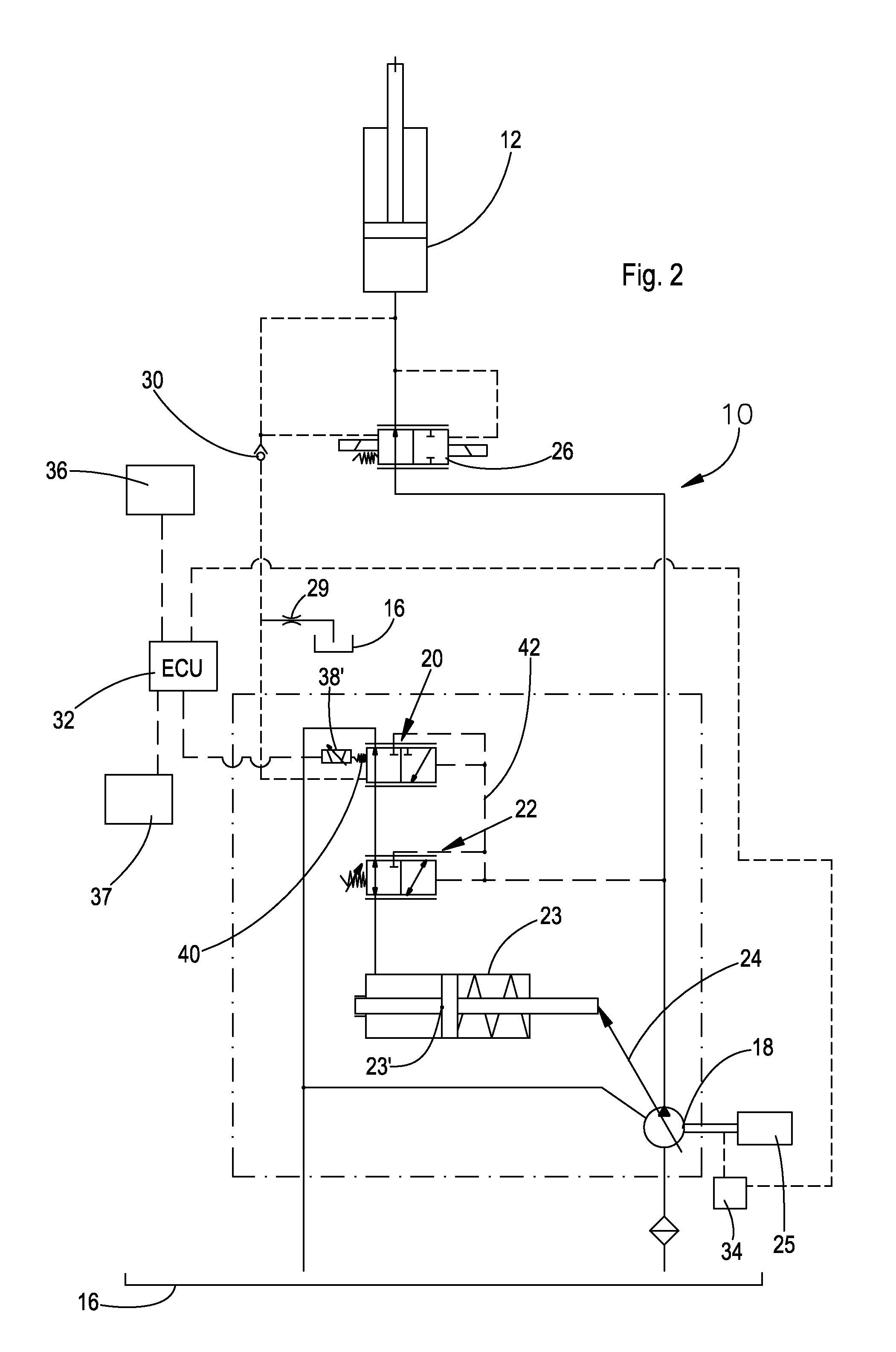

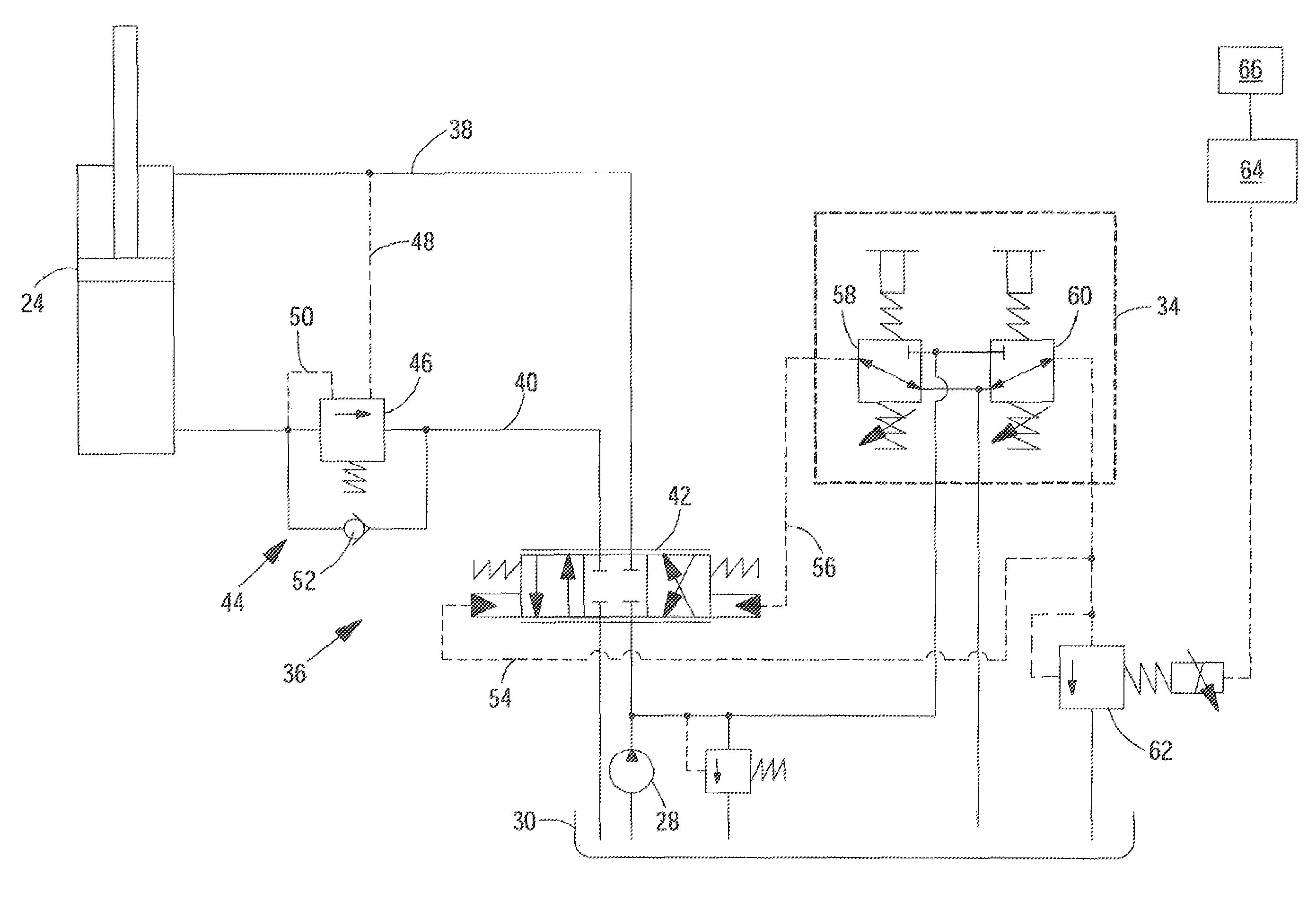

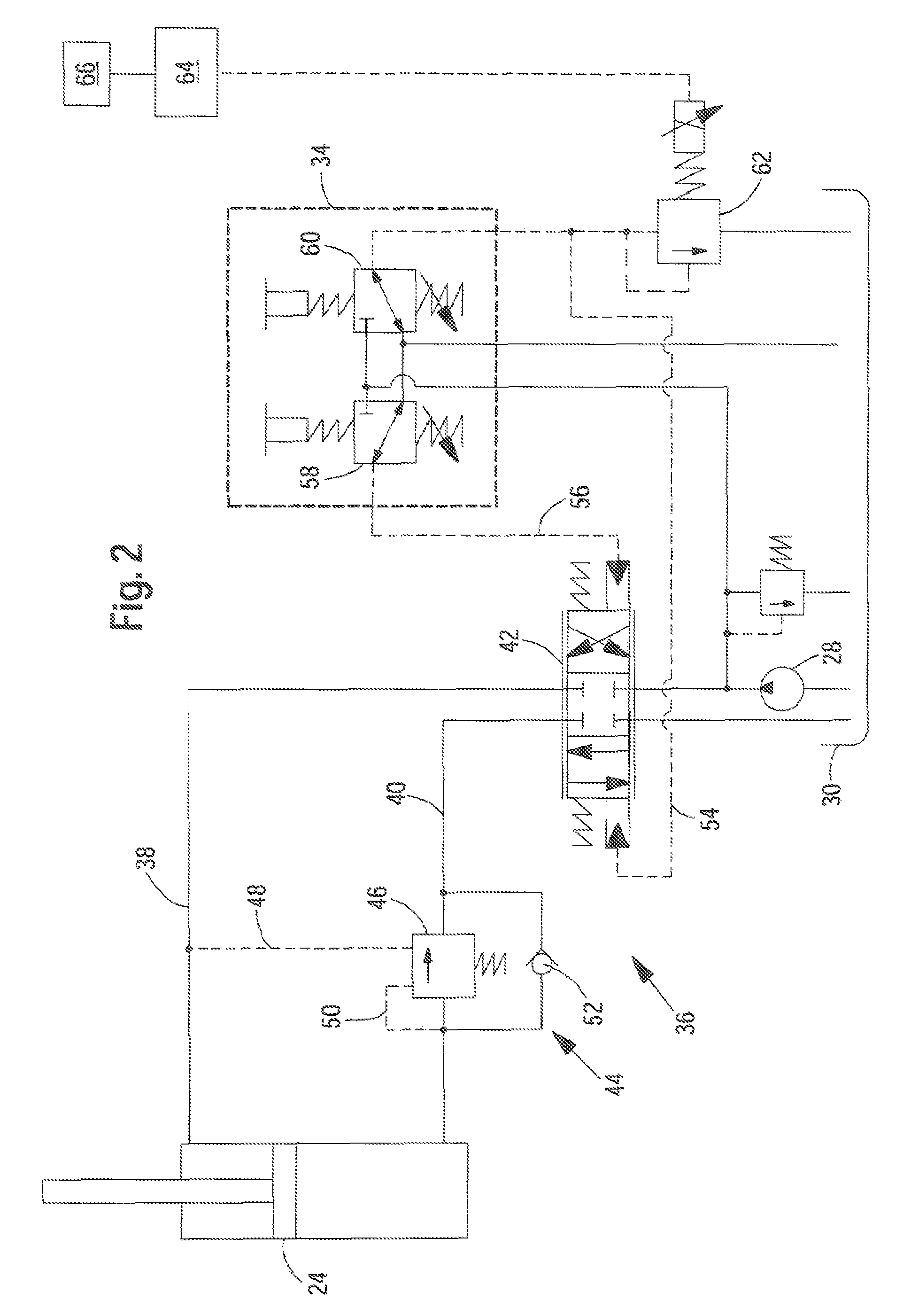

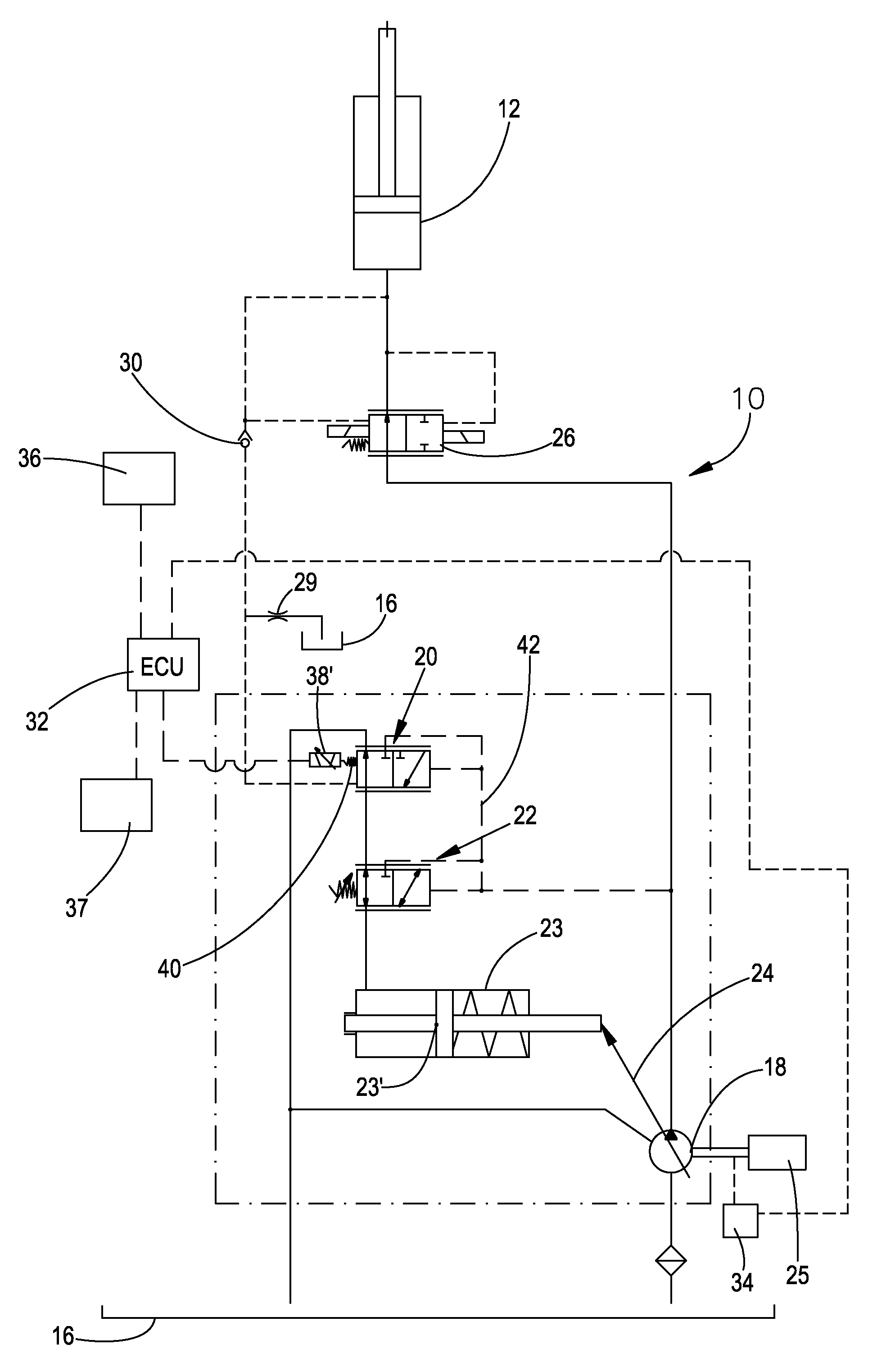

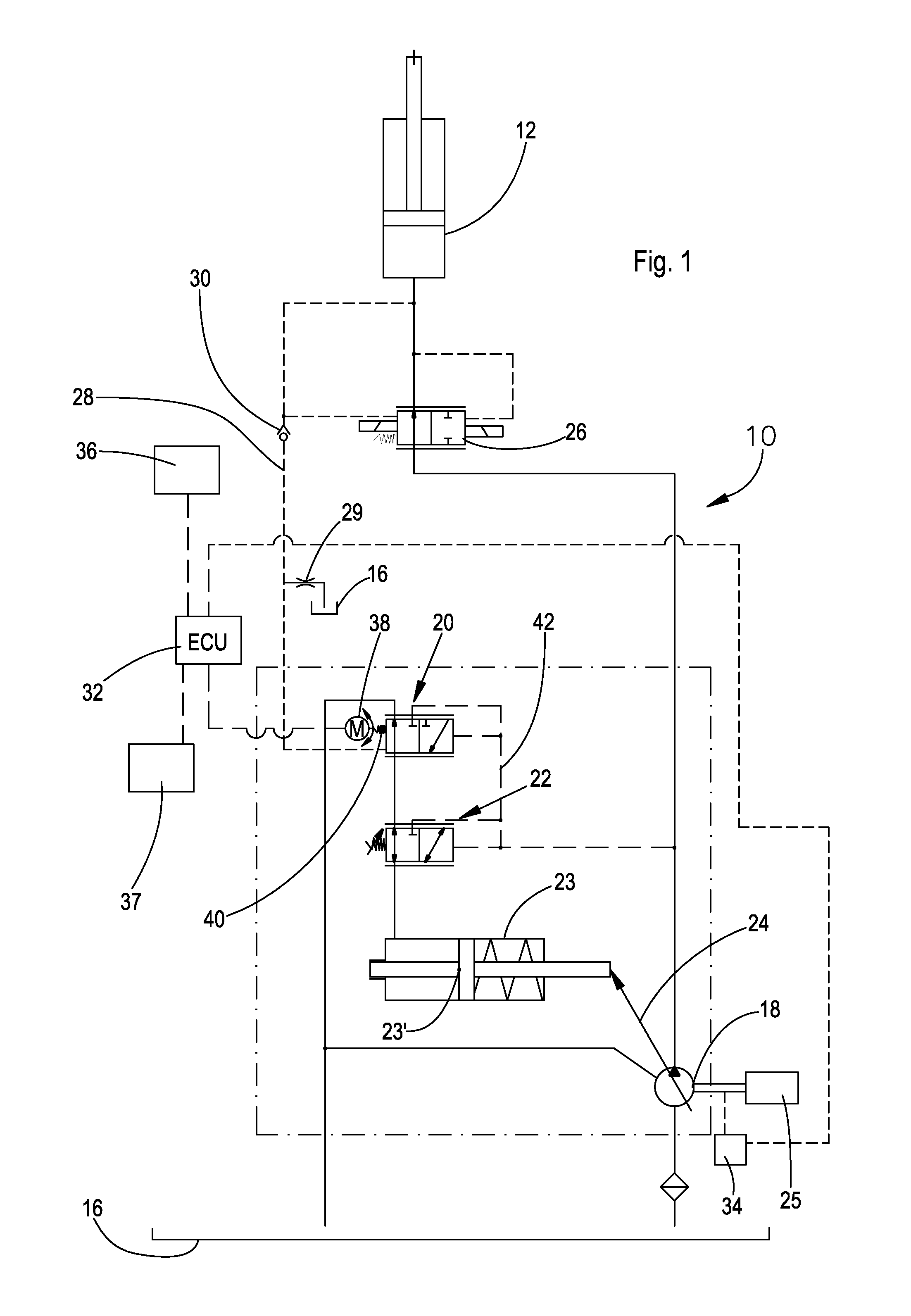

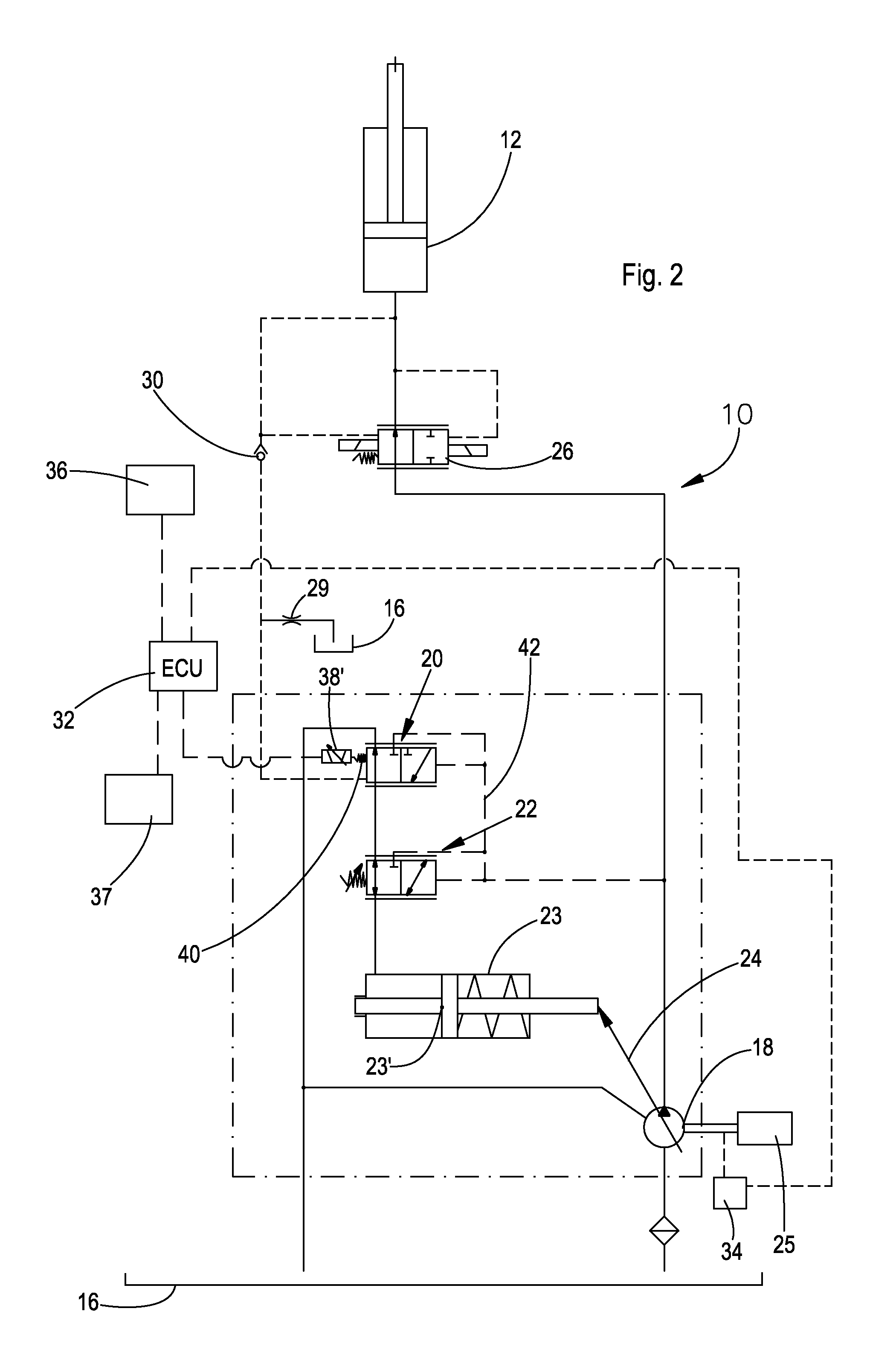

Hydraulic system

ActiveUS20100154404A1Reduce power lossHigh trafficFluid couplingsServomotorsHydraulic pumpPressure difference

A hydraulic system includes an engine driven adjustable hydraulic pump which supplies fluid to a hydraulic consumer, and an electronic control unit. The adjustable pump includes flow controller for controlling a pressure difference between the consumer and the adjustable pump to a pre-determined control pressure difference. The flow controller includes an actuator controlled by the control unit, through which the pressure difference can be controlled. The electronic control unit receives an engine speed signal and controls the actuator to control the pressure difference, in order to make power delivery of the adjustable pump conform to the operating conditions of a vehicle.

Owner:DEERE & CO

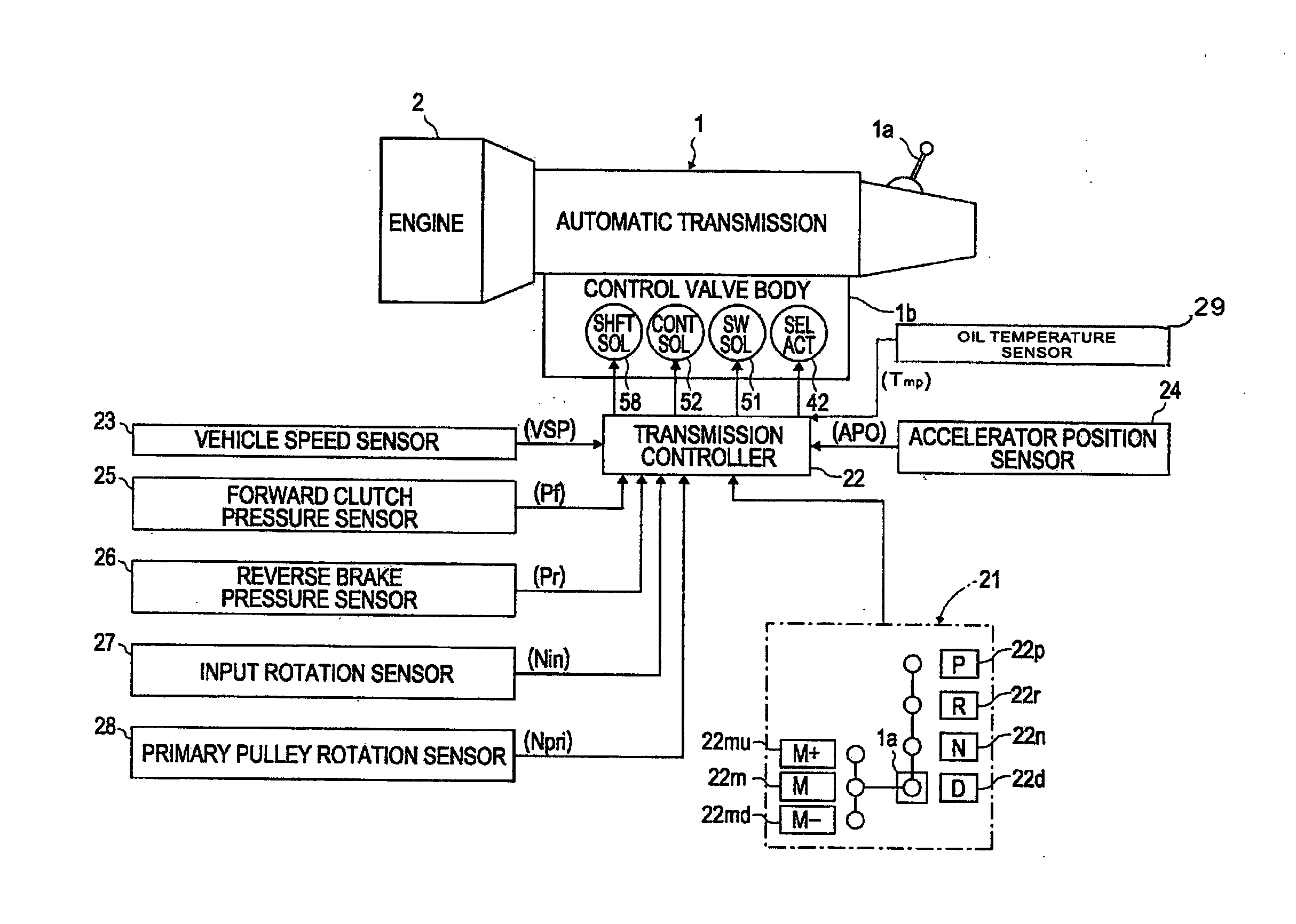

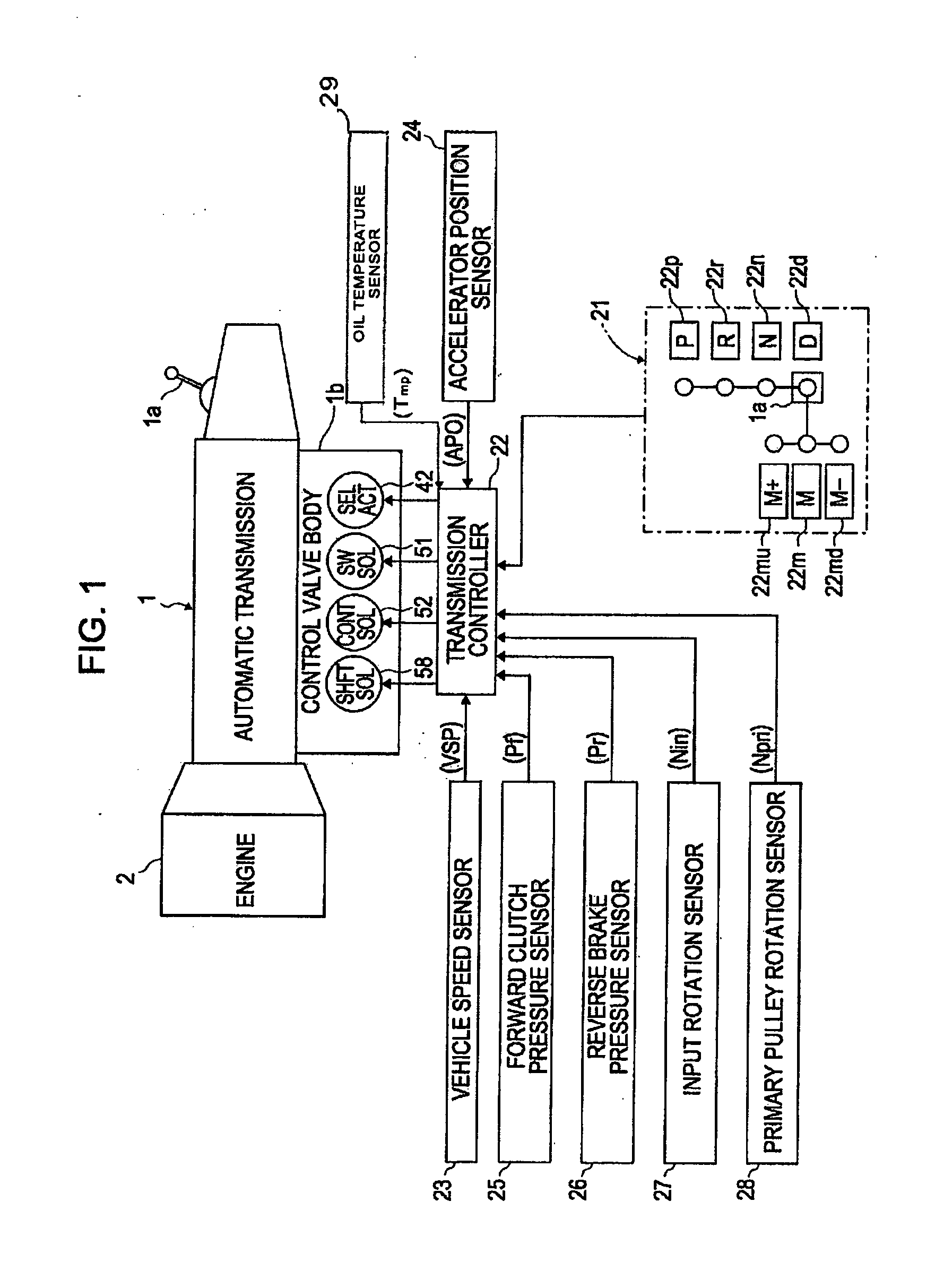

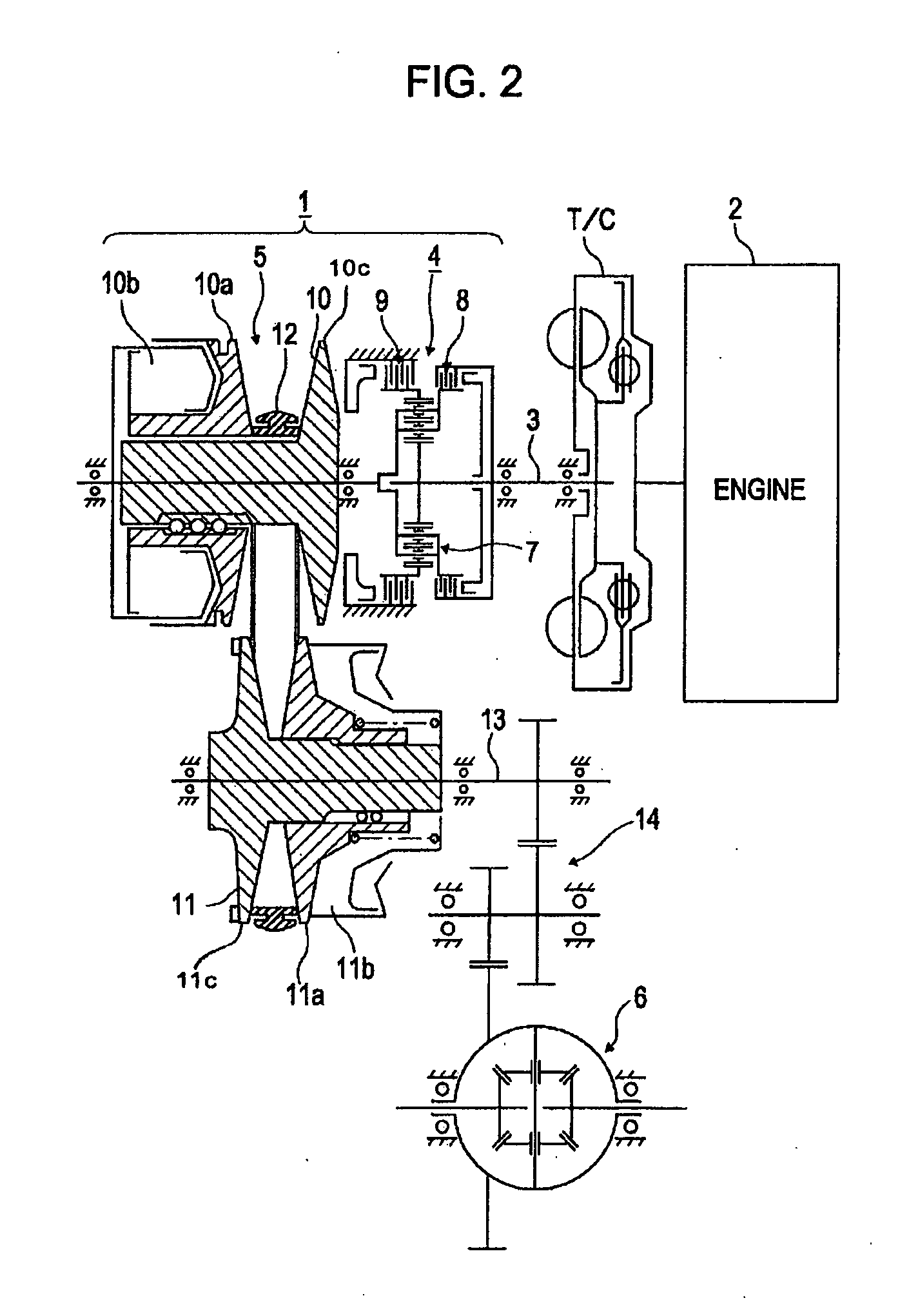

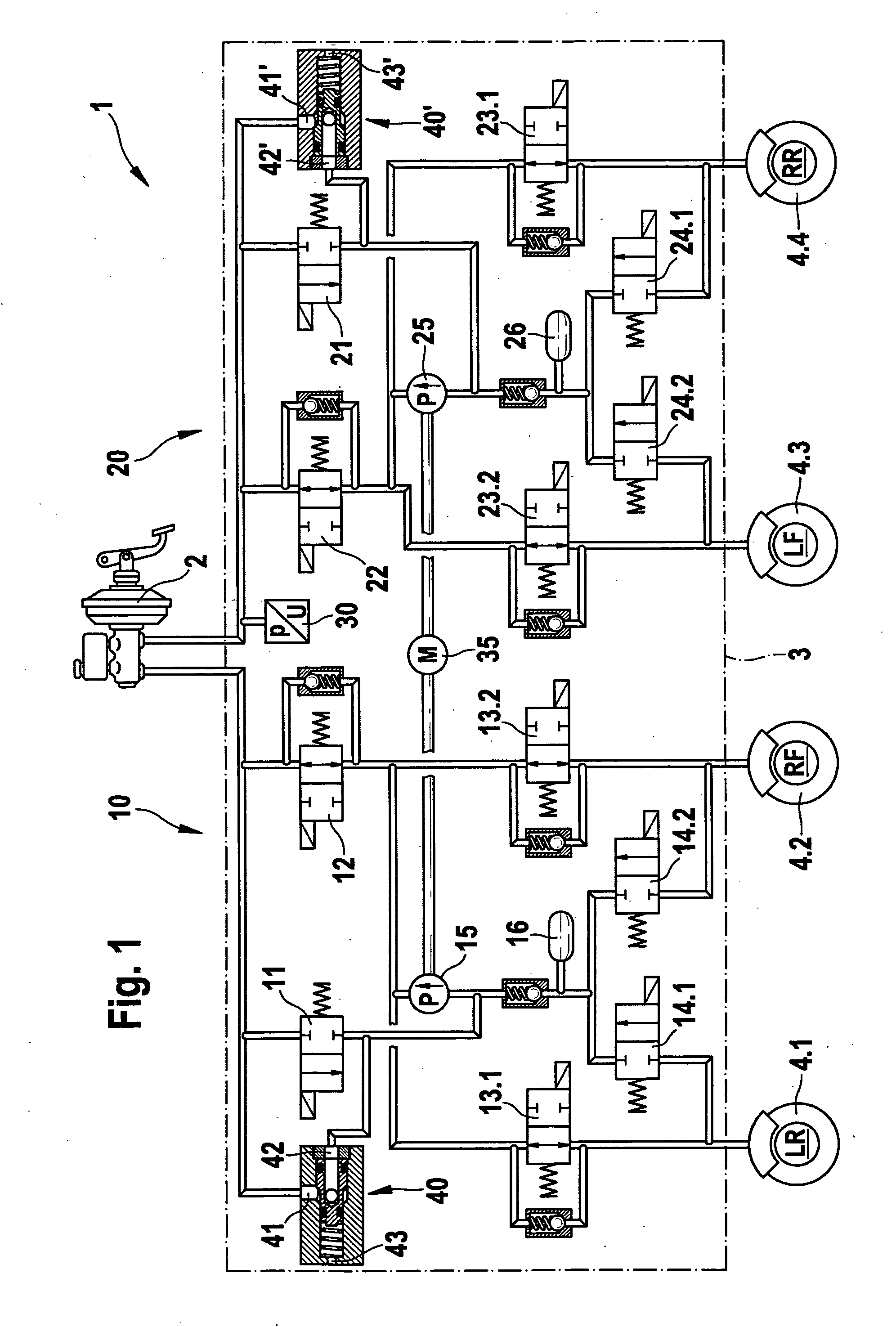

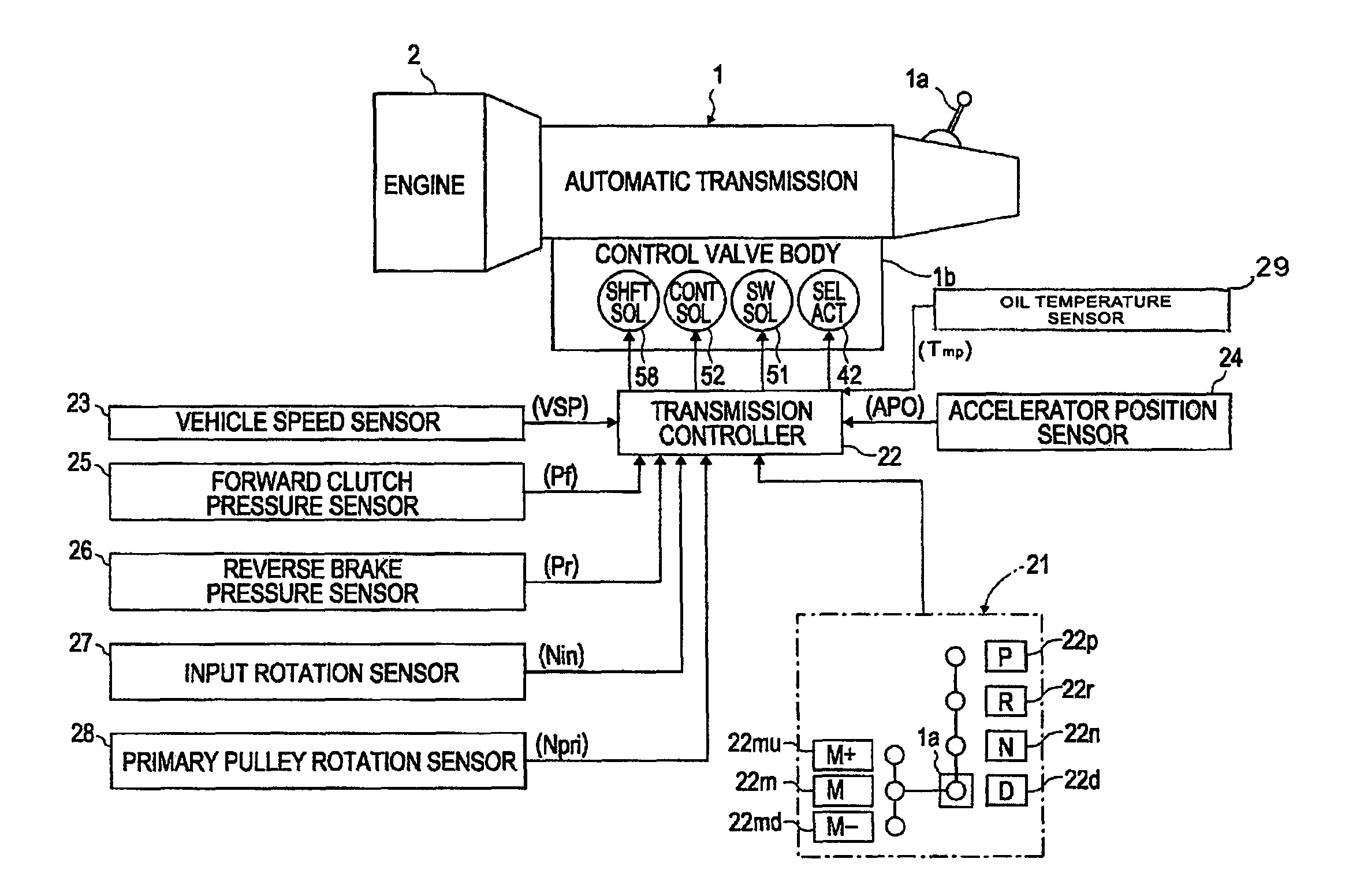

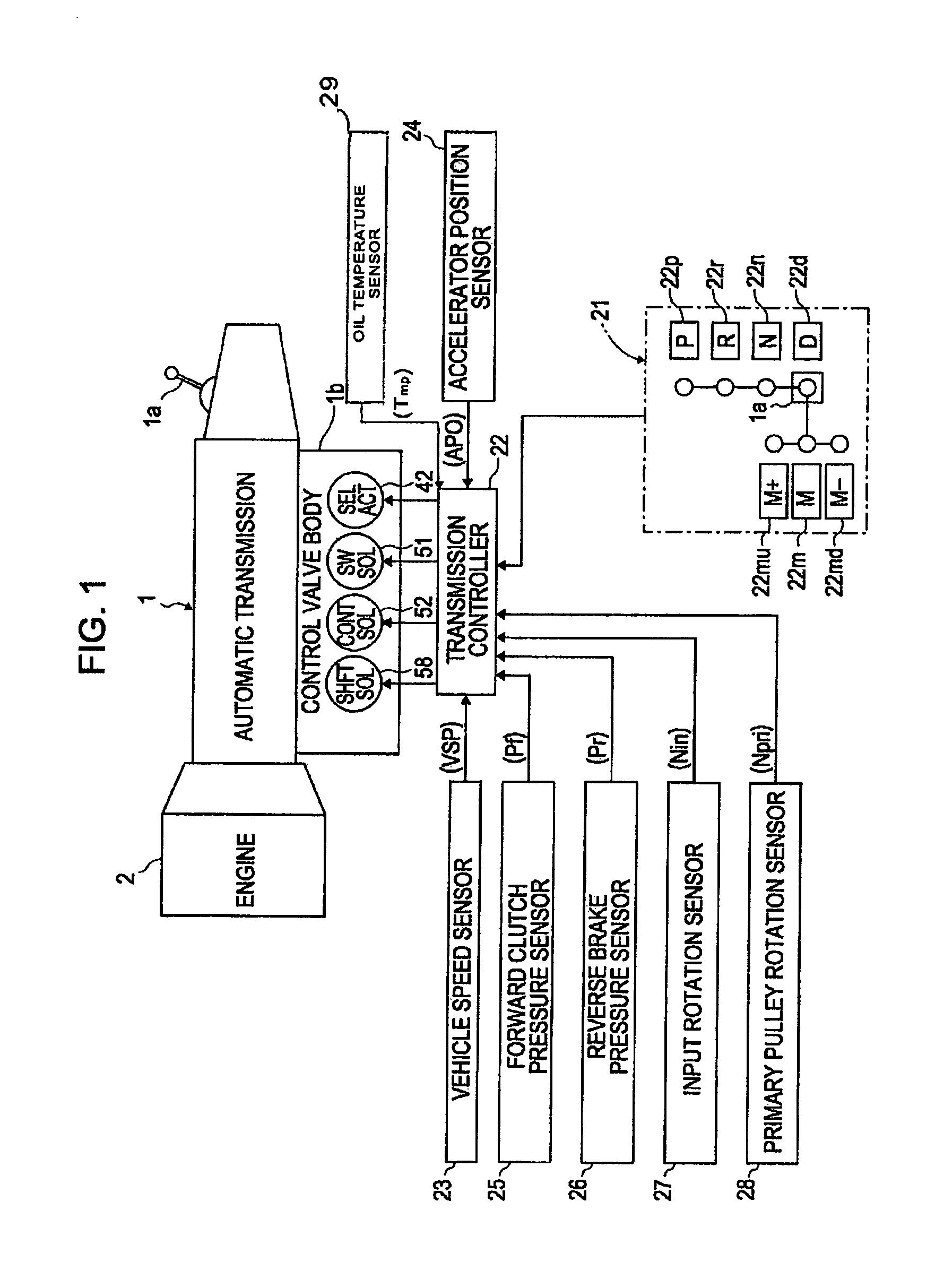

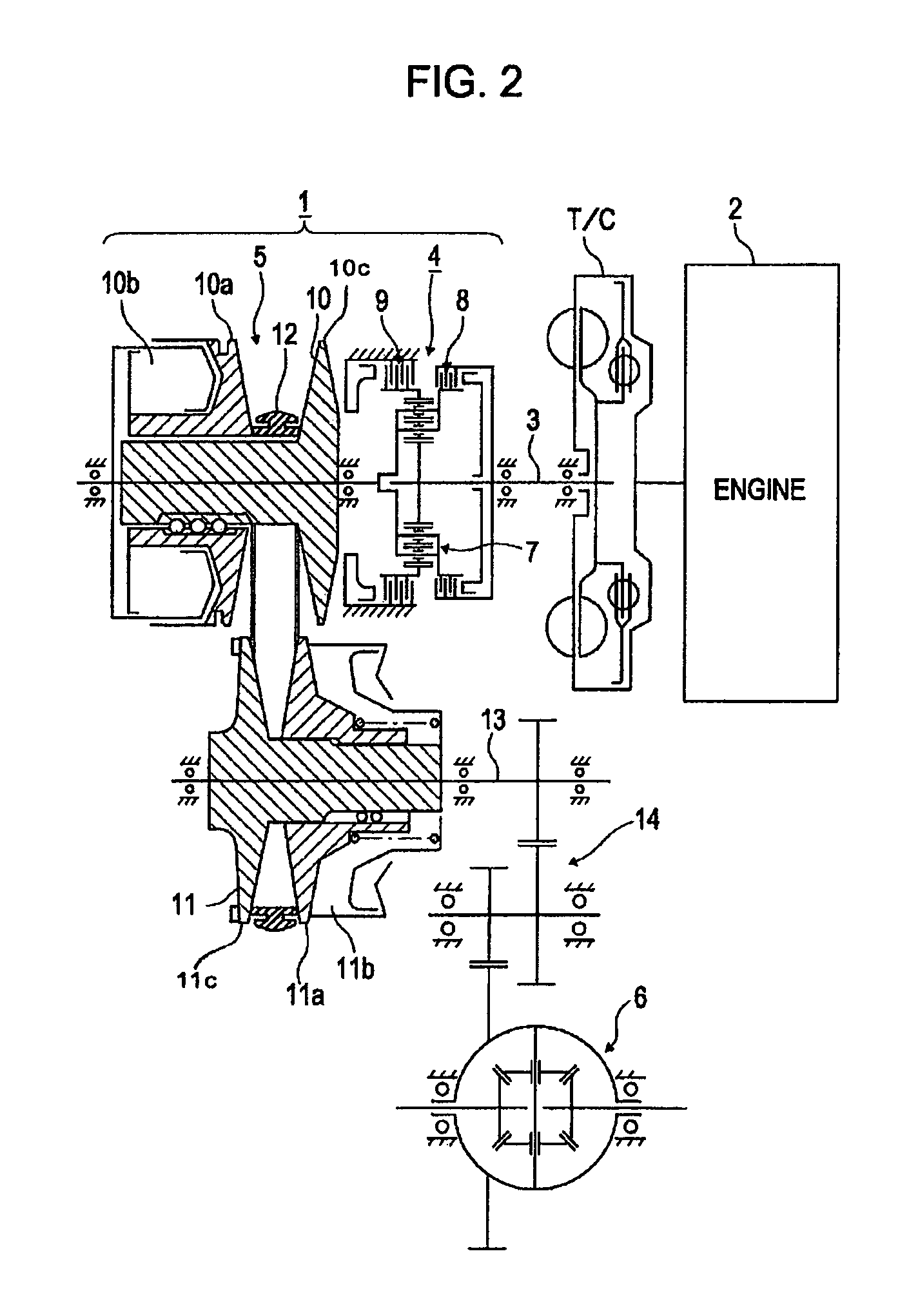

Transmission oil-pressure control apparatus and methods

InactiveUS20100294065A1Low control pressureGas pressure propulsion mountingGearing controlHydraulic circuitOil pressure

A control apparatus of a vehicle transmission includes a hydraulic circuit configured to activate at least one friction element with a control pressure, a selector configured to select a range of the transmission, a valve configured to switch a transmission shifter, and a control unit configured to direct the valve to switch the transmission shifter in response to the selected transmission range and to reduce the control pressure prior to switching the transmission shifter. A method to control a vehicle transmission includes activating at least one friction element with a control pressure, selecting a desired range of the transmission, switching a transmission range in response to the selected desired transmission range, and reducing the control pressure prior to switching the transmission range.

Owner:NISSAN MOTOR CO LTD

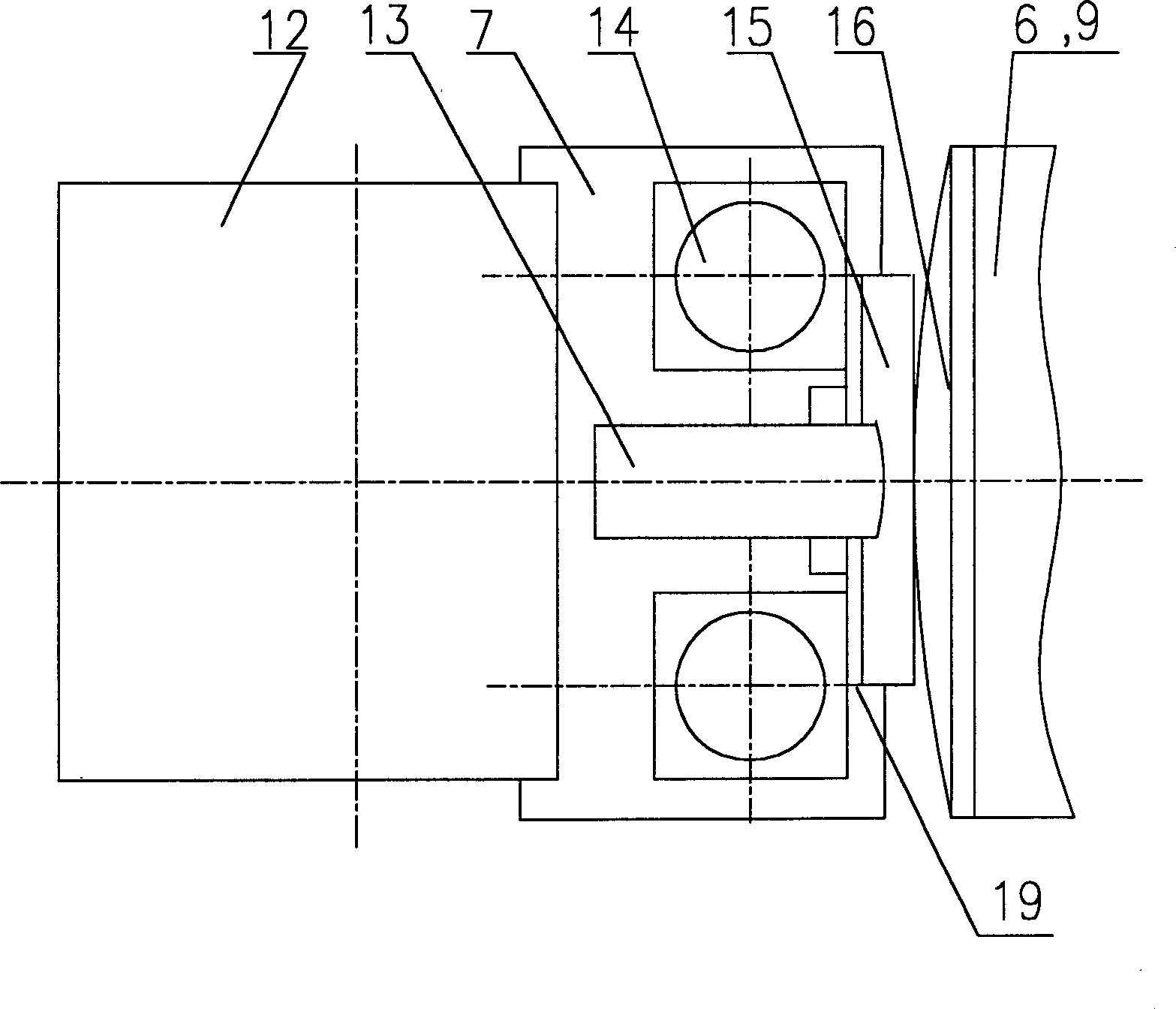

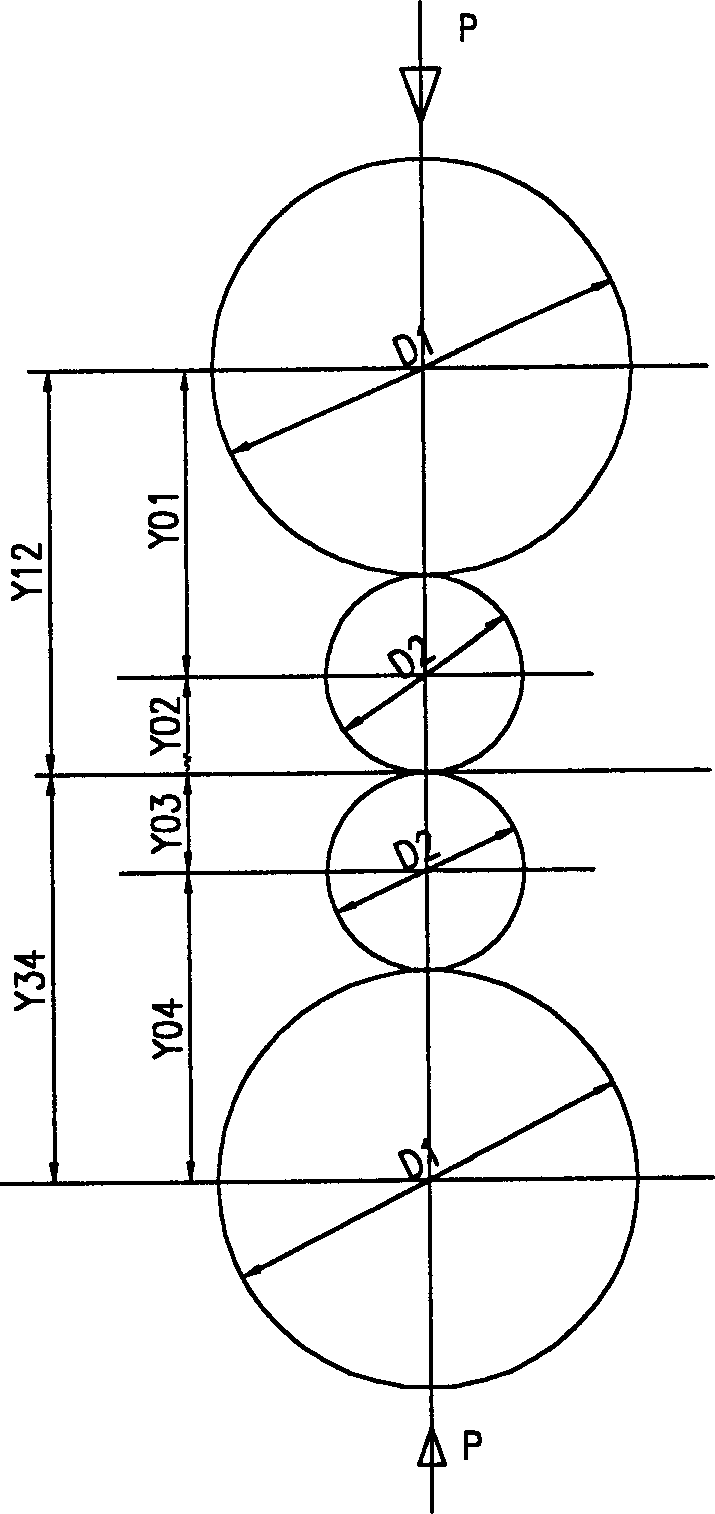

Plate shape and thickness-controlling rolling method and corresponding gap-less roller mill

InactiveCN1436613ASimple methodLow control pressureProfile control deviceMetal rolling arrangementsWork rollAutomatic control

The plate shape and thickness-controlling rolling method is to use "move work roll" roller mill, where the gap is changed to regulate the plate shape and thickness via transversely shifting and symmetrizing crossed work rolls. The roller mill includes frame, hold down mechanism, upper support roll mechanism, upper work roll mechanism, lower support roll mechanism, lower work roll mechanism, and cross shift mechanism comprising waist block and shift cylinder. The cross shift mechanism is used to replace available expensive automatic thickness controller and results in simple roller mill structure, low cost, low pressure for plate shape and thickness control and raised control precision. In addition, using the hold down cylinder, the waist block and the shift cylinder can realize gap-less rolling.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

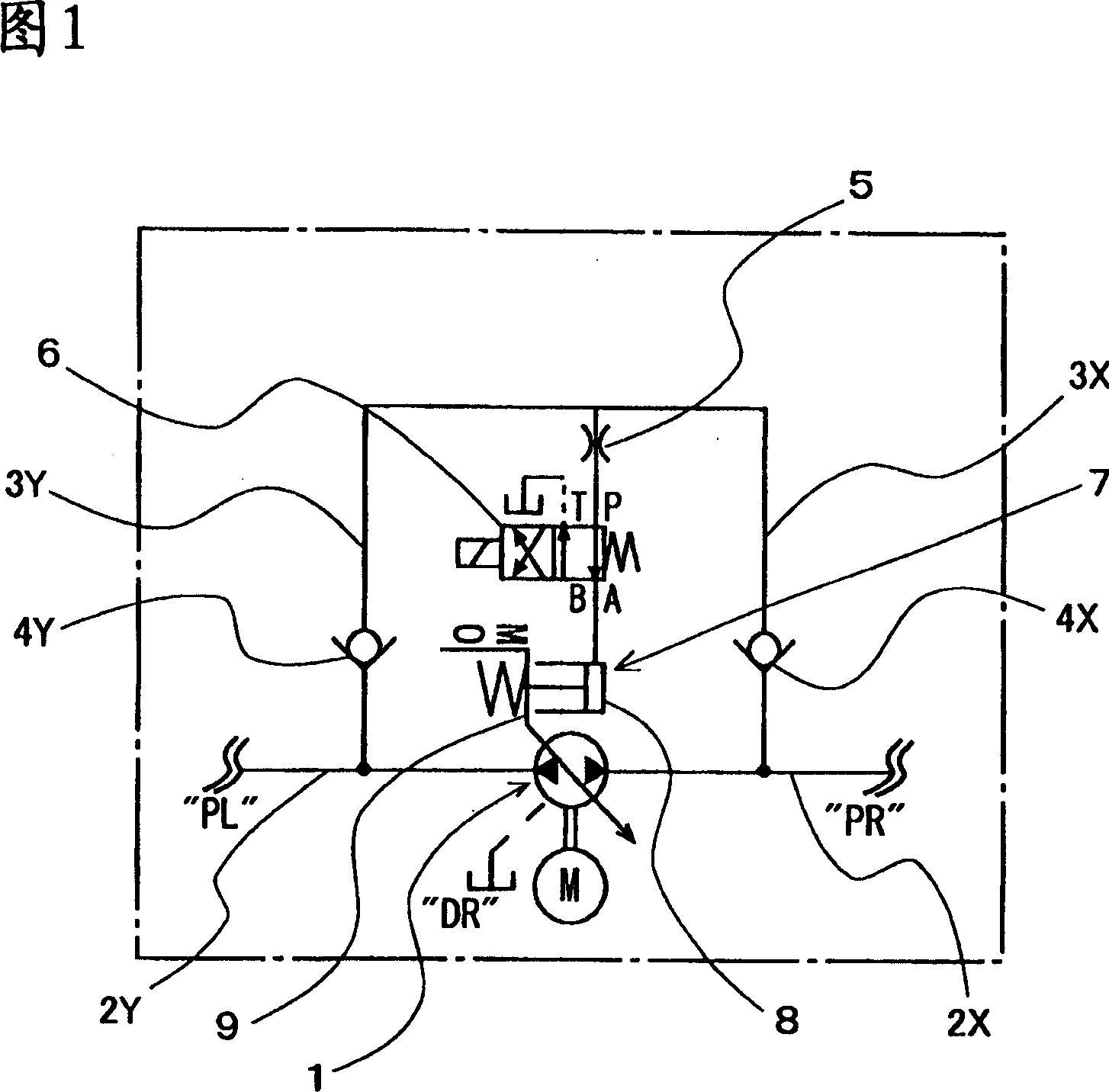

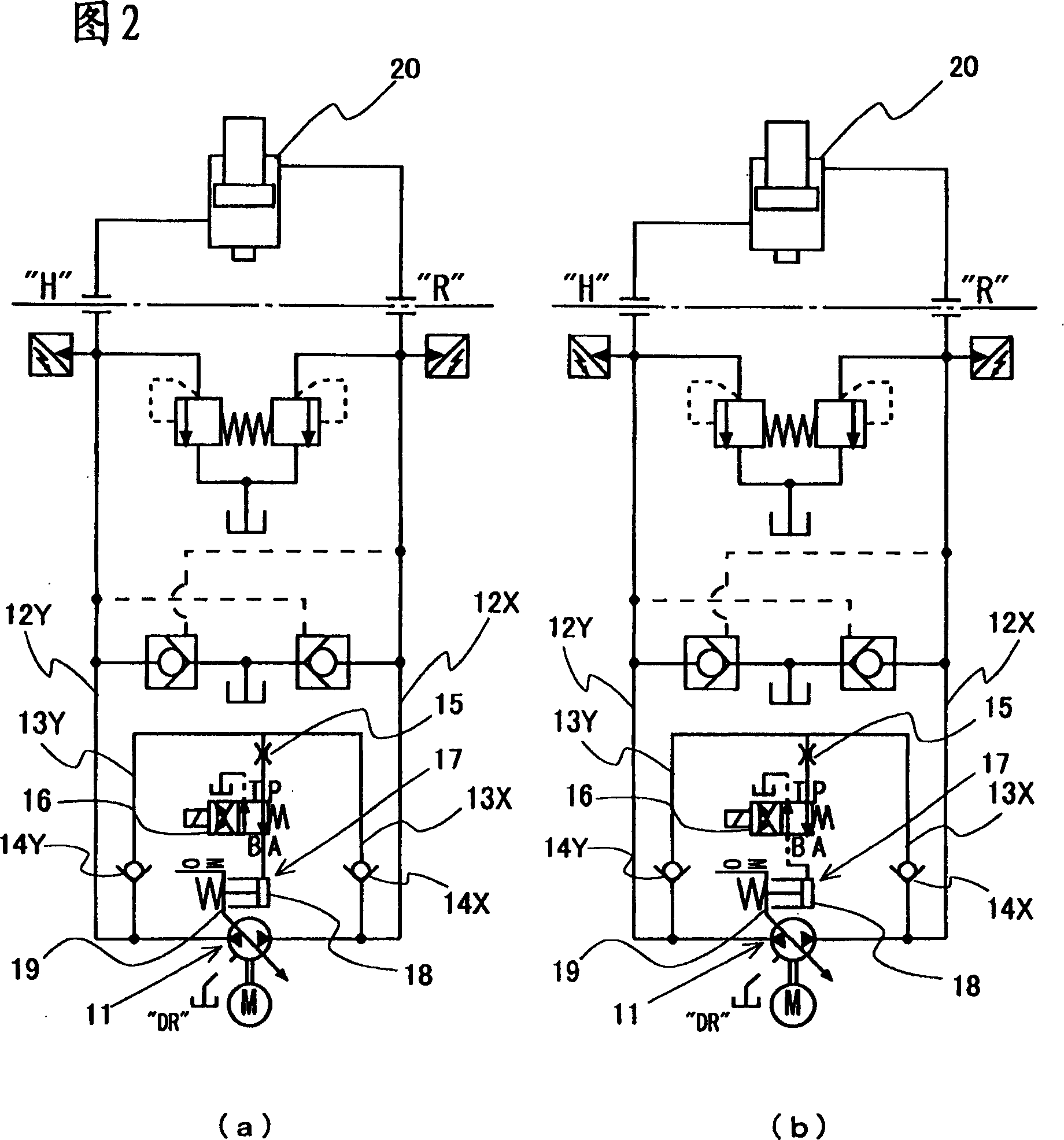

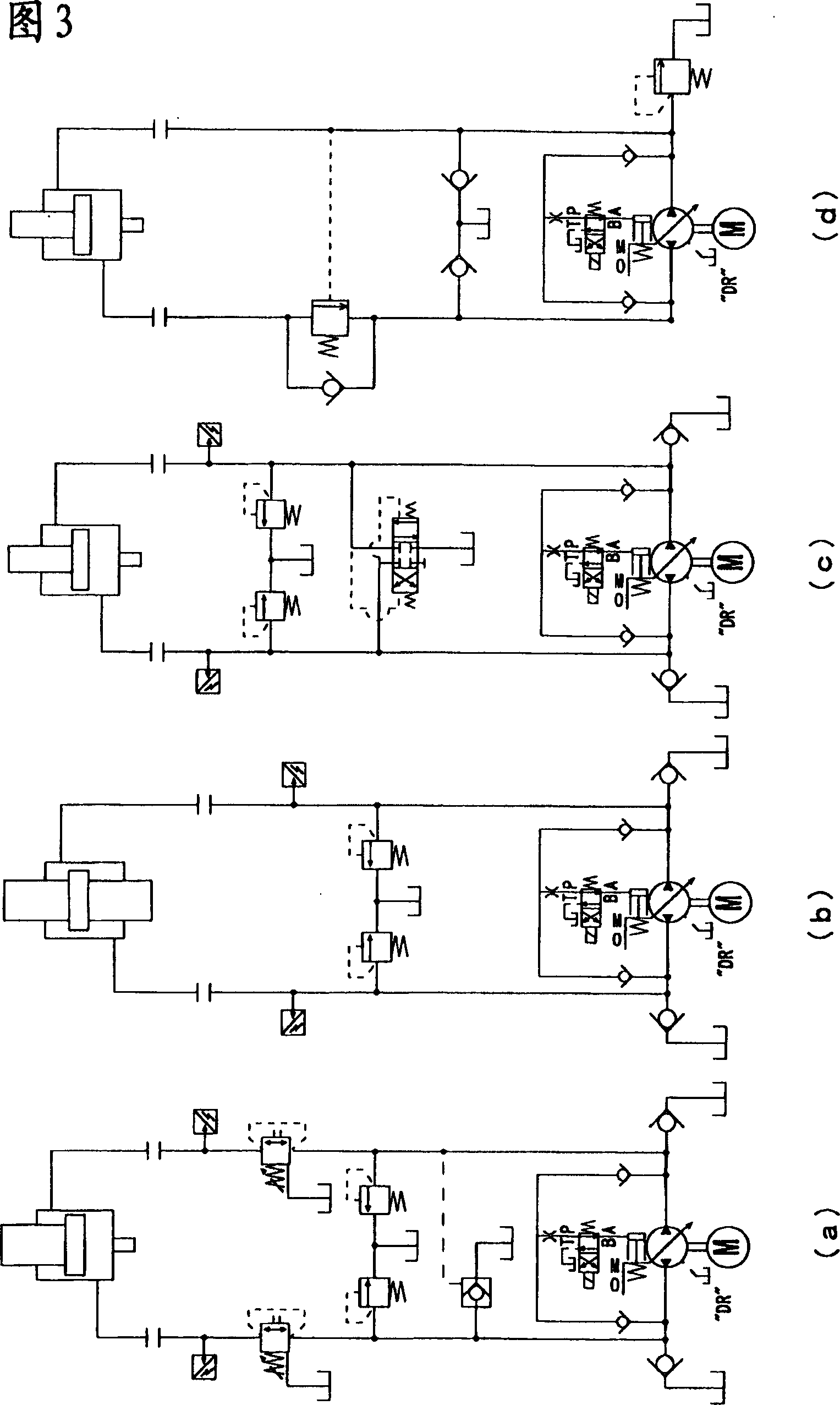

Volume-variable bi-directional rotary pump and hydraulic loop using the pump

The invention provides a bi-directional rotary pump, which can form large flow when controlling flow, and can reduce load torque exerting on the electric engine when controlling pressure, making the electric engine miniaturization and with higher efficiency than the existing bi-directional rotary pump. The volume-variable bi-directional rotary pump includes a bi-directional rotary pump mechanism, a volume-variable mechanism for carrying out mechanical modification based on the increase and decrease of the control pressure acting on the press part, which causes the discharge volume for rotating per unit of the pump mechanism to change; a change-over valve, forming the first loop connection for reducing said control pressure, connecting the press part with low press side loop, when making the volume-variable mechanism modify to the large volume, at the same time the second loop connection is formed for guiding the discharge pressure of said pump mechanism itself as control pressure, when making the volume-variable mechanism modify to the small volume.

Owner:YUKEN KOGYO

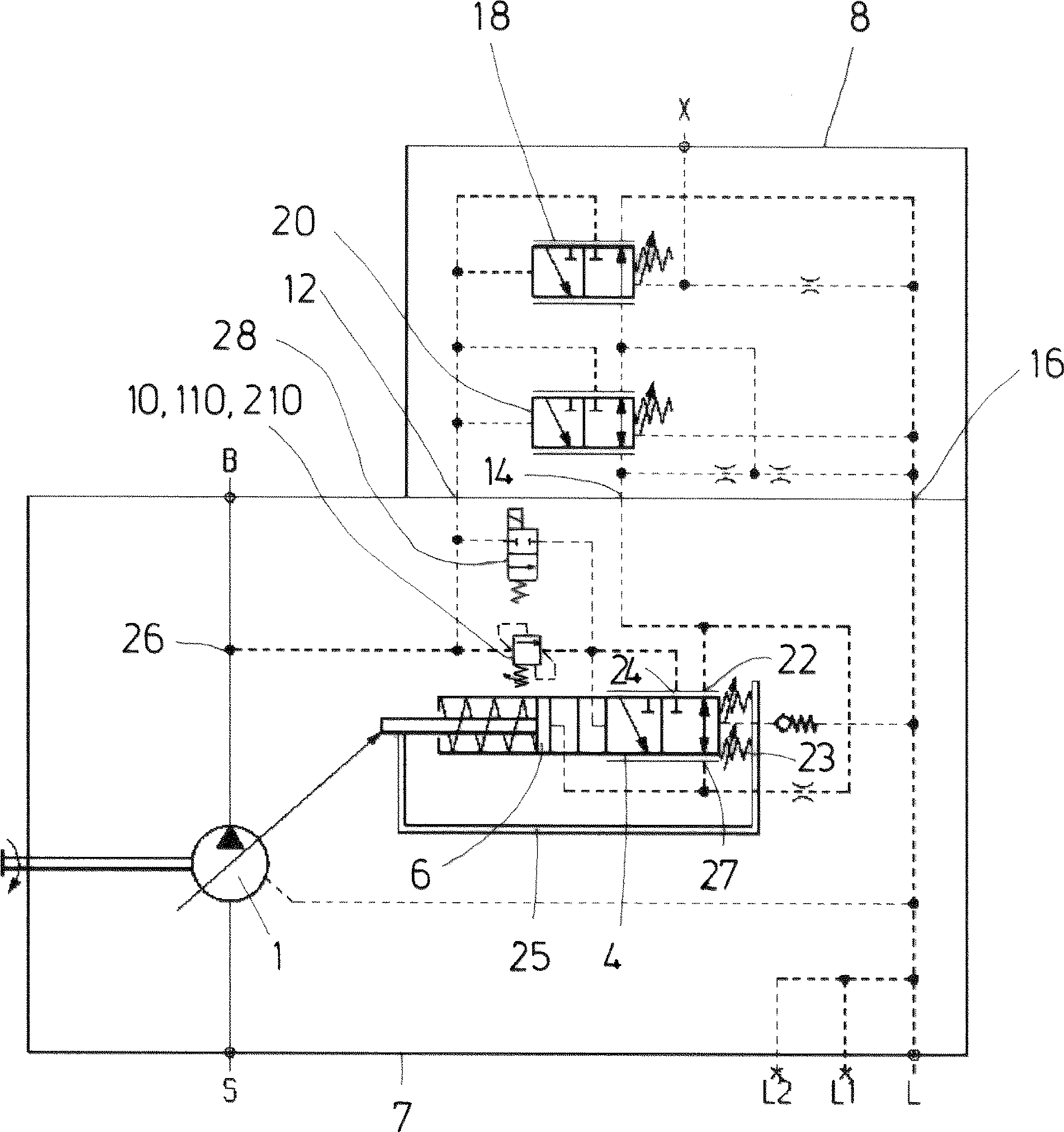

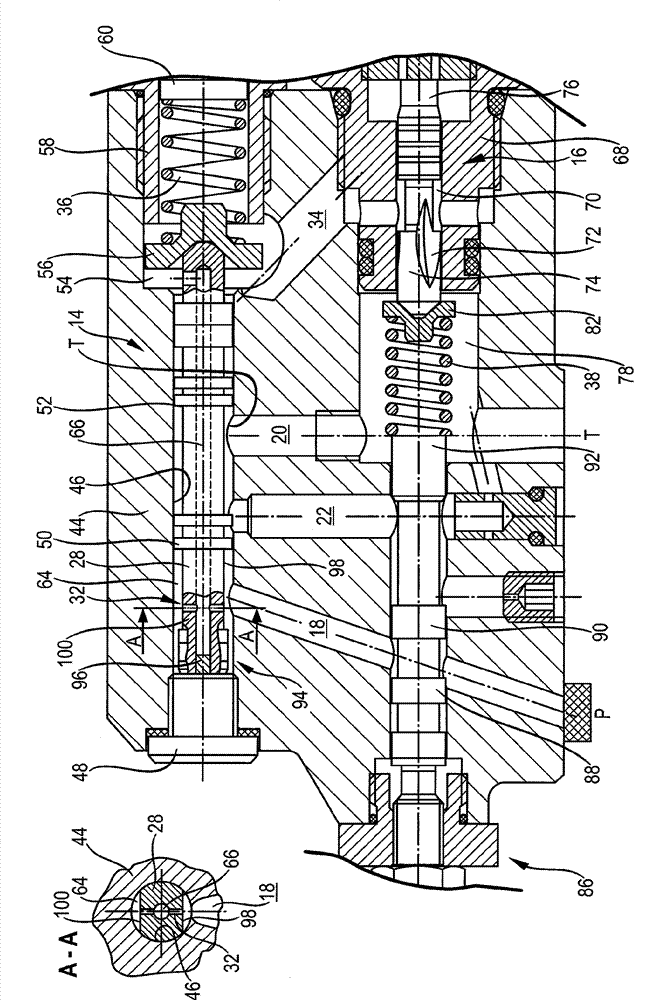

Adjusting device used for fluid static force pump and fluid static force pump

ActiveCN103671058ALow servo pressureSimple device technologyPump controlPositive-displacement liquid enginesPressure decreaseFuel tank

The invention discloses an adjusting device used for adjusting discharge volume of the fluid static force pump and provided with a power adjusting valve. The power adjusting valve is provided with a first port, a second port, a third port and a valve slide block. Hydraulic pressure oil can flow into the first port from a pressure port of the pump. The second port can be connected with an oil tank. The third port is connected with a servo cavity in a servo piston. The valve slide block can be loaded through controlling pressure in a condition when the discharge volume of the pump is decreased and the valve slide block can be loaded with a spring device in a condition that a swing angle is increased. The invention aim at adjusting different power levels by arranging the adjusting device adopting the above structure. The device is realized by that the valve device can load control pressure that is amount to pressure in a pressure port of the pump or can load control pressure decreasing relative to pressure in the pressure port of the pump based on adjustment of the valve slide block of the power adjusting valve.

Owner:ROBERT BOSCH GMBH

Loader

ActiveUS7717664B2Low control pressureReduced volume flowSafety devices for lifting equipmentsFluid couplingsHydraulic cylinderPressure transmission

Owner:DEERE & CO

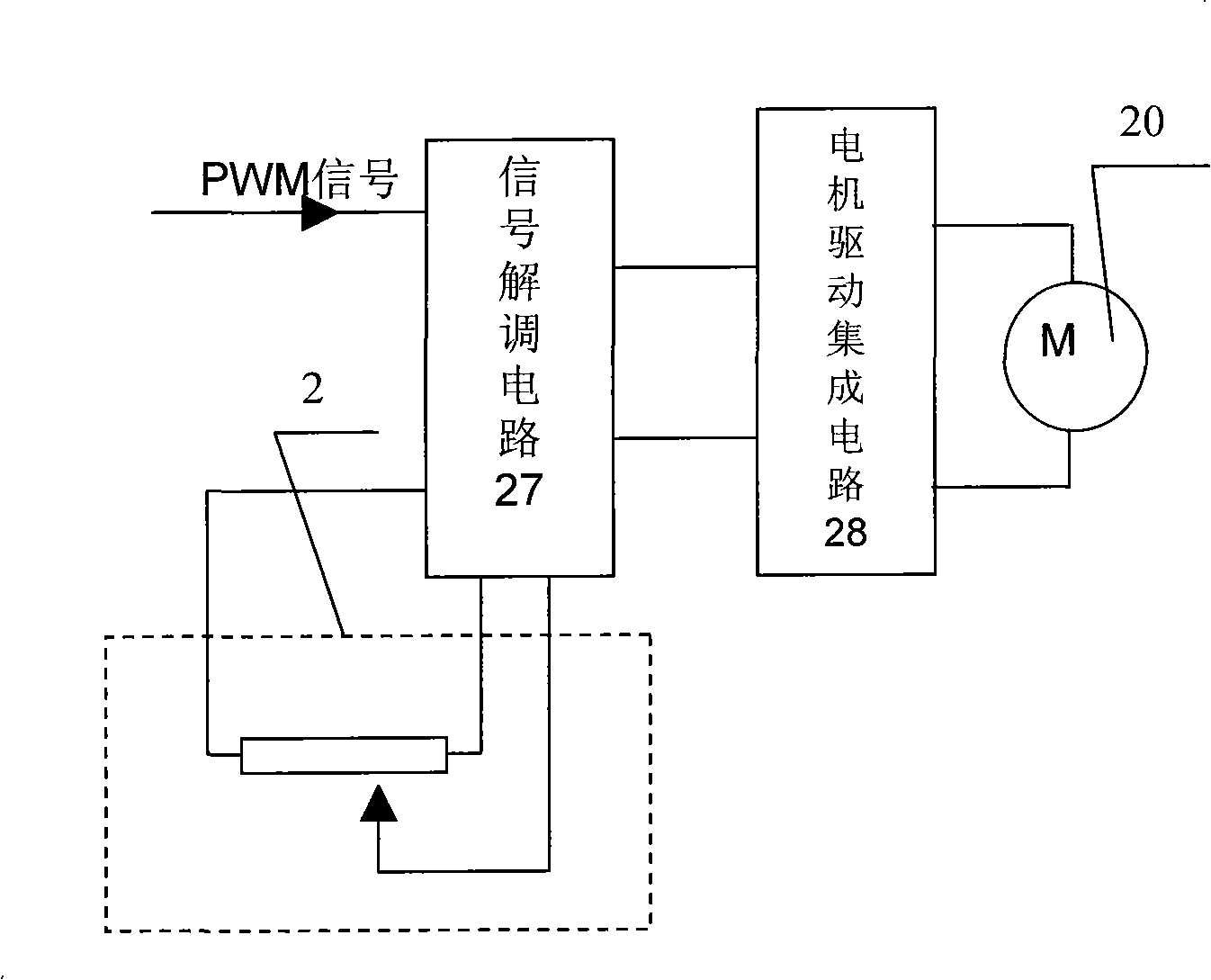

Intelligent electric steering engine based on CAN bus communication

InactiveCN101256423AAutomatically adjust duty cycleLow control pressureControl using feedbackTotal factory controlHumanoid robot naoActuator

The invention relates to an intelligent electric actuator based on CAN bus communication, belonging to the field of control technology for airplane moles and anthropomorphic robots. The intelligent electric actuator comprises a signal demodulation circuit, a motor driving integrated circuit and a DC motor, which are successively connected, the output shaft of the DC motor is connected with a reduction gear unit, the output shaft of the reduction gear unit is coaxially connected with a potentiometer. The intelligent electric actuator comprises a micro-control chip and a CAN bus driver. The micro-control chip is connected with a host computer through the CAN bus driver and a CAN bus, receives the control commands of the host computer, generates PWM signals and transmits the signals to the signal demodulation circuit. The potentiometer is connected with the micro-control chip 26 which collects the position signals of the potentiometer, and transmits the position signals to the host computer. The intelligent electric actuator has small volume, high reliability, low power consumption and high intelligence, is suitable for composing distributed control systems, greatly lowers the control pressure of a host control machine, and reduces the leas number of the host control machine.

Owner:BEIJING UNIV OF TECH

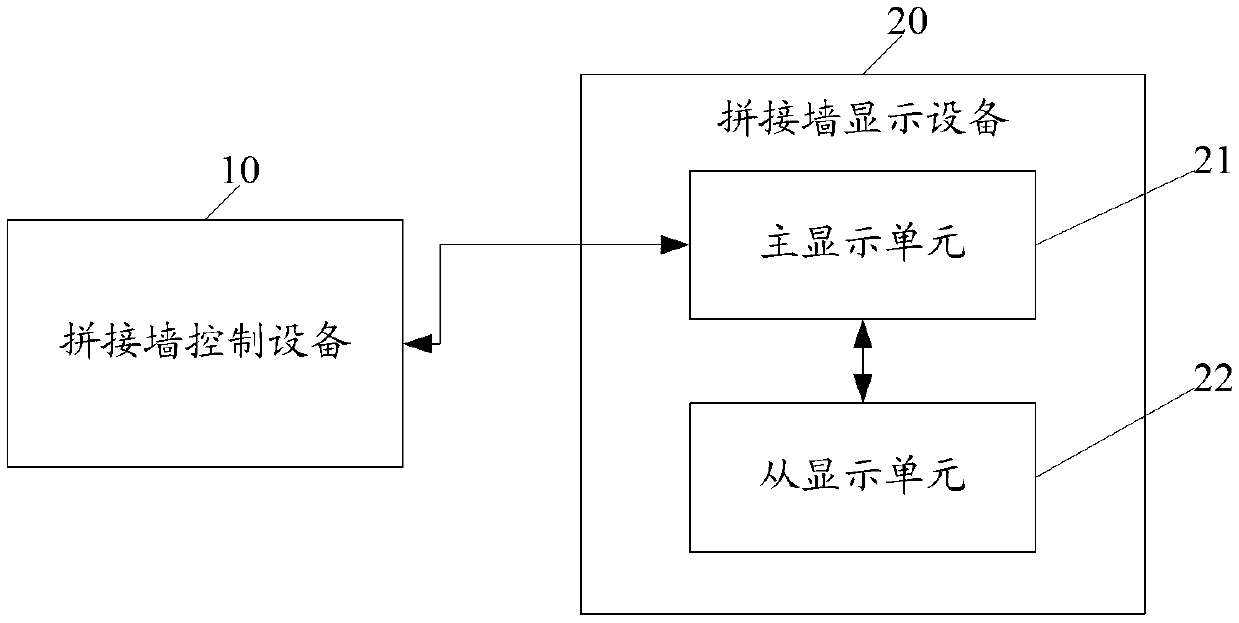

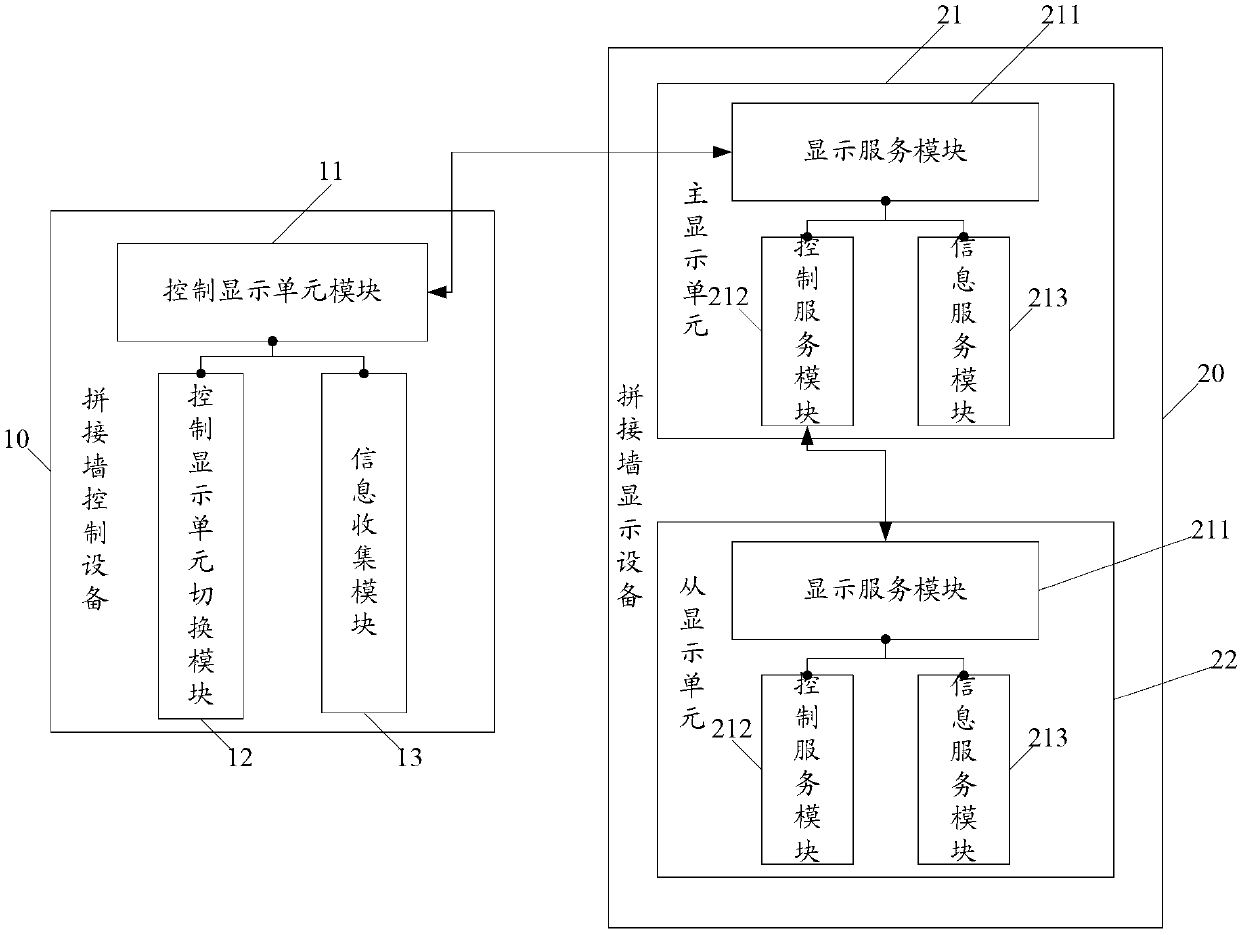

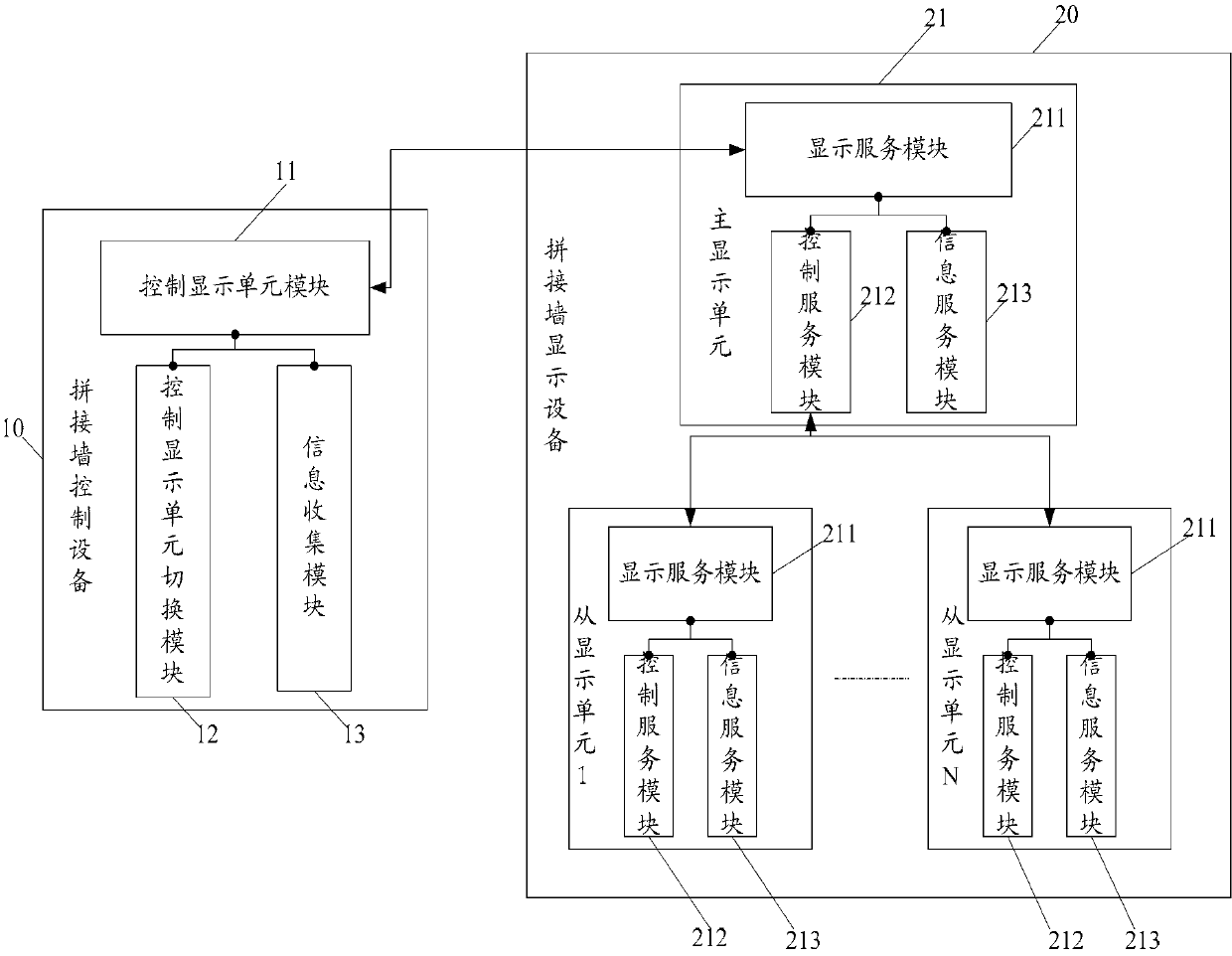

Control system and method for dynamic splicing wall display

InactiveCN103345375AImprove fault toleranceLow control pressureDigital output to display deviceFault toleranceControl system

The embodiment of the invention discloses a control system and a control method for dynamic splicing wall display, which are used for improving the fault tolerance of control systems, and are simple and flexible to operate. The control system disclosed by the embodiment of the invention comprises a splicing wall control device and a splicing wall display device, wherein the splicing wall display device comprises a master display unit and at least one slave display unit, the splicing wall control device is connected with the master display unit of the splicing wall display device, and the master display unit is connected with all the slave display units. When the master display unit has a fault, the splicing wall control device is switched and connected to any slave display unit, then the master display unit is converted into a slave display unit, and the slave display unit connected with the splicing wall control device is converted into a master display unit.

Owner:GUANGDONG VTRON TECH CO LTD

Application of high strength titanium alloys in last stage turbine buckets having longer vane lengths

InactiveUS20060039794A1Low control pressureHigh strengthPropellersPump componentsStress reliefHeat treated

A new high-strength titanium-based alloy bucket specifically suited for use as the last stage buckets in steam turbine engines having vane lengths of about 40 inches or greater and the method for forming such bucket. Exemplary buckets according to the invention are formed from a titanium-based alloy containing up to about 6.25% aluminum; (b) about to 3.5% vanadium; (c) about 2.25% tin, (d) about 2.25% zirconium, (e) about 1.75% molybdenum, (f) about 2.25% chromium, (g) about 0.7% silicon; and (h) about 2.3% iron, with the balance being titanium. After forming, the bucket can be heat treated to provide stress relief and then machined in a conventional manner.

Owner:GENERAL ELECTRIC CO

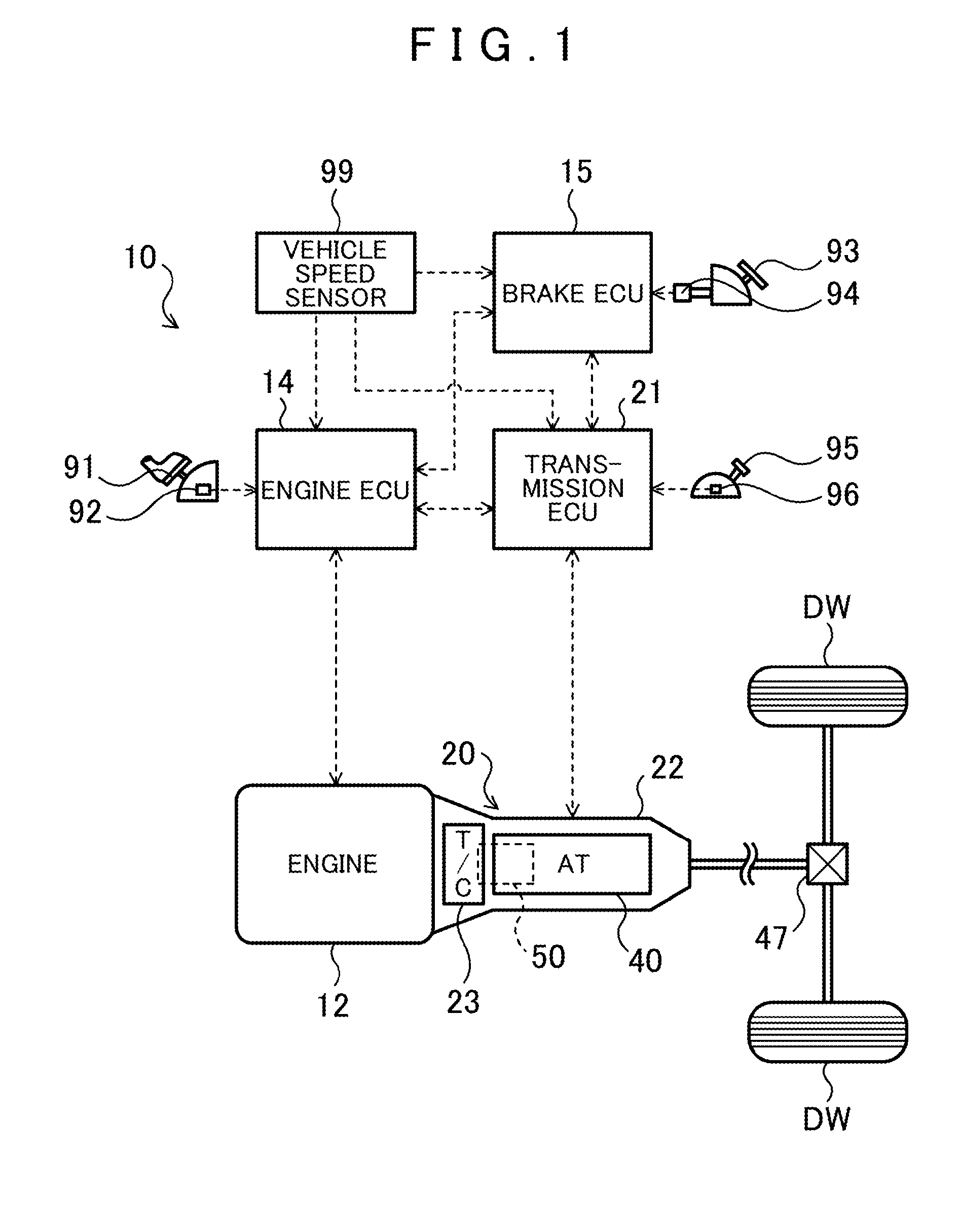

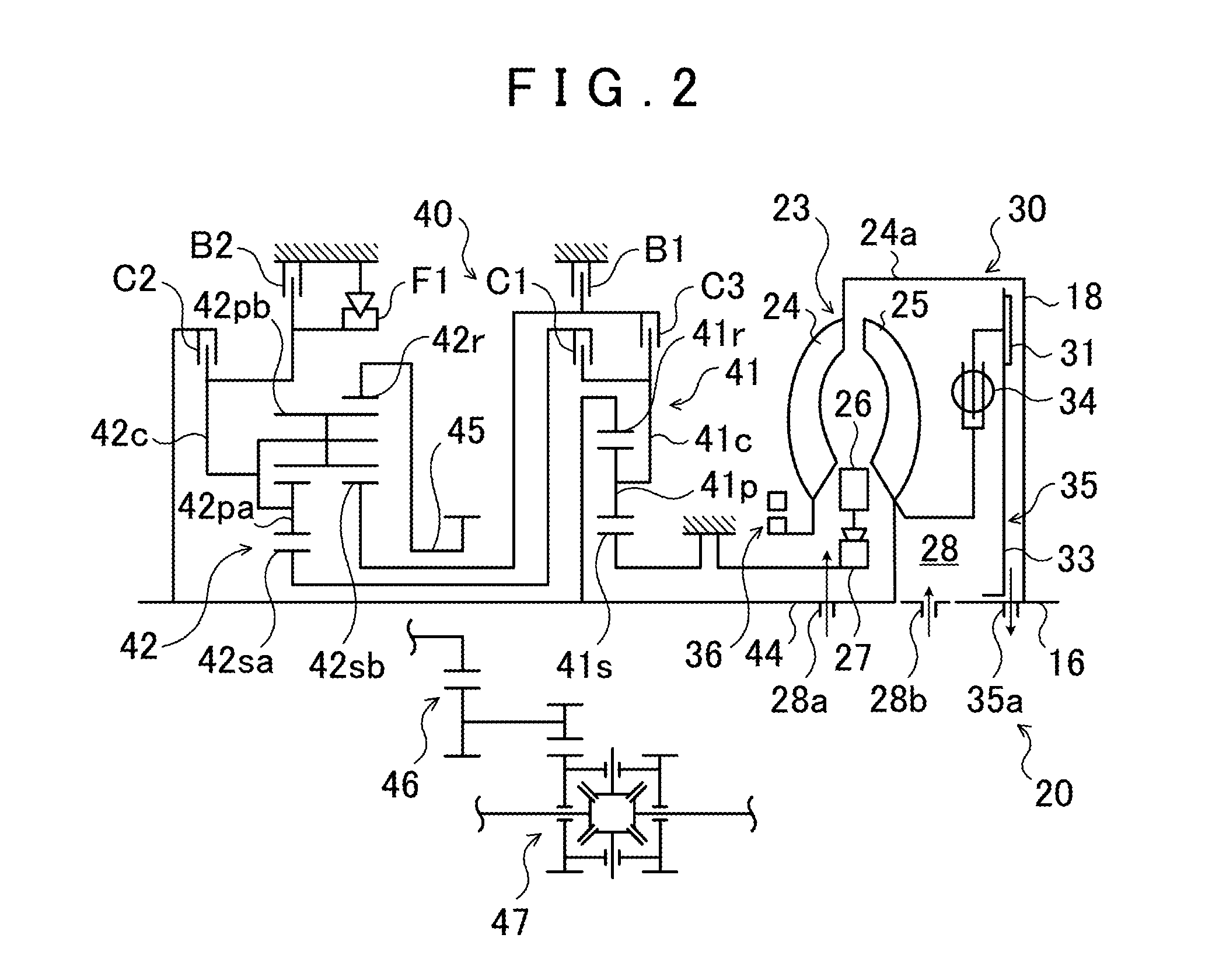

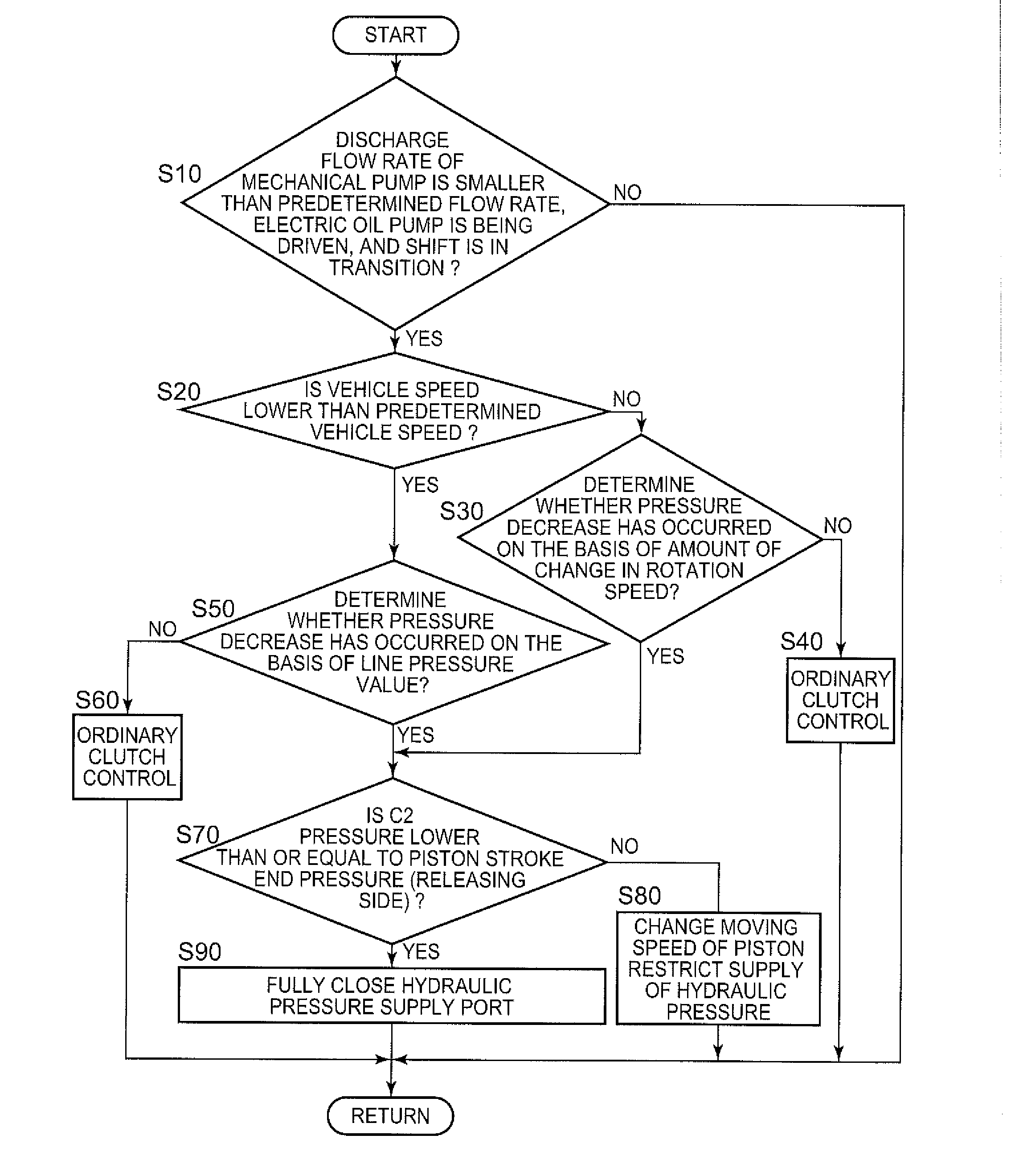

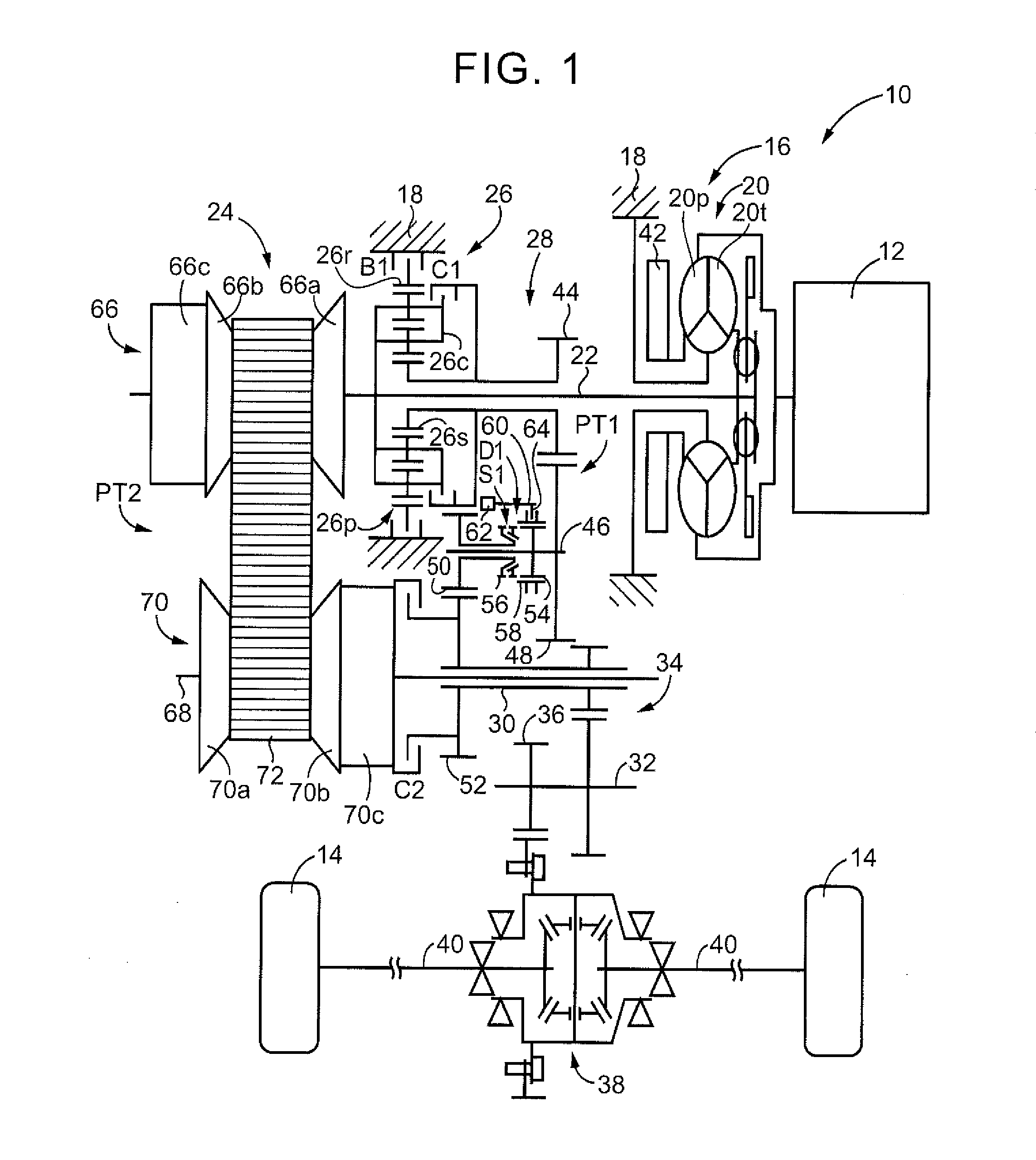

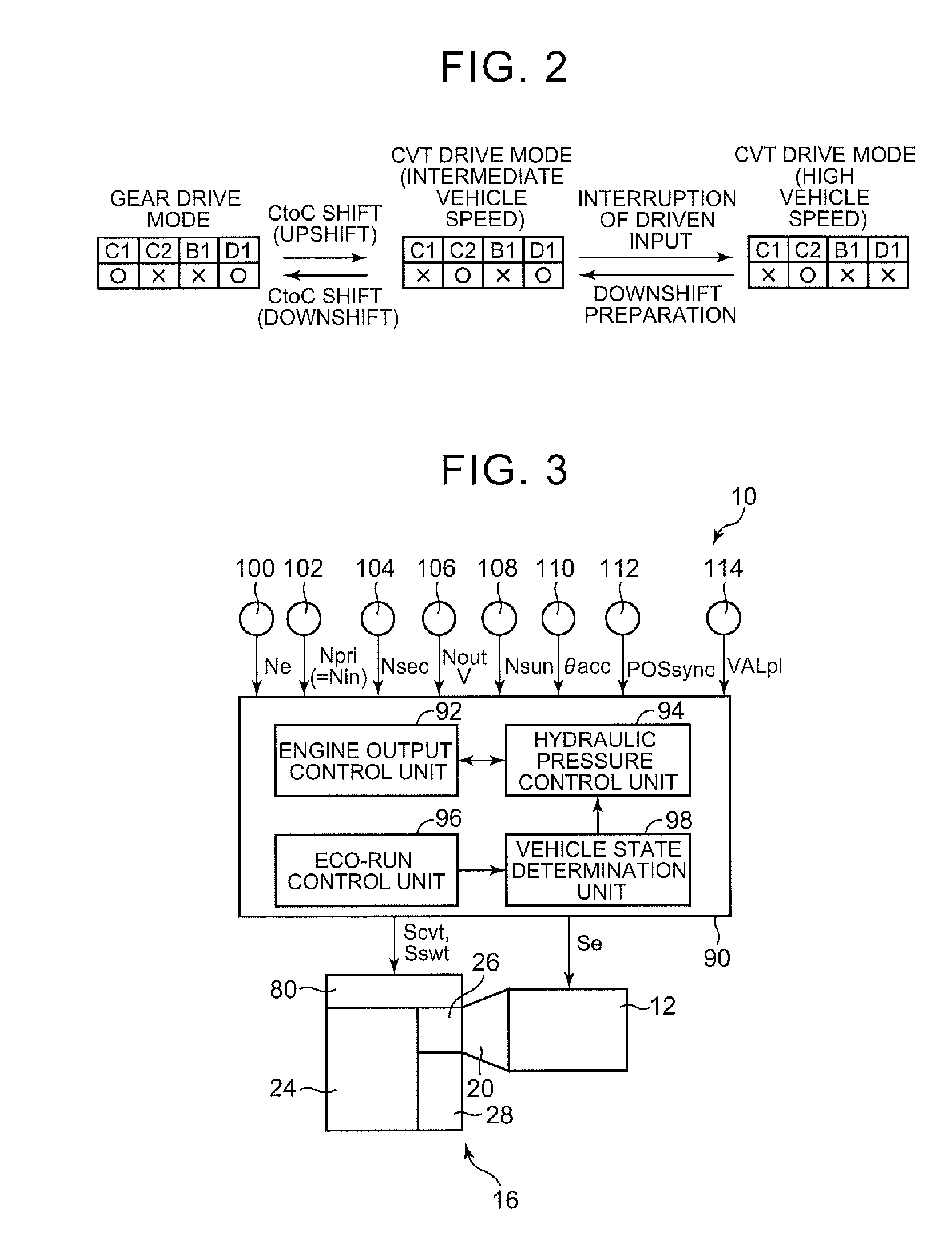

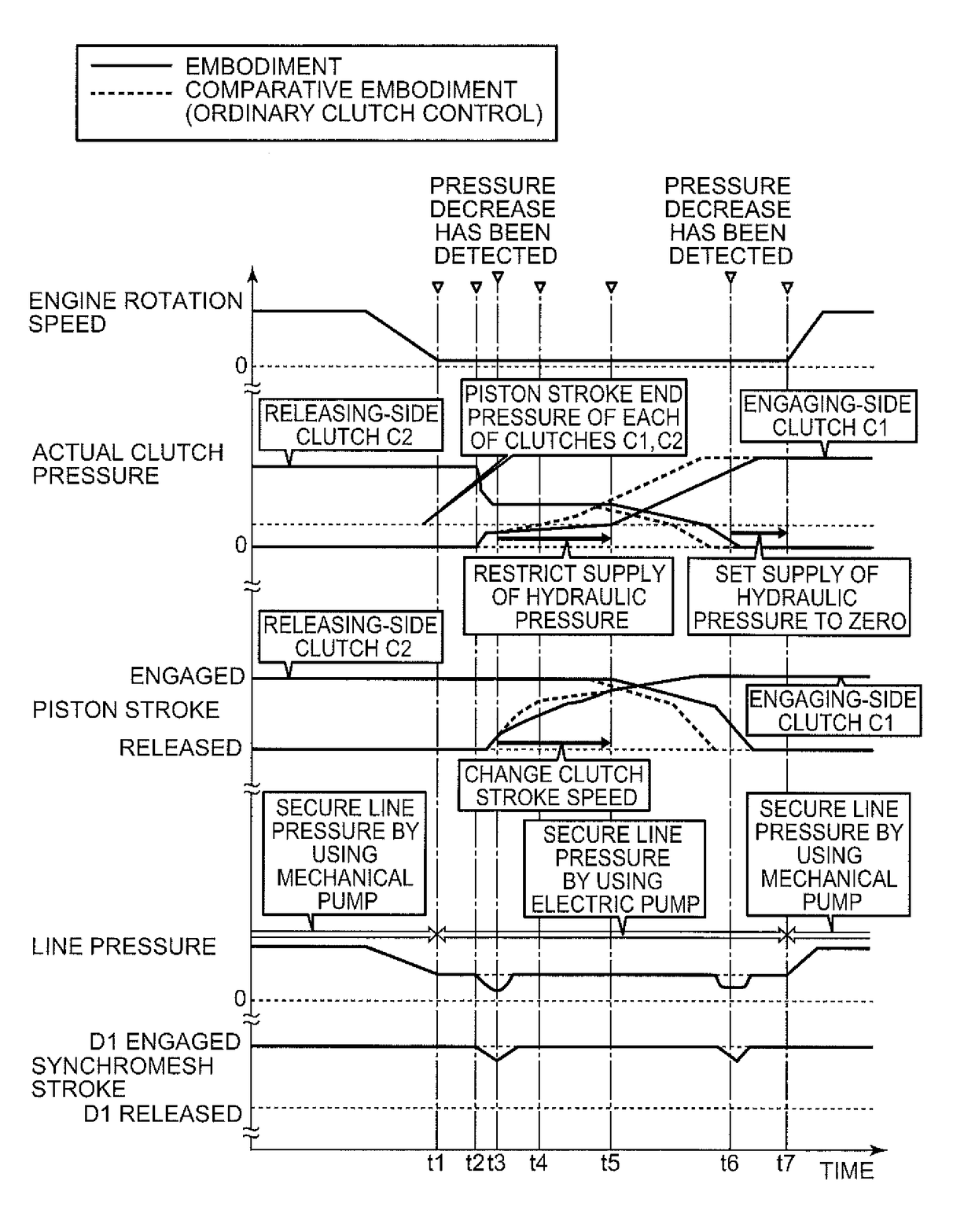

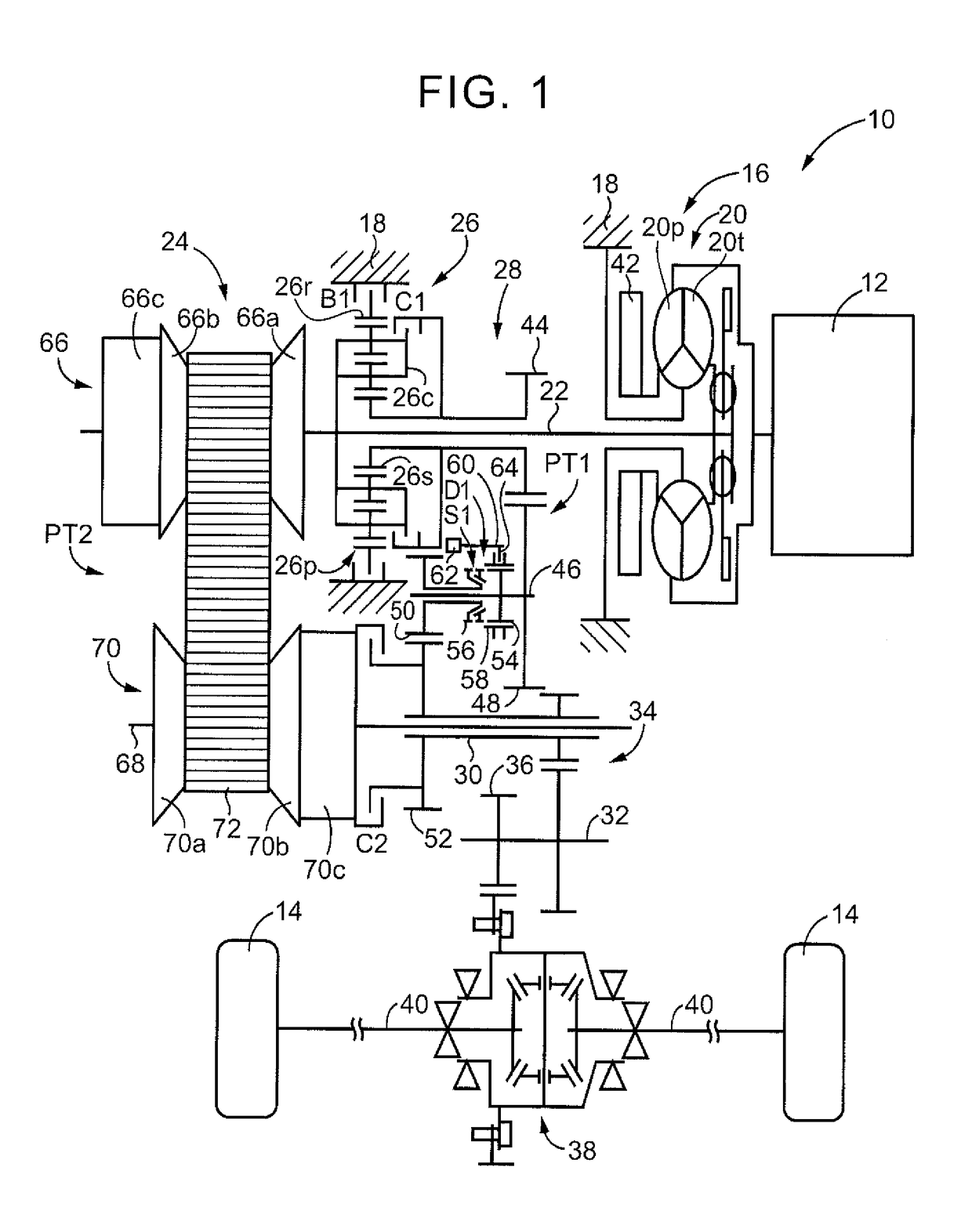

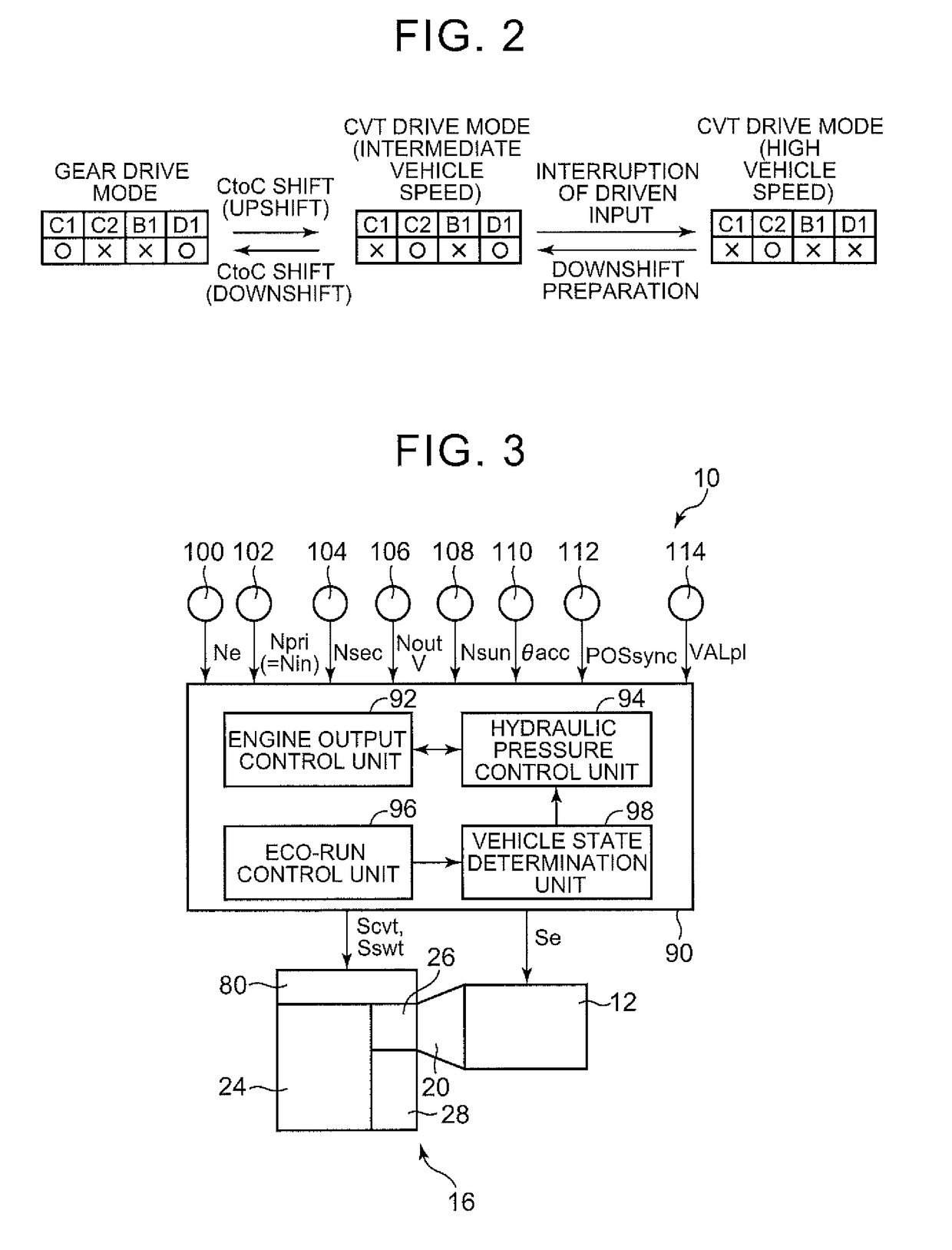

Control apparatus for power transmission system

ActiveUS20160369856A1Prevent and reduce shockLow control pressureFluid actuated clutchesGearing controlElectric power transmissionDrivetrain

A control apparatus for a power transmission system is provided. The control apparatus includes an electronic control unit. The electronic control unit is configured to, when a discharge flow rate of a mechanical oil pump is smaller than a predetermined flow rate and an electric oil pump is being driven while a vehicle is traveling, determine whether a decrease in the operating hydraulic pressure has occurred. The electronic control unit is configured to, when a first engagement device is controlled from a released state toward an engaged state, control a first control pressure such that the first control pressure in a case where a decrease in a operating hydraulic pressure has occurred is lower than the first control pressure in a case where a decrease in the operating hydraulic pressure does not occur.

Owner:TOYOTA JIDOSHA KK

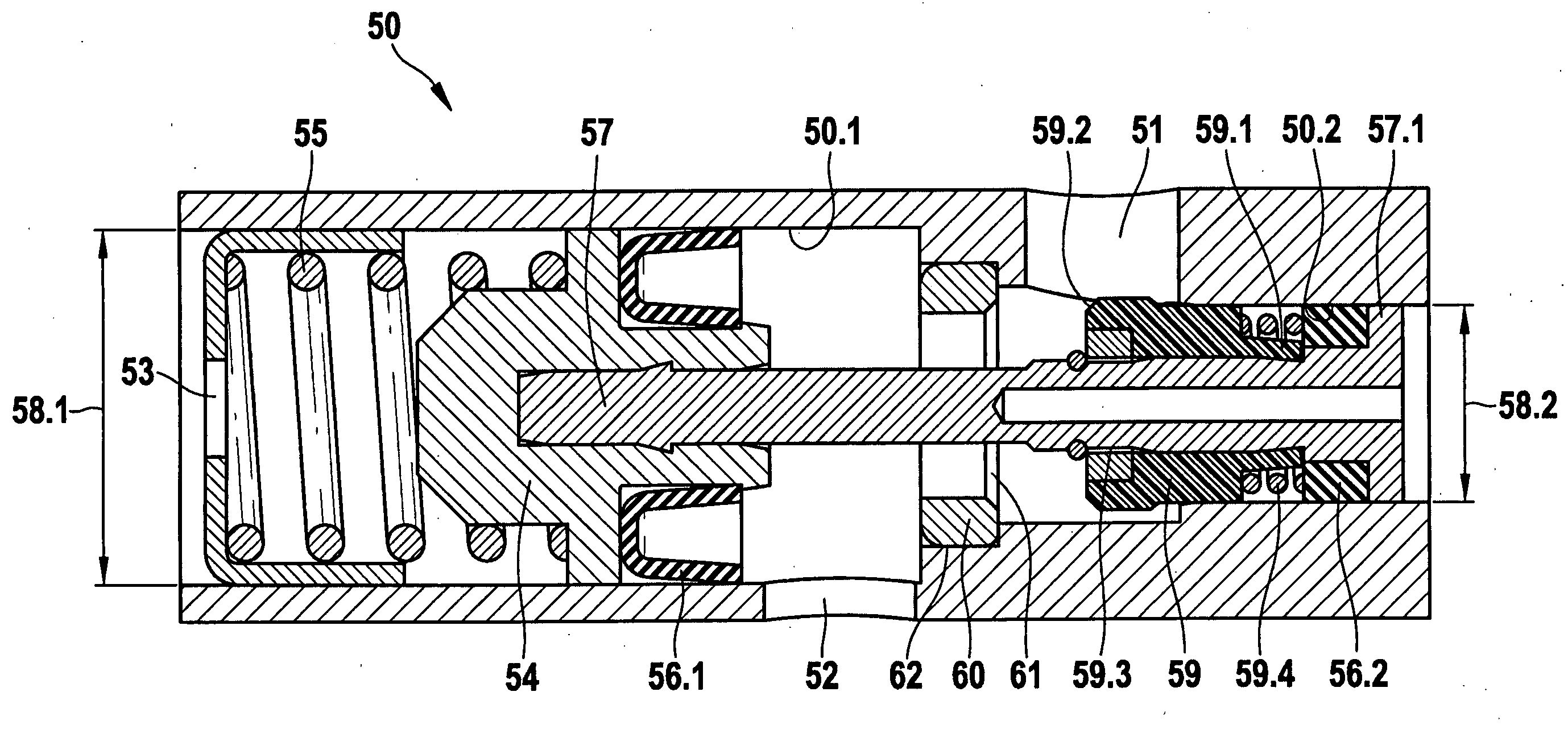

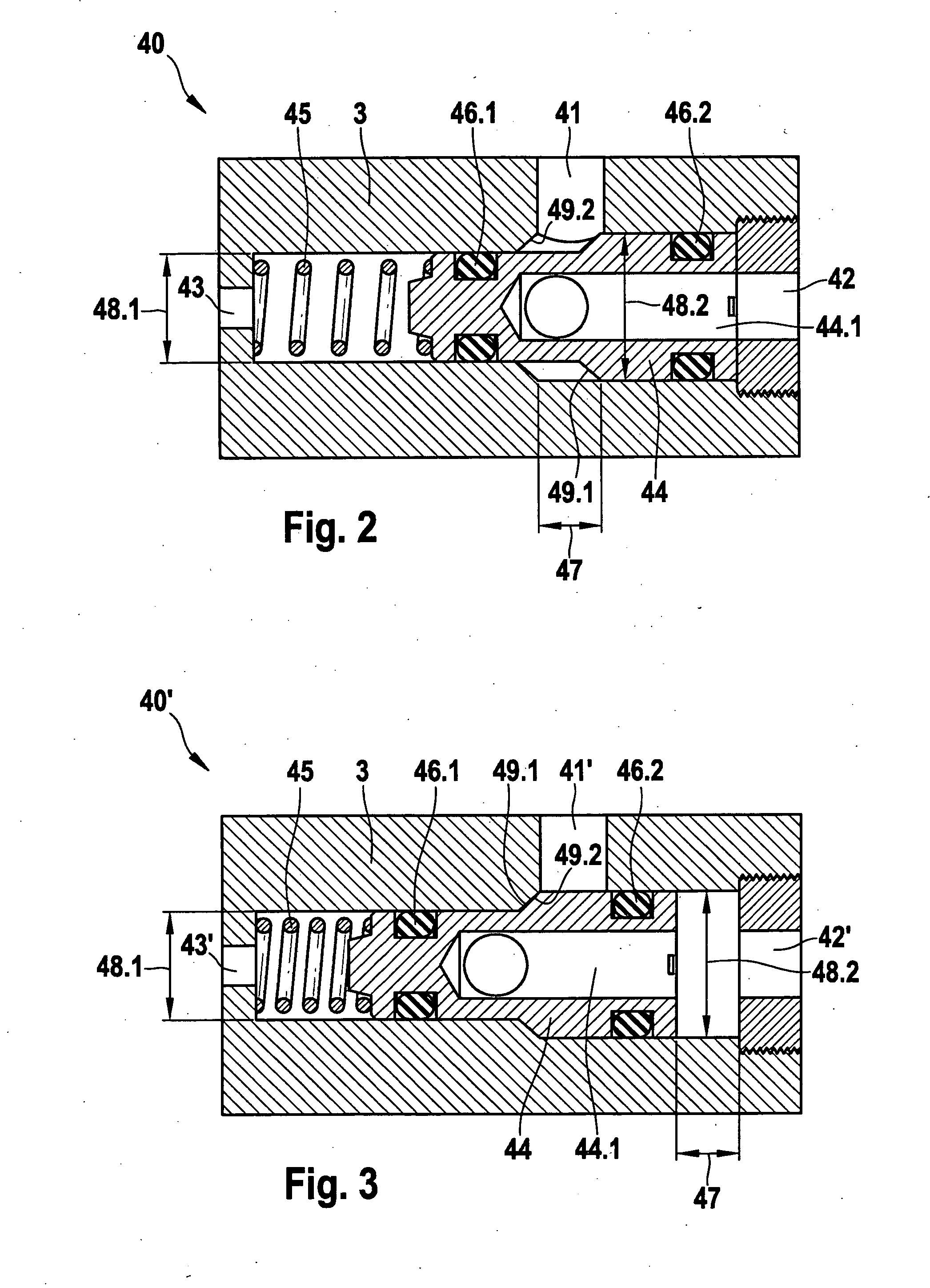

Control valve for a vehicle brake system, and vehicle brake sysem having such a control valve

InactiveUS20110101772A1Quality is easy to controlLow control pressureOperating means/releasing devices for valvesBraking action transmissionSpring forceEngineering

The invention relates to a control valve for a vehicle brake system having a first fluid connection, a second fluid connection, and a decompressed connection toward the atmosphere. An adjustment spring applies a spring force to a control piston moving in longitudinal direction on the decompressed side, the control piston completely releasing a fluid connection between the first fluid connection and the second fluid connection in an initial position, and to a corresponding vehicle brake system having such a control valve. According to the invention the control valve includes a valve body having a seal seat and a sealing element coupled to a control piston. A sealing region of the sealing element interacts with the seal seat of the valve body in order to limit an effective pressure present on the second fluid connection to a predetermined maximum pressure value. The effective diameter of the control piston is greater than or equal to an effective diameter of the sealing element.

Owner:ROBERT BOSCH GMBH

Transmission oil-pressure control apparatus and methods

InactiveUS8282529B2Low control pressureGas pressure propulsion mountingGearing controlHydraulic circuitEngineering

A control apparatus of a vehicle transmission includes a hydraulic circuit configured to activate at least one friction element with a control pressure, a selector configured to select a range of the transmission, a valve configured to switch a transmission shifter, and a control unit configured to direct the valve to switch the transmission shifter in response to the selected transmission range and to reduce the control pressure prior to switching the transmission shifter. A method to control a vehicle transmission includes activating at least one friction element with a control pressure, selecting a desired range of the transmission, switching a transmission range in response to the selected desired transmission range, and reducing the control pressure prior to switching the transmission range.

Owner:NISSAN MOTOR CO LTD

Hydraulic system

ActiveUS8495871B2Low control pressureSuppress pressure differenceFluid couplingsServomotorsHydraulic pumpPressure difference

Owner:DEERE & CO

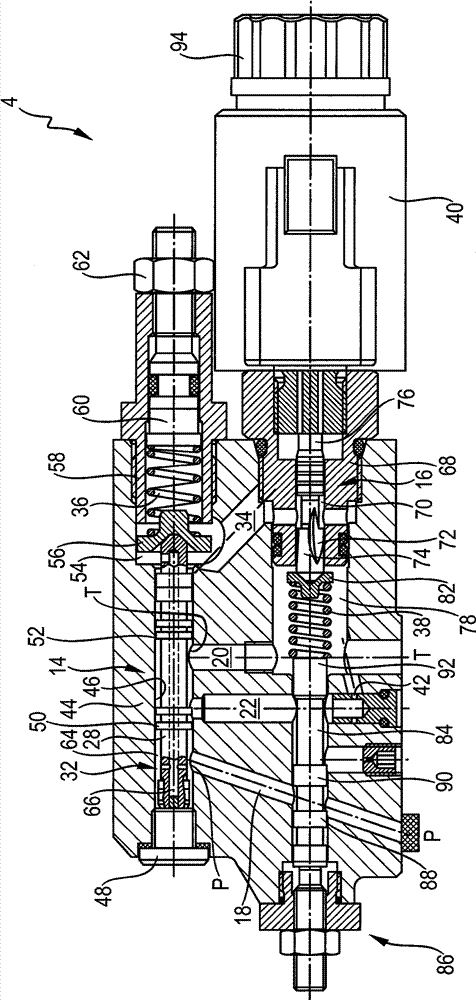

Hydraulic valve arrangement and hydraulic machine arrangement having same

ActiveCN103775402AGood removal effectReduce maintenance technology costsFluid-pressure actuator safetyServomotor componentsHydraulic pumpEngineering

The invention discloses a hydraulic valve arrangement, especially a regulating valve arrangement of a hydraulic machine whcihi s particularly a hydraulic pump. The valve arrangement has at least one valve. A valve body of the valve is penetrated by a pressure medium passage which has a minimum cross section, and, thus in normal operation, controls pressure downstream of the minimum cross section with a pressure acting at a pressure port of the valve. The minimum cross section is arranged close to a pressure medium passage mouth which is arranged upstream or is configured to be subjected to the high pressure. Additionally, a hydraulic machine arrangement, in particular a pump arrangement, includes the hydraulic valve arrangement.

Owner:ROBERT BOSCH GMBH

Prefill valve

The invention supplies a liquid feeding valve that includes case body and valve body. Low-pressure oil mouth on the case body is connected to the valve body. And control piston, spring, main valve core, and precursor are set in the valve body. The oil drain is set on the main valve core; the oil way is set on the valve body. The feature is that pulling bar is set between the man valve core and the control piston. The spring is enlaced on the bulling bar. A clearance is set between the pulling bar and the main valve core. A precursor valve bar is set on the precursor valve core on the bottom of the main valve core. And the precursor valve bar is fixed through the main valve core and the pulling bar. The clearance between the pulling bar and the main valve core is 2-5mm. The precursor valve fixed to pulling bar by precursor valve fixing nut.

Owner:王诚谦

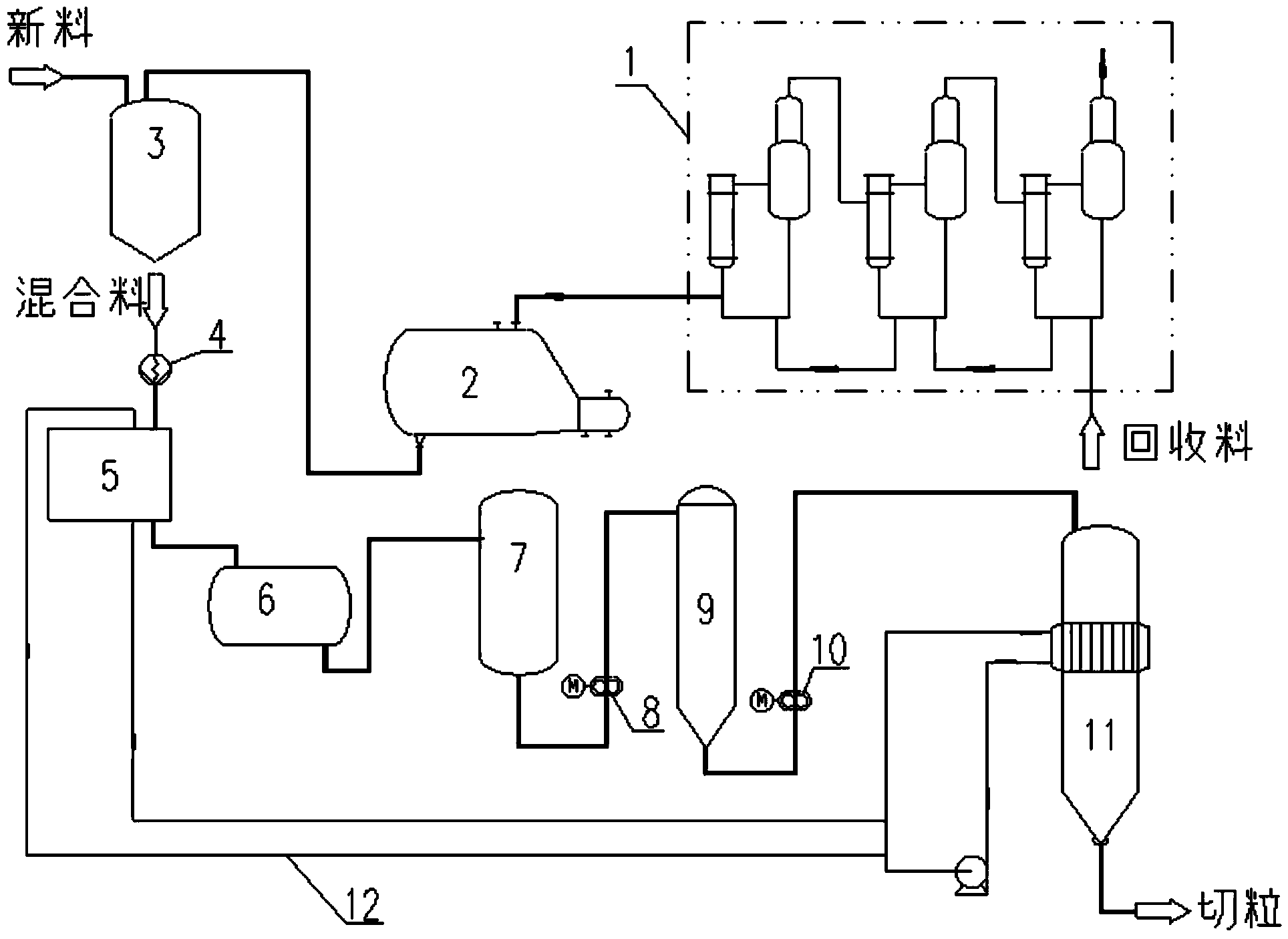

Novel three kettle polymerization process of chinlon 6

The invention discloses a novel process of continuously polymerizing and producing chinlon 6 slices. The process comprises the following steps: directly a pure caprolactam raw material with a reclaimed material through concentration by conventional triple effect evaporation; carrying out reactions in a pre-reaction kettle, a pre-polymerization kettle and a post-polymerization kettle; and carrying out subsequent conventional treatment processes to produce the high quality chinlon 6 slices. Compared with the conventional methods, the low concentration reclaimed material is efficiently utilized, and the needed high concentration slurry treated by the concentration kettle can be used for continuous and stable production. The proportion adjustment range of the reclaimed material permitted in the used raw materials is great, and the water content range of the material permitted is great. The whole technical process is simple to operate and simple in equipment structure. The three reaction kettles have different technical control parameters, so that the conversion ratio of materials is effectively improved. The relative viscosity of the obtained chinlon 6 product can reach 2.4-3.6, and the strength and the tensile property of the chinlon 6 product can be widely applied to production of downstream products.

Owner:DALIAN HISCIEN ENG

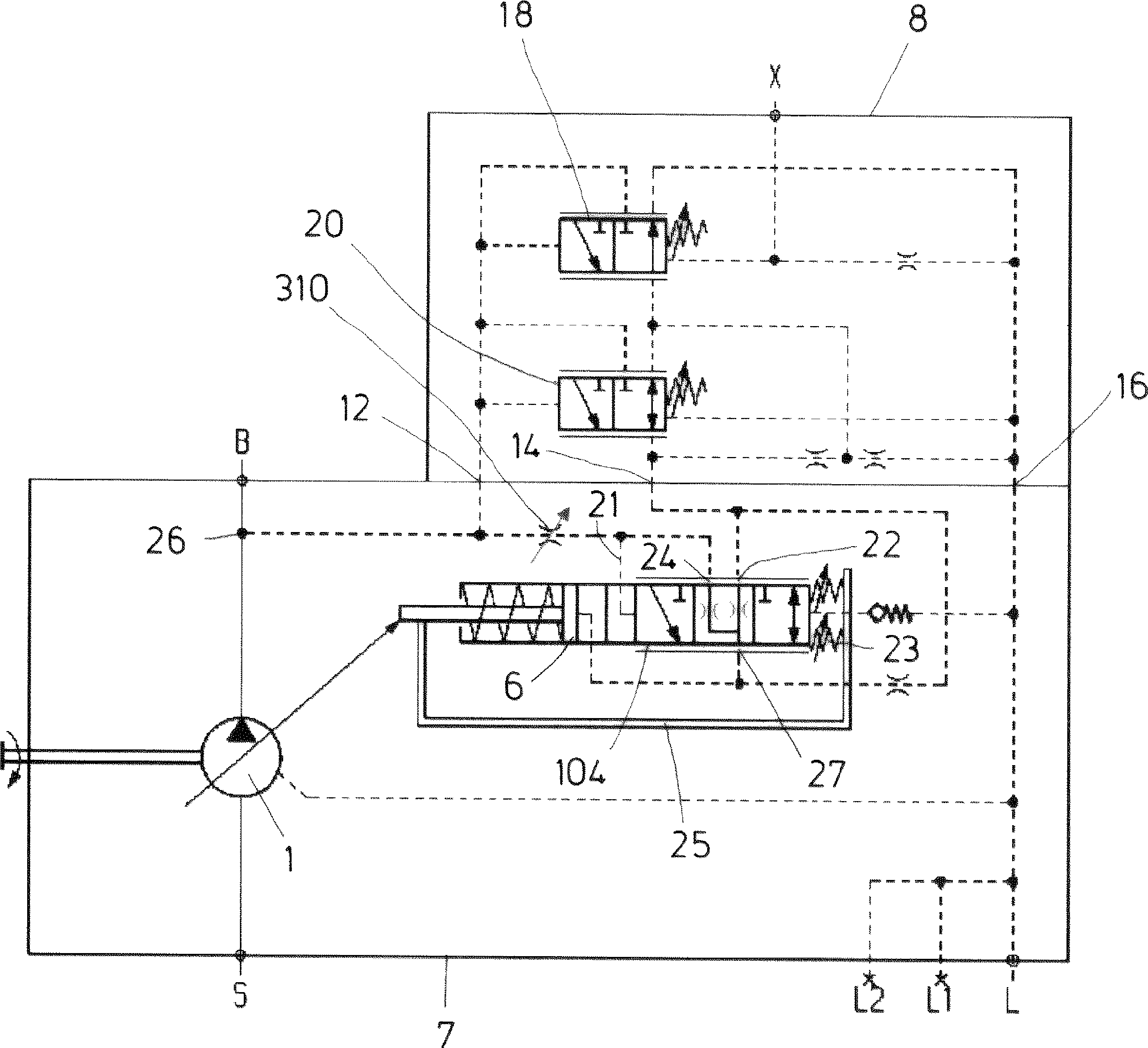

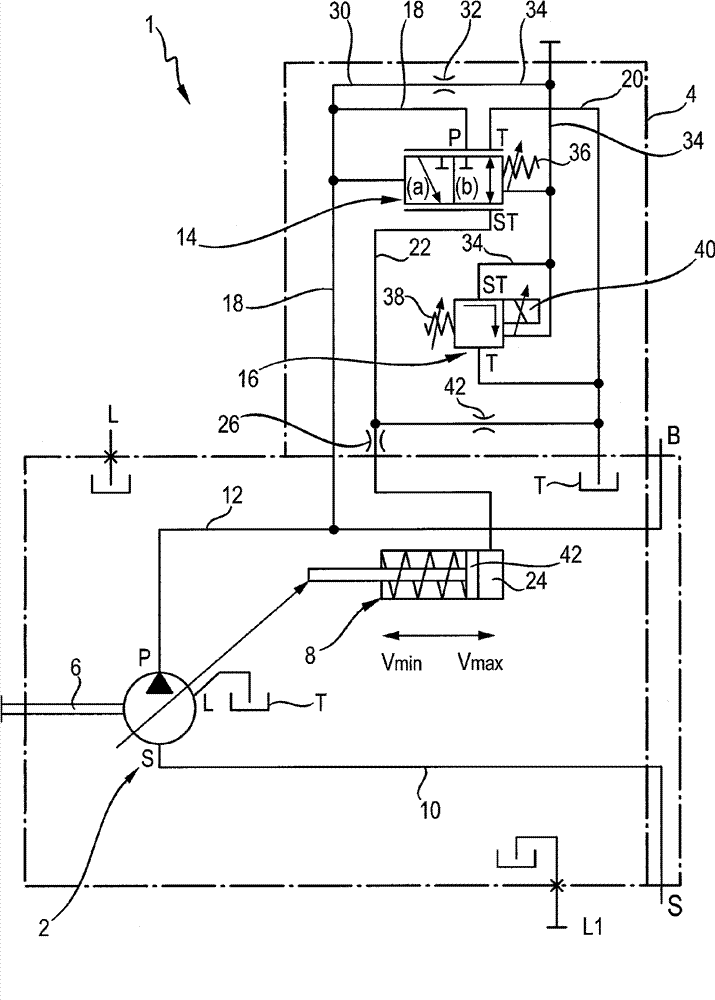

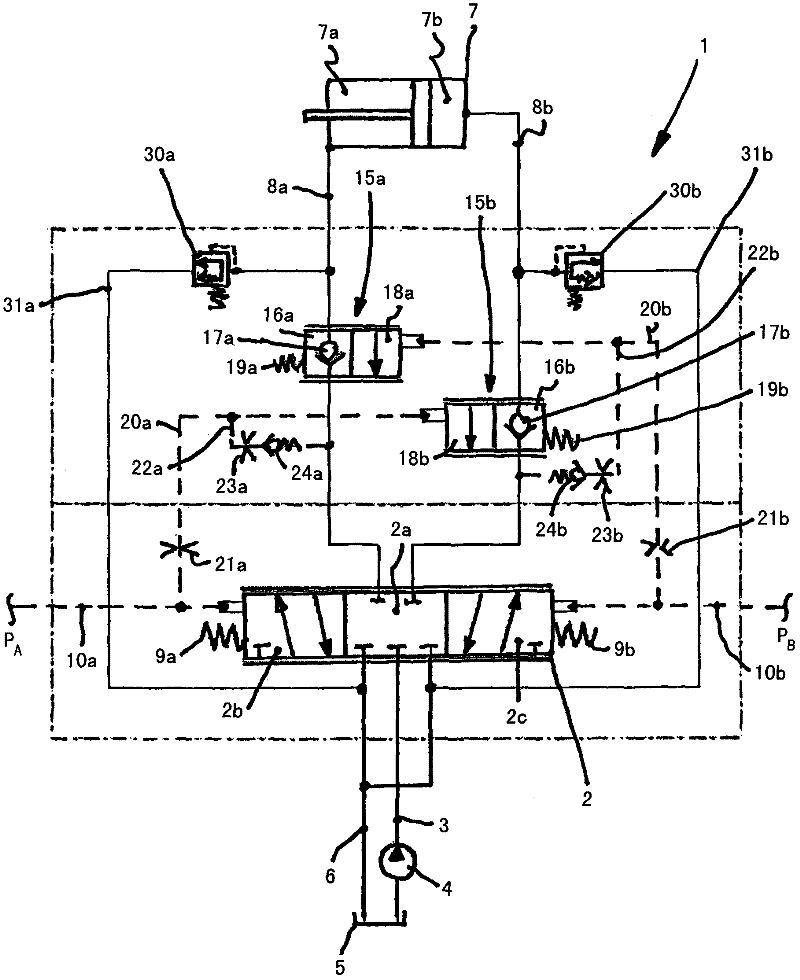

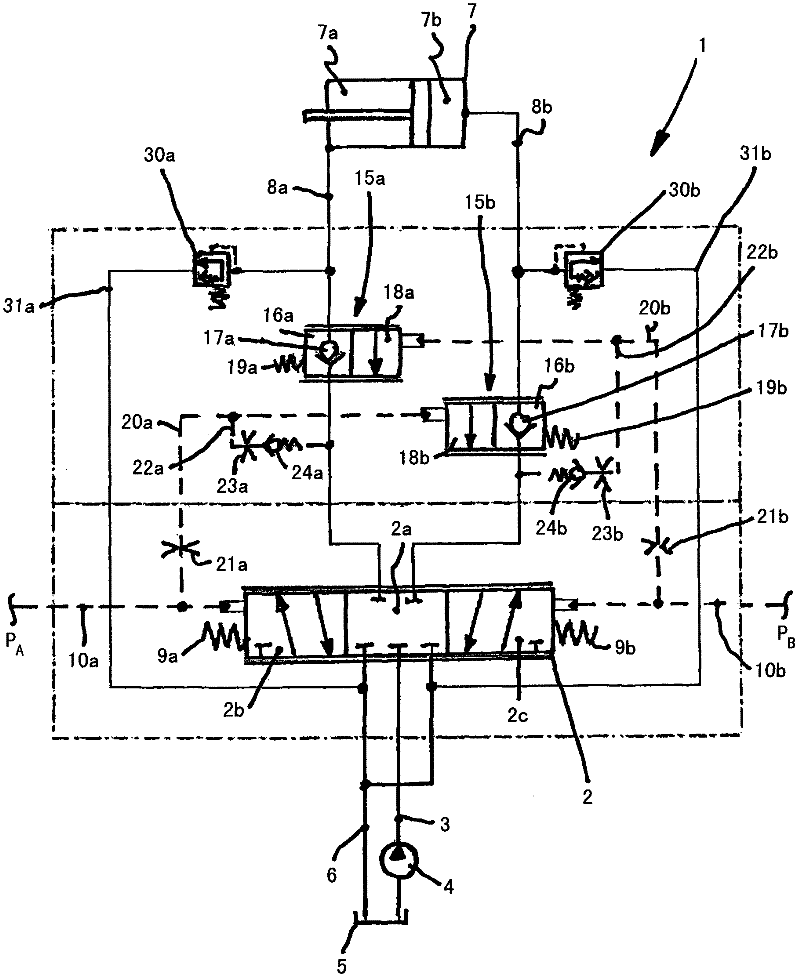

Hydraulic control valve device

ActiveCN102691683AStability Adjustment CharacteristicsSolve Vibration ProblemsServomotorsServometer circuitsThrottle controlEngineering

The hydraulic control valve device (1) has a throttling control valve (2), which is arranged in an intermediate position with a conveying line (3) and a pump (4), where an outlet side fitting tight counter-balance valve (15a) is arranged in the direction of a flow position (18a) for being operated with a control pressure (pA) of the control valve. Multiple throttle units (21a,21b,23a,23b) are formed as diaphragms or nozzles.

Owner:LINDE HYDRAULICS

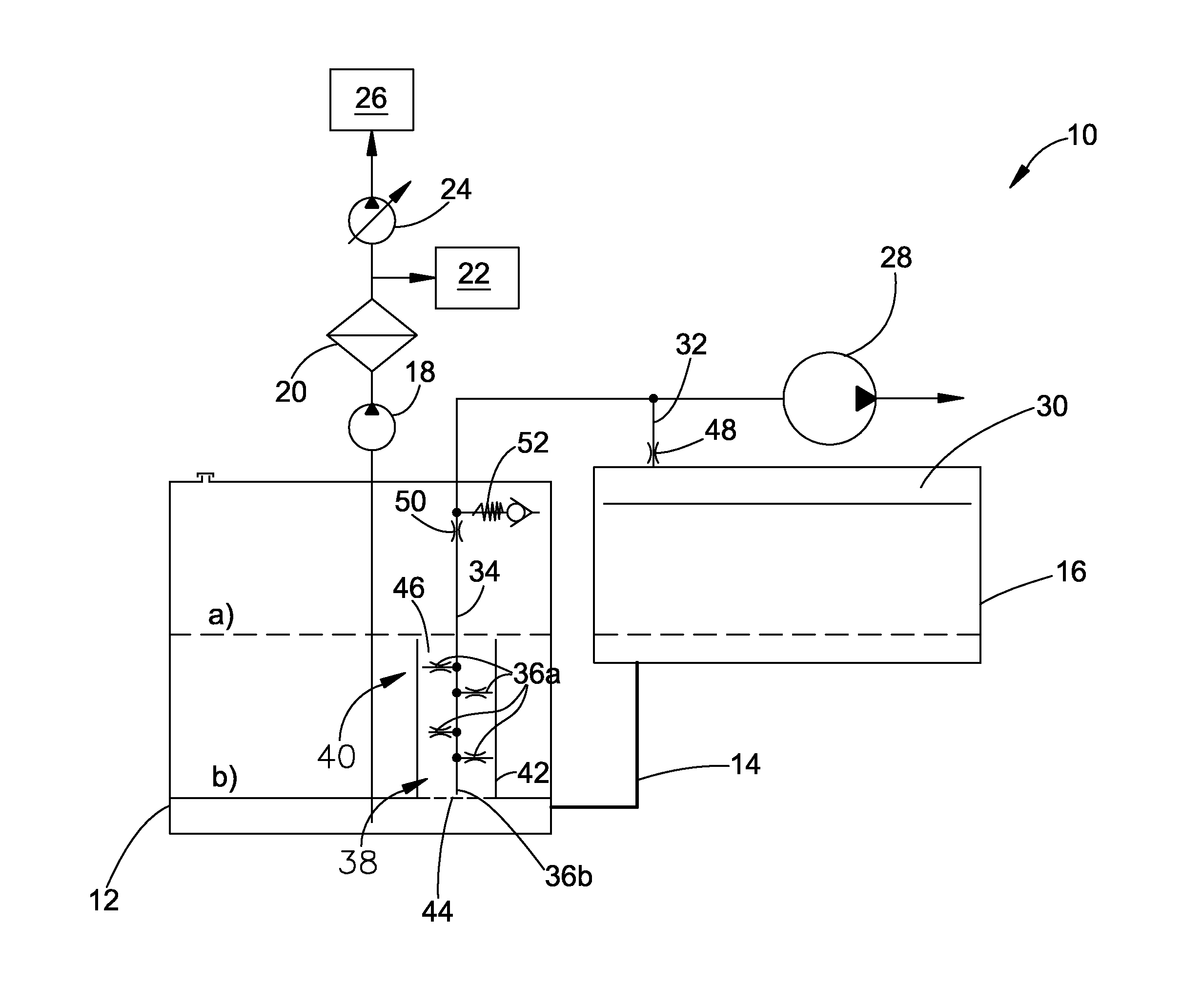

System for supplying hydraulic fluid

ActiveUS20100051123A1Speed up the flowLow control pressureFluid dynamicsPipe elementsControl lineAir pump

The invention concerns a system for supplying hydraulic fluid to a hydraulic system, with an operating reservoir that accepts the hydraulic fluid provided for the operation of the hydraulic system and an auxiliary reservoir connected to the operating reservoir over a hydraulic line for intermediate storage of hydraulic fluid withdrawn from the operating reservoir. According to the invention, an air pump is available that is connected on the one hand on its low pressure side to a suction line that ends in a fluid free area of the auxiliary reservoir, so that a negative pressure can be built up in the auxiliary reservoir as against the external atmospheric pressure, and that is connected, on the other hand, to a control line that is provided with a control opening that is covered by the hydraulic fluid in the operating reservoir at least before the air pump is put into operation.

Owner:DEERE & CO

Control apparatus for power transmission system

ActiveUS10001179B2Prevent and reduce shockLow control pressureClutchesGearing controlElectric power transmissionDrivetrain

A control apparatus for a power transmission system is provided. The control apparatus includes an electronic control unit. The electronic control unit is configured to, when a discharge flow rate of a mechanical oil pump is smaller than a predetermined flow rate and an electric oil pump is being driven while a vehicle is traveling, determine whether a decrease in the operating hydraulic pressure has occurred. The electronic control unit is configured to, when a first engagement device is controlled from a released state toward an engaged state, control a first control pressure such that the first control pressure in a case where a decrease in a operating hydraulic pressure has occurred is lower than the first control pressure in a case where a decrease in the operating hydraulic pressure does not occur.

Owner:TOYOTA JIDOSHA KK

Double-gain clutch control system

The invention discloses a double-gain clutch control system of automobiles, which comprises a main pressure source, a variable electromagnetic valve, a clutch regulating valve, a gain control device and a cutch. The clutch is provided with a pressure oil chamber which is connected to the regulating valve oil outlet of the clutch regulating valve through a clutch pressure oil passage; the clutch regulating valve is connected to the main pressure source through an oil-supply oil passage; the gain control device comprises a pressure increasing valve, a trigger pressure oil passage, a clutch control oil passage, a gain control oil passage and an oil outlet, is connected to the clutch regulating valve through the clutch control oil passage and the gain control oil passage and controls the gain of a clutch control pressure according to the signals of the trigger pressure oil passage so that the clutch has a high gain for a high torque and has a low gain for a low torque. Therefore, the automatic gearbox has a high torque range at a low speed and has a better gear-shifting quality at a high speed.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

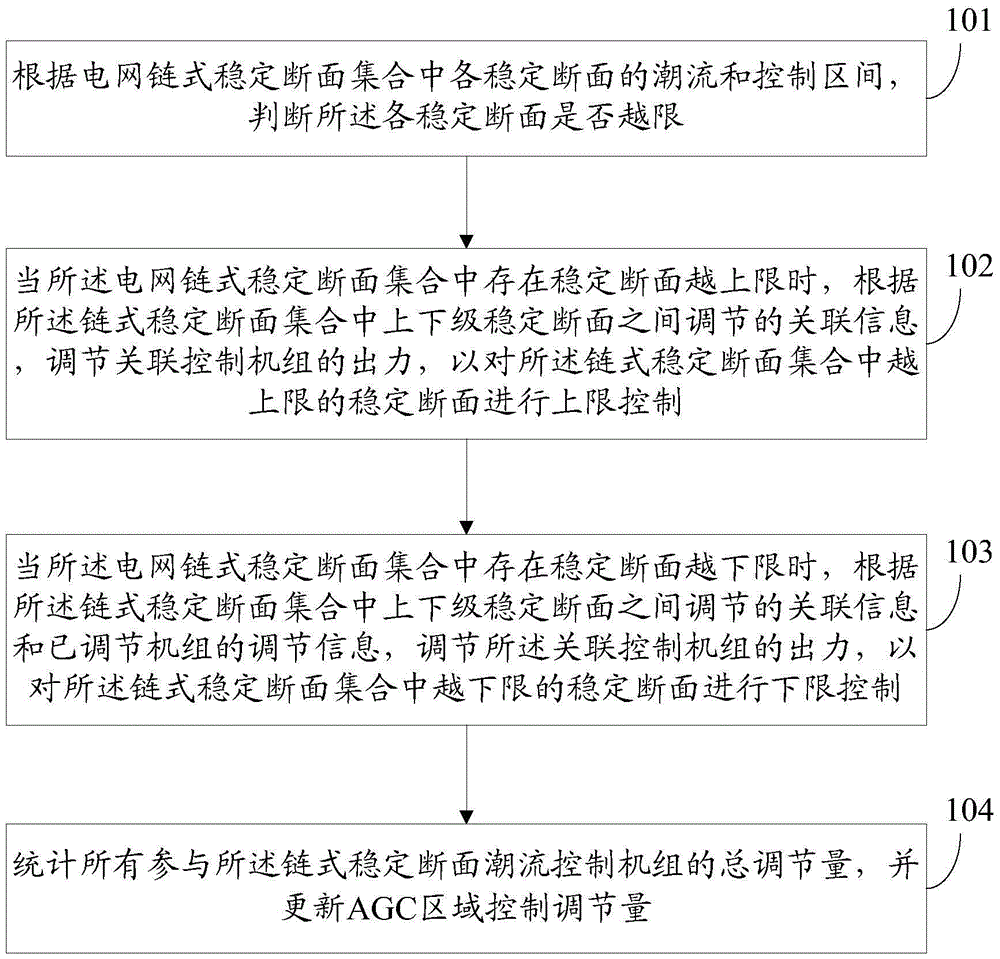

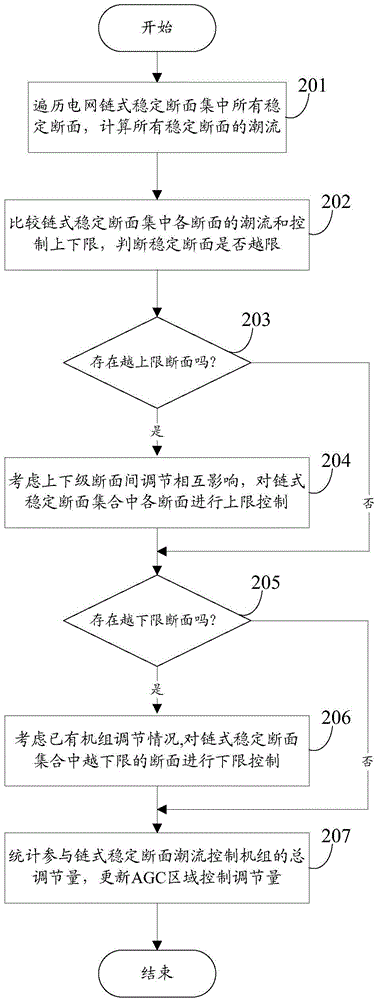

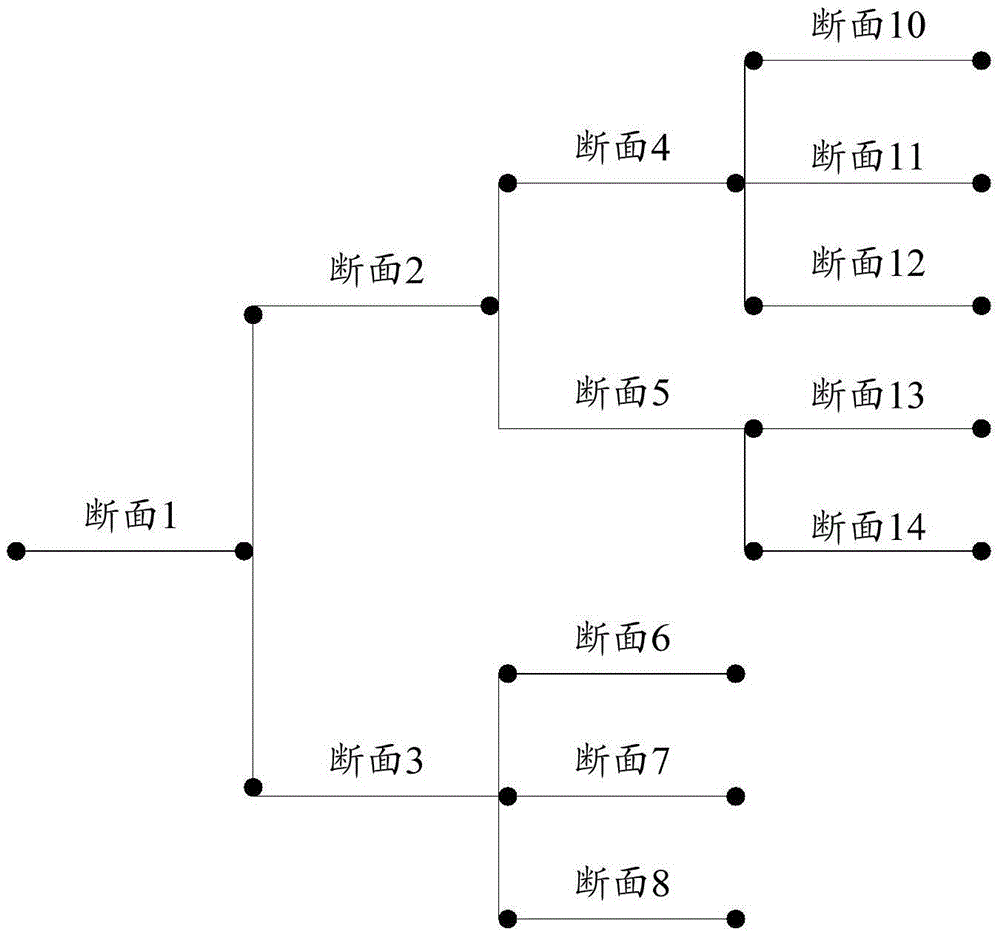

Power grid linkage type stable sectional power flow control method and server

ActiveCN105490277AImprove controlRealize automatic controlSingle network parallel feeding arrangementsAc networks with different sources same frequencyAutomatic Generation ControlLower limit

The invention discloses a power grid linkage type stable sectional power flow control method and a server. The power flow control method comprises the following steps of judging whether each stable section is out of limit or not according to power flow and a control zone of each stable section in a power grid linkage type stable sectional set; adjusting the output of a correlated control machine set so as to carry out upper limit control on the stable section exceeding an upper limit in the linkage type stable sectional set according to adjusted associated information between an upper-stage stable section and a lower-stage stable section in the linkage type stable sectional set when the stable section exceeds the upper limit; adjusting the output of the correlated control machine set so as to carry out lower limit control on the stable section exceeding a lower limit in the linkage type stable sectional set according to the adjusted associated information between the upper-stage stable section and the lower-stage stable section in the linkage type stable sectional set when the stable section exceeds the lower limit; and counting total adjustment quantity of all participated linkage type stable sectional power flow control machine sets, and updating the control adjustment quantity of an automatic generation control (AGC) region.

Owner:NR ELECTRIC CO LTD

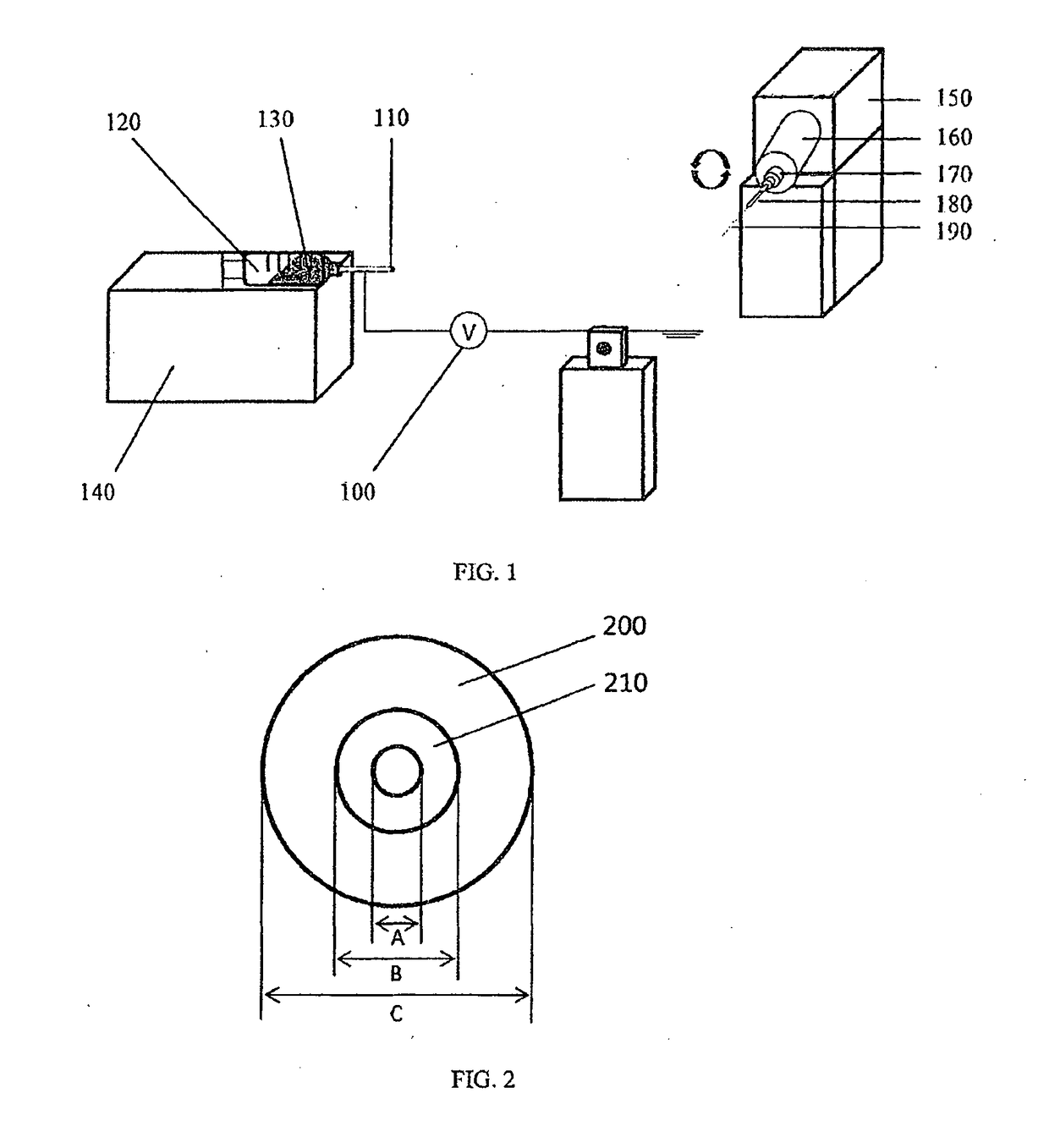

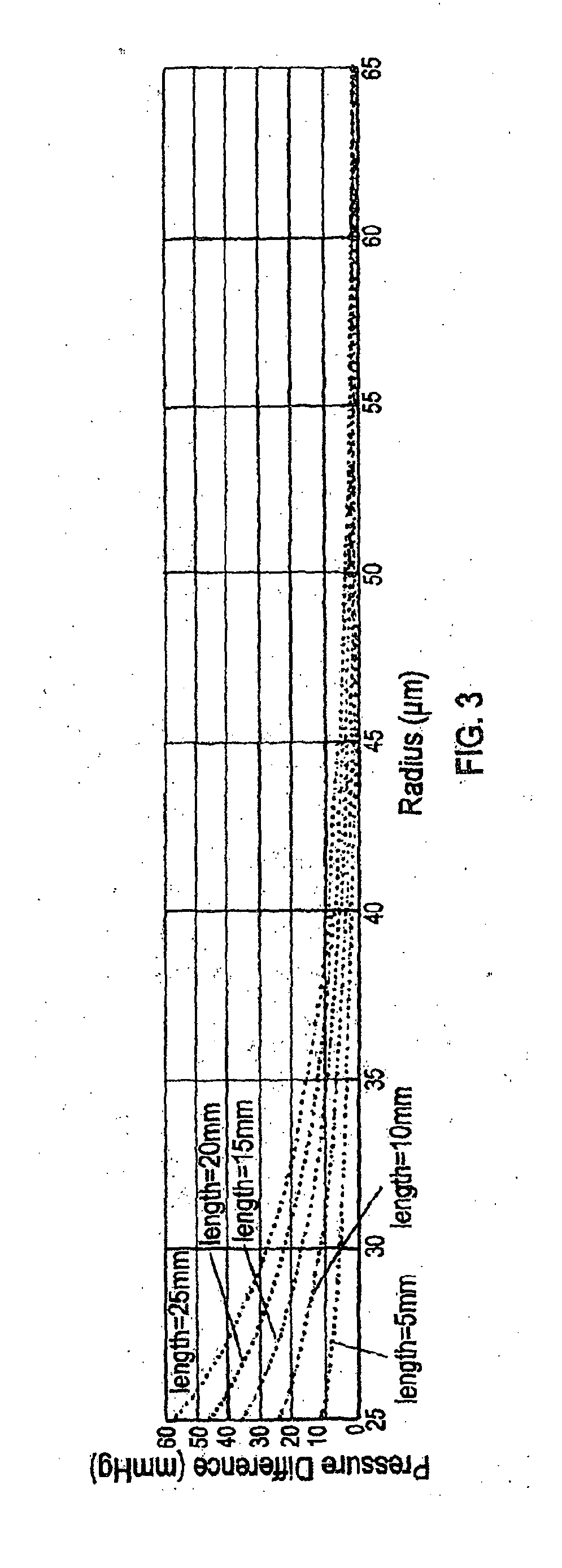

Partially degradable stents for controlled reduction of intraocular pressure

Partially degradable stents formed of electrospun polymeric fibers have been developed. The lumen of the stent enlarges as the degradable polymeric inner luminal wall of the stents degrades over. When inserted in the eye of a subject connecting anterior chamber to the subconjunctival space, the stents allows for controlled outflow of aqueous humor, providing controlled of the rate of change in the intraocular pressure (TOP) and sustained decrease of TOP to treat eye disorders such as glaucoma. Methods of making these fibers via electrospinning and heat processing, as well as their uses in medical applications, are also provided.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

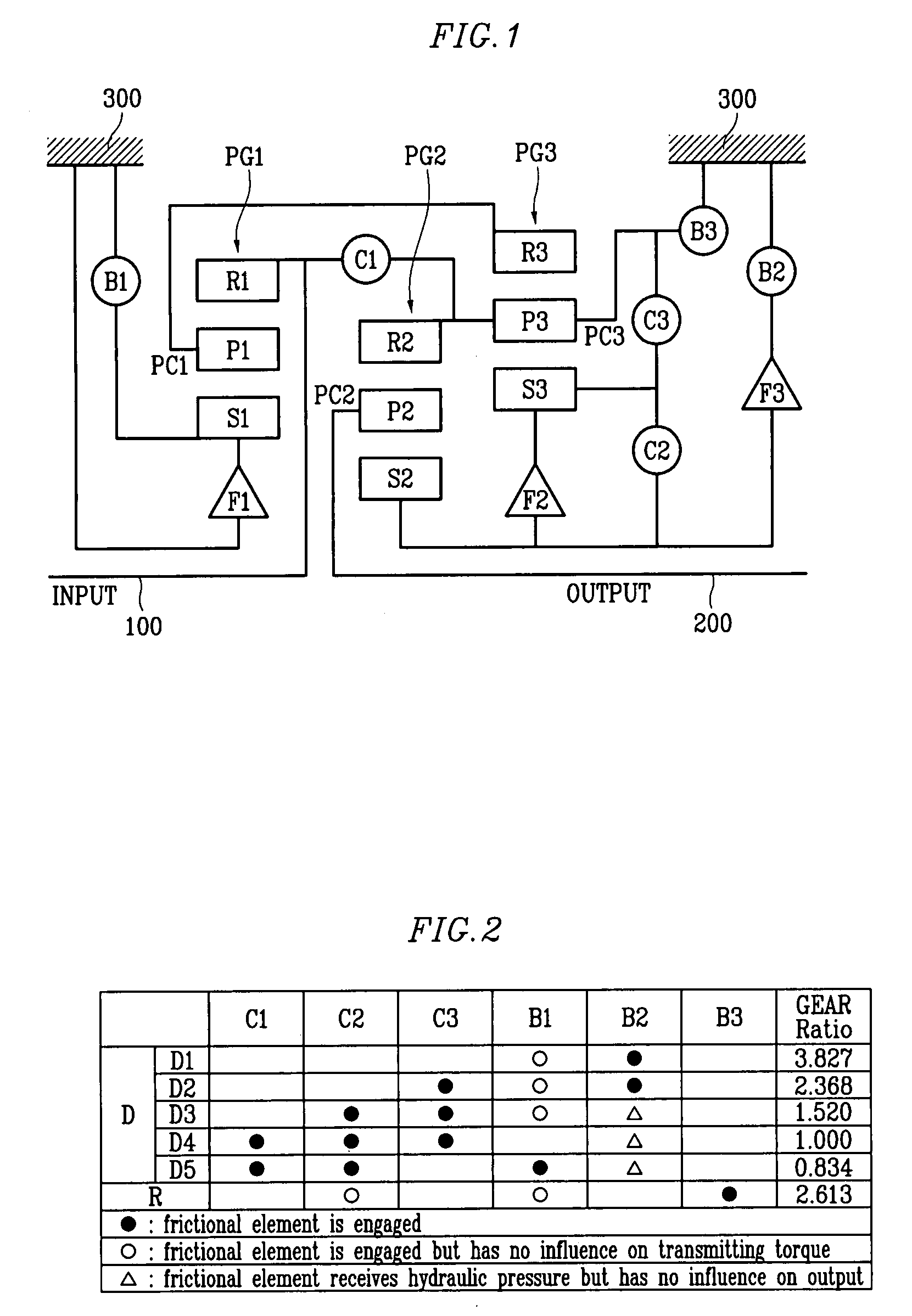

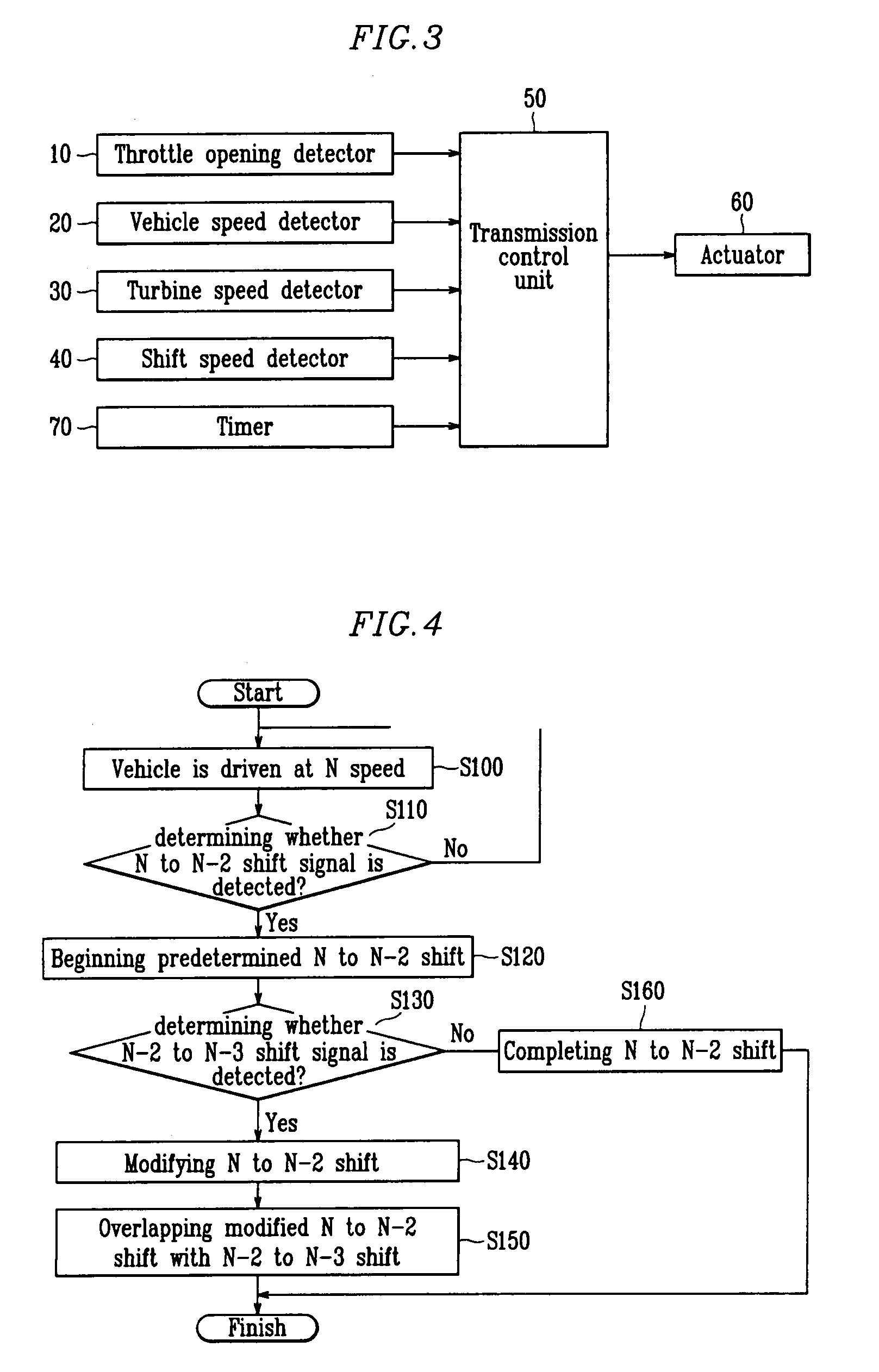

Method for controlling shift during shift of automatic transmission

InactiveUS7769515B2Increase control pressureLow control pressureDigital data processing detailsGearingAutomatic transmissionEngineering

A method for controlling a shift during a shift of an automatic transmission controls to complete an N to N-2 shift and an N-2 to N-3 shift simultaneously such that the shift during a shift is smoothly performed when the N-2 to N-3 shift where one frictional element is released is required to be performed during the N to N-2 shift where another frictional element is released and the other frictional element is engaged. A method for controlling a shift during a shift of an automatic transmission may overlap an N to N-2 shift where a first frictional element is engaged and a second frictional element is released with an N-2 to N-3 shift where a third frictional element is released, wherein a release of the second frictional element begins after an engagement of the first frictional element begins, and a release of the third frictional element begins after an N-2 to N-3 shift signal is detected, wherein the engagement of the first frictional element and the release of the second and third frictional elements are simultaneously completed.

Owner:HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com