Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Increase the number of coils" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

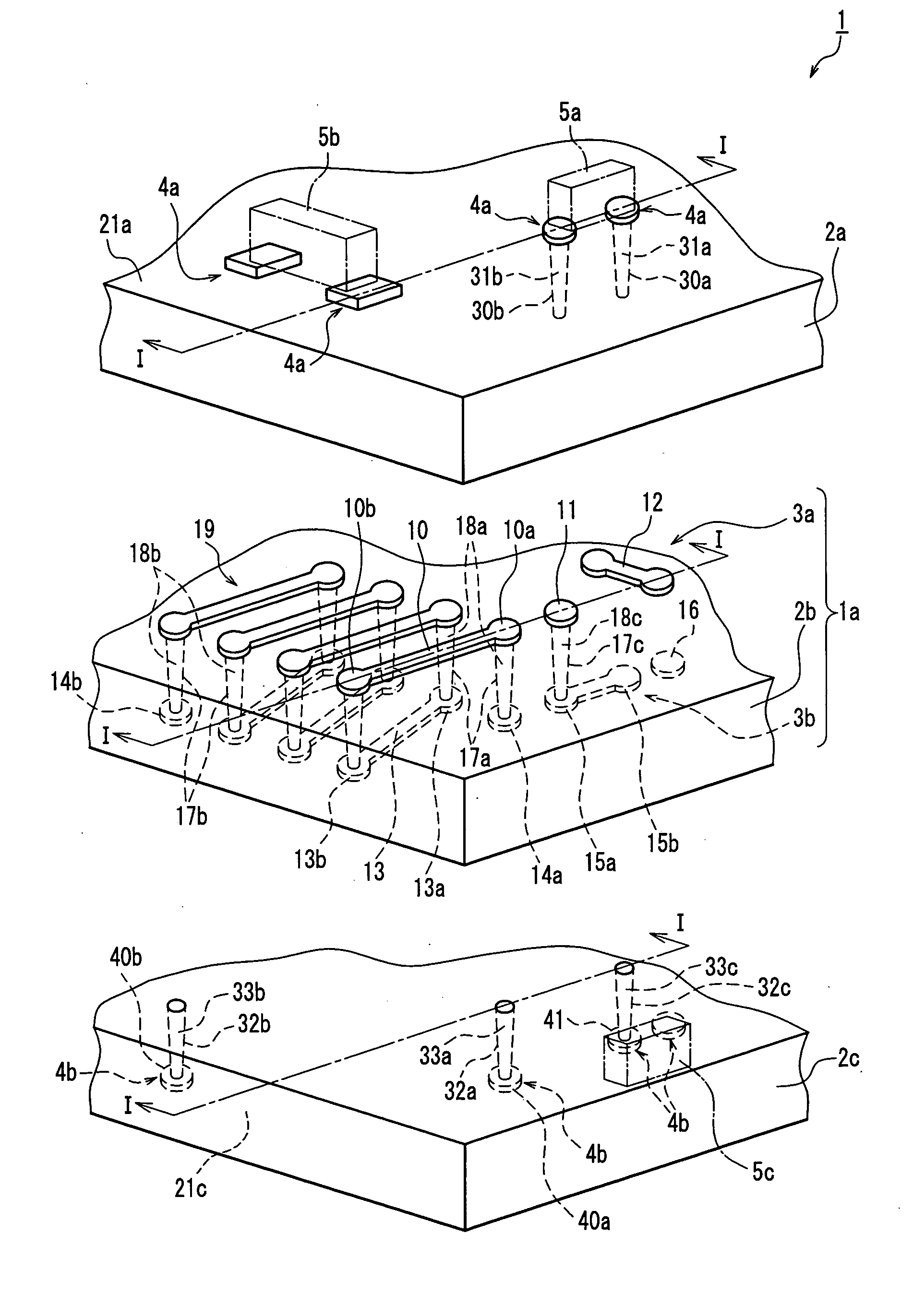

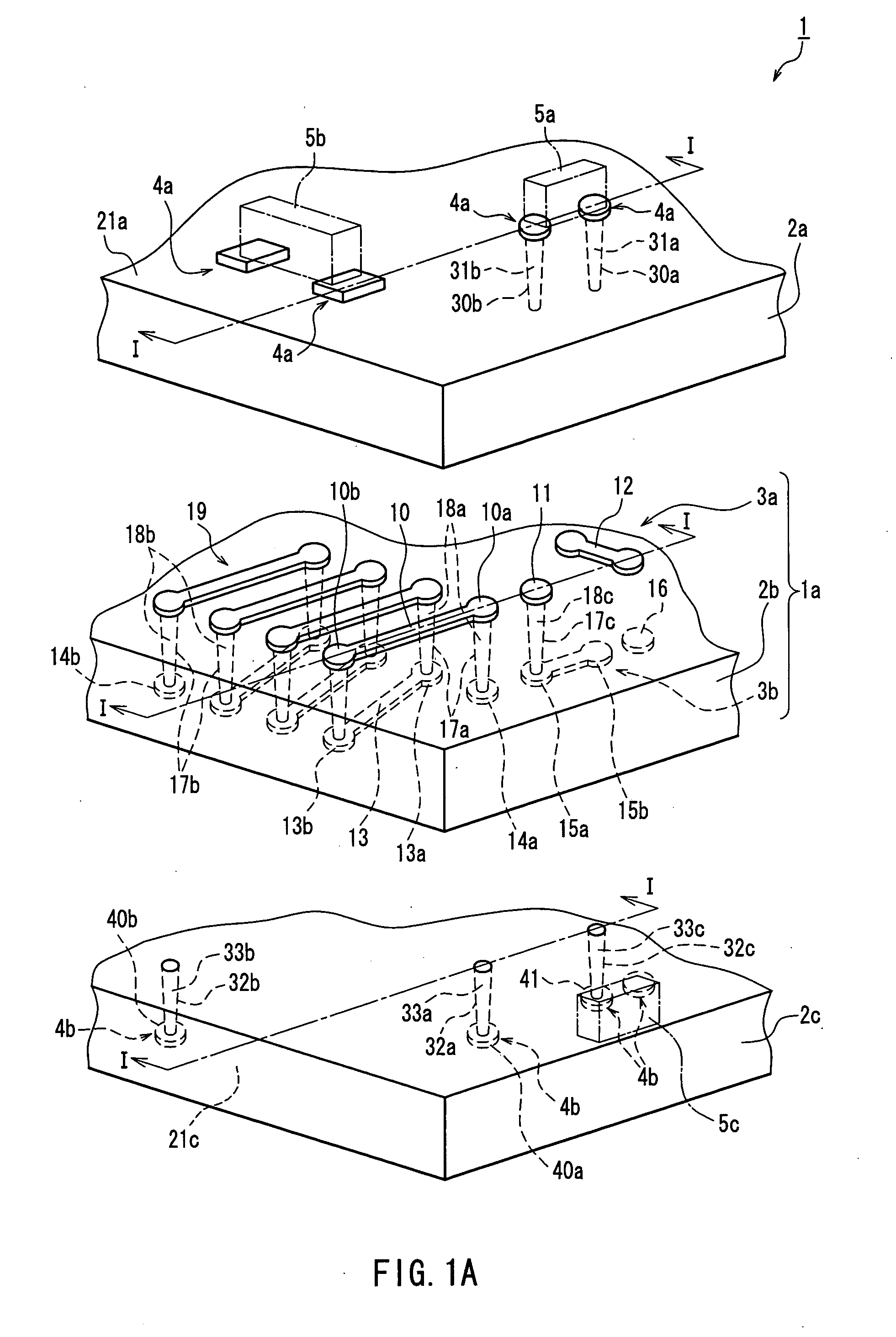

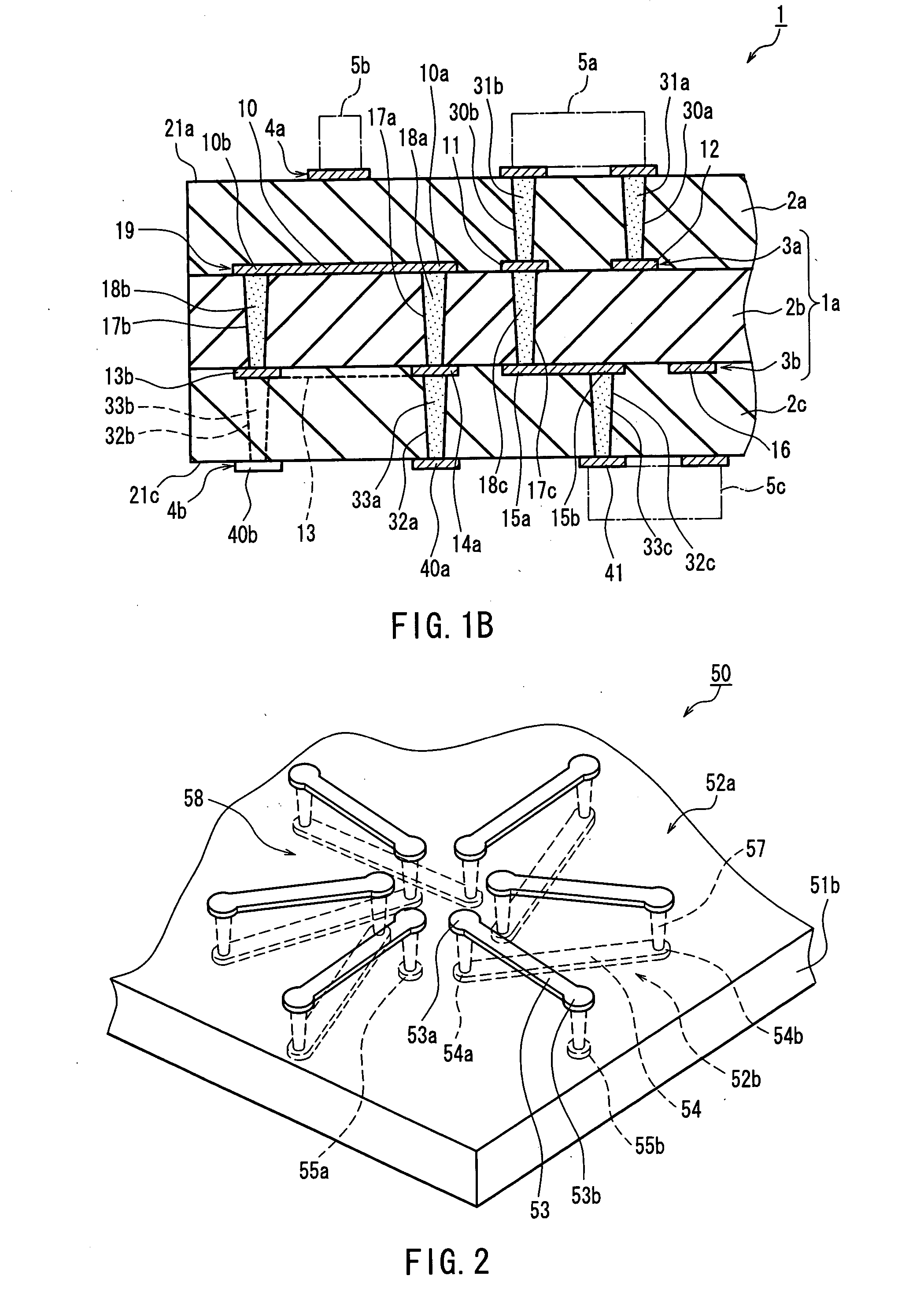

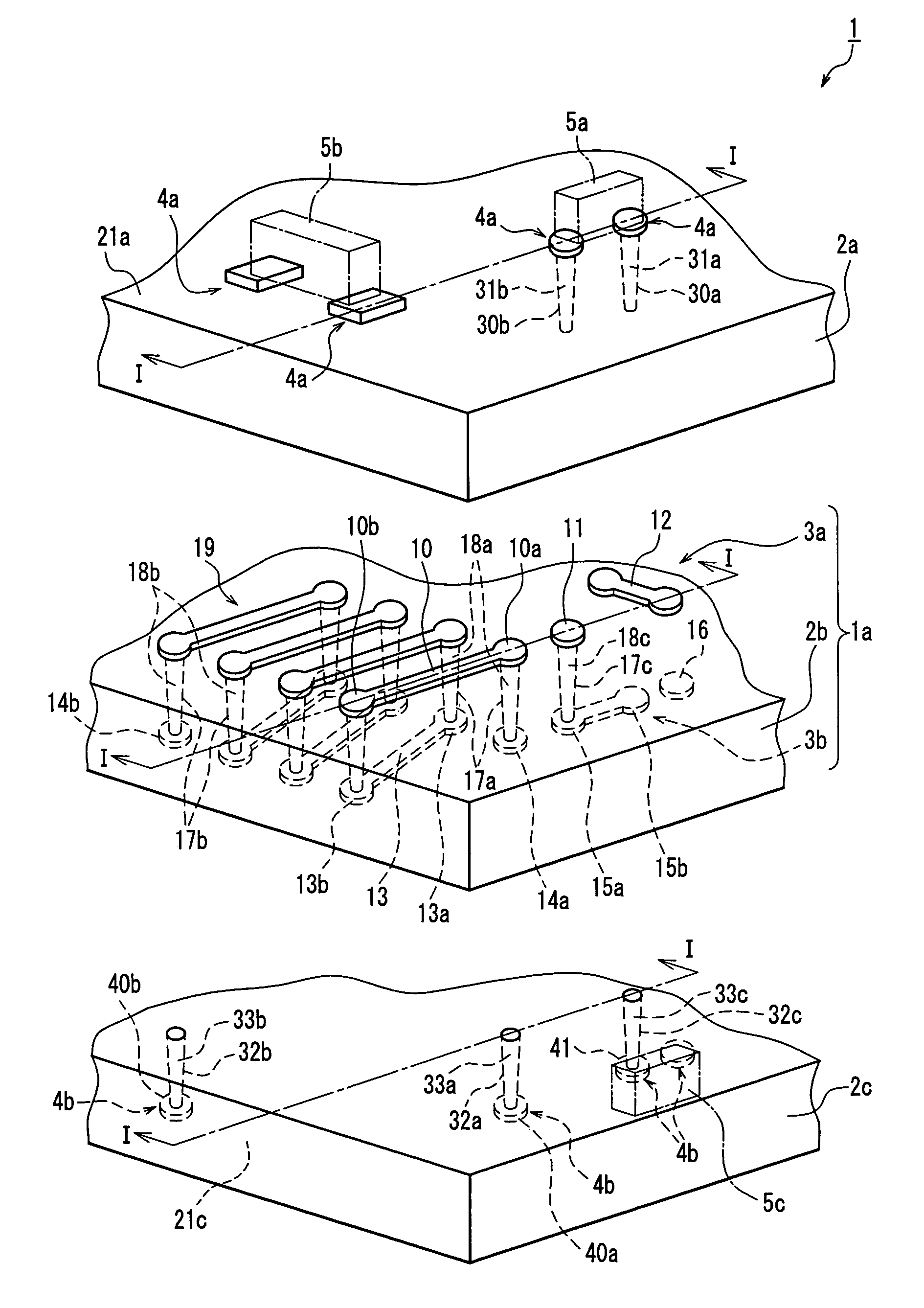

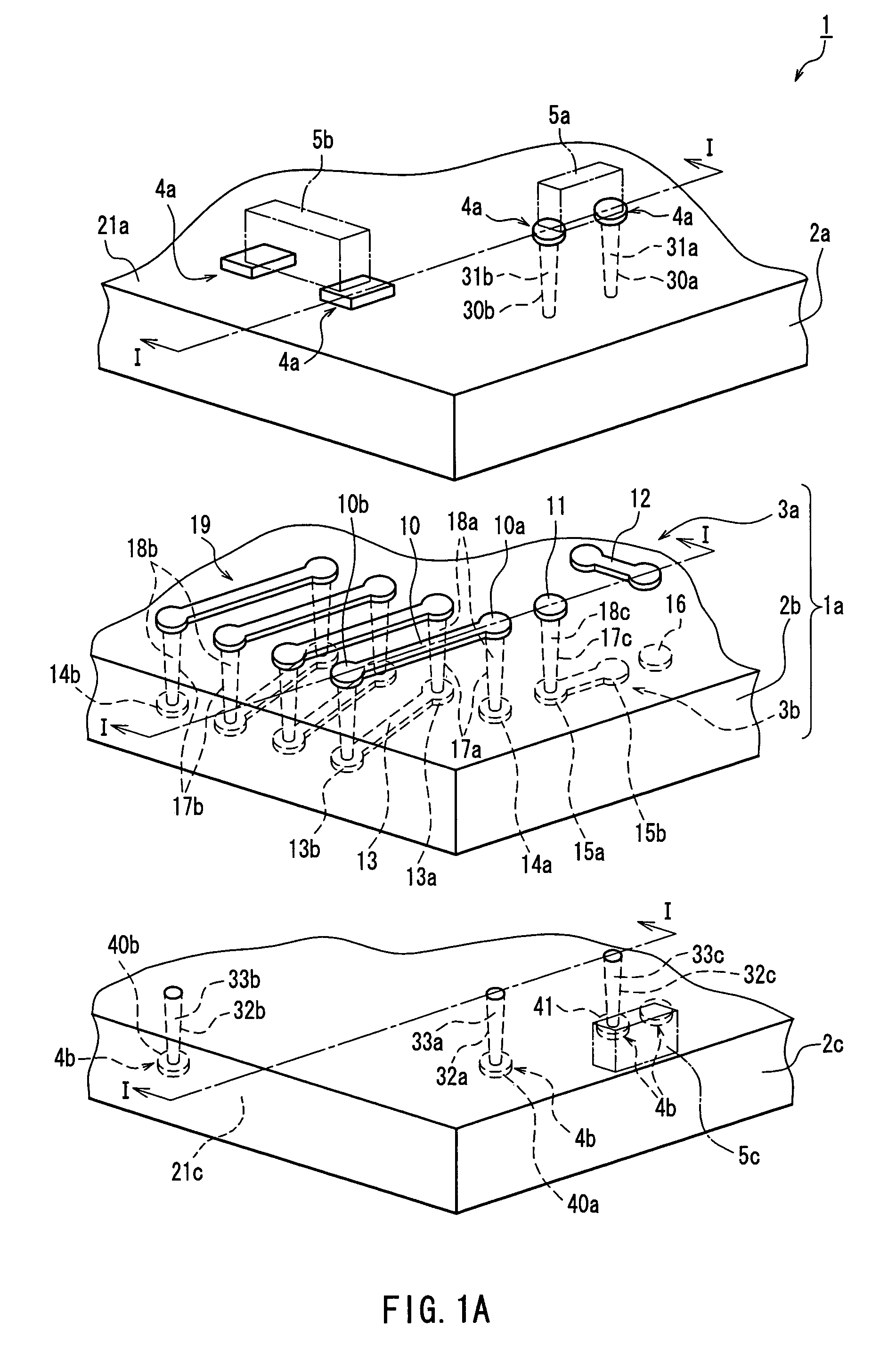

Multilayer circuit board

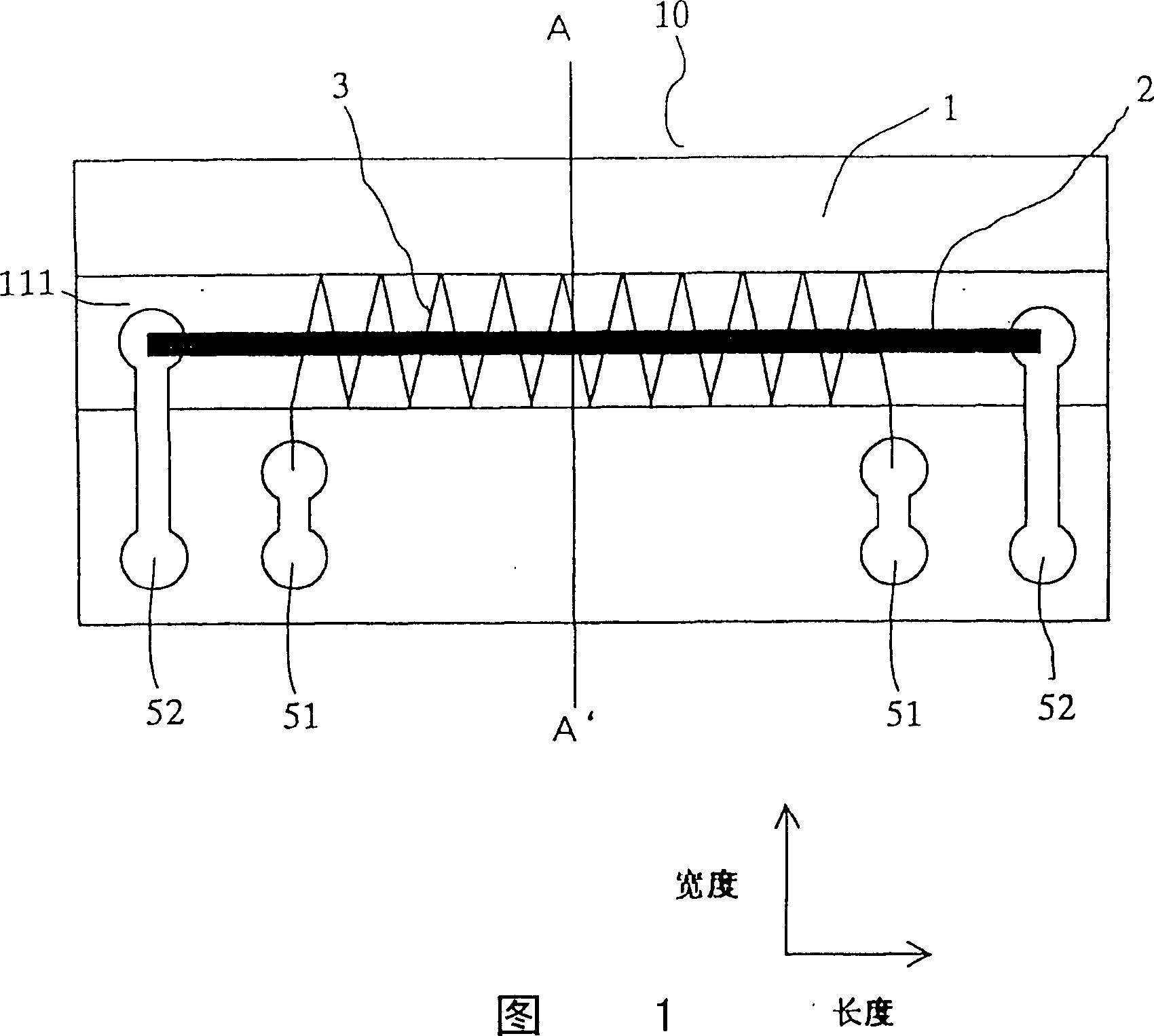

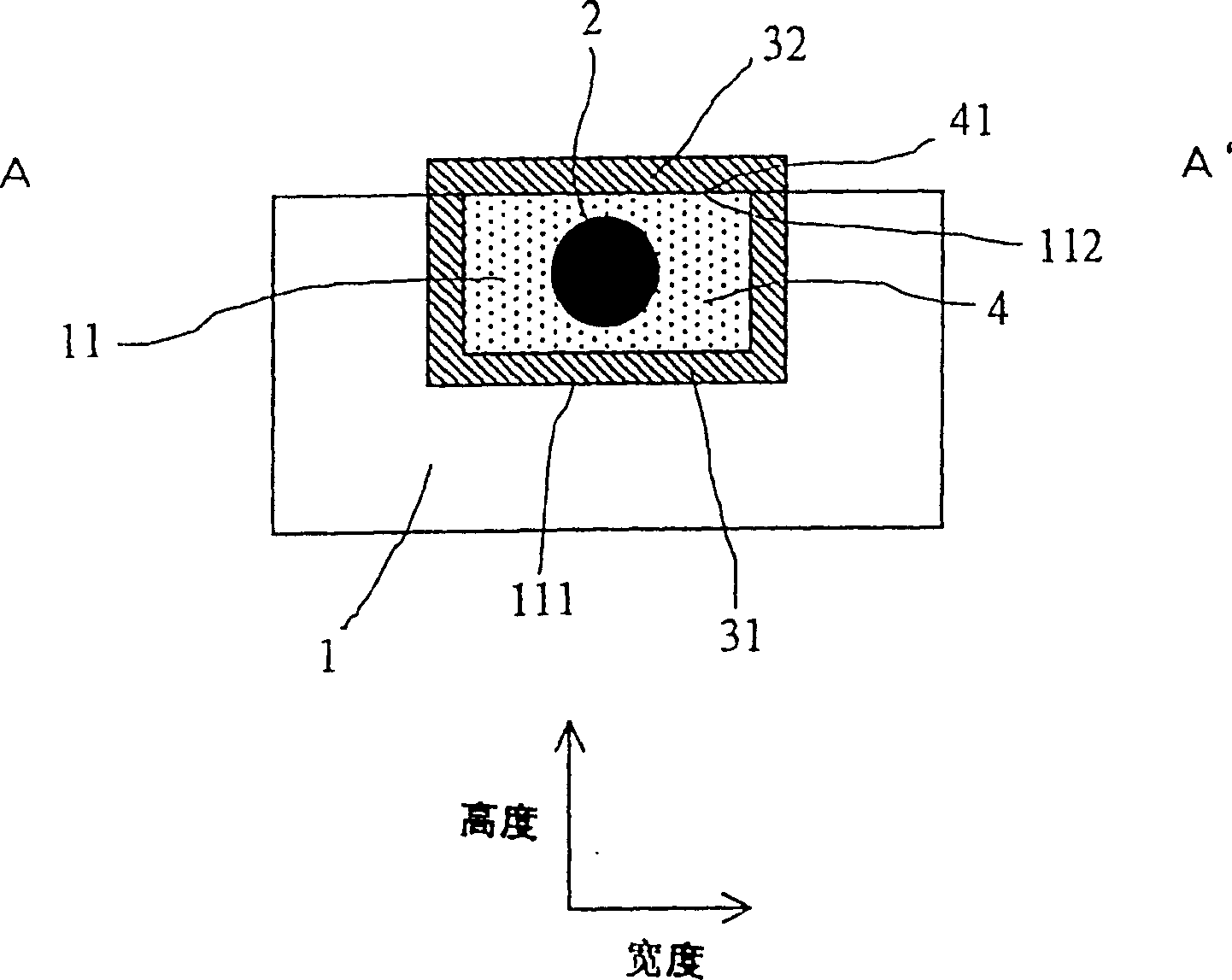

InactiveUS20060081397A1Facilitates increase wind numberExcellent flexibilityPrinted circuit aspectsTransformers/inductances coils/windings/connectionsElectrically conductiveElectrical connection

A multilayer circuit board includes: two or more layers of electrical insulative base members; and two or more layers of conductive patterned layers. At least two of the conductive patterned layers include coil patterns that will be a part of a coil, through holes are provided at predetermined positions of the electrical insulative base members, the positions being sandwiched between the coil patterns, so as to enable communication between respective end portions of the coil patterns, and conductive paste charged in the through holes allows electrical connection to be established between the respective end portions. The coil is formed so as to be wound in a direction perpendicular to a thickness direction of the multilayer circuit board. With this configuration, a multilayer circuit board can be provided, which facilitates increasing the winding number of a coil and has excellent flexibility of circuit design.

Owner:PANASONIC CORP

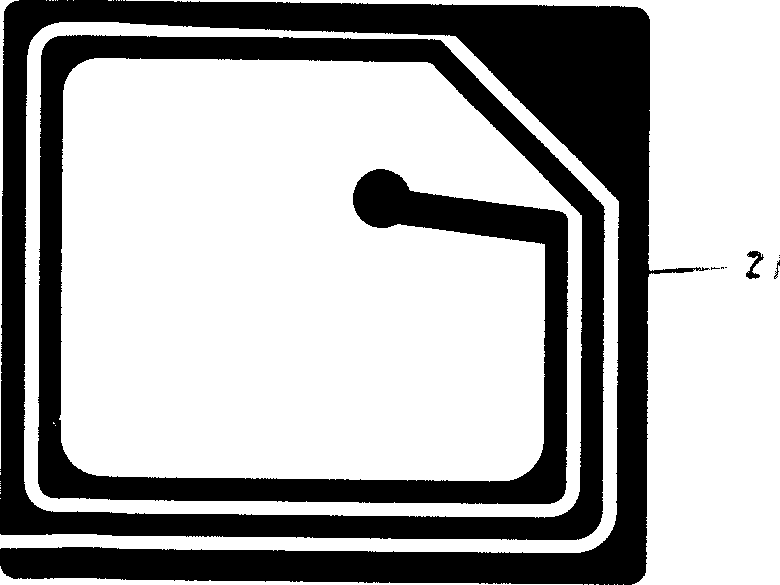

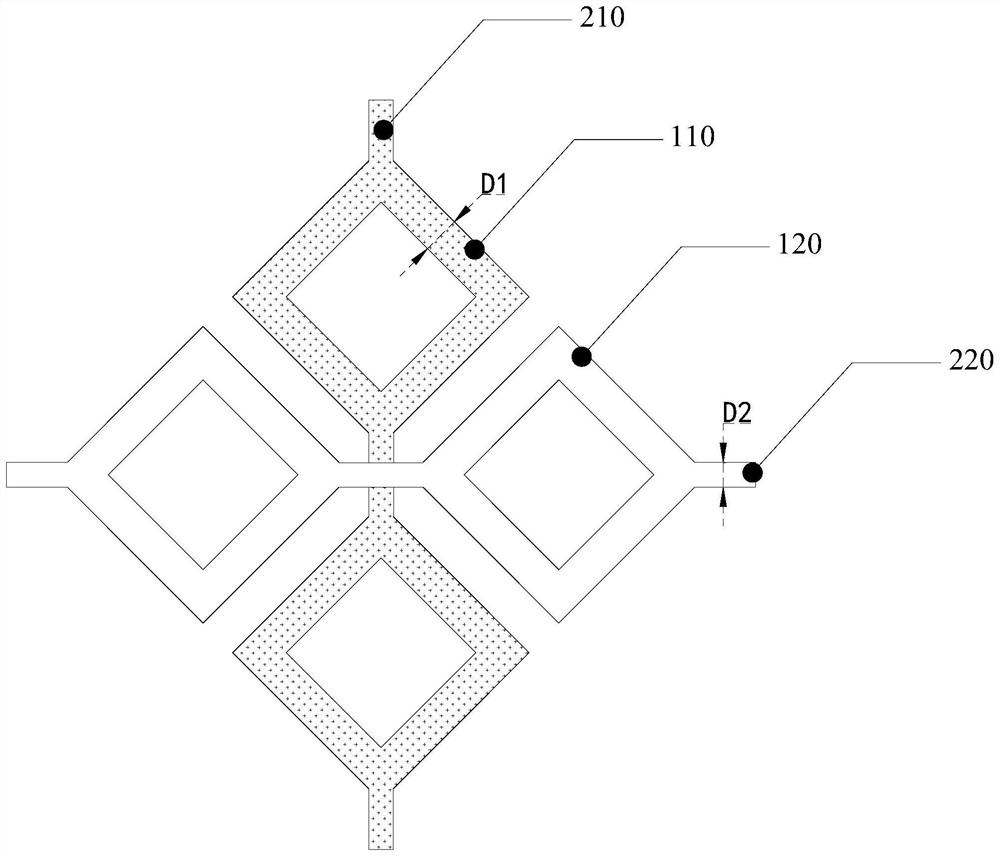

High-precision radio frequency soft tag

ActiveCN100423026CLarge capacityHigh precisionRecord carriers used with machinesCapacitanceEngineering

Owner:齐克庞德电子(江苏)有限公司

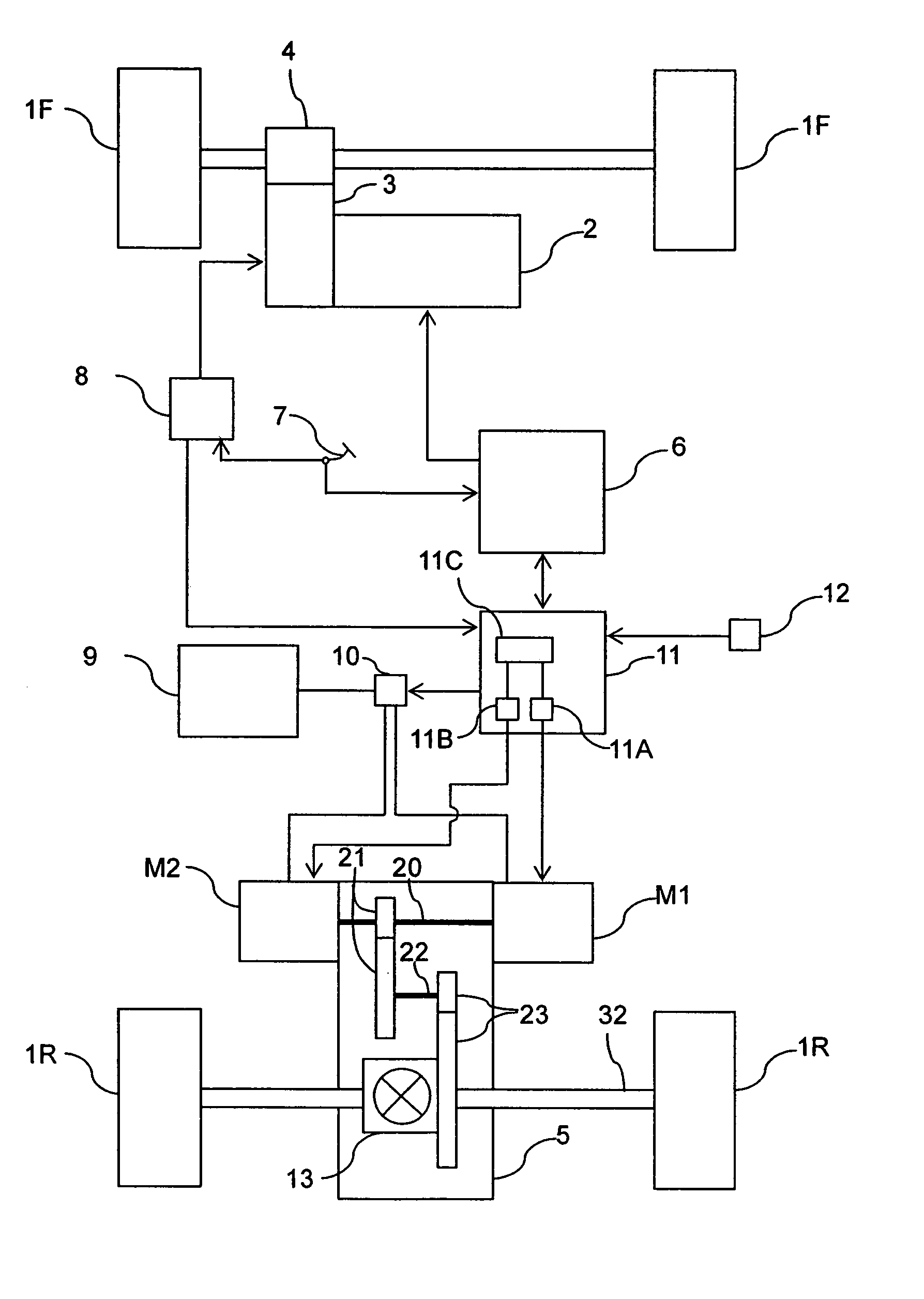

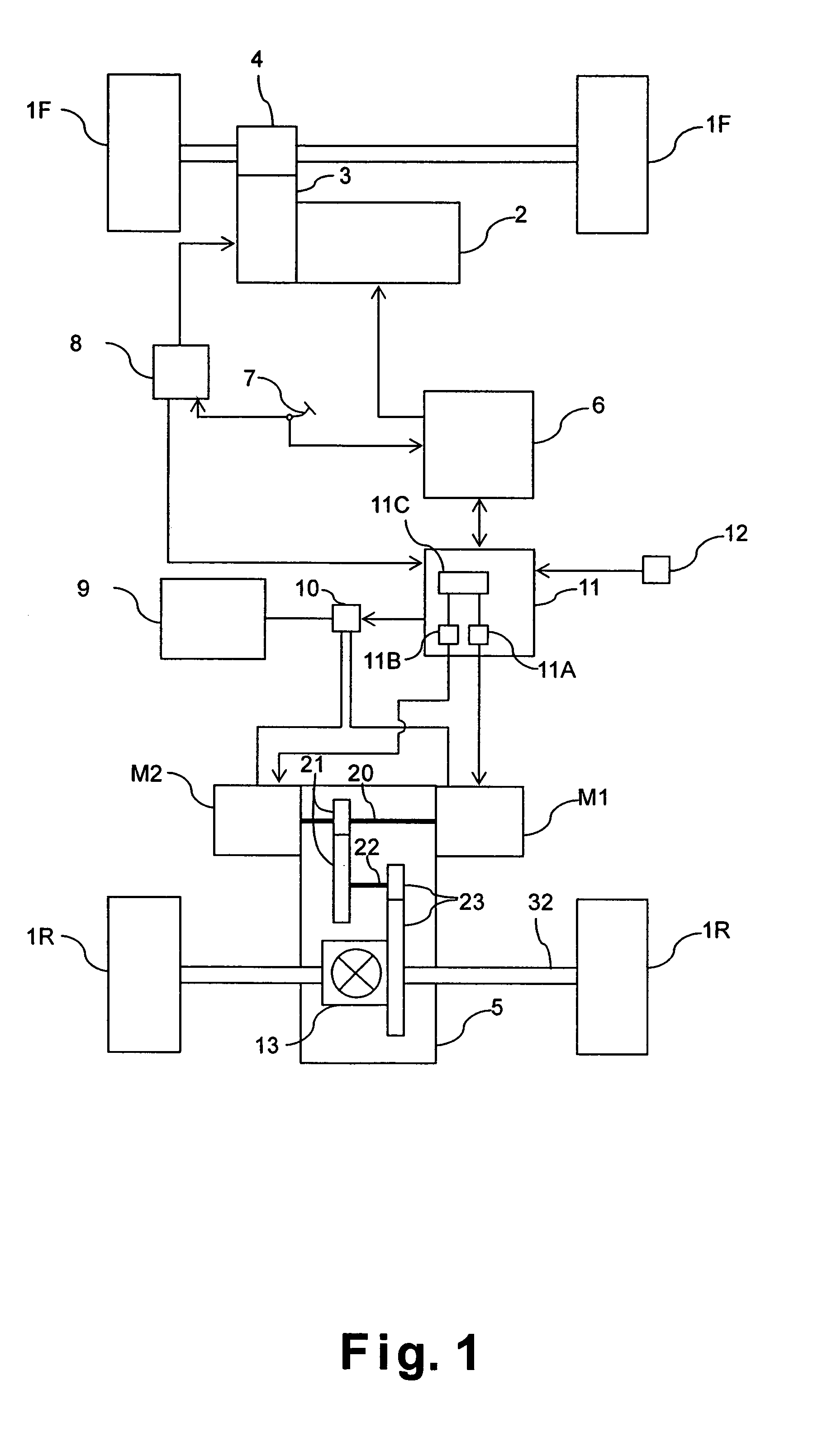

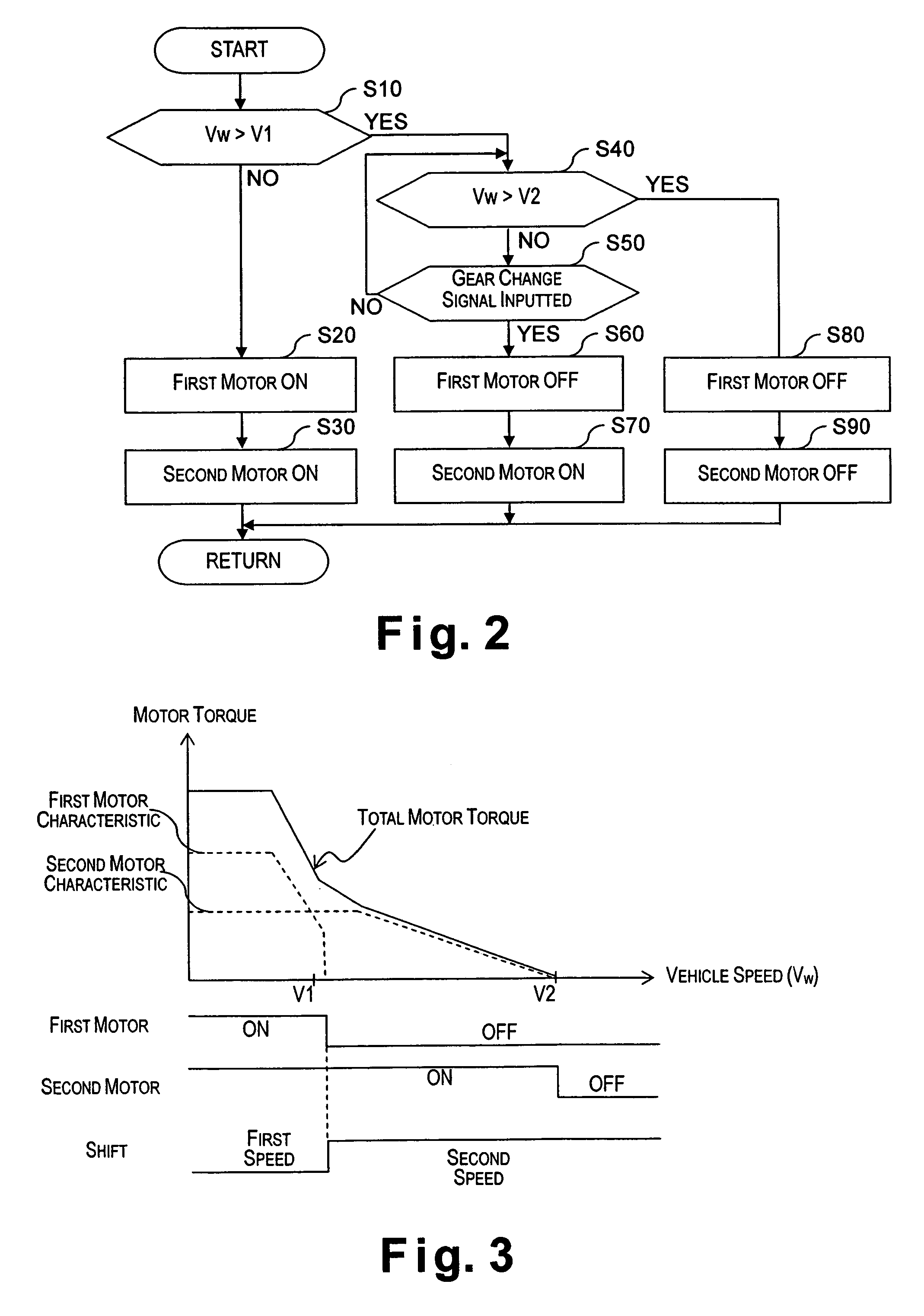

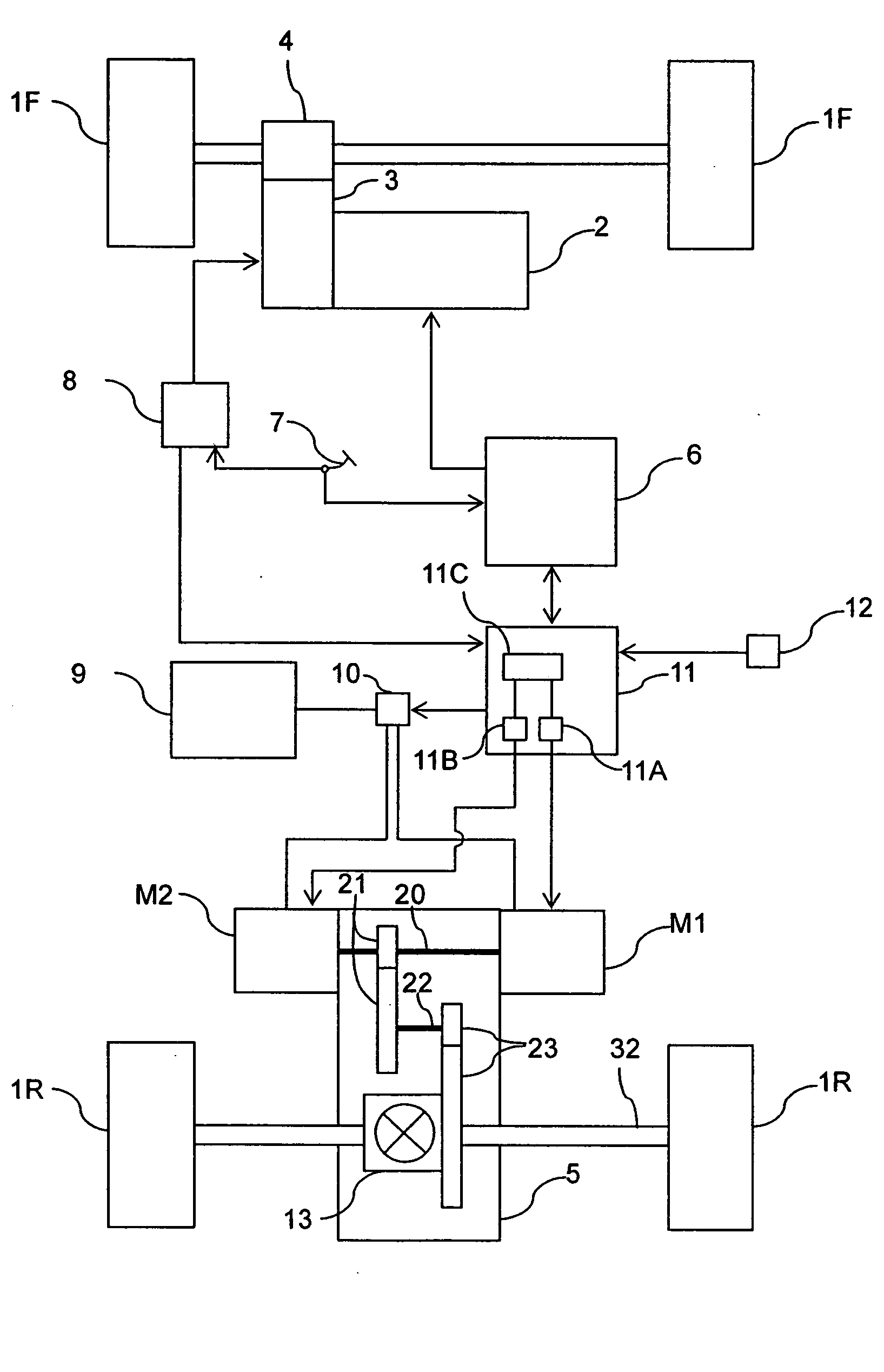

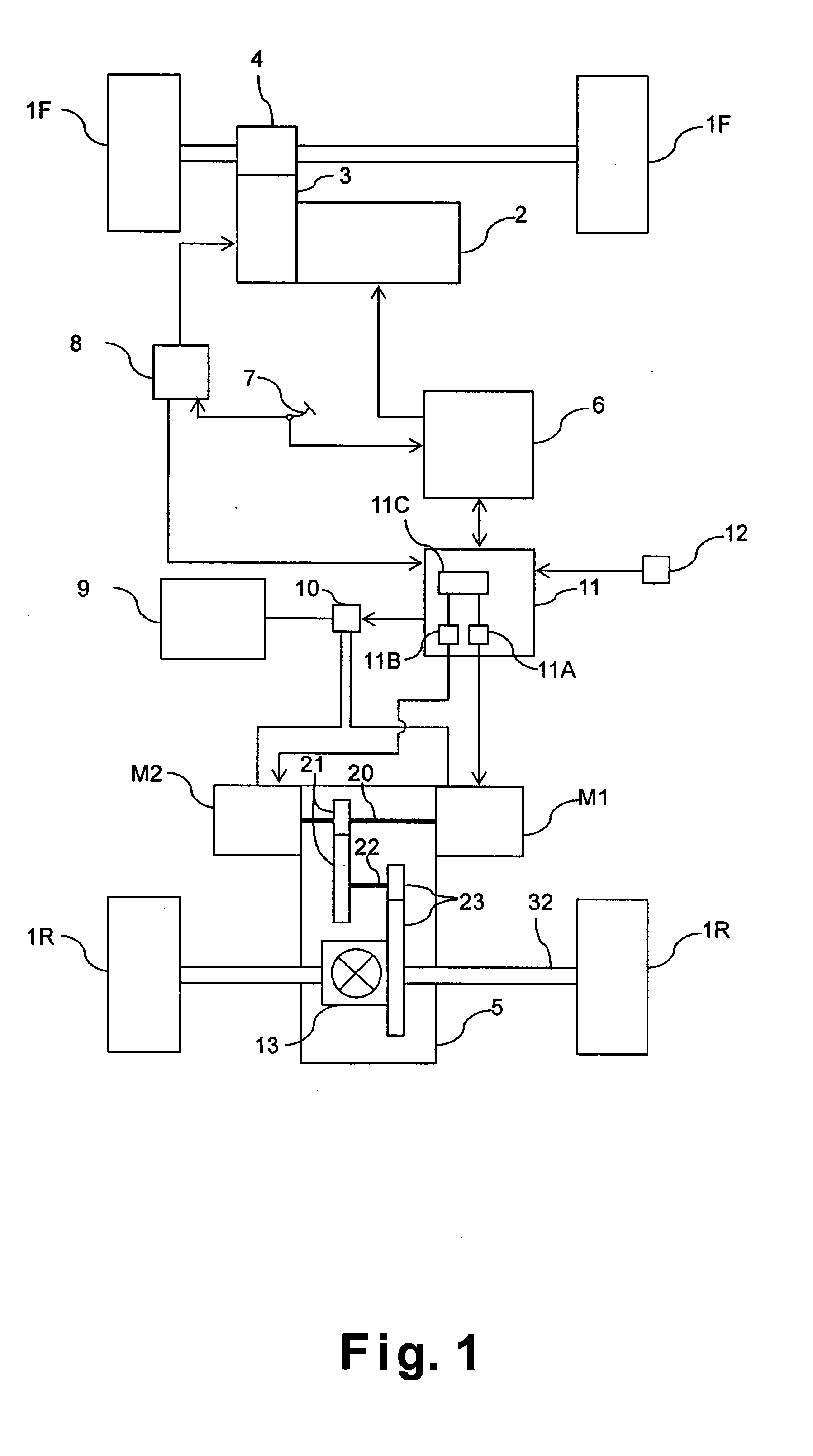

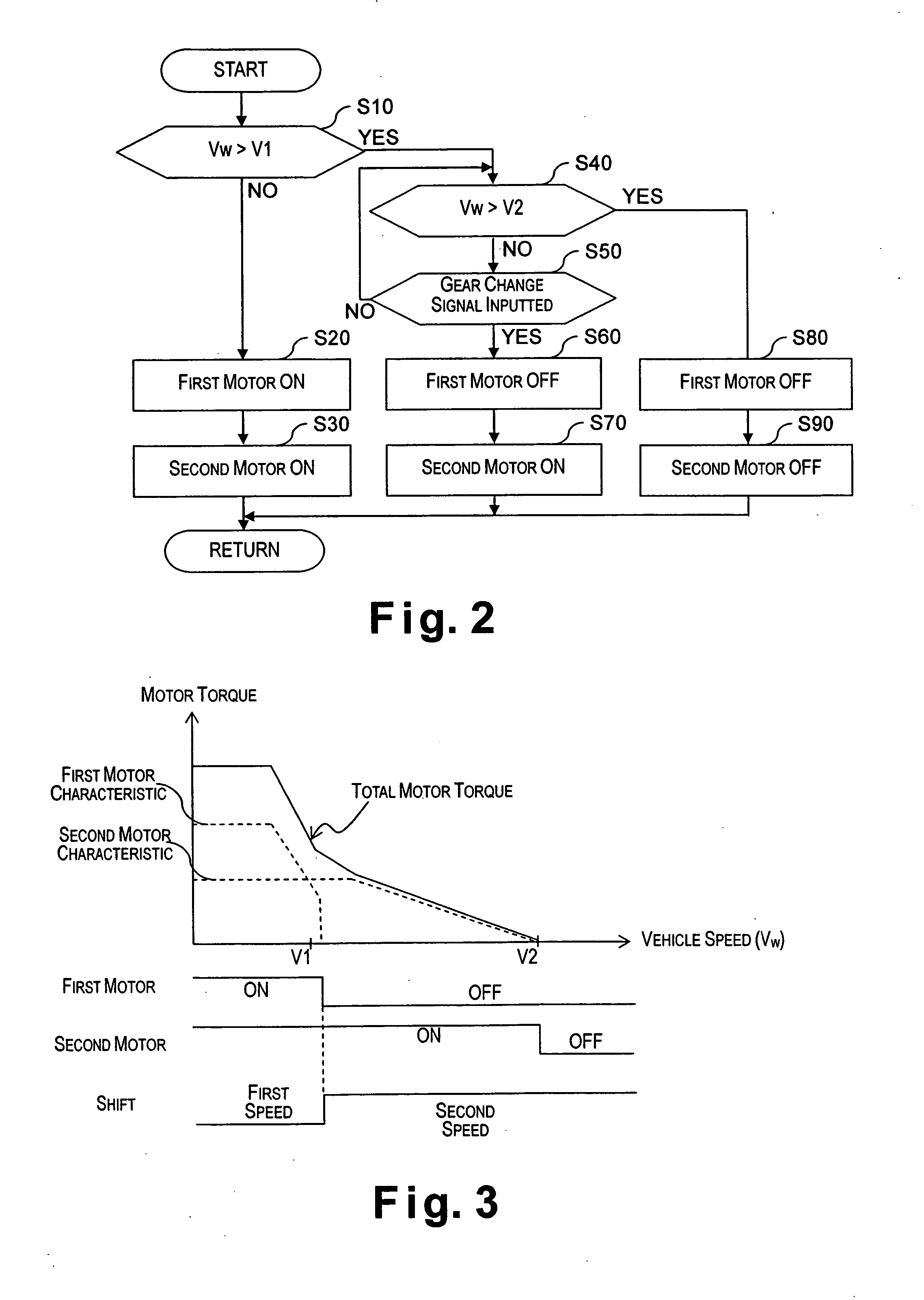

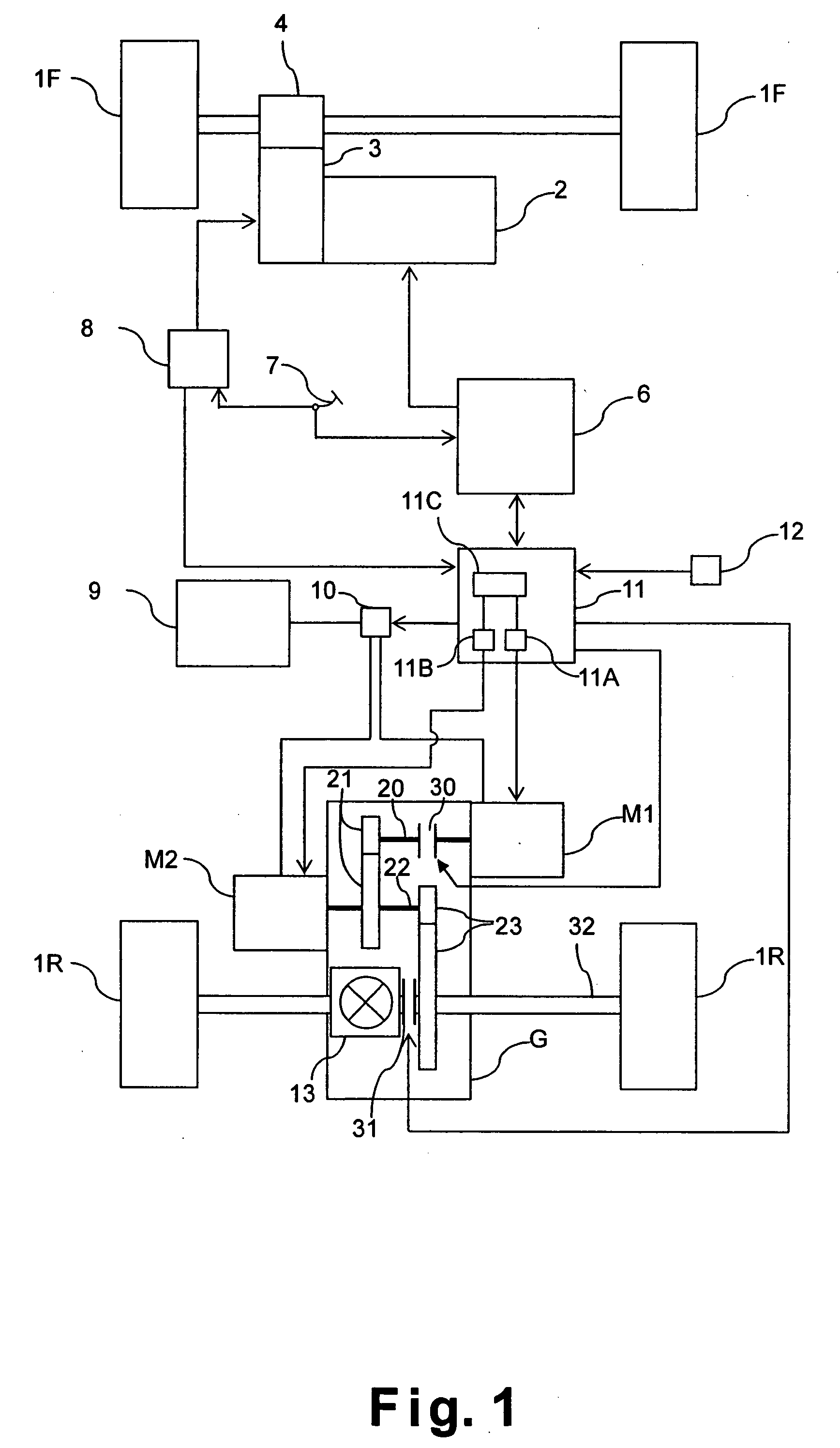

Vehicle drive system

InactiveUS7264070B2Large output capacityIncrease productionAuxillary drivesDigital data processing detailsLow speedElectric machine

In a vehicle drive system, a pair of rear wheels is driven by first and second motors. The first motor is designed to specifications suited to delivering torque at low rotational speeds and the second motor is designed to specifications suited to delivering torque at high rotational speeds. The motor used to drive the rear wheels is selected based on the vehicle speed. The change in the operations of the first and second motors is synchronized with a shifting of a transmission disposed between an engine and a pair of front wheels. Thus, the vehicle drive system is configured and arranged to accommodate speeds ranging from low speeds to high speeds in a sufficient manner without requiring the drive source to become large.

Owner:NISSAN MOTOR CO LTD

Vehicle drive system

InactiveUS20050067202A1Large output capacityIncrease productionAuxillary drivesDigital data processing detailsLow speedElectric machine

In a vehicle drive system, a pair of rear wheels is driven by first and second motors. The first motor is designed to specifications suited to delivering torque at low rotational speeds and the second motor is designed to specifications suited to delivering torque at high rotational speeds. The motor used to drive the rear wheels is selected based on the vehicle speed. The change in the operations of the first and second motors is synchronized with a shifting of a transmission disposed between an engine and a pair of front wheels. Thus, the vehicle drive system is configured and arranged to accommodate speeds ranging from low speeds to high speeds in a sufficient manner without requiring the drive source to become large.

Owner:NISSAN MOTOR CO LTD

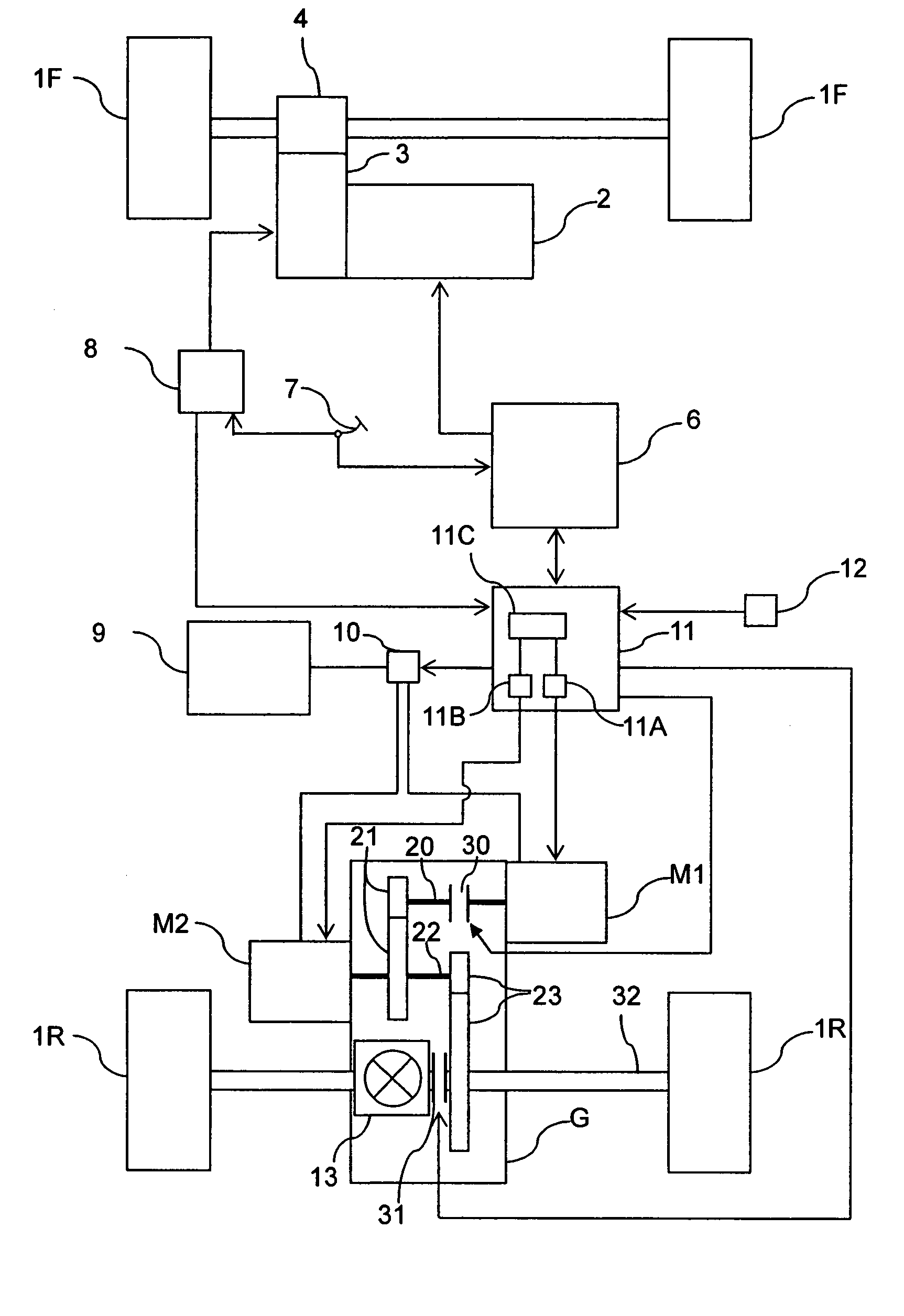

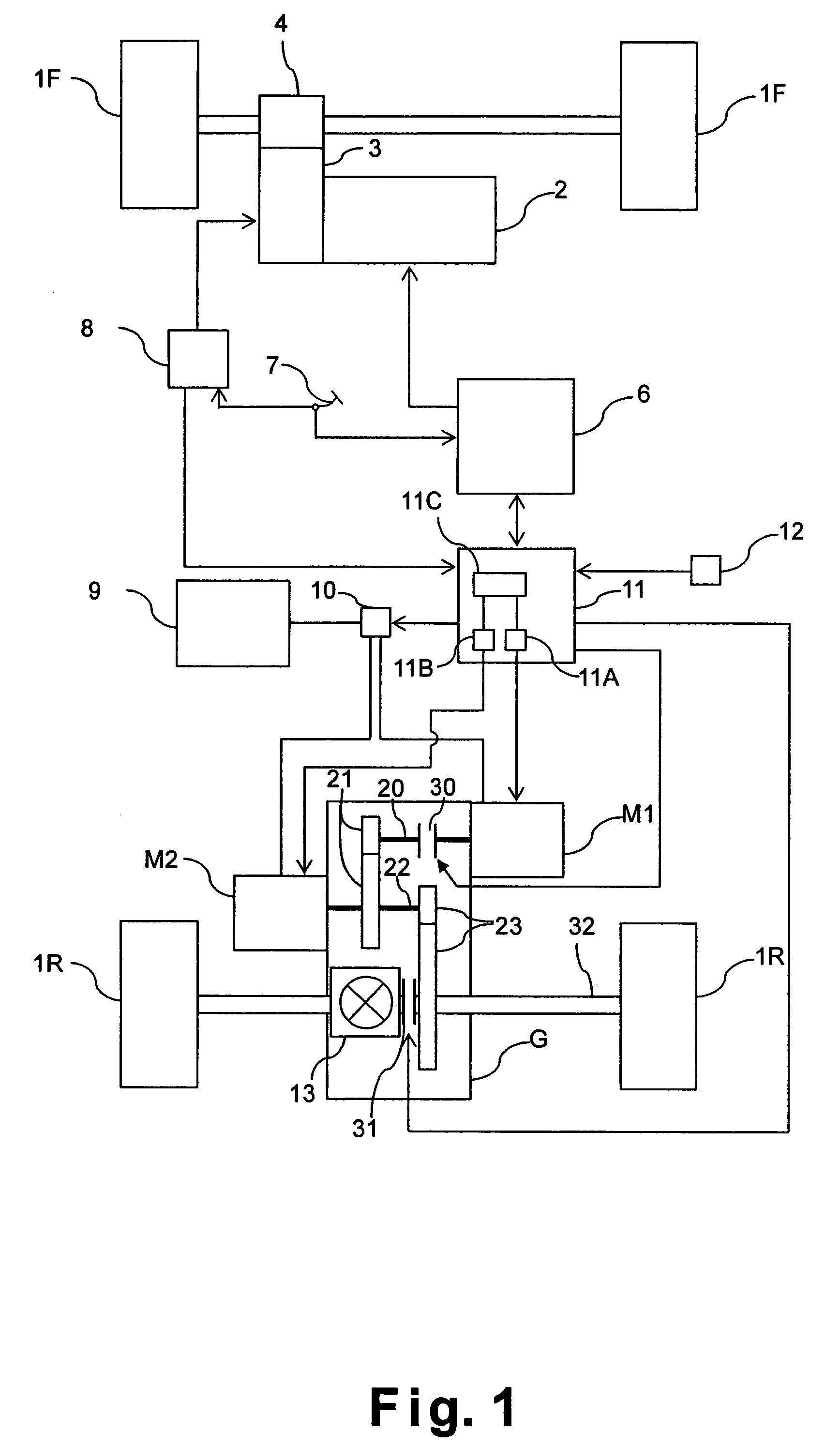

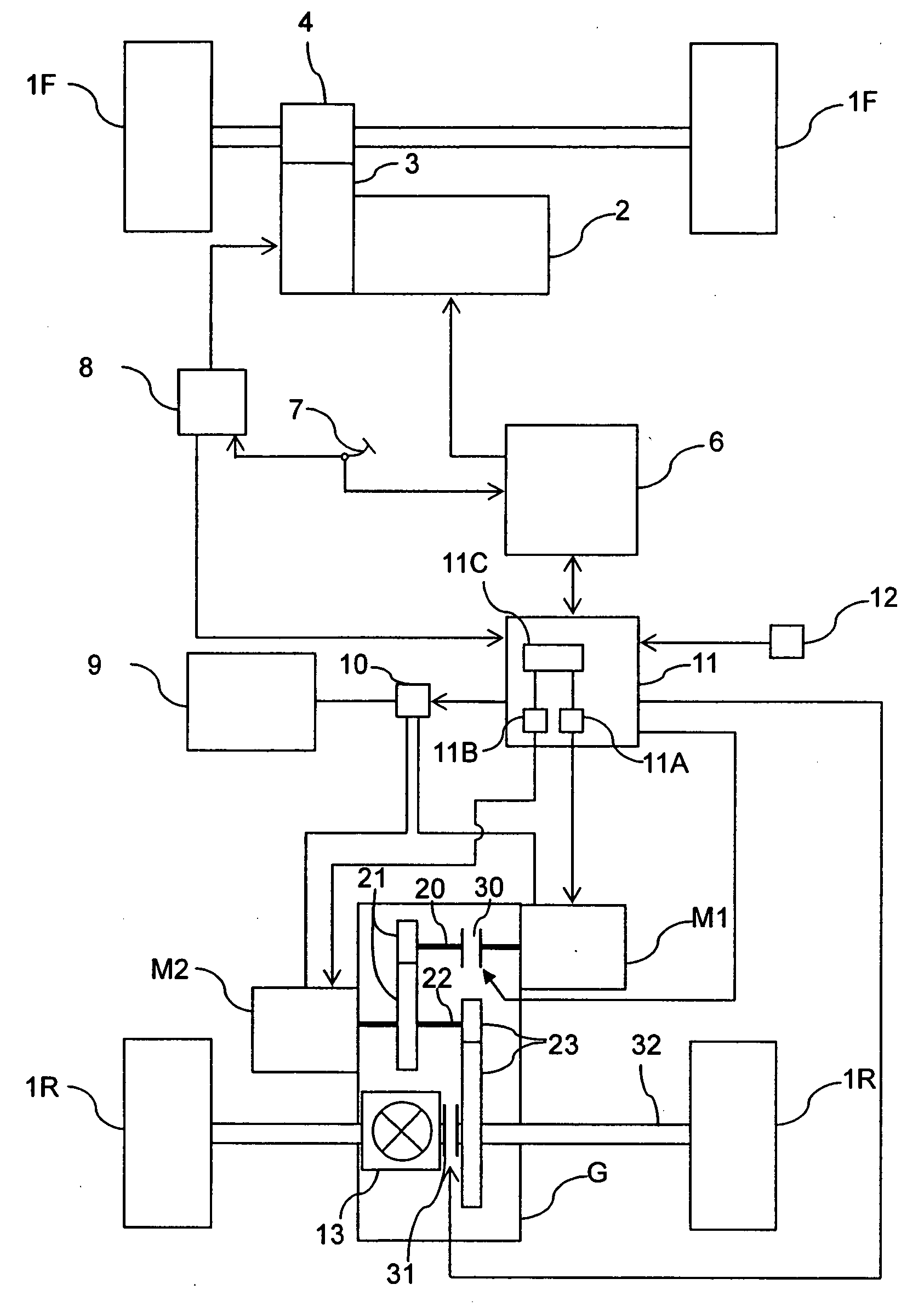

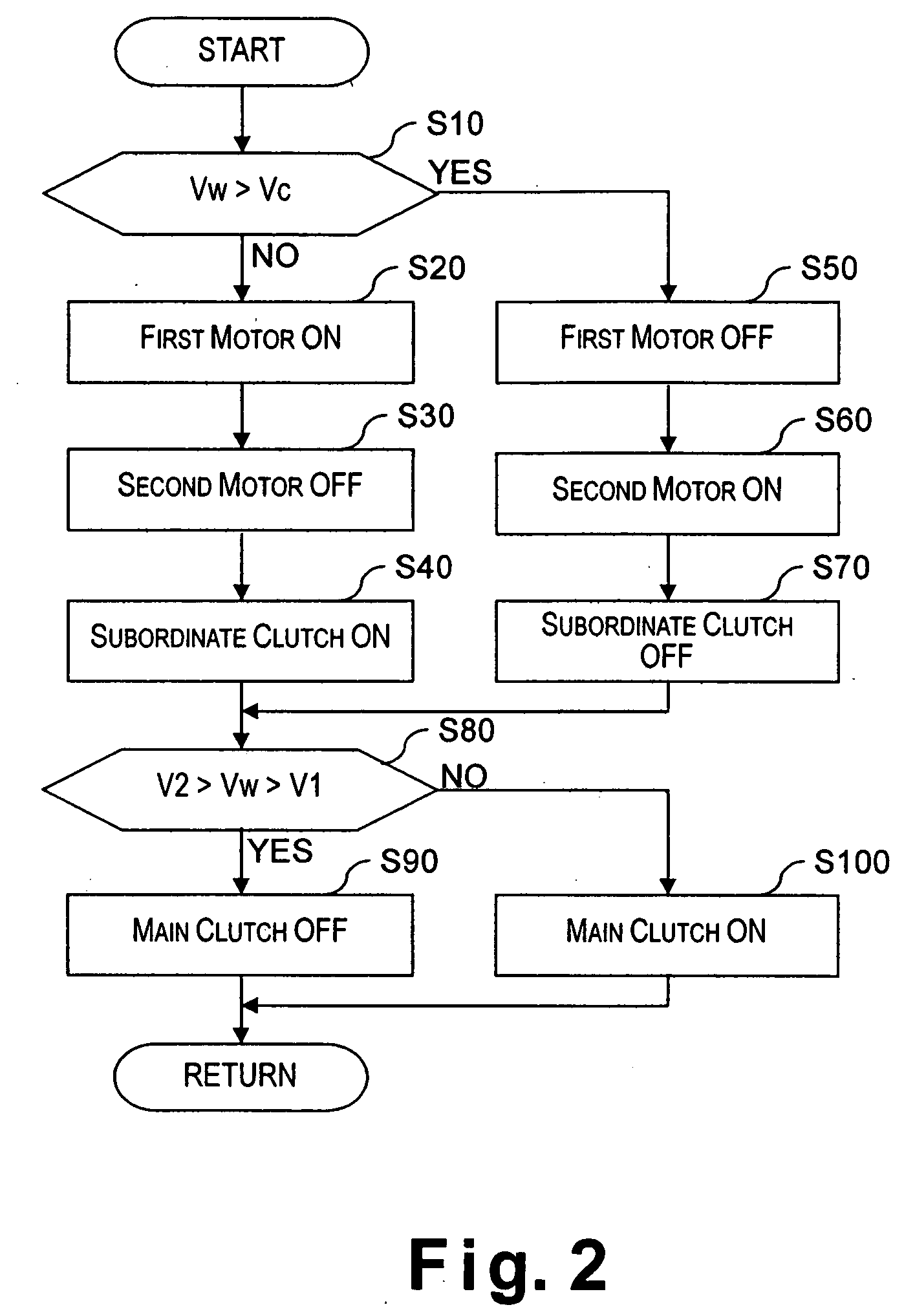

Vehicle drive apparatus

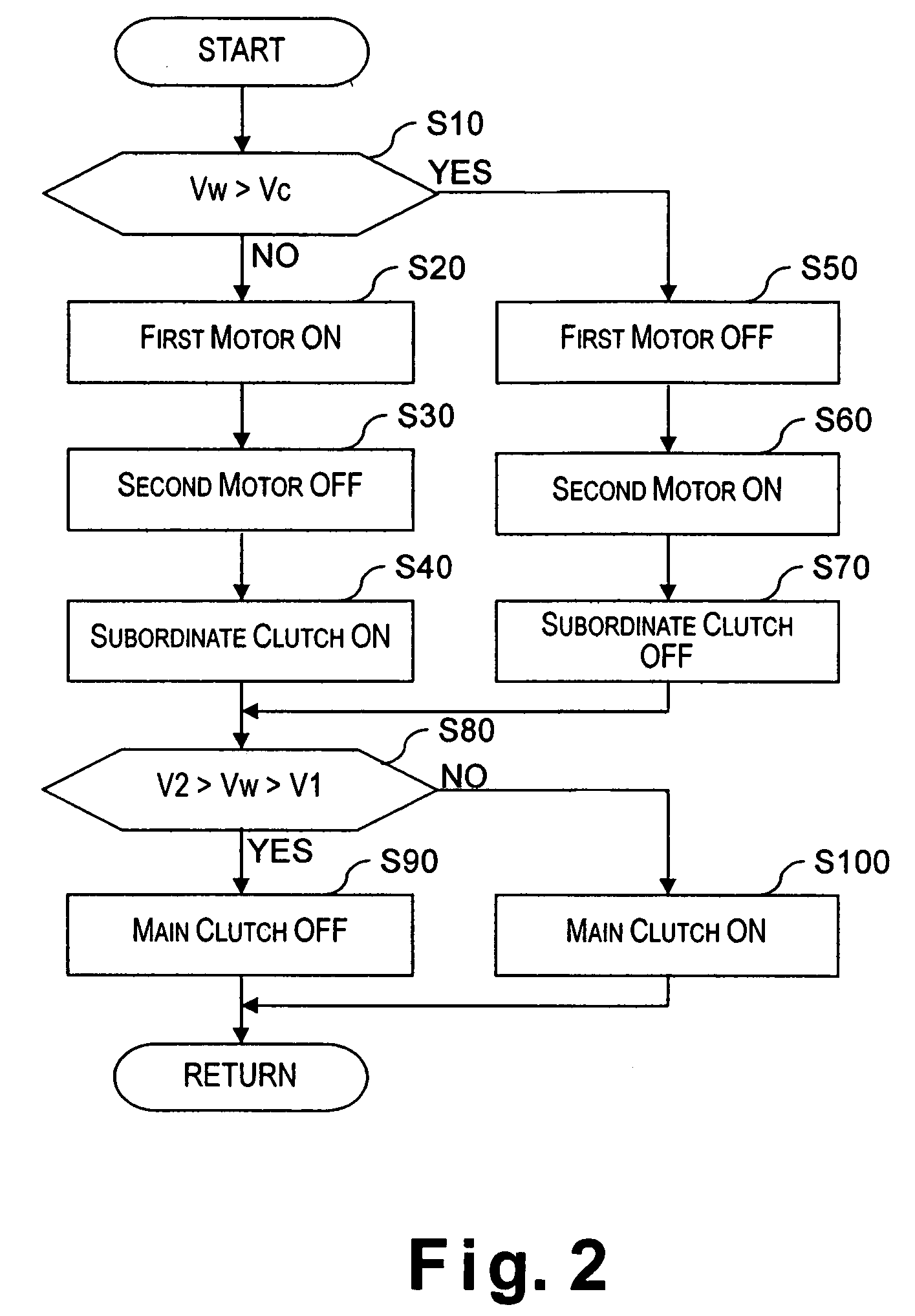

InactiveUS7104921B2Large output capacityIncrease productionHybrid vehiclesClutchesClutch controlEngineering

A vehicle drive apparatus is provided that comprises first and second drive sources, a main clutch, a subordinate clutch, a drive source selecting section, and a clutch control section. The first and second drive sources output drive forces to a first wheel. The main clutch is configured to simultaneously shut off delivery of outputs from the first and second drive sources. The subordinate clutch coupled to the first drive source is configured to shut off delivery of only the output from the first drive source. The drive source selecting section is configured to select at least one of the first and second drive sources to output the drive force. The clutch control section is configured to release the subordinate clutch while the main clutch is temporality released upon a determination of the first drive source being switched from an output delivery state to an output stop state.

Owner:NISSAN MOTOR CO LTD

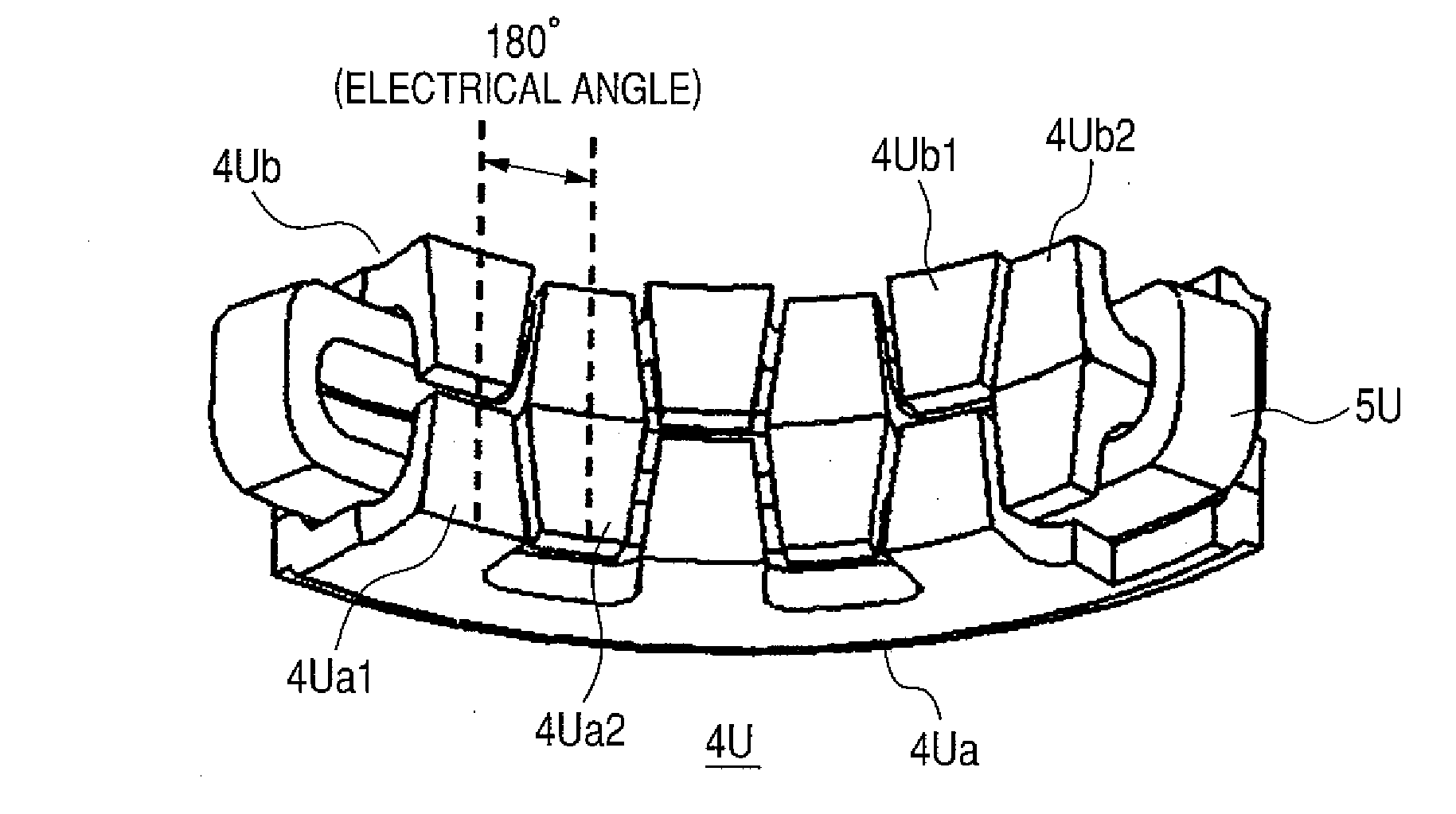

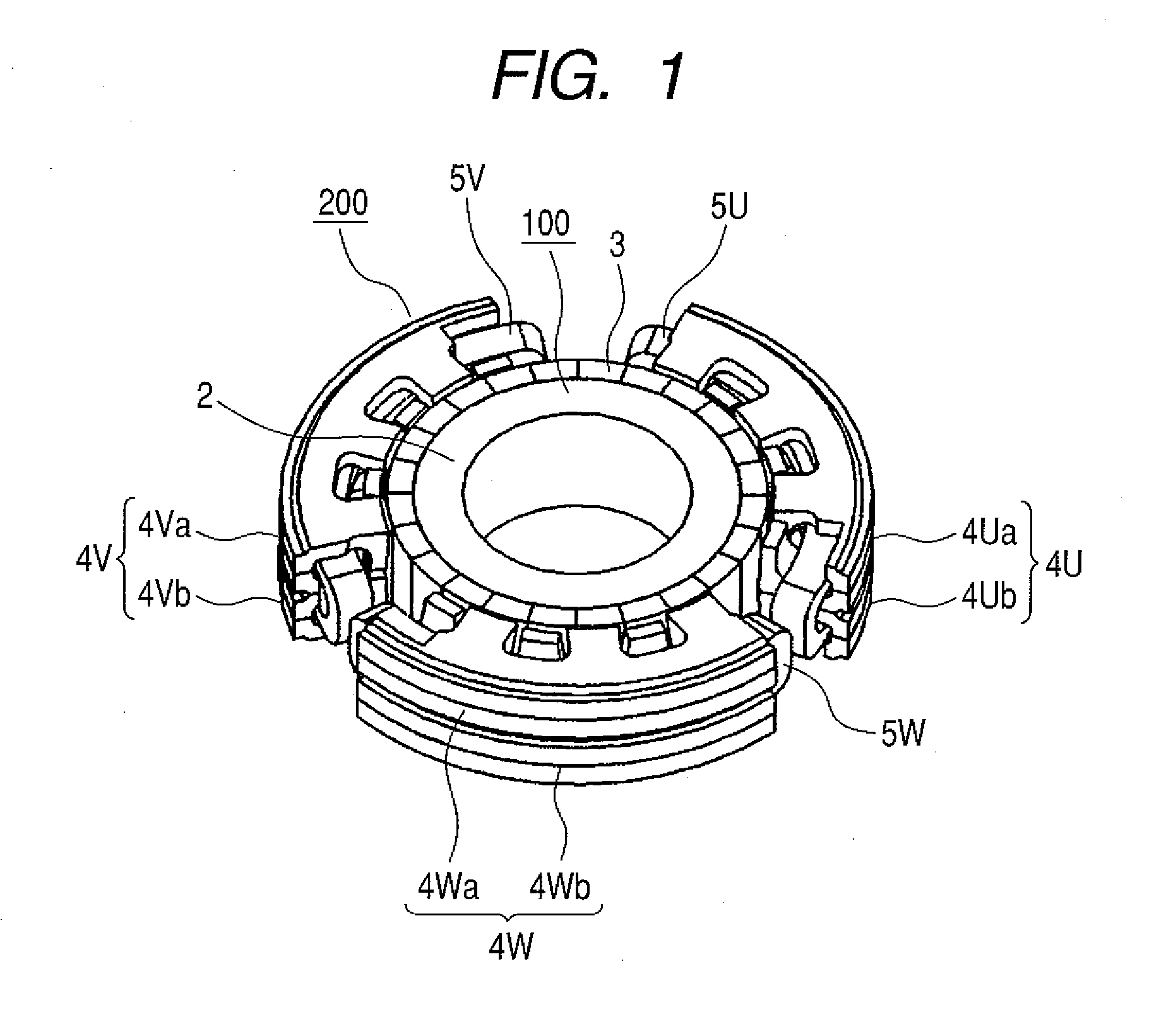

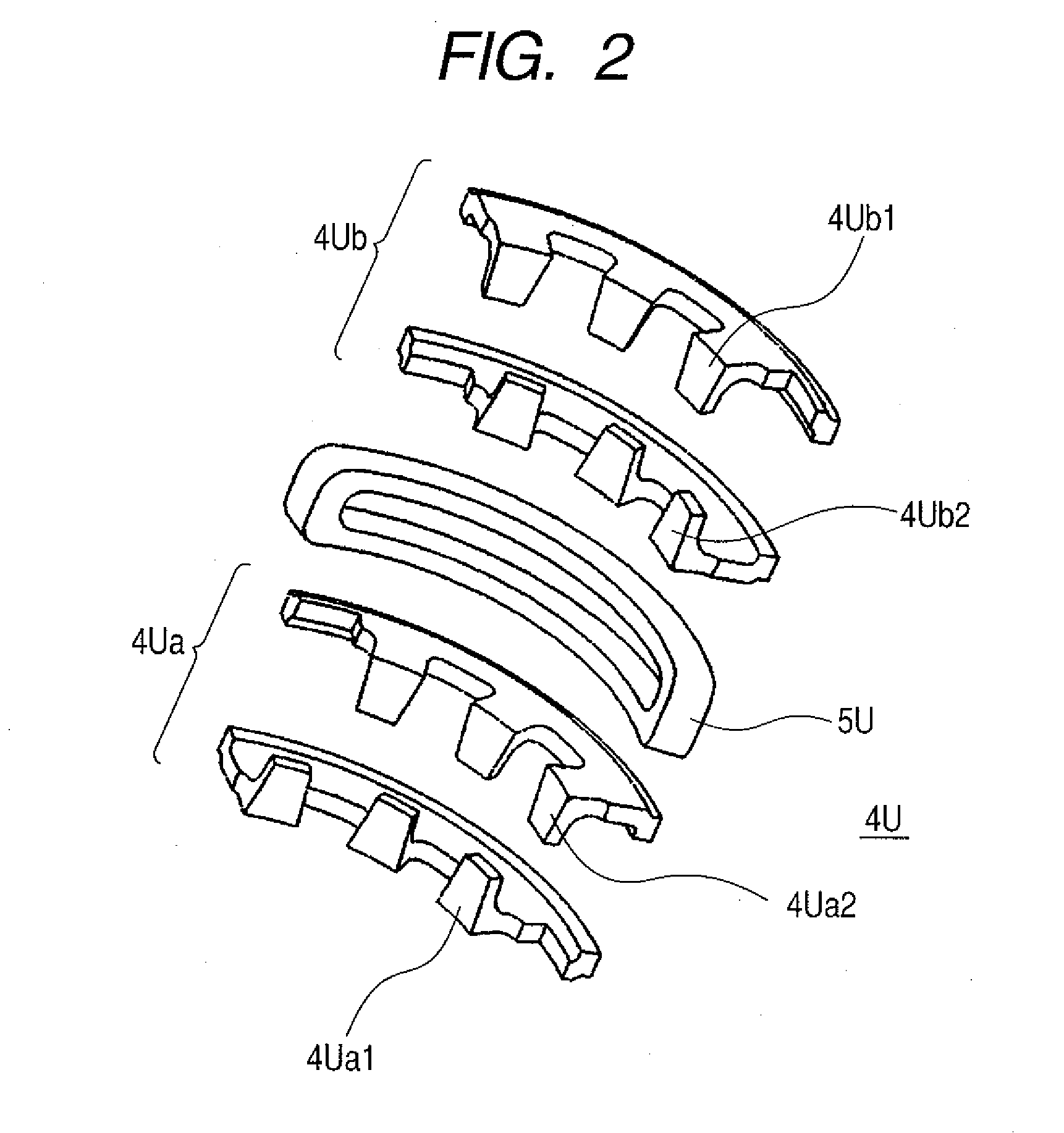

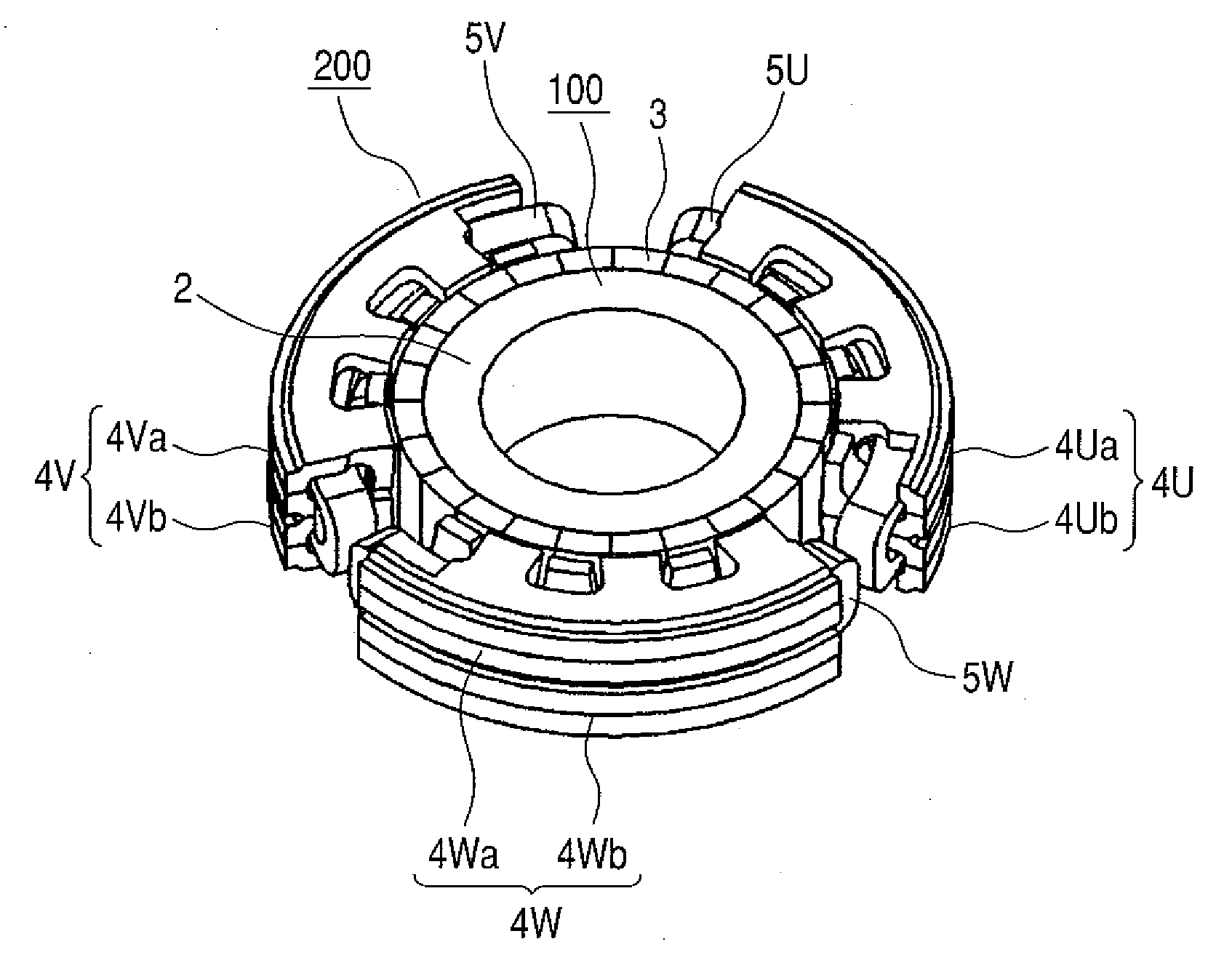

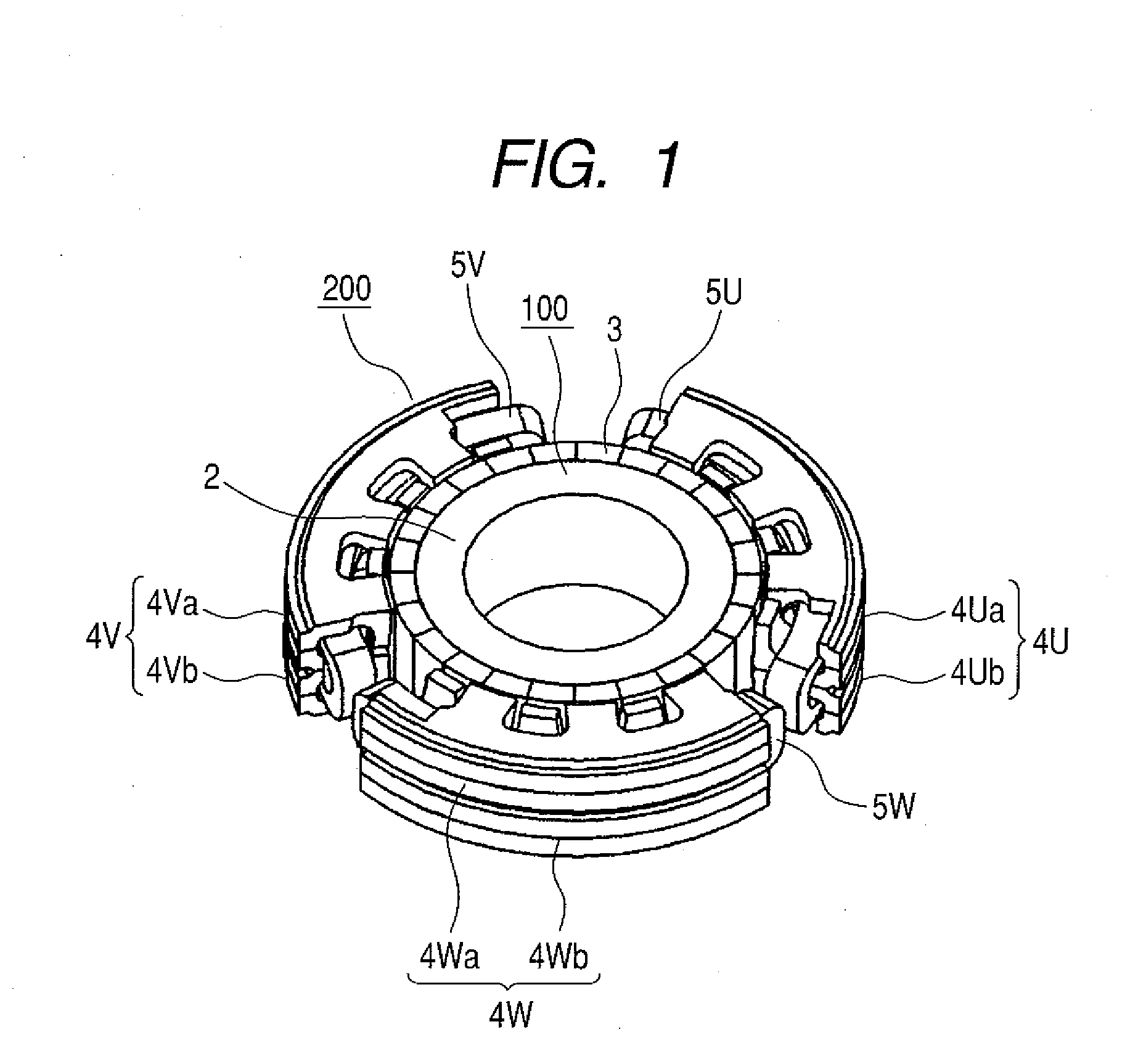

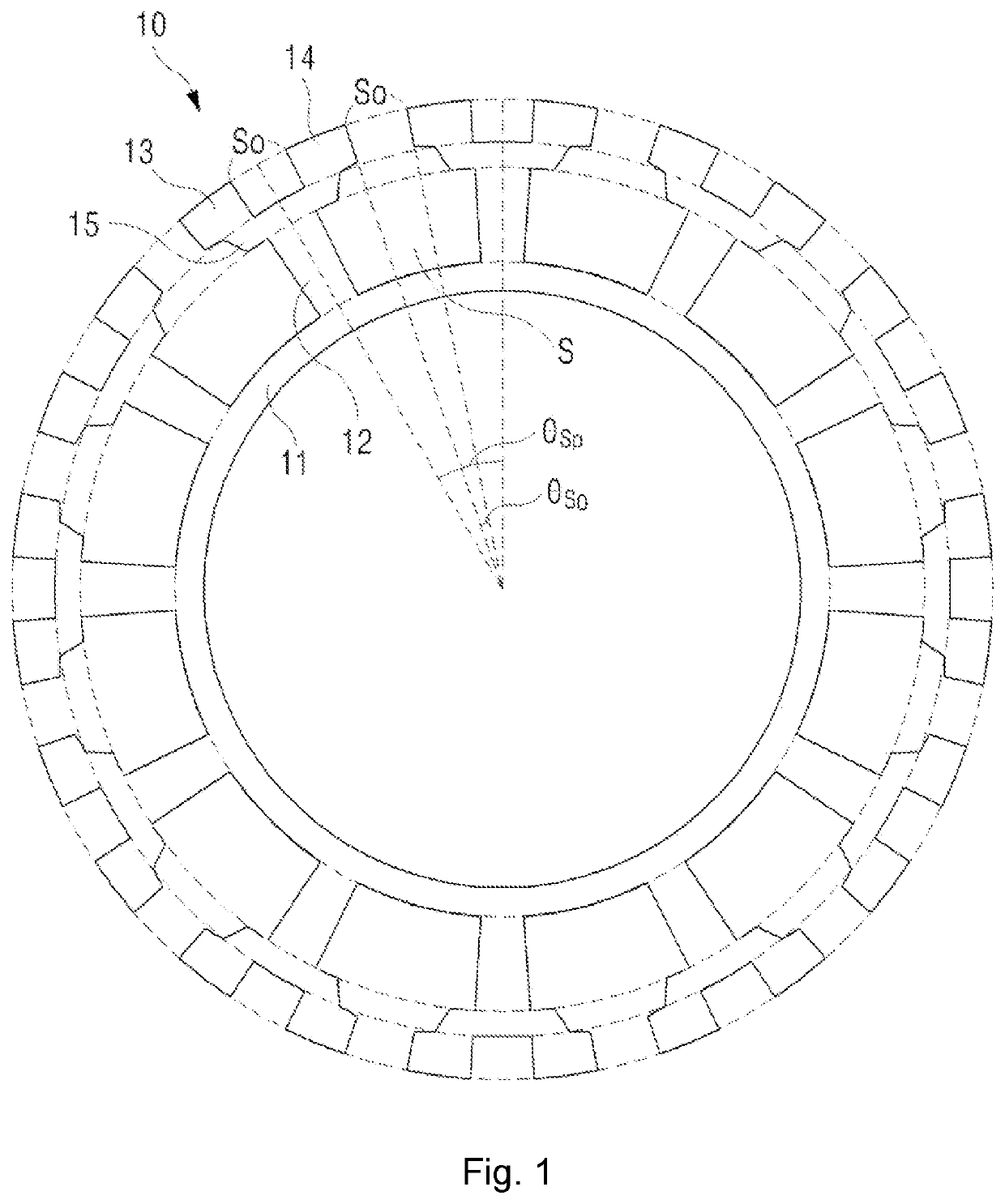

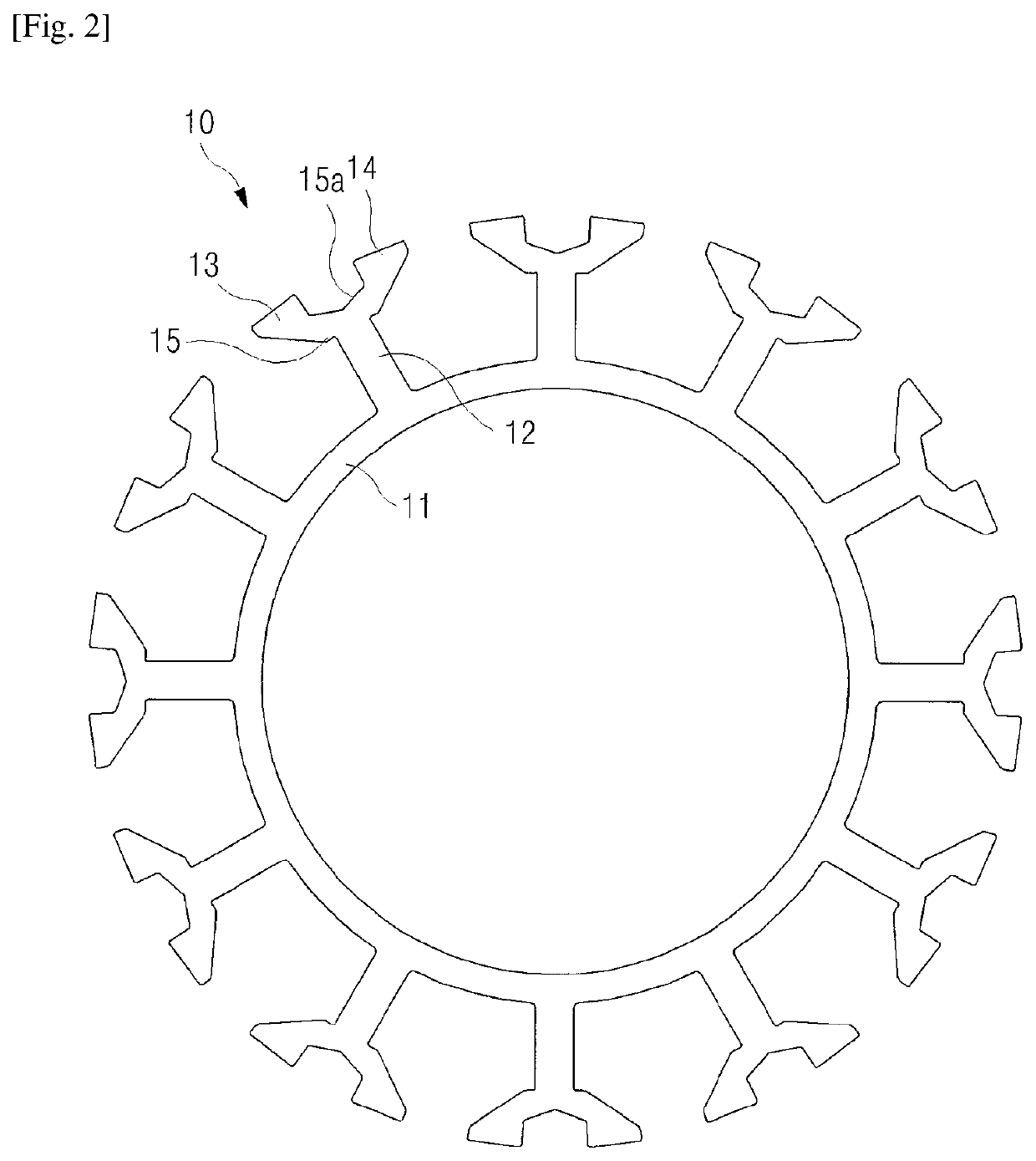

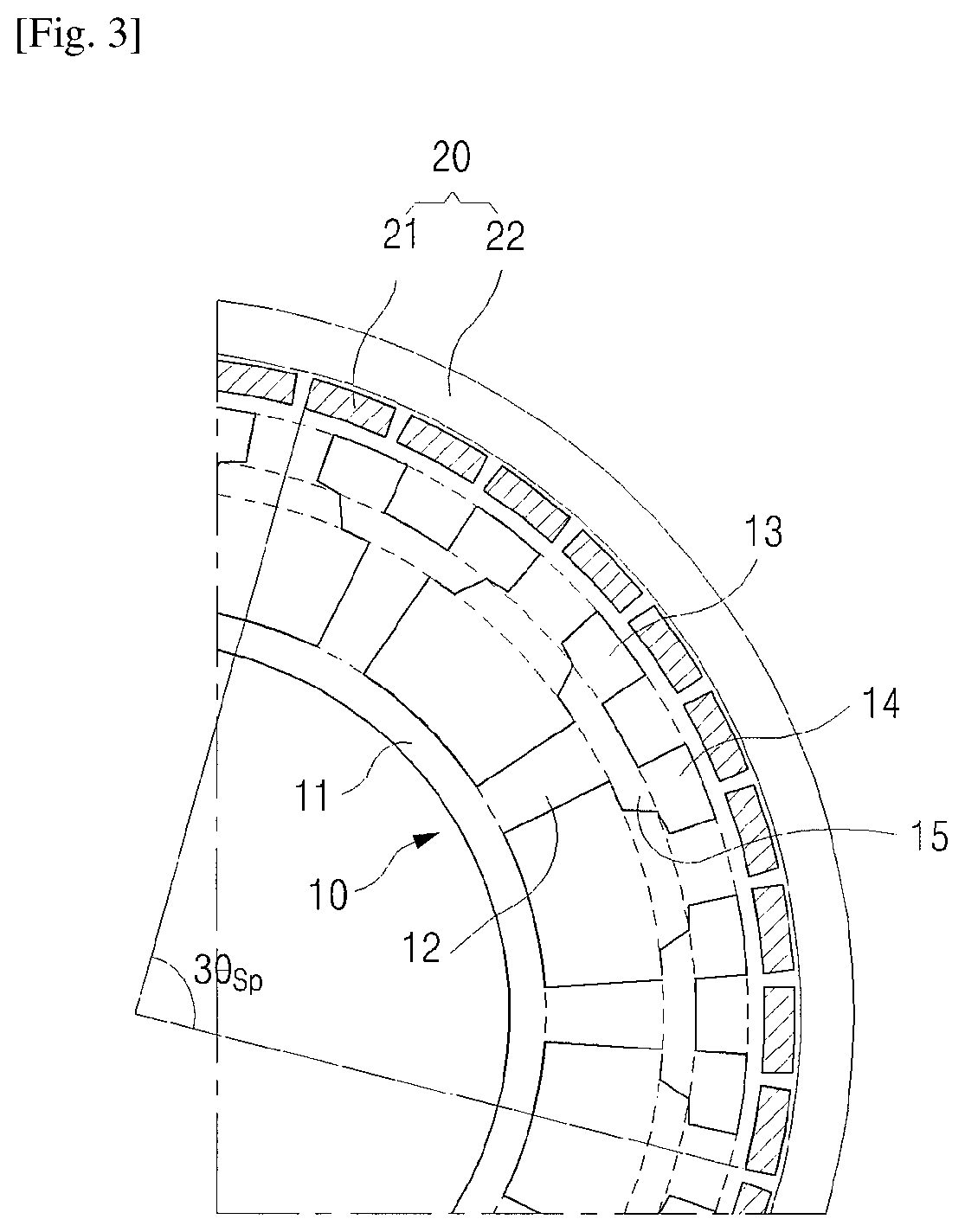

Permanent-magnet synchronous motor

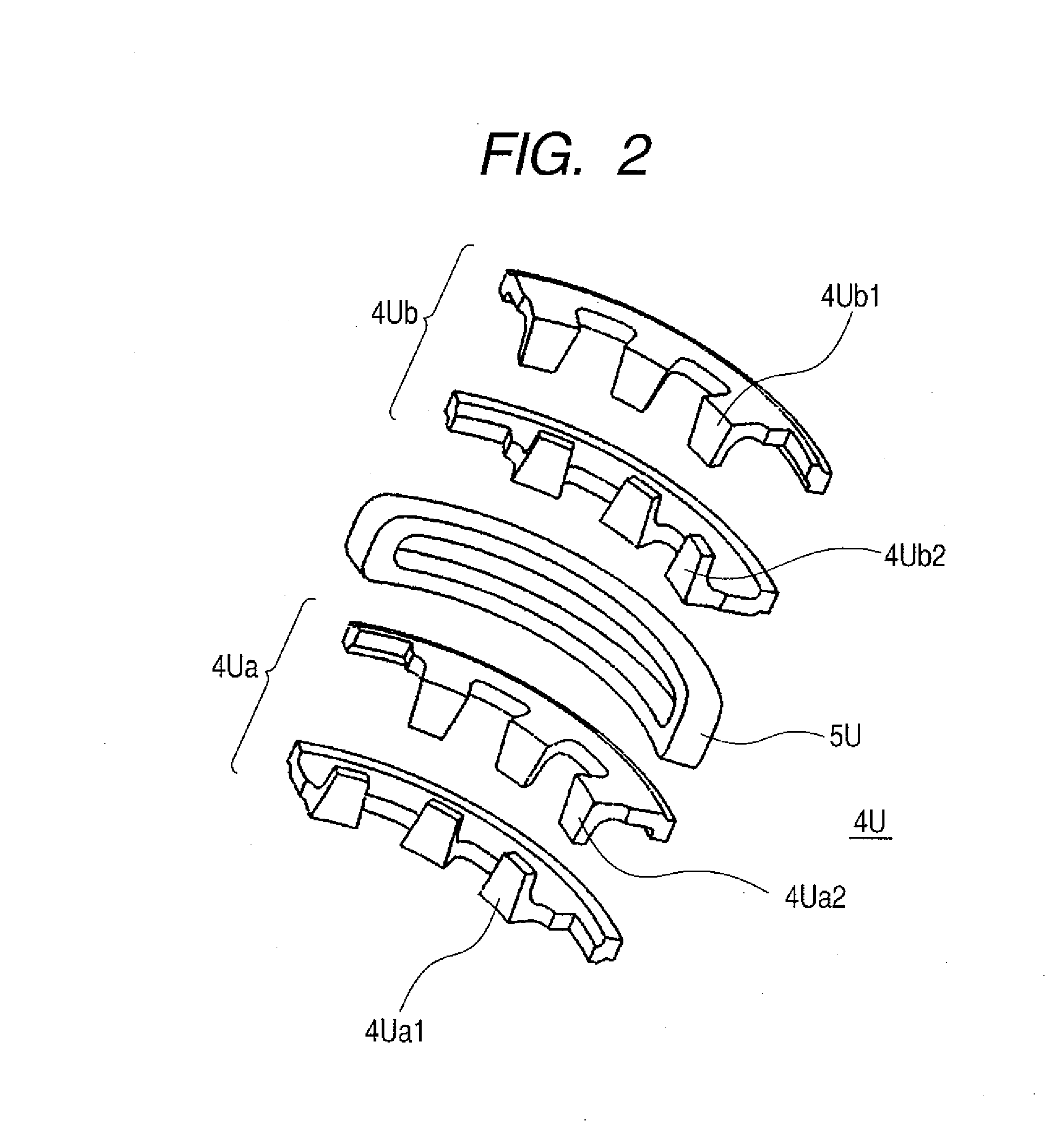

InactiveUS20100253178A1Increase the number of coilsIncrease axial lengthMagnetic circuit rotating partsMagnetic circuit stationary partsRotational axisSynchronous motor

The present invention can achieve a highly efficient permanent-magnet synchronous motor that can obtain output in a high-speed area without prolonging the axis of the permanent-magnet synchronous motor.The present invention provides a highly efficient permanent-magnet synchronous motor that can obtain output in a high-speed area without prolonging the axis of the permanent-magnet synchronous motor, in which stator magnetic poles are formed by dividing a magnetic pole in each phase into a plurality of parts and placing them in a circumferential direction with respect to a rotational axis, at least one divided stator magnetic pole being made movable in the circumferential direction with respect to the rotational axis, and the phase of the movable stator is controlled.

Owner:HITACHI LTD

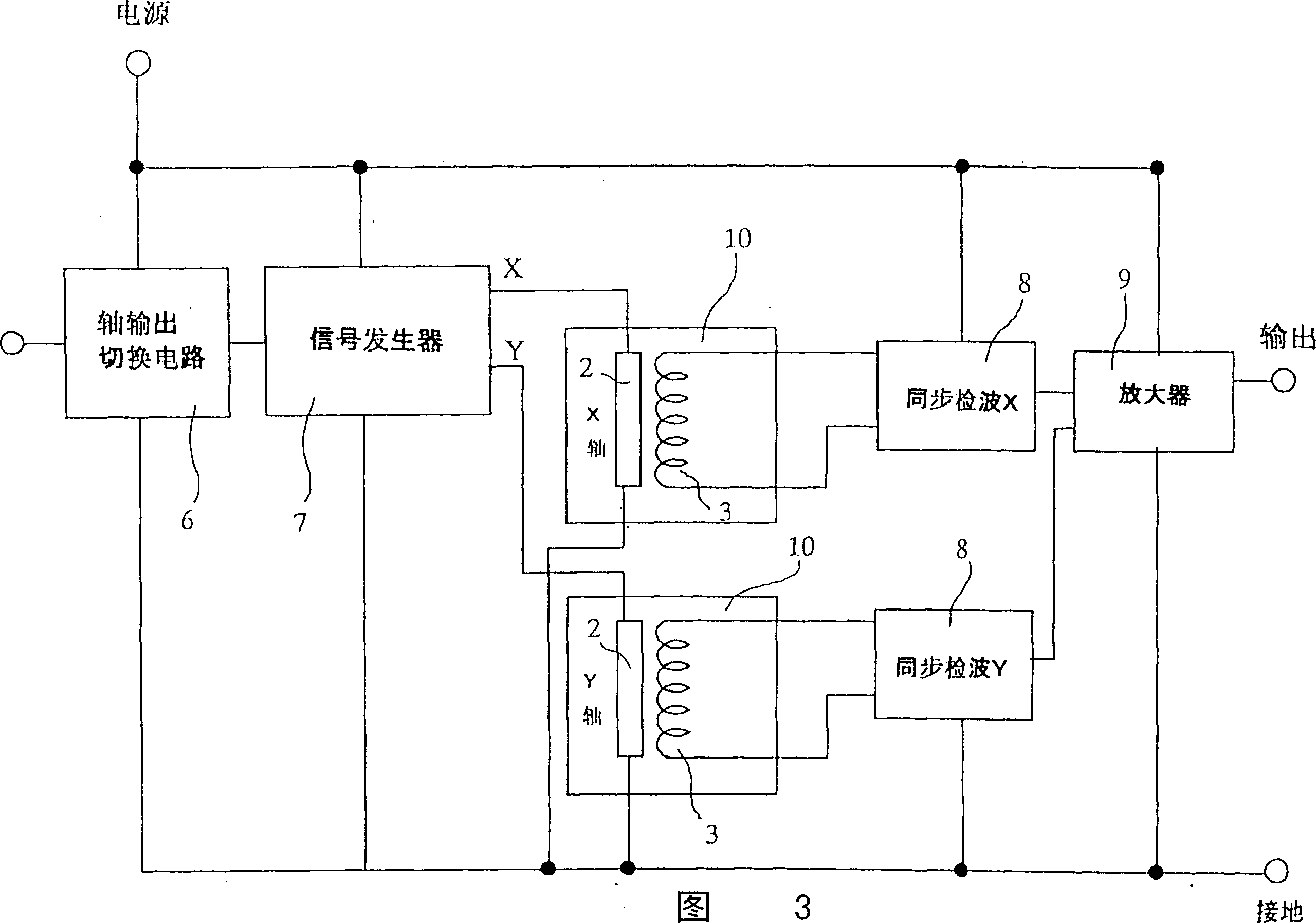

Two-demensional magnetic sensors

InactiveCN1439888AReduce electricity consumptionShorten the lengthVariable inductances/transformersMagnitude/direction of magnetic fieldsSupply currentIntegrated circuit

The patent relates to a two-dimensional magnetic sensor to detect the external magnetic field, which is characterized in comprising a first MI element disposed to detect the component in the direction of the first coordinate axis, which is composed of a first induction magnetic body with length below 2mm and a first electromagnetic coil wound around the periphery of the induction magnetic body; a second MI element disposed to detect the component in the direction of the second coordinate axis, which is composed of a second induction magnetic body with length below 2mm and a second electromagnetic coil wound around the periphery of the induction magnetic body; an integrated circuit having the oscillation means to provide the pulse current or high-frequency current; a switch means to alternatively supplying current to the first MI element and the second MI element; a detection means to detect the output voltage of each electromagnetic coil of the first MI element and the second MI element; and an amplifier to amplify the output voltage of said detection means. According to the invention, the two-dimensional magnetic sensor which boasts a wide magnetic field measurability range, low power consumption, and an extremely small size.

Owner:AICHI MICRO INTELLIGENT

Multilayer circuit board

InactiveUS7423884B2Increase the number of coilsGood flexibilityTransformers/inductances coils/windings/connectionsPrinted circuit aspectsConductive pasteElectrical connection

A multilayer circuit board includes: two or more layers of electrical insulative base members; and two or more layers of conductive patterned layers. At least two of the conductive patterned layers include coil patterns that will be a part of a coil, through holes are provided at predetermined positions of the electrical insulative base members, the positions being sandwiched between the coil patterns, so as to enable communication between respective end portions of the coil patterns, and conductive paste charged in the through holes allows electrical connection to be established between the respective end portions. The coil is formed so as to be wound in a direction perpendicular to a thickness direction of the multilayer circuit board. With this configuration, a multilayer circuit board can be provided, which facilitates increasing the winding number of a coil and has excellent flexibility of circuit design.

Owner:PANASONIC CORP

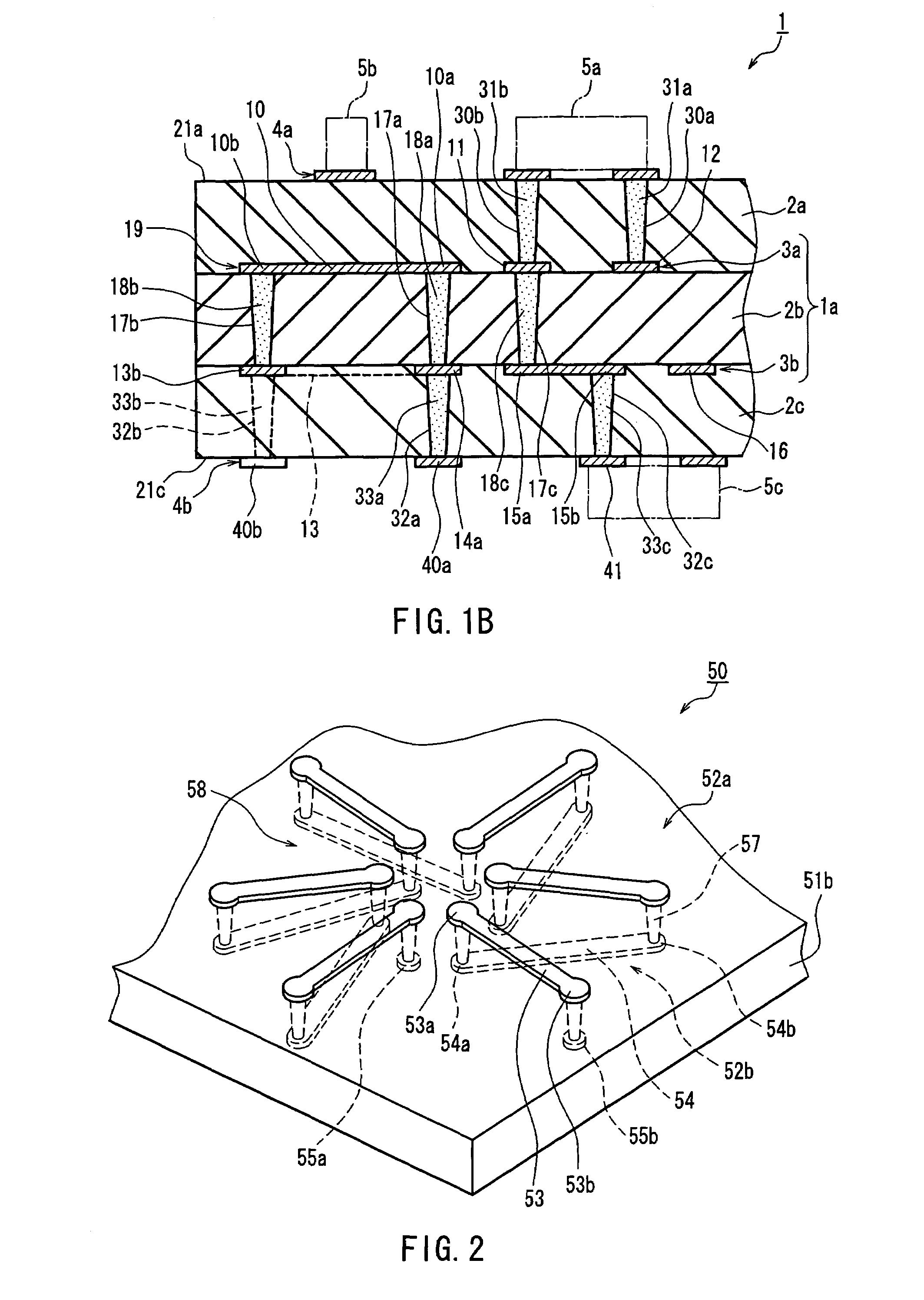

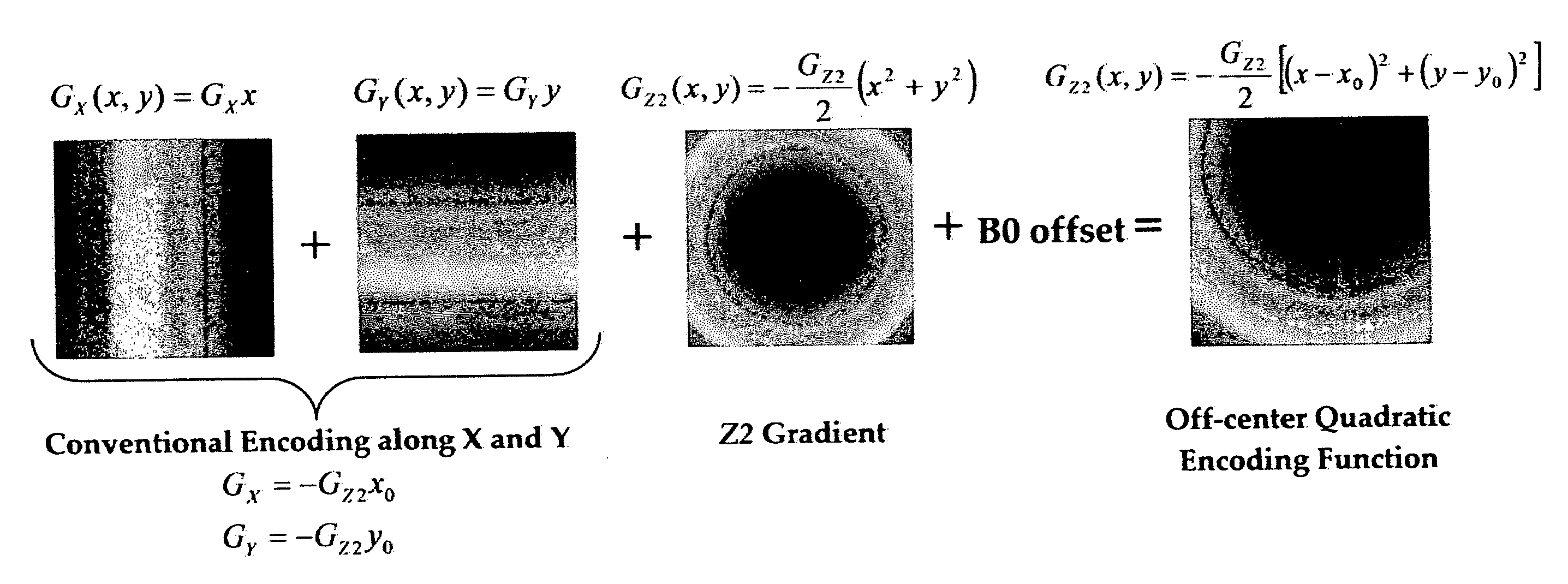

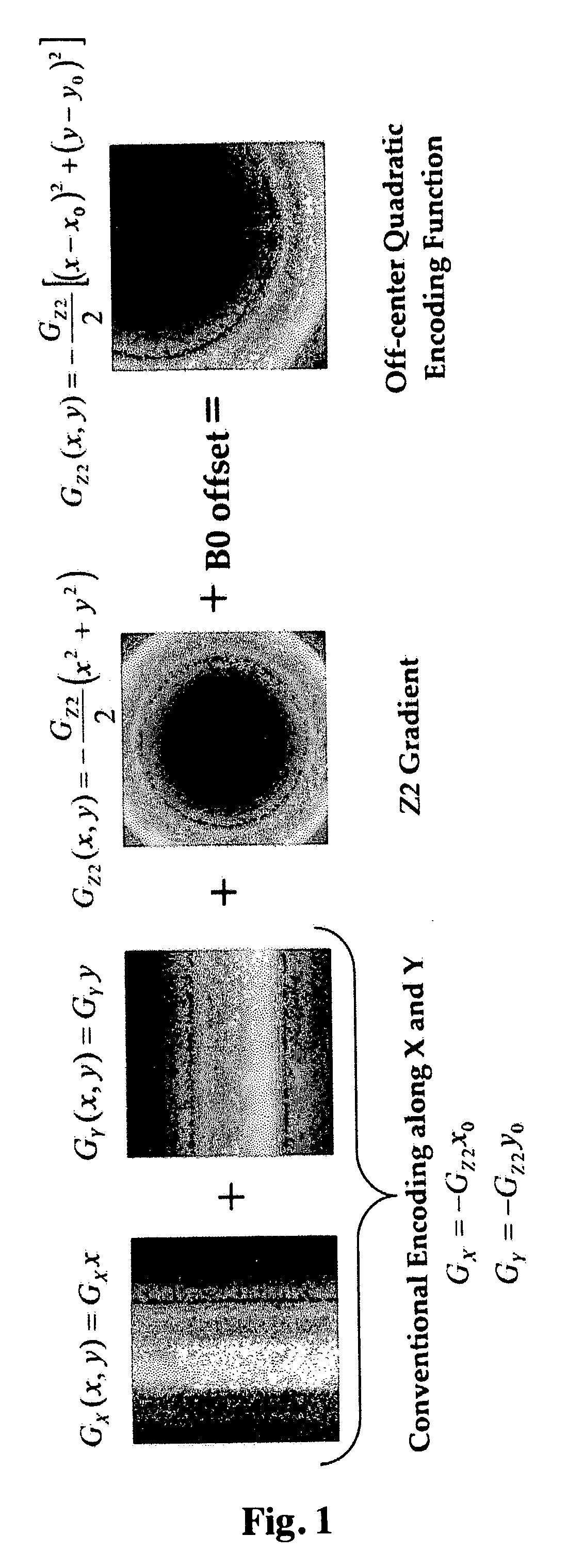

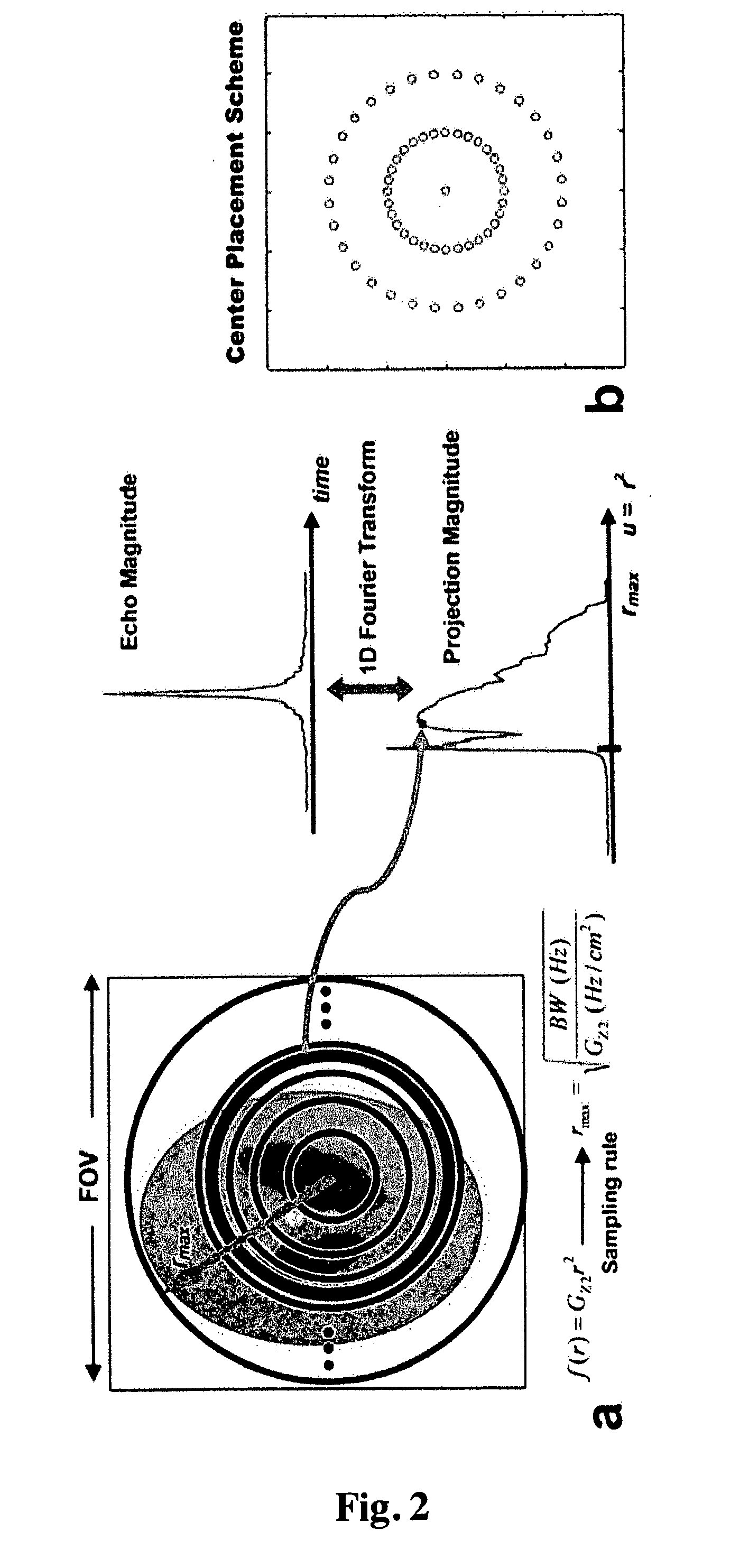

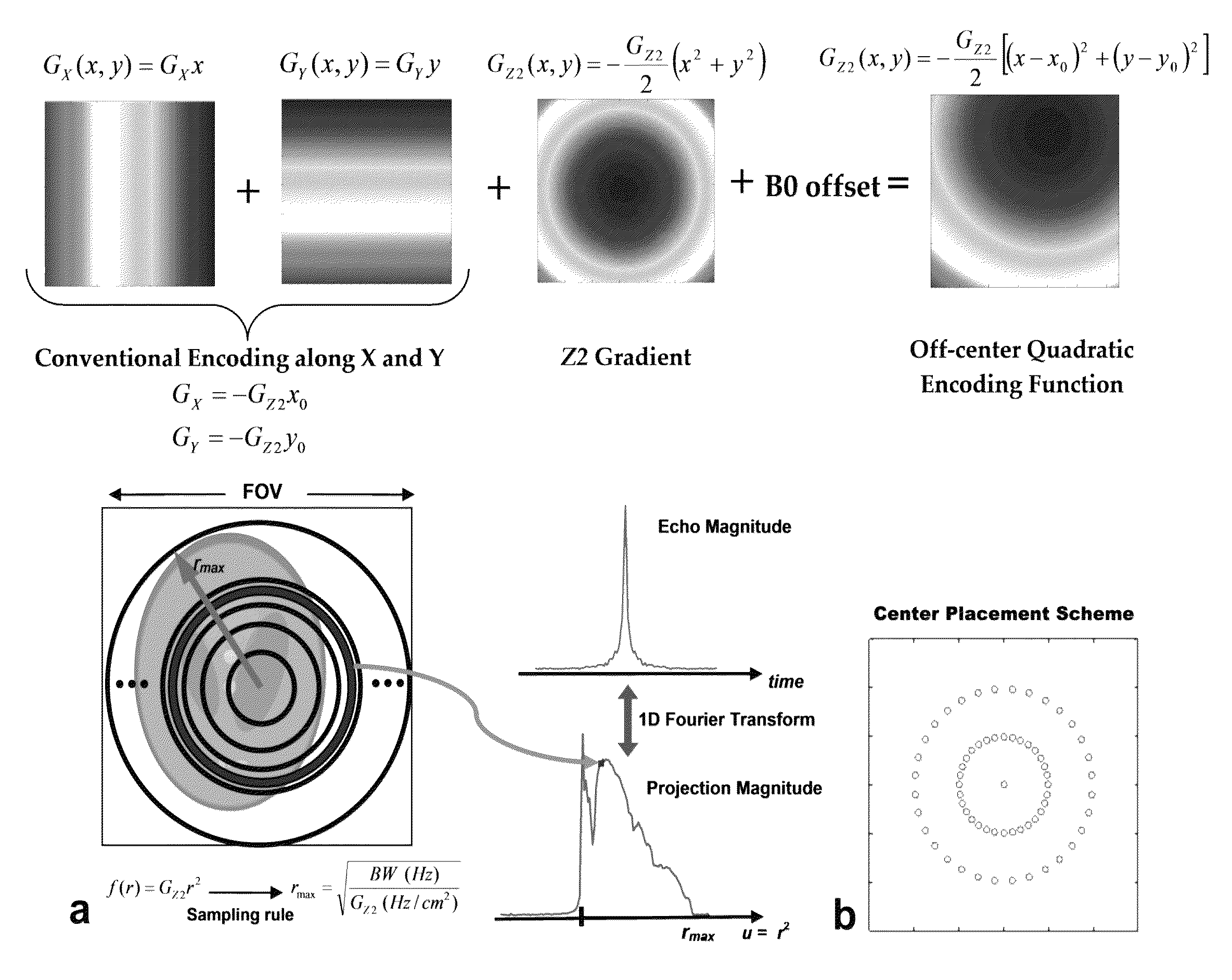

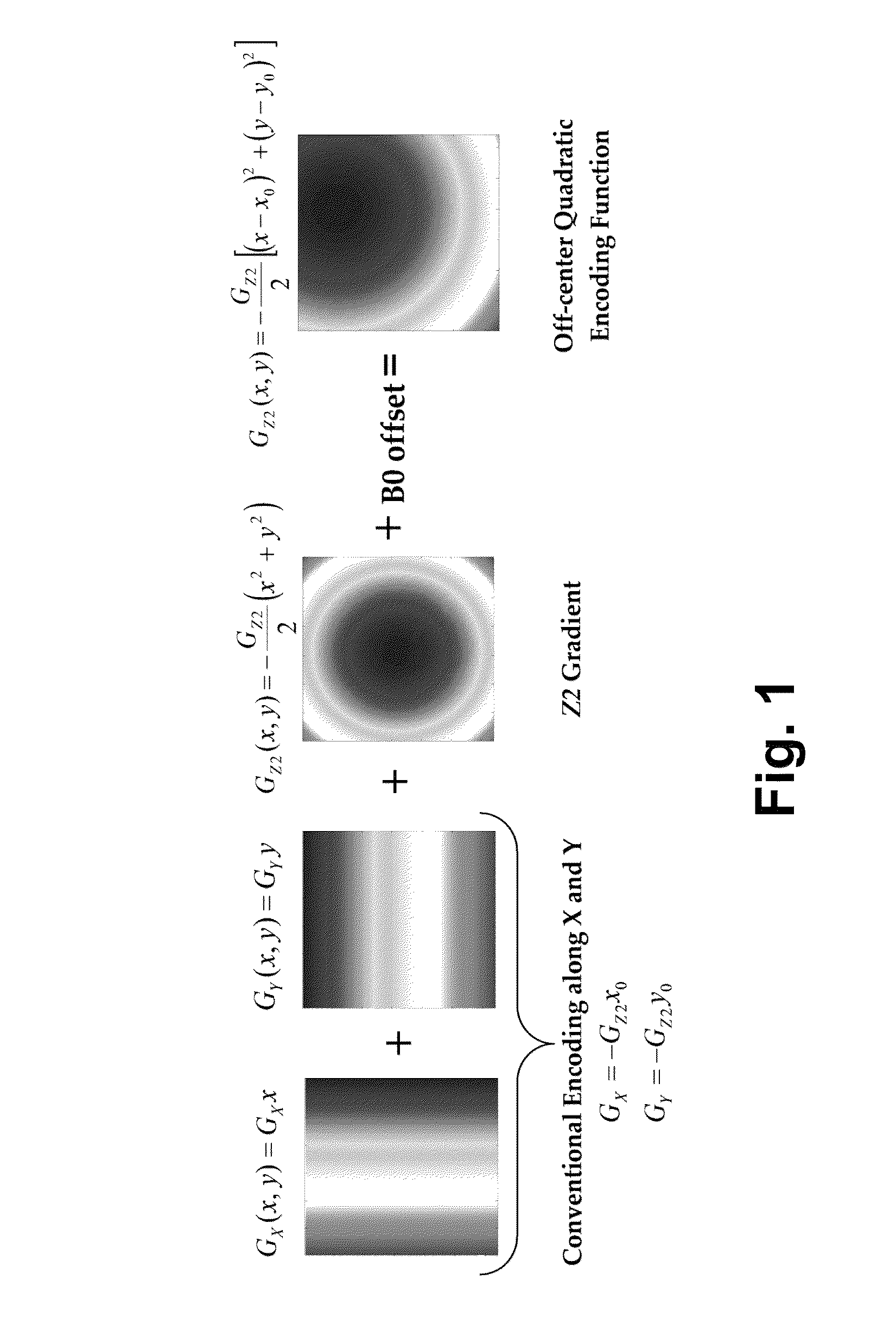

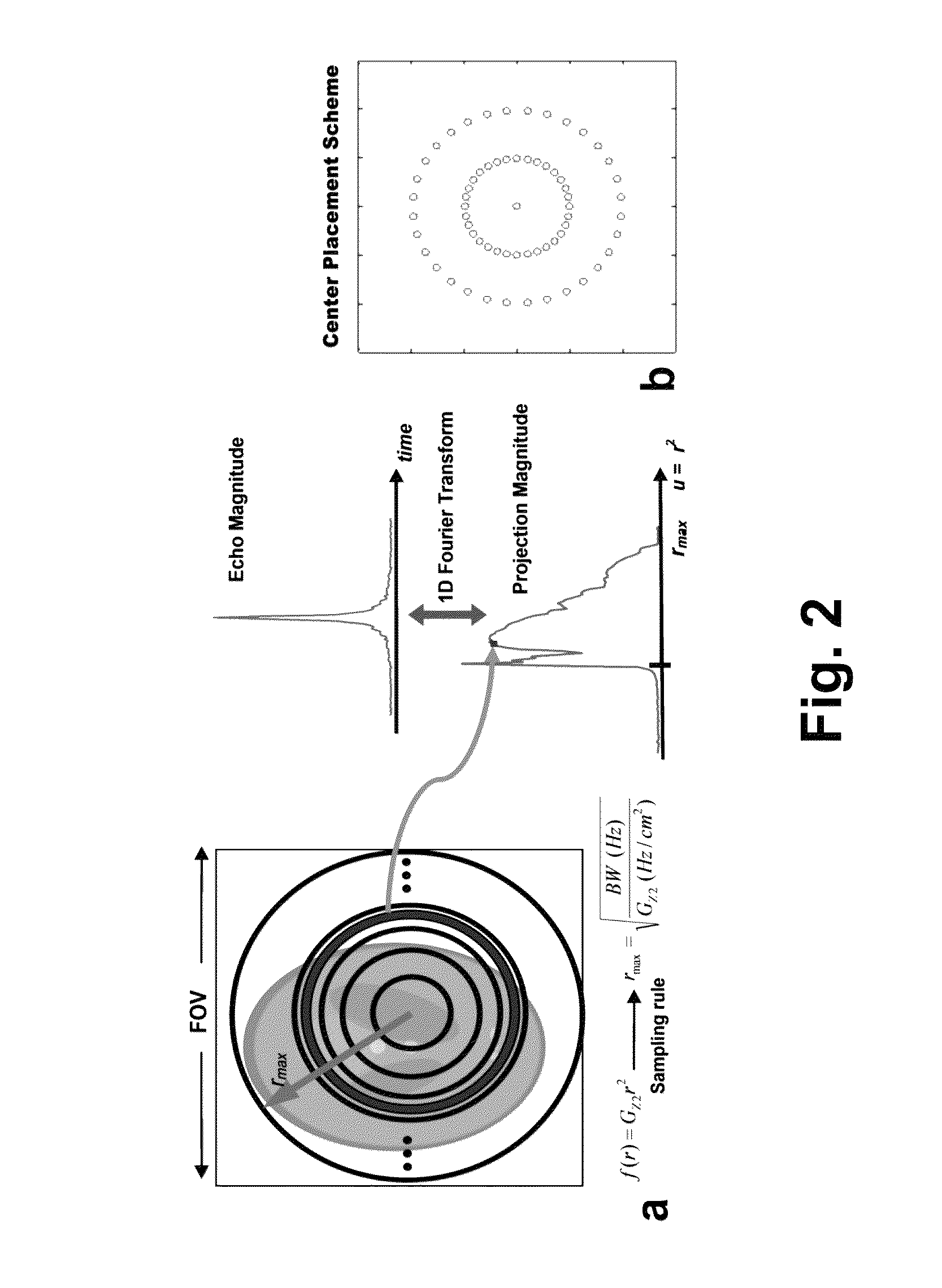

O-space imaging

ActiveUS20110241675A1Minimizing aliasingIncrease the number of coilsMeasurements using NMR imaging systemsElectric/magnetic detectionMagnetic gradientCoil array

In MRI by excitation of nuclear spins and measurement of RF signals induced by these spins in the presence of spatially-varying encoding magnetic fields, signal localization is performed through recombination of measurements obtained in parallel by each coil in an encircling array of RF receiver coils. Through the use of magnetic gradient fields that vary both as first-order and second-order Z2 spherical harmonics with position, radially-symmetric magnetic encoding fields are created that are complementary to the spatial variation of the encircling receiver coils. The resultant hybrid encoding functions comprised of spatially-varying coil profiles and gradient fields permits unambiguous localization of signal contributed by spins. Using hybrid encoding functions in which the gradient shapes are thusly tailored to the encircling array of coil profiles, images are acquired in less time than is achievable from a conventional acquisition employing only first-order gradient fields with an encircling coil array.

Owner:YALE UNIV

Vehicle drive apparatus

InactiveUS20050070401A1Large output capacityIncrease productionHybrid vehiclesClutchesClutch controlEngineering

A vehicle drive apparatus is provided that comprises first and second drive sources, a main clutch, a subordinate clutch, a drive source selecting section, and a clutch control section. The first and second drive sources output drive forces to a first wheel. The main clutch is configured to simultaneously shut off delivery of outputs from the first and second drive sources. The subordinate clutch coupled to the first drive source is configured to shut off delivery of only the output from the first drive source. The drive source selecting section is configured to select at least one of the first and second drive sources to output the drive force. The clutch control section is configured to release the subordinate clutch while the main clutch is temporality released upon a determination of the first drive source being switched from an output delivery state to an output stop state.

Owner:NISSAN MOTOR CO LTD

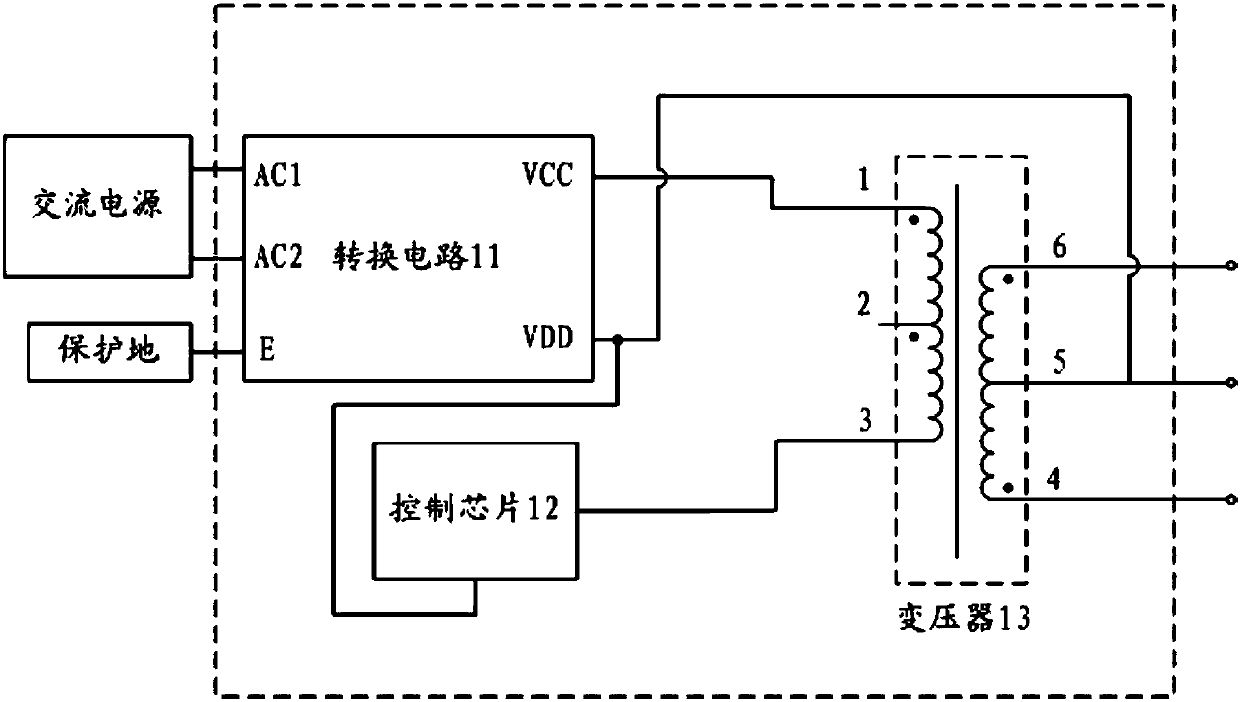

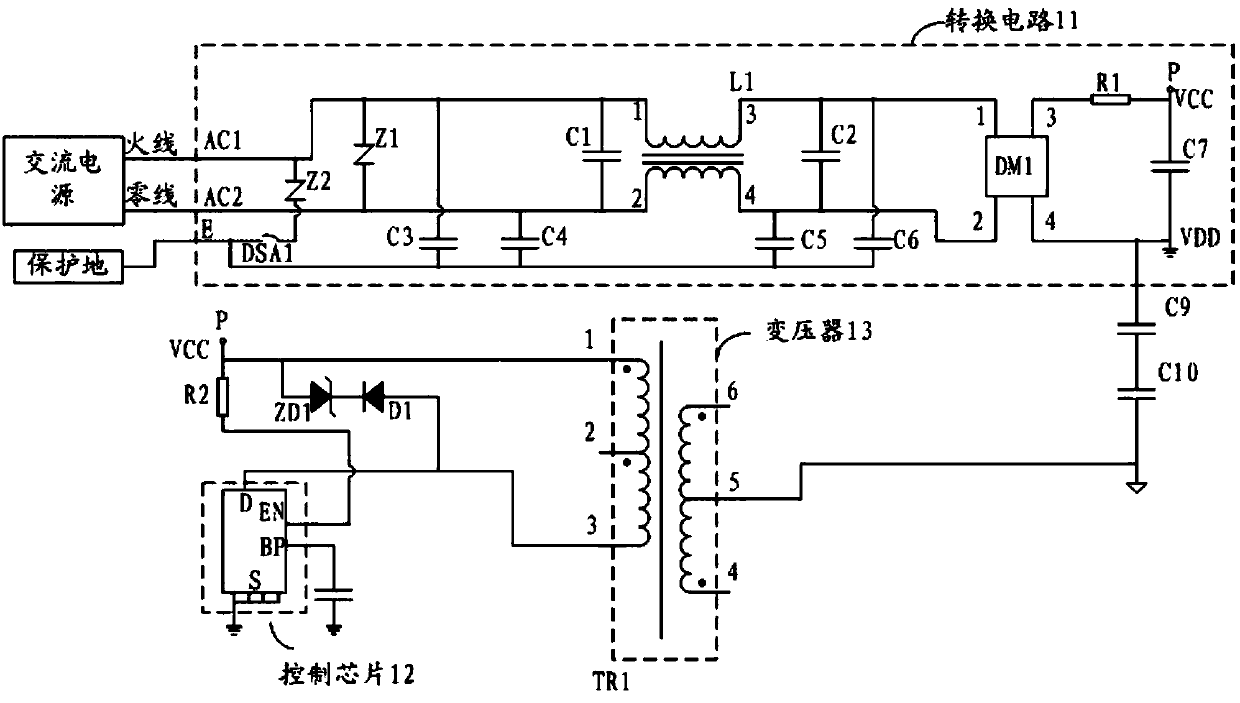

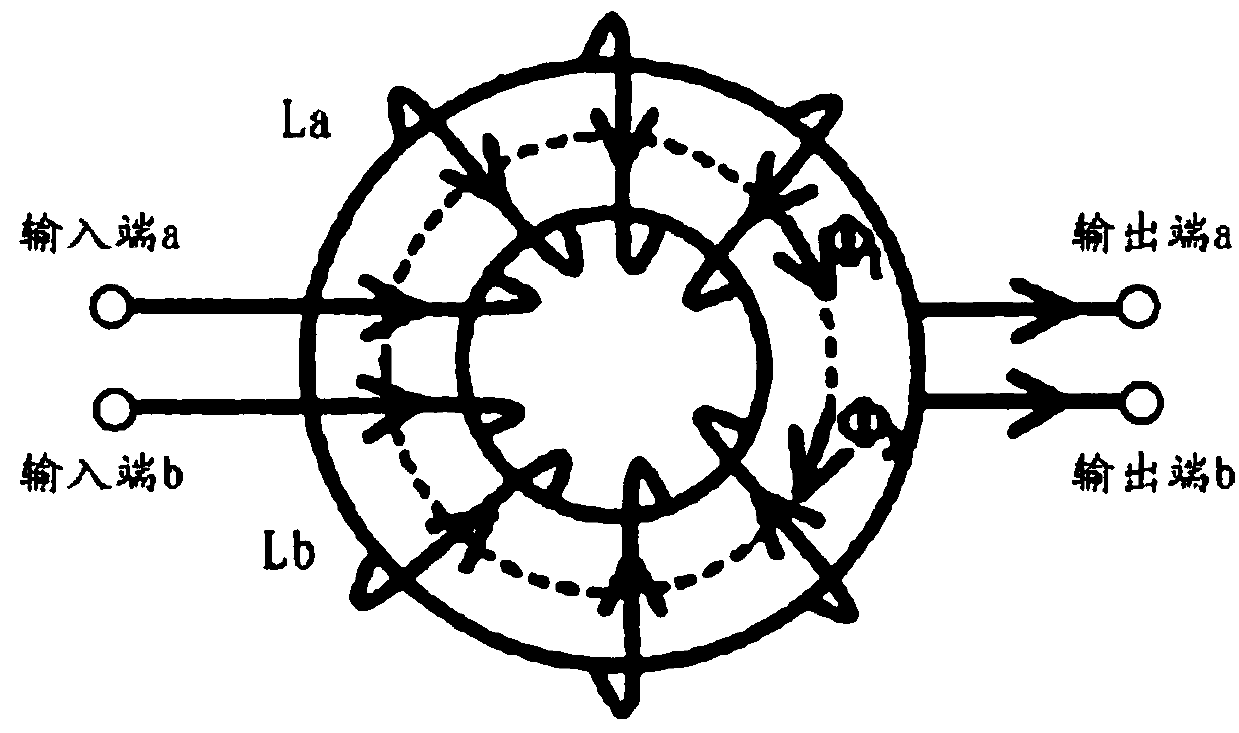

Filter, power circuit and air conditioner

ActiveCN107612307AIncrease the number of coilsReduce the number of coilsTransformers/inductances coils/windings/connectionsInductance with magnetic coreCapacitanceInductor

The invention relates to a filter, a power circuit and an air conditioner and relates to the technical field of electronic engineering. By means of the embodiment of the invention, the distributed capacitance of the filter can be effectively reduced, and the disturbance of high-frequency-band EMC can be better restrained. The filter comprises a first common mode inductor which includes a magneticcore and a first coil winding wound on the magnetic core, wherein the first coil winding is formed in the mode that a flat wire is laid and wound, and the flat wire is high in thickness in the direction of the radius of the magnetic core section and low in thickness in the magnetic core extending direction. The filter is used for restraining the disturbance of the EMC.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

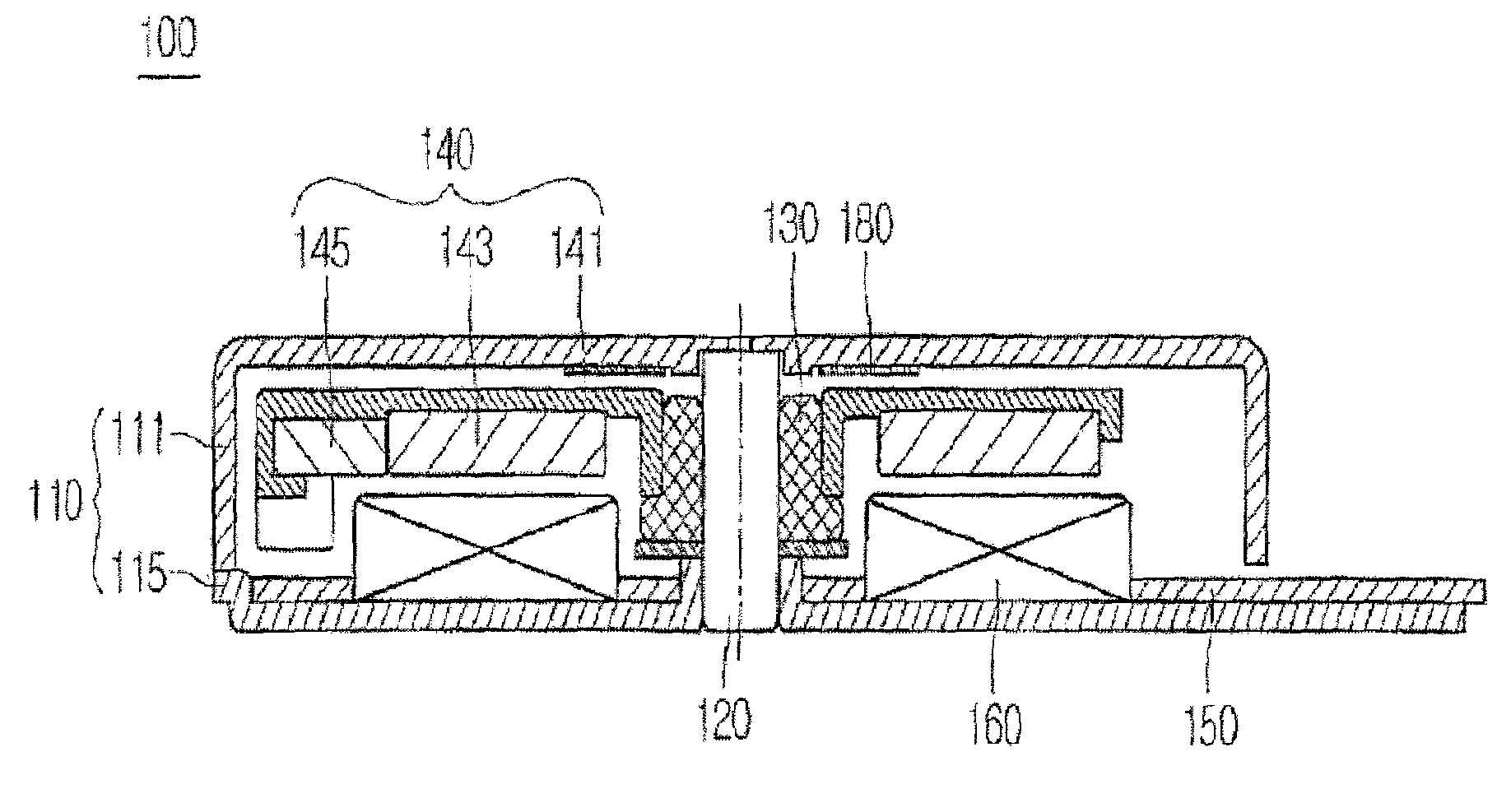

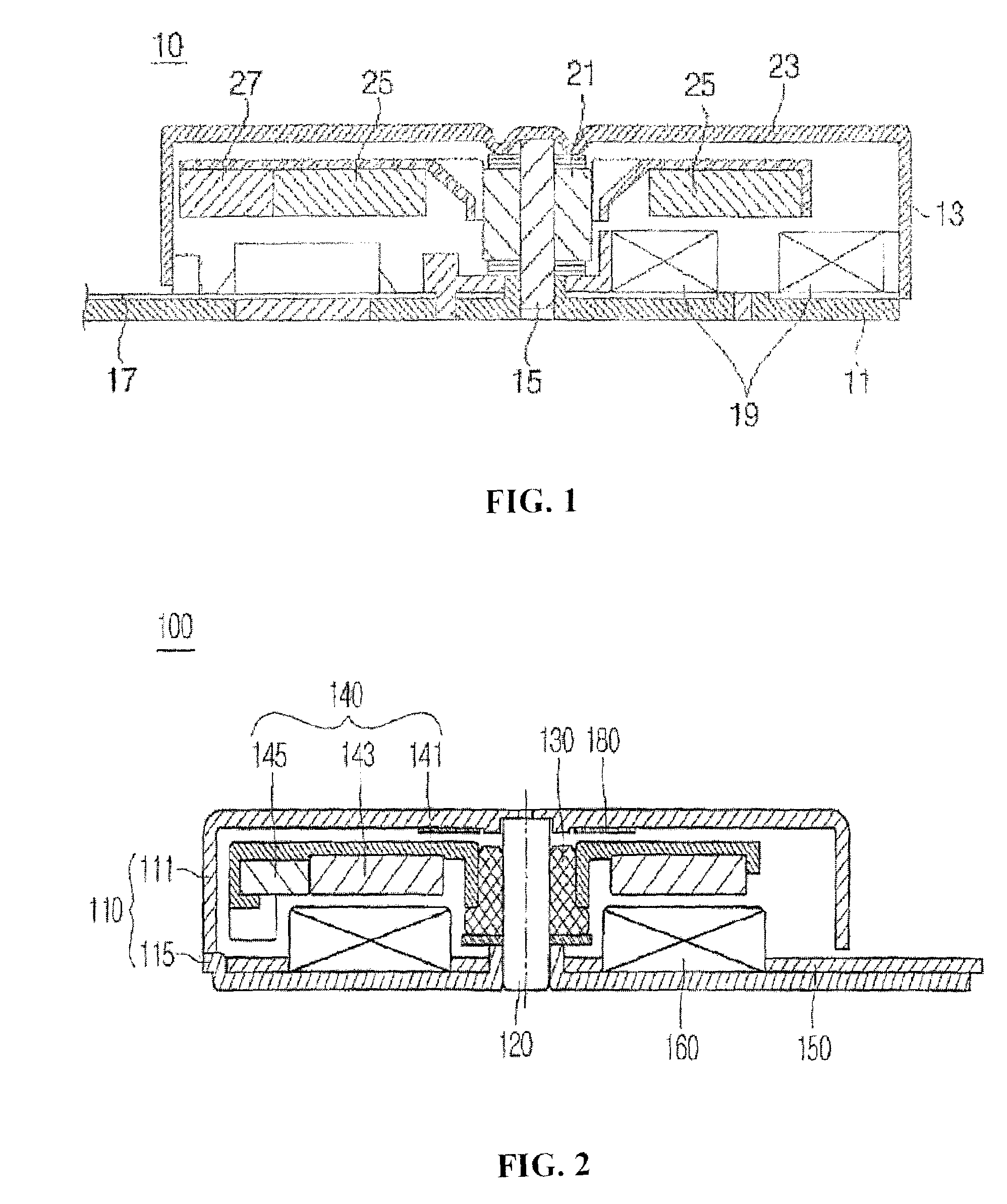

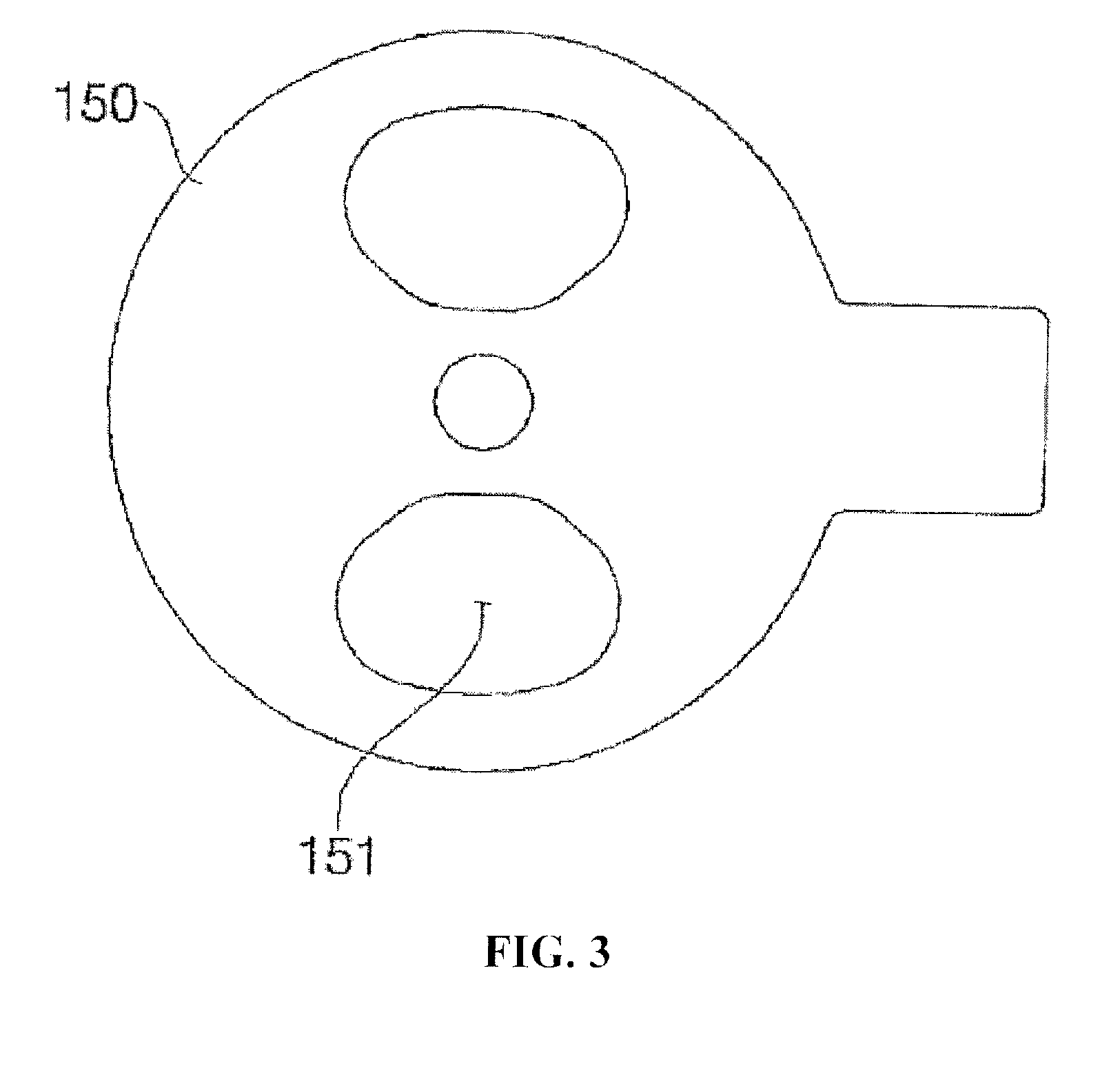

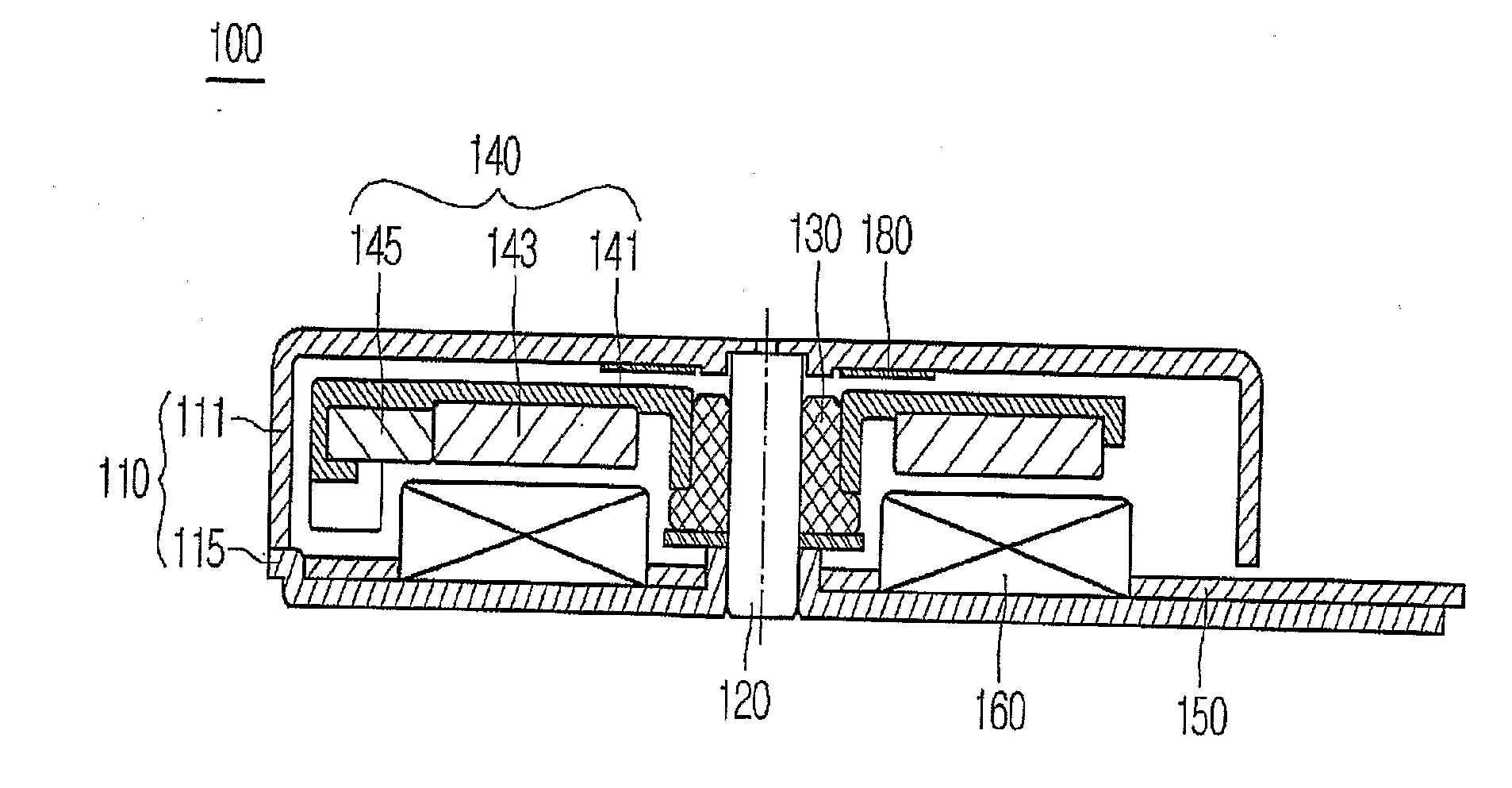

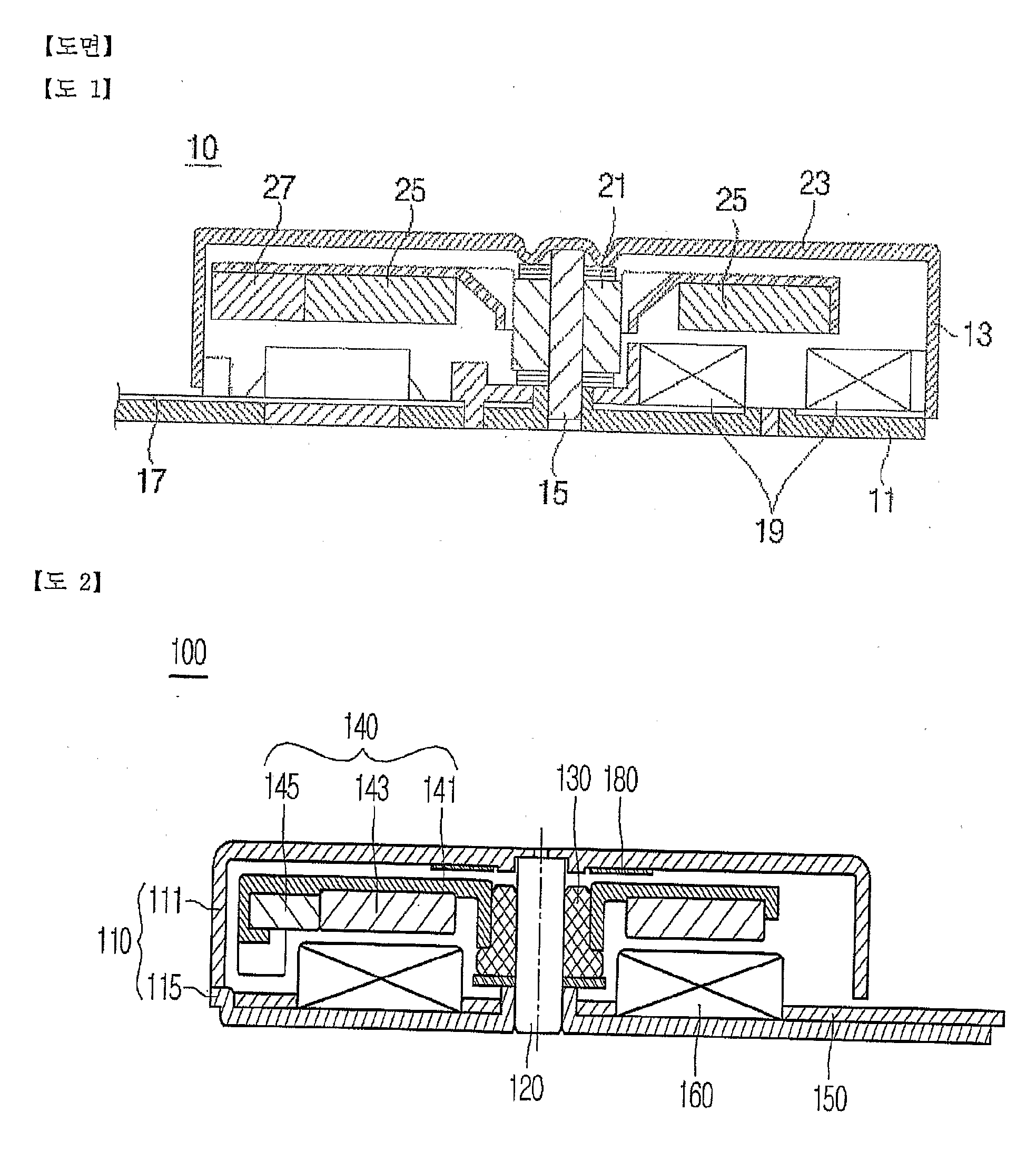

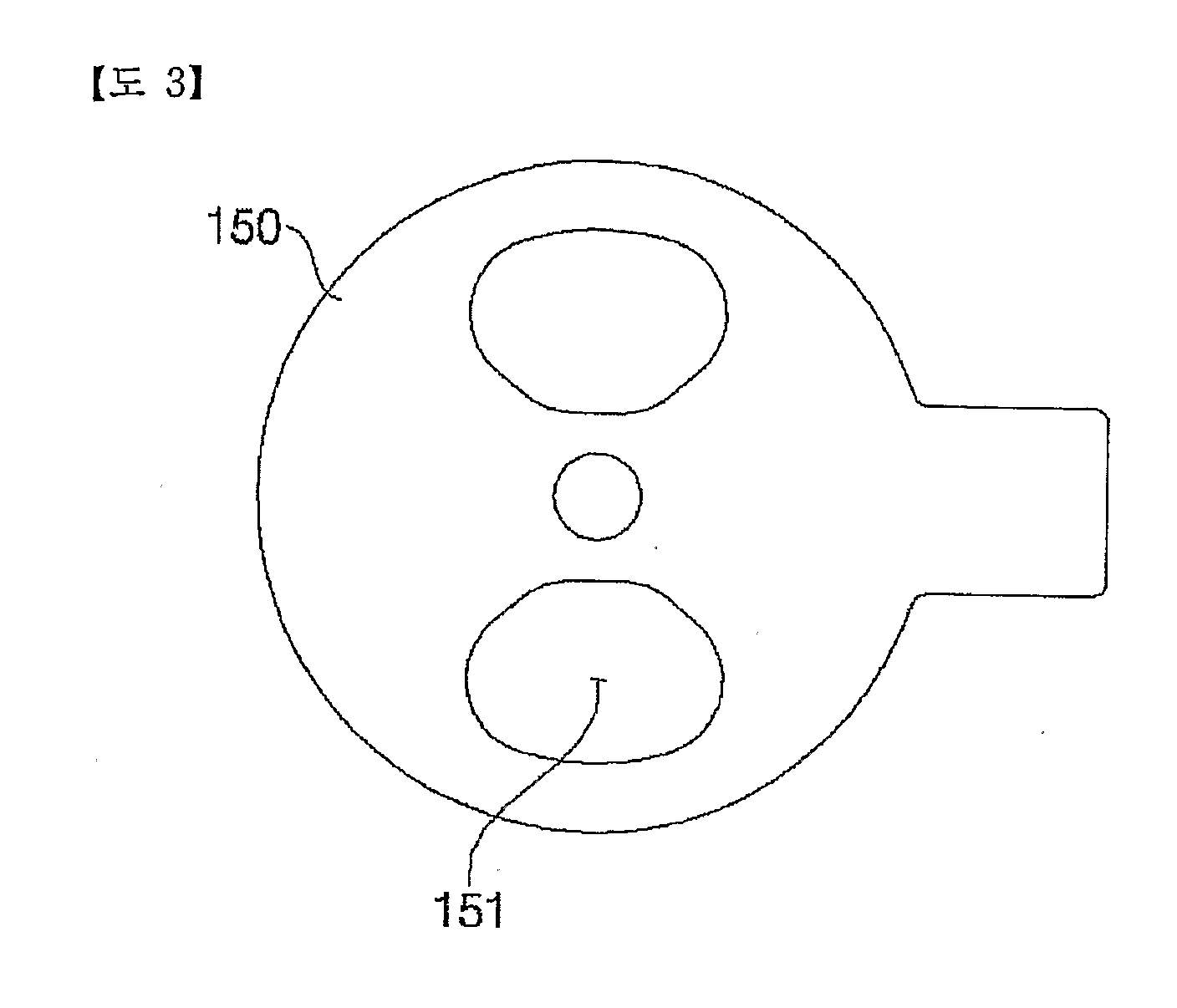

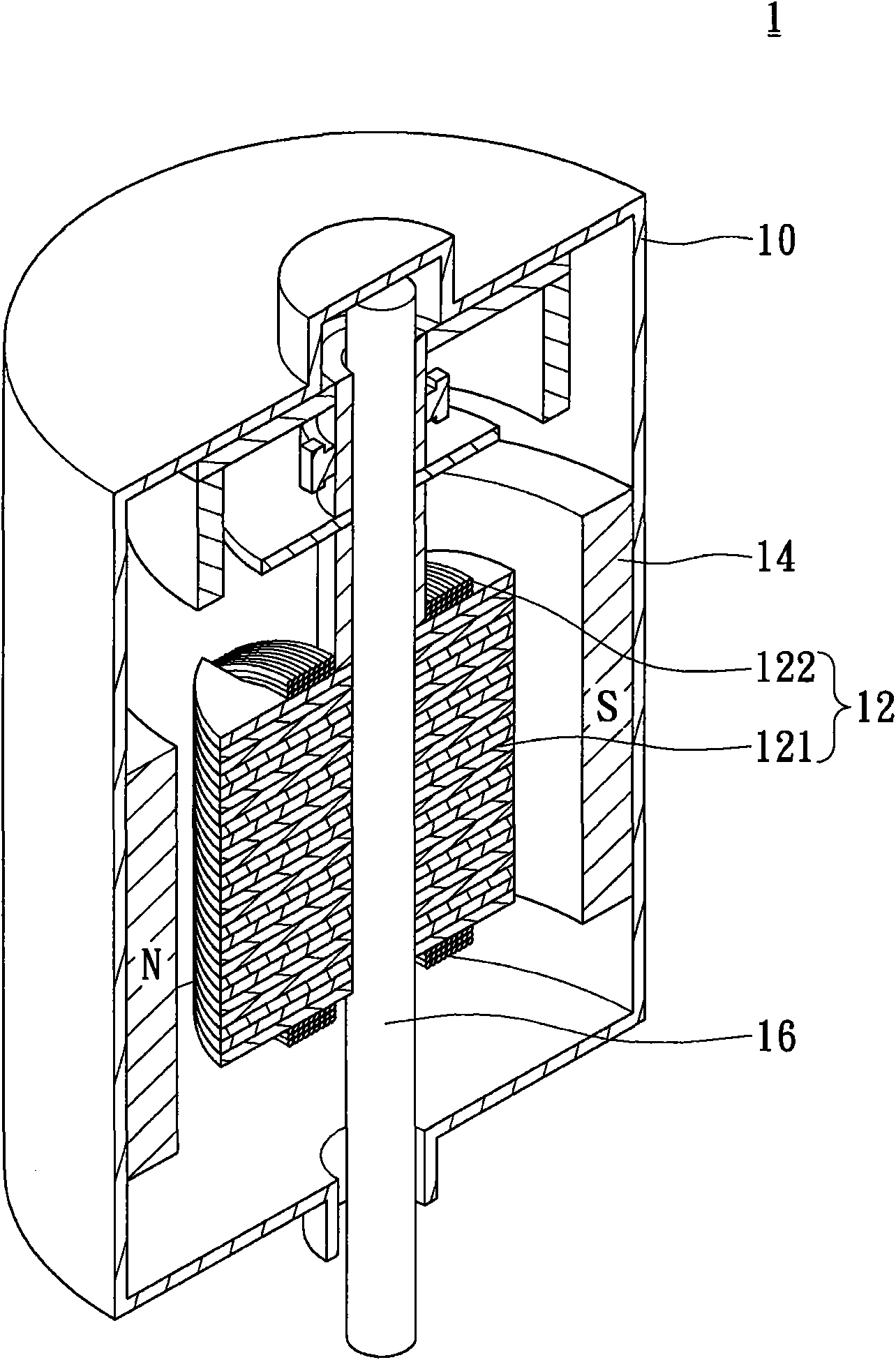

Slim type vibration motor

InactiveUS7615901B2Increase in sizeIncreasing the thicknessSynchronous machinesAsynchronous induction motorsPrinted circuit boardMagnet

A slim type vibration motor is provided. The slim type vibration motor includes a case, a shaft, a rotor, a printed circuit board, and a plurality of coils. The shaft has at least one end thereof fixed to a central portion of the case. The rotor rotates about the shaft within the case, and includes a rotor yoke, a magnet fixed to the rotor yoke, and a weight imparting eccentricity to the rotor. The printed circuit board is installed to a bottom surface of the case, and forms a coil hole in a region thereof facing the magnet. The plurality of coils passes through the coil hole and is installed on the bottom surface of the case.

Owner:TL ELECTRONICS CO LTD

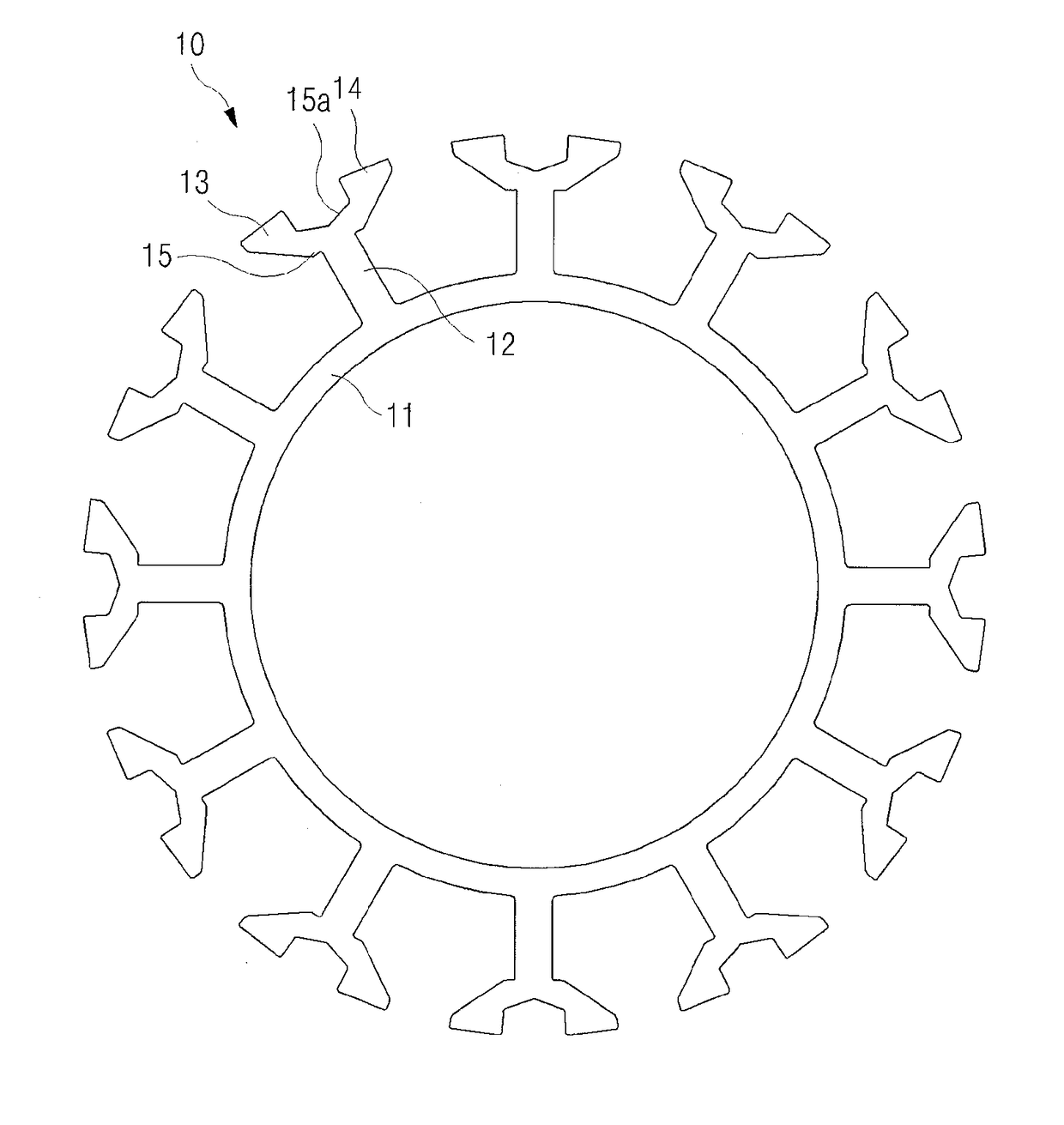

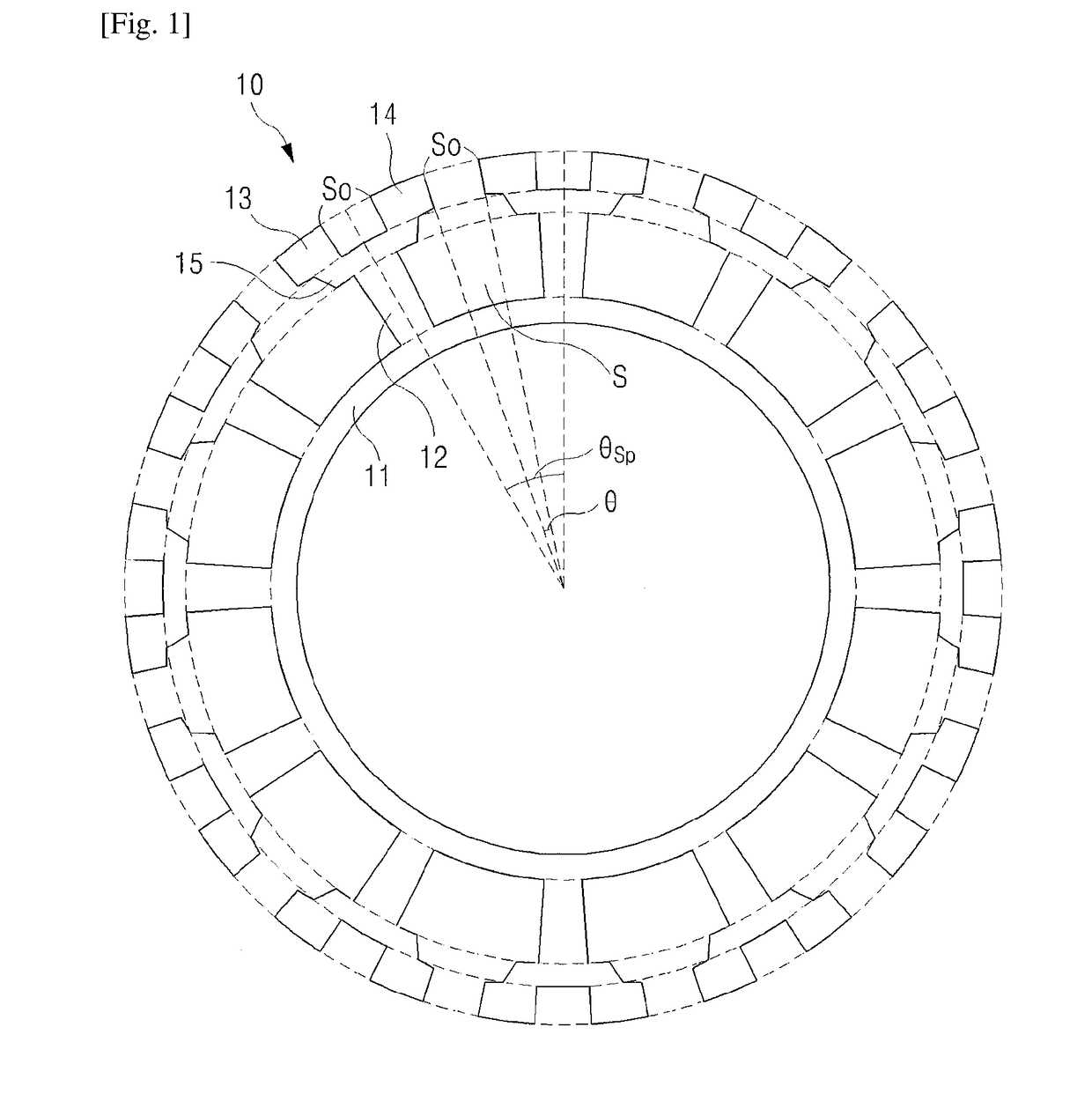

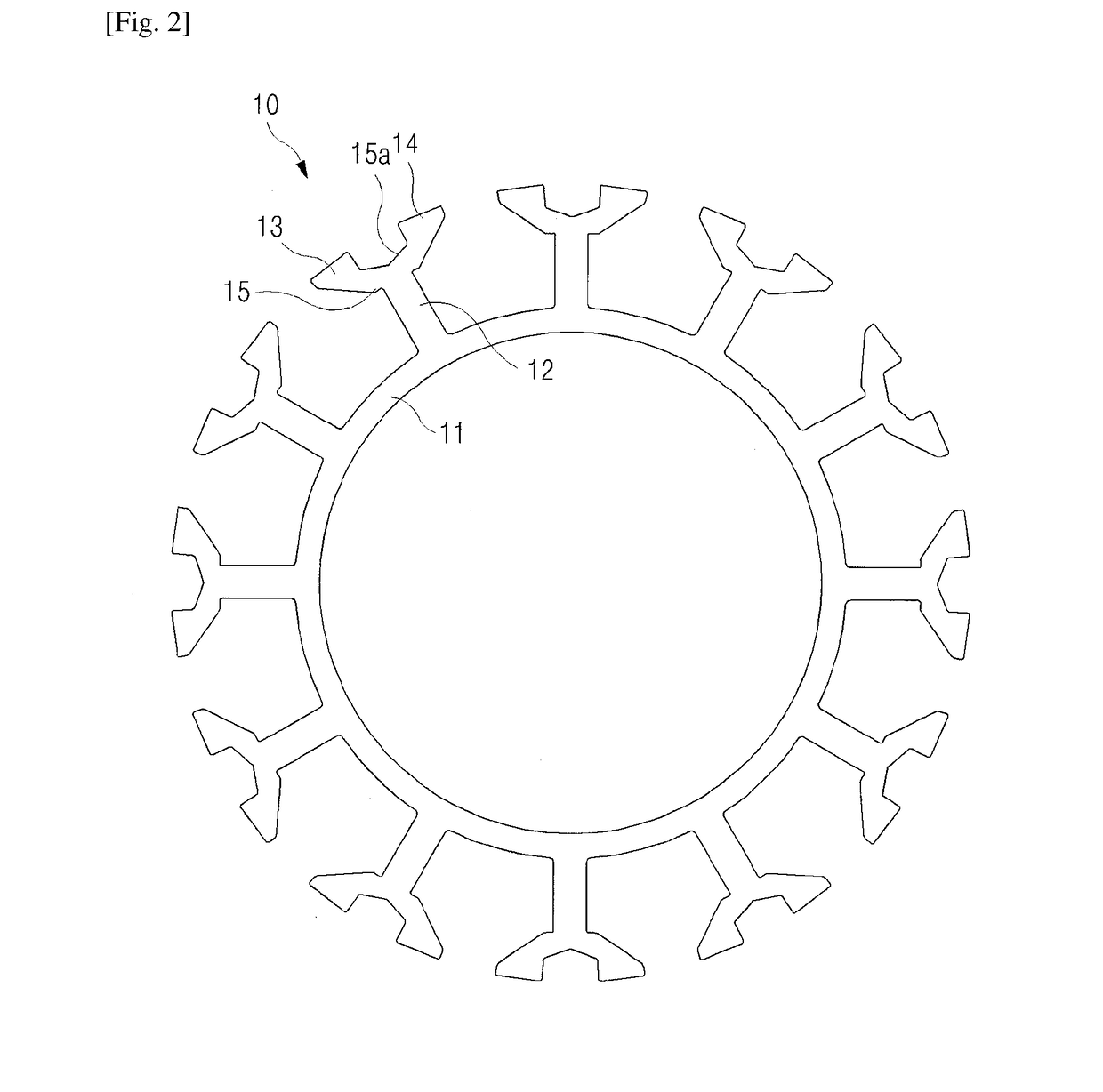

Motor having stator with coupled teeth

ActiveUS20180323662A1Increase forceHigh outputMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetElectric motor

A motor having a stator with coupled teeth according to the present invention includes a stator which includes a circular base, a plurality of poles radially formed in the base, and a plurality of teeth formed on an outer diameter of the pole; and a rotor which includes a rotor housing in which the stator is positioned inside and a plurality of magnets facing the teeth are formed on an inner wall, wherein two teeth are symmetrically formed on an outer diameter portion for each pole, and the number of teeth is twice the number of poles.

Owner:NEW MOTECH +1

O-space imaging: highly efficient parallel imaging using complementary nonlinear encoding gradient fields and receive coil geometries

ActiveUS8710839B2Minimizing aliasingIncrease the number of coilsMagnetic measurementsElectric/magnetic detectionMagnetic gradientCoil array

In MRI by excitation of nuclear spins and measurement of RF signals induced by these spins in the presence of spatially-varying encoding magnetic fields, signal localization is performed through recombination of measurements obtained in parallel by each coil in an encircling array of RF receiver coils. Through the use of magnetic gradient fields that vary both as first-order and second-order Z2 spherical harmonics with position, radially-symmetric magnetic encoding fields are created that are complementary to the spatial variation of the encircling receiver coils. The resultant hybrid encoding functions comprised of spatially-varying coil profiles and gradient fields permits unambiguous localization of signal contributed by spins. Using hybrid encoding functions in which the gradient shapes are thusly tailored to the encircling array of coil profiles, images are acquired in less time than is achievable from a conventional acquisition employing only first-order gradient fields with an encircling coil array.

Owner:YALE UNIV

Air processor and alternating current plastic-sealed motor and stator thereof

ActiveCN105141061AImprove efficiencyIncrease full rateWindings conductor shape/form/constructionElectric machineAir handler

The invention discloses a stator of a motor, which comprises a winding and a stator iron core with a groove, wherein the winding comprises a plurality of sub-windings distributed along the periphery of the stator; the sub-windings comprise a first phase windings and a second phase windings; the first phase windings comprise even numbers of windings; each of the windings is wound in a groove of a yoke portion of the stator iron core; the second phase windings comprise at least a groove-crossing coil; and the groove-crossing coil is wound inside the groove of the stator iron core by crossing the groove. The stator of the invention comprises the first phase windings wound on the yoke portion of the stator iron core and the second phase windings located inside the groove of the stator iron core by crossing the groove; the first phase windings are distributed on the outer circumference of the stator iron core; the outer circumference space that can be occupied is wound with large amount of vanished wires and the groove on which the second phase windings are located won't be blocked; the number of coils of the groove-crossing coil inside the groove to which the second phase windings are located are added; and the two phase windings are not interfered with each other, thus the rate of filling the groove with windings is improved and further the efficiency of the motor is improved. The invention also comprises an alternating current plastic-sealed motor and an air processor that are provided with the stator.

Owner:ZHUHAI KAIBANG MOTOR MFR +4

Slim Type Vibration Motor

InactiveUS20080246356A1Increase in sizeIncreasing the thicknessSynchronous machinesAsynchronous induction motorsPrinted circuit boardMagnet

A slim type vibration motor is provided. The slim type vibration motor includes a case, a shaft, a rotor, a printed circuit board, and a plurality of coils. The shaft has at least one end thereof fixed to a central portion of the case. The rotor rotates about the shaft within the case, and includes a rotor yoke, a magnet fixed to the rotor yoke, and a weight imparting eccentricity to the rotor. The printed circuit board is installed to a bottom surface of the case, and forms a coil hole in a region thereof facing the magnet. The plurality of coils passes through the coil hole and is installed on the bottom surface of the case.

Owner:TL ELECTRONICS CO LTD

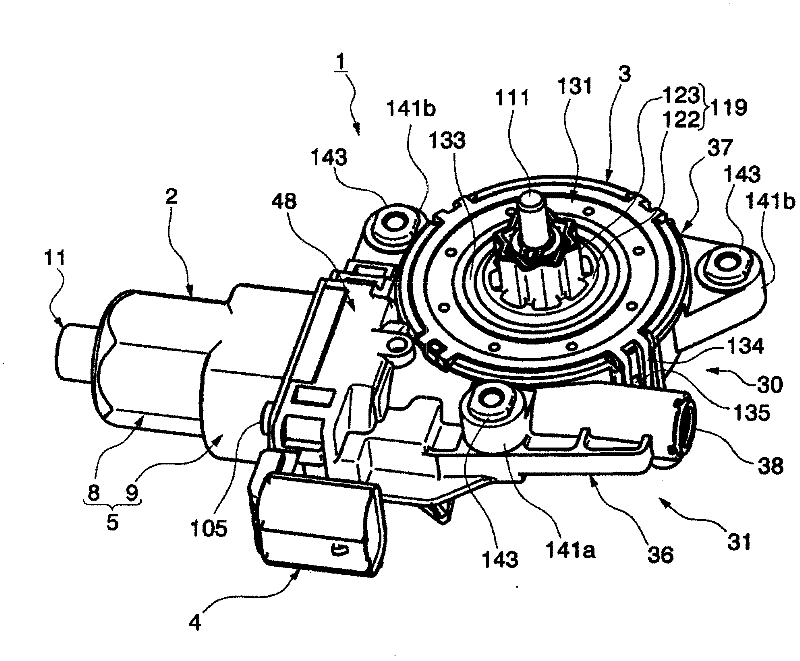

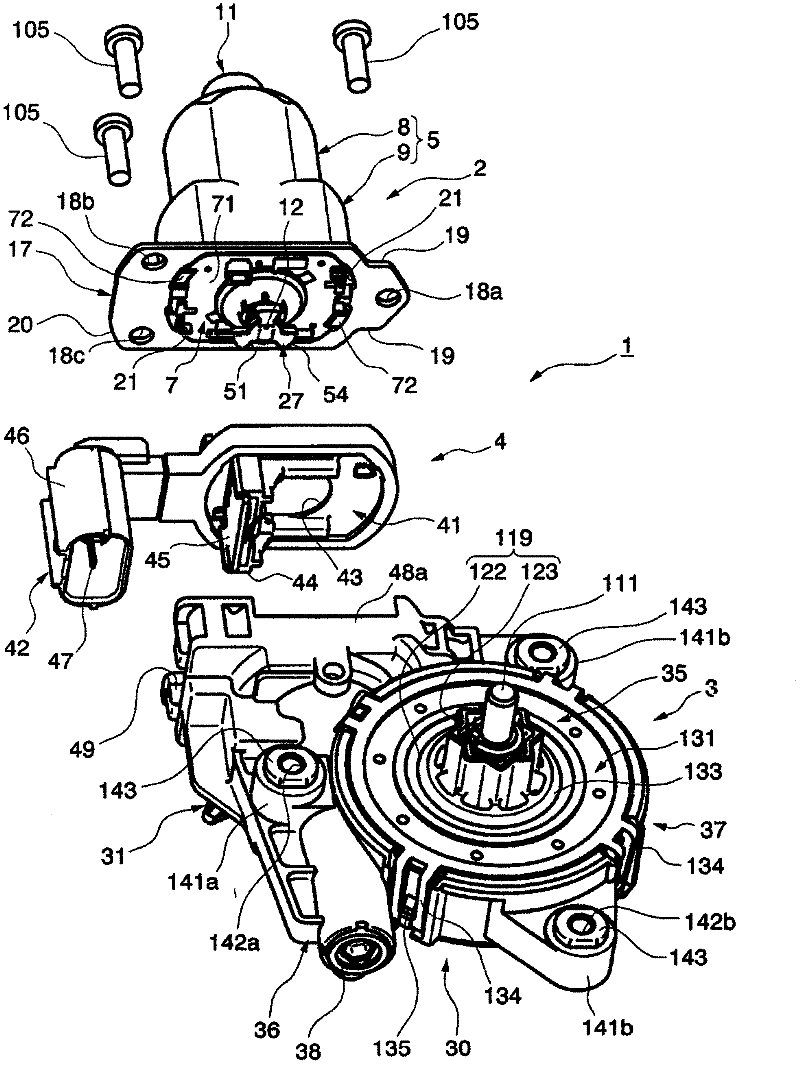

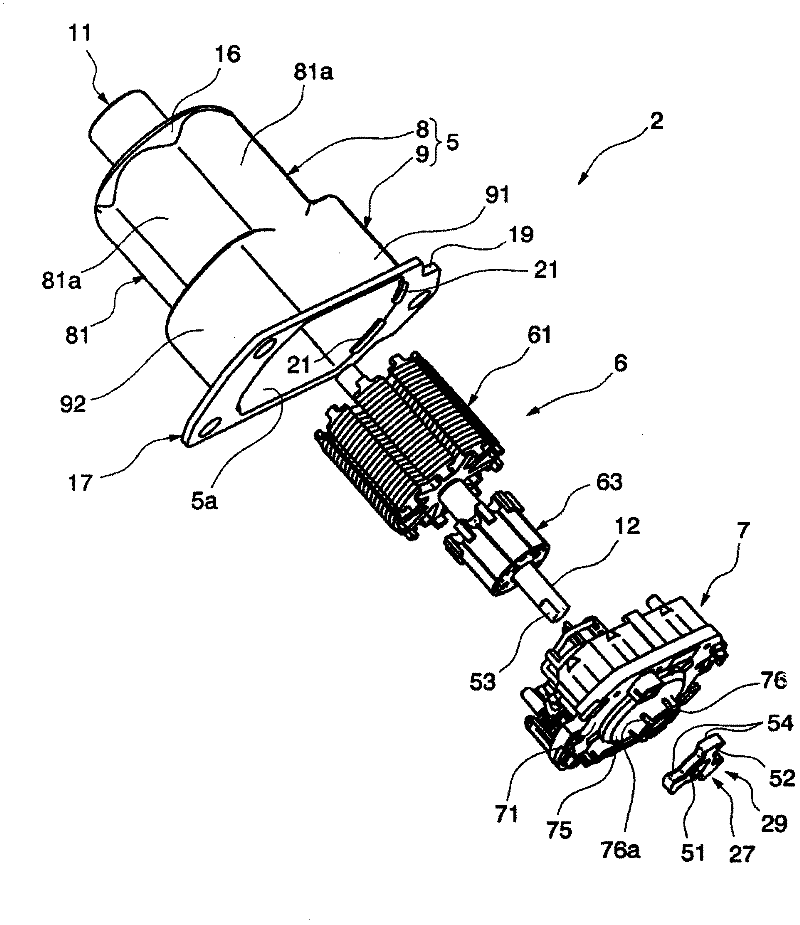

Electric motor, and motor with a reduction gear

ActiveCN102414968AMiniaturizationAchieve thinningMagnetic circuit stationary partsDC commutatorEngineeringMagnet

In an electric motor, the peripheral wall of a yoke is formed in a polygonal shape in plan view in the axial direction. A permanent magnet is arranged in a flat section of the peripheral wall. A first bearing section for rotatably supporting one end of a rotary shaft is integrally formed in the bottom wall of the yoke. A brush holder accommodating section that is capable of accommodating a brush holder unit that holds a brush is integrally formed in the opening of the yoke.

Owner:MITSUBA CORP

Permanent-magnet synchronous motor

InactiveUS20110163641A1Increase the number of coilsIncrease axial lengthMagnetic circuit stationary partsStructural associationRotational axisSynchronous motor

Owner:KOYAMA TAKAYUKI +2

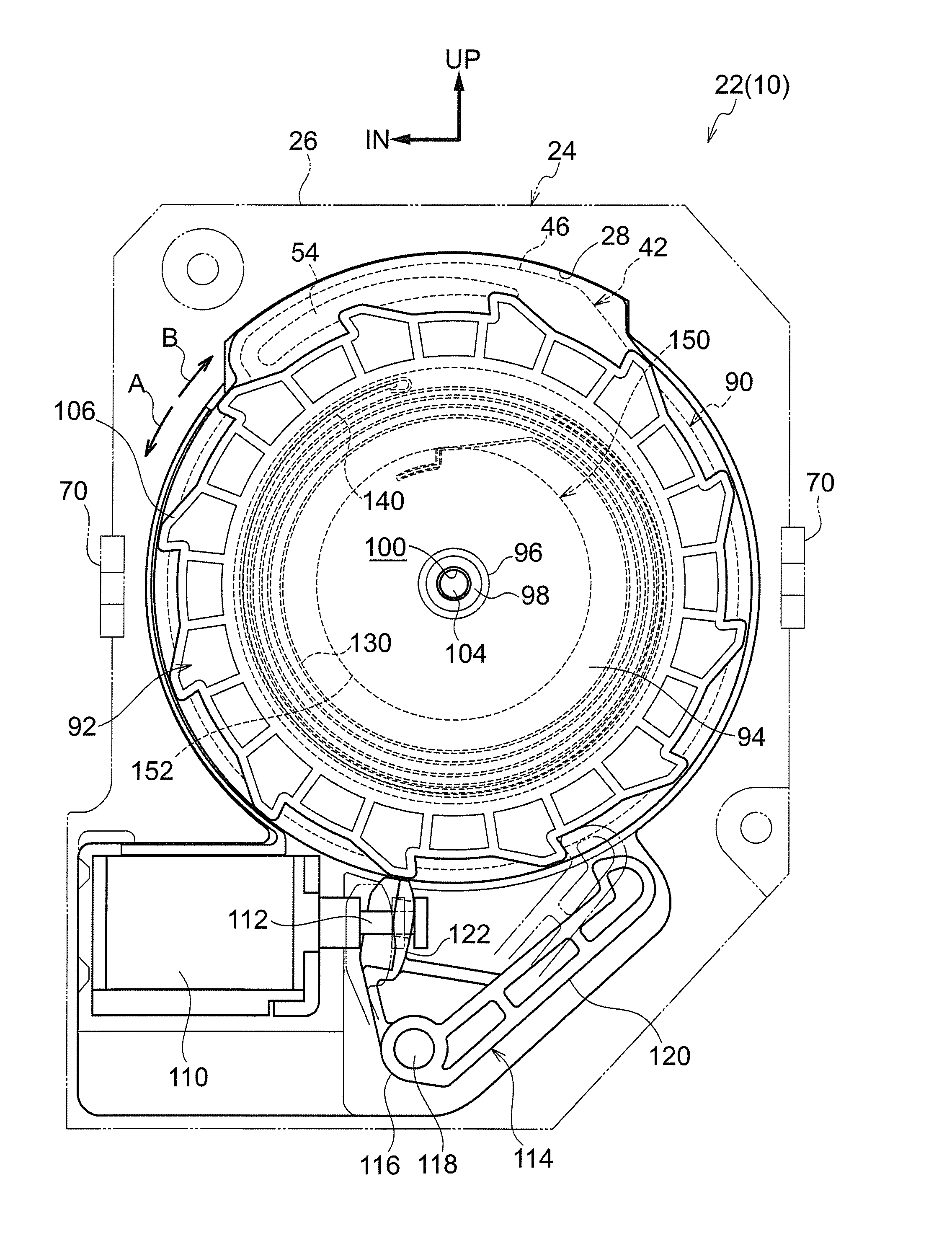

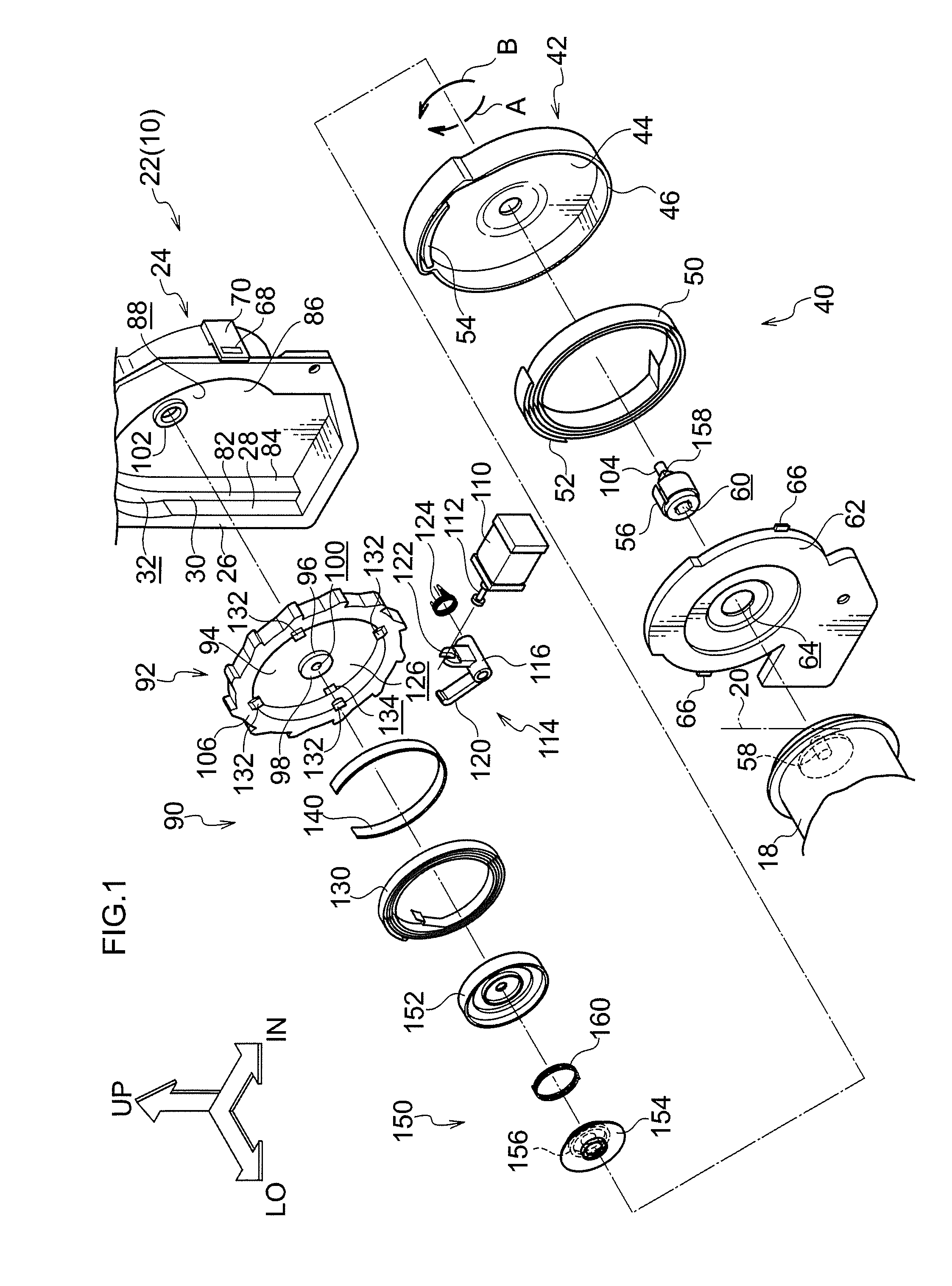

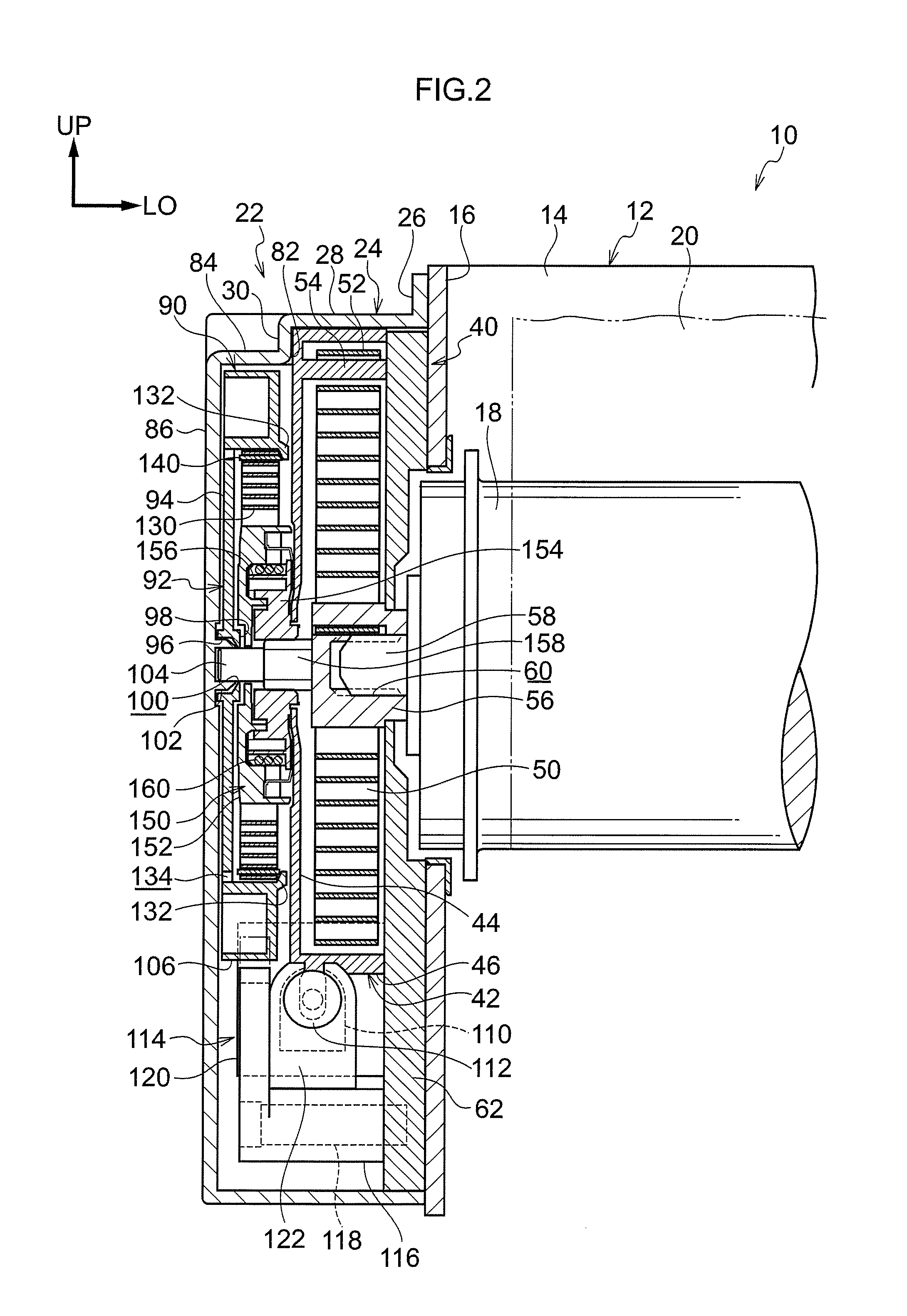

Webbing winding device

ActiveUS20120048982A1Increase the differenceIncrease the number of coilsBelt retractorsWind forceFlange

A difference in limiting torques of rotation between a spring and a rotary member is increased without increasing a number of coils of the spring. In a webbing winding device, an outer diameter of a clutch wall of a clutch wheel increases from a flange side to a stopping flange side of the clutch wall. When a clutch spring is tightly wound on the clutch wall, the clutch spring is subjected to a movement force toward the stopping flange side. Thus, a winding force of the clutch spring onto the clutch wall is effectively increased. Therefore, a difference in limiting torques of rotation between the clutch spring and the clutch wheel between when the clutch spring is not tightly wound on the clutch wall and when it is wound on the clutch wall is increased, without increasing a number of coils of the spring.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

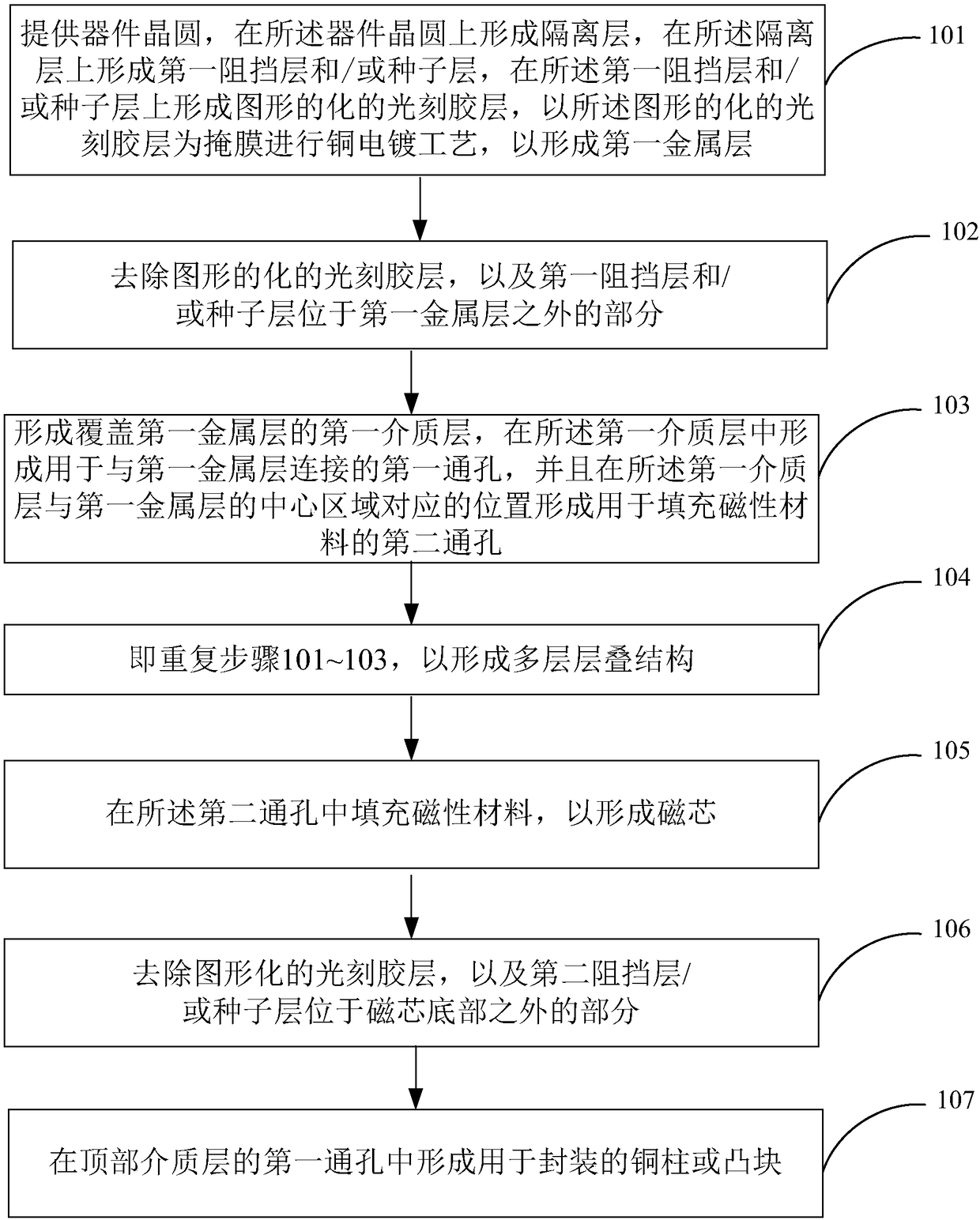

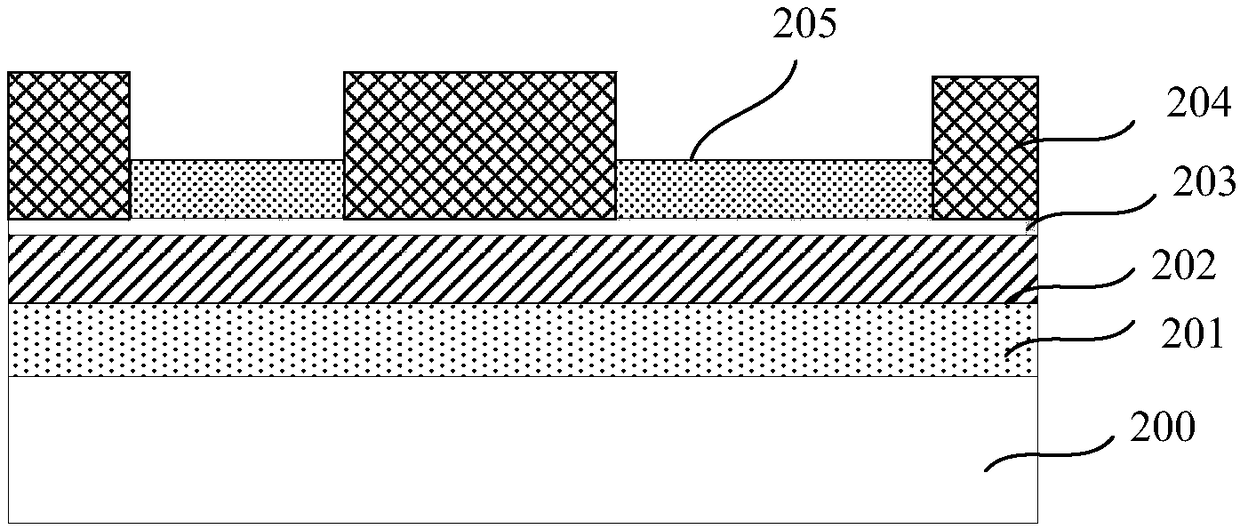

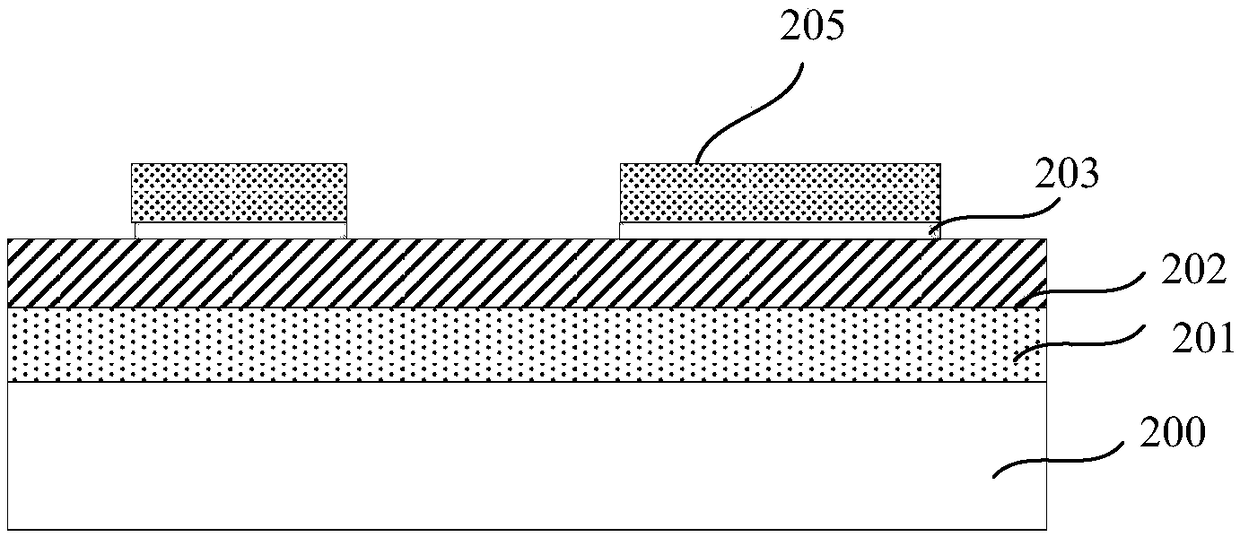

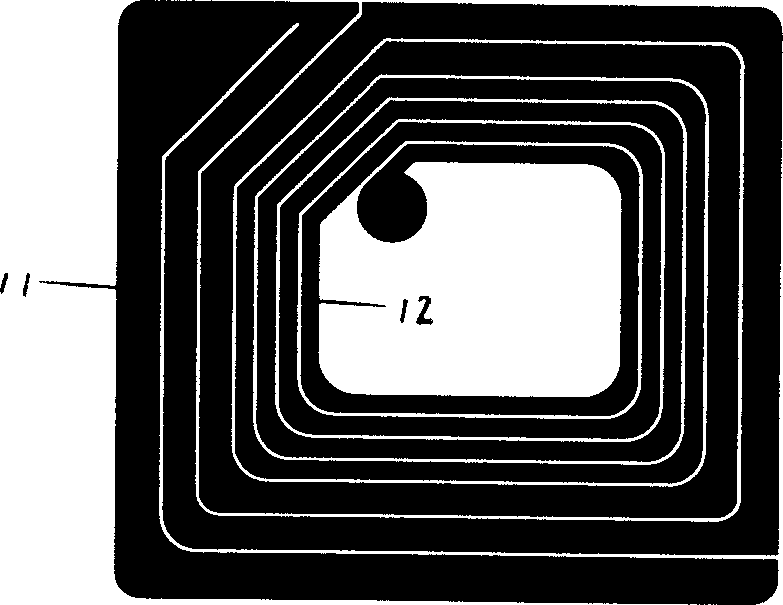

Semiconductor device, manufacturing method thereof and electronic device

InactiveCN108231747AImprove RF performanceImprove inductance performanceSemiconductor/solid-state device detailsSolid-state devicesIsolation layerRadio frequency

The invention provides a semiconductor device, a manufacturing method thereof and an electronic device. The manufacturing method comprises the steps of providing a device wafer; forming an isolation layer on the device wafer; forming a multi-layer laminated structure on the isolation layer, wherein each layer of the laminated structure comprises a metal layer and a dielectric layer covering the metal layer, the multiple metal layers form at least one inductive coil structure; and forming a magnetic core at the position corresponding to a central area of the laminated structure and the inductive coil structure. According to the manufacturing method, the induction coefficient and inductance of an inductance device, and thus the radio frequency performance of semiconductor devices such as anRF device is improved. The semiconductor device and the electronic device have the similar advantages.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

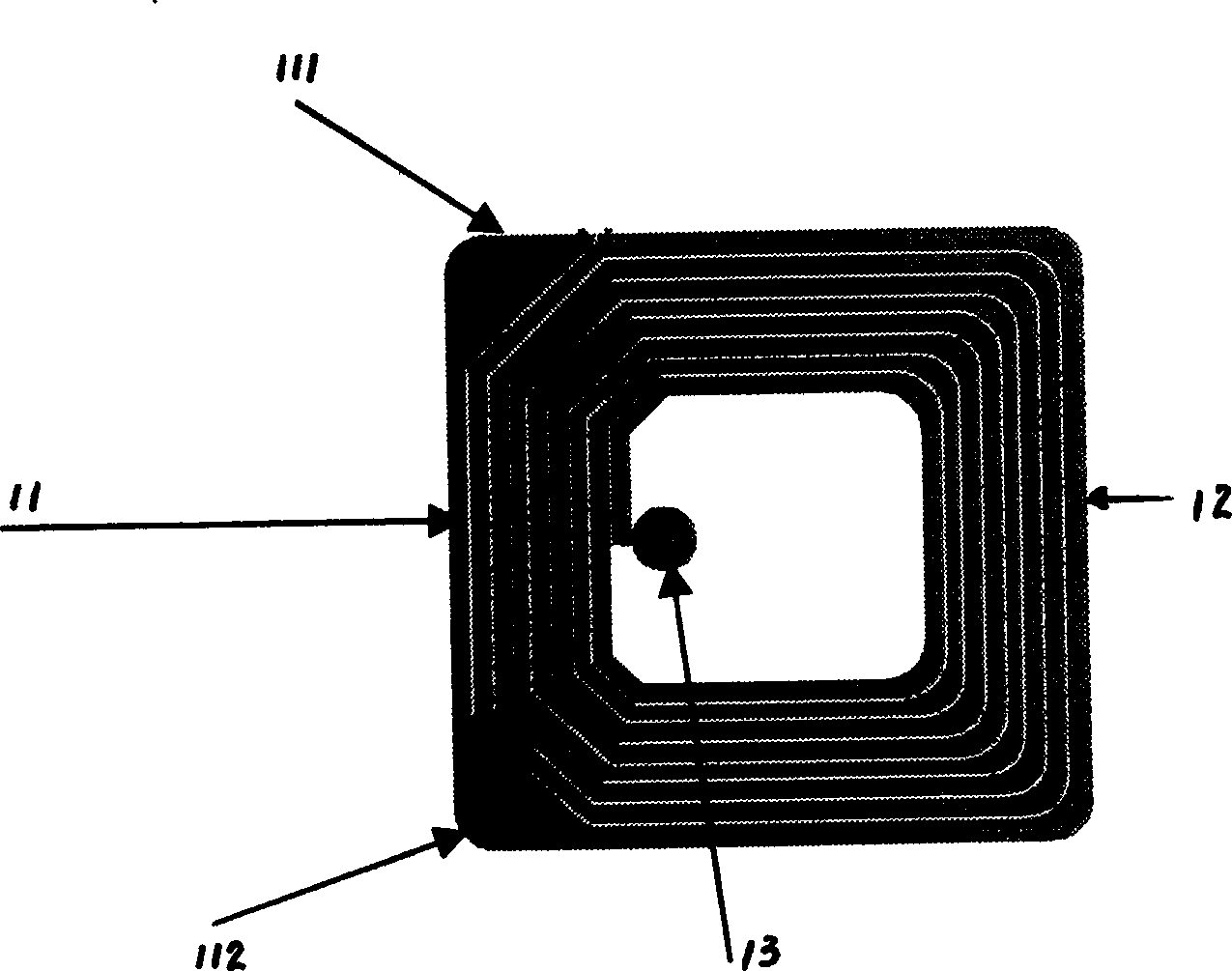

High-precision radio frequency soft tag

ActiveCN1870011ALarge capacityHigh precisionRecord carriers used with machinesCapacitanceEngineering

A high-precision soft tag of radio frequency is prepared as forming countermark base layer by the first insulation film layer and conductive layer stuck separately on the first and second surface of insulation film layer, setting a decoding circuit formed by capacity and wire as well as decoding point on said conductive layer, setting capacity at periphery of coil formed by wire. It features that the width of capacity wire and coil wire is decreased gradually from outside to inside.

Owner:齐克庞德电子(江苏)有限公司

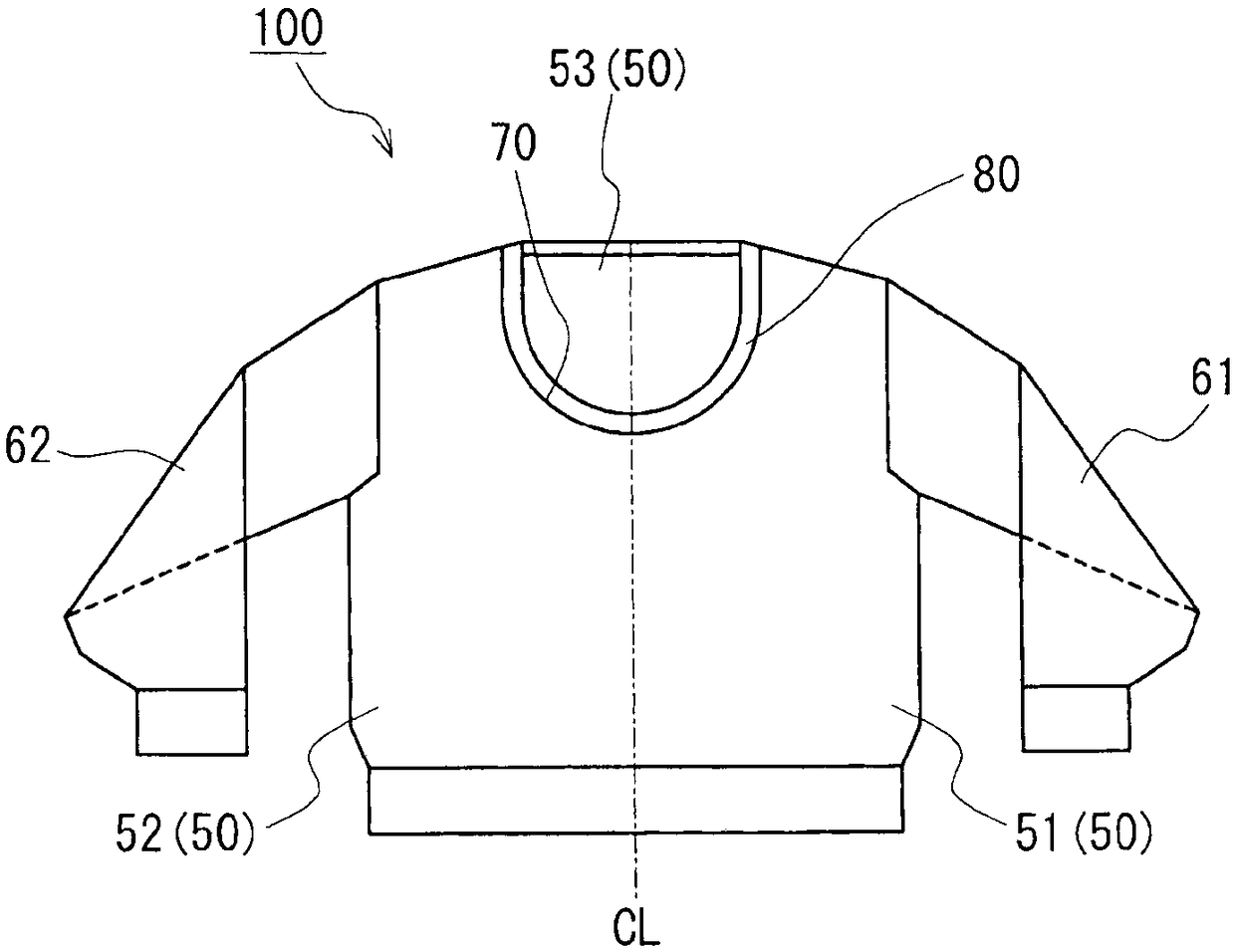

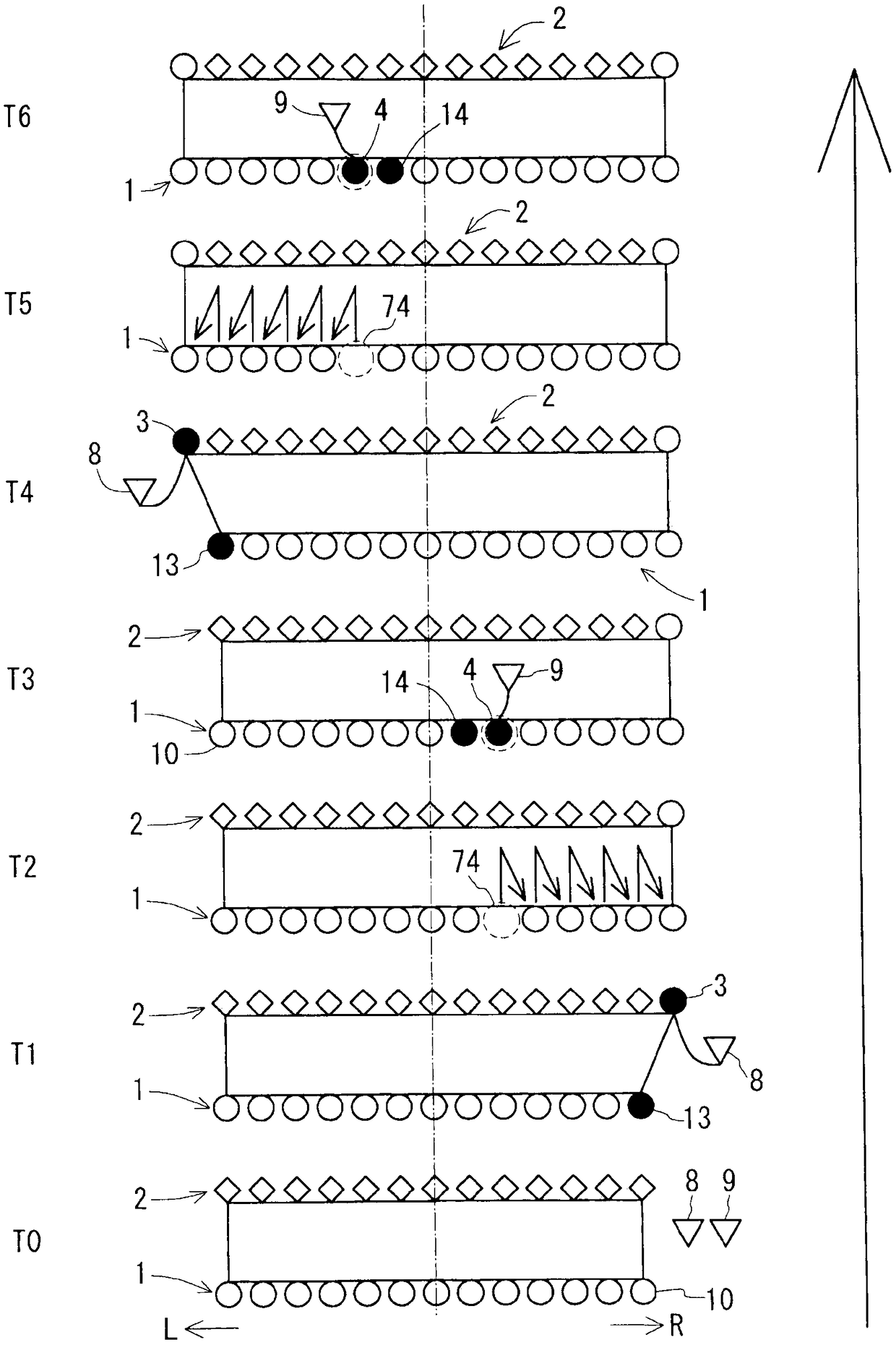

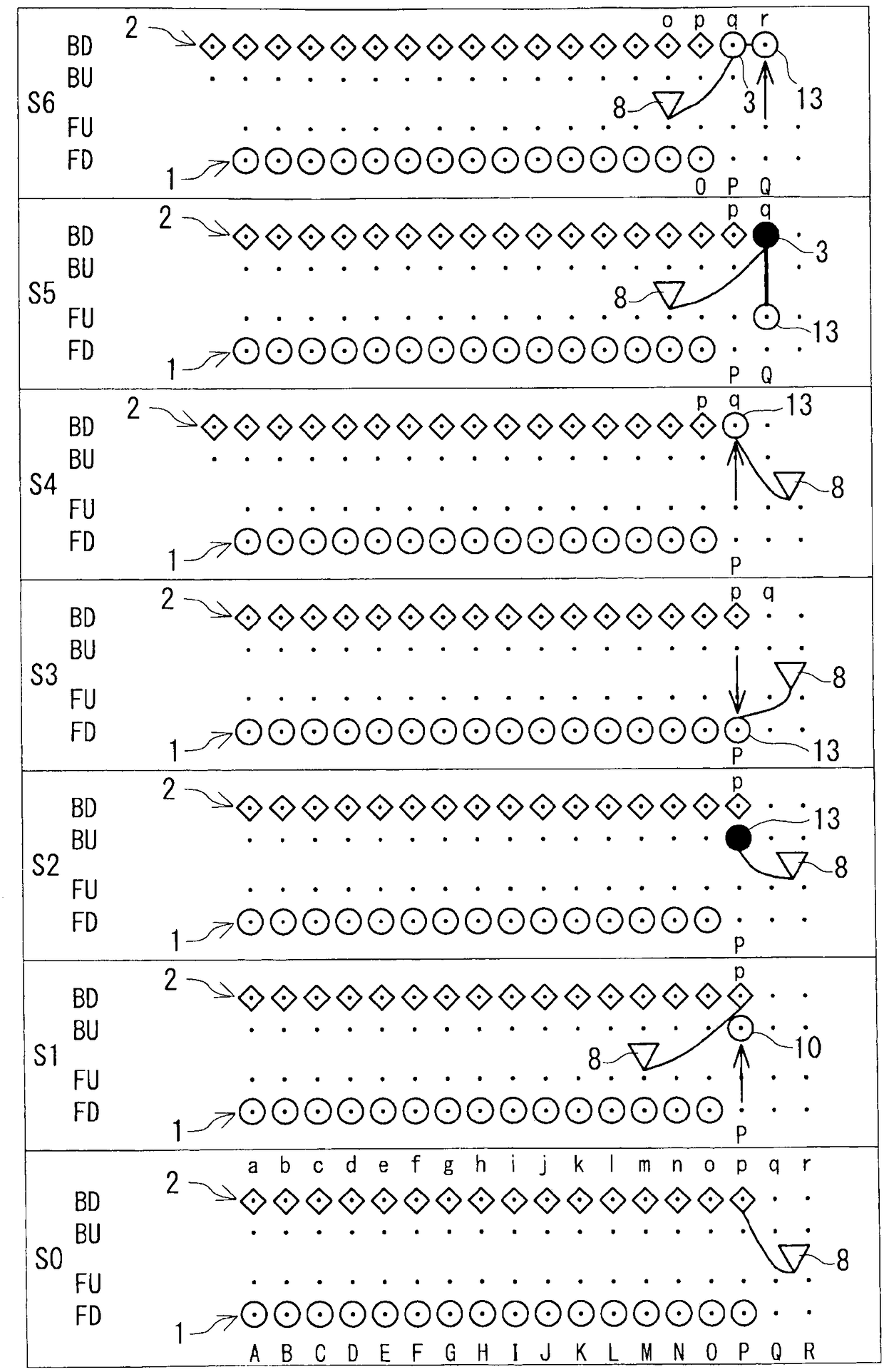

Fabric knitting method

ActiveCN109322052ANot easy to disconnectIncrease the number of coilsFlat-bed knitting machinesYarnEngineering

The present invention provides a fabric knitting method. The fabric knitting method is a knitting method for a fabric in which the steps (A) to (C) are repeated a plurality of times. In the step (A),a first yarn supplying member is used, and an end portion side enhancing ring connected with an end portion coil on one side of a needle bed of one side of the fabric part is formed on the boundary ofone side of the fabric part and the end portion in the knitting width direction of the other side of the fabric part, and the end portion side enhancing ring is arranged on the outer side in the knitting width direction of the other side of the fabric part. In the step (B), a part of the one knitted fabric portion is moved toward the boundary side, and at least one stitch insertion space is formed in the knitting width of the one knitted fabric portion. In the step (C), the second yarn supplying member is used to form an inner side widening ring that is connected to the existing coil close tothe insertion space in the one side knitted fabric portion, and the coil insertion space is filled with the existing coil or the inner side reinforcing ring. .

Owner:SHIMA SEIKI MFG LTD

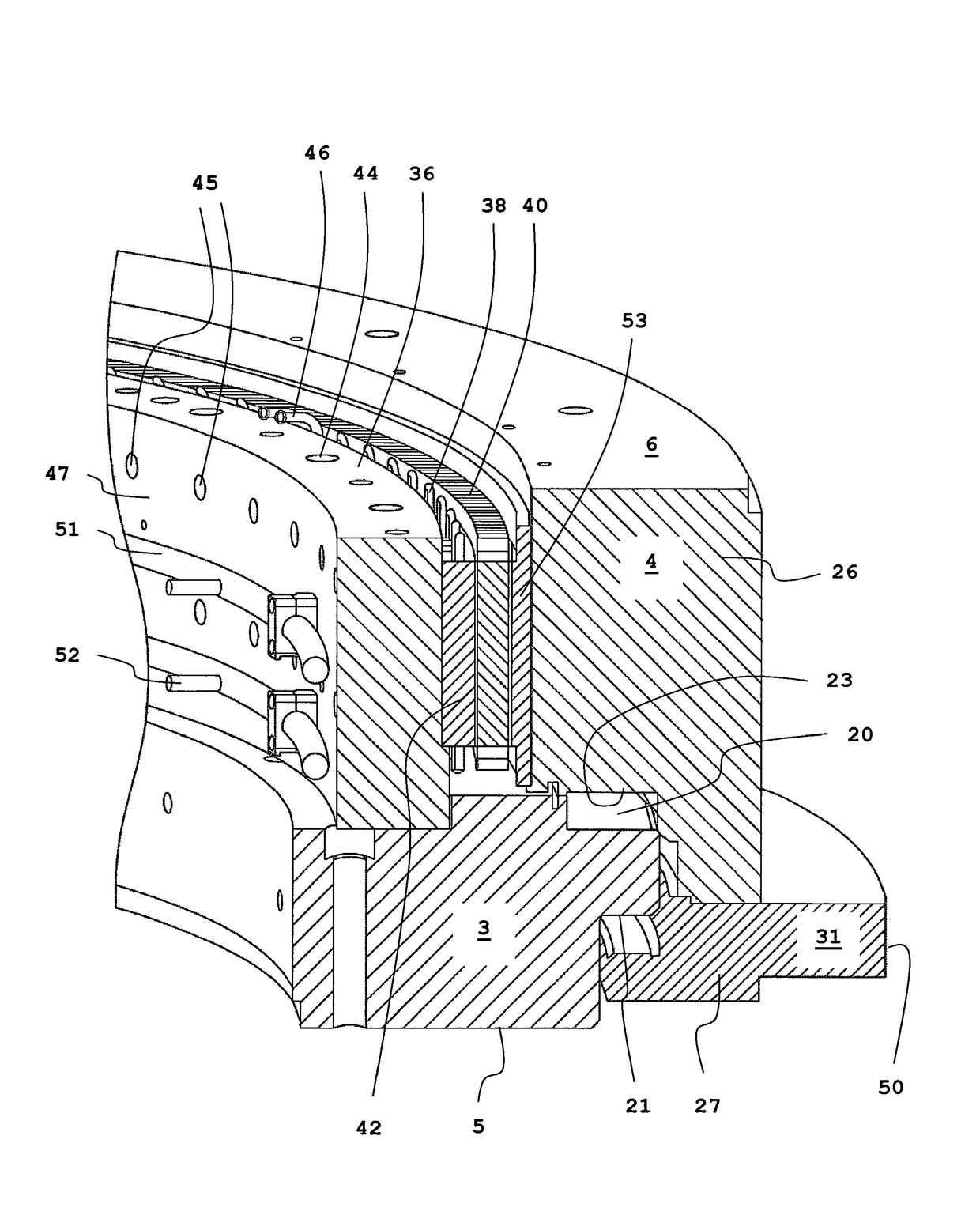

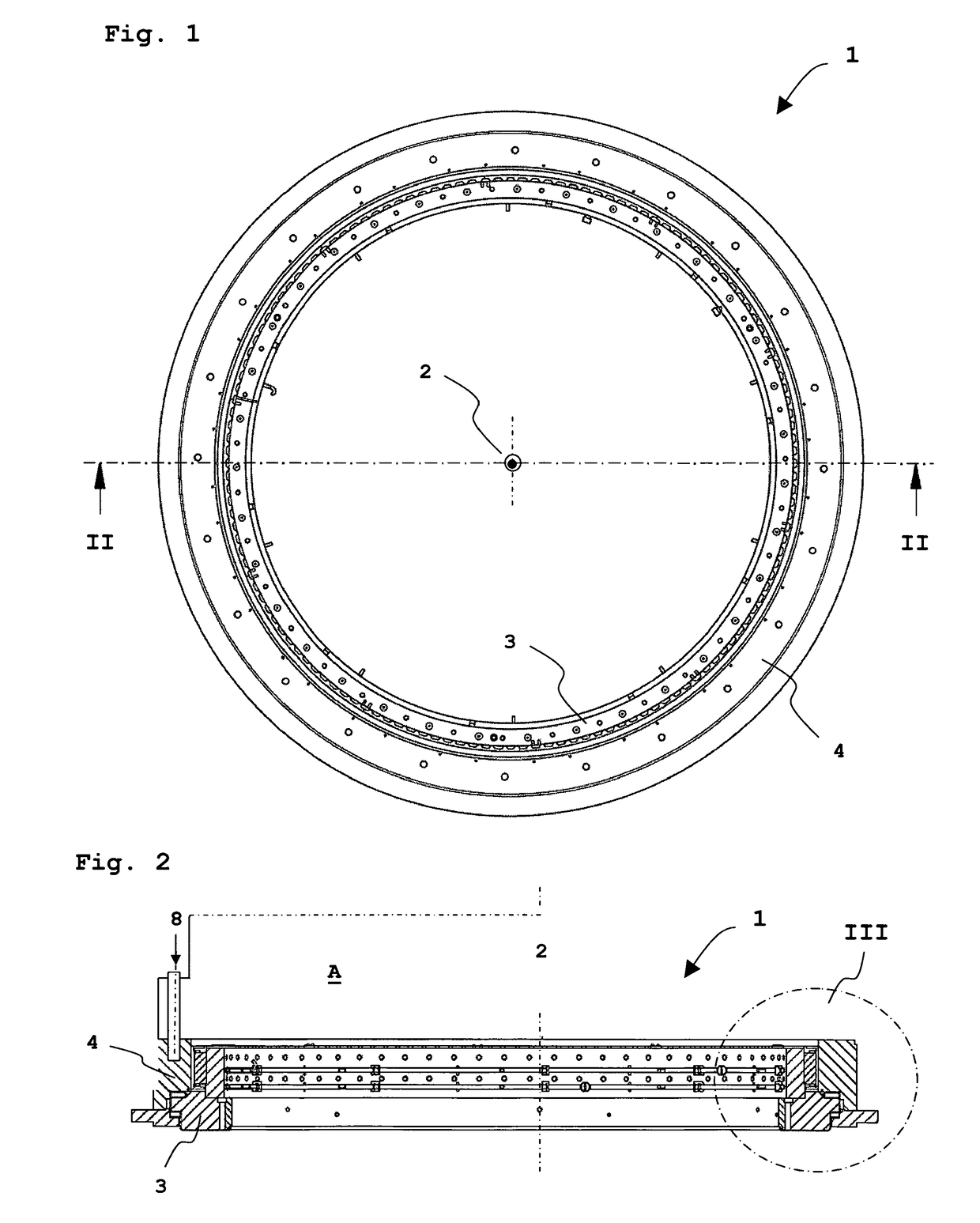

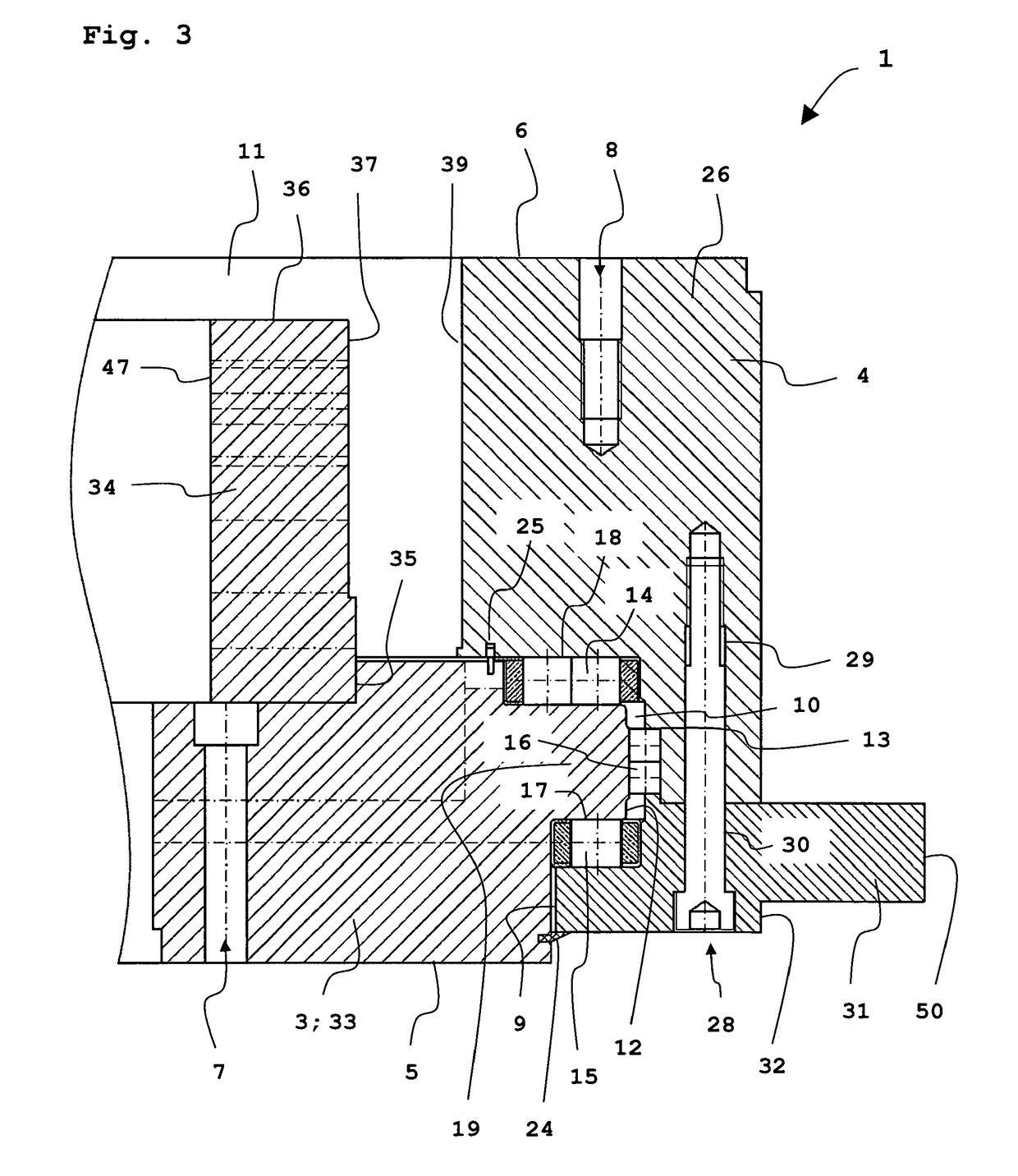

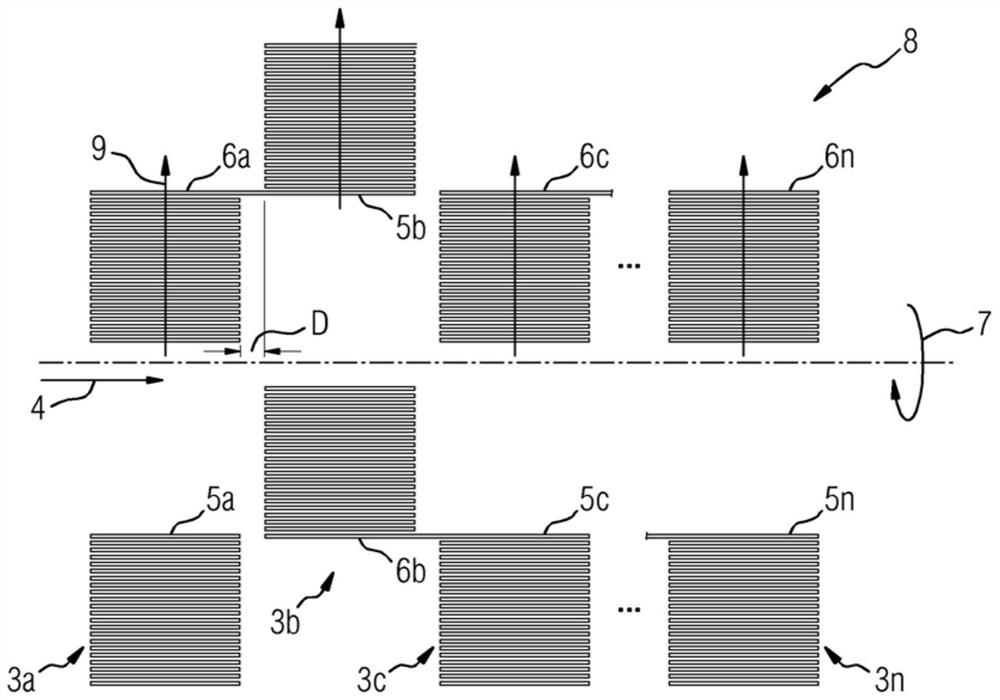

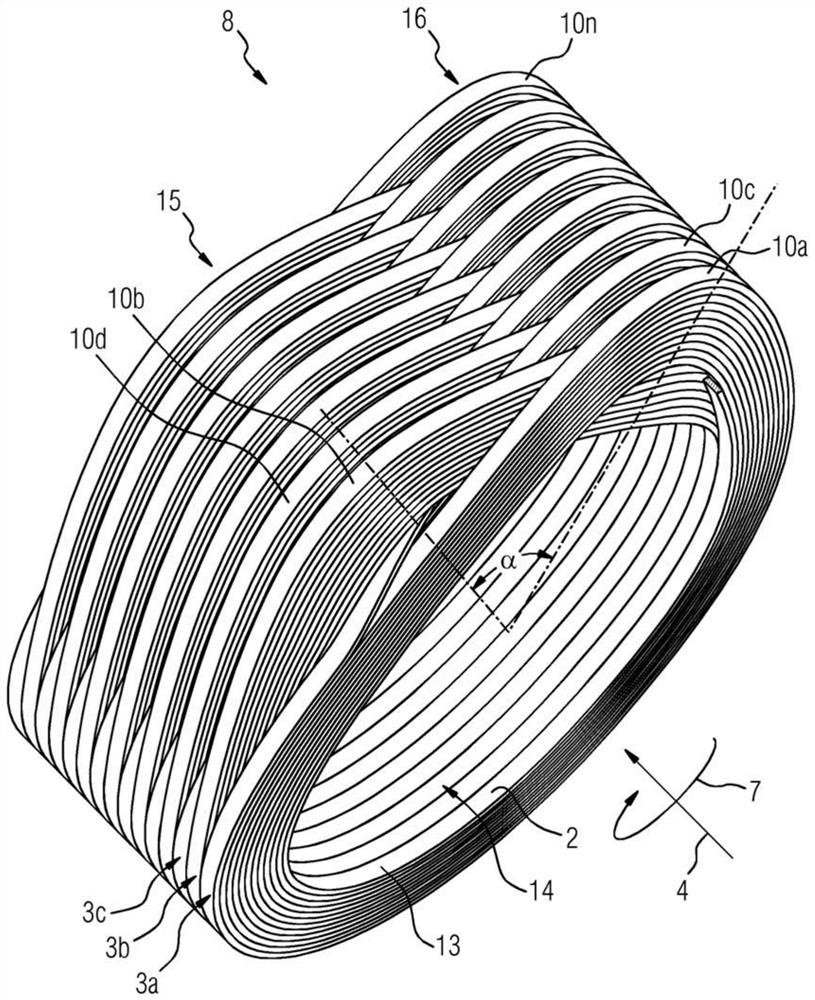

Drive mechanism for rotatably coupling a system part or a machine part

ActiveUS9793776B2Equally distributedMaintain good propertiesRoller bearingsTransformersCommon baseMachine parts

The invention relates to a drive mechanism (1) for rotatably coupling a first system part or machine part, preferably an assembly (A), to a base, pedestal or frame or to another system part or machine part, for example for rotary positioning during the processing of large workpieces or during the moving of loads, which drive mechanism comprises two ring-shaped connecting elements (3, 4) each having at least one planar connecting surface (5, 6) and fastening means (7, 8) that are arranged distributed in a crown shape therein and effect connection to different system parts or machine parts or the like, said two connecting elements (3, 4) being arranged concentrically with each other and radially one inside the other with a gap-shaped interspace (9) in which are disposed one or more rows of rolling elements (14, 15, 16), each row whereof rolls between two respective raceways (17, 18) on the two connecting elements (3, 4), thus enabling same to rotate relative to each other, at least one connecting surface (5, 6) and at least one raceway (17, 18) being formed by machining or shaping a common base body. The invention is characterized in that at least one fully circumferentially extending row of magnets (40) is arranged inside the gap (9) on one connecting element (3, 4) and at least one fully circumferentially extending row of coils (38) is arranged directly opposite said magnets on the other connecting element (4, 3). According to the invention, at least one fully circumferentially extending row of magnets is arranged inside the gap on one connecting element and at least one fully circumferentially extending row of coils is arranged directly opposite said magnets on the other connecting element.

Owner:IMO HOLDING GMBH

Motor device

InactiveCN102255409AIncrease torqueIncrease speedMagnetic circuit rotating partsMagnetic energyConductor Coil

The invention discloses a motor device, comprising a stator part and a rotor part, wherein the rotor part is arranged in an inner ring of the stator part; magnetic action is generated between the rotor part and the stator part so that the rotor part rotates in the inner ring of the stator part; the rotor part comprises a rotor iron core; the rotor iron core is integrally formed from magnetic powder through a powder metallurgy process; the magnetic powder is a soft magnetic material with a core-shell structure; and the soft magnetic material comprises a core main body for supplying magnetic force and a shell layer for supplying connection intensity. According to the motor device disclosed by the invention, the rotor part is structurally improved; therefore, the rotor part is not influenced by a coil; the winding turn number or wire diameter can be increased; the motor torque and rotation speed can be increased; the magnetic energy loss can be reduced effectively; on the premise of having the same unit output power, the size of the motor is reduced; and the design concept of the traditional motor rotor is broken through.

Owner:CHESHIRE ELECTRIC COMPANY

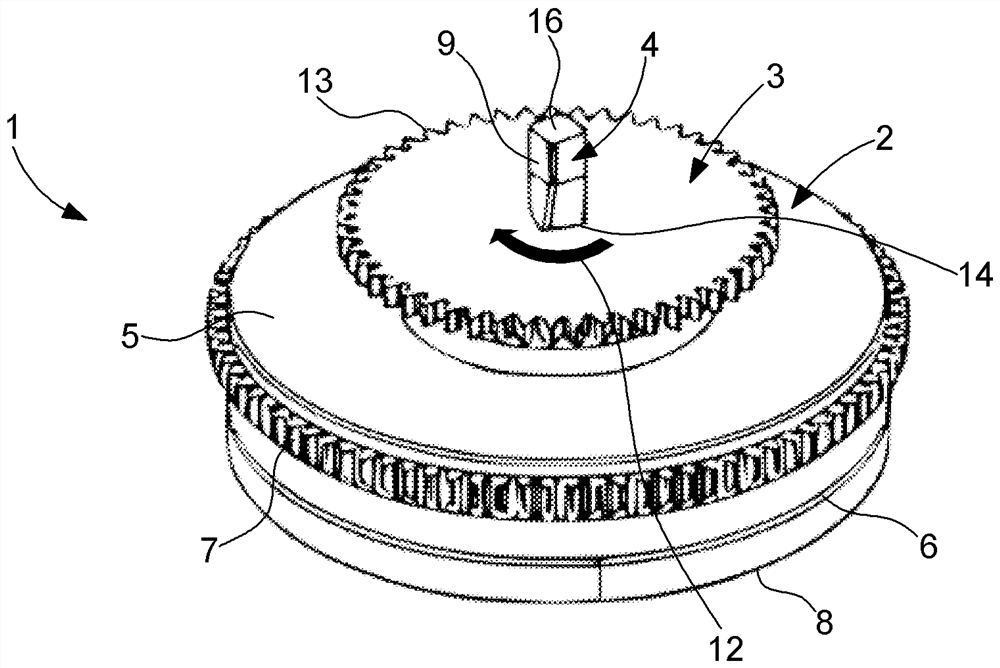

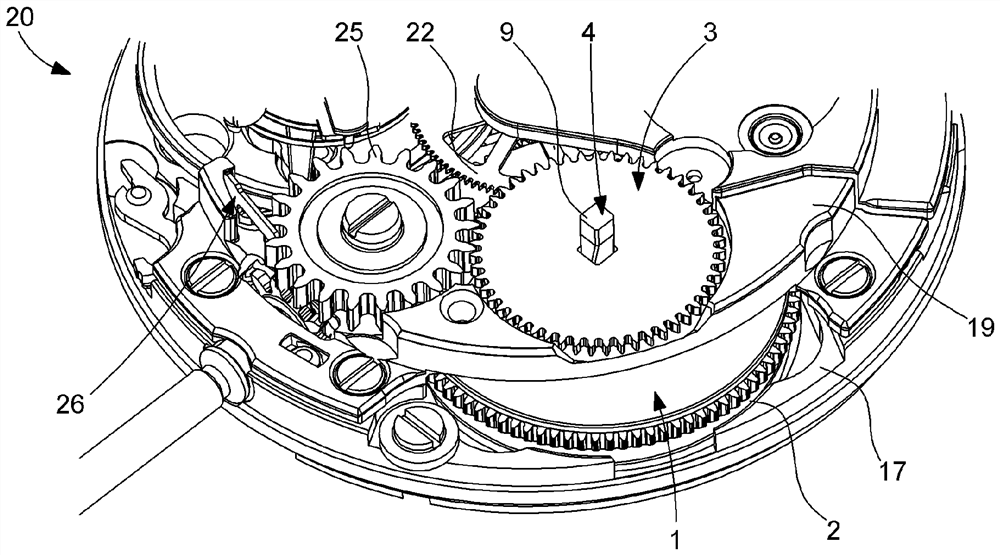

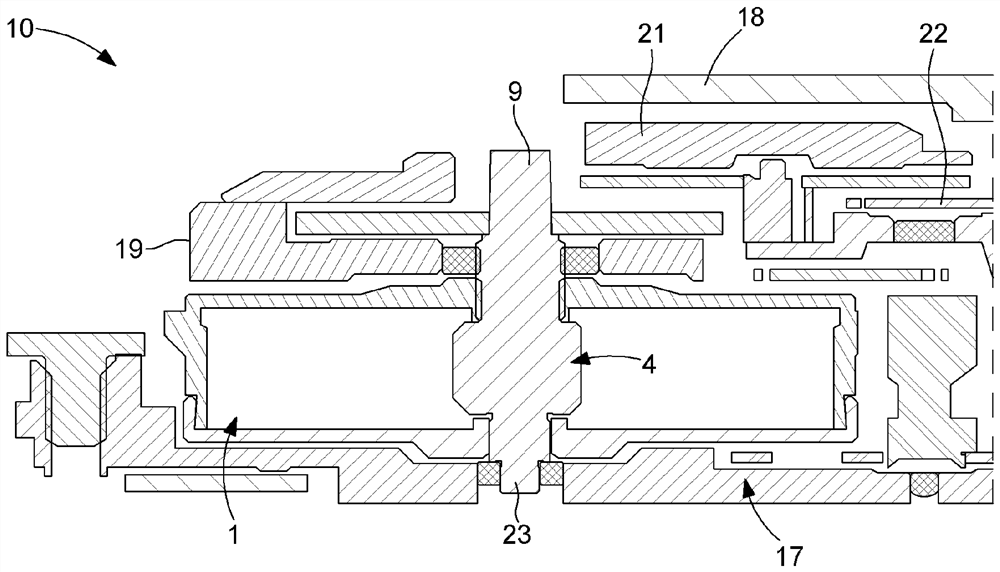

Timepiece barrel with twisted arbor

The invention relates to a timepiece barrel with a twisted arbor. A twisted arbour barrel (1), including a barrel drum (2) provided with a housing, a spring arranged in the housing of the barrel drum (2), an arbour (4) at least partially passing through the housing, the spring being compressed by rotation of the arbour in a first direction of rotation (12), the arbour (4) being provided with a protruding end (9) of the drum (2), a ratchet (3) arranged on the drum (2), the ratchet (3) being configured to allow the rotation of the arbour (4) in the first direction of rotation (12), the protruding end (9) passing through the ratchet (3) through an opening (14) cooperating by interlocking with the protruding end (9), the protruding end (9) of the arbour (4) having a twisted shape around its axis.

Owner:ETA SA MFG HORLOGERE SUISSE

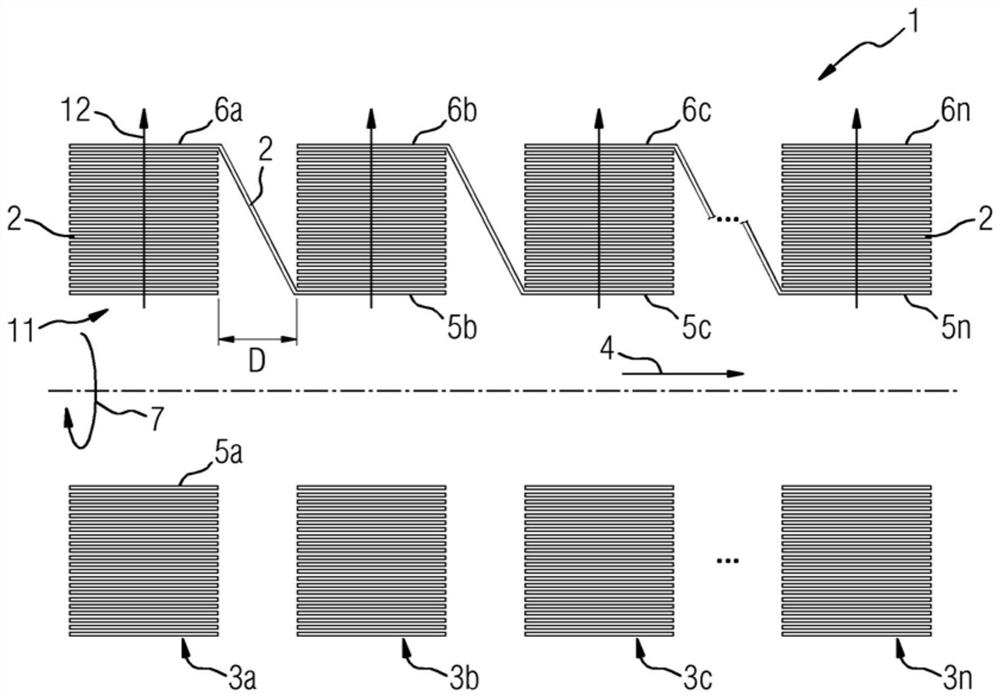

Winding device

InactiveCN108369854BReduce spacingReduce manufacturing costTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureElectrical conductorEngineering

Owner:SIEMENS AG

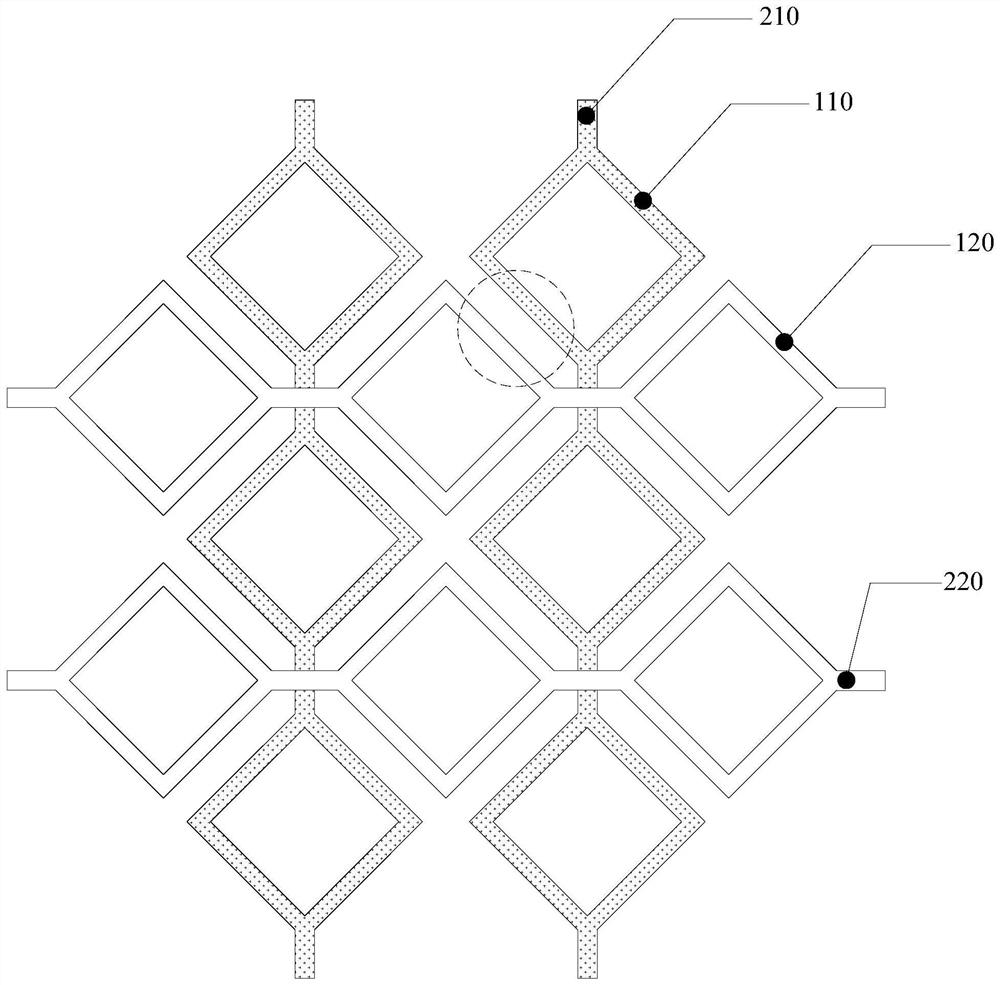

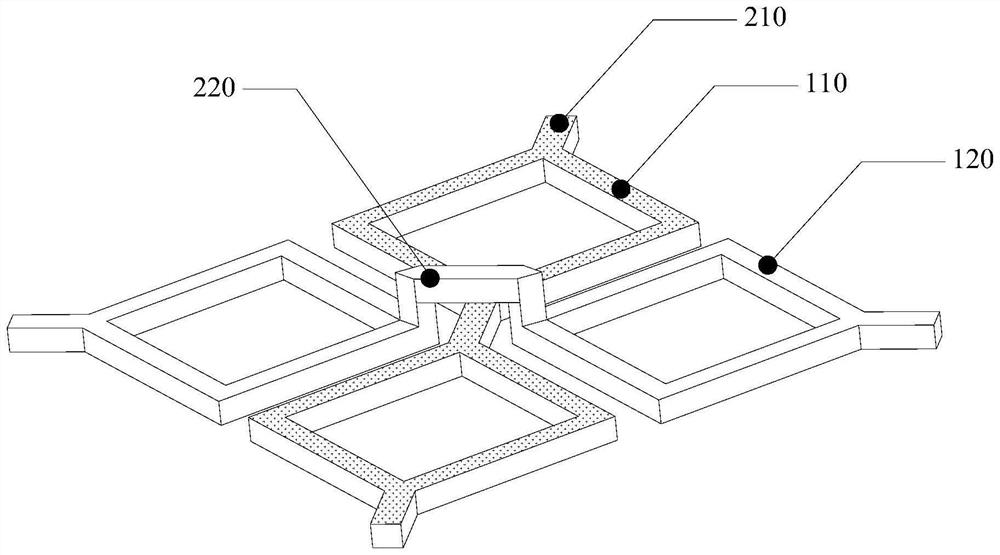

Touch module and display screen

PendingCN114860113AImprove sensor detection accuracyIncrease line widthCharacter and pattern recognitionInput/output processes for data processingCapacitanceEngineering

According to the touch module and the display screen provided by the embodiment of the invention, by increasing the line width of the first grid and the second grid in the metal grid layer or increasing the number of winding turns of the first grid and the second grid, the area ratio of the first grid and the second grid can be increased; therefore, the capacitance between the first grid and the second grid is improved, the sensing detection precision of the touch module can be improved, and the touch module can achieve fingerprint recognition through the metal grid.

Owner:YUNGU GUAN TECH CO LTD

Motor having stator with coupled teeth

ActiveUS10622851B2Increase forceHigh outputMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineMagnetic poles

Owner:NEW MOTECH +1

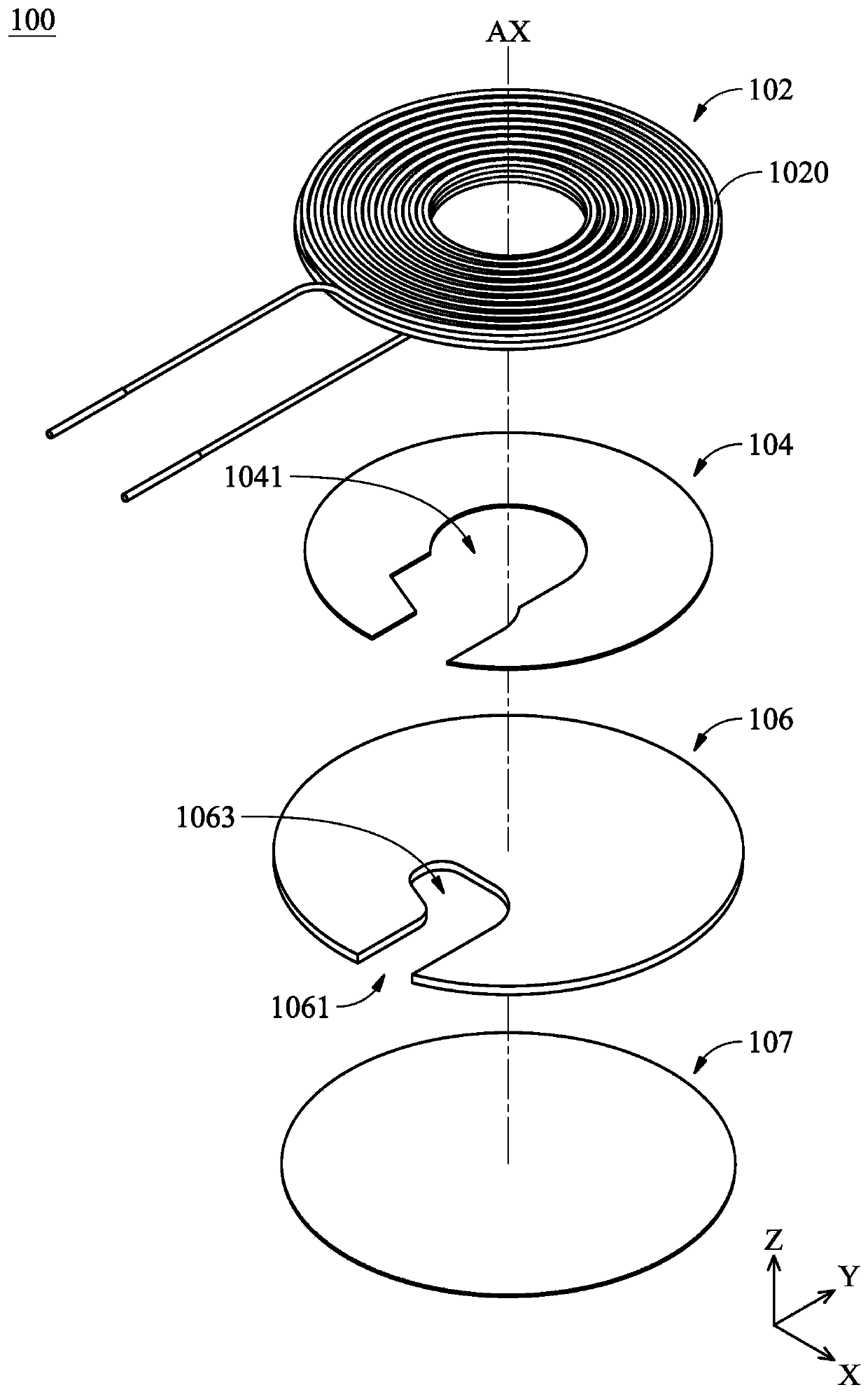

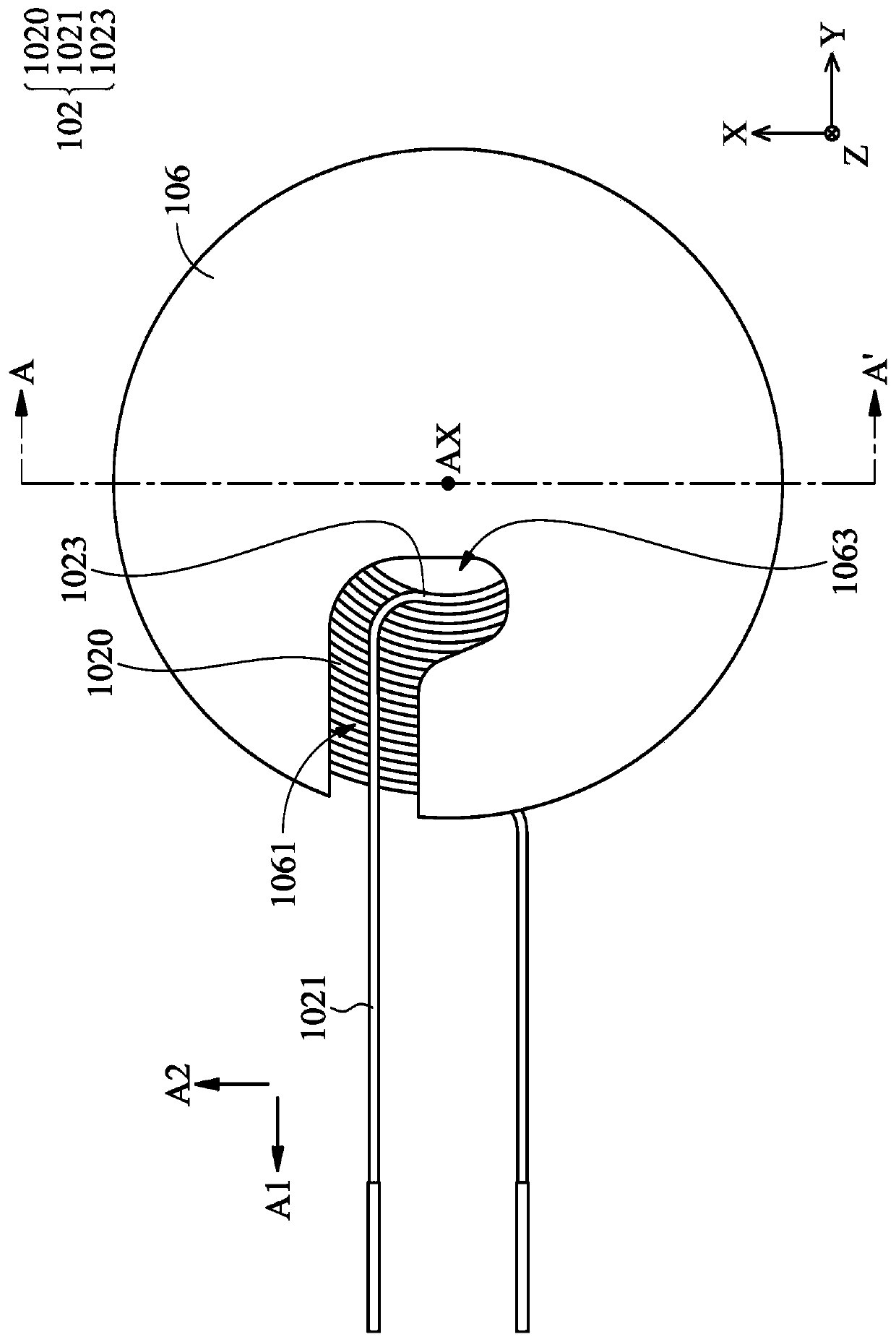

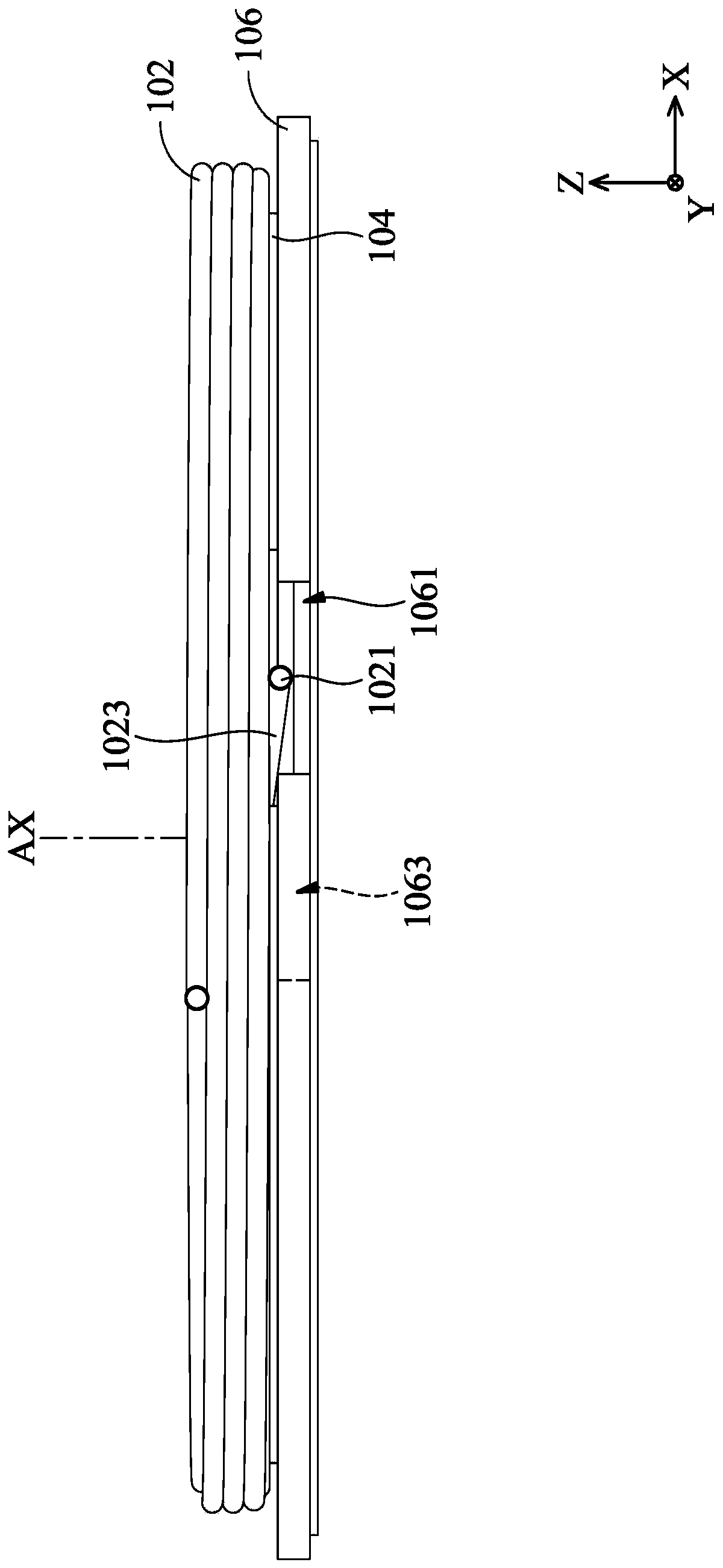

Wireless module

ActiveCN111525943AMiniaturizationIncrease the number of coilsNear-field transmissionWirelessElectrical and Electronics engineering

A wireless module comprises a coil assembly and an induction substrate. The coil assembly is provided with a coil body and an outgoing line. The outgoing line is electrically connected with the coil body to an outgoing line segement. When observed along the direction of a winding shaft, the coil body and the outgoing line are partially overlapped. The induction substrate is provided with an outgoing line accommodating part and an outgoing line segment accommodating part. The outgoing line accommodating part accommodates part of the outgoing line and the outgoing line segment accommodating partis configured to accommodate part of the outgoing line segment. The outgoing line segment and the outgoing line are arranged along a first direction, the size of the outgoing line segment accommodating part is greater than that of the outgoing line accommodating part in a second direction, and the second direction is not parallel to the first direction and the winding shaft.

Owner:TDK TAIWAN

Soft label in radio frequency of double capacitances

InactiveCN1873667ALarge capacityHigh precisionRecord carriers used with machinesCapacitanceEngineering

The invention relates to anti-theft and anti-falsification device technical fields, especially a double-capacitor radio frequency soft label. And its substrate is composed of an insulating layer and conductive layers arranged on the first and second surfaces of the insulating layer, the conductive layer has decoding circuit composed of capacitor, lead and decoding point, and the capacitor is located at the periphery of a coil, and it is characterized in that: leading of each capacitor has two capacitance regions, oppositely arranged, so as to compose double capacitors. And it can further improve accuracy of radio frequency label and benefit anti-theft and anti-falsification works.

Owner:黄光伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com