Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97results about How to "Increase the mix rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fuel injector and swirler assembly with lobed mixer

InactiveUS8511087B2Increase the mix rateReduce total pressure lossTurbine/propulsion fuel supply systemsContinuous combustion chamberFuel supplyGas turbines

Owner:SIEMENS AG

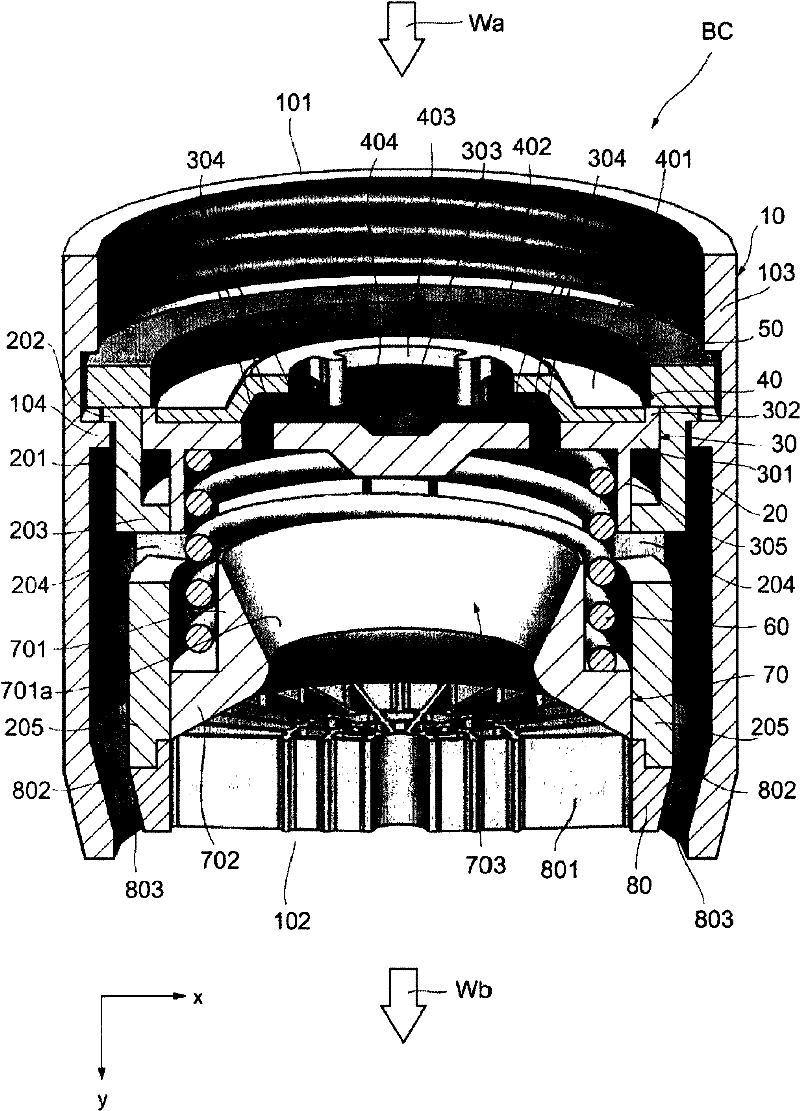

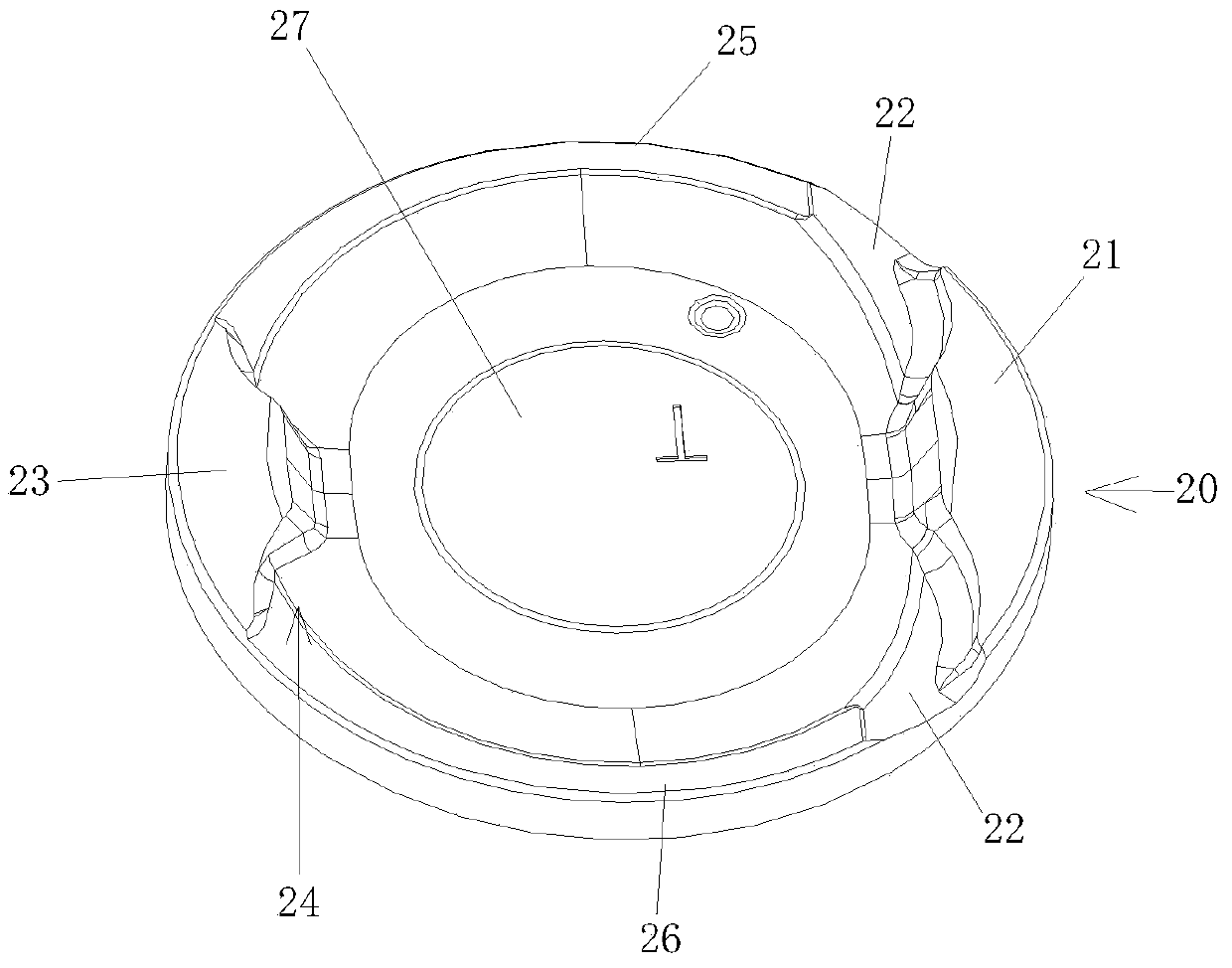

Water spouting device

A water spouting device which enables air bubble entrained water with an increased entrainment rate of air bubbles to be discharged at a low flow rate, the present water spouting device further enabling, at a high flow rate stage, prevention of discharge of air bubble entrained water with such a total amount as makes the user feel that the resultant amount of water significantly exceeds that intended by the user. A spout cap (BC) serving as the present water spouting device includes a pressure reducing portion (30) serving as an entrainment rate adjusting portion to adjust the entrainment rate of air bubbles entrained in air bubble entrained water in an air bubble entraining portion (703). The pressure reducing portion (30) serving as the entrainment rate adjusting portion increases the entrainment rate until inflow water from an inflow port (101) reaches a predetermined flow rate, and suppresses an increase in entrainment rate when the inflow water from the inflow port (101) exceeds the predetermined flow rate.

Owner:TOTO LTD

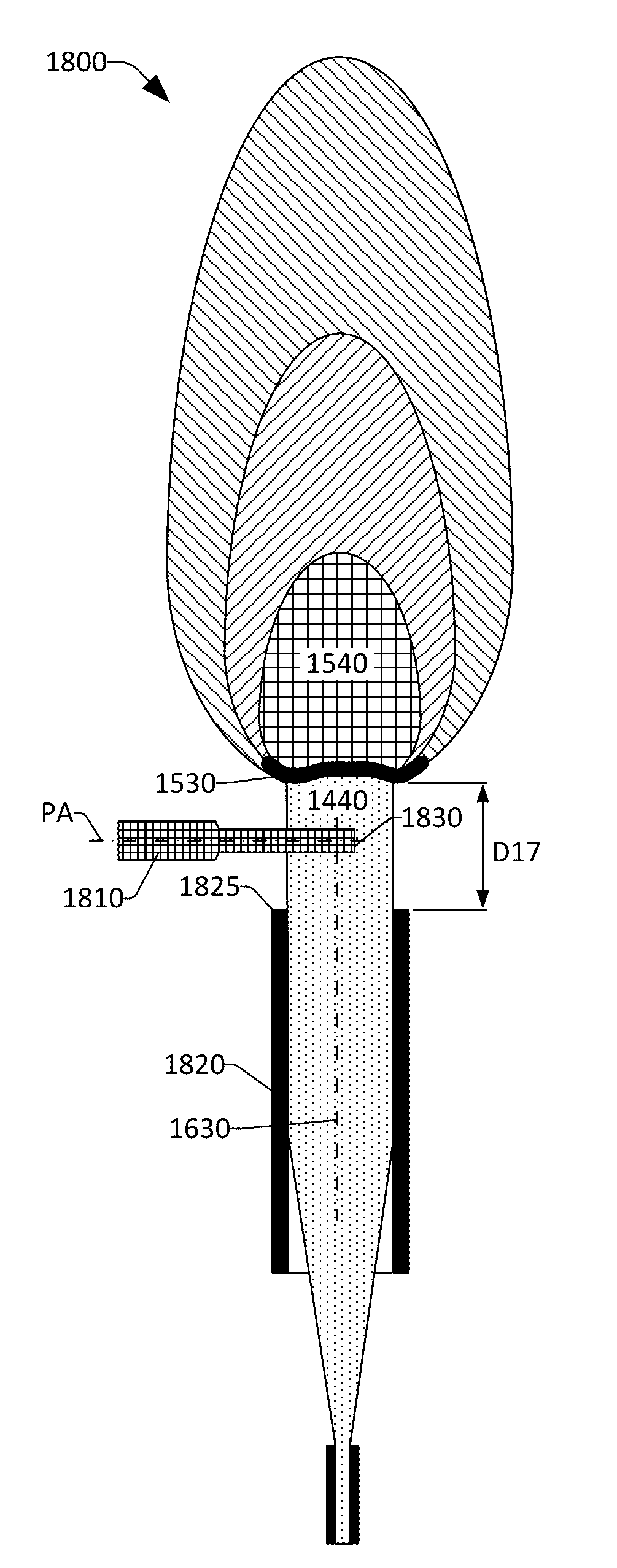

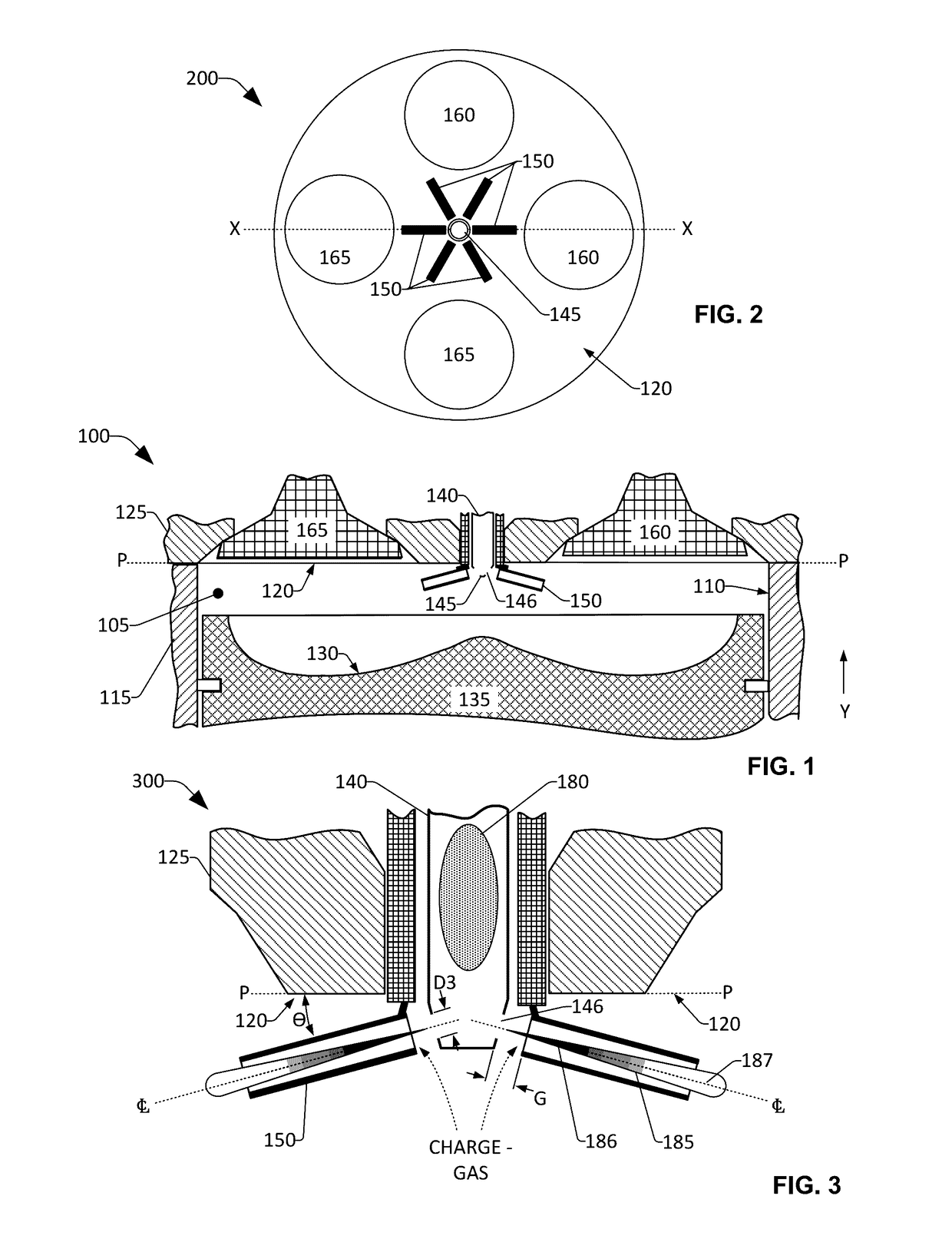

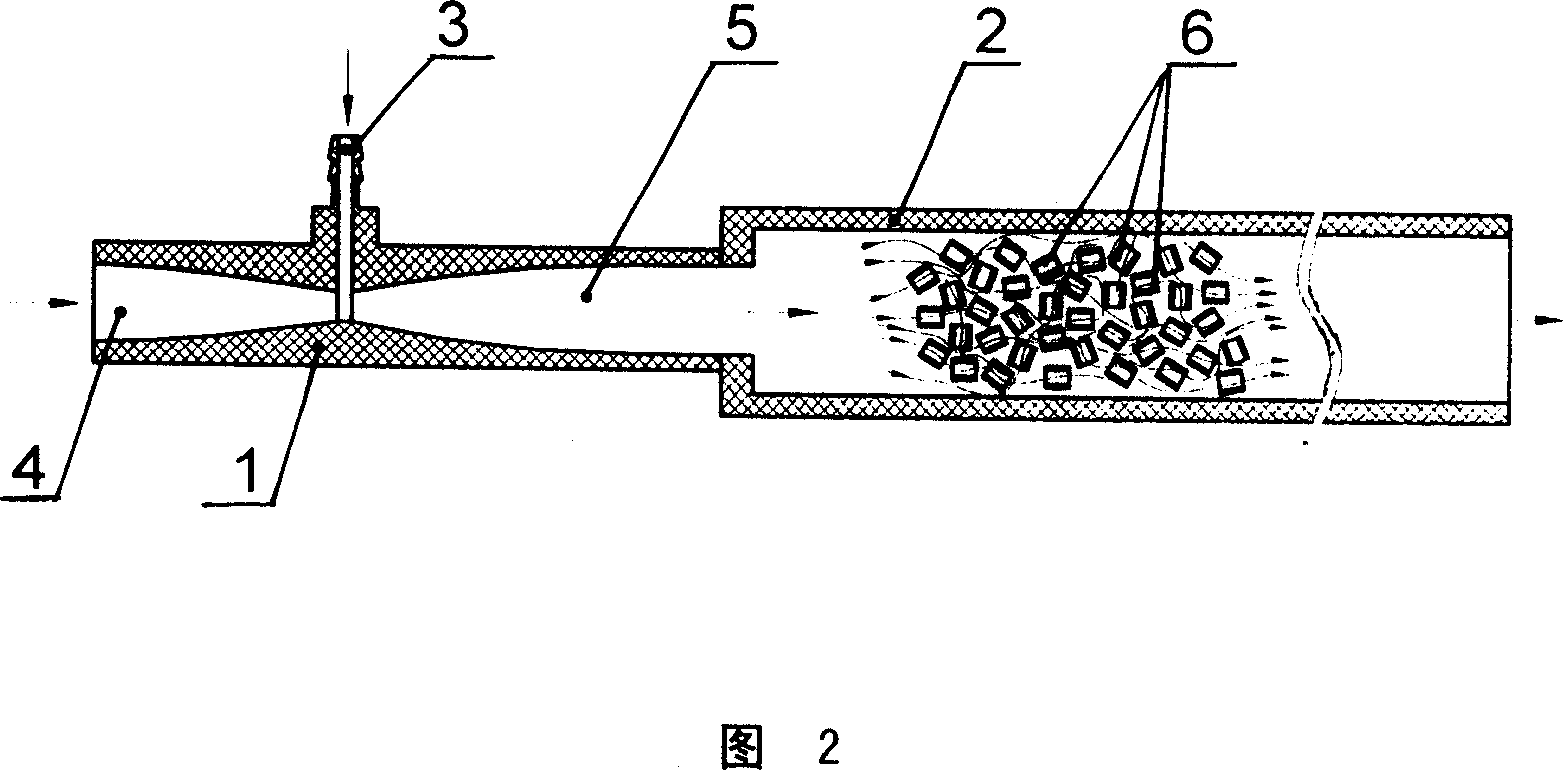

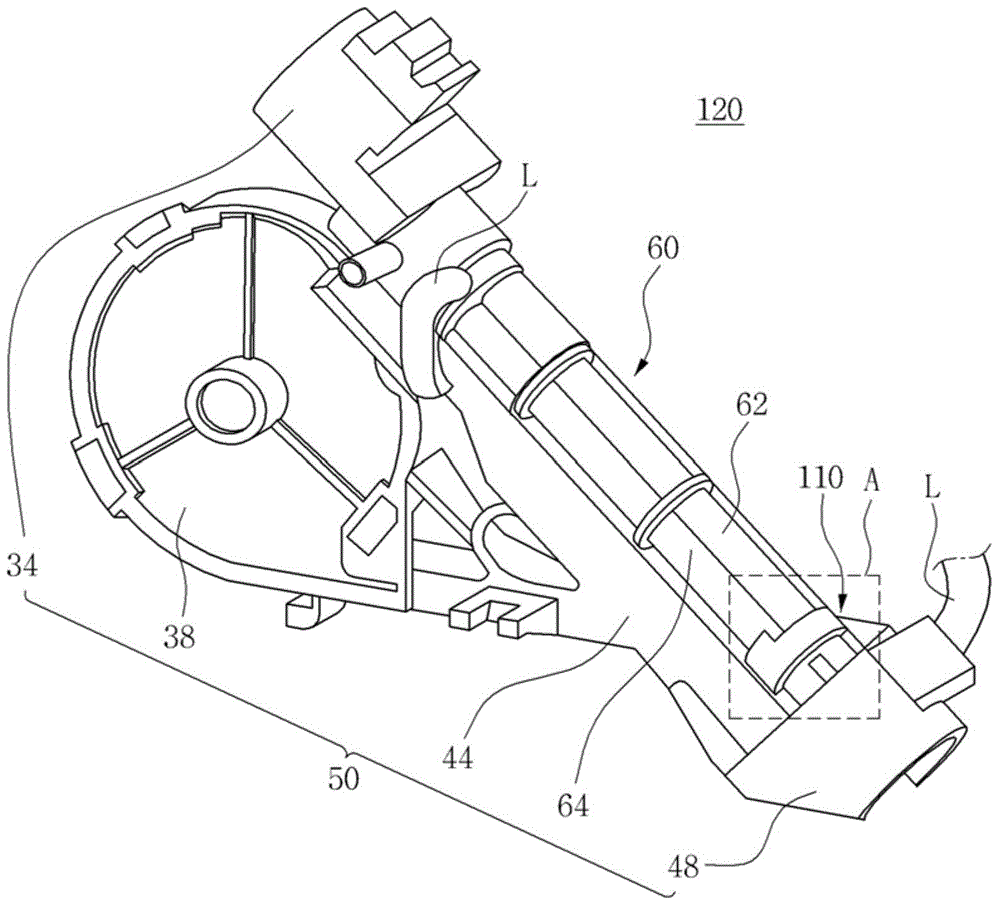

Ducted fuel injection with ignition assist

ActiveUS20170114763A1Increase ignition delayWell mixedInternal combustion piston enginesFuel injection apparatusCombustion chamberSoot

Various technologies presented herein relate to enhancing mixing inside a combustion chamber to form one or more locally premixed mixtures comprising fuel and charge-gas to enable minimal, or no, generation of soot and / or other undesired emissions during ignition and subsequent combustion of the locally premixed mixtures. To enable sufficient mixing of the fuel and charge-gas, a jet of fuel can be directed to pass through a bore of a duct causing charge-gas to be drawn into the bore creating turbulence to mix the fuel and the drawn charge-gas. The duct can be located proximate to an opening in a tip of a fuel injector. An ignition assist component can be located downstream of the duct to facilitate ignition of the fuel / charge-gas mixture.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

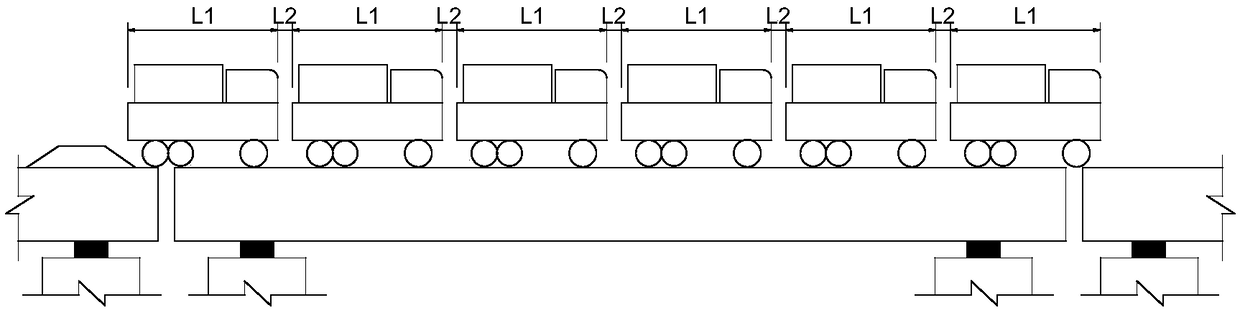

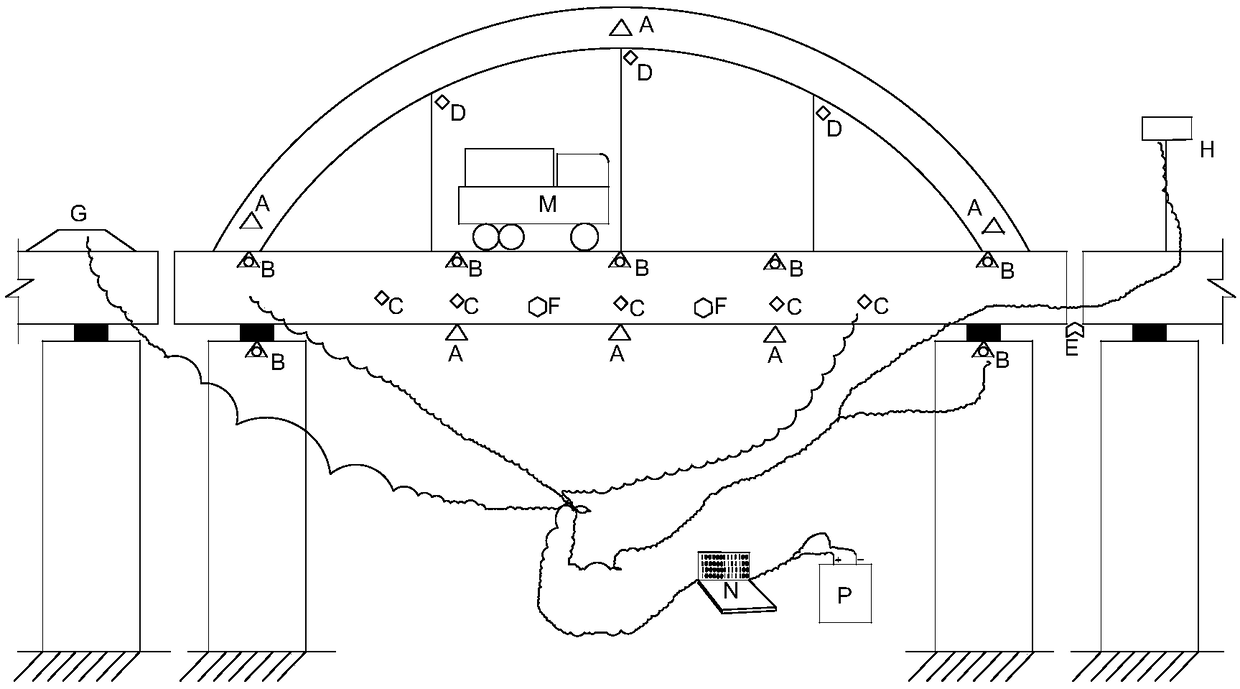

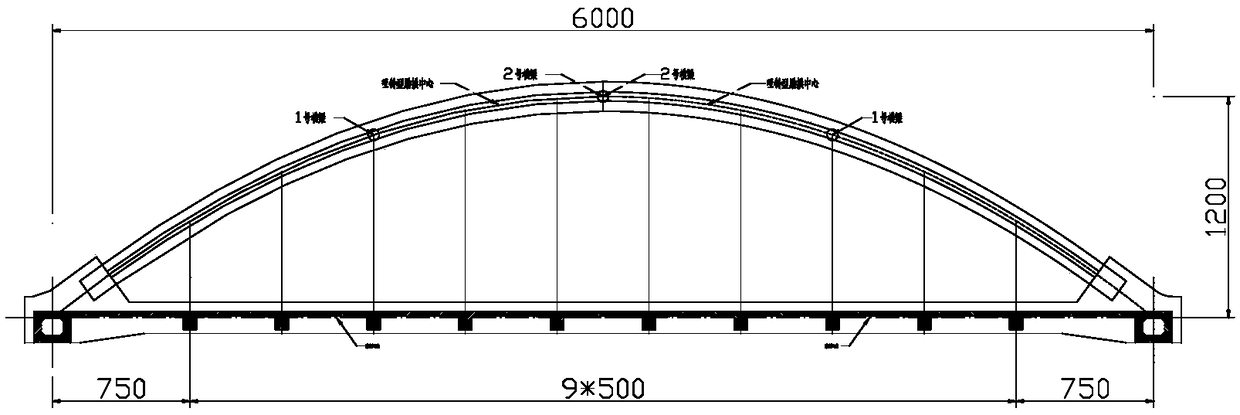

Short-term monitoring and bearing capacity evaluation method for existing bridges

InactiveCN108982030AHigh technical contentIncrease added valueElasticity measurementData acquisitionEngineering

The invention discloses a short-term monitoring and bearing capacity evaluation method for existing bridges, and belongs to the technical field of highway engineering detection. The method comprises determining a loaded verification coefficient by a quasi-static equivalent load test; determining the static dynamic characteristics of a bridge by a dynamic equivalent load test and an operation loadtest, wherein the quasi-static equivalent load test includes the determination of a test type, the determination of an equivalent vehicle and the installation and commissioning process of a sensor; performing the equivalent load test and the operation load test; performing data acquisition and data processing. The method provided by the invention has less investment in practical application, but has high technical added value; has little impact on traffic, can achieve monitoring and evaluation without traffic interruption, and has a large amount of data that can be processed, complete information, and high evaluation accuracy.

Owner:YUNNAN UNIV

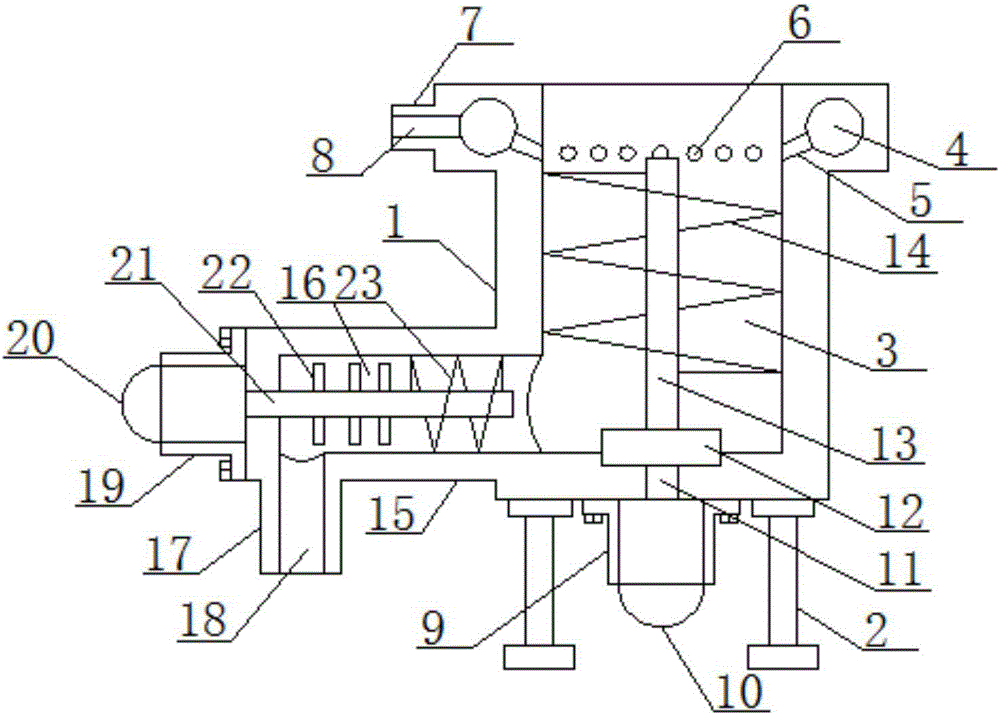

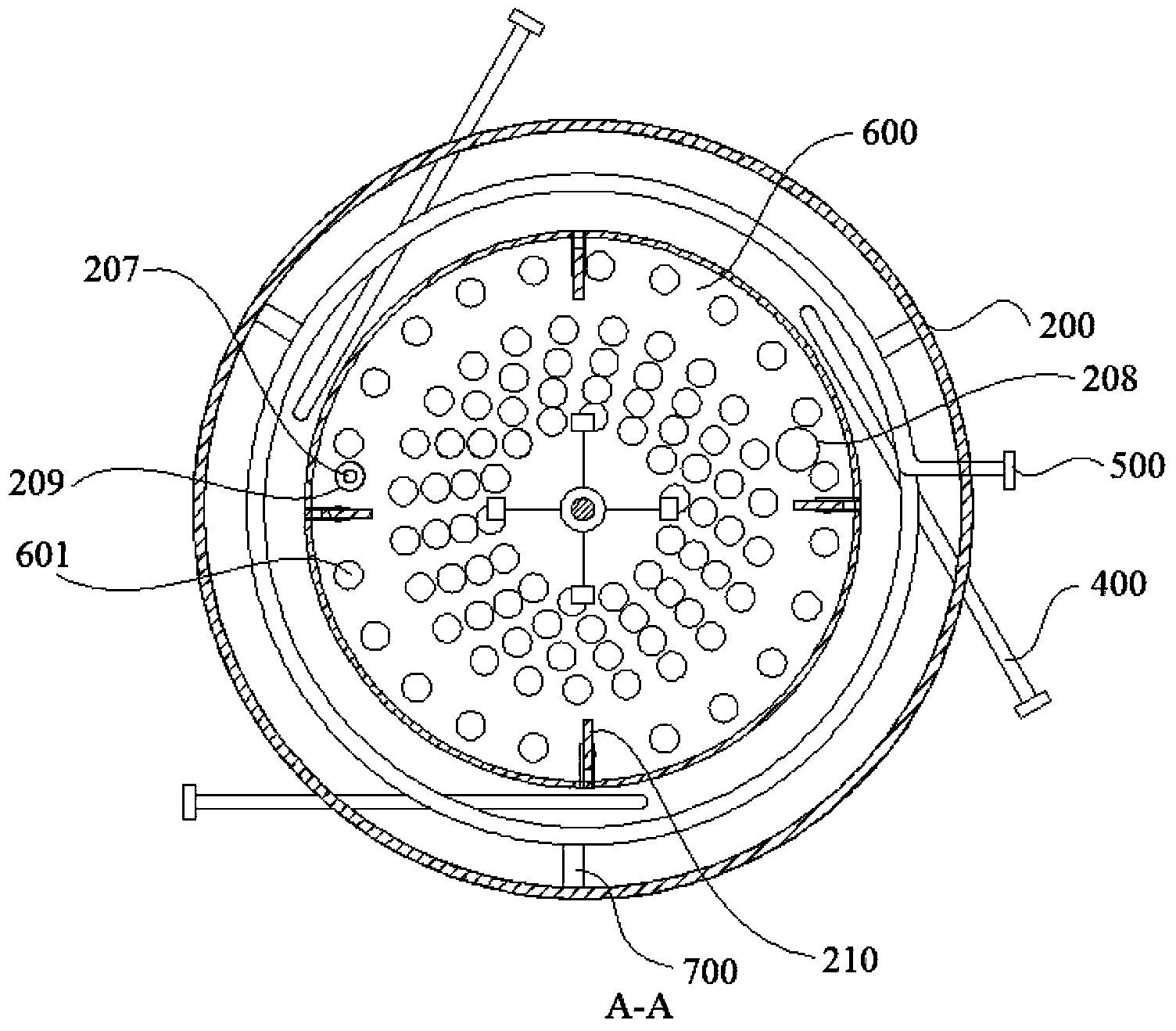

Mixer for adding oil into sludge in sewage treatment

ActiveCN107433164AIncrease burn rateIncrease profitTransportation and packagingMixer accessoriesCombustionRotation method

The invention discloses a mixer for adding oil into sludge in sewage treatment. The mixer comprises a kettle-type housing, a stirring space is arranged in the center of the kettle-type housing, the side of the bottom of the kettle-type housing is fixedly provided with support legs through bolts, an annular hollow chamber is arranged in the side of the top of the kettle-type housing, the outer surface of the kettle-type housing is provided with a fuel injection pipe integrated with the kettle-type housing, a fuel injection hole communicated with the annular hollow chamber is arranged in the fuel injection pipe, oblique spray holes communicated with the annular hollow chamber and the stirring space are arranged in the kettle-type housing and a mist spray nozzle is installed in each one of the oblique spray holes. The mixer can spray fuel in the form of mist to the sludge surface, control sludge under stirring or downward conveying action according to a rotation method of a spiral blade and realize multiple purposes, has a high utilization ratio, effectively realizes liquid-solid mixing, increases a mixing rate and increases the combustion rate of sludge.

Owner:湖南仁天环保工程有限公司

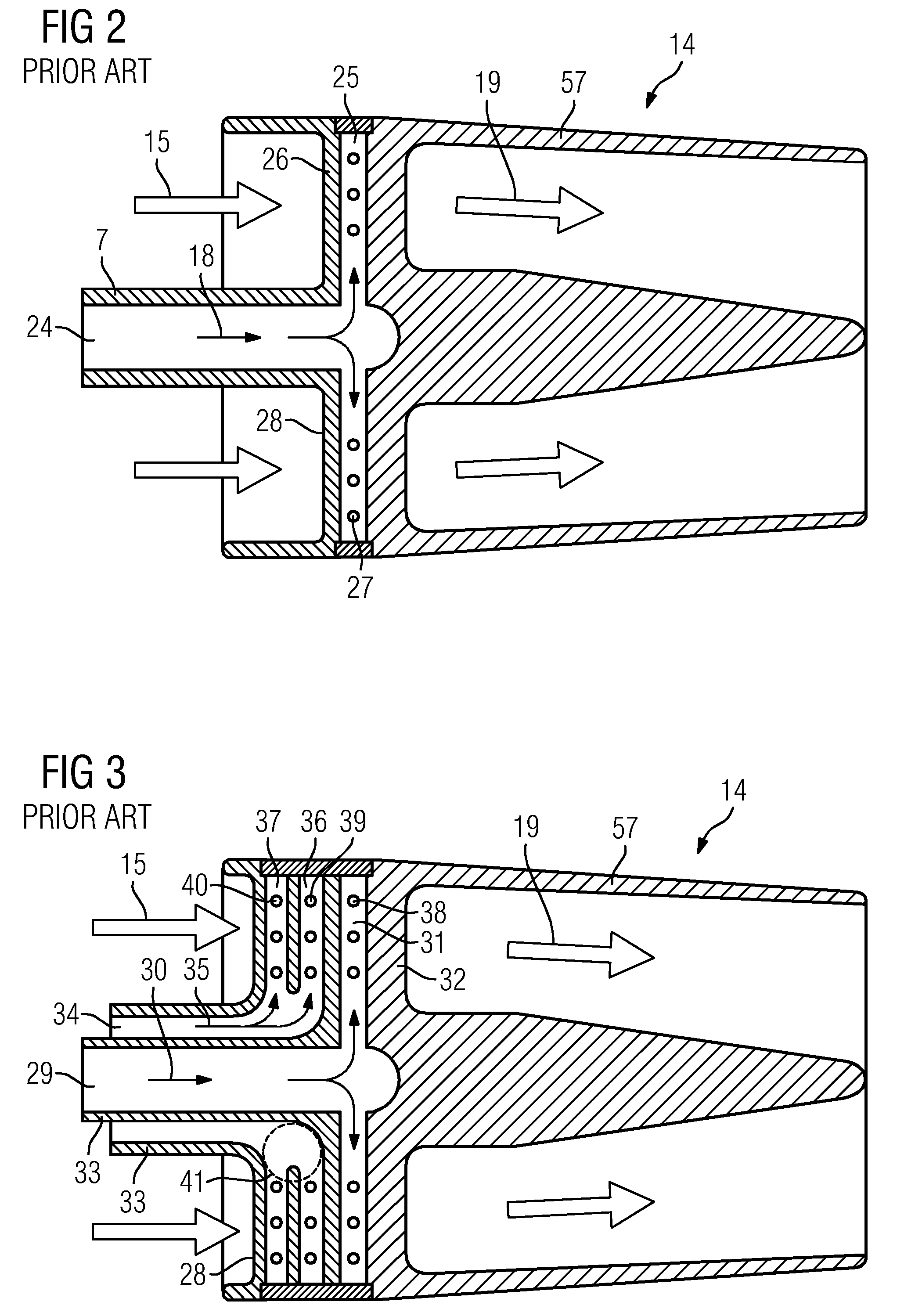

Apparatus and method of using supersonic combustion heater for hypersonic materials and propulsion testing

InactiveUS6948306B1Enhance rate of mixCombustion efficiency be increaseCosmonautic condition simulationsContinuous combustion chamberHybrid systemSpeed of sound

A supersonic combustion apparatus and method of using the same including a side wall cavity having an enhanced mixing system with ground-based oxygen injection for hypersonic material and engine testing.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

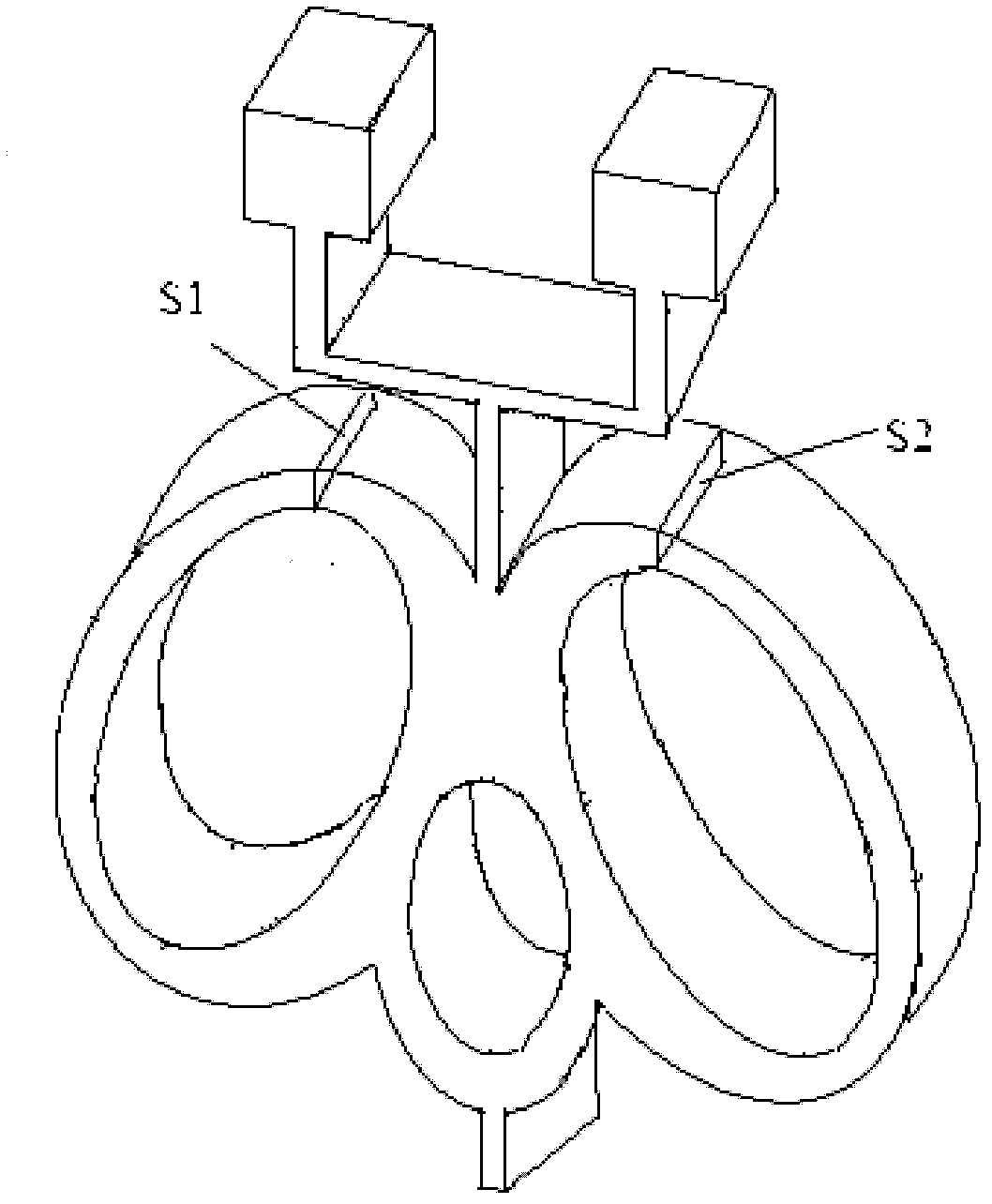

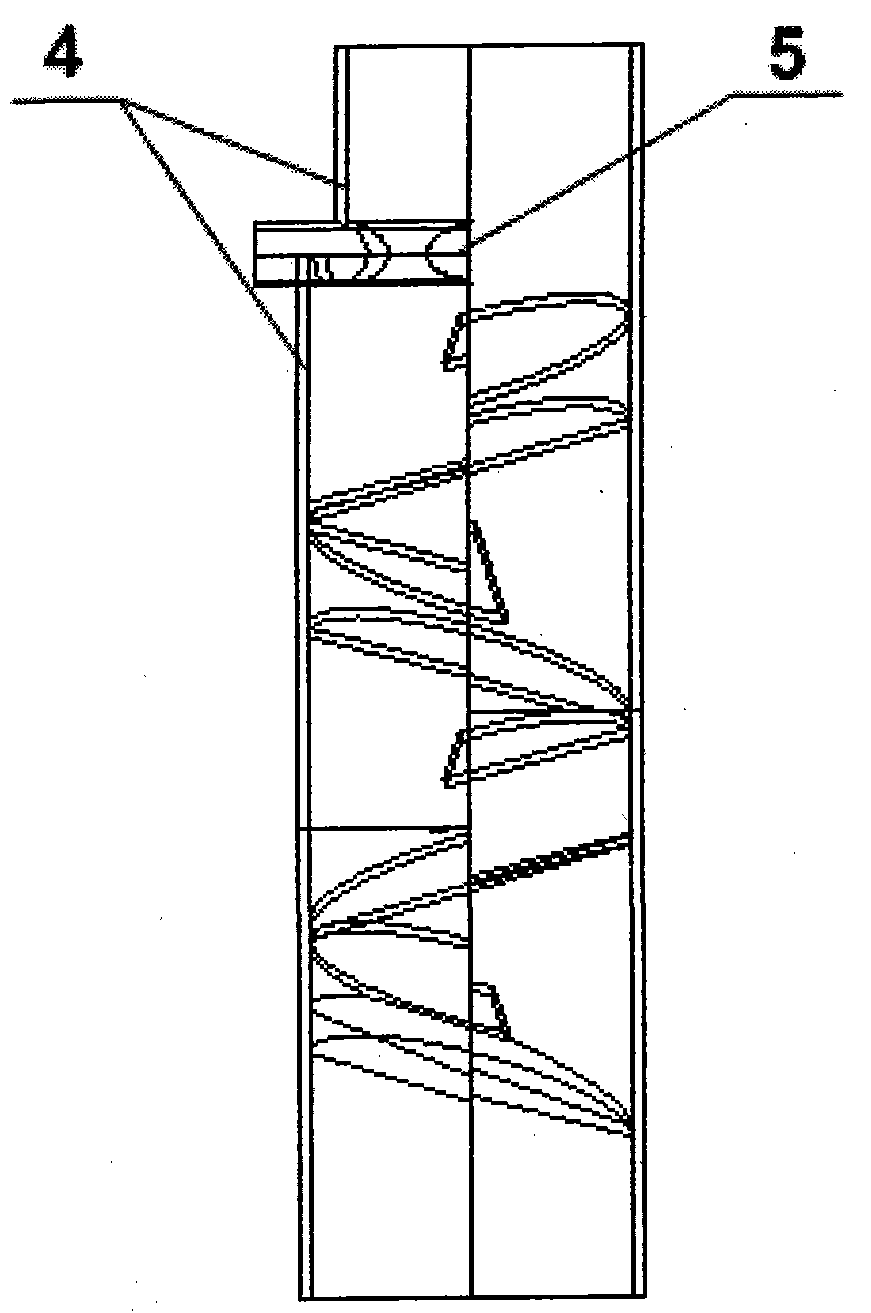

Novel backflow-type micro mixer

InactiveCN102553482AIncrease contact areaIncrease the lengthMixersLaboratory glasswaresJet flowInlet channel

The invention discloses a novel backflow-type micro mixer which comprises a mixing cavity, wherein the mixing cavity is respectively communicated with at least two inlet channels and an outlet channel; the at least two inlet channels are respectively communicated with a primary mixing channel which is of a jet flow structure; the primary mixing channel is communicated with an inlet of the mixing cavity; each of two sides of the inlet of the mixing cavity is provided with an oval annular feedback channel; one end of each oval annular feedback channel is communicated with the upper part of the mixing cavity, and the other end of each oval annular feedback is communicated with the lower part of the mixing cavity; and the outlet of the lower end of the mixing cavity is communicated with the outlet channel. The novel backflow-type micro mixer provided by the utility model is capable of improving the mixing efficiency.

Owner:张端 +1

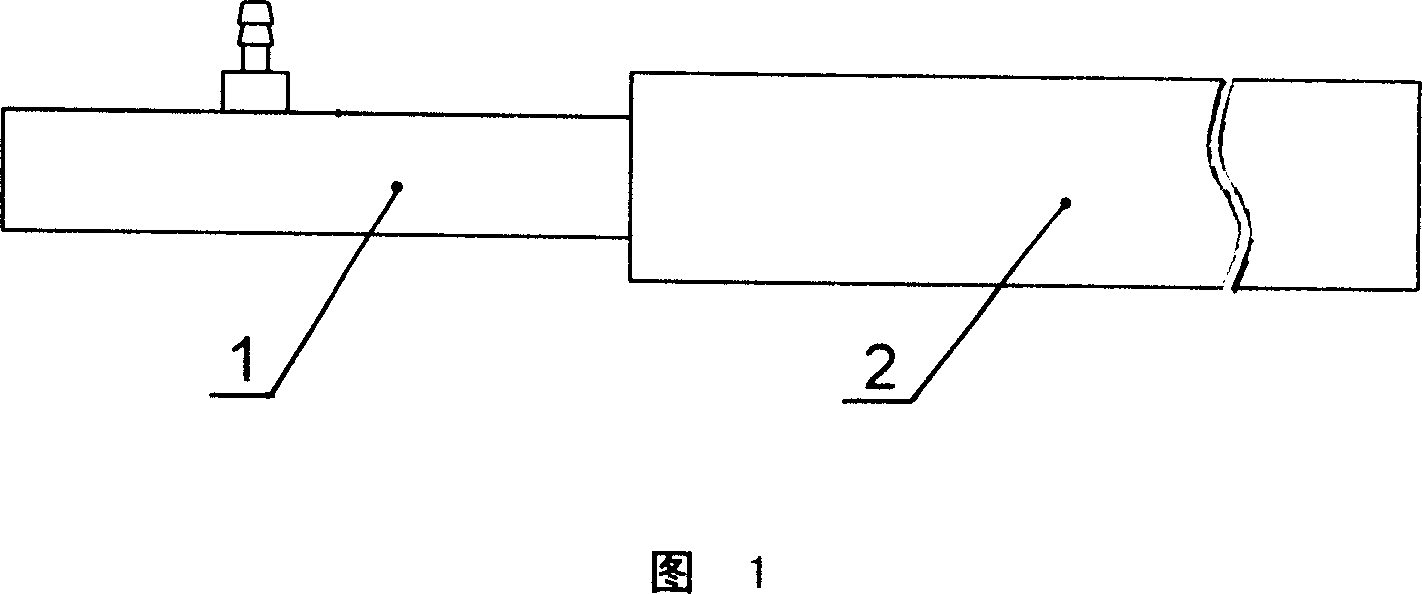

Gas-water turbulent flow re-mixing tube

InactiveCN1973977AImprove air-water mixing ratioSimple structureFlow mixersMixing methodsEngineeringWater gas

Owner:朱鲁曰

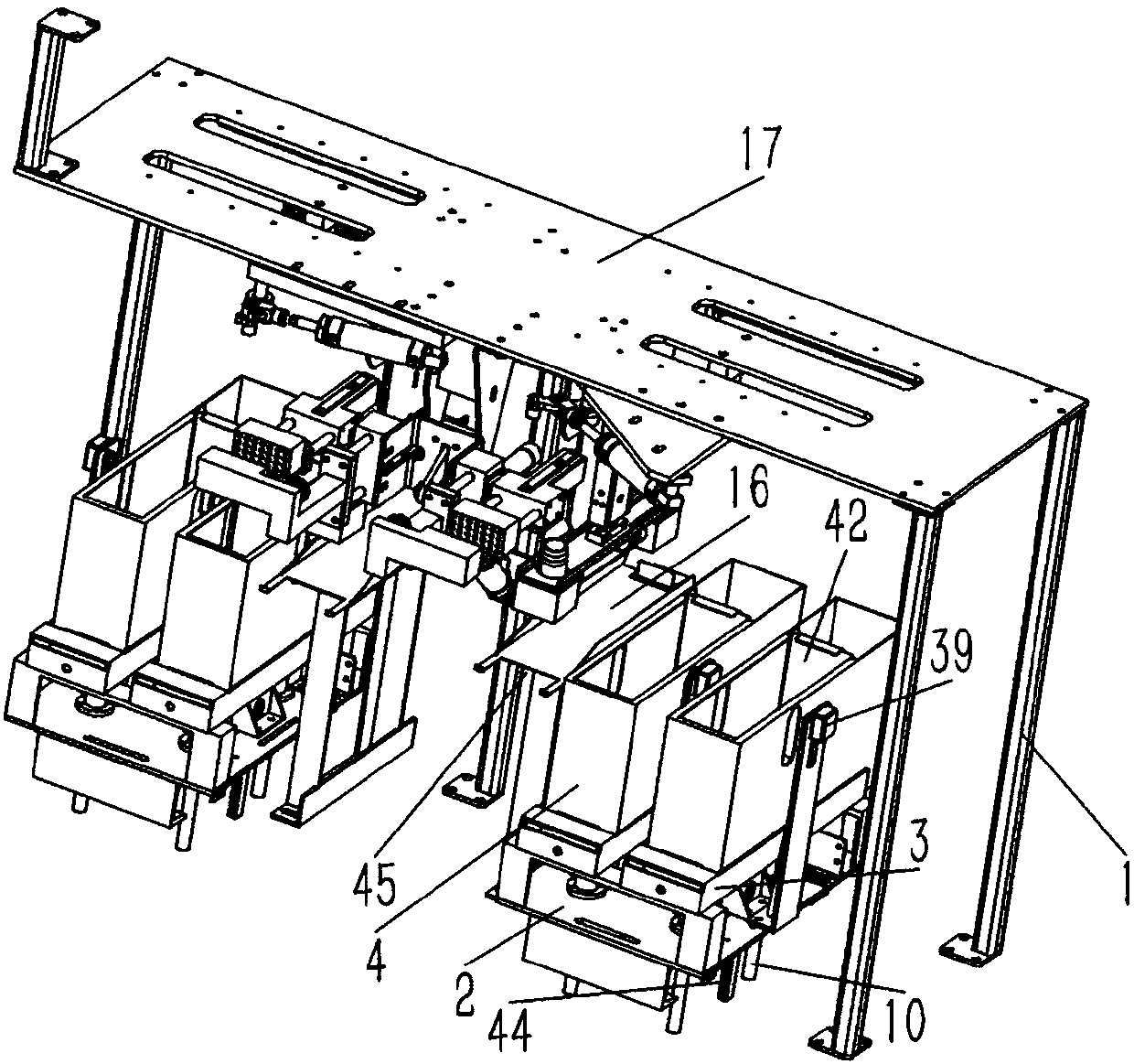

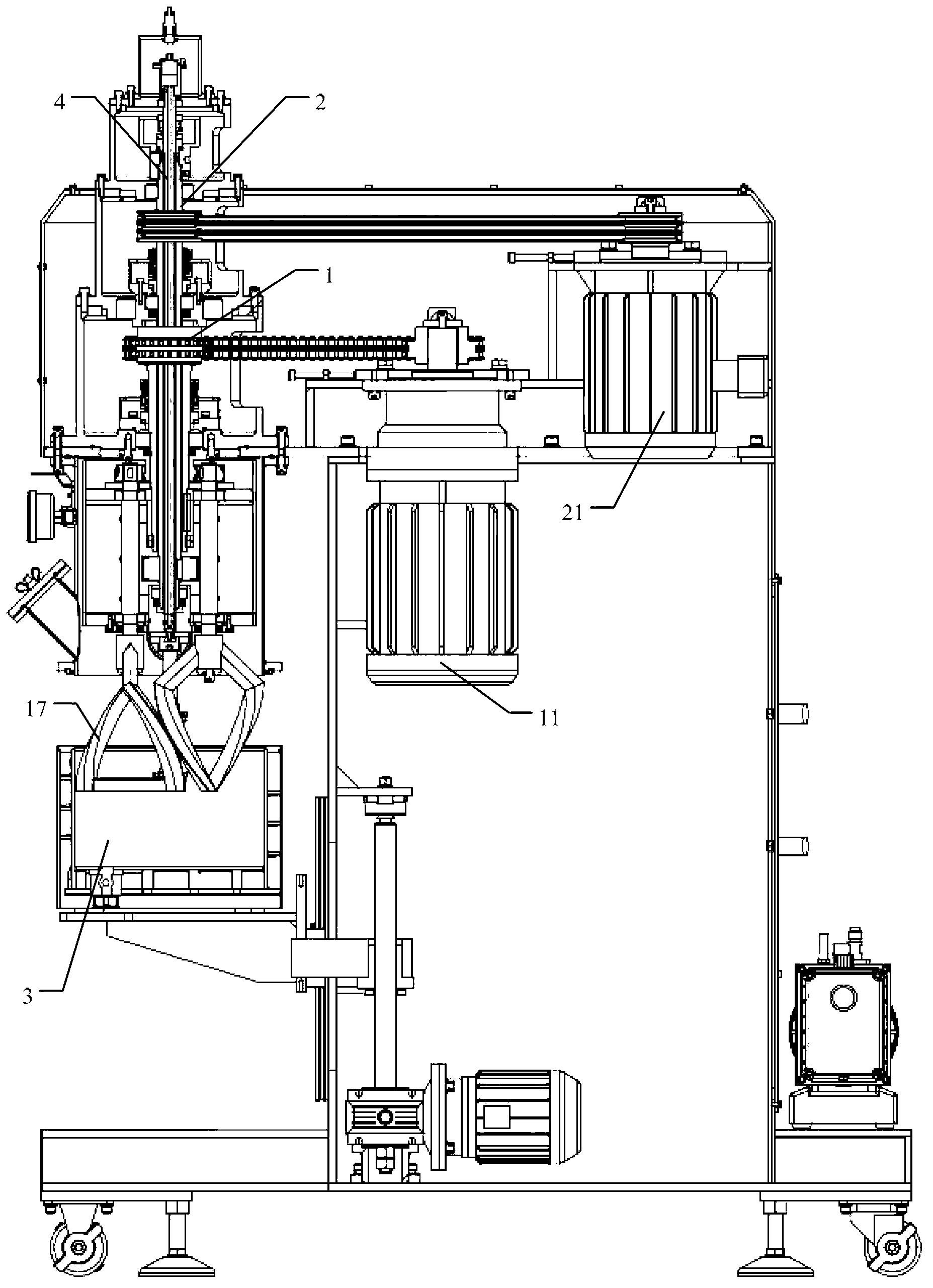

Full-automatic material and bag arranging type packing machine

ActiveCN107600473AOutstanding and Beneficial Technical EffectsPrevent Dry Run ConditionsWrapper twisting/gatheringPackaging automatic controlEdible mushroomEngineering

The invention provides a full-automatic material and bag arranging type packing machine, belongs to the technical field of packing machines, and aims at overcoming the shortages of low automation degree, low production efficiency and high labor input in the prior art. The machine comprises a packing bag absorbing part which is arranged on a rack, a culture material bagging part which is arranged above the packing bag absorbing part, a packing sealing part which is arranged at one side of the culture material bagging part, and a culture material bagged product outlet part which is formed in oneend of the packing sealing part, wherein a display screen for human-machine interaction and a PLC control box are arranged beside the culture material bagged product outlet part. Compared with the prior art, the machine has the advantages of being high in automation degree, high in production efficiency, and low in labor input cost; the machine is applicable to packing bag arranging, etc., and particularly applicable to the environment of massive bagging of edible mushroom culture materials.

Owner:ZHEJIANG HONGYE EQUIP TECH

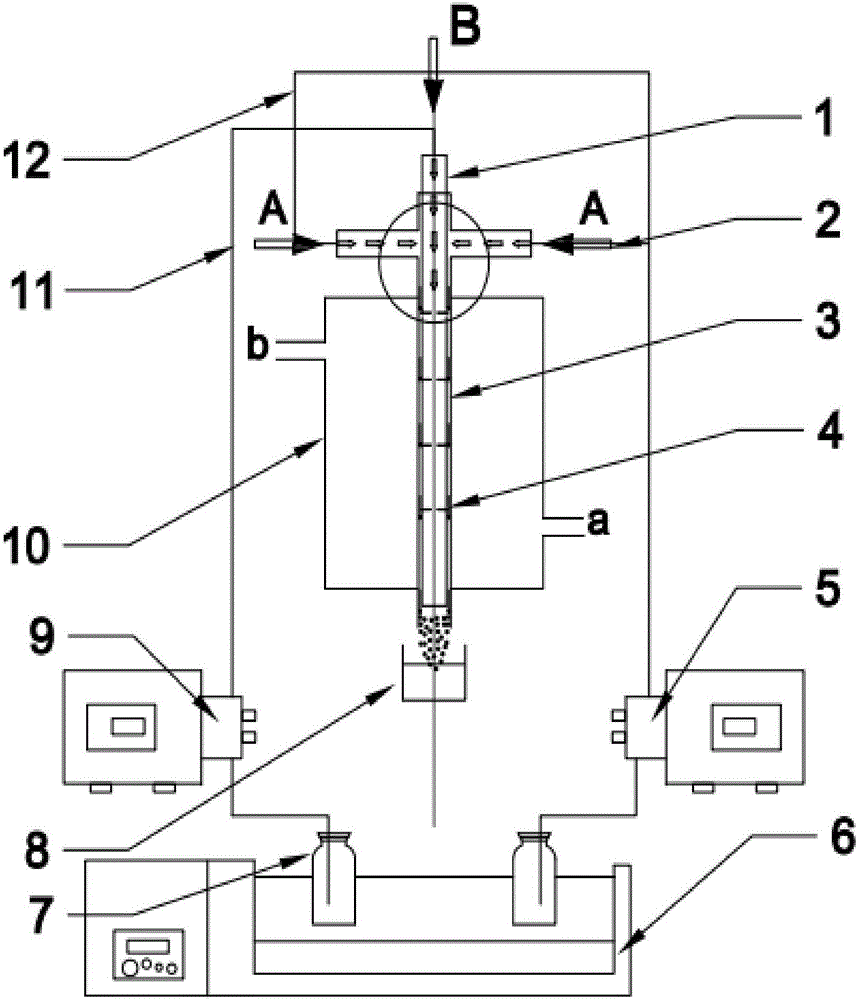

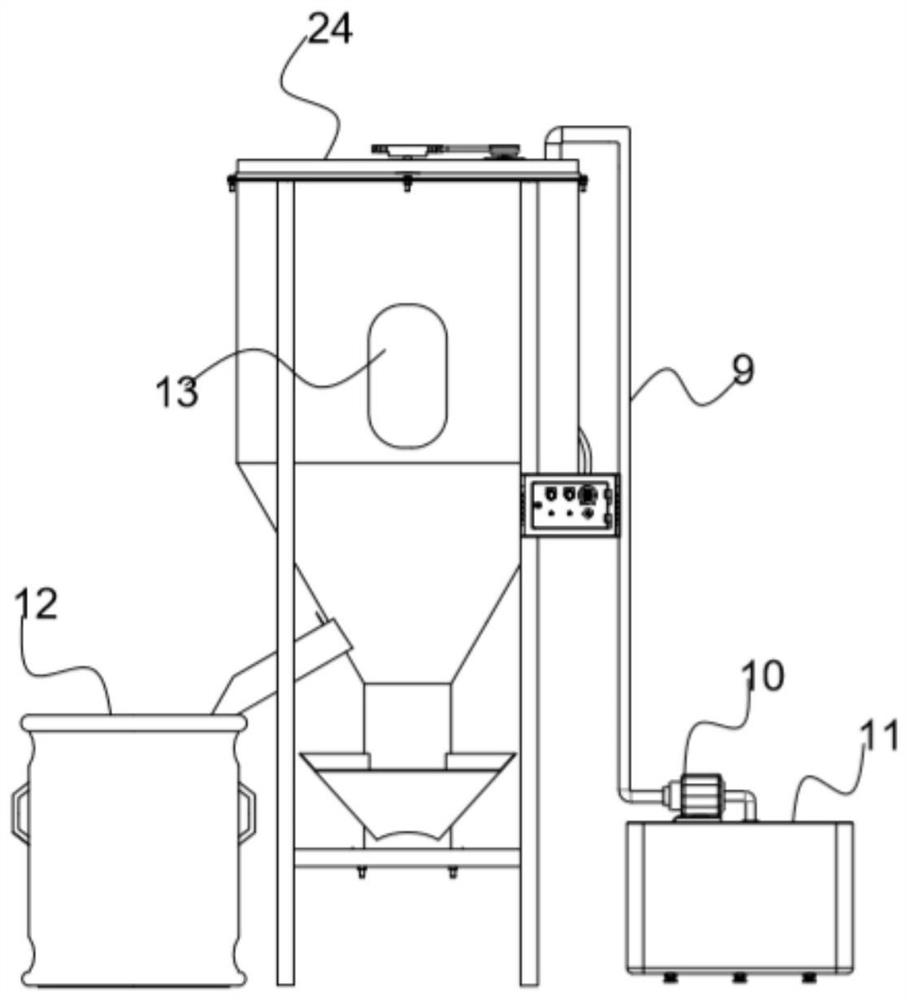

Coaxial impinging-stream reactor and method for continuously preparing nanometer material

InactiveCN106475025AIncrease the mix rateIncrease productivityFlow mixersTransportation and packagingProcess engineeringThermal water

The invention discloses a coaxial impinging-stream reactor and a method for continuously preparing a nanometer material. The coaxial impinging-stream reactor can be used for preparing the nanometer material through a liquid phase method. The main structure of the coaxial impinging-stream reactor comprises a reactor inner tube, a reactor outer tube, a feeding tube, a hot-water cyclic heat-preserving tank, etc., wherein the reactor inner tube and the reactor outer tube adopt a vertical design manner and maintain to be coaxial to form an annular microchannel reaction area; the reactor inner tube is uniformly provided with 6 rows of micropores along an axial direction, wherein each row of the micropores has a spacing of 12 mm; the reactor inner tube is uniformly provided with 5 micropores along a radial direction, wherein the diameters of the micropores are 0.5 mm; the bottom part of the reactor inner tube is sealed; an opening is arranged between the reactor inner tube and the reactor outer tube, so a product can flow out; and the product synthesis process and the material taking process can be simultaneously performed, so continuous preparation of the nanometer material is realized. The coaxial impinging-stream reactor provided by the invention can provide good reaction conditions for strengthening alternate heat and mass transfer processes, and has extremely great application potential in the aspect of promoting continuous preparation of the nanometer material through the liquid phase method.

Owner:QINGDAO UNIV OF SCI & TECH

Fluid mixer and mixing element member

InactiveUS20080106969A1Efficient mixingIncrease the mix rateFlow mixersTransportation and packagingEngineeringMechanical engineering

Disclosed is a fluid mixer to mix different fluids, the fluid mixer that includes a top section and a holder section. The top section has a plurality of inlets and a mixing portion communicates with the plurality of inlets. The holder section has a discharge portion that communicates with the mixing portion through a passage and a mixing member to mix the different fluids in the middle of the passage.

Owner:ANEMOS

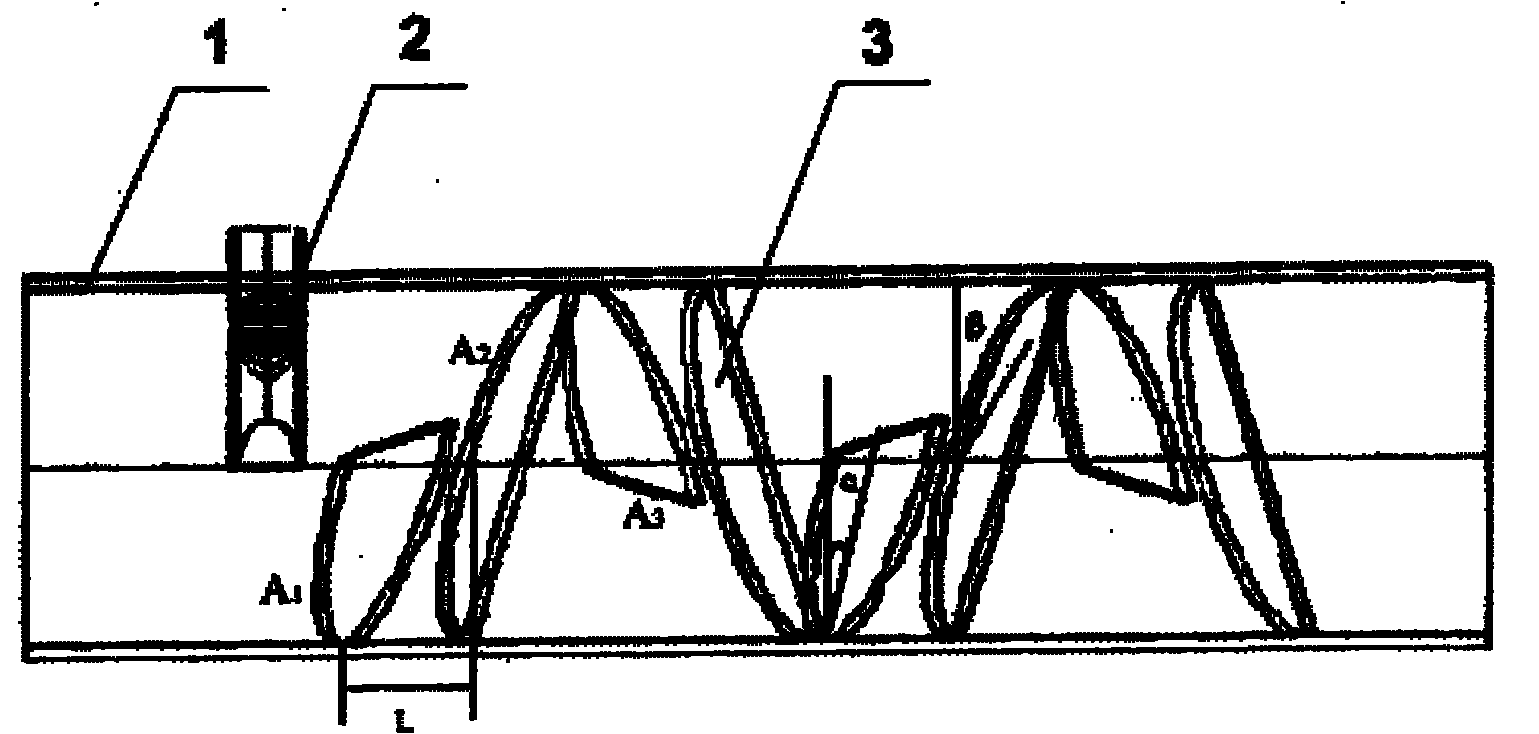

Novel static mixer for gas mixing

InactiveCN101940886AExtended stayIncreased turbulence intensityFlow mixersSulfur preparation/purificationSEMI-CIRCLESulfur

The invention relates to a novel static mixer for gas mixing in a natural gas sulfur recovery super Claus process, which can effectively solve the problem of full-mixing incapability in a turbulent mixing process and improve gas mixing effect. The technical scheme is that: a main pipe is a circular steel pipe, while an auxiliary pipe is vertically inserted into the main pipe from a central line of a right semi-circle of the section of the main pipe; an outlet of the auxiliary pipe has a wedged structure; eight blades are arranged in the main pipe; each blade has a circular arc shape, an inclined angle alpha, a rotating angle beta and a height H; an axial interval between every two blades is L; the pipe walls of the main pipe and the auxiliary pipe are 5 to 10mm thick; and the wedged outlet is 5 to 10mm wide. The static mixer can prolong the residence time of gases in the mixture, and improve the turbulence intensity of the gases to further improve the mixing rates of the mixed gases, and can be used for the natural gas purification sulfur recovery super Claus process.

Owner:SOUTHWEST PETROLEUM UNIV

Metal powder mixing device and method and high-throughput metal alloy preparing system

ActiveCN107570696AIncreased chance of collisionImprove mixing efficiencyAdditive manufacturing apparatusFlow mixersMetal alloyHigh flux

The invention relates to a metal powder mixing device and method and a high-throughput metal alloy preparing system. The metal powder mixing device comprises a cylinder and a metal powder carrier gaspipeline. A metal powder carrier gas inlet is further formed in the side wall of the upper end of the cylinder. The metal carrier gas pipeline is parallel to the tangential direction of the side wallof the cylinder. Metal powder and carrier gas can form carrier gas carrying metal powder after passing through the metal powder carrier gas pipeline, the formed carrier gas enters the cylinder from the metal powder carrier gas inlet at a constant speed, and annular turbulent flow is formed in the cylinder to be mixed and scattered. In the metal powder mixing method, the carrier gas carrying metalpowder enters the cylinder and forms the annular turbulent flow, and therefore the probability of metal powder colliding is improved, and the metal powder mixing efficiency is further improved. By means of the high-throughput metal alloy preparing system, metal powder mixed evenly through the metal powder mixing device can be machined, and a needed metal alloy can be more accurately obtained.

Owner:向勇

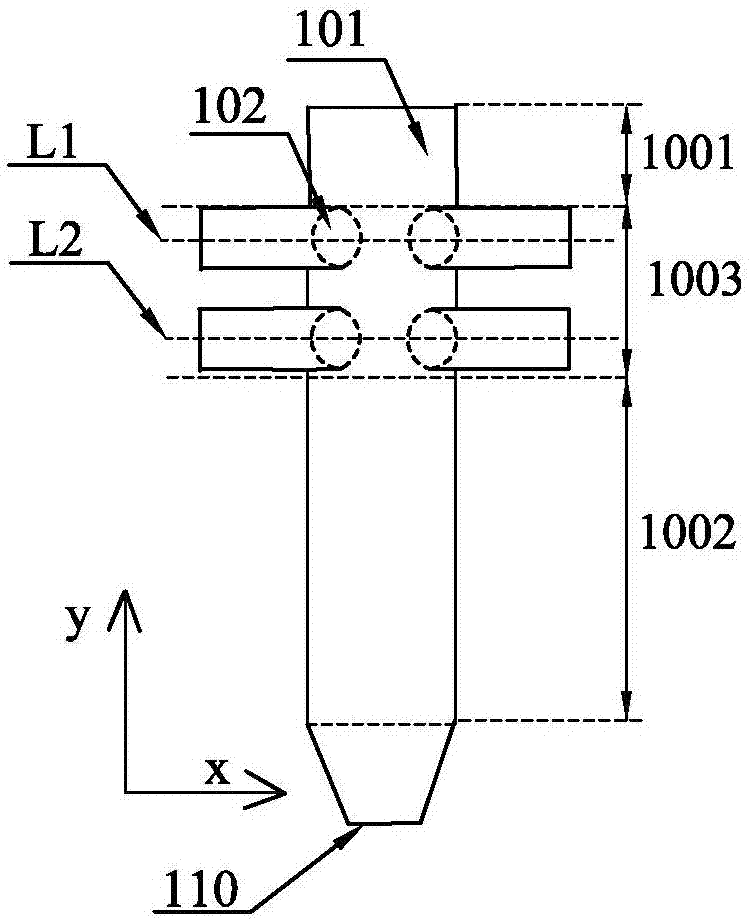

Plant glue stirring device

InactiveCN106731951AWell mixedIncrease viscosityRotary stirring mixersTransportation and packagingEngineeringMetal sheet

The invention provides a plant glue stirring device. The plant glue stirring device structurally comprises a container tank; a first stirring mechanism is mounted in the container tank along the vertical direction; a second stirring mechanism is mounted in the container tank along the horizontal direction; the first stirring mechanism is provided with a first motor and a vertical rotary shaft; the vertical rotary shaft is horizontally provided with a first connecting rod, and a first stirring rod and a second stirring rod which are located on the first connecting rod; metal sheets are arranged at two sides of the first stirring rod and the second stirring rod respectively; the second stirring mechanism is provided with a second motor and a horizontal rotary shaft; a third stirring rod and a fourth stirring rod are arranged at upper and lower sides of the horizontal rotary shaft respectively; metal sheets are arranged on the third stirring rod and the fourth stirring rod, and liquid at the lower part of the container tank and liquid at the upper part of the container tank are sufficiently mixed, so that multilayered and all-directional stirring is realized; plant glue in the container tank is sufficiently mixed to form the plant glue with relatively high viscosity and stable performance.

Owner:HUZHOU GUANGBO BIOTECH

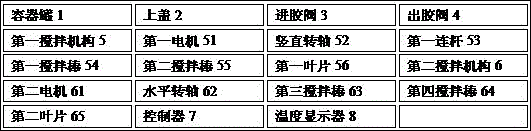

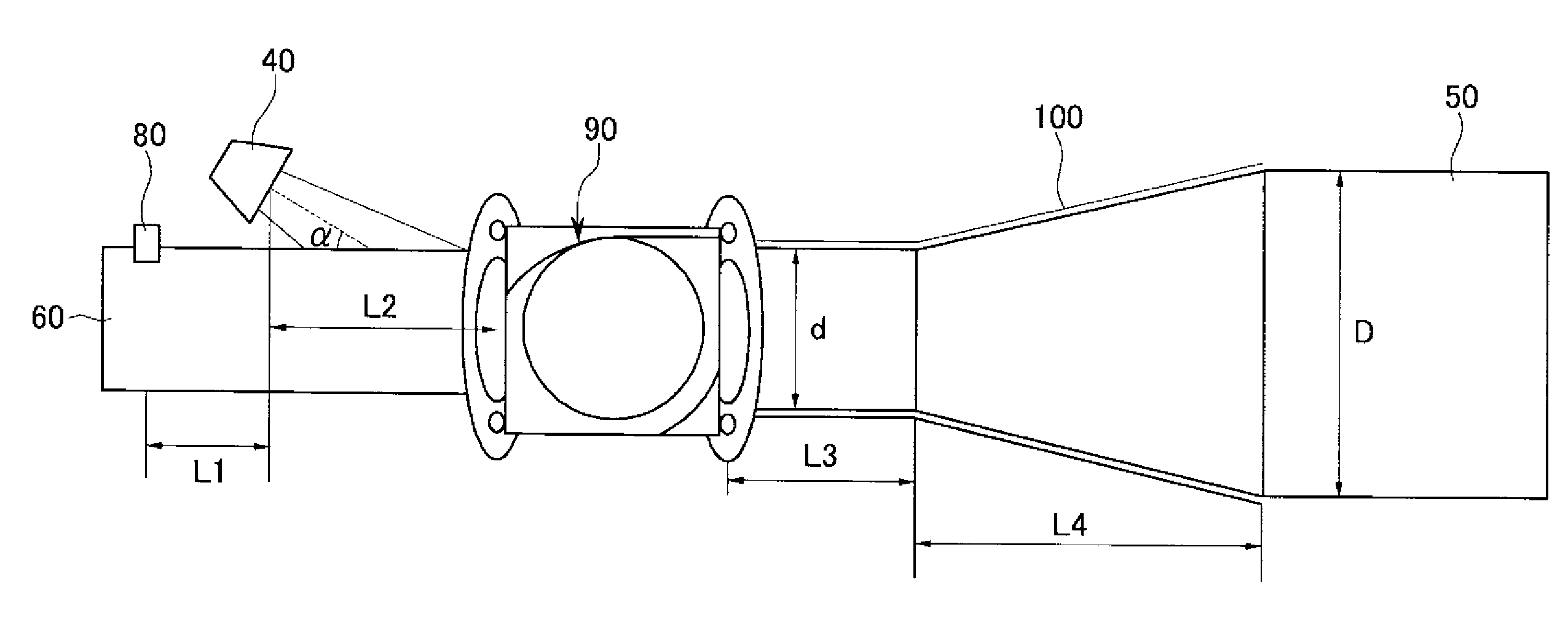

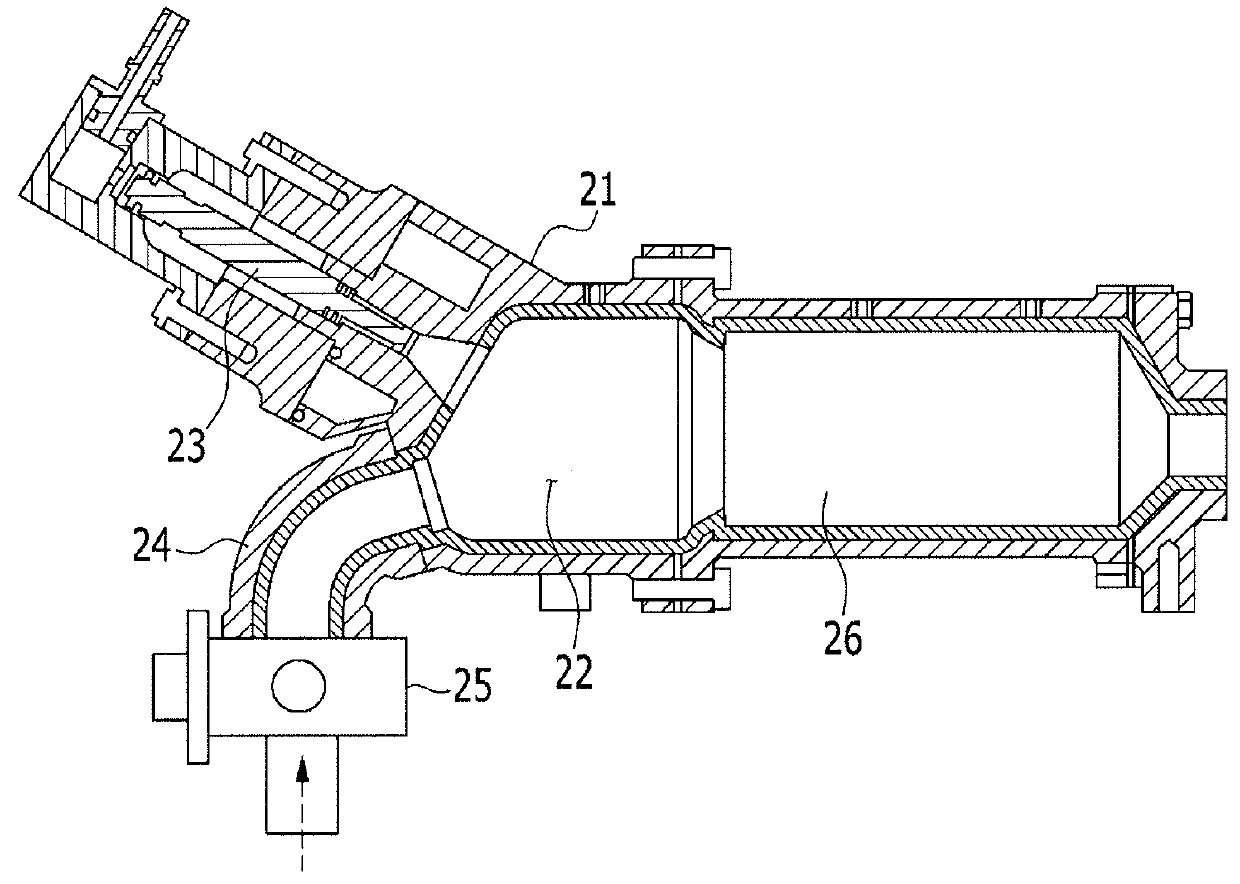

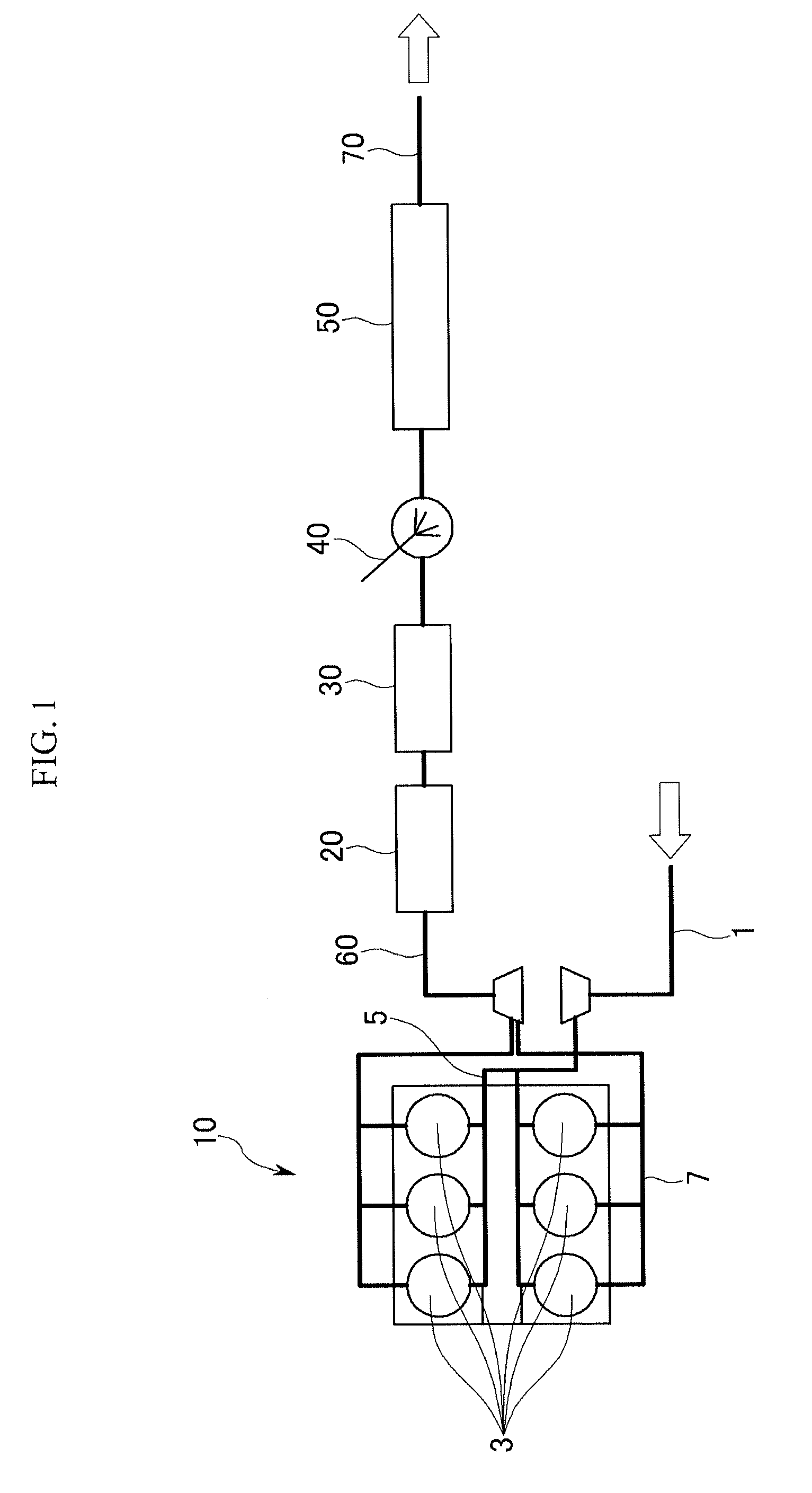

Apparatus for Reducing Nitrogen Oxide in Exhaust Pipe

ActiveUS20090151334A1Increase the mix rateReducing nitrogen oxideGas treatmentInternal combustion piston enginesExhaust fumesEngineering

An apparatus for reducing nitrogen oxide in an exhaust pipe, may include a nitrogen oxide sensor that is mounted in the exhaust pipe and that measures amount of the nitrogen oxide in exhaust gas, a nozzle that is disposed on the exhaust pipe to be spaced apart from the nitrogen oxide sensor to a downstream side of the nitrogen oxide sensor by a first predetermined length and that injects urea corresponding to the amount of the nitrogen oxide, a mixer that mixes the urea with the exhaust gas and that is disposed at a downstream side of the nozzle on the exhaust pipe to be spaced apart by a second predetermined length from the nozzle, and a de-nitrification catalyst reaction device that is disposed at a downstream side of the mixer on the exhaust pipe, purifies the nitrogen oxide, and includes an inlet portion having a predetermined length.

Owner:HYUNDAI MOTOR CO LTD +1

Stirring machine

ActiveCN104107655AWell mixedIncrease the mix rateFlow mixersRotary stirring mixersMixing effectBiochemical engineering

The invention provides a stirring machine which is simple in structure, good in material uniform-mixing effect, adjustable in material mixing temperature and material discharging temperature, and high in efficiency. The stirring machine comprises a transmission apparatus, an accepting apparatus and a stirring apparatus; the transmission apparatus and the stirring apparatus are both arranged on the accepting apparatus and are in connection; the accepting apparatus consists of a body sleeve and a tank body; a heating apparatus and a cooling apparatus are arranged between the body sleeve and the tank body; the body sleeve is provided with a support plate; the tank body is connected with a connection plate; the tank body is provided with a flow baffle plate; and the tank body is provided with a filtering apparatus.

Owner:GUIZHOU CHIEN YEH PLASTIC

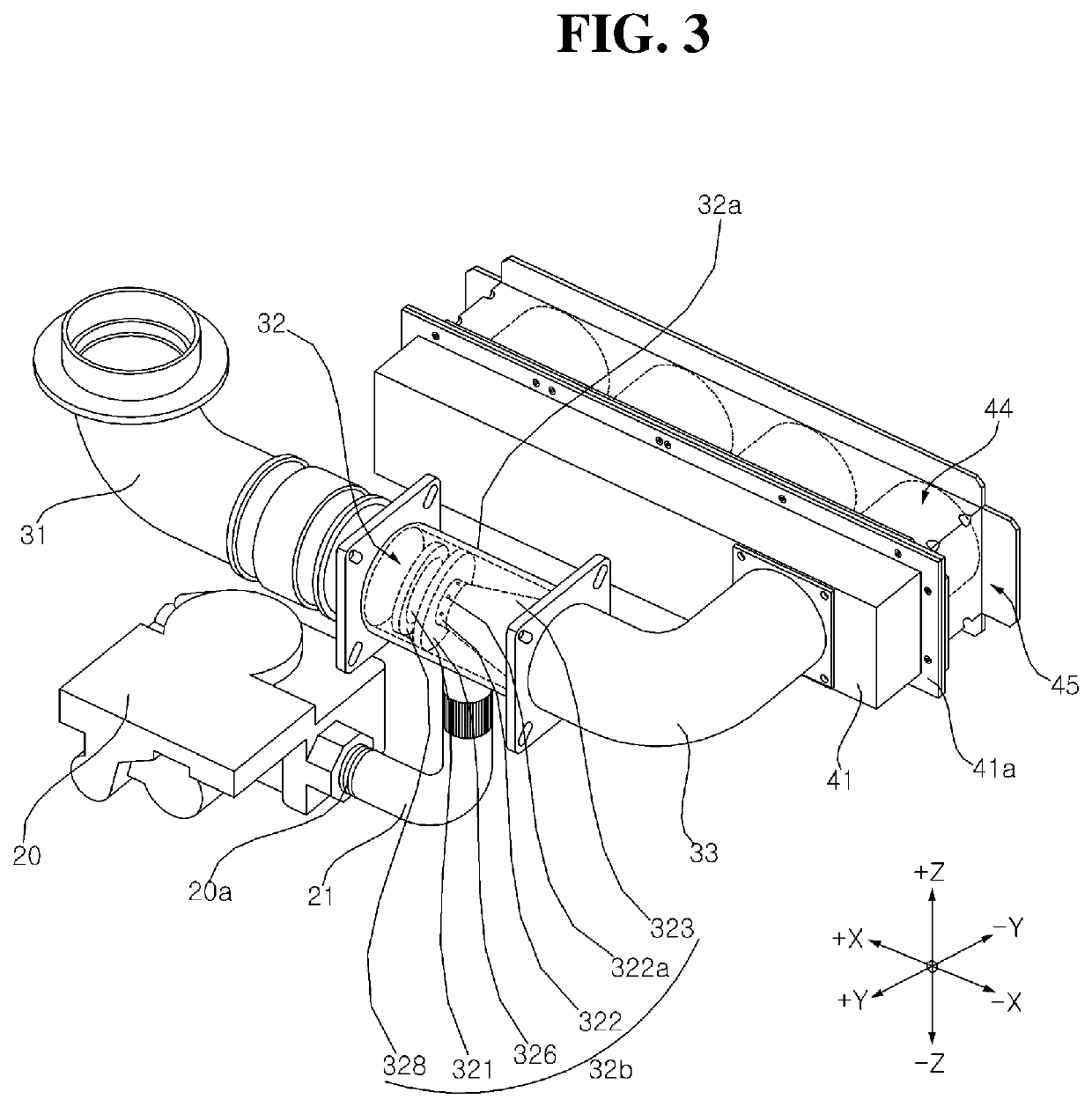

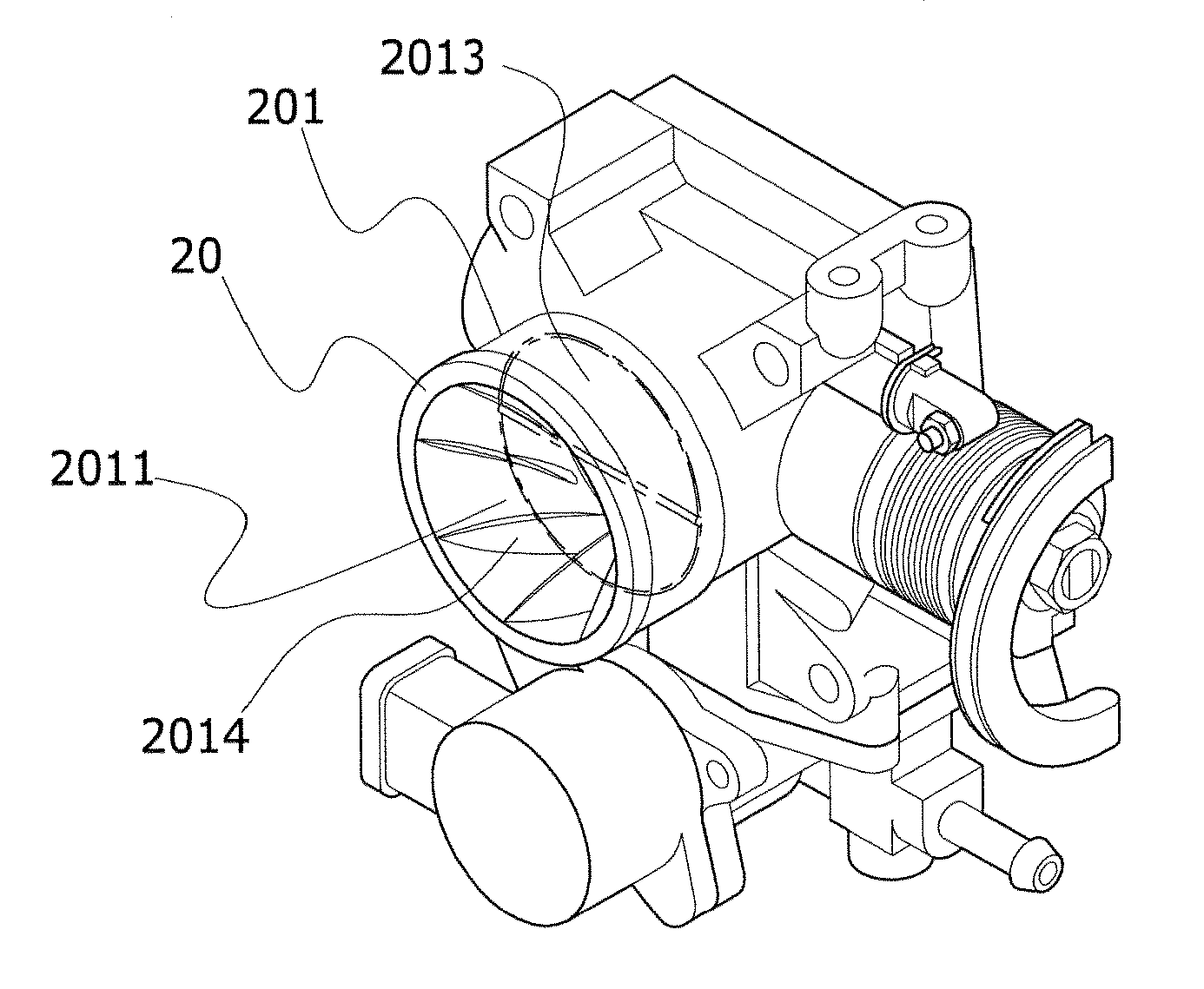

Gas furnace

ActiveUS20210140632A1Reduce nitrogen oxide emissionsIncrease temperatureFluid heatersFuel supply regulationCombustorExhaust fumes

A gas furnace according to an embodiment of the present disclosure includes: a mixer for mixing air and a fuel gas, which are introduced through an intake pipe and a manifold, respectively, to form a mixture; a mixing pipe through which the mixture, having passed through the mixer, flows; a burner assembly for producing a combustion gas by burning the mixture having passed through the mixing pipe; a heat exchanger through which the combustion gas flows; an exhaust pipe through which an exhaust gas, as the combustion gas having passed through the heat exchanger, is discharged outside of the gas furnace; and an inducer for inducing a flow of a fluid through the intake pipe, the mixer, the mixing pipe, the burner assembly, the heat exchanger, and the exhaust pipe. In this case, the mixer has a front end connected to the intake pipe, a rear end connected to the mixing pipe, and a side surface connected to the manifold.

Owner:LG ELECTRONICS INC

Aeration device

ActiveUS20160207805A1High strengthEfficient executionFlow mixersLighting and heating apparatusImpellerDrive shaft

Aeration device includes a hollow casing having a motor therein; a mixing unit formed on front side of the casing and having a discharge hole formed in radial direction and an intake hole formed on front thereof; an impeller located inside the mixing unit and coupled to a driving shaft of the motor, the driving shaft extended to the mixing unit, so as to be rotated with the driving shaft, to generate flow in outward radial direction upon rotation, an air inflow unit having one side end located in front of the impeller and serving as an air inflow pipe for introducing air to the mixing unit; and an auxiliary intake unit located on front side of the impeller to be rotated with the driving shaft of the motor and inserted into the air inflow unit to allow fluid in the air inflow unit to flow backward upon rotation.

Owner:JANG SUN WON

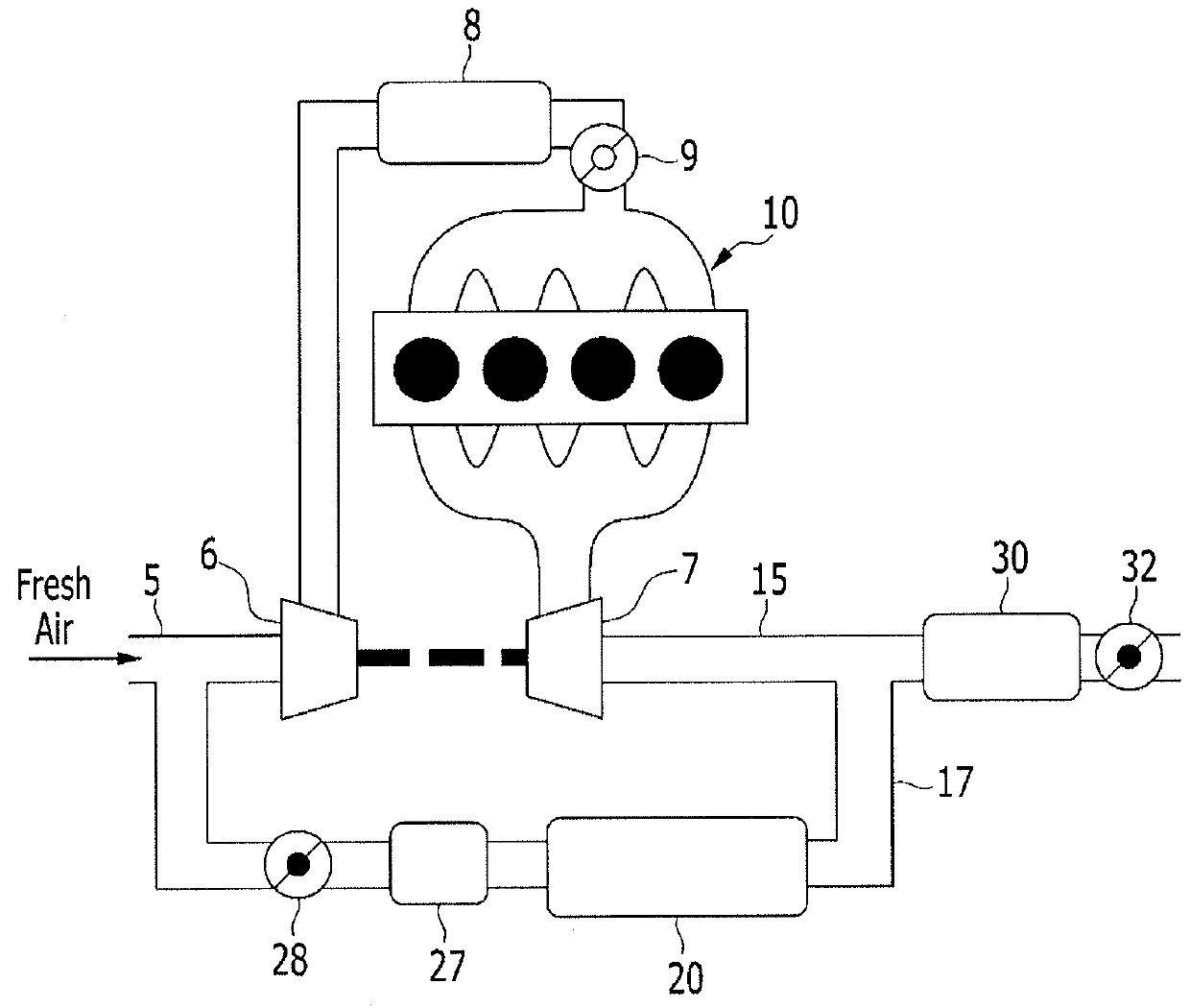

Fuel reforming system and method of controlling flow rate of exhaust gas recirculation gas in a fuel reformer

ActiveUS20180163648A1Degree of opening is decreasedHigh degree of opennessElectrical controlInternal combustion piston enginesGas passingControl valves

A fuel reforming system may include an engine combusting reformed gas to generate mechanical power; an intake line connected to the engine to supply reformed gas and air to the engine; an exhaust line connected to the engine to circulate exhaust gas exhausted from the engine; a fuel reformer provided at an exhaust gas recirculation (EGR) line diverging from the exhaust line, mixing the EGR gas passing through the EGR line with the fuel and reforming the fuel mixed in the EGR gas; and an EGR flow controller determining a target opening degree of a flow rate control valve according to engine running condition, whether or not in a reforming running condition, required amount of EGR gas along to running condition, and controlling opening degree of the flow rate control valve on a basis of the target opening degree.

Owner:HYUNDAI MOTOR CO LTD +1

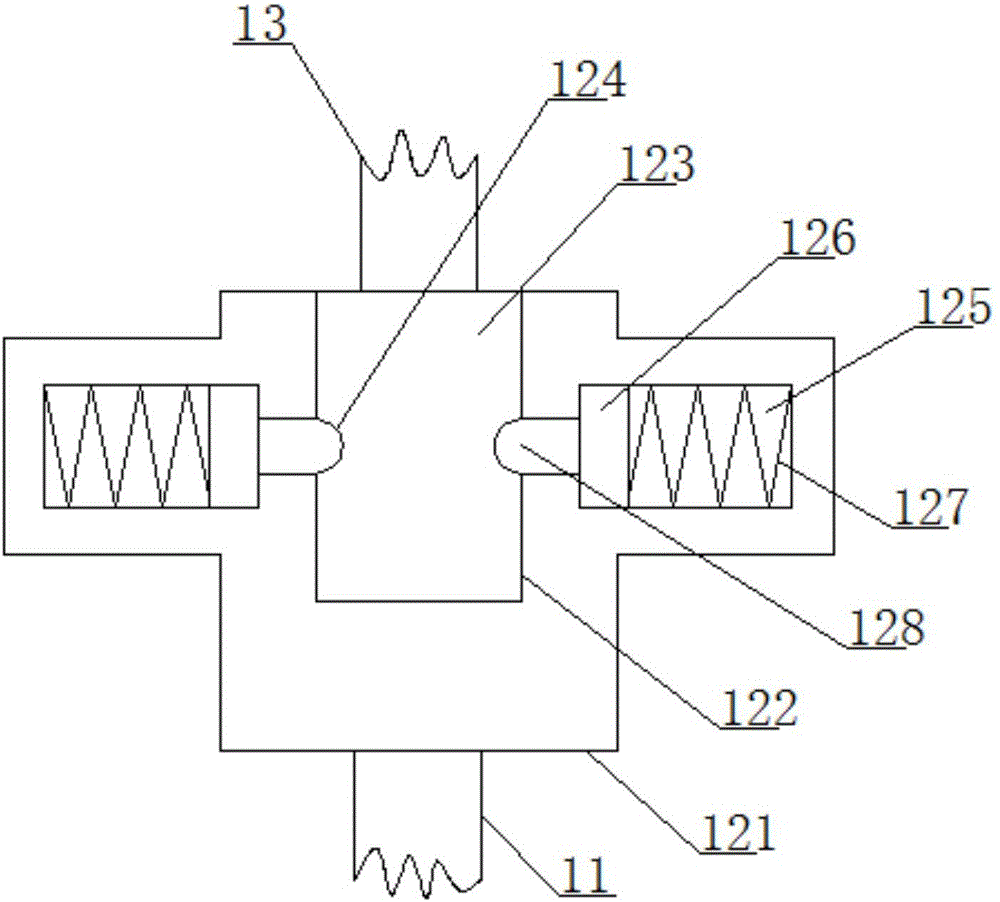

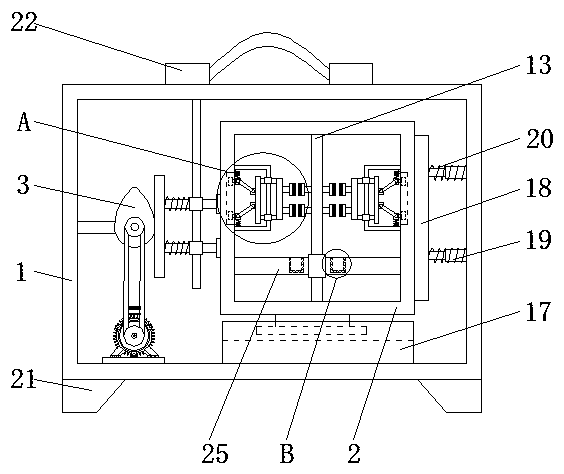

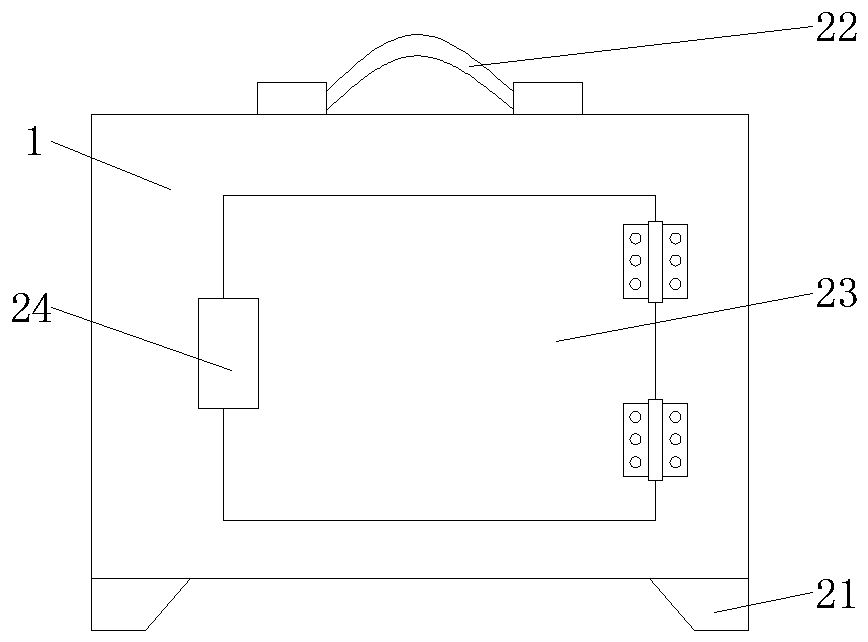

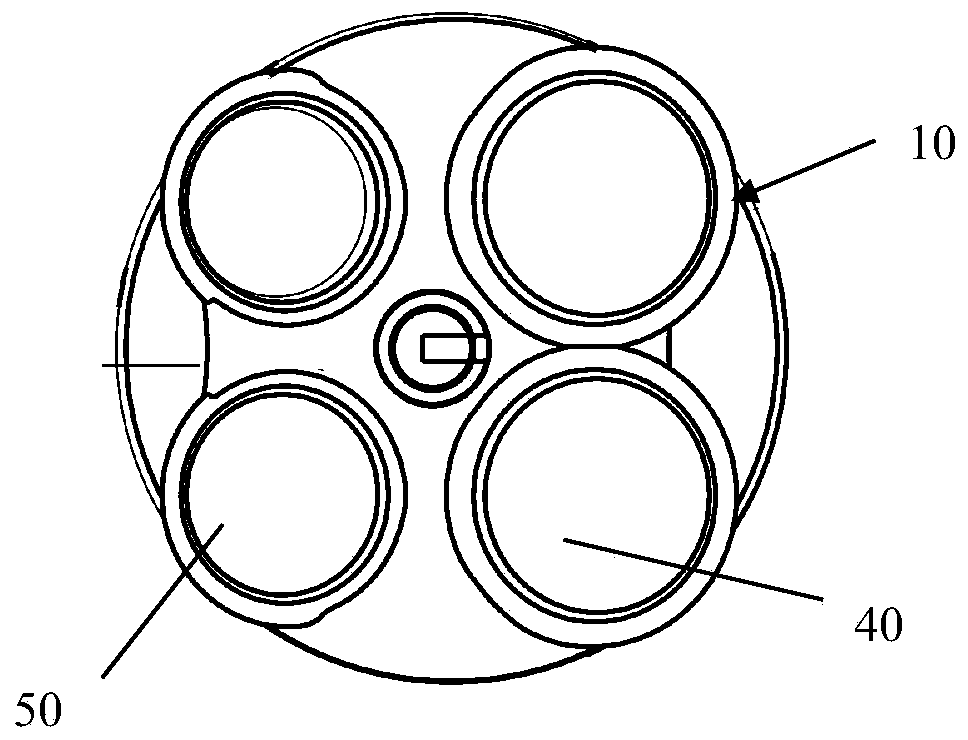

Power mixing machine

InactiveCN103285764AIncrease the mix rateRotary stirring mixersEmulsificationSolventMechanical engineering

The embodiment of the invention discloses a power mixing machine which can effectively improve the mixing rate. The power mixing machine includes: a dispersing main shaft 22 and a stirring main shaft 12 are of a center shaft bushing structure; a dispersing motor 21 is connected to the dispersing main shaft 22 through a belt drive mechanism 23; the dispersing main shaft 22 is connected with at least two dispersing shafts 24 through synchronous belt drive mechanisms 25; each of the dispersing shafts 24 is mounted on a planetary frame 15 by a bearing, and revolves around the planetary frame 15; the dispersing shafts 24 perform autorotation driven by the synchronous belt drive mechanisms; with a high speed rotation of the dispersion main shaft 22, dispersing parts and stirring parts are driven to together form a strong shearing force to materials, solid ingredient materials are rapidly dispersed into solvent materials, and the mixing rate is effectively improved.

Owner:FOSHAN GOLD SILVER RIVER INTELLIGENT EQUIP CO LTD

Powder coating bonding machine

InactiveCN106345346AGood cooling effectImprove work efficiencyRotary stirring mixersTransportation and packagingEngineeringNitrogen gas

The invention discloses a powder coating bonding machine. The powder coating bonding machine comprises a rack, a stirring paddle, a bonding cylinder, a discharge hopper, a driving device, a nitrogen-making device and a first cooling device, wherein one end of the stirring paddle is fixed to the rack, the other end of the stirring paddle extends into the bonding cylinder and is used for stirring powder in the bonding cylinder, and the driving device is used for driving the stirring paddle to rotate; the discharge hopper is communicated with the bonding cylinder and is used for adding the powder to the bonding cylinder; the nitrogen-making device is communicated with the bonding cylinder and is used for conveying nitrogen to the bonding cylinder; the first cooling device comprises a first cooling machine, a first circulating pipeline and a first cooling medium, a first interlayer is arranged on the outer side of the bonding cylinder, and the first cooling machine is communicated with the first interlayer through the first circulating pipeline. The powder coating bonding machine has the advantages of good cooling effect on the powder and high working efficiency, and long-term bonding can be kept.

Owner:佛山市置胜隆机械科技有限公司

Biomass gas three-level swirling flow air distribution low-nitrogen burner

InactiveCN106765104AEfficient combustionEffective emberAir supply regulationGaseous fuel burnerThree levelCombustor

The invention discloses a biomass gas three-level swirling flow air distribution low-nitrogen burner. The burner comprises a biconical burner port; a tertiary air tangential blade is fixedly welded to a throat ring interlayer of the biconical burner port; a tertiary air bellow is fixedly connected to the bottom of the biconical burner port; the biconical burner port is fixedly connected with the top of a secondary air outer sleeve steel pipe through a flange and bolts; the bottom of the secondary air outer sleeve steel pipe is welded to the top of a primary air bellow and the top of a secondary air bellow; and a secondary air heat resistance inner sleeve steel pipe is welded to the inner side of the secondary air outer sleeve steel pipe. According to the biomass gas three-level swirling flow air distribution low-nitrogen burner, through a three-time classified swirling flow air distribution and combustible gas effective combining combustion mode, and matching of the biconical burner port, the primary air bellow and the secondary air bellow, the effect that the mixing ratio of air to combustible gas is increased, so that combustion is more sufficient is achieved, and meanwhile, low nitrogen discharge can be realized, and the low-nitrogen efficient combustion effect is really achieved.

Owner:广州汇迪新能源科技有限公司

Nozzle assembly inside warm water body cleaning device

The invention provides a nozzle assembly inside a warm water body cleaning device. The nozzle assembly, arranged inside a warm water body cleaning device, includes: a cylinder portion, configured in a direction and having one end and the other end; an operation portion, positioned between one end and the other end of the cylinder portion to support the cylinder portion; and a nozzle module, positioned on the other end of the cylinder portion, and having a nozzle structural body and a nozzle cover wrapping the nozzle structural body.

Owner:KOHLER NOVITA

Air Intake Device

InactiveUS20100031920A1Superior mixing rate of air and fuelComplete combustionInternal combustion piston enginesAir intakes for fuelAir currentThrottle

An air intake device, having application in engine air intake systems, and causes air to be rapidly and effectively guided into the engine fuel chambers, which primarily includes a plurality of swirl plates successively circumferentially formed on the inner walls of an air inlet end of an engine throttle body. When air is drawn into the air inlet end, then the swirl plates cause the air to form a vortex air current, which is used to increase the speed of mixing fuel with the air and improve the mixing rate, thereby enabling more complete fuel combustion in the engine fuel chambers.

Owner:CHIEN CHANG HO

Ocean engineering cable recovery device

PendingCN113753673AImprove wiping efficiencyReduce workloadFilament handlingCleaning using toolsMarine engineeringWire wrap

The invention relates to the technical field of ocean engineering, and discloses an ocean engineering cable recovery device. The ocean engineering cable recovery device comprises a box body, an inlet is formed in one side of the box body, an electric wire spool and a cable are arranged in the box body, one end of the cable makes contact with the outer wall of the electric wire spool, and a cable recovery cleaning mechanism is arranged in the box body. According to the ocean engineering cable recovery device, by arranging the cable recovery cleaning mechanism, dirt on the outer wall of the cable can be scraped and wiped in real time when the cable is rotationally stored through the electric wire spool, and meanwhile, the dirt wiping efficiency can be further improved through left-right sliding vibration of a wiping block; the cable can be stored and cleaned in an integrated mode, the workload of workers is greatly relieved, a poke rod automatic ejection mechanism is arranged, cleaning liquid is sprayed to the outer wall of the cable while a telescopic poke rod ascends back and forth, and then the cleaning strength and cleanliness are greatly improved when the cable is wiped by the wiping block in the follow-up process.

Owner:王俊英

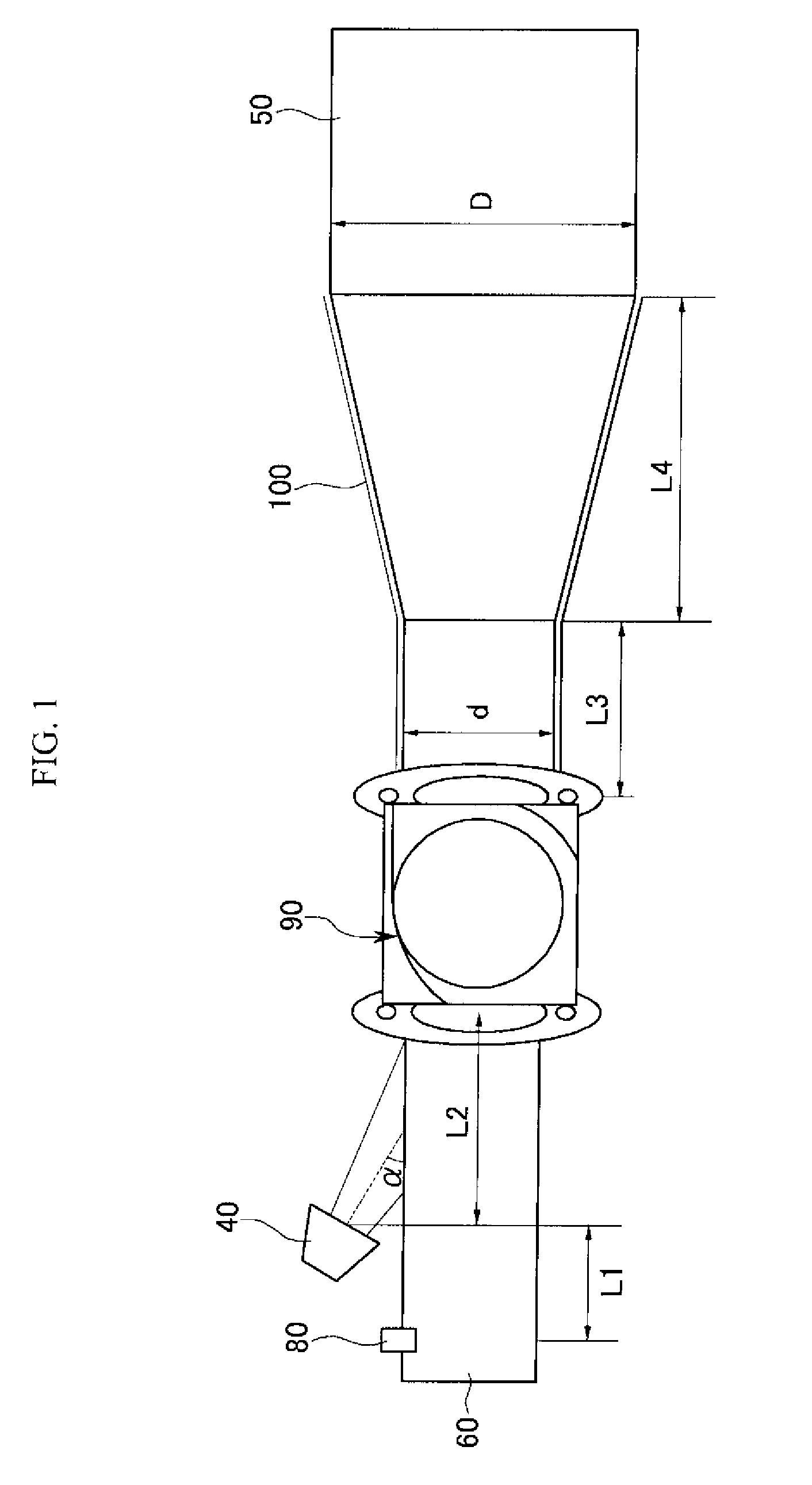

Liquid foundation raw material mixing equipment for cosmetic production

InactiveCN111701515AAccelerated dilutionIncrease the mix rateTransportation and packagingMixer accessoriesSpiral bladeElectric machine

The invention discloses liquid foundation raw material mixing equipment for cosmetic production. The equipment comprises a shell with a conical bottom, and a stirring assembly and an oscillation assembly arranged in an inner cavity of the shell. An opening is formed in the top end of the shell, and an upper end cover is installed at the top end of the shell in a sealed mode; the shell is arrangedon a workbench through a supporting frame; an attachment frame is fixedly welded to the top end of one side of the supporting frame; a motor is installed on the attachment frame; and the output end ofthe motor is in driving connection with a synchronous wheel located at the top end of the shell through a belt. According to the invention, the motor provides height rotation for the spiral shaft; the spiral shaft drives the stirring assembly and the spiral blades to rotate at the same time, so that the feeding speed of dry powder raw materials is high, the stirring assembly efficiently stirs a mixed liquid, the mixing effect is better, the device can work without shutdown, and the step that traditional mixing equipment shuts down halfway for filling is omitted.

Owner:SUZHOU XINPAITE INFORMATION TECH CO LTD

Oscillatory device convenient to use and used for blood detection in internal medicine department

ActiveCN108362544AEasy to useImprove stabilityShaking/oscillating/vibrating mixersTransportation and packagingShake upWorkload

The invention discloses an oscillatory device convenient to use and used for blood detection in the internal medicine department and relates to the technical field of blood detection. The device comprises a oscillating box, wherein an oscillating mechanism is fixedly connected to the bottom of the inner wall of the oscillating box, a detection box is fixedly connected to the right side of the oscillating box, pressure boxes are fixedly connected to two sides of the inner wall of the detection box, sliders are fixedly connected to the tops and the bottoms of the inner walls of the pressure boxes through first springs, and the surfaces of the sliders are glidingly connected with one side of the inner wall of the detection box; rotating rods are rotationally connected to the surfaces of the sliders, one end, away from the corresponding slider, of each rotating rod is rotationally connected with a fixed block, a push rod is fixedly connected to the surfaces of the fixed blocks, and connecting rods are fixedly connected to the top and the bottom of one side of each push rod. The oscillatory device convenient to use and used for blood detection in the internal medicine department is simple in structure and convenient to operate, can shake up multiple blood samples by oscillating, the working efficiency of shaking for blood detection in the internal medicine department is improved, and the workload of medical workers is reduced.

Owner:山东东升医特智能装备有限公司

Thermal cracking process of acetic acid

The invention discloses a thermal cracking process of acetic acid, which comprises the following steps of: vaporizing the acetic acid, and then, enabling the acetic acid to enter a preheating furnace; dissolving a catalyst into a solvent to form a solution before the acetic acid enters the preheating furnace; adding the catalyst solution into acetic acid gas; and mixing the acetic acid gas and the catalyst solution, and then, enabling the mixture to enter a cracking furnace for cracking, wherein the catalyst is ammonium phosphate salt. The process has simple working procedure and low cost and is convenient for being widely used industrially.

Owner:SUZHOU HOPE TECH

Air intake passage injection type charged gasoline engine high-efficiency combustion chamber

PendingCN110259569AFace ratio is smallIncrease the intensity of air movementInternal combustion piston enginesCylinder headsCombustion chamberTop dead center

The invention provides an air intake passage injection type charged gasoline engine high-efficiency combustion chamber which comprises a combustion chamber cavity area A formed by a part under a cylinder cover combustion chamber dome, a part above the top surface of a piston, and a cylinder barrel between the cylinder cover combustion chamber dome and the piston in an enclosing and sealing way. An air intake door, an air exhaust door and a sparking plug are arranged on a cylinder cover and communicate to an air intake door and an air exhaust door of the combustion chamber cavity area A from the cylinder cover. The air intake passage injection type charged gasoline engine high-efficiency combustion chamber is characterized in that inclined air extrusion areas B and C are arranged on an air intake side and an air exhaust side; and each air extrusion gap is 0.9 to 1.1.mm. According to the air intake passage injection type charged gasoline engine high-efficiency combustion chamber provided by the invention, during upgrading air intake passage injection type gasoline engine pressurization, the cylinder cover and piston combustion chamber structure is customized and improved, and the combustion chamber adopts a two-inclined-air-extrusion technology, so that the airflow motion strength at a top dead center in an engine cylinder is improved, the oil-gas mixing rate is improved, and the combustion speed is improved; and a surface-to-volume ratio of the cylinder cover combustion chamber is reduced, the heat transfer loss and the near-wall unburned emission are reduced, and the design requirements on an engine power performance and an emission performance are met.

Owner:CHERY AUTOMOBILE CO LTD

Apparatus for reducing nitrogen oxide in exhaust pipe

ActiveUS8336295B2Increase the mix rateReducing nitrogen oxideGas treatmentInternal combustion piston enginesExhaust fumesNitrogen oxide sensor

An apparatus for reducing nitrogen oxide in an exhaust pipe, may include a nitrogen oxide sensor that is mounted in the exhaust pipe and that measures amount of the nitrogen oxide in exhaust gas, a nozzle that is disposed on the exhaust pipe to be spaced apart from the nitrogen oxide sensor to a downstream side of the nitrogen oxide sensor by a first predetermined length and that injects urea corresponding to the amount of the nitrogen oxide, a mixer that mixes the urea with the exhaust gas and that is disposed at a downstream side of the nozzle on the exhaust pipe to be spaced apart by a second predetermined length from the nozzle, and a de-nitrification catalyst reaction device that is disposed at a downstream side of the mixer on the exhaust pipe, purifies the nitrogen oxide, and includes an inlet portion having a predetermined length.

Owner:HYUNDAI MOTOR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com