Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Improve the performance of three defenses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Finishing process for nano three-protective dacron fabrics

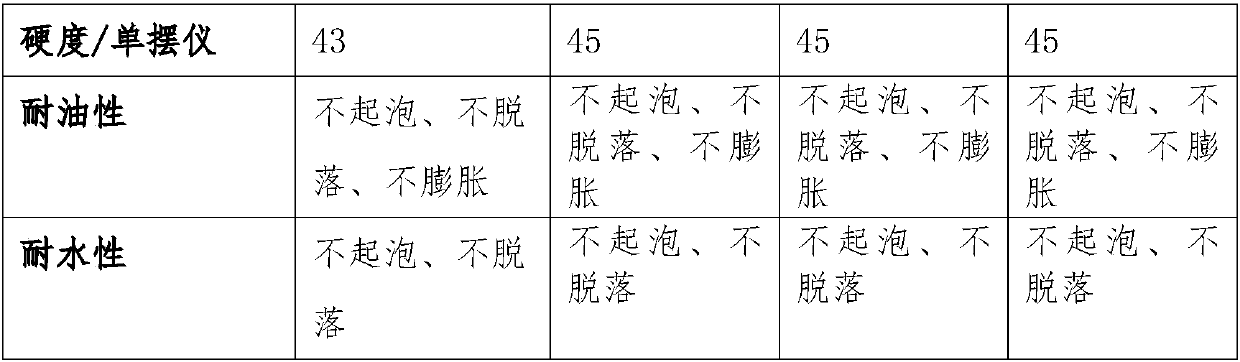

InactiveCN1424456AImprove the performance of three defensesGood synergyFibre treatmentPolyesterAdhesive

A technology for finishing the water-, oil-and dirt repellent polyester fabric includes such steps as preparing the finishing liquid from organofluorine composite nano material dispersed liquid and flexible-type self-crosslinking adhesive, dipping it in the finishing liquid for 0.5-1 min, squeezing, prebaking at 100-110 deg.C for 1-2 min, and baking at 130-180 deg.C for 3-5 min. Its advantages are excellent "three repelling" function, better durability and high washing resistance.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing water, oil and stain repellent and easy-to-clean household fabric

InactiveCN102051824AImprove washabilityImprove the performance of three defensesFibre treatmentChemistryTreated water

The invention provides a method for preparing a water, oil and stain repellent and easy-to-clean household fabric, and belongs to a method for preparing a household fabric. The method comprises the following steps: a, performing pretreatment to the household fabric serving as the raw material, and then cleaning out the household fabric; b, preparing finishing liquor, i.e., adding finishing agent, softening agent, cross-linking agent and penetrating agent into water during the preparation; and c, padding the finishing liquor, i.e., soaking and padding, preshrinking, and finally obtaining the water, oil and stain repellent and easy-to-clean household fabric. The method has the advantage that the easy cleaning property of the treated water, oil and stain repellent fabric stained with oil is enhanced; the treated water, oil and stain repellent and easy-to-clean fabric has high water, oil and stain repellent properties in air medium and shows relative hydrophilic and oleophilic properties in aqueous medium; the purpose of organically combining the oil and stain repellent properties with the easy-to-clean property is achieved, so that the oil stained on the fiber is easily removed in aqueous medium; and the method can be widely applicable to tablecloth, window curtains, kitchen cloth and the like.

Owner:SHANDONG WEIQIAO PIONEERING GROUP

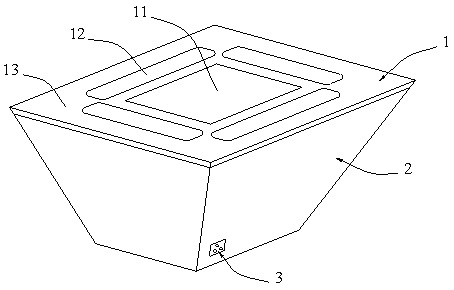

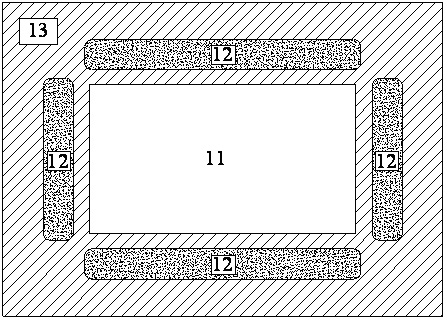

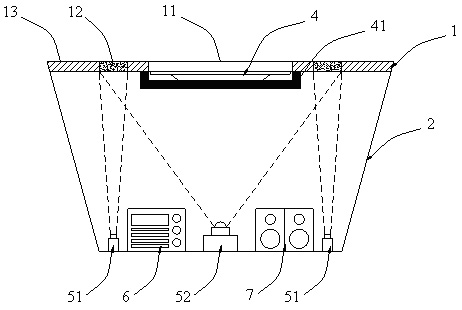

Multi-point touch sensing method and equipment

ActiveCN102023760AHighly integratedEasy to moveInput/output processes for data processingFinger touchInfrared

The invention relates to the field of game equipment, aims to solve the technical problems in the prior art, and designs a multi-point touch sensing method and equipment, which are accurate in touch and high in image accuracy and can be used in various places. The method comprises the following steps that: a camera and an infrared transmitting device are arranged on backs of a panel and a display device, the infrared transmitting device projects infrared ray onto the panel, a strip-shaped touch belt is formed on the front of the panel; the panel can be transmitted by the infrared ray in a region of the touch belt, and the camera transmits an image on the touch belt on the same side of the infrared transmitting device to a host; a finger touches the region of the touch belt on the front of the panel for operation, and reflects the infrared ray passing through the touch belt; the infrared ray reflected by the finger forms a white point in the image shot by the camera, and the host realizes touch by analyzing the action of the white point; and the host displays action of a computer program corresponding to the touch action through the display device.

Owner:广州市迪拓信息科技有限公司

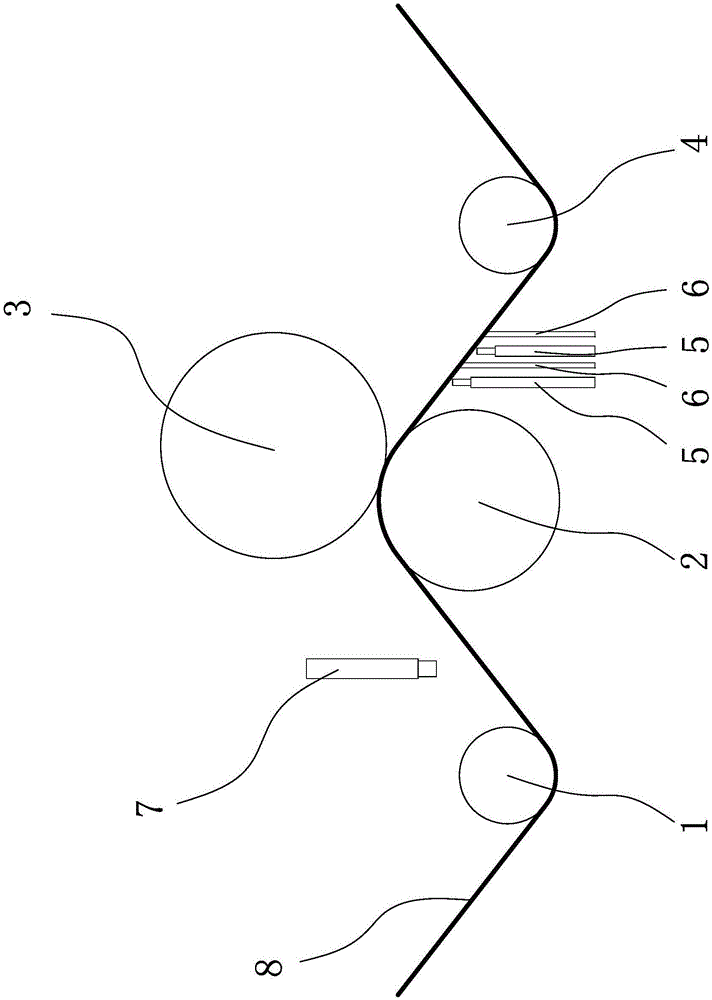

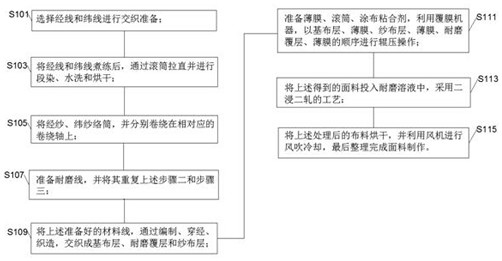

Finishing process of waterproof, oil-proof and antifouling fabric

ActiveCN106320024AImprove the performance of three defensesSmooth and soft surfaceSucessive textile treatmentsDry-cleaning apparatus for textilesTextile technologyEngineering

The invention provides a finishing process of waterproof, oil-proof and antifouling fabric, belongs to the technical field of textile, and solves the problem that an existing fabric finishing process is complex and cannot improve the waterproof performance, oil-proof performance and antifouling performance of fabric. The finishing process of the waterproof, oil-proof and antifouling fabric is characterized by including the steps of 1), dyeing; 2), performing first washing; 3), performing second washing; 4), performing third washing; 5), performing fourth washing; 6), performing hot rolling; 7), performing film coating; 8), napping. The finishing process has the advantages that the process is little in damage on the fabric, and the surface of the fabric is allowed to be smooth and soft and good in comfortableness; the hot rolling and the film coating can be performed at the same time, and the waterproof performance, oil-proof performance and antifouling performance of the fabric can be improved.

Owner:南通茧缘丝绸纺织有限公司

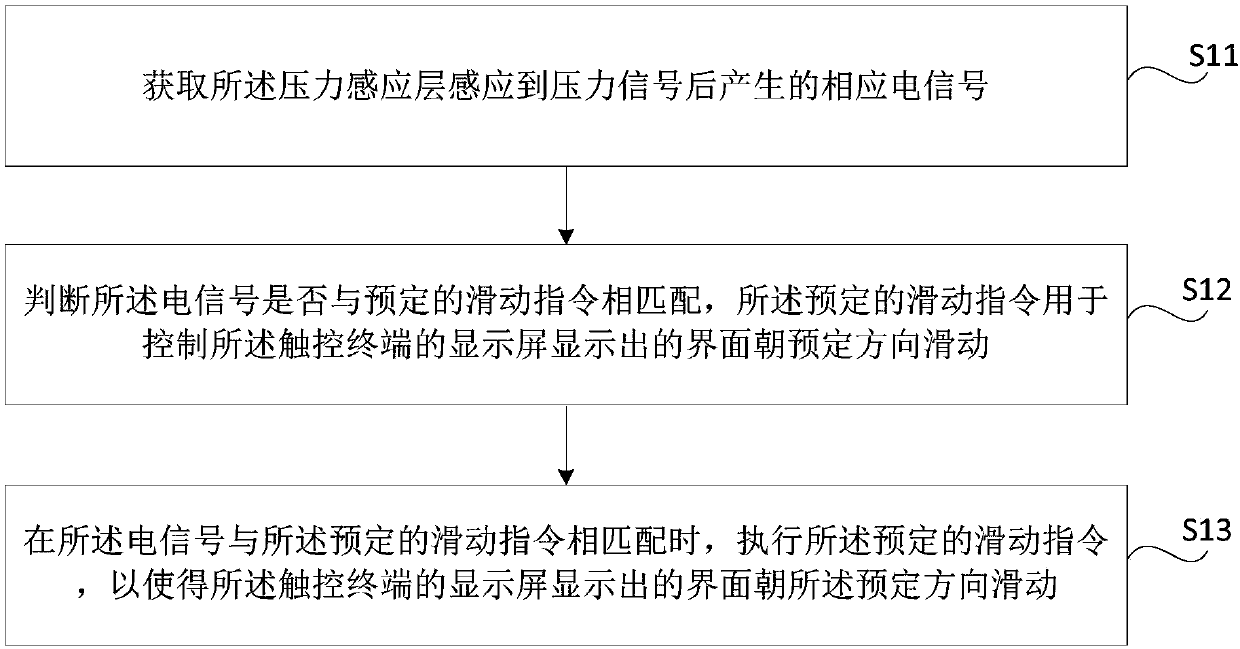

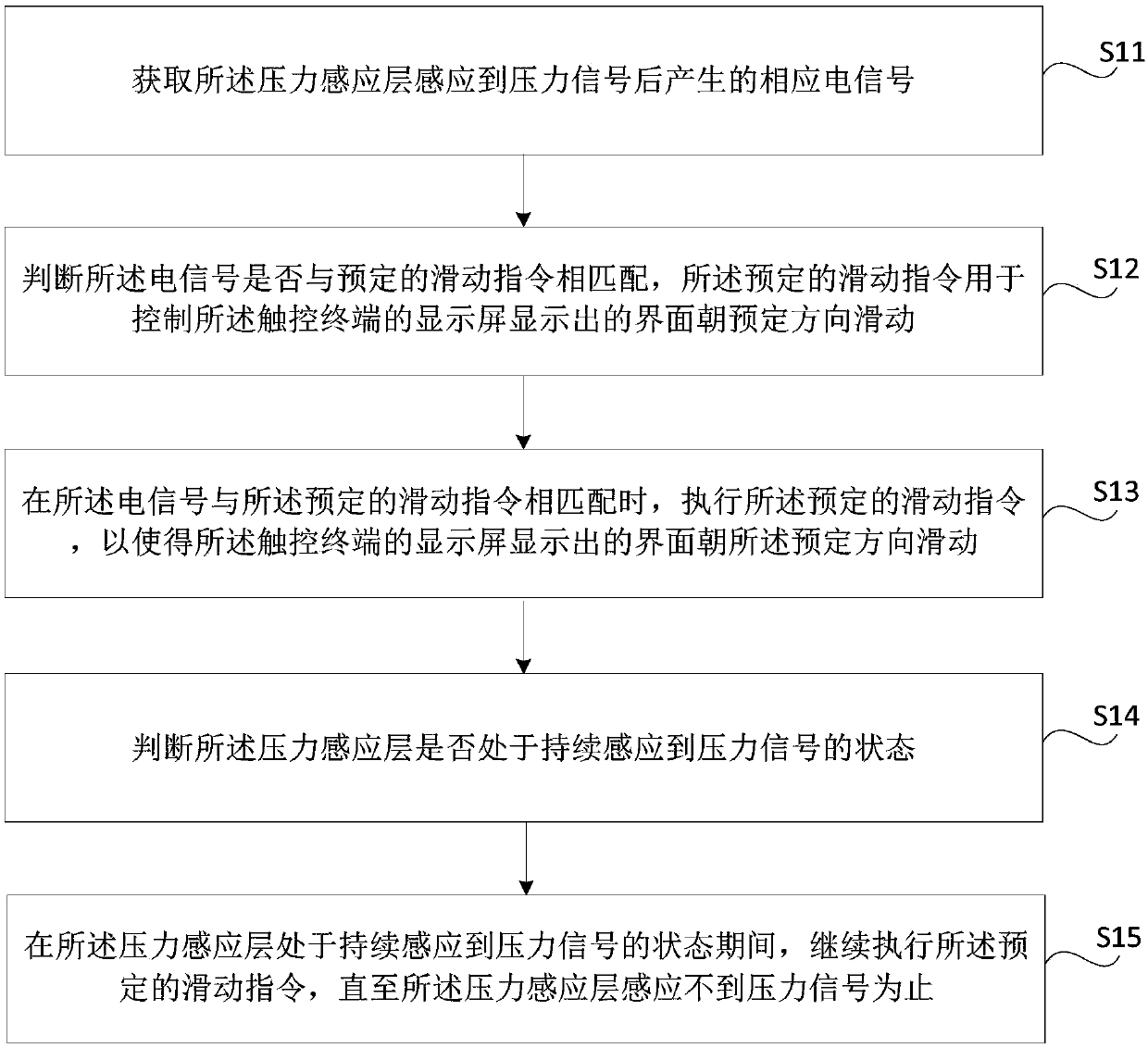

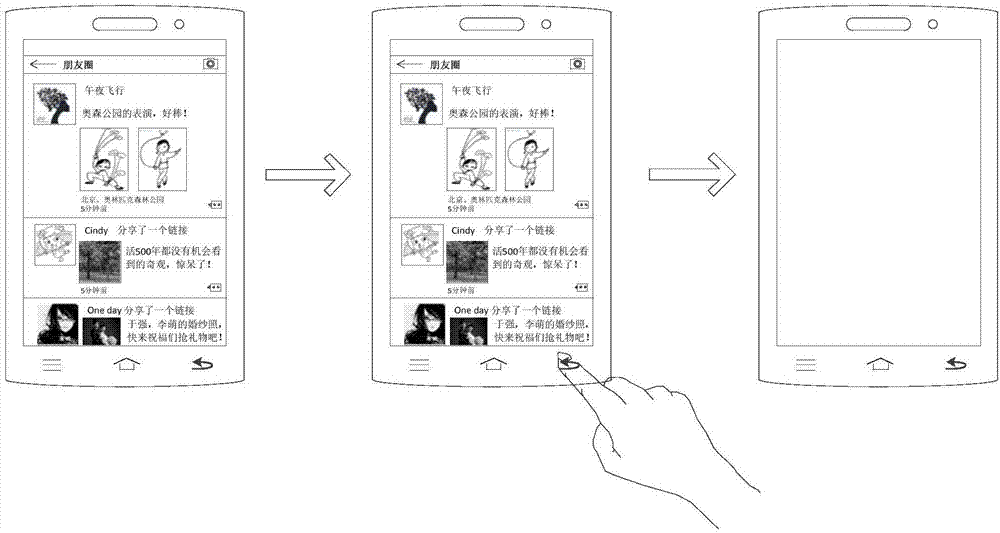

Method for controlling display interface to slide, and touch terminal

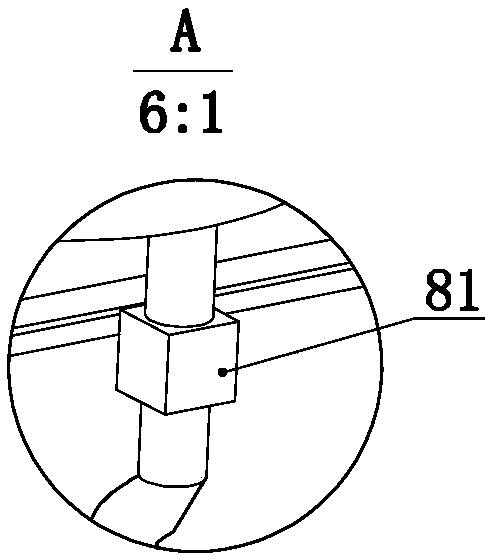

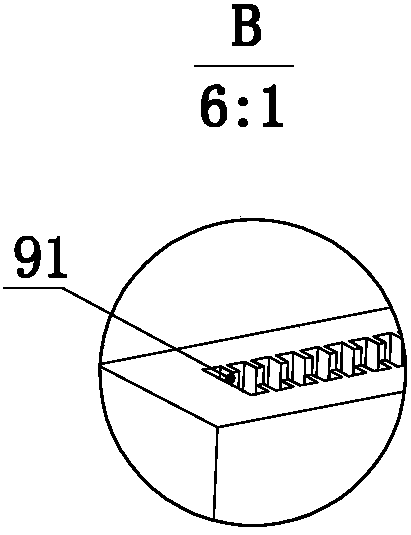

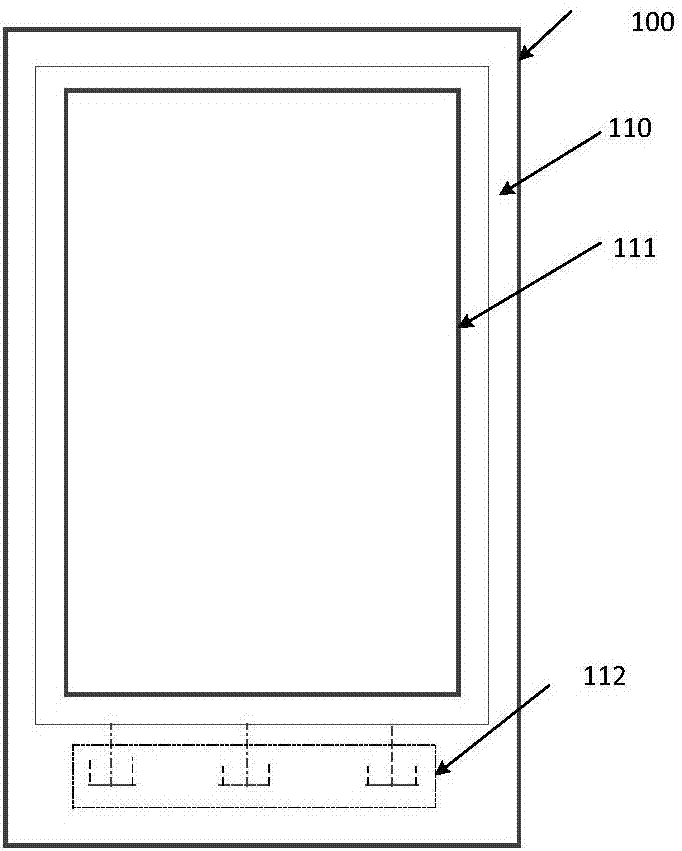

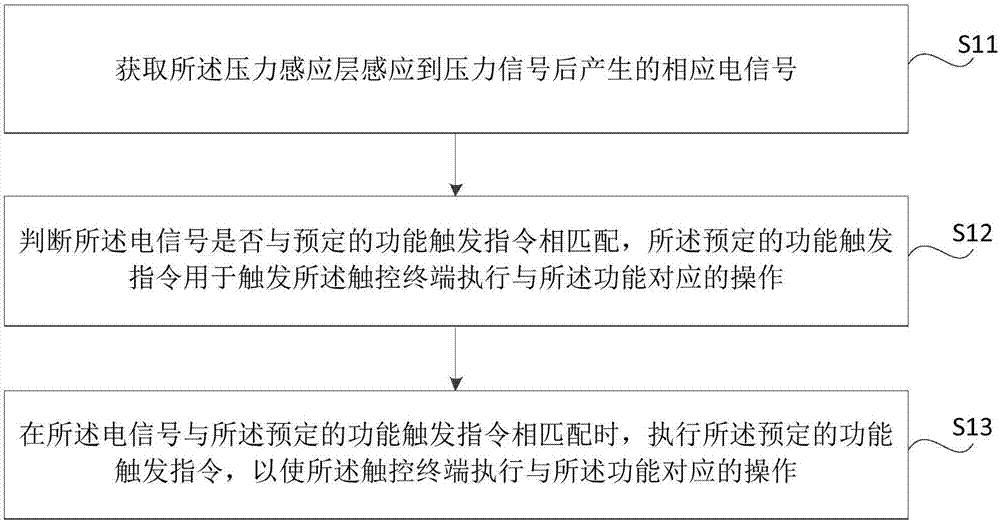

InactiveCN108021322AImprove aestheticsImprove the performance of three defensesInput/output processes for data processingPressure senseHuman–computer interaction

The invention relates to a method for controlling a display interface to slide, and a touch terminal. The method is a new method for controlling the display interface to slide, and is applied to the touch terminal comprising a touch key. The display interface is controlled to slide through a pressure signal sensed by a pressure sensing layer in the touch key; a function of simulating arrow buttonsat two ends of a scrollbar is realized; and a user can control the display interface to slide by pressing the touch key, until the display interface slides to a position where the user wants to perform viewing. The user does not need to use a touch body to control a touch display screen to slide to the position where the user wants to perform viewing after performing multi-time sliding on the touch display screen. The process of controlling the display interface to slide is more humanized, and the operation is simple.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Three-proofing school uniform and making method thereof

InactiveCN109778543AExcellent "three defenses" effectImprove hygieneConjugated cellulose/protein artificial filamentsWoven fabricsFiberPolyester

The invention discloses a three-proofing school uniform and a making method thereof. The three-proofing school uniform is made of a three-proofing fabric; the three-proofing fabric is formed in the mode that a composite fiber A and a composite fiber B are blended and finished through a compound three-proofing finishing agent. The composite fiber A comprises, by weight, 82-95 parts of cotton fibers, 5-16 parts of devil's rush herb fibers and 4-12 parts of superfine pearl powder. The composite fiber B comprises, by weight, 25-35 parts of polyurethane fibers, 45-60 parts of polyester fibers, 8-14parts of devil's rush herb fibers, 1-2.2 parts of fatty alcohol ether phosphate sylvite and 1.5-3.5 parts of a dandelion extract. The compound three-proofing finishing agent comprises, by weight, 45-55 parts of an oleophobol SLA-NEW three-proofing finishing agent, 2-3.5 parts of fatty alcohol polyoxyethylene ether, 48-60 parts of a nano zinc oxide dispersion solution and 0.6-0.9 part of citric acid. The three-proofing school uniform has a good three-proofing effect and good performance such as moisture absorption and air permeation.

Owner:百裕世纪(集团)有限公司

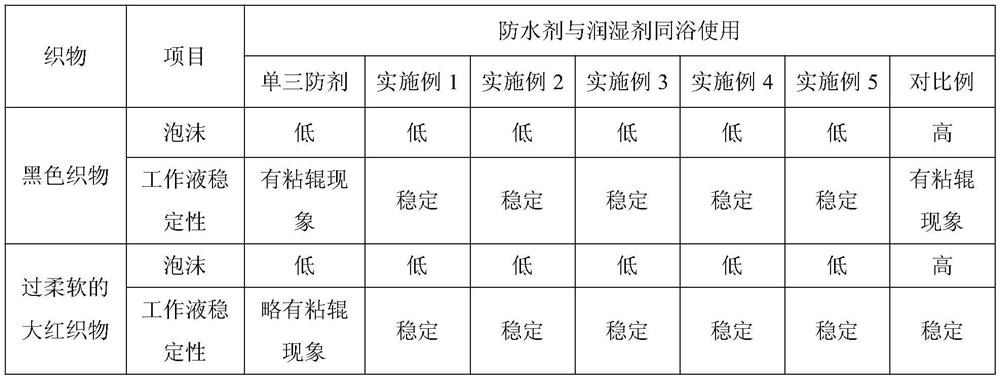

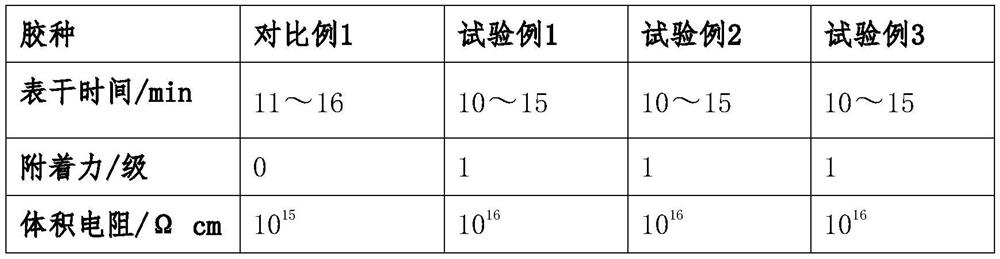

Three-proofing treatment process method

ActiveCN107931066AImprove the performance of three defensesImprove environmental adaptabilityAntifouling/underwater paintsPretreated surfacesVarnishMetallurgy

The invention provides a three-proofing treatment process method and belongs to the technical field of electronic device treatment. According to the combination treatment method, firstly, the outer surface of an aluminum alloy piece is subjected to chemical electric conduction oxidation, then spraying of primer, scrape coating of putty, and spraying of three-proofing enamel are conducted, and finally, varnish is sprayed to the outer surface of the aluminum alloy piece. The good grounding requirement of electronic products is met, meanwhile, the three-proofing performance of the aluminum alloypiece is greatly improved, and thus the environmental adaptability of the electronic products is improved so that the electronic products can reliably work under the severe environments such as dampness, heat, salt mist and mould; and the method is simple in process, convenient and quick to operate, low in cost, stable and reliable.

Owner:GUIZHOU AEROSPACE ELECTRONICS TECH

Production process of high wear-resistant chenille three-proofing fabric

ActiveCN109811454AImprove flame retardant performanceImprove the performance of three defensesSucessive textile treatmentsLiquid/gas/vapor removalYarnWear resistant

The invention discloses a production process of a high wear-resistant chenille three-proofing fabric. The production process comprises the following steps of S1 preparation of chenille yarns, S2 chenille yarn space dyeing, S3 chenille fabric weaving, S4 chenille fabric flame retardant finishing, and S5 chenille fabric three-proofing finishing. According to the production process of the high wear-resistant chenille three-proofing fabric, by changing the structure of the chenille yarns, a plurality of core yarns including hot-melt filaments are used, and the degree of twist of the core yarns isincreased, so that the wear resistance of the chenille yarns is improved, and wool slip is reduced as much as possible; and a flame retardant and three-proofing finishing process of the chenille fabric is optimized, the flame retardant properties and three-proofing effect of the chenille fabric are improved through the selection of a suitable flame retardant and three-proofing finishing agent andthe reasonable selection of the process, and the fabric still has good flame retardant properties and three-proofing effect after repeated washing.

Owner:浙江瓒成新材料科技有限公司

Three-proofing finishing agent for hard water and preparation method thereof

InactiveCN107245883AImprove stabilityImprove the performance of three defensesStain/soil resistant fibresLiquid repellent fibresWater qualityPolymer

The invention discloses a preparation method of a three-proofing finishing agent for hard water. The three-proofing finishing agent for the hard water is an oil-in-water type high-molecular polymer emulsion, wherein the high-molecular polymer is prepared by emulsifying perfluoroalkylated (methyl) acrylate and (methyl) acrylate through a composite surfactant and then polymerizing by initiating of an initiator. The three-proofing finishing agent is generally that tap water or water from river is diluted to reach a certain concentration during the actual use in a printing and dyeing mill, and the tap water, in particular the water from the river, contains a certain amount of metal ions which influence the stability and the use effect of the three-proofing finishing agent. To solve the abovementioned problem, the three-proofing finishing agent is added with organic acid capable of chelating, the pH can be regulated, and the water quality can be improved, and as a result, the three-proofing finishing agent has a good three-proofing effect in the hard water, and the performance in the actual use is greatly improved.

Owner:苏州联胜化学有限公司

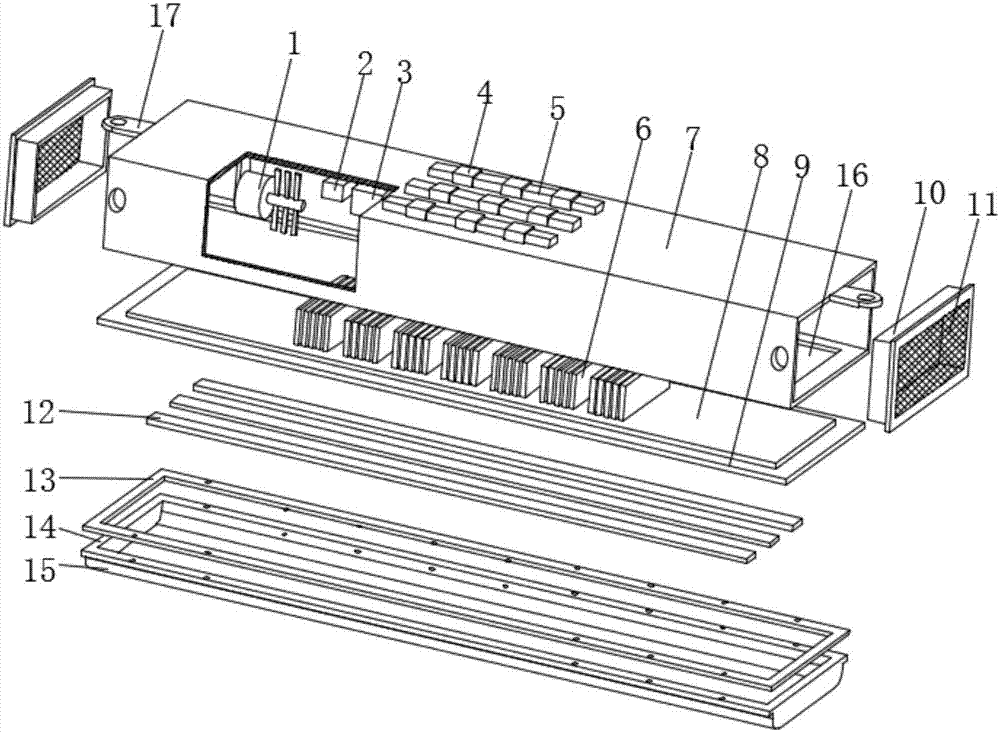

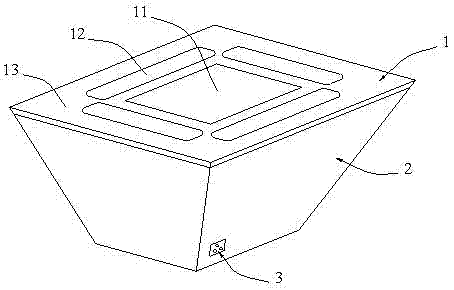

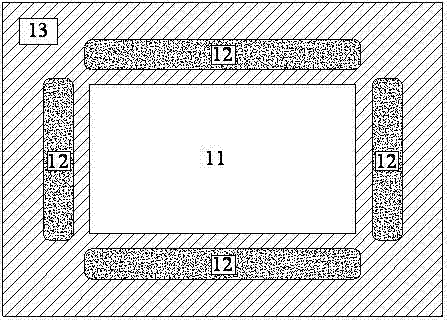

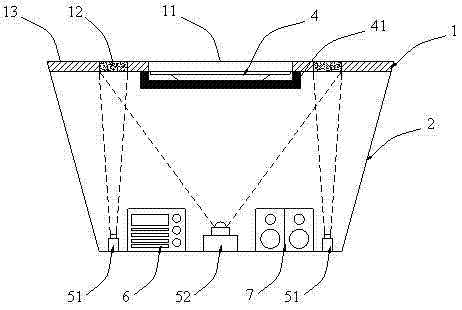

Radiating method for LED with high overall structural strength

InactiveCN107514587AImprove structural strengthImprove cooling effectElectric circuit arrangementsLighting heating/cooling arrangementsTemperature controlEngineering

The invention discloses a method for dissipating heat from LEDs with high overall structural strength, which comprises a heat dissipation box, the interior of the heat dissipation box is hollow, and the left and right ends of the heat dissipation box are open, and the left and right ends of the heat dissipation box are both clamped with clips. There are ventilation holes on the sides of the two blocks, and dust-proof nets are installed on the ventilation holes of the two blocks, and a through groove is opened on the lower surface of the cooling box, and the through groove is connected with the heat conduction plate, and the fan works so that the outside The air enters the heat dissipation box through the dust-proof net to dissipate heat from the radiator, which improves the heat dissipation of the LED tri-proof light with high overall structural strength. The dust-proof net removes dust from the air entering the heat dissipation box to prevent dust on the radiator Accumulation improves the stability of the radiator. When the temperature in the radiator box exceeds the set value, the bimetal sheet temperature control switch guides the fan to work. The structure is simple and the reliability is high. The reinforcement clip improves the overall structural strength of the radiator box .

Owner:杨航杰

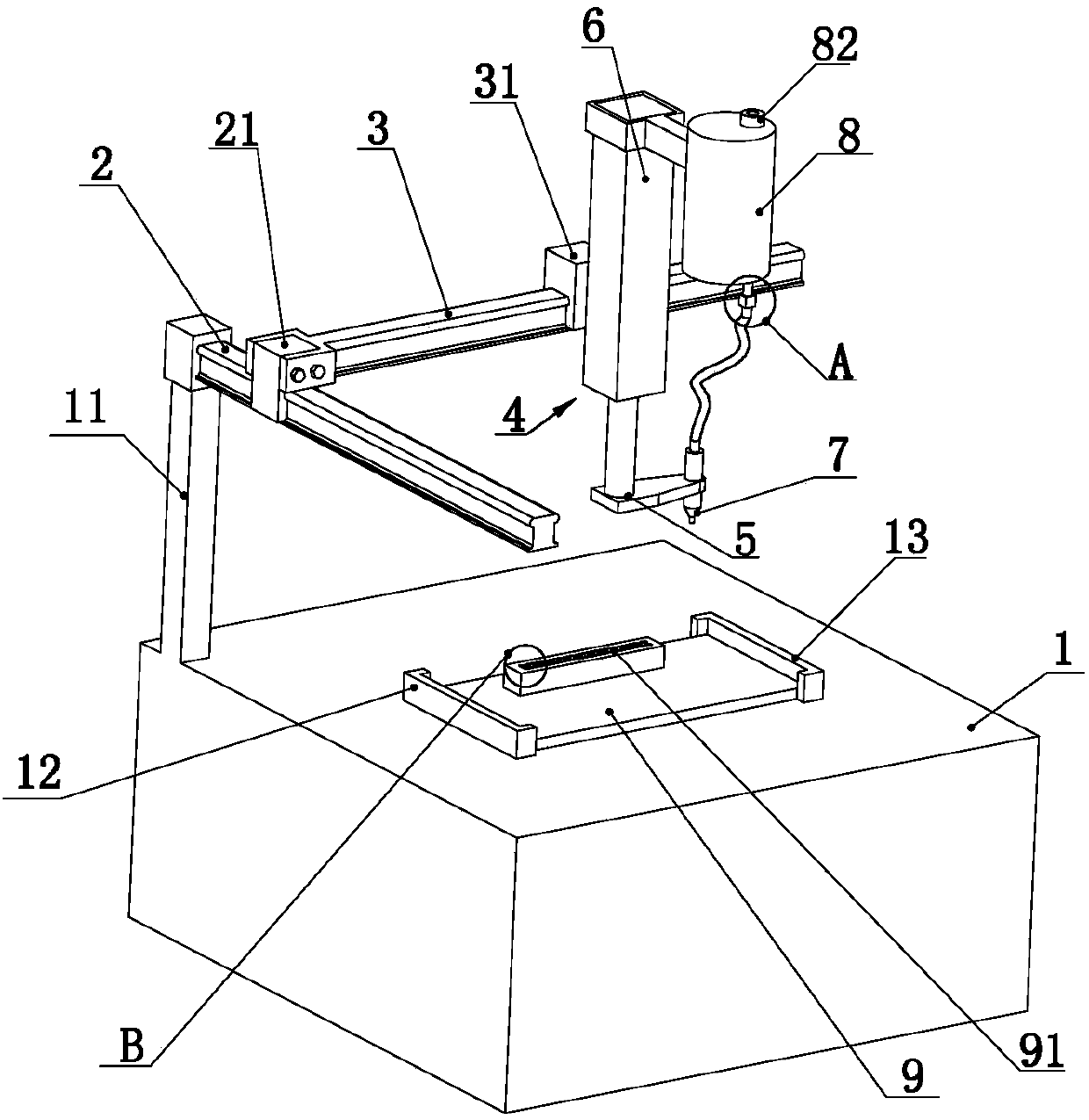

A robotic arc welding method suitable for horn structure splicing

InactiveCN103480950BImprove uniformityImprove stabilityArc welding apparatusWelding/soldering/cutting articlesEngineeringWeld seam

The invention provides a robot arc welding method suitable for splicing of horn-shaped structures. The method comprises the following steps that every two horn-shaped plates to be assembled are spliced, and protrusion parts are arranged on splicing heads and are used for filling materials into welding seams in a splicing welding mode; the horn-shaped plates to be assembled are assembled and fixed; a welding space lattice is set; welding gun paths are determined according to the welding space lattice and are stored in an arc welding robot. The robot arc welding method improves welding seam forming evenness and welding quality stability. Compared with manual argon tungsten-arc welding, pulse welding of the arc welding robot forms fish scale-shaped welding seams which are even and beautiful. Acquired welding seams are uniform in weld penetration under connector size characteristic control. Compared with a horn body formed by furnace brazing in a furnace, welding seams formed by welding according to the robot arc welding method do not have residual brazing fluxes, follow-up machining processes are reduced, and salt mist resisting performance, hot and humid resisting performance and mildew preventing performance of a connector are improved.

Owner:CHENGDU SIWI HIGH TECH IND GARDEN

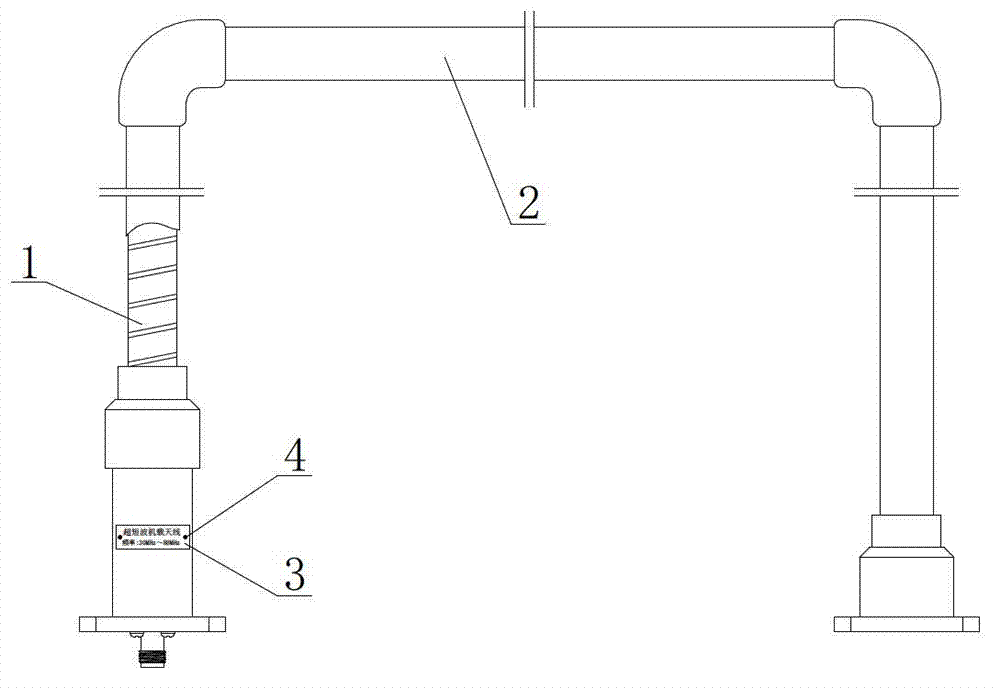

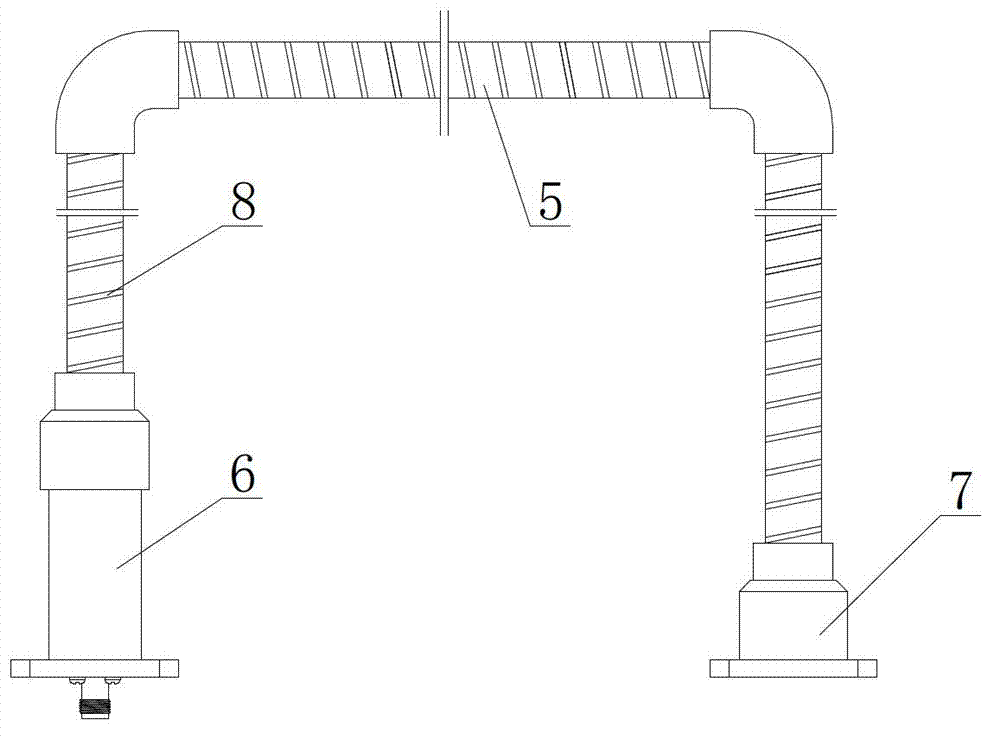

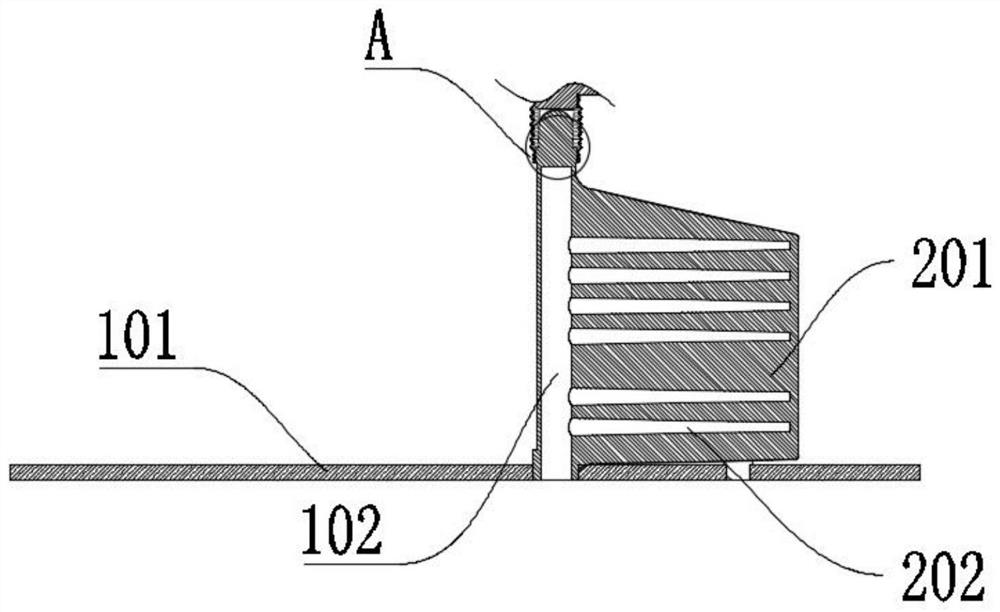

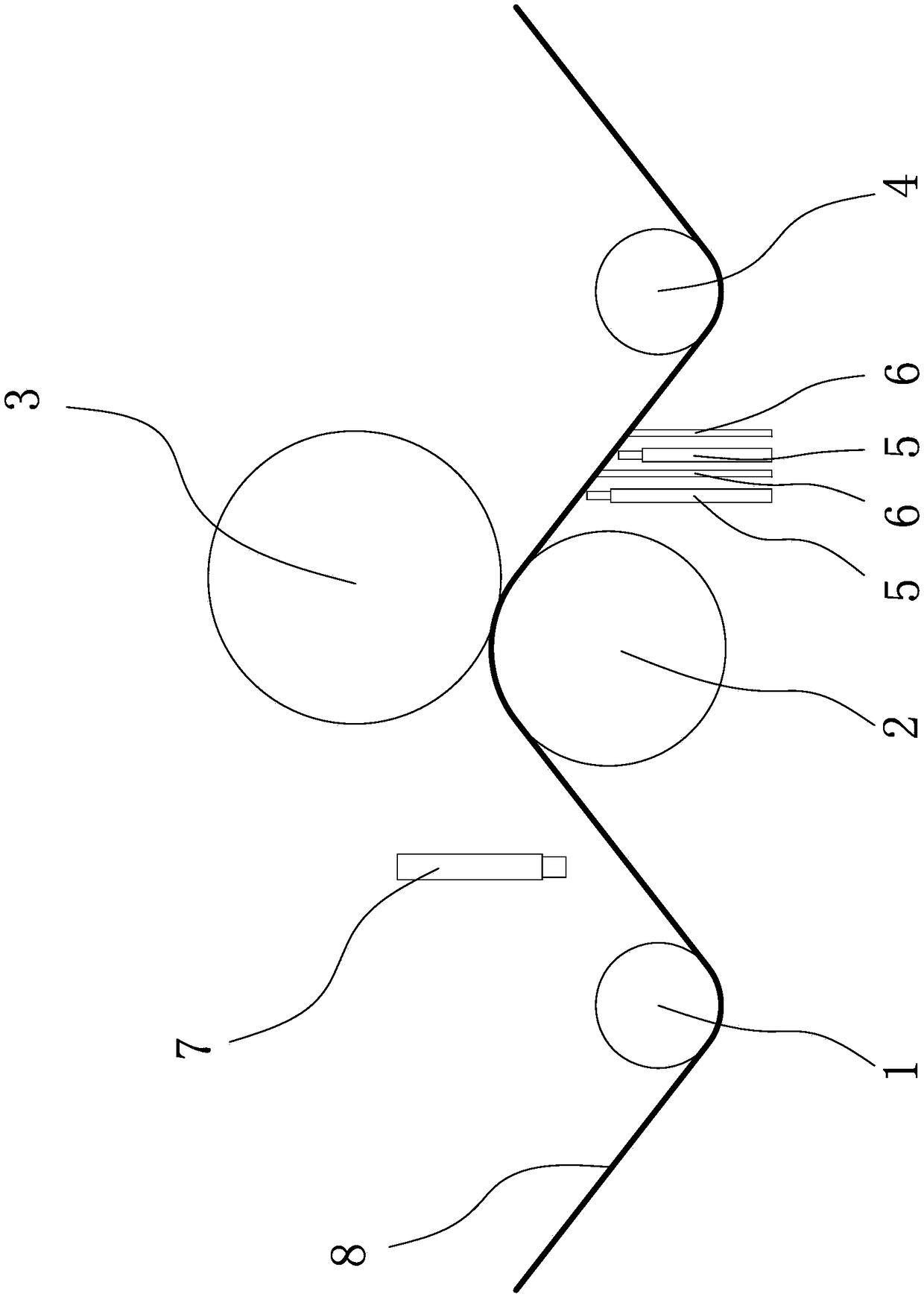

U-shaped VHF (very high frequency) antenna of unmanned aerial vehicle

ActiveCN102868019AImproving Impedance MatchingSolve height problemAntenna supports/mountingsRadiating elements structural formsAntenna gainEngineering

A U-shaped VHF (very high frequency) antenna of an unmanned aerial vehicle comprises a U-shaped radiator. The radiator is sleeved in an insulating sheath, the radiator comprises a U-shaped radiator support, a radiator belt is wound on the radiator support at uniform pitches, a fixed seat is connected with one end of the radiator support, an antenna pedestal is connected with the other end of the radiator support, and the radiator belt is connected with a matcher in the antenna pedestal. The U-shaped VHF antenna of the unmanned aerial vehicle adopts a broadband impedance matching technique and an Advanced Design System2009 simulation optimization technique, the problem of antenna height is solved well, fine broadband impedance matching is achieved, and accordingly radiation efficiency of the antenna is effectively improved, antenna gain is enhanced, and the U-shaped VHF antenna of the unmanned aerial vehicle has the advantages of convenience in dismounting and mounting, destroy resistance and good three-proofing performance.

Owner:陕西烽火诺信科技有限公司

General coded lock core

InactiveCN104141422ASimple securityImprove securityPuzzle locksPermutation locksSocial benefitsElectrical and Electronics engineering

A general coded lock core comprises a steel disc, a steel disc spindle, a sawtooth disc, a driving angle iron clamp and a stopping angle iron clamp. The lock core is equivalent to a lock cylinder of a key lock or a coded lock with a one-digit code, the lock core has no practical significance when being used separately, a practical coded lock with extremely high safety can be manufactured with multiple lock cores equipped with some auxiliary components, and the number of the lock cores is the digit of the coded lock. The lock core realizes setting, input, storage and decoding unlocking of the code in a pure mechanical manner. The coded lock manufactured with the lock cores is simple and convenient in code setting, quick and easy to unlock, stable in performance and purely digital, the safety performance of the coded lock is improved in a leap-type manner when being compared with that of various coded locks sold in the market at present, and the coded lock is applicable to various security doors, boxes and cabinets; the lock core can also be used for manufacturing a coded padlock, so that a user can get rid of the burden of keys and feel the convenience in life. Once the lock core is put into production, enormous economic and social benefit will be produced certainly.

Owner:肖守宇

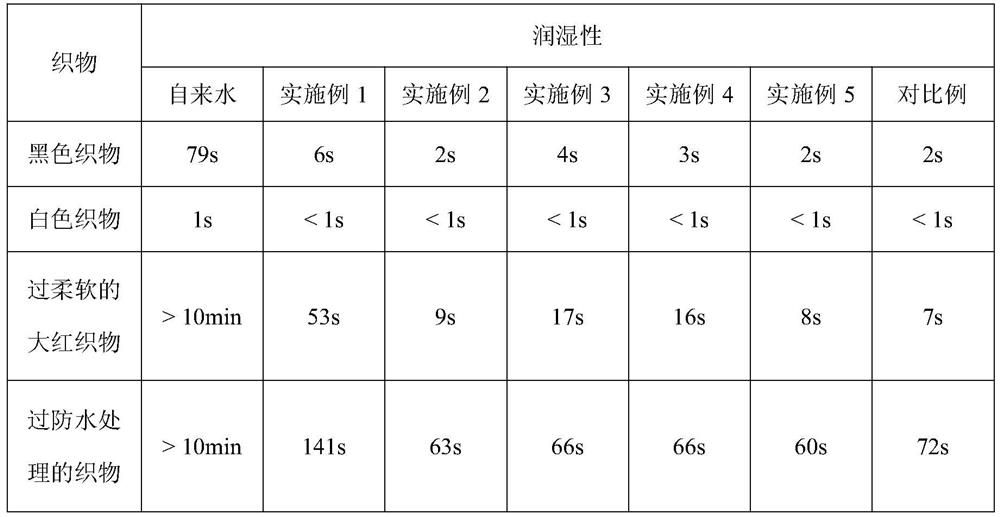

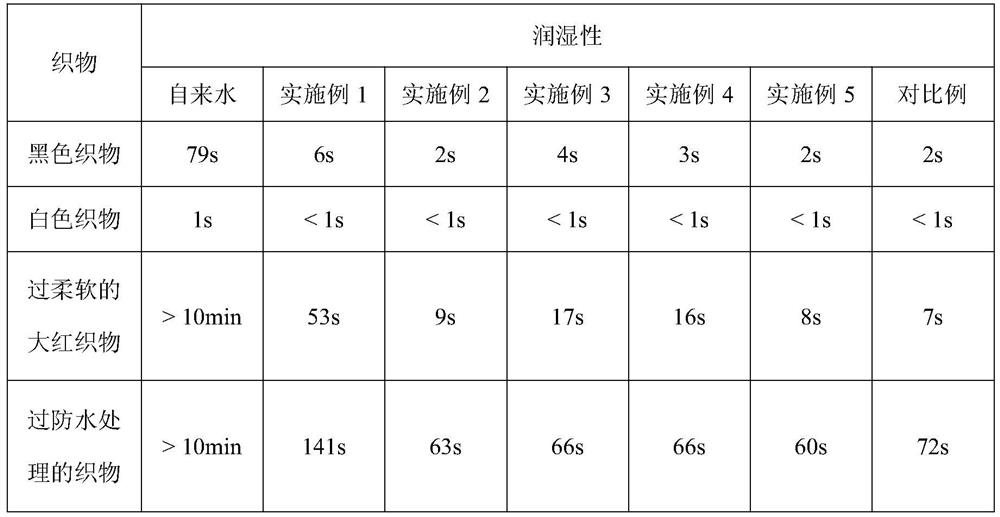

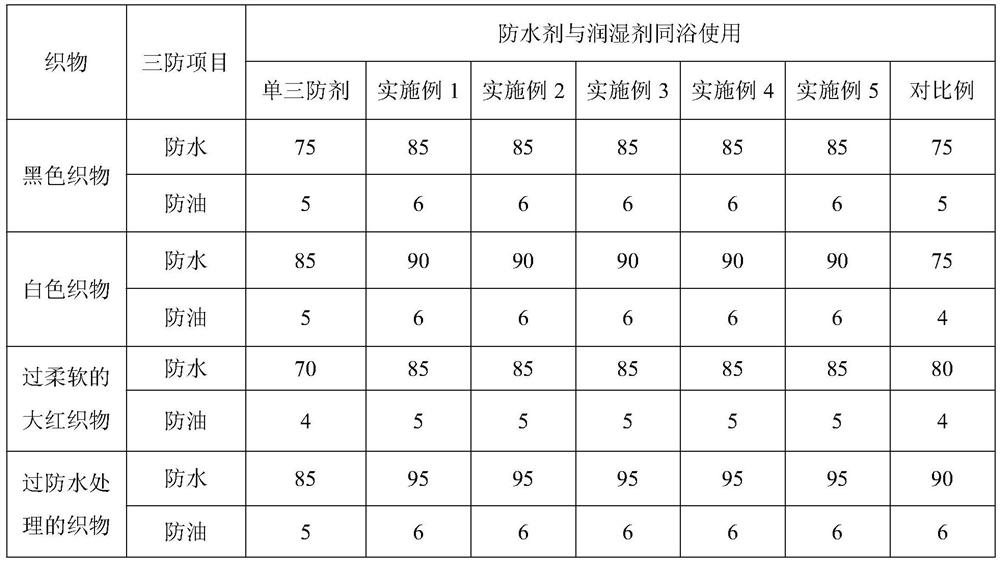

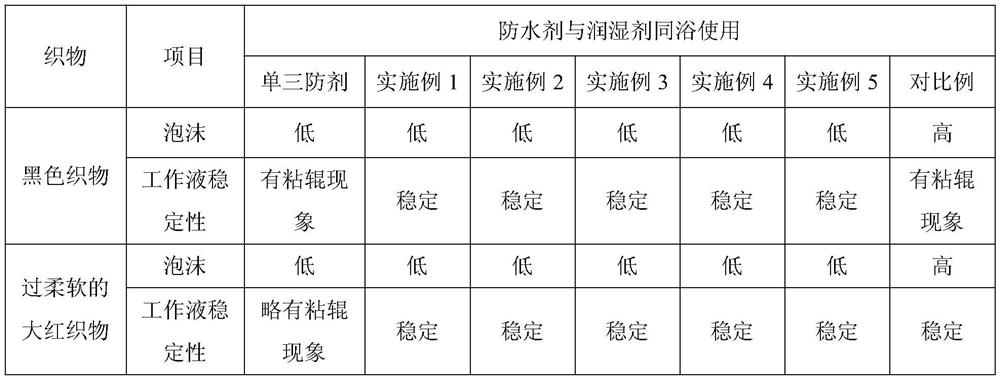

Wetting agent for three-proofing finishing and preparation method thereof

ActiveCN111910437AOvercoming the bubbleImprove stabilityStain/soil resistant fibresLiquid repellent fibresSolventActive agent

The invention discloses a wetting agent for three-proofing finishing and a preparation method thereof. The wetting agent comprises the following raw materials in parts by mass: 1-10 parts of a surfactant, 5-20 parts of a substance with the molecular formula of C6H5-O-R-OH, 5-10 parts of an environment-friendly solvent and 60-90 parts of water. A normal-temperature secondary mixing method is adopted for preparation, the reaction process is carried out at 60 DEG C, the reaction conditions are very mild, the decomposition phenomenon during reaction can be effectively reduced, in addition, the excellent dispersity and surface activity of the surfactant and the good dissolving and solubilizing assisting performance of the environment-friendly solvent are utilized respectively, the stability andreliability of the reaction are guaranteed, and the dissolving property and the dispersing property of the substance with the molecular formula of C6H5-O-R-OH in a mixed system are improved. According to the wetting agent for three-proofing finishing, the liquid carrying rate, the liquid carrying uniformity and the three-proofing effect of fabric with poor permeability during three-proofing finishing can be improved, and the performance of a three-proofing finishing agent cannot be affected.

Owner:GUANGDONG ZHAN FENG FINE CHEM CO LTD

A kind of three anti-treatment process method

ActiveCN107931066BImprove the performance of three defensesImprove environmental adaptabilityAntifouling/underwater paintsPretreated surfacesSaline mistVarnish

Owner:GUIZHOU AEROSPACE ELECTRONICS TECH CO LTD

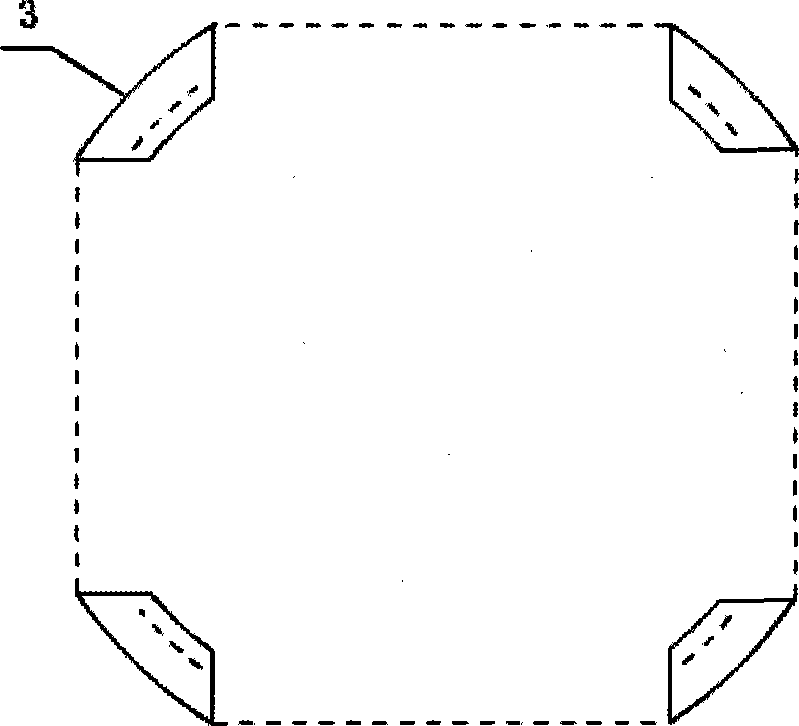

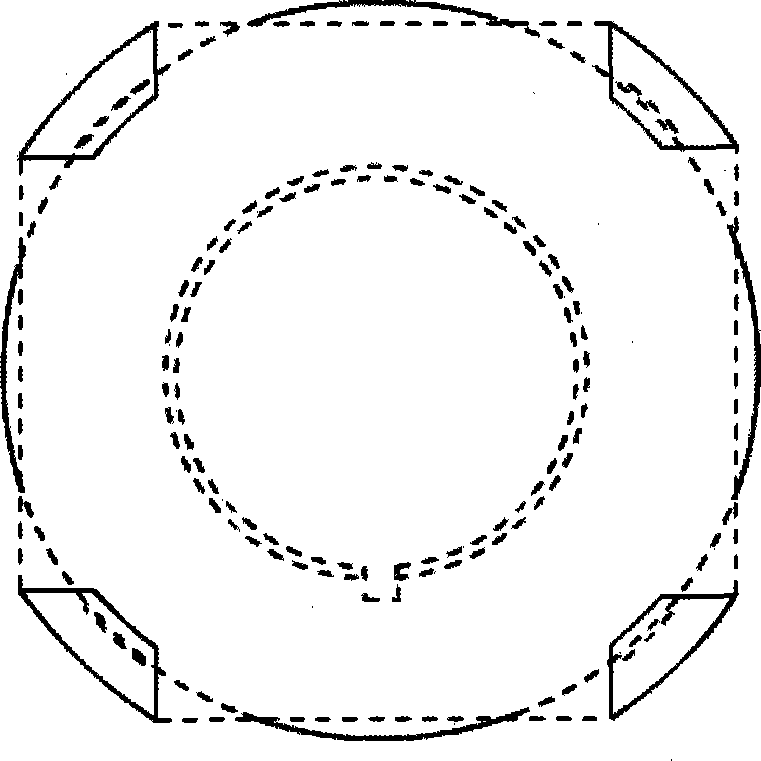

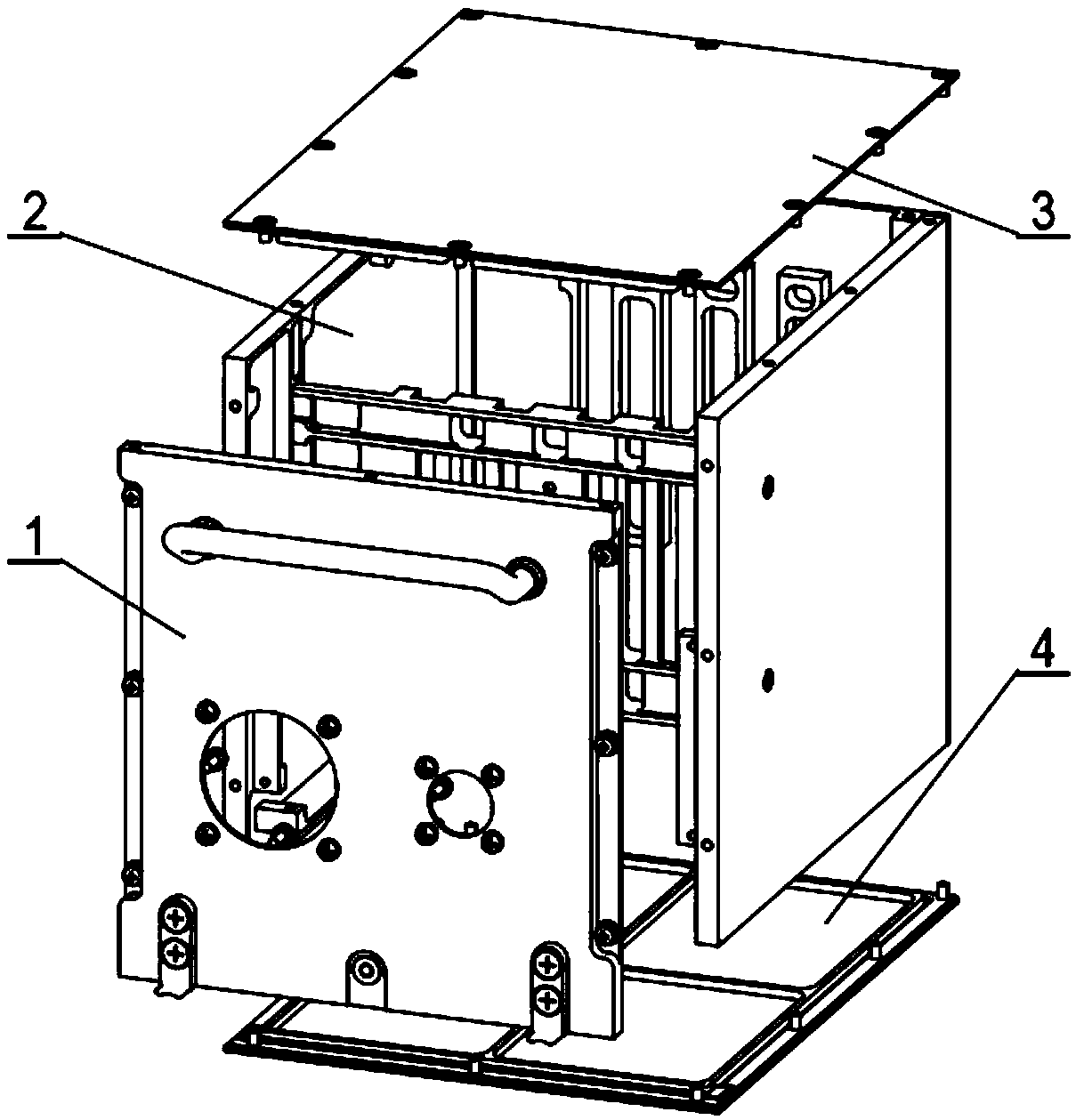

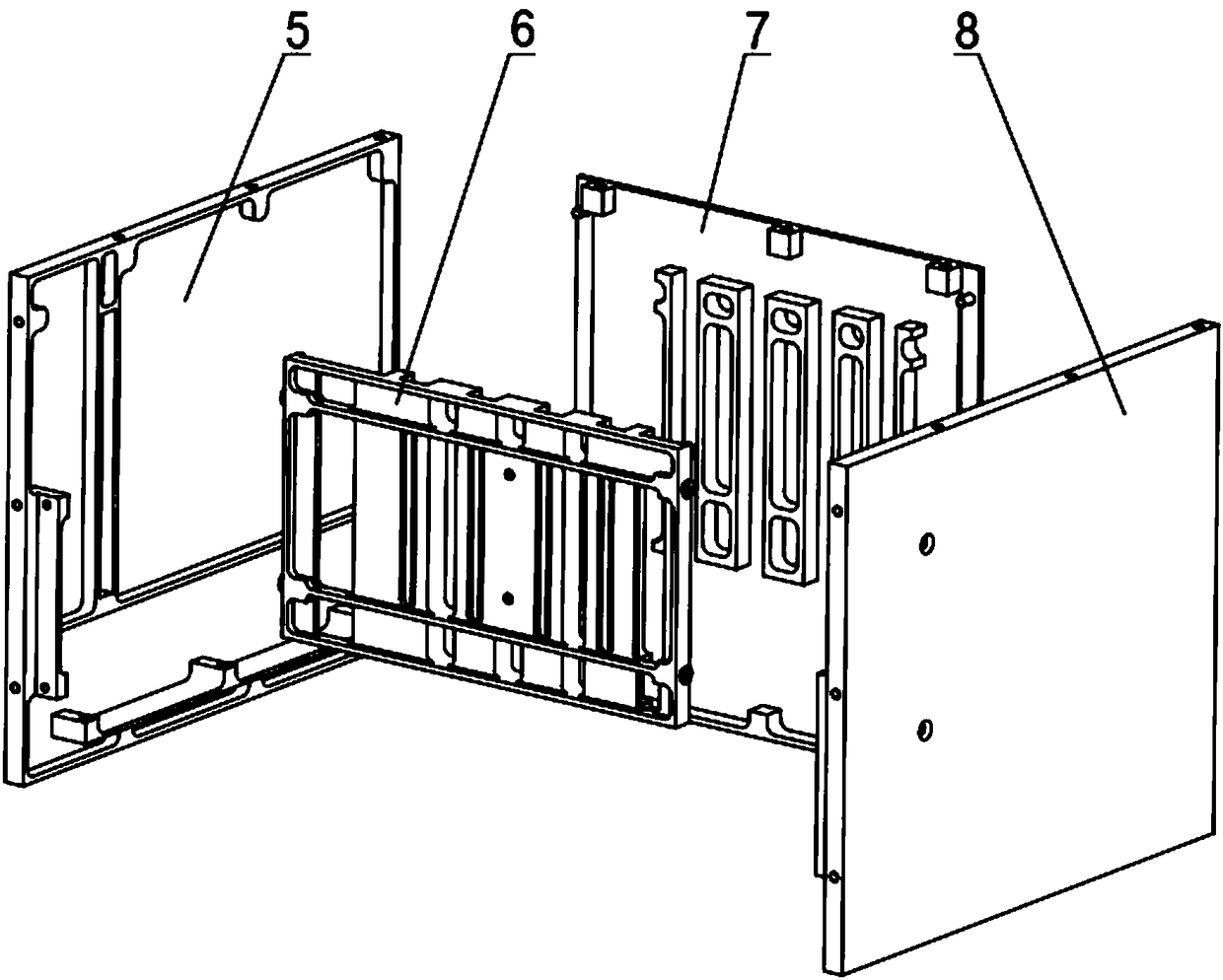

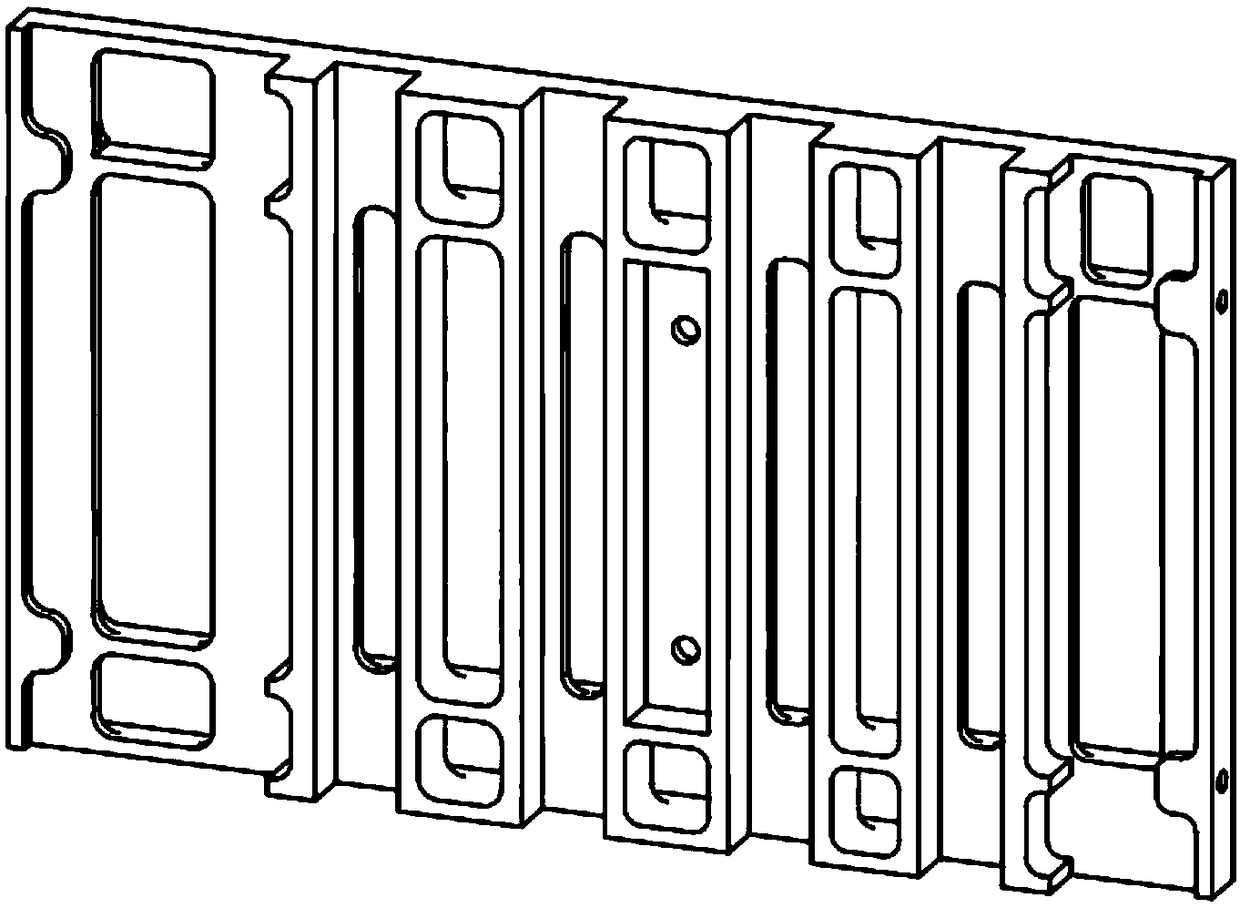

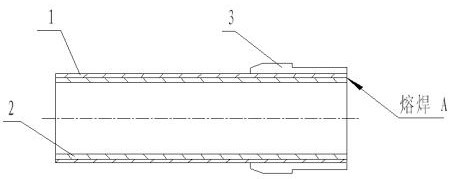

Brazed sealed machine box having internal support and used for ocean environment

InactiveCN109346946AShorten the overall cycleLow costSubstation/switching arrangement detailsHermetically-sealed casingsEngineeringOcean environment

The invention relates to a brazed sealed machine box having an internal support and used for an ocean environment. The brazed sealed machine box is composed of a front panel (1), a shell part (2), anupper cover plate (3) and a lower bottom plate (4). According to the vacuum brazed sealed machine box, a tool clamp does not need to be customized for welding, so that the production period is shortened, the production cost is reduced, and the product assembly process performance and the sealing performance required by the ocean environment can be met.

Owner:天津航空机电有限公司

Method for conducting three-proofing work on memory

InactiveCN107728728AImprove the performance of three defensesDigital processing power distributionMemory bankComputer science

The invention provides a method for conducting three-proofing work on a memory and relates to the technical field of memory maintenance. The method specifically comprises the following steps that 1, athree-proofing material is added to a memory groove; 2, a memory bank is connected into the memory groove in an inserted mode. According to the method for conducting three-proofing work on the memory, the three-proofing material is injected into the memory groove firstly, the memory groove can contain more three-proofing materials, accordingly, after the memory bank is inserted into the memory groove, the three-proofing material in the memory groove can form a layer of three-proofing film which is thicker than the film in the prior art between the memory bank and the memory groove, and accordingly the three-proofing effect on the memory is improved.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Method for controlling touch terminal and touch terminal

InactiveCN108008899AImprove aestheticsImprove the performance of three defensesDigital data authenticationSound input/outputHuman–computer interaction

The invention discloses a method for controlling a touch terminal and the touch terminal. The method is a new method for controlling the touch terminal and is applied to the touch terminal including touch keys, and the touch terminal is controlled through pressure signals inducted by pressure induction layers in the touch keys. Due to the fact that a physical key does not need to be installed on one side of the touch terminal, the attractiveness and three-proofing performance of the touch terminal are enhanced while the touch terminal is controlled.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Multi-point touch sensing method and equipment

ActiveCN102023760BHigh resolutionNarrow reflection areaInput/output processes for data processingInfraredTouch Senses

The invention relates to the field of game equipment, aims to solve the technical problems in the prior art, and designs a multi-point touch sensing method and equipment, which are accurate in touch and high in image accuracy and can be used in various places. The method comprises the following steps that: a camera and an infrared transmitting device are arranged on backs of a panel and a displaydevice, the infrared transmitting device projects infrared ray onto the panel, a strip-shaped touch belt is formed on the front of the panel; the panel can be transmitted by the infrared ray in a region of the touch belt, and the camera transmits an image on the touch belt on the same side of the infrared transmitting device to a host; a finger touches the region of the touch belt on the front ofthe panel for operation, and reflects the infrared ray passing through the touch belt; the infrared ray reflected by the finger forms a white point in the image shot by the camera, and the host realizes touch by analyzing the action of the white point; and the host displays action of a computer program corresponding to the touch action through the display device.

Owner:广州市迪拓信息科技有限公司

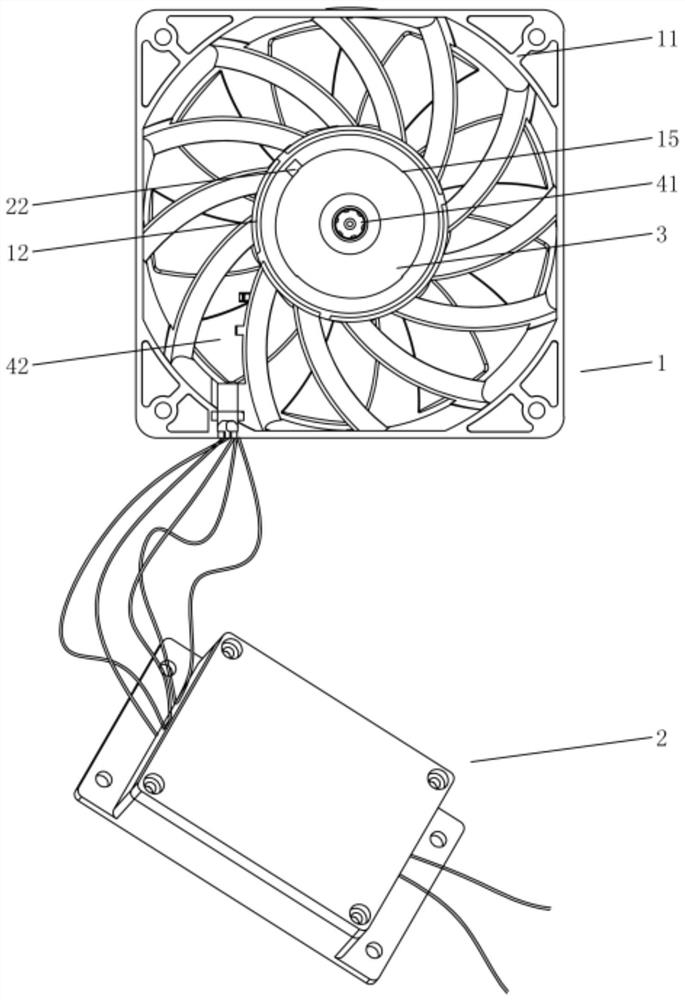

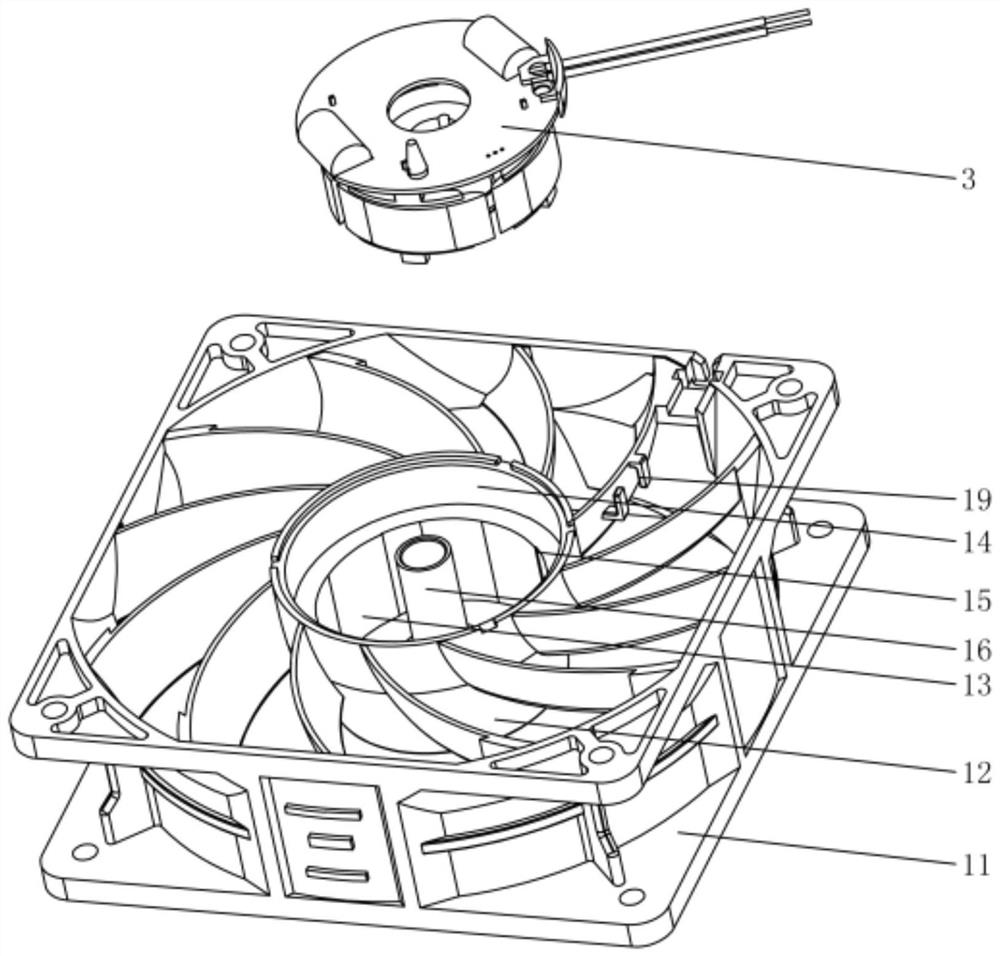

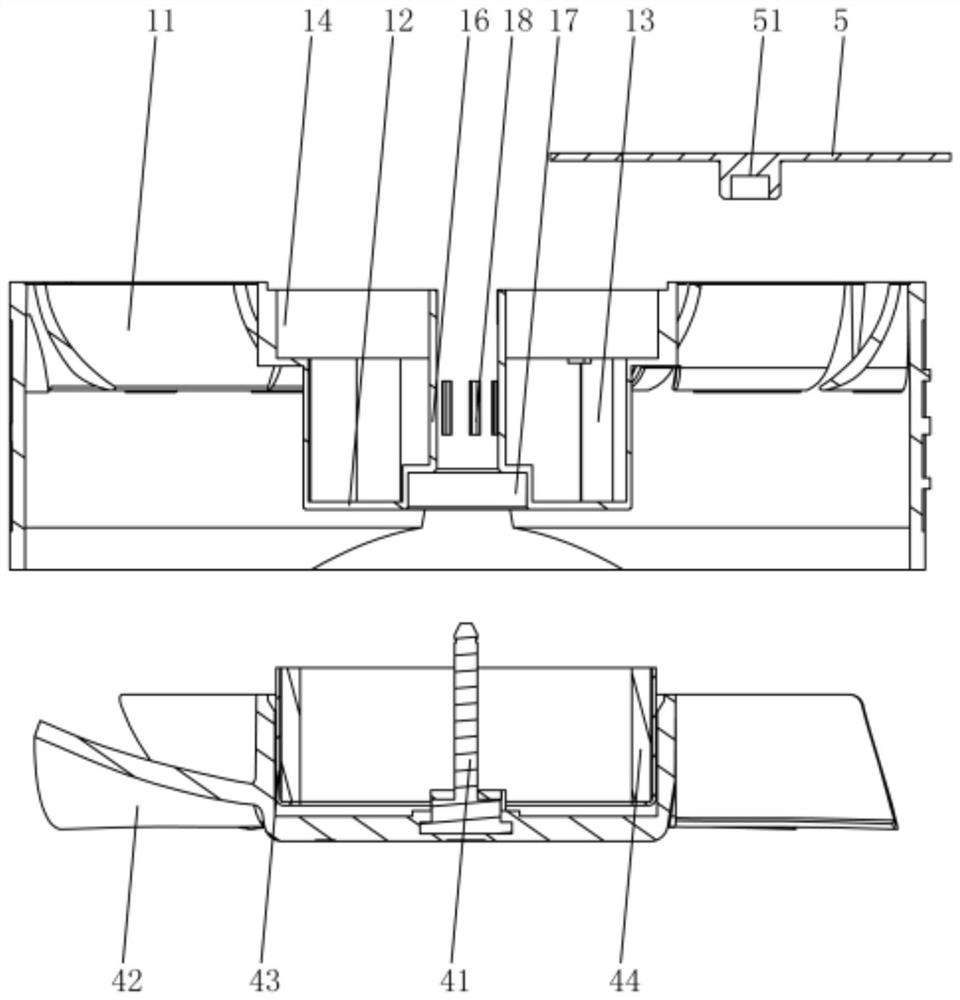

Separated potting waterproof fan

PendingCN114583874AExtended service lifeReasonable structureSupports/enclosures/casingsElectronic componentPrinted circuit board

The invention relates to the technical field of fans, in particular to a separated type potting waterproof fan. Comprising a fan body and a control box, the fan body comprises a fan frame, a stator assembly and a fan assembly, a potting body is arranged in the center of the fan frame, and the fan assembly is rotationally connected with the potting body; the lower inner cavity of the potting body is an assembling cavity, and the upper inner cavity of the potting body is a filling cavity; the stator assembly is arranged in the assembling cavity in a penetrating mode and connected with the filling and sealing body in a matched mode, and the filling cavity is filled with sealing filler. A PCB (Printed Circuit Board) is arranged in the control box; a circuit on the stator assembly penetrates through the filling cavity so as to be electrically connected with the PCB; the waterproof fan is reasonable in structure, compliance detection is carried out after the fan assembly, the fan frame and the stator assembly are assembled, the sealing filler is injected into the filling cavity, the stator assembly is packaged in the potting body, electronic elements which are not resistant to low temperature are integrated in the control box, the waterproof fan can work in severe environments such as high temperature, low temperature and dust, and the service life of the waterproof fan is prolonged.

Owner:SANJU TECH MOTOR SHENZHEN CO LTD

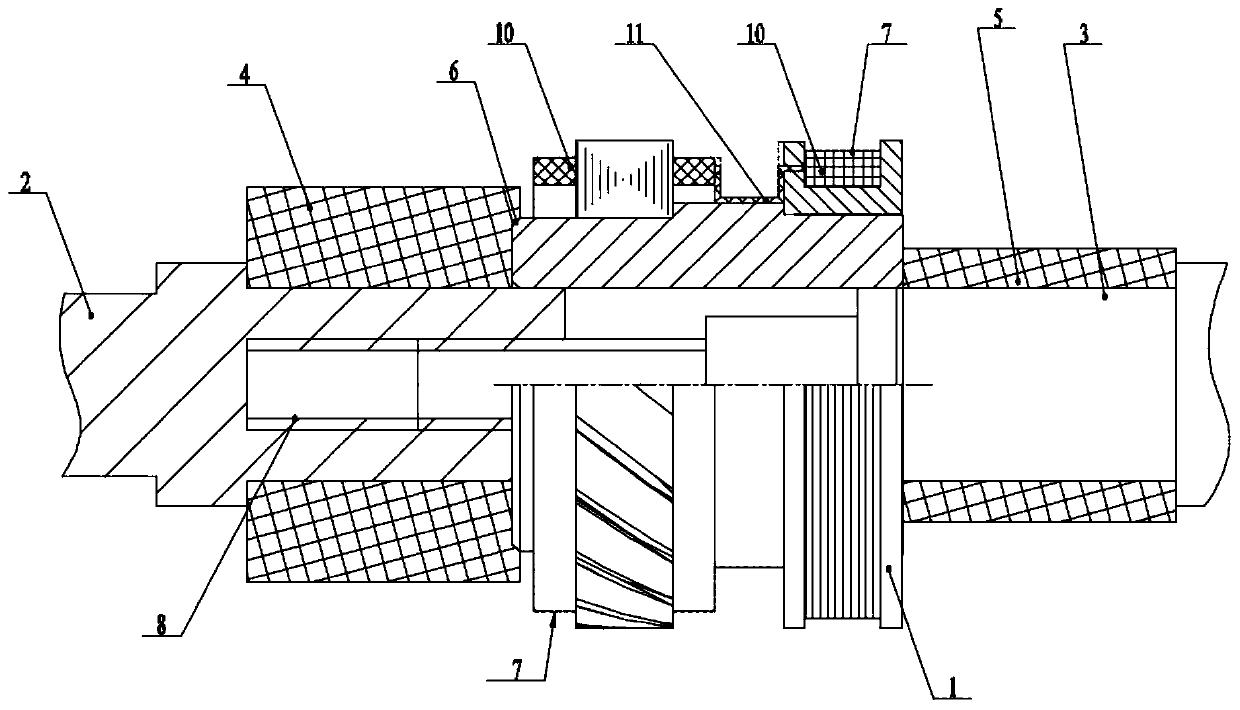

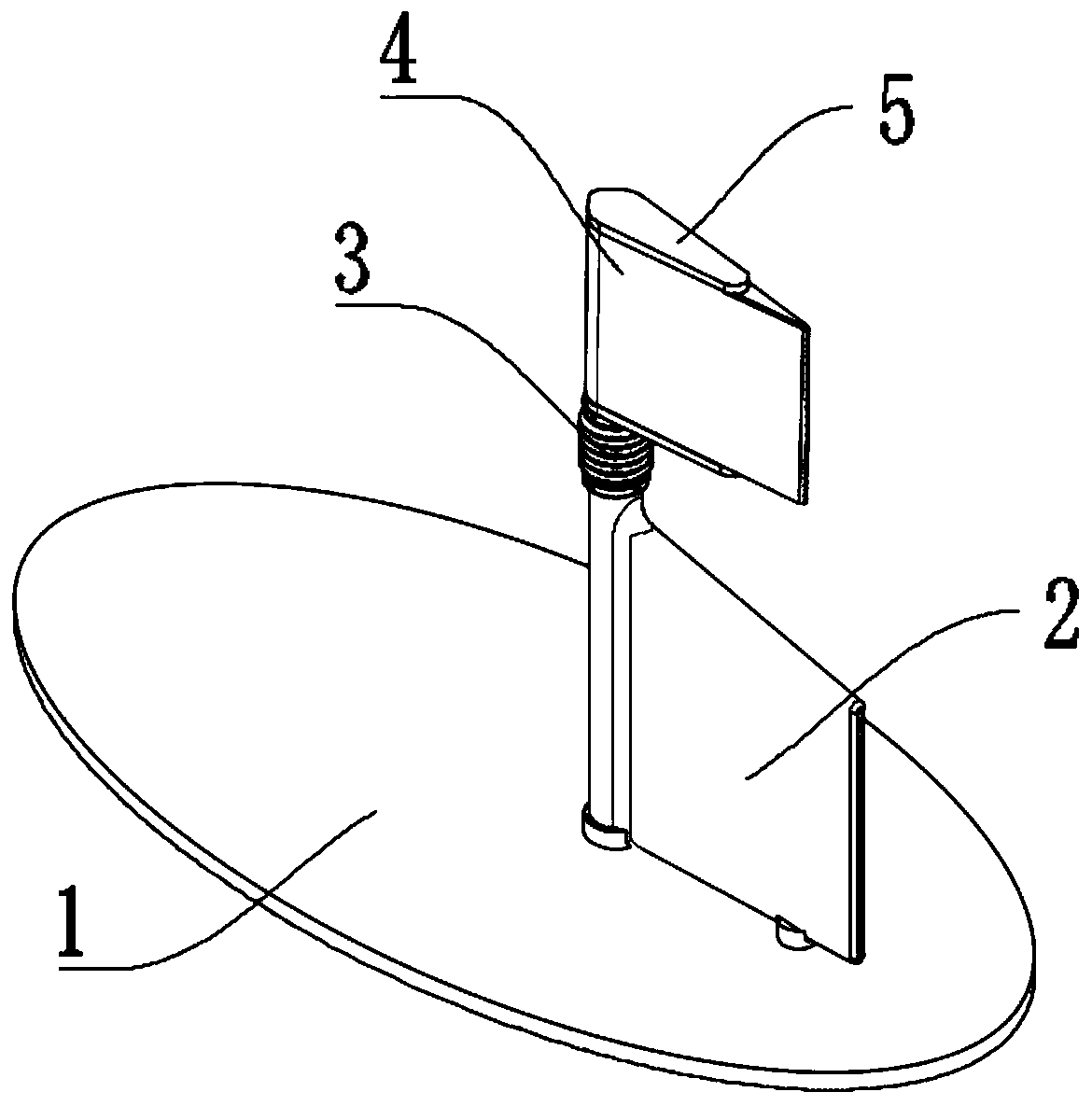

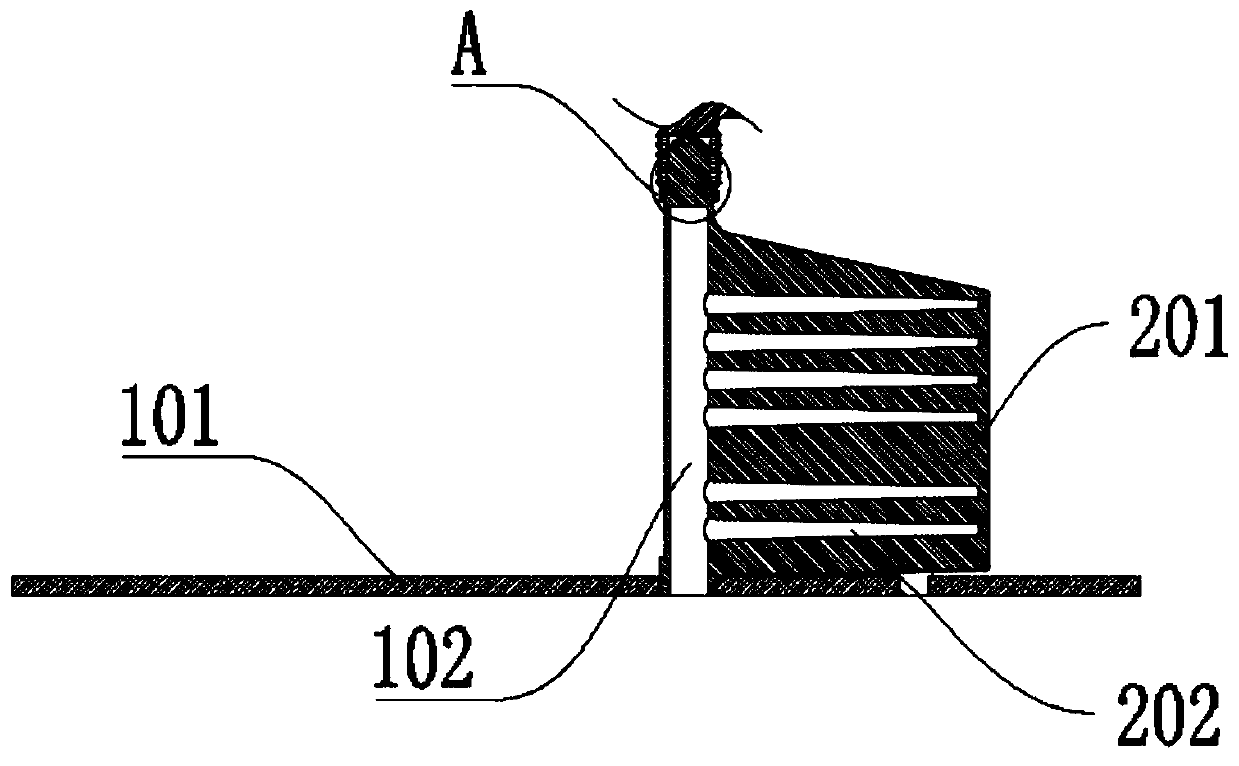

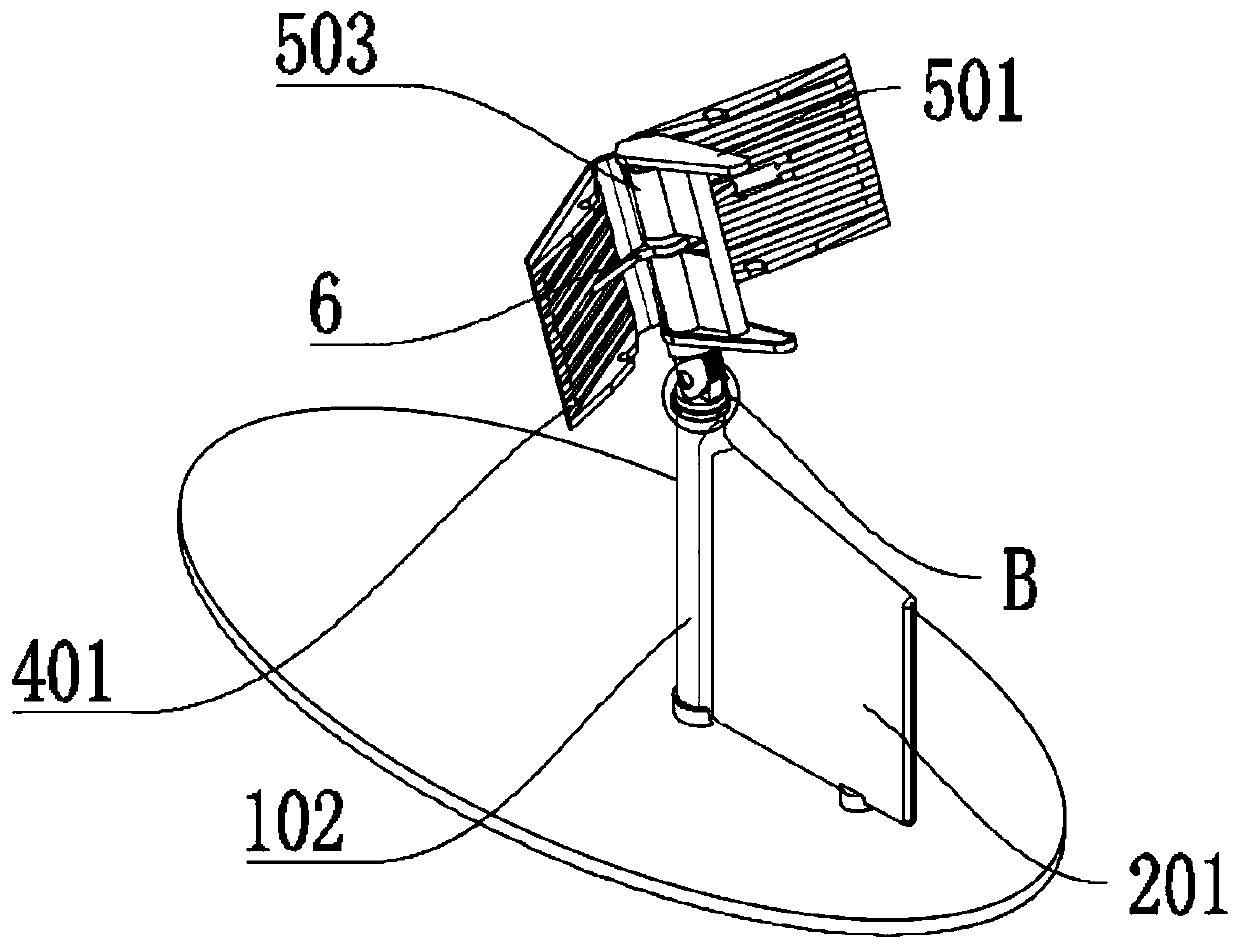

A highly integrated external three-proof antenna structure

ActiveCN111244596BWill not affect the signalImprove the performance of three defensesAntenna supports/mountingsAntenna adaptation in movable bodiesEngineeringMechanical engineering

Owner:浙江001集团有限公司

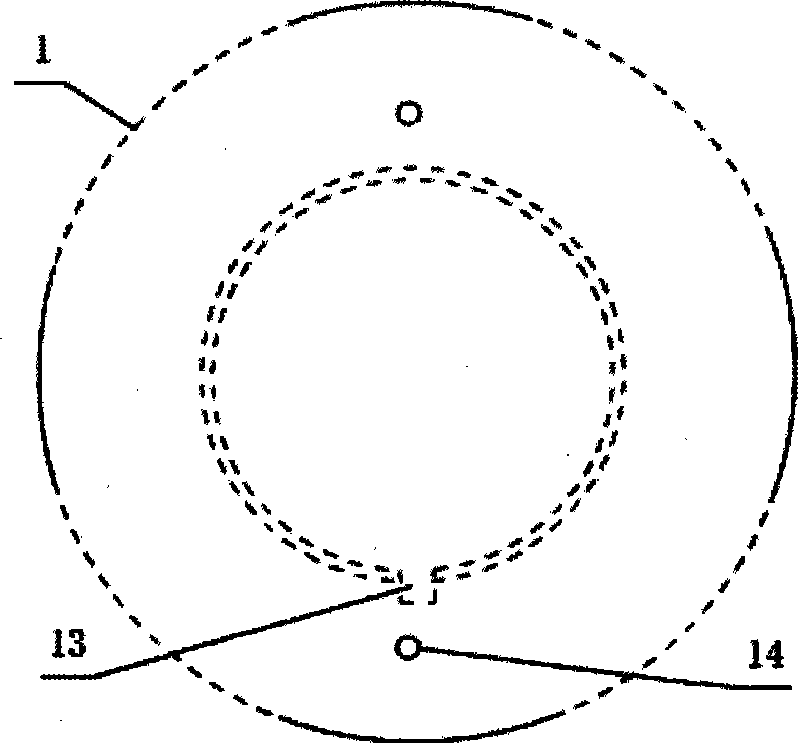

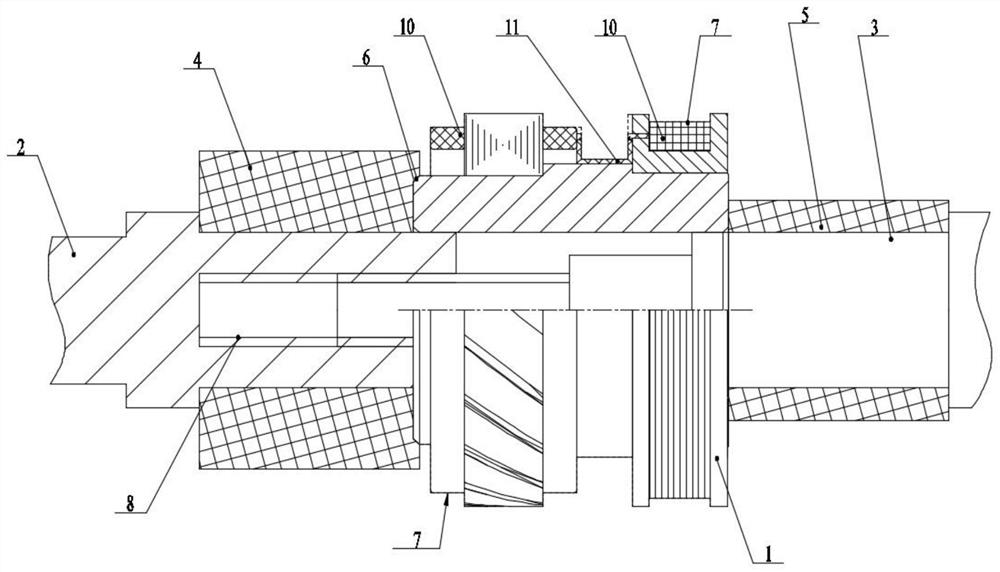

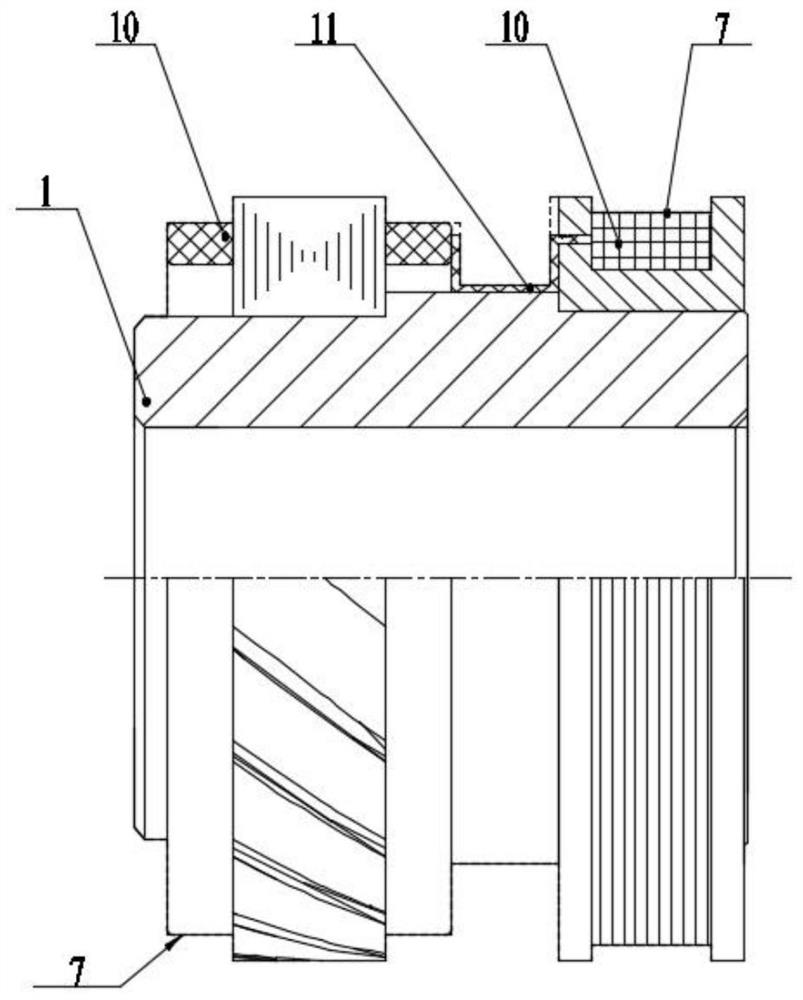

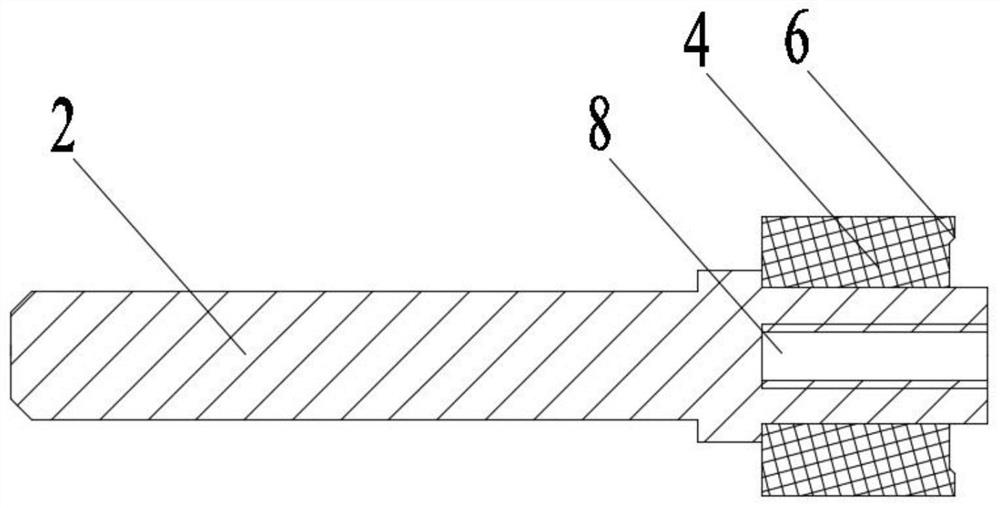

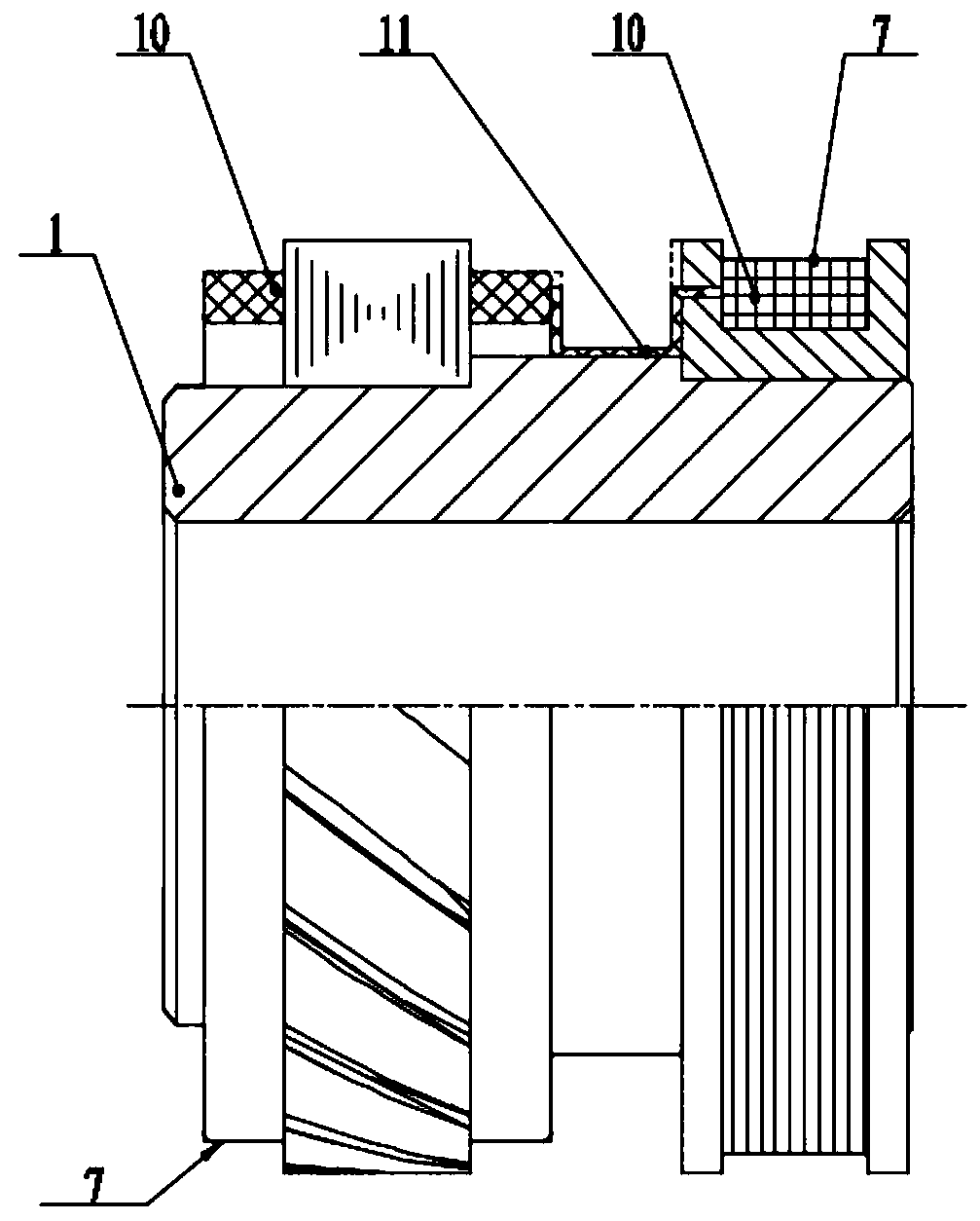

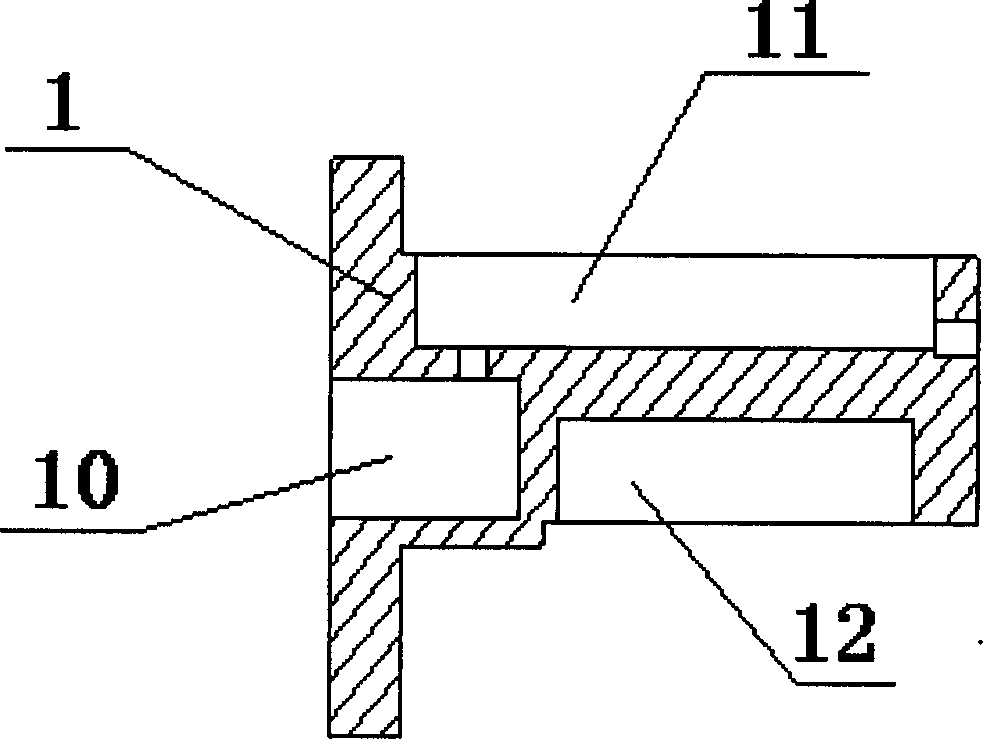

A packaging structure and method for a wound resolver rotor

ActiveCN110428961BAvoid enteringHigh mechanical strengthMagnetic circuit rotating partsTransformersControl theoryMechanical engineering

The present invention provides a package structure and method for the rotor of a wire-wound rotary transformer, which can effectively protect the rotor windings and wiring ends under the circumstances of the rotor falling to the ground, bumping, water ingress, etc., and greatly improving the service life of the rotary transformer and Reliable, and the appearance is beautiful and generous; it includes the rotor and the first and second toolings that are set oppositely. Inside, and the opposite ends of the first and second tooling are connected with the first and second locking parts in corresponding tight fit respectively, and the ends of the first and second tooling respectively protrude from the end faces of the corresponding first and second locking parts, The outer diameters of the first locking piece and the second locking piece are larger than the inner diameter of the inner hole of the rotor, and the outer diameter of the first locking piece is larger than the outer diameter of the corresponding end of the rotor. There are grooves to match the end of the rotor, and the outer circumference of the rotor is coated with epoxy.

Owner:苏州工业园区代尔塔电机技术有限公司

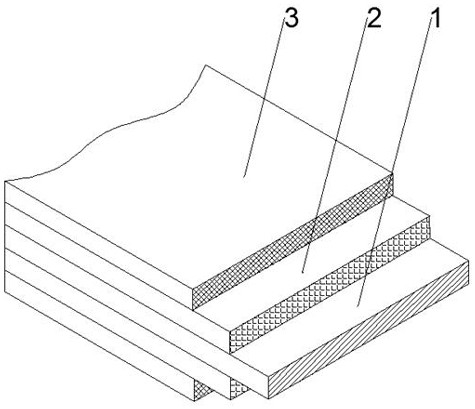

Chenille fabric with high-wear-resistance coatings and production process of chenille fabric

InactiveCN113306253AImprove wear resistanceEnhance layeringLiquid/gas/vapor removal by gas jetsVegetal fibresPolymer scienceWear resistance

The invention discloses a chenille fabric with high-wear-resistance coatings and a production process of the chenille fabric. The chenille fabric is characterized by comprising a base cloth layer, wherein gauze layers are arranged at the top end and the bottom end of the base cloth layer, and the wear-resistant coatings matched with the gauze layers is arranged on the sides, away from the base cloth layer, of the gauze layers. The fabric has the beneficial effects that multiple cloth layers are respectively interwoven and coined in a staggered manner, so every two cloth layers are connected with each other in a compacted manner; the wear resistance of the surface of the fabric can be greatly improved due to the existence of the wear-resistant coatings; in the process, the wear-resistant coatings are not specially produced in advance, materials capable of improving wear resistance, such as titanium boride particles and a simethicone solution, are used for preparing a solvent, and secondary soaking and a corresponding process are conducted, so the overall wear resistance of the fabric is improved, and the overall toughness and stability of the fabric can be improved; and in addition, the hand feeling and the three-proofing performance of the fabric can be improved, and the chenille fabric has higher layering sense, air permeability and strength.

Owner:江苏多来运纺织有限公司

A production process of high wear-resistant chenille three-proof fabric

ActiveCN109811454BImprove flame retardant performanceImprove the performance of three defensesSucessive textile treatmentsLiquid/gas/vapor removalYarnProcess engineering

The invention discloses a production process of a high wear-resistant chenille three-proof fabric, comprising the following steps: step S1 preparation of chenille yarn, step S2, step dyeing of chenille yarn, step S3 preparation of chenille fabric Weaving, step S4 flame retardant finishing of chenille fabric, step S5 three-proof finishing of chenille fabric. The production process of a high wear-resistant chenille three-proof fabric involved in the present invention uses a plurality of core yarns including hot-melt filaments by changing the structure of the chenille yarn, and increases the twist of the core yarn, The wear resistance of the chenille yarn is improved, and the problem of hair shedding is reduced as much as possible. And optimized the flame retardant and three-proof finishing process of chenille fabric. Through the selection of suitable flame retardant and three-proof finishing agent, as well as the reasonable selection of technology, the flame retardant performance and three-proof finishing of chenille fabric were improved. Anti-proof effect, and the fabric still has good flame-retardant performance and three-proof effect after repeated washing.

Owner:浙江瓒成新材料科技有限公司

Package structure and method for wound-type rotary transformer rotor

ActiveCN110428961AAvoid enteringHigh mechanical strengthMagnetic circuit rotating partsTransformersEngineeringConductor Coil

The invention provides a package structure and a method for a wound-type rotary transformer rotor, which can effectively protect a rotor winding and a wiring wire head under the conditions of the rotor landing, bumping and water entering, greatly improve the service life and the reliability of the rotary transformer and the appearance is beautiful and elegant. The package structure comprises a rotor and first and second tools which are oppositely arranged, the first and second tools are cylindrical shapes, the opposite end portions of the first and second tools are respectively correspondinglylocked in the inner holes of the two ends of the rotor, the opposite end portions of the first and second tools are respectively, correspondingly and tightly cooperated and connected with first and second locking pieces, the first and second tool end portions are respectively extruded to the corresponding end portions of the first and second locking pieces, the outer diameters of the first locking piece and the second locking piece are larger than the inner diameters of the inner holes of the rotor, the outer diameter of the first locking piece is larger than the outer diameter of the corresponding end portion of the rotor, the end face of the first locking piece of the rotor side is provided with the groove matching with the end portion of the rotor, and the outer round surfaces of the rotor are coated with epoxy layers.

Owner:苏州工业园区代尔塔电机技术有限公司

A post-finishing process of waterproof, oil-proof and antifouling fabric

ActiveCN106320024BImprove the performance of three defensesSmooth and soft surfaceSucessive textile treatmentsDry-cleaning apparatus for textilesTextile technologyEngineering

The invention provides a finishing process of waterproof, oil-proof and antifouling fabric, belongs to the technical field of textile, and solves the problem that an existing fabric finishing process is complex and cannot improve the waterproof performance, oil-proof performance and antifouling performance of fabric. The finishing process of the waterproof, oil-proof and antifouling fabric is characterized by including the steps of 1), dyeing; 2), performing first washing; 3), performing second washing; 4), performing third washing; 5), performing fourth washing; 6), performing hot rolling; 7), performing film coating; 8), napping. The finishing process has the advantages that the process is little in damage on the fabric, and the surface of the fabric is allowed to be smooth and soft and good in comfortableness; the hot rolling and the film coating can be performed at the same time, and the waterproof performance, oil-proof performance and antifouling performance of the fabric can be improved.

Owner:南通茧缘丝绸纺织有限公司

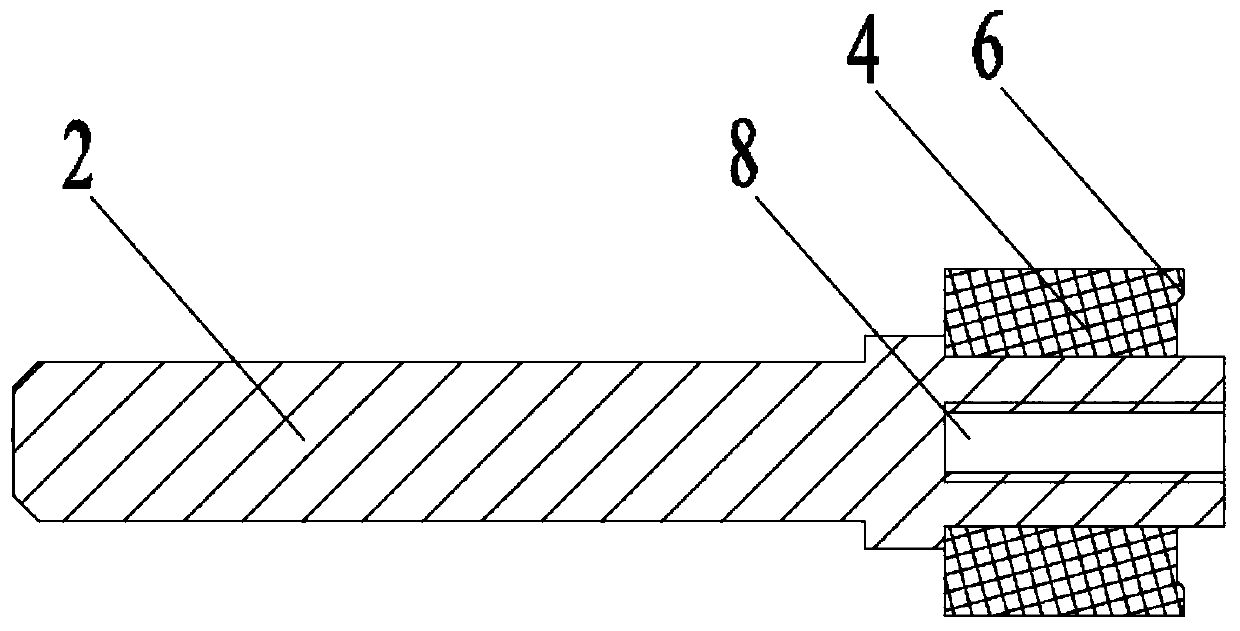

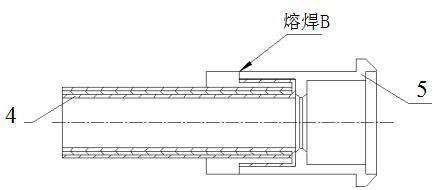

Aircraft ignition cable assembling method

InactiveCN112397966AHigh strengthImprove the performance of three defensesLine/current collector detailsWelding/cutting auxillary devicesStructural engineeringFusion welding

The invention discloses an aircraft ignition cable assembling method, and the method comprises the following steps: sleeving the outer side of the end part of a metal hose with a first connecting sleeve, and carrying out primary fusion welding on the end part to obtain a hose assembly; enabling the copper braided sleeve to penetrate through the hose assembly and to be turned outwards at the end ofthe hose assembly; sleeving the outer side of the end of the hose assembly with a second connecting sleeve, arranging a copper braided sleeve between the first connecting sleeve and the second connecting sleeve, and performing secondary fusion welding on the joint of the first connecting sleeve, the second connecting sleeve and the copper braided sleeve. According to the method, the original assembling and welding process is divided into two times, one original metal part is divided into two parts, and meanwhile original brazing machining is improved into two times of fusion welding forming.The assembly structure is high in practicability, and the problem that an existing assembly structure cannot meet the three-proofing performance of a product is solved. Meanwhile, the structural strength is improved, the appearance is attractive, the manufacturability is good, and the universal applicability is achieved.

Owner:四川泛华航空仪表电器有限公司

A kind of wetting agent for three-proof finishing and preparation method thereof

ActiveCN111910437BImprove finishing effectImprove stabilityStain/soil resistant fibresLiquid repellent fibresSolubilityActive agent

The invention discloses a wetting agent for three-proof finishing and a preparation method thereof, which comprises the following raw materials in parts by mass: 1-10 parts of surfactant, and the molecular formula is C 6 h 5 5-20 parts of ‑O‑R‑OH substances, 5‑10 parts of environmentally friendly solvents, and 60‑90 parts of water. The present invention is prepared by secondary mixing method at room temperature, and the reaction process is carried out at 60°C. The reaction conditions are very mild, which can effectively reduce the phenomenon of decomposition during the reaction. In addition, the excellent dispersibility and surface activity of the surfactant and the environmentally friendly solvent are used respectively. Good dissolution and solubilization, ensure the stability and reliability of the reaction, and improve the molecular formula of C 6 h 5 ‑O‑R‑OH substances have solubility and dispersion properties in mixed systems. The wetting agent for three-proof finishing obtained in the present invention can improve the liquid-carrying rate and uniformity of the fabric and the three-proof effect of the fabric during the three-proof finishing of fabrics with poor permeability, but will not affect the performance of the three-proof finishing agent .

Owner:GUANGDONG ZHAN FENG FINE CHEM CO LTD

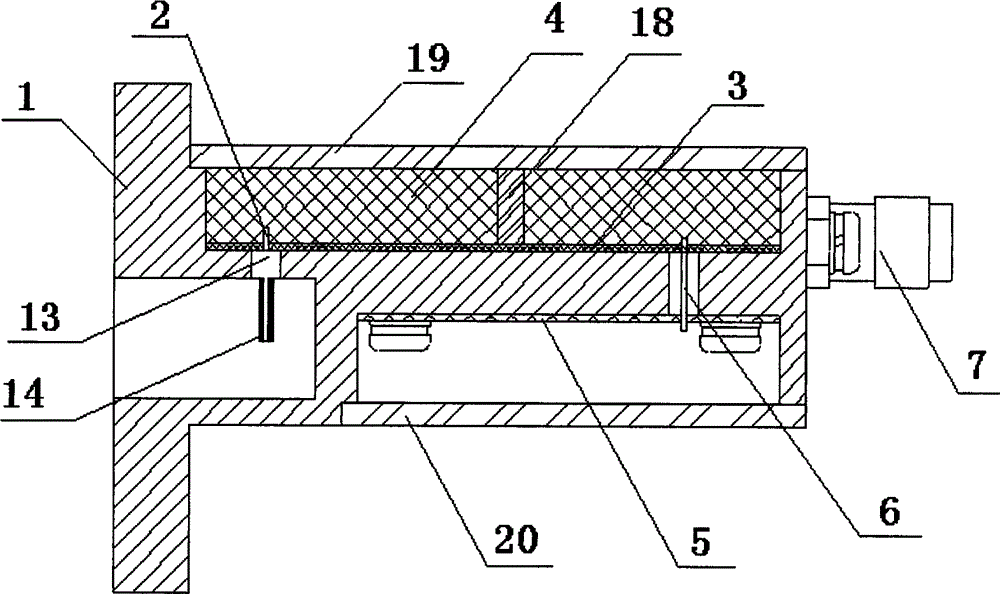

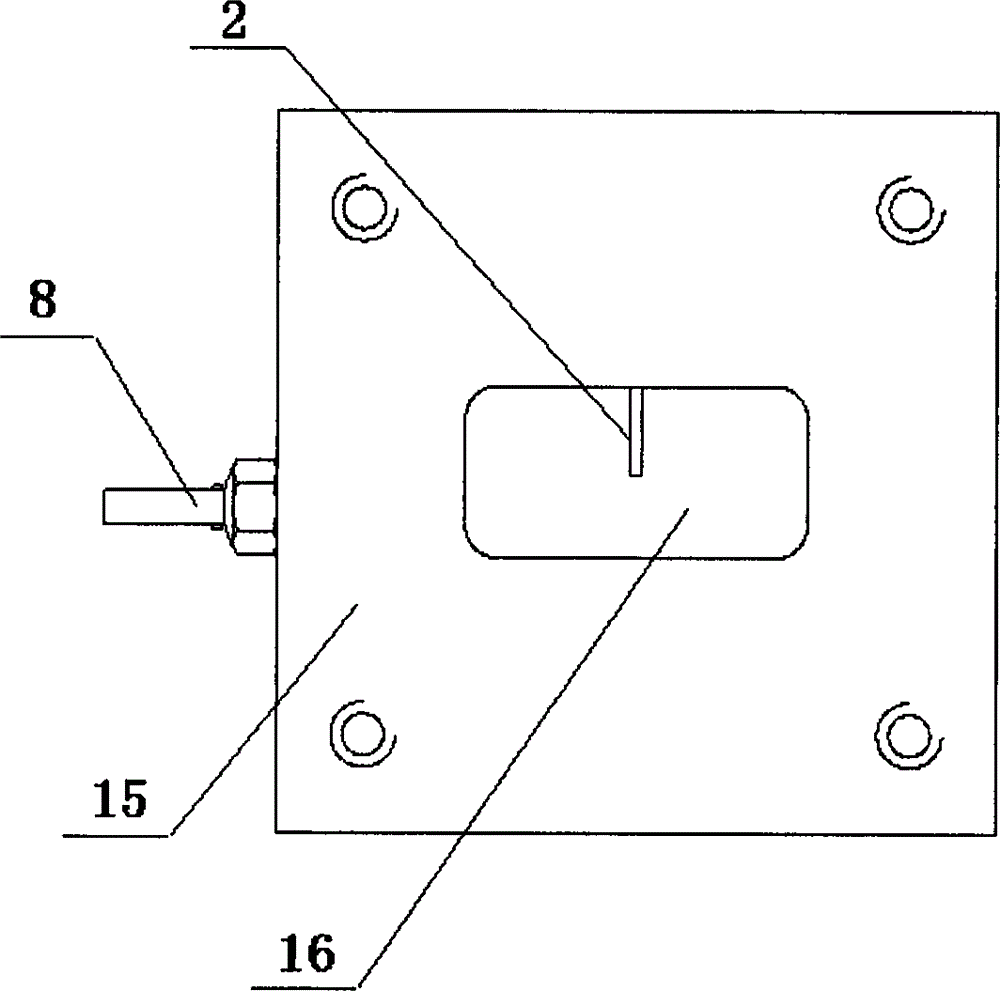

Ku frequency band low-noise amplifier

ActiveCN102510266BSimple structureEasy to installAmplifier modifications to reduce noise influenceAudio power amplifierEngineering

The invention discloses a Ku frequency band low-noise amplifier which comprises a shell, a probe, a radio-frequency circuit board, movable separating tendons, a power supply board, a direct-current feed needle, a coaxial connector, a feed-through capacitor and an earthing rod, wherein the shell is provided with three cavities communicated with the outside, and the three cavities respectively serve as a wave guide cavity, an upper shielding box body and a lower shielding box body; the movable separating tendons are symmetrically distributed above the radio-frequency circuit board, and are fixed in the upper shielding box body together with the radio-frequency circuit board by adopting a demountable static connection mode; the probe penetrates through a transitional pore between the upper shielding box body and the wave guide cavity; the upper end of the probe and the radio-frequency circuit board are welded; the lower end of the probe is positioned in the wave guide cavity; the feed-through capacitor and the power supply board are welded; the earthing rod is connected with the shell; the power supply board is fixed in the lower shielding box body; the direct-current feed needle penetrates through a structure hole between the upper shielding box body and the lower shielding box body, the upper end of the direct-current feed needle and the radio-frequency circuit board are welded, and the lower end of the direct-current feed needle and the power supply board are welded; and the coaxial connector for outputting amplification signals and the radio-frequency circuit board are welded. According to the invention, the structure of the shell of the amplifier is simplified, the mounting of the circuit board is simpler, and the Ku frequency band low-noise amplifier is convenient to dismount repeatedly.

Owner:BEIJING RES INST OF TELEMETRY

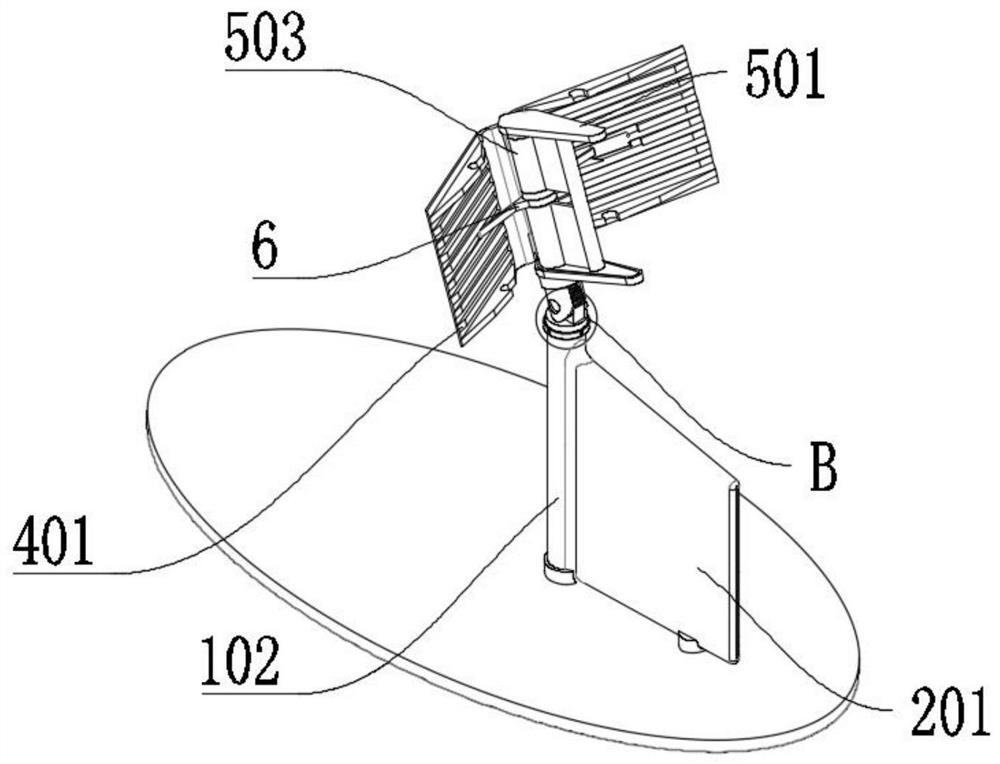

High-integration external three-proofing antenna structure

ActiveCN111244596AWill not affect the signalImprove the performance of three defensesAntenna supports/mountingsAntenna adaptation in movable bodiesSignal linesStructural engineering

The invention provides a high-integration-level external three-proofing antenna structure. The high-integration-level external three-proofing antenna structure comprises a fixing structure. A side antenna structure is mounted on one side of the upper end of the fixing structure; the side antenna structure comprises a side signal plate and an inner signal lines, a side signal plate of the antennastructure is arranged on one side of the mounting fixing column; the side signal plate and the mounting fixing column are mutually fixed in a welding mode, a plurality of transverse open grooves i formed in the side signal plate. The inner signal lines are mounted in the formed open grooves, and the fixing structure and the collecting plate structure are mutually connected through an adjusting mechanism; the root portion of the collecting plate structure is connected to the fixed sealing structure in a hinged mode. The root of the inner extending structure is arranged on the fixed sealing structure in a sleeving mode, the tail end of the inner extending structure is fixedly connected to the inner wall of the collecting plate structure, and the side signal plate and the mounting fixing column are sealed through welding, so that the side signal plate can enhance the three-proofing effect on the interior, and signals cannot be affected.

Owner:浙江001集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com