Brazed sealed machine box having internal support and used for ocean environment

An internal support, marine environment technology, applied in sealed enclosures, electrical components, substation/switch layout details, etc., can solve problems such as electromagnetic compatibility and three-proof performance can not be guaranteed, to increase the three-proof performance, reduce product weight, Increase the effect of tightness and electromagnetic compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings.

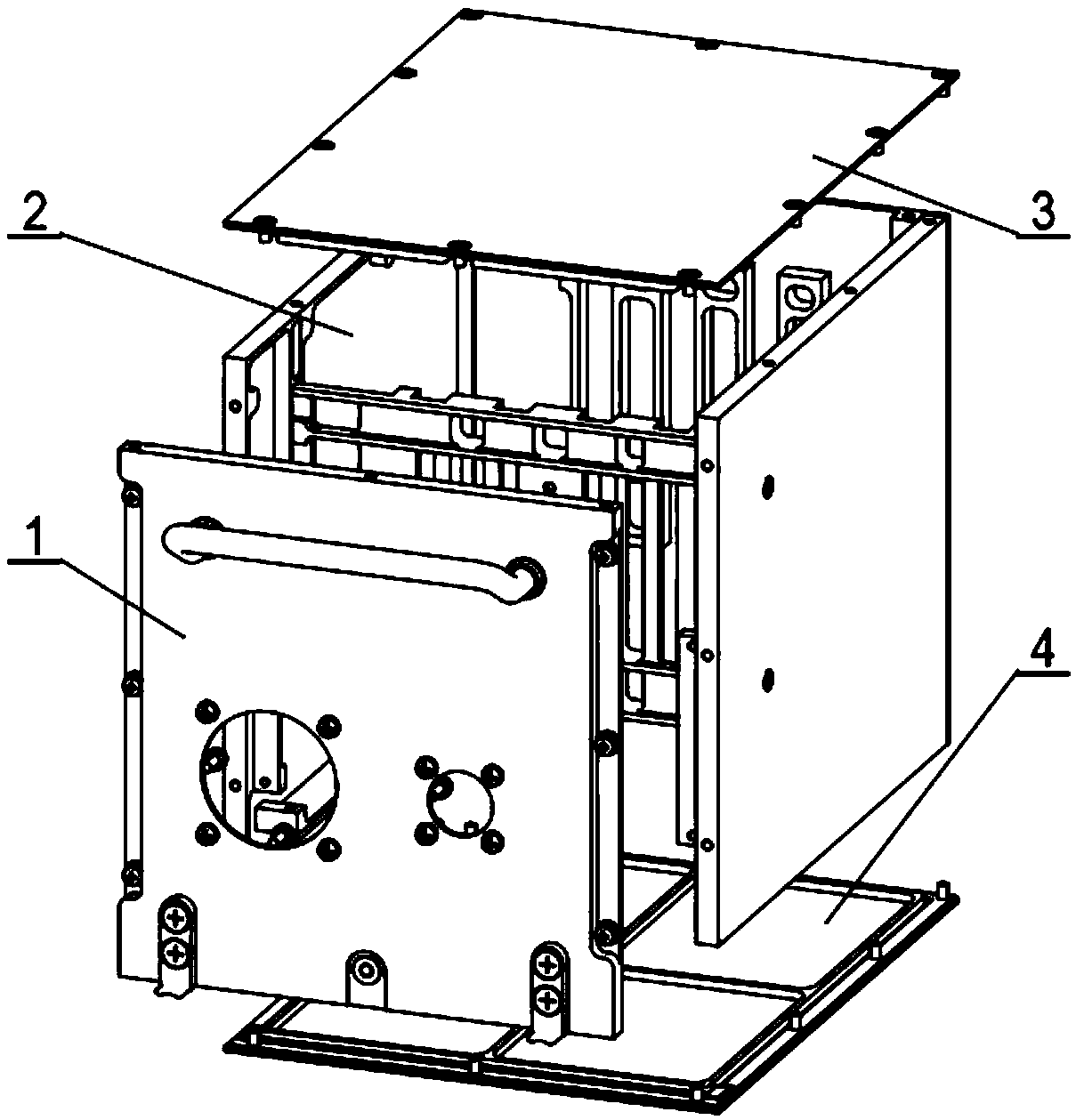

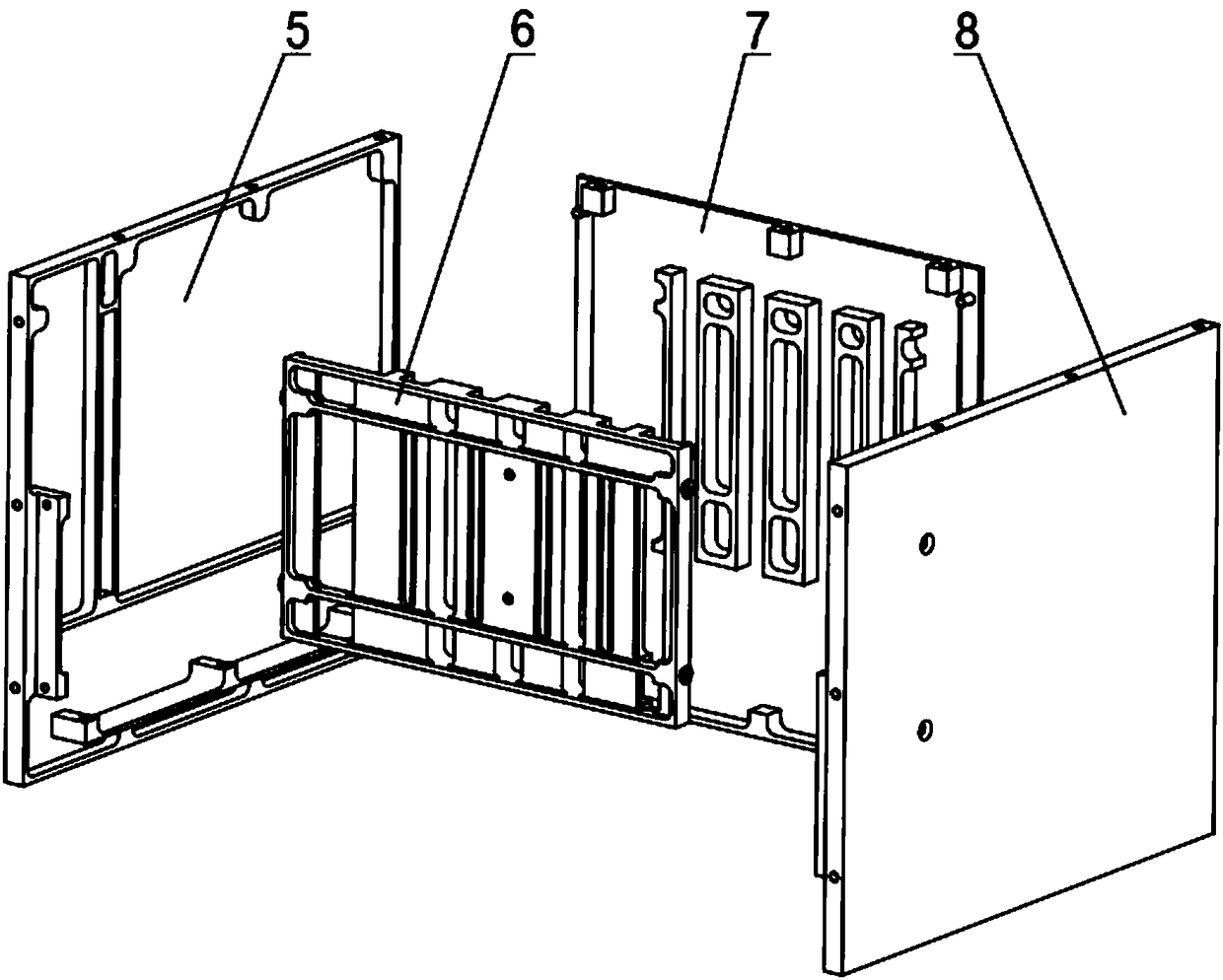

[0033] Such as figure 1 As shown, the chassis is composed of a front panel 1, a housing part 2, an upper cover 3 and a lower bottom plate 4, wherein the housing part 2 is as figure 2 As shown, it is made up of left side plate 5, dividing plate 6, rear panel 7 and right side plate 8. Among them, there are grooves on the inner surface of the left side plate 5 and the right side plate 8, and vacuum brazing solder is placed in the grooves, the partition plate 6 is inserted into the grooves, fixed with screws, and the rear panel 7 is respectively connected to the left and right side plates Fix with screws after adding solder. After fixing, put the shell part 2 into a vacuum brazing furnace for welding, and after the welding is completed, retighten the screws to enhance the fixing effect.

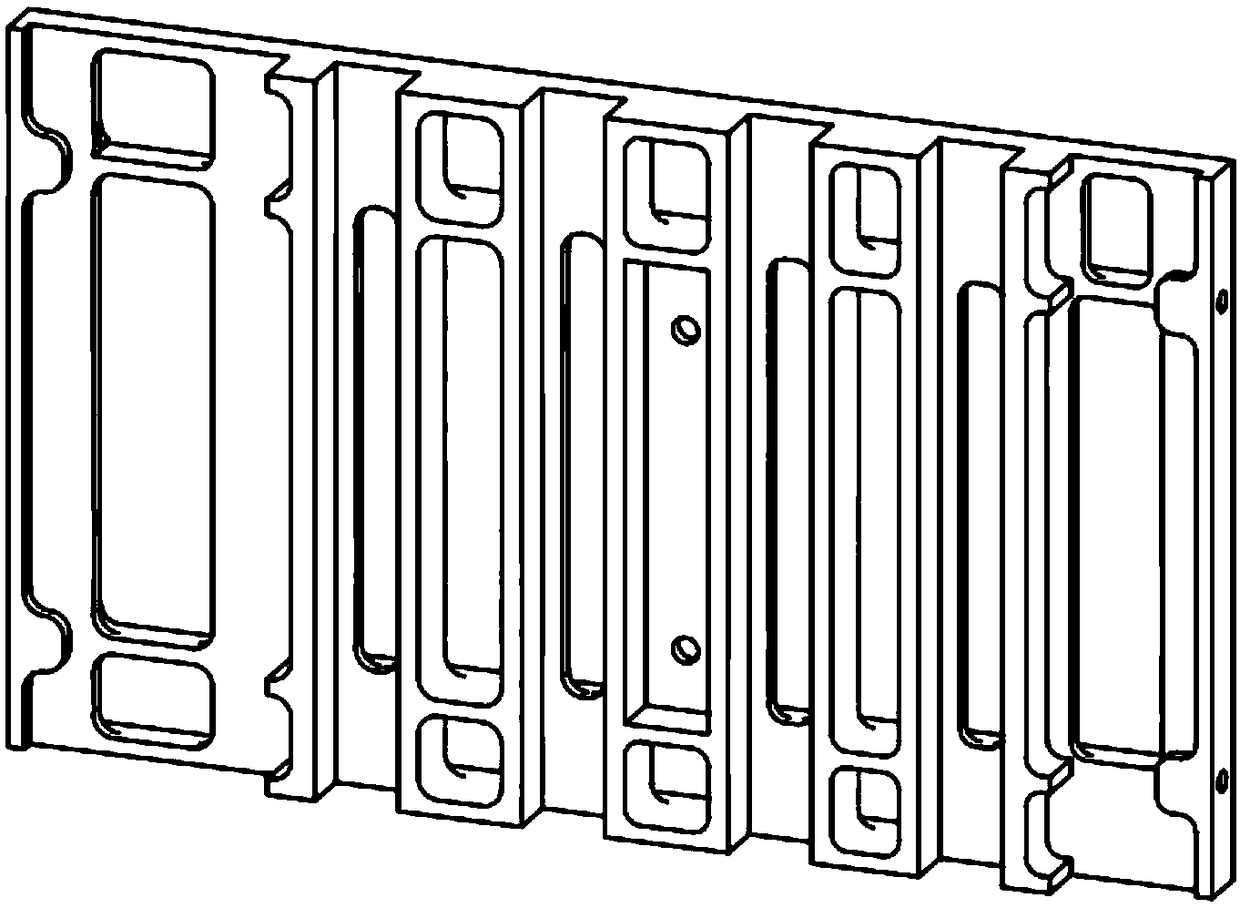

[0034] Internal partitions 6 such as image 3 As shown, the main funct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com