Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Improve plastic quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

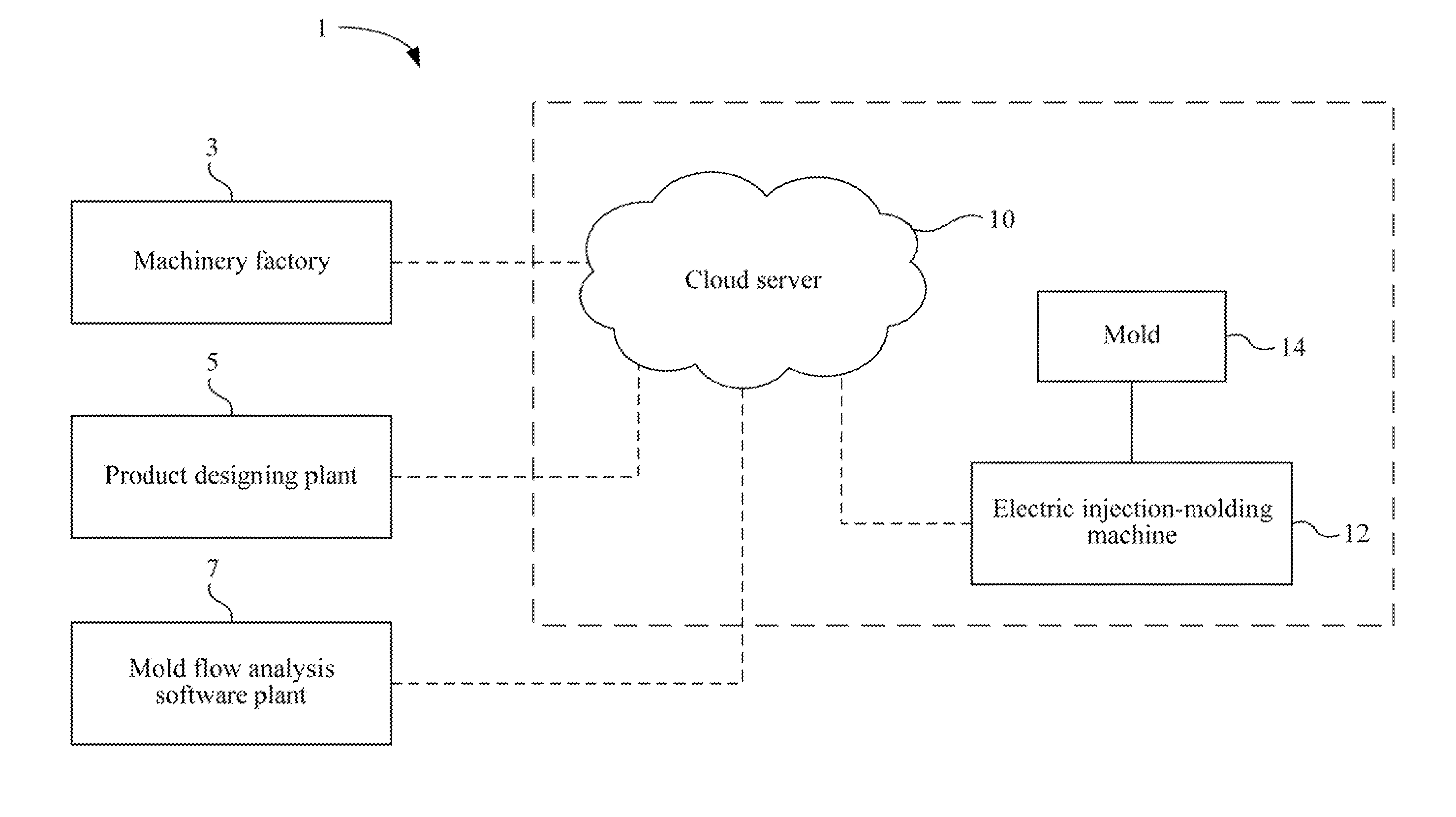

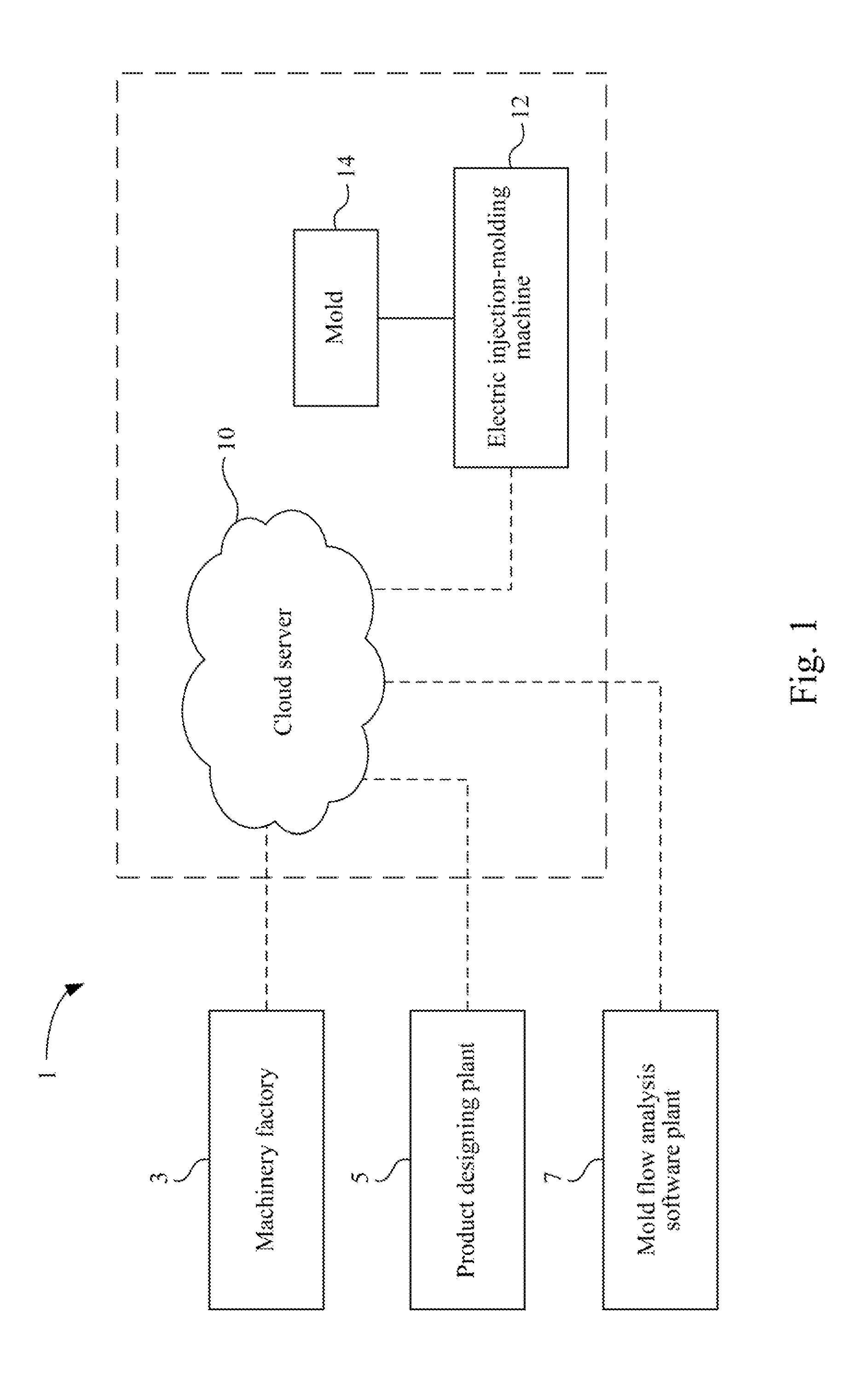

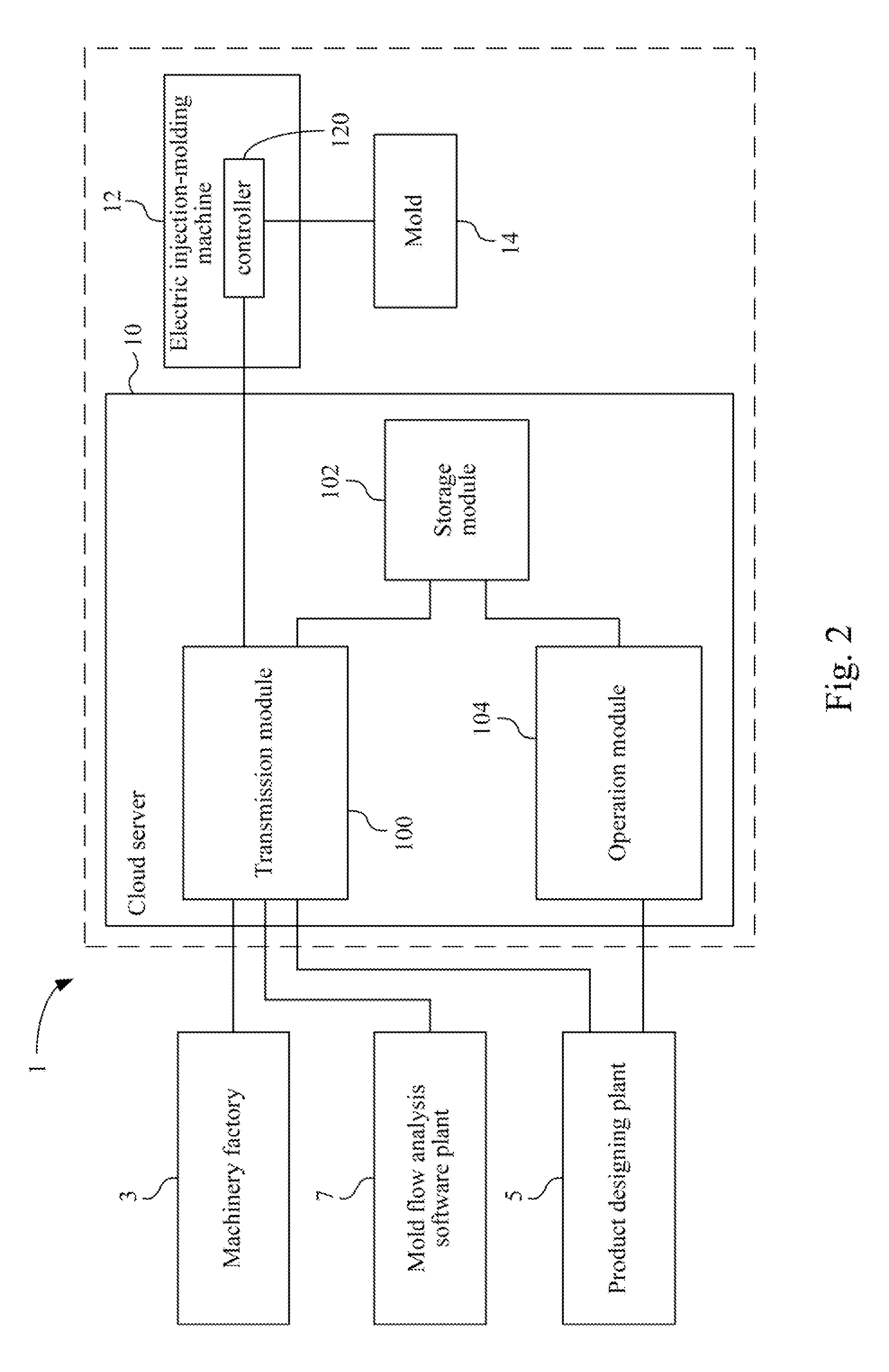

Plastic product manufacturing method and all-electric injection-molding machine

ActiveUS20130345855A1Improved plastic product manufacturing methodSystematically storedPasswordInjection molding machine

A plastic product manufacturing method includes (a) providing a cloud server which stores a machine number and machine parameters of an all-electric injection-molding machine that includes a controller; (b) downloading the machine parameters from the cloud server according to the machine number; (c) executing mold flow analysis software to generate model data and optimal injection conditions of a mold according to the machine parameters; (d) setting a mold number and a password to the model data and the optimal injection conditions and then storing the same in the cloud server after packaging; (e) connecting to the cloud server using the machine number, the mold number, and the password by the controller; (f) downloading the optimal injection conditions to the controller after the cloud server confirms the machine number, the mold number, and the password; and (g) driving the all-electric injection-molding machine by the controller according to the optimal injection conditions.

Owner:DELTA ELECTRONICS INC

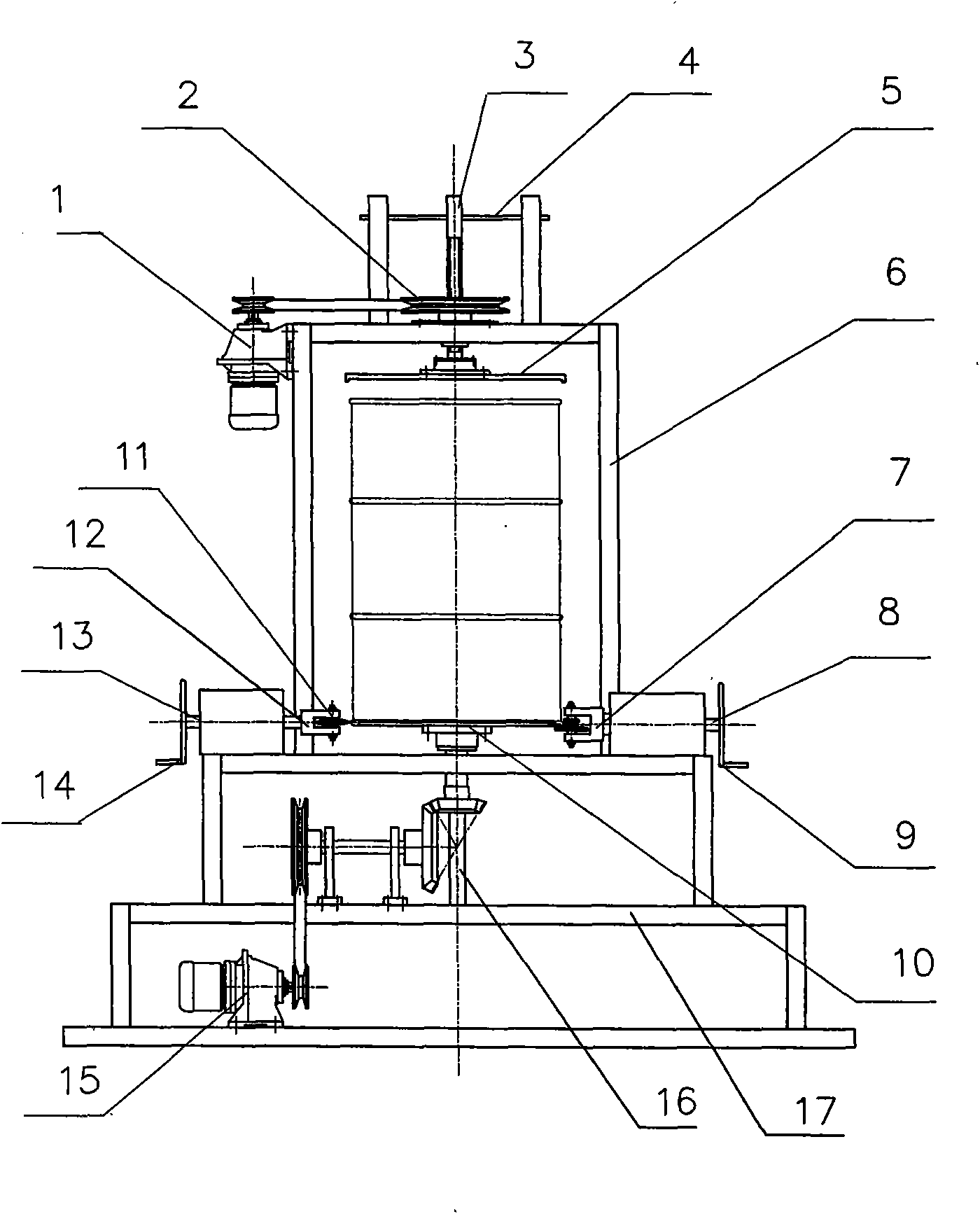

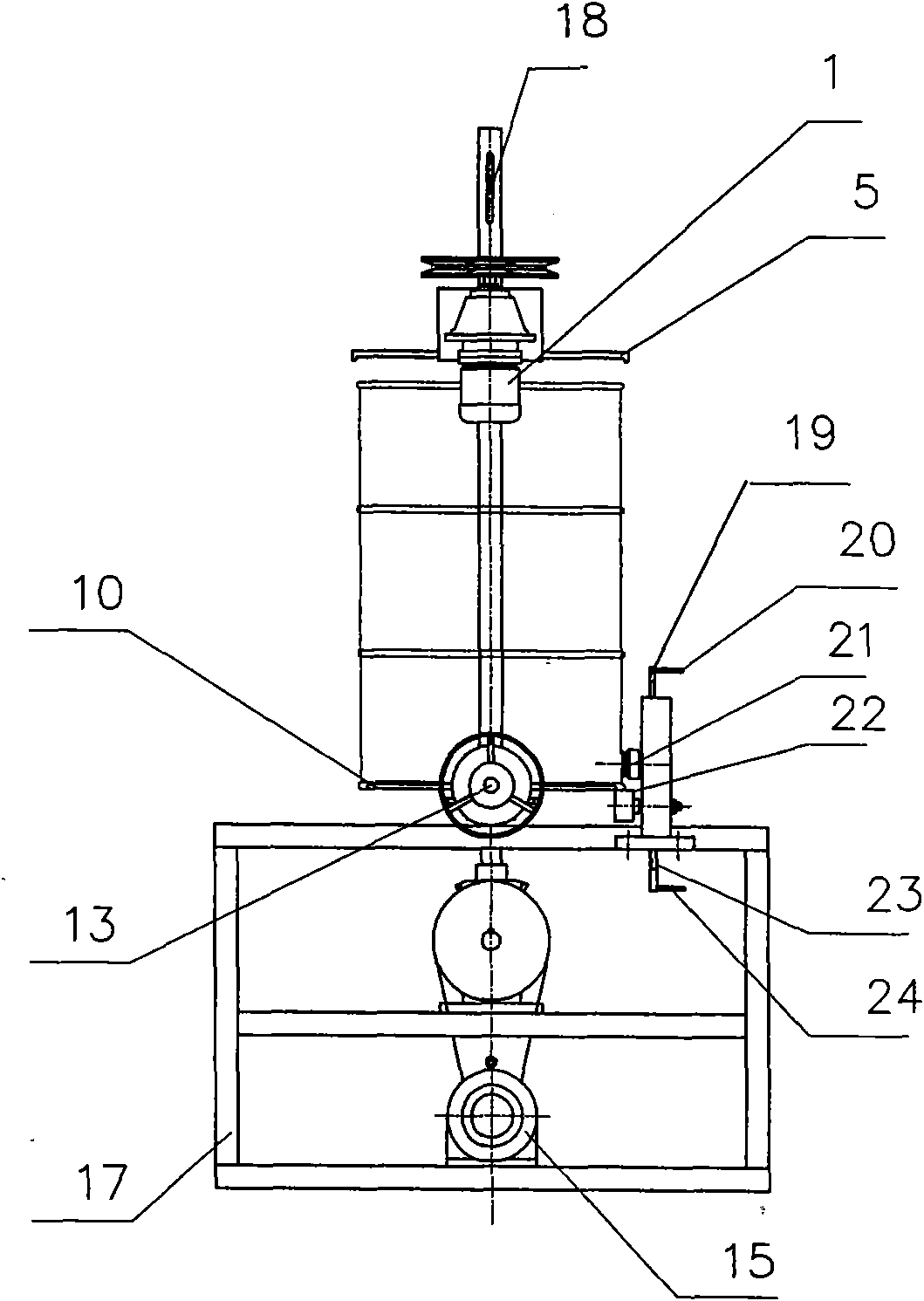

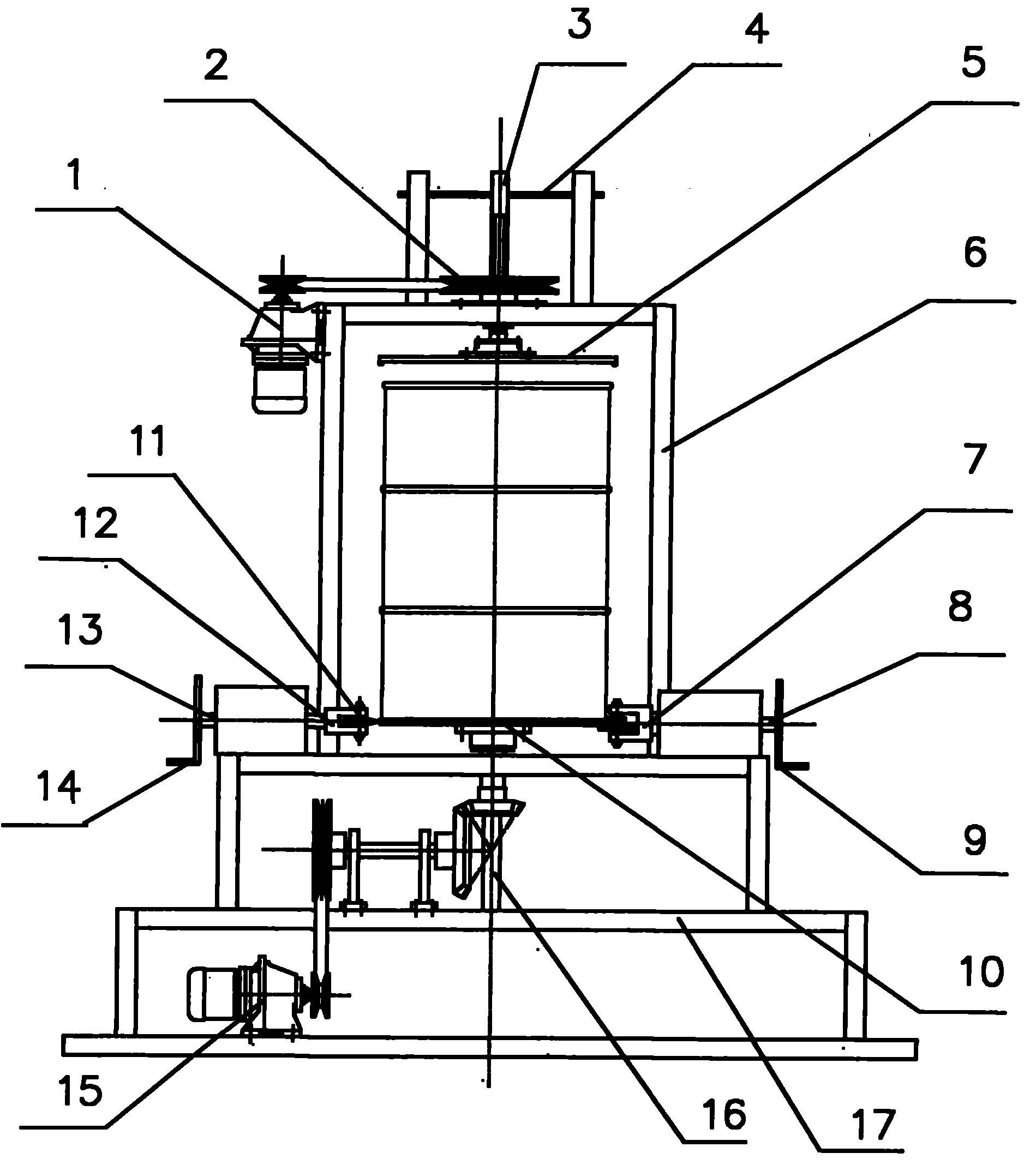

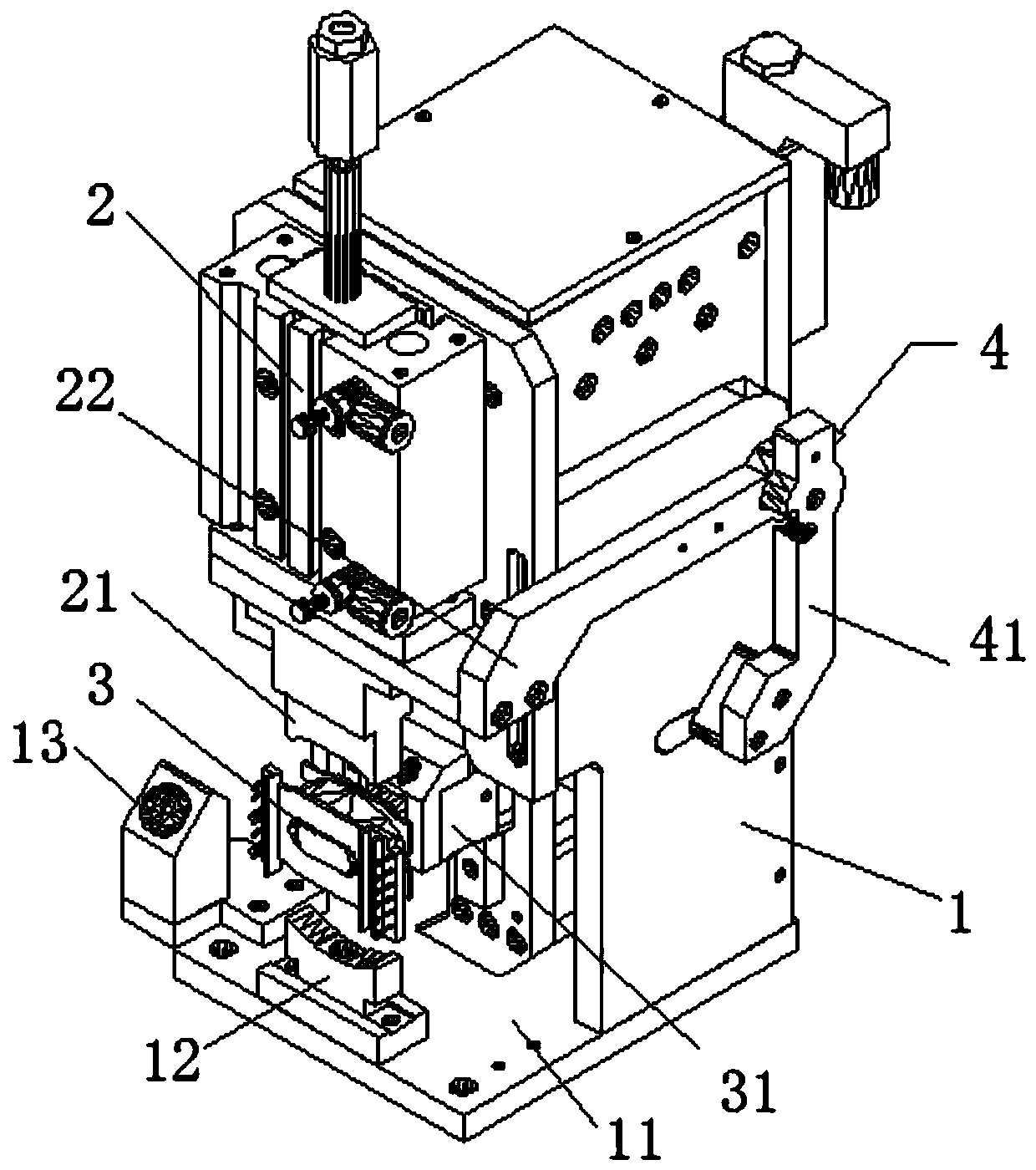

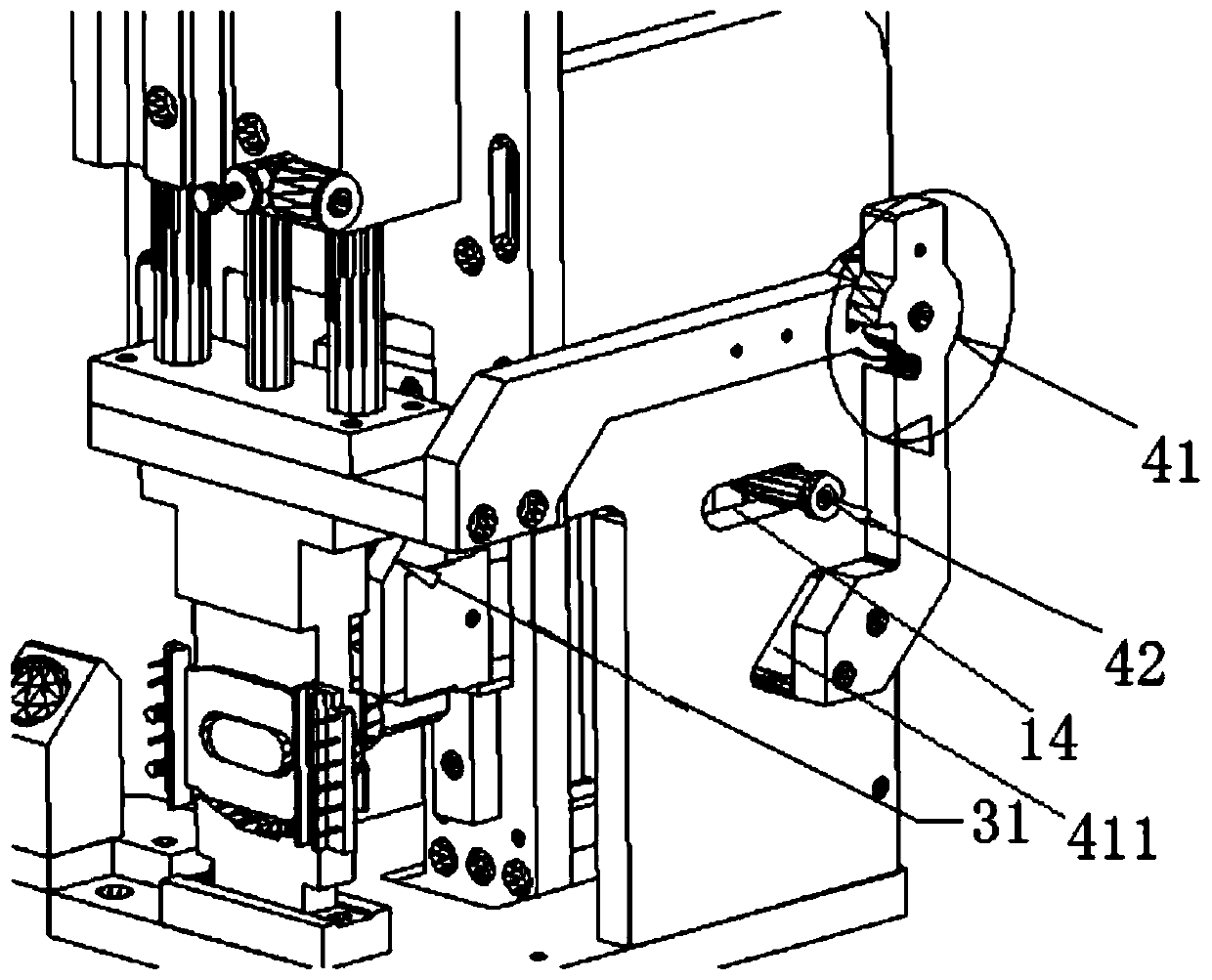

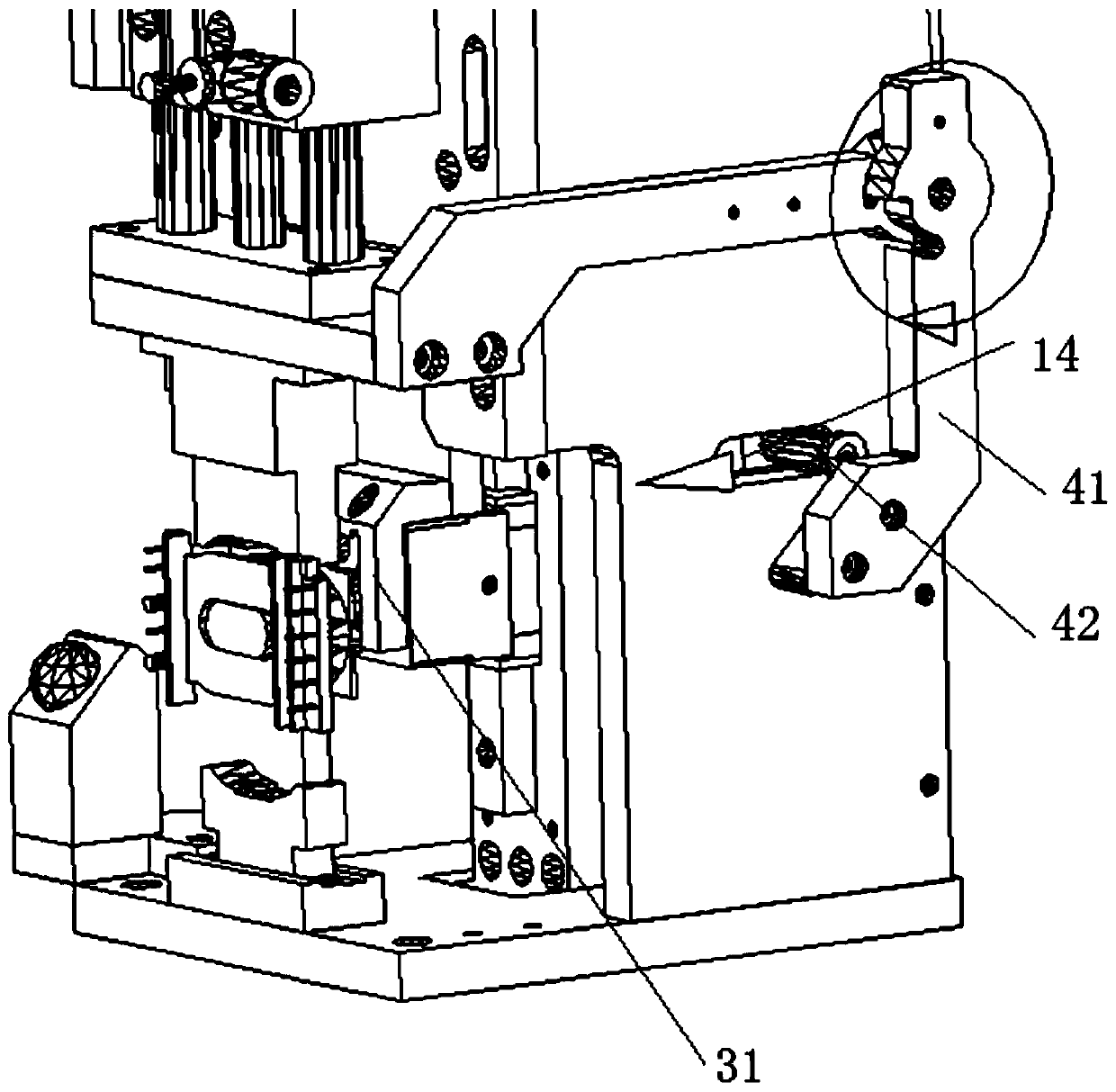

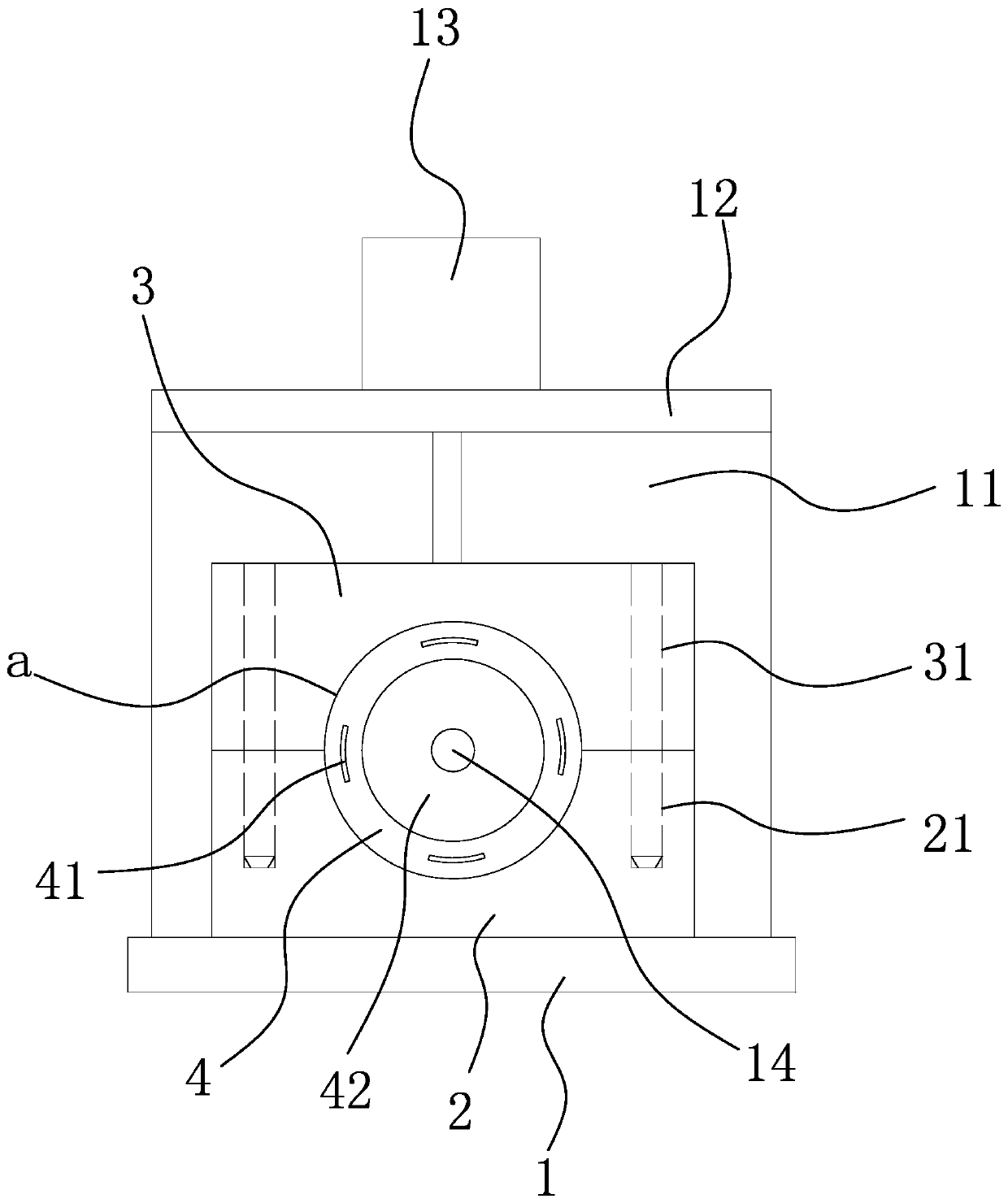

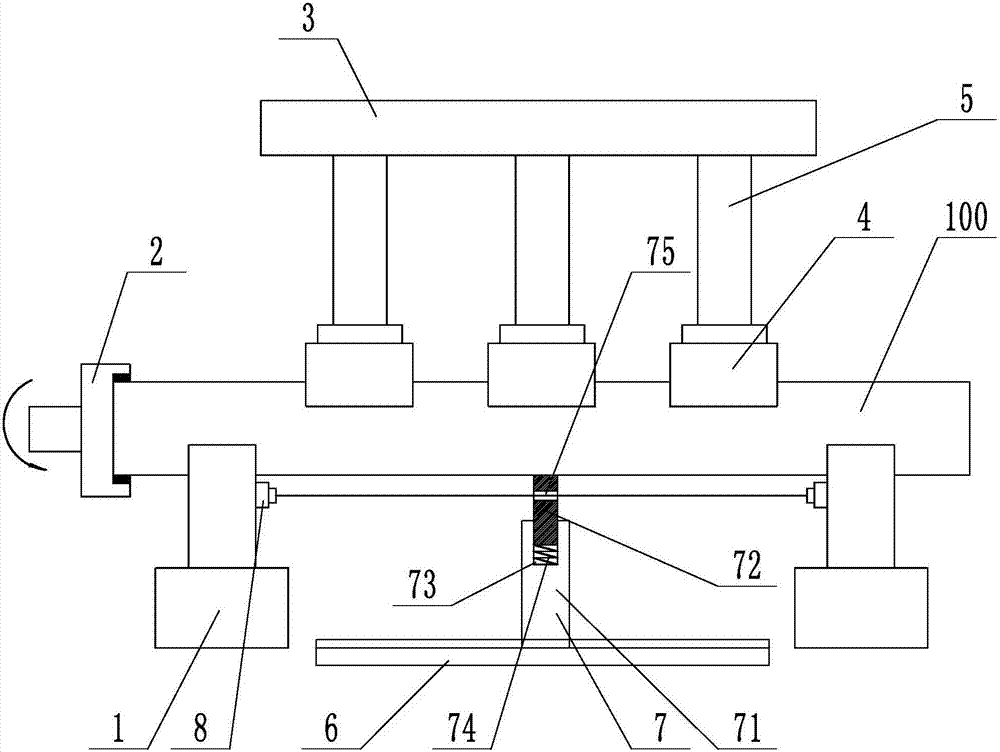

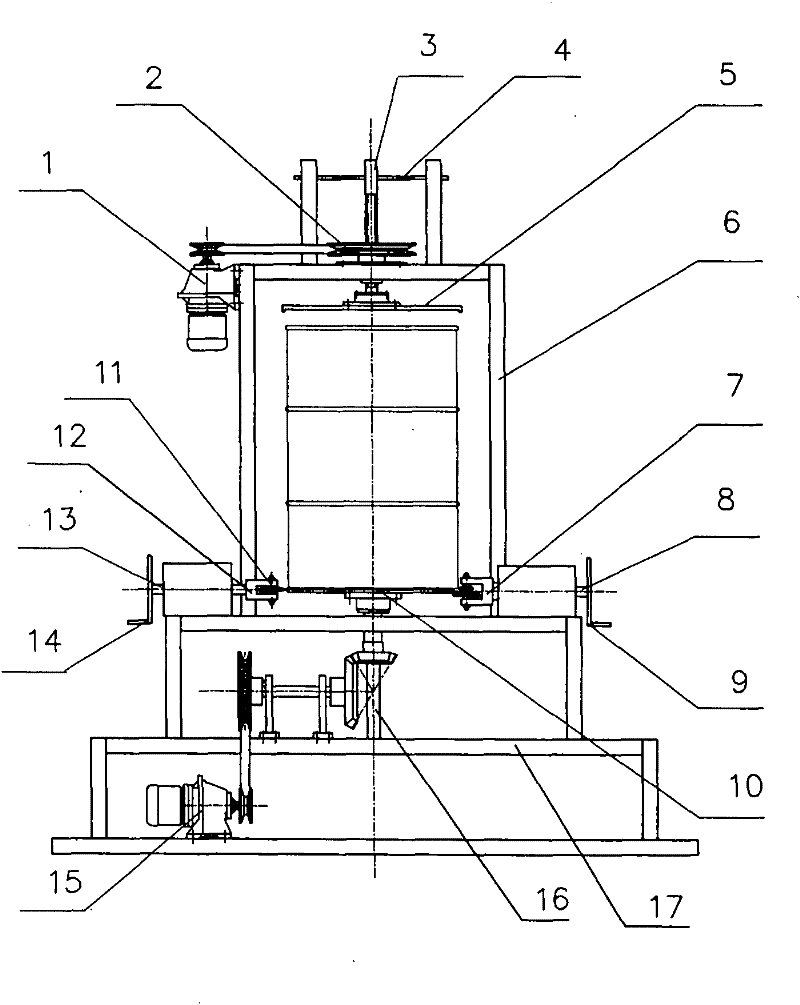

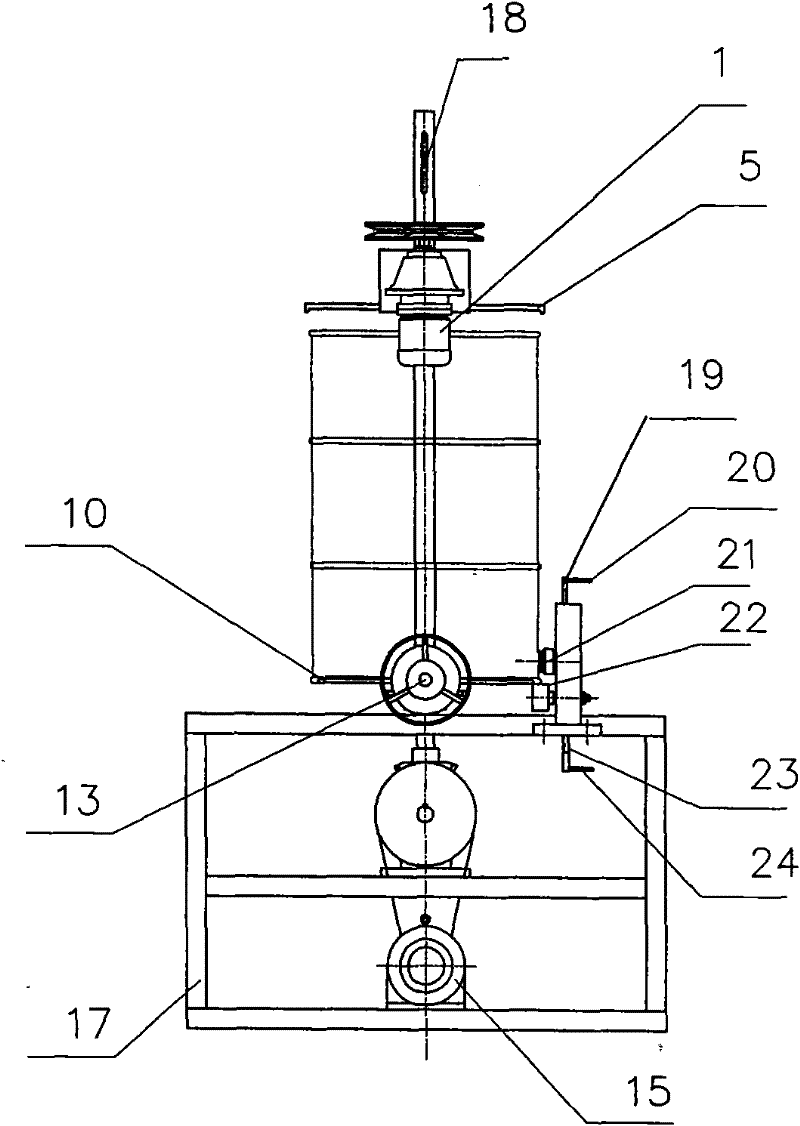

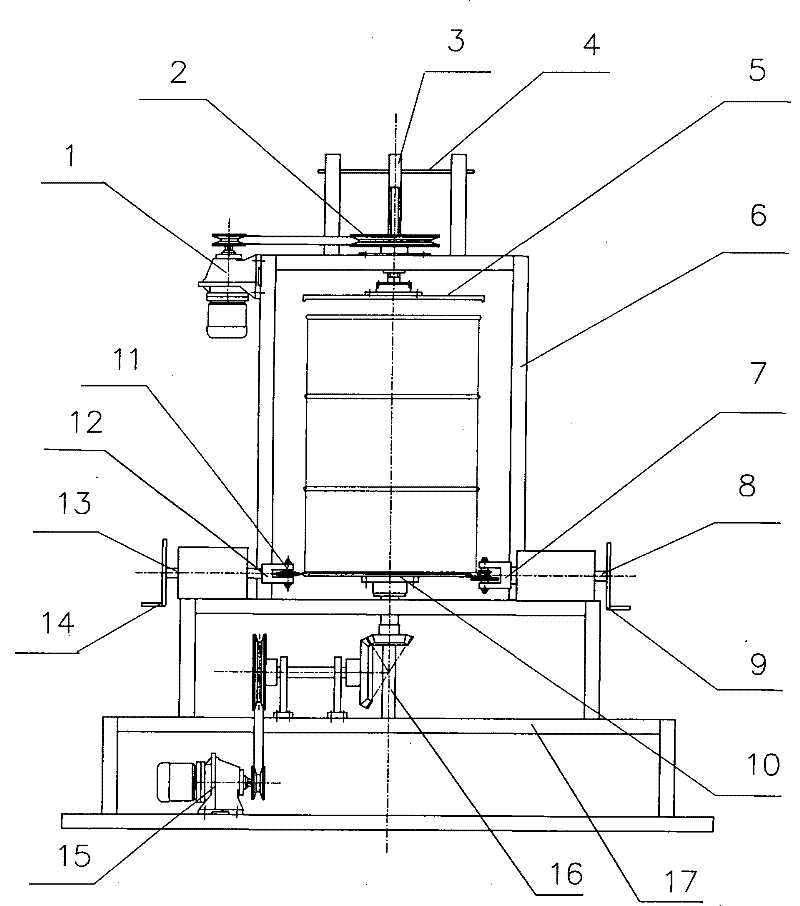

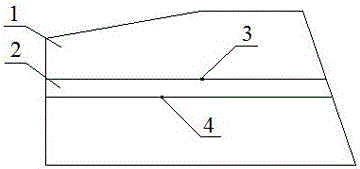

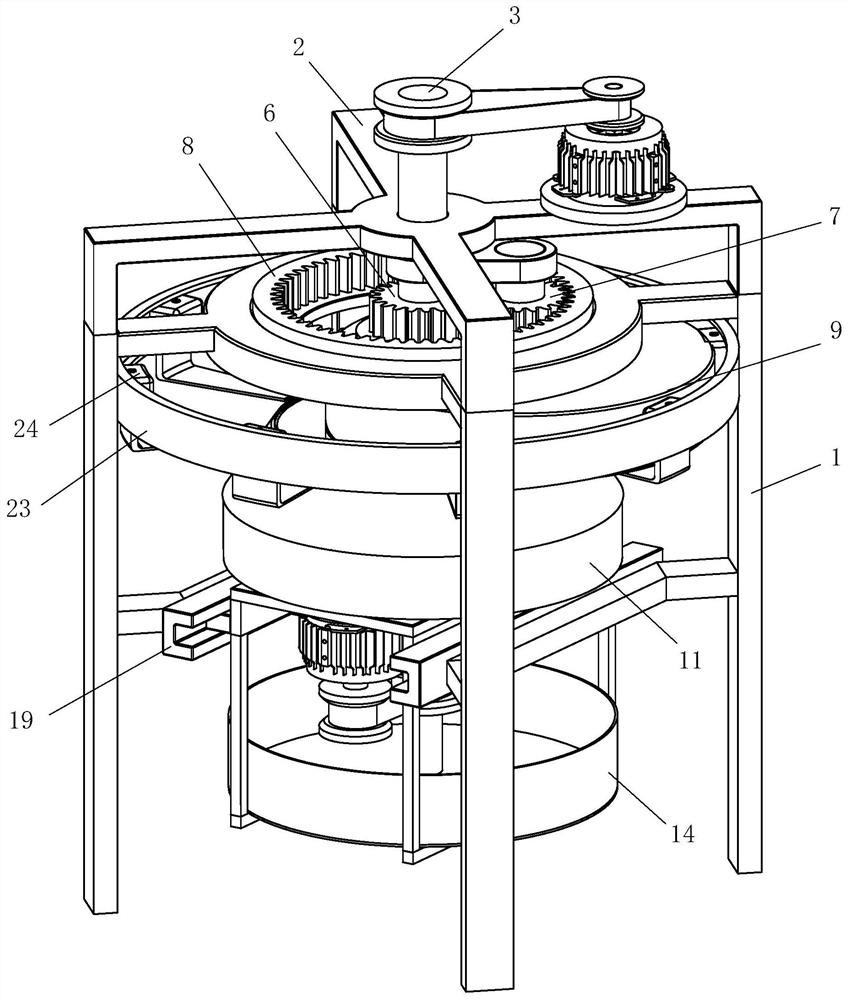

Shaping system for integrally cutting, crimping and pressing edge

InactiveCN102069383AIncrease productivityImprove plastic qualityOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention discloses a shaping system for integrally cutting, crimping and pressing edge, aiming to provide a shaping system which can finish cutting, crimping and pressing edge in one working procedure by mechanical operation and improve production efficiency and shaping quality. A main rack is provided with a bucket hoisting rack; the position on the main rack, which corresponds to the bucket cover, is respectively provided with an edge cutting mechanism, an edge crimping mechanism and an edge pressing mechanism; a bucket supporting tray is fixedly connected with the rotation shaft of the bucket; the rotation shaft of the bucket is connected with the rotation motor of the bucket by a transmission mechanism; the bucket hoisting rack is provided with a platen fixedly connected with a platen rotation shaft; the plant rotation shaft and the platen elevation driving mechanism can be in rotating connection. The shaping system of the invention can finish cutting, crimping and pressing edge in one working procedure by mechanical operation, improve production efficiency and shaping quality, and lower production cost.

Owner:TIANJIN LYUBOTE ENVIRONMENTAL PROTECTION EQUIP MFG

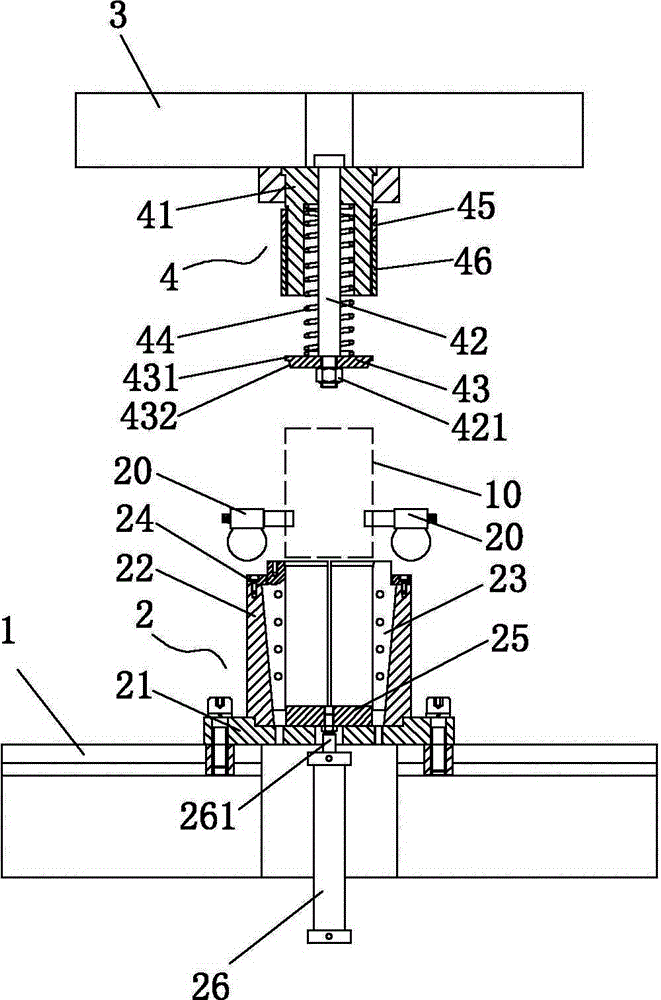

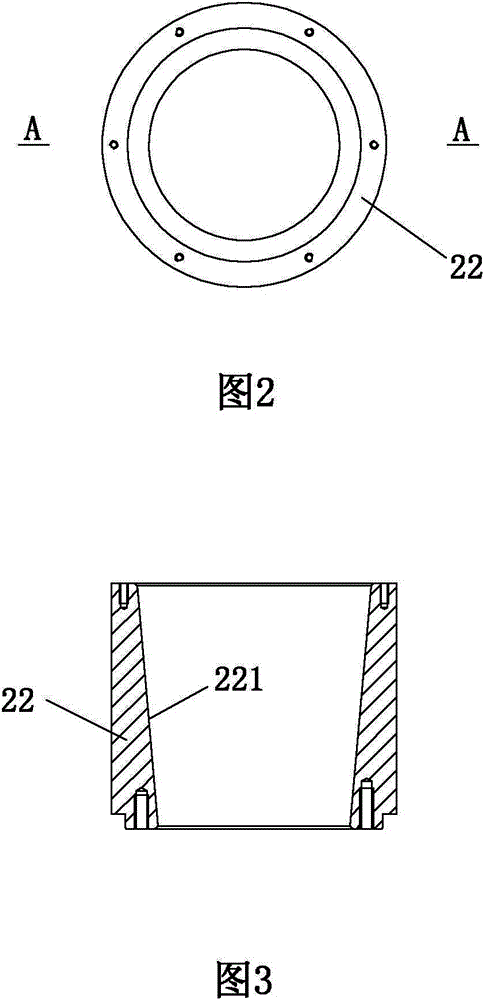

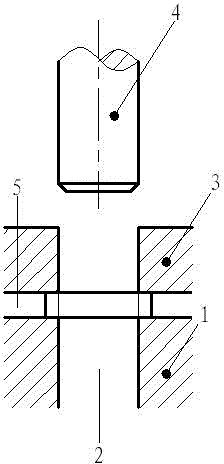

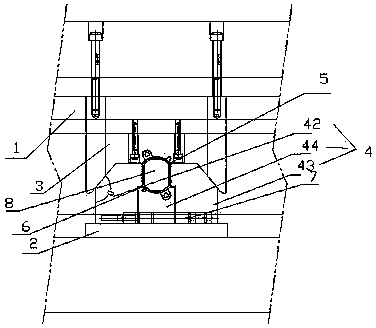

Reshaping mechanism for cylinderical workpiece mounted to pressing machine

The invention discloses a reshaping mechanism for a cylinderical workpiece mounted to a pressing machine. The reshaping mechanism comprises a female die component and a male die component, the female die component comprises a base and an outer sleeve fixed to the upper portion of the base, an axial inverted conical through hole matching with an inner sleeve with the outer surface in the shape of an inverted cone is processed in the middle of the outer sleeve, an axial cylindrical through hole is processed in the middle of the inner sleeve, and a stripping plate is mounted on the lower portion of the axial through hole in the middle of the inner sleeve. The inner sleeve is axially cut into four equant components, a plurality of corresponding holes are processed among the side end faces of the equant components, and compression springs are mounted among the corresponding holes. The male die component comprises a fixed sleeve fixed with a slider of the pressing machine, a push rod capable of moving up and down is mounted in the middle of the fixed sleeve, a pressing plate is fixed at the lower end of the push rod, a pressure spring is mounted on the push rod between the pressing plate and the fixed sleeve, the pressing plate moves downwards along with the slider to press the workpiece into the inner sleeve, and the fixed sleeve moves downwards along with the slider to enable the inner sleeve to move downwards. The reshaping mechanism can well protect the appearance of the workpiece and a reshaping female die and is high in reshaping efficiency.

Owner:厦门锻压机床有限公司

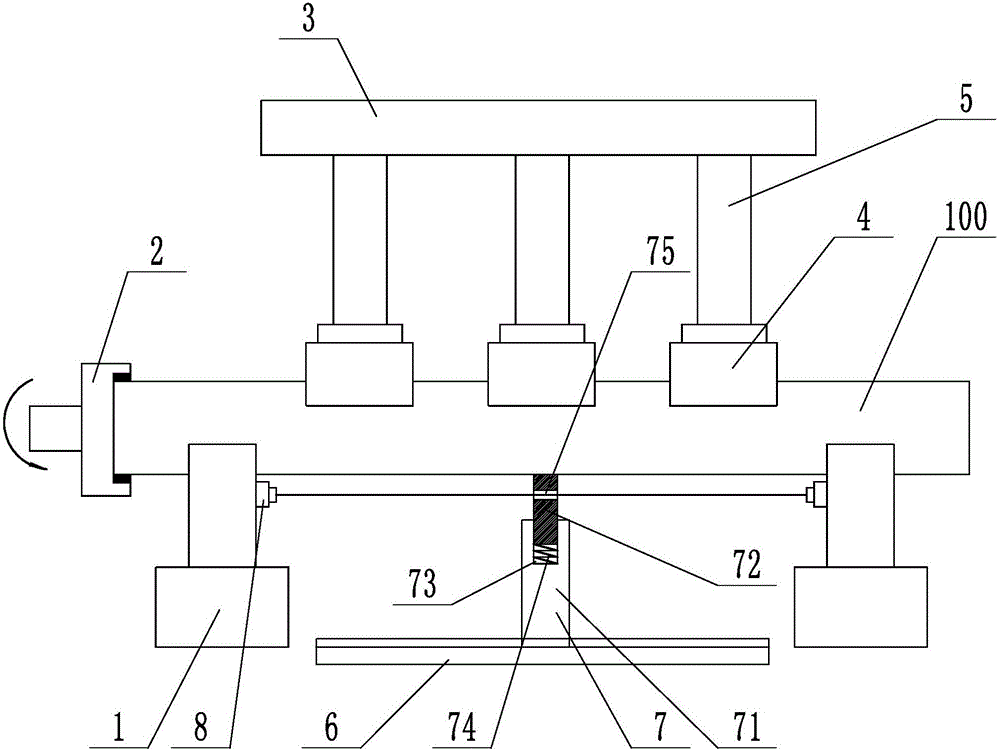

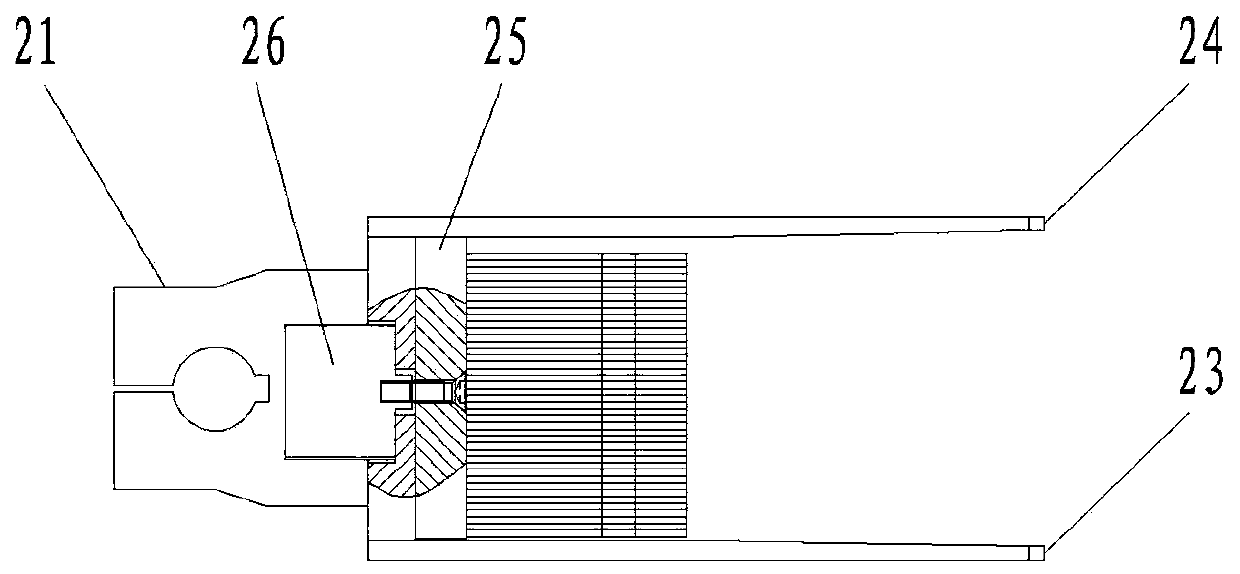

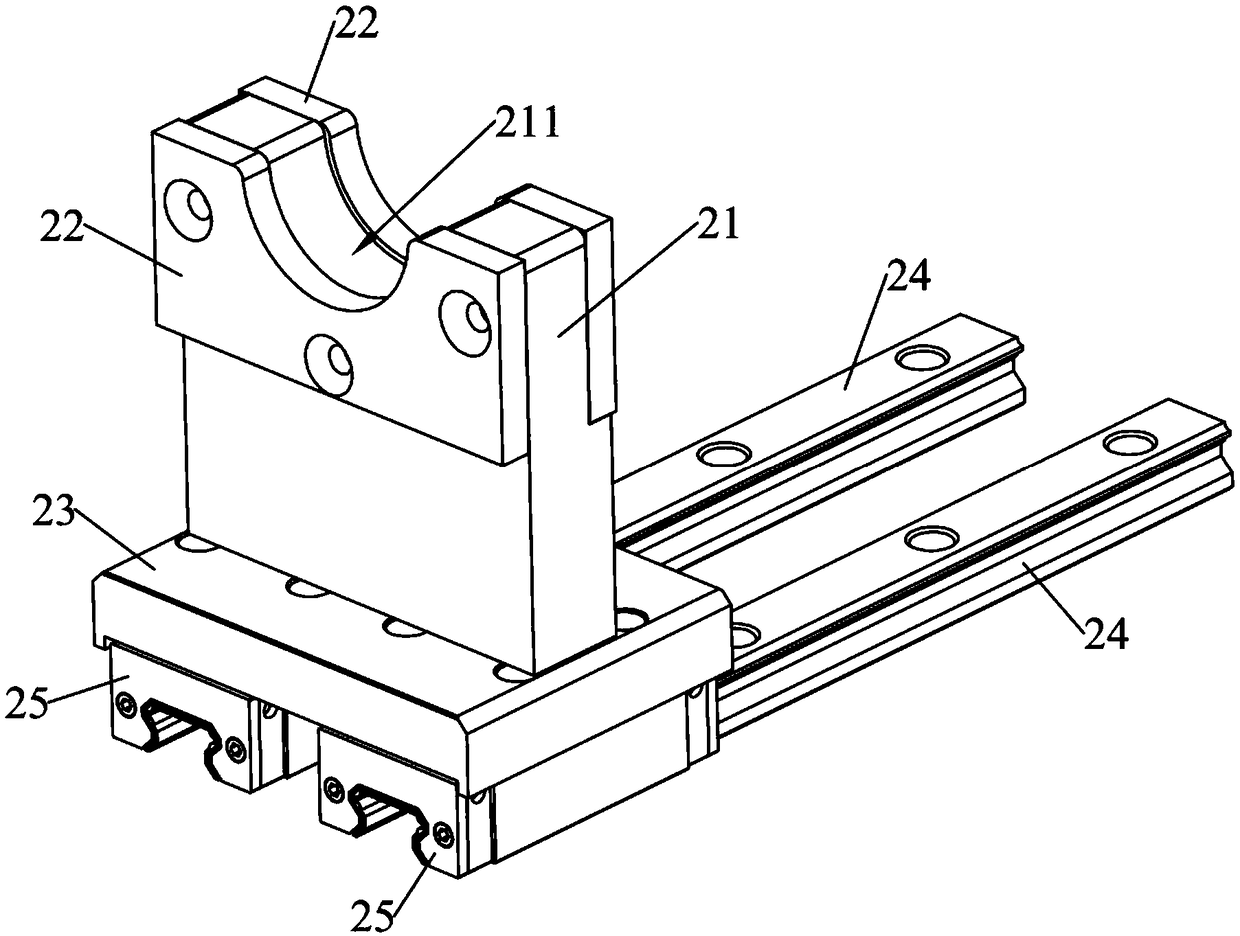

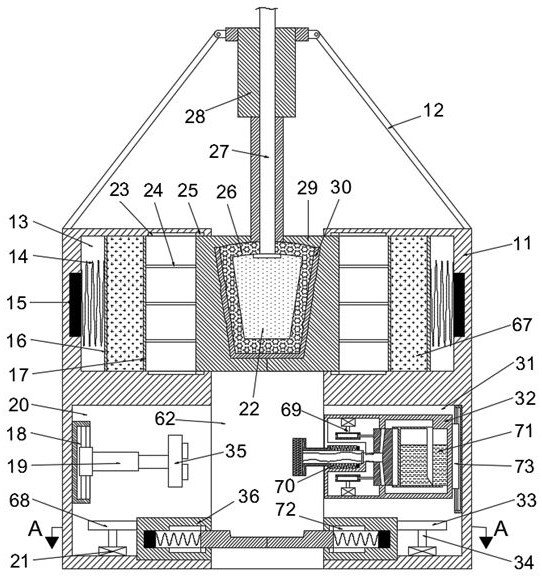

Shaping device for drill stem

ActiveCN105880318AEasy to adjustImprove plastic qualityMetal working apparatusHydraulic cylinderLaser sensor

The invention relates to a shaping device for a drill stem. The shaping device comprises two supporting seats supporting the two ends of the drill stem. A drill stem rotation driving head is installed at one end of the drill stem. Multiple pressing heads are installed above the drill stem and driven by independent hydraulic cylinders. The hydraulic cylinders are installed on a movable supporting plate in a centralized mode. A guide rail is installed below the drill stem. A shaping detection frame is installed on the guide rail in a sliding mode. The shaping detection frame comprises a detection base and a detection rod, wherein the detection base can slide on the guide rail for adjustment, the detection rod is installed on the detection base, the lower end of the detection rod is inserted in an installing hole in the detection base, a spring is installed between the lower end of the detection rod and the bottom of the installing hole, a detection hole is formed in the upper end of the detection rod, and a opposite-type laser sensor used for detecting the detection hole is installed between the two supporting seats. By the adoption of the pressing heads and the hydraulic cylinders, different axial positions of the drill stem can be shaped, and adjustment operation is easy; by the adoption of a laser detection mode, the shaping quality and reliability are improved.

Owner:重庆市潼南区龙泉水利开发有限公司

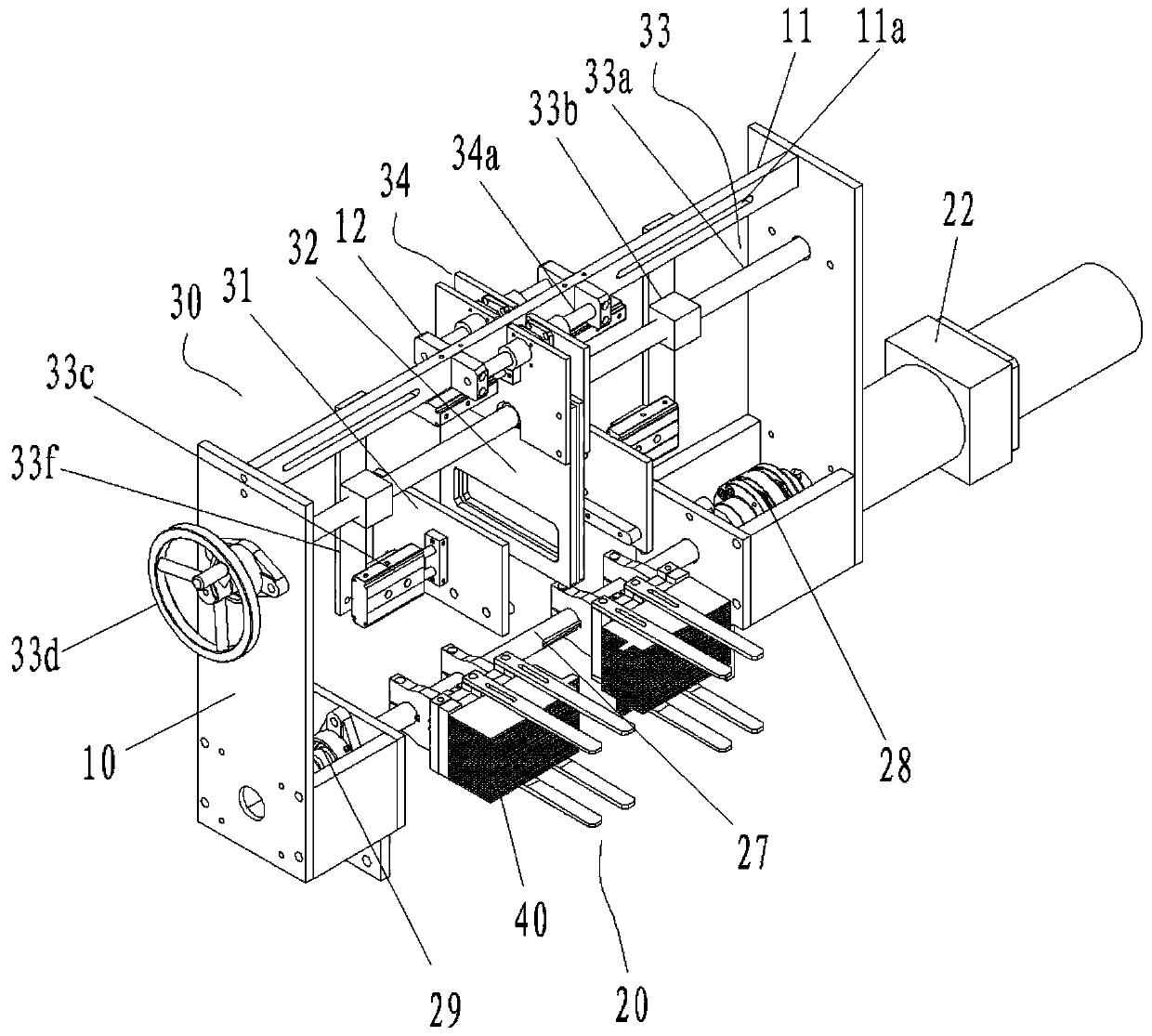

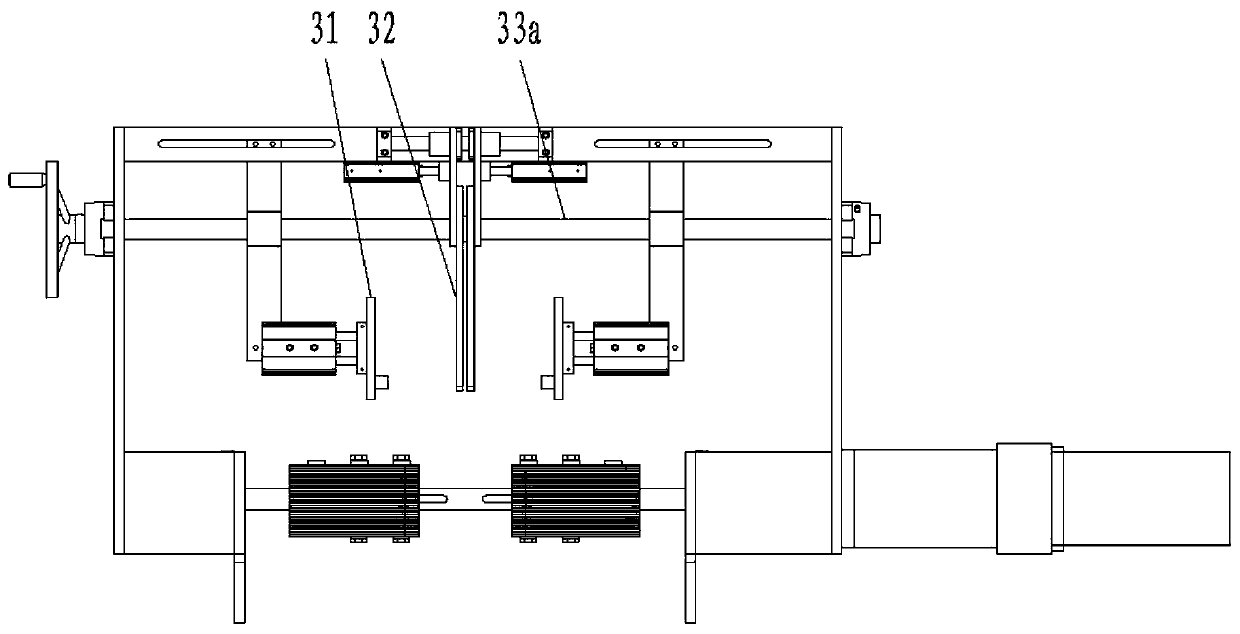

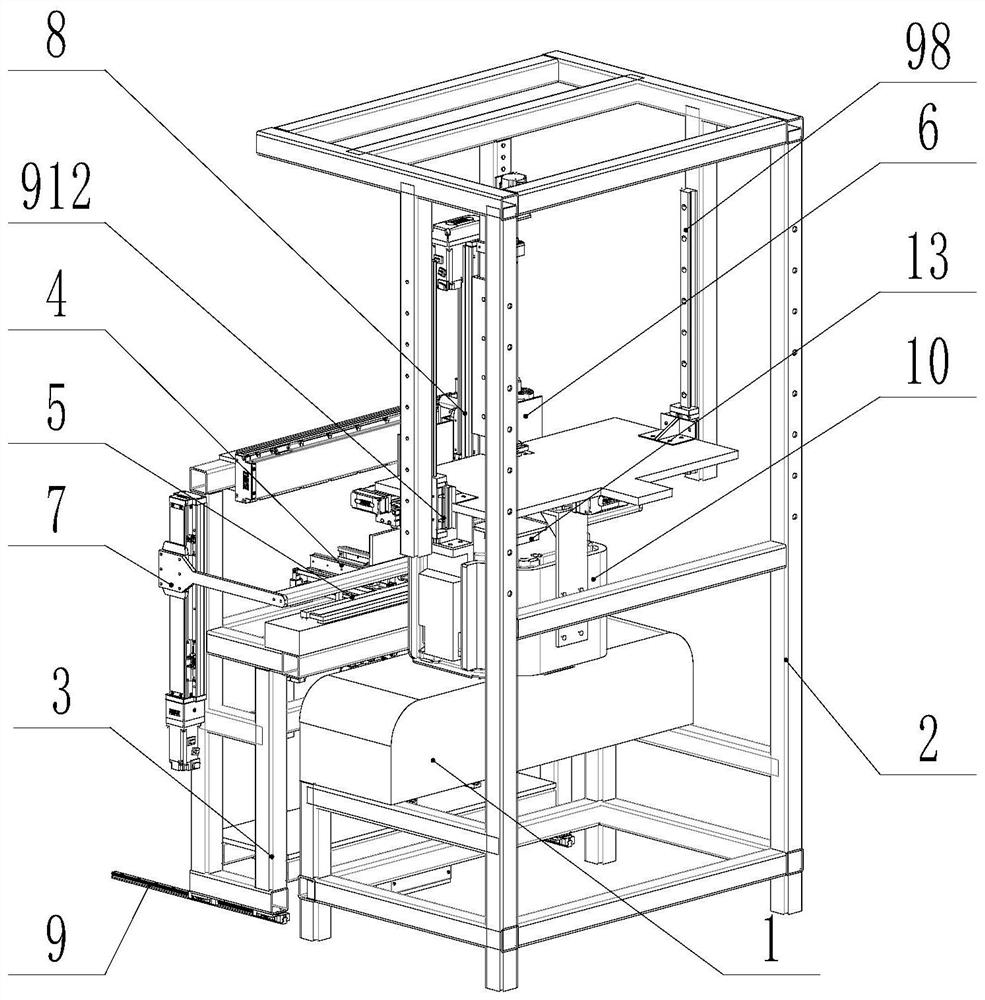

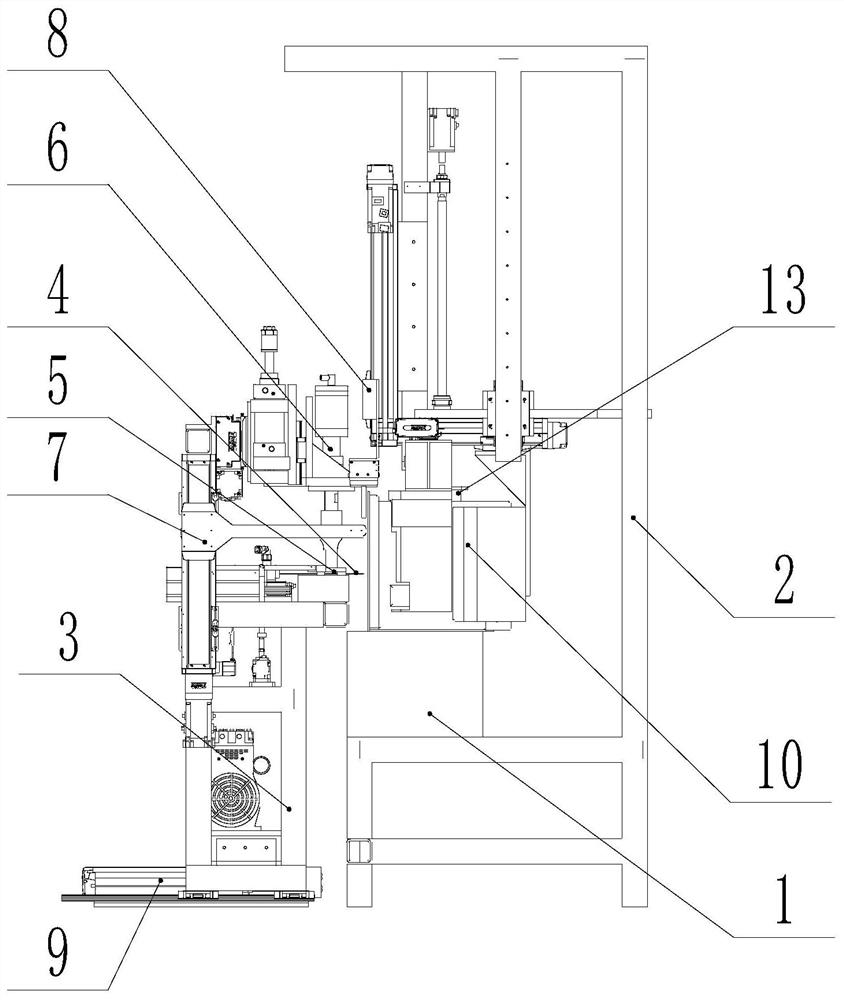

Shaping manipulator for storage battery

PendingCN111591776ARealize automatic stackingReduce manufacturing costStacking articlesDe-stacking articlesControl engineeringManipulator

The invention discloses a shaping manipulator for a storage battery. The shaping manipulator for the storage battery comprises a rack, an overturning manipulator mounted on the rack in a manner of rotating in a direction perpendicular to the transverse direction, and a transverse shaping assembly mounted on the rack in a manner of transversely sliding; and the overturning manipulator is used for receiving stacked parts and longitudinally shaping the stacked parts, and the overturning manipulator rotates to convey the stacked parts to the transverse shaping assembly for transverse shaping of the stacked parts. According to the shaping manipulator, the stacked parts can be reshaped in all directions, and the stacked parts with regular shapes are output, so that the automatic stacking of a stacking manipulator is realized, the labor intensity is reduced, the production efficiency of a continuous plate coating line is improved, and the production cost of an enterprise is reduced.

Owner:中国船舶重工集团衡远科技有限公司

Expansion machine

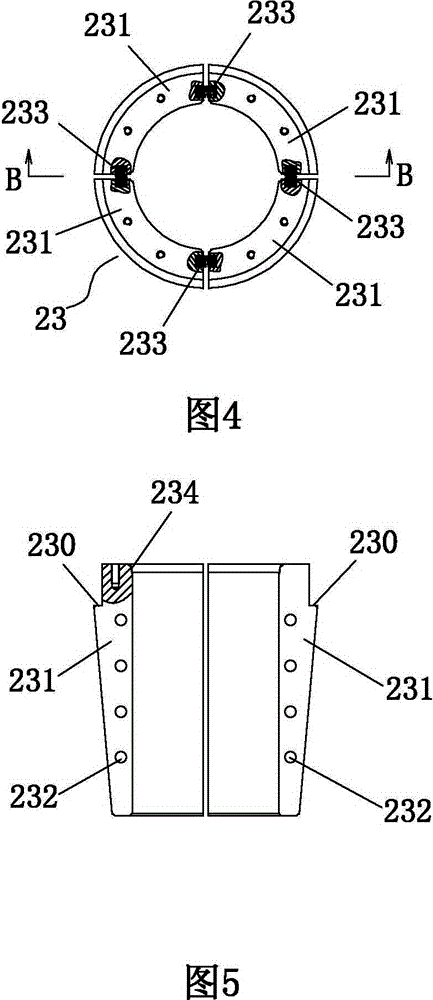

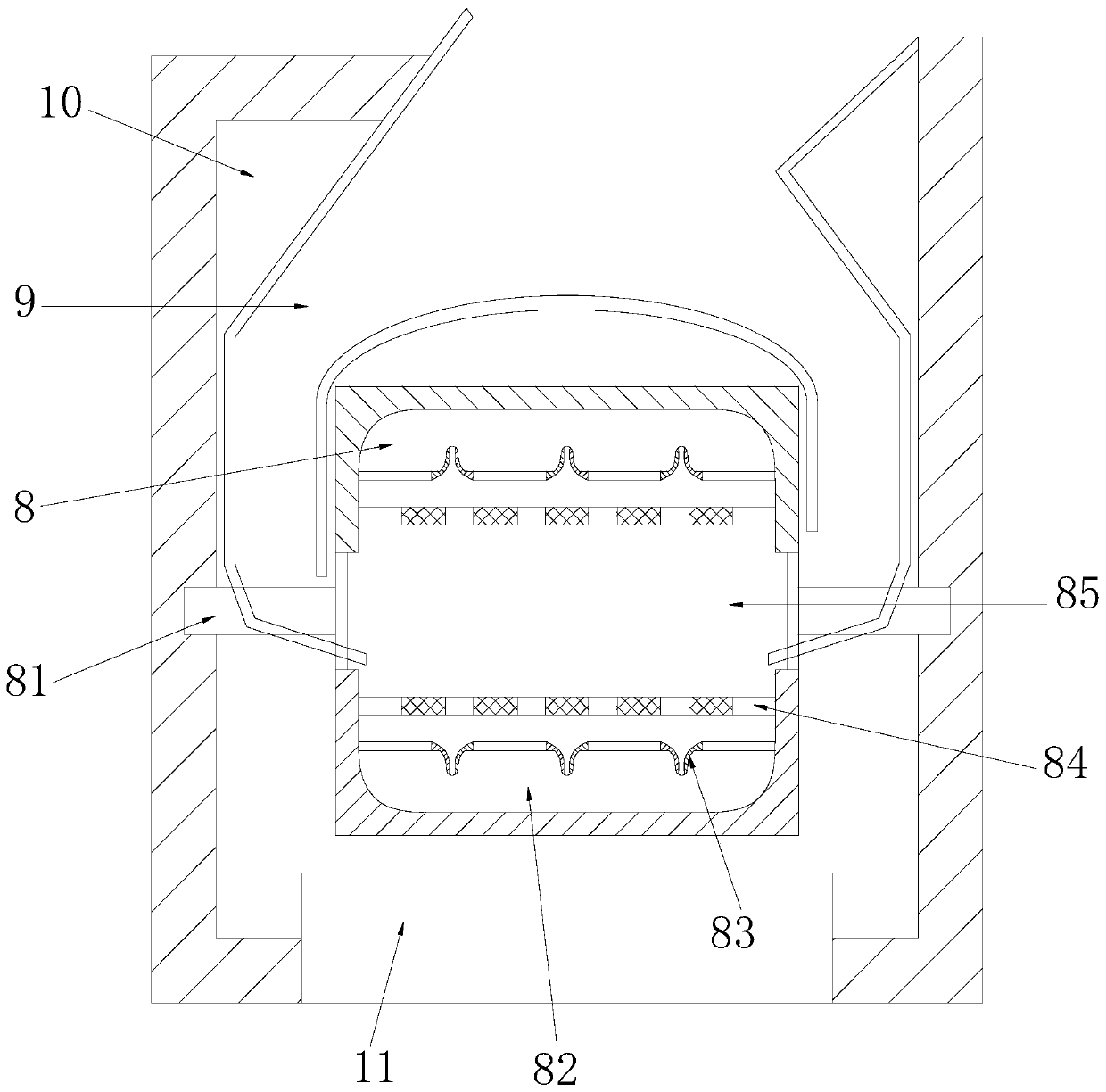

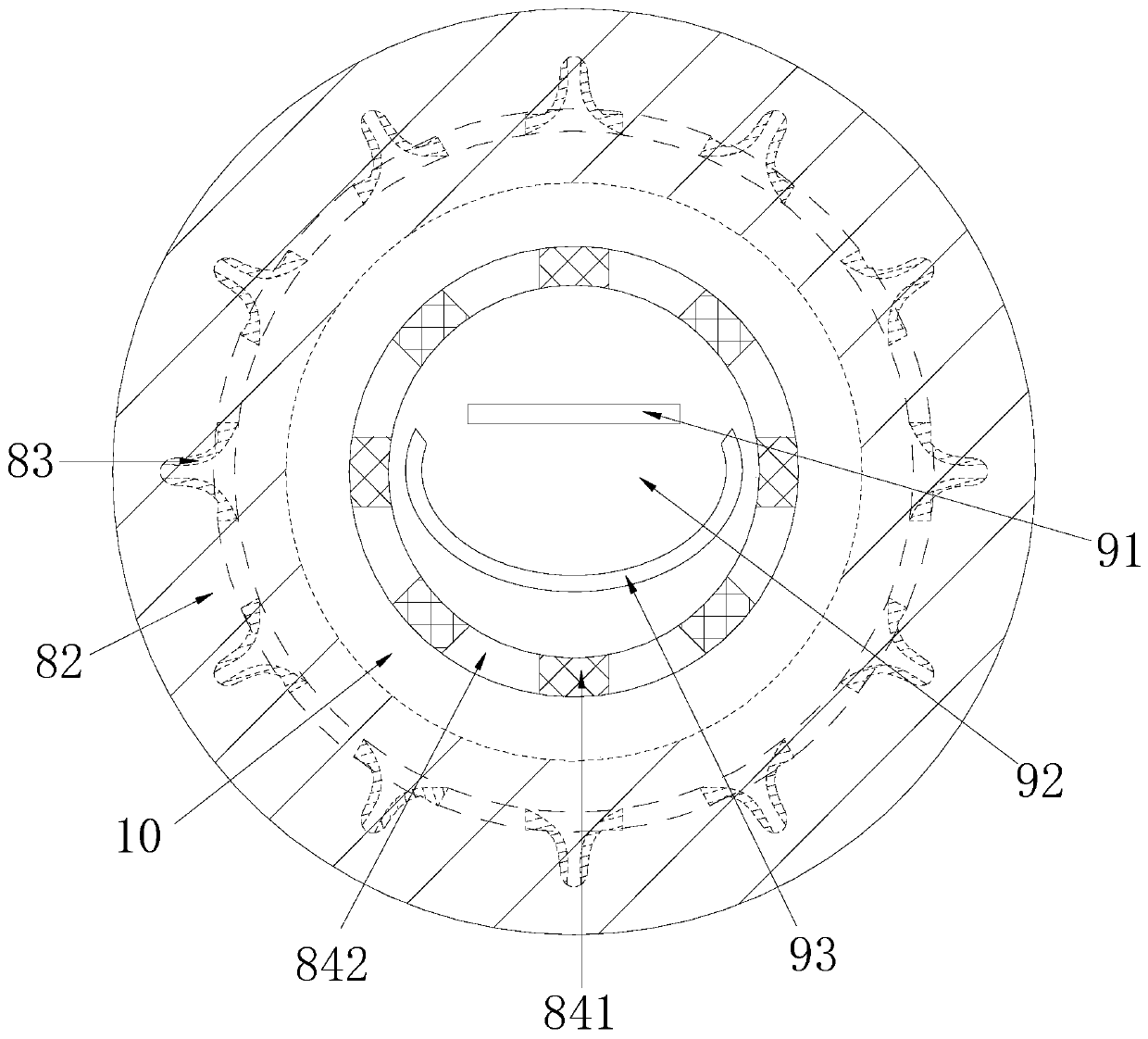

PendingCN109378953AImprove shaping efficiencyImprove consistencyEmbedding prefabricated windingsEngineeringAutomation

The invention discloses an expansion machine, and belongs to the technical field of automation equipment. The expansion machine includes a machine base, a clamping mechanism and an expansion mechanism. The clamping mechanism is arranged on the machine base and can clamp a stator to be shaped. The expansion mechanism is arranged on the machine base and is located on one side of the clamping mechanism. The expansion mechanism includes multiple expansion plates which are annularly distributed. The expansion plates can diffuse and move away from the central axis of the ring. One of the clamping mechanism and the expansion mechanism can move toward the other one, and so the expansion plates can extend into a coil of the stator. The expansion plates can diffuse and move away from the central axis of the ring so as to expand the coil. The expansion machine can automatically expand the coil on the stator, and so the labor cost is reduced and the shaping efficiency of the coil is high. The multiple expansion plates synchronously expand outward, mechanical action has good consistency on the coil shaping, and the shaping quality is high.

Owner:SUZHOU AICHI TECH CO LTD

Coil shaping device for motor

InactiveCN111564938AAvoid offsetEnsure shapingManufacturing dynamo-electric machinesElectric machineHydraulic ram

Owner:安徽聚益德电子科技有限公司

Novel furniture shaping device

InactiveCN109049808AImprove mobile convenienceRapid prototyping heatingPressesFilling materialsEngineering

The invention discloses a novel furniture shaping device. The novel furniture shaping device structurally comprises a vacuum tank, a top truss, support columns, a processing platform, an electric control cabinet, a heat dissipation groove and a control panel. The left end and the right end of the processing platform are provided with the support columns. The upper ends of the support columns and the two ends of the top truss are fastened. The vacuum tank is arranged at the top of the top truss. The top of the processing platform is connected with the lower end of the top truss. The arranged processing platform drives a material trough on a lifting device to cooperate with a flattening mechanism for pressing forming through a transmission mechanism when the flattening mechanism presses down, after the flattening mechanism is reset, the arranged lifting device is automatically reset through reset springs, the material trough is buckled into a shaping mechanism, a linkage mechanism is started to cut and conduct heating forming integrated treatment on a filling material in the material trough through the shaping mechanism, when the novel furniture shaping device is used as a whole, theeffect that the shape of the furniture filling material is regular after pressing can be ensured, the function of heating forming is achieved, bulging is avoided, and the shaping quality is greatly improved.

Owner:湖州友星木业有限公司

Device for processing material by mixing and/or plasticating

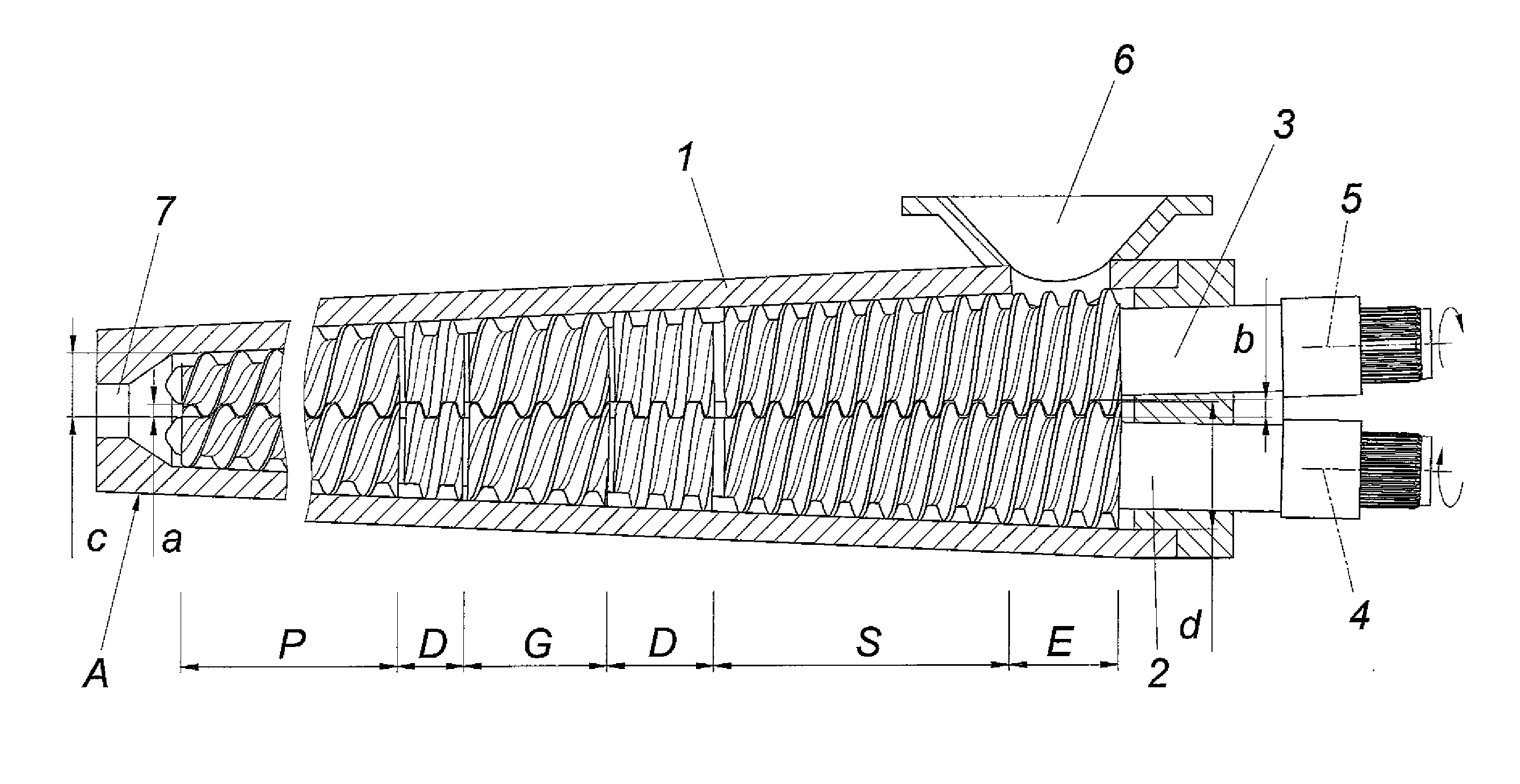

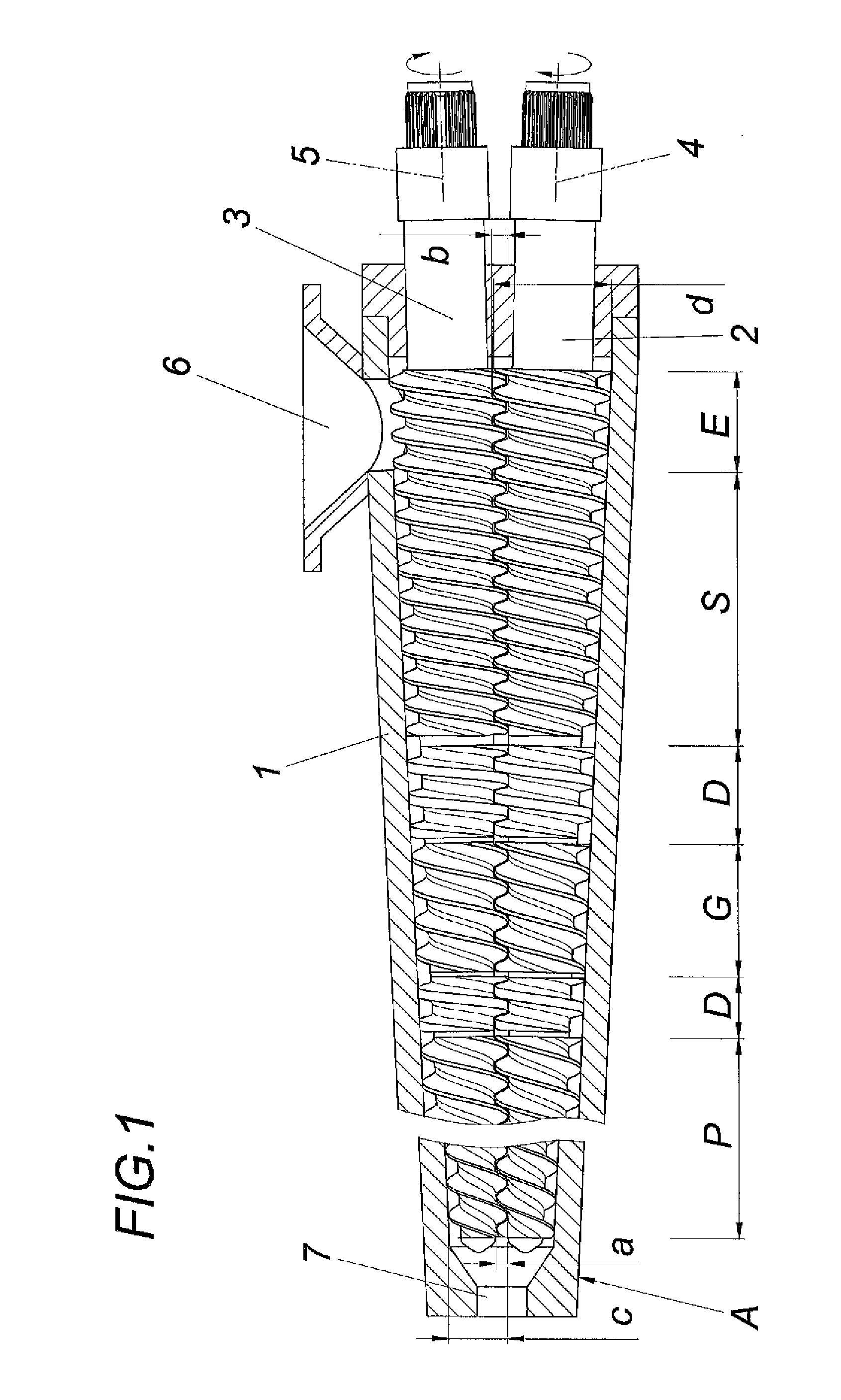

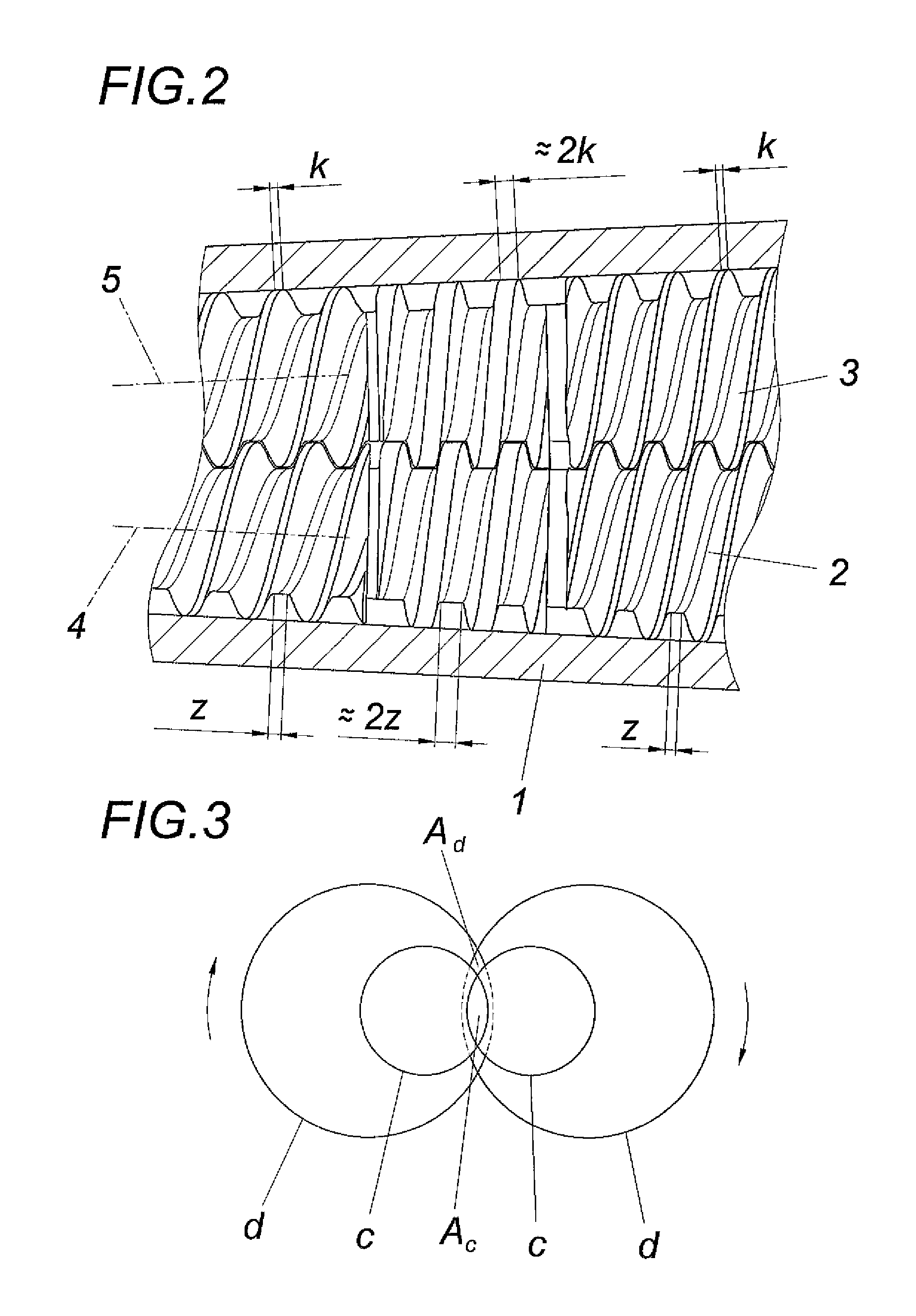

The invention relates to a device for processing material by mixing and / or plasticating, comprising at least two conical screws (2, 3) which are arranged next to each other in a common screw casing (1) and the flights of which engage with one another and are driven to rotate in the same direction of rotation about the respective screw axis (4, 5) by at least one motor, with the material that is to be processed being fed to the screws (2, 3) through at least one feed opening (6) in the screw casing (1) which is arranged in the feed zone (E) of one end face of the screws (2, 3), and with the material that has been processed by the screws (2, 3) leaving the screw casing (1) through at least one outlet opening (7) in the screw casing (1) that is arranged in the discharge zone (A) of the other end face of the screws (2, 3). In order to provide advantageous plasticating conditions it is proposed that the ratio of the numerical values of the screw outside diameter (c, d) to the profile overlap, i.e. to the overlapping area of the two screws (2, 3), both in the feed zone (E) and in the discharge zone (A) is in the range of between one to one and one to two.

Owner:SCHULZ KATHARINA

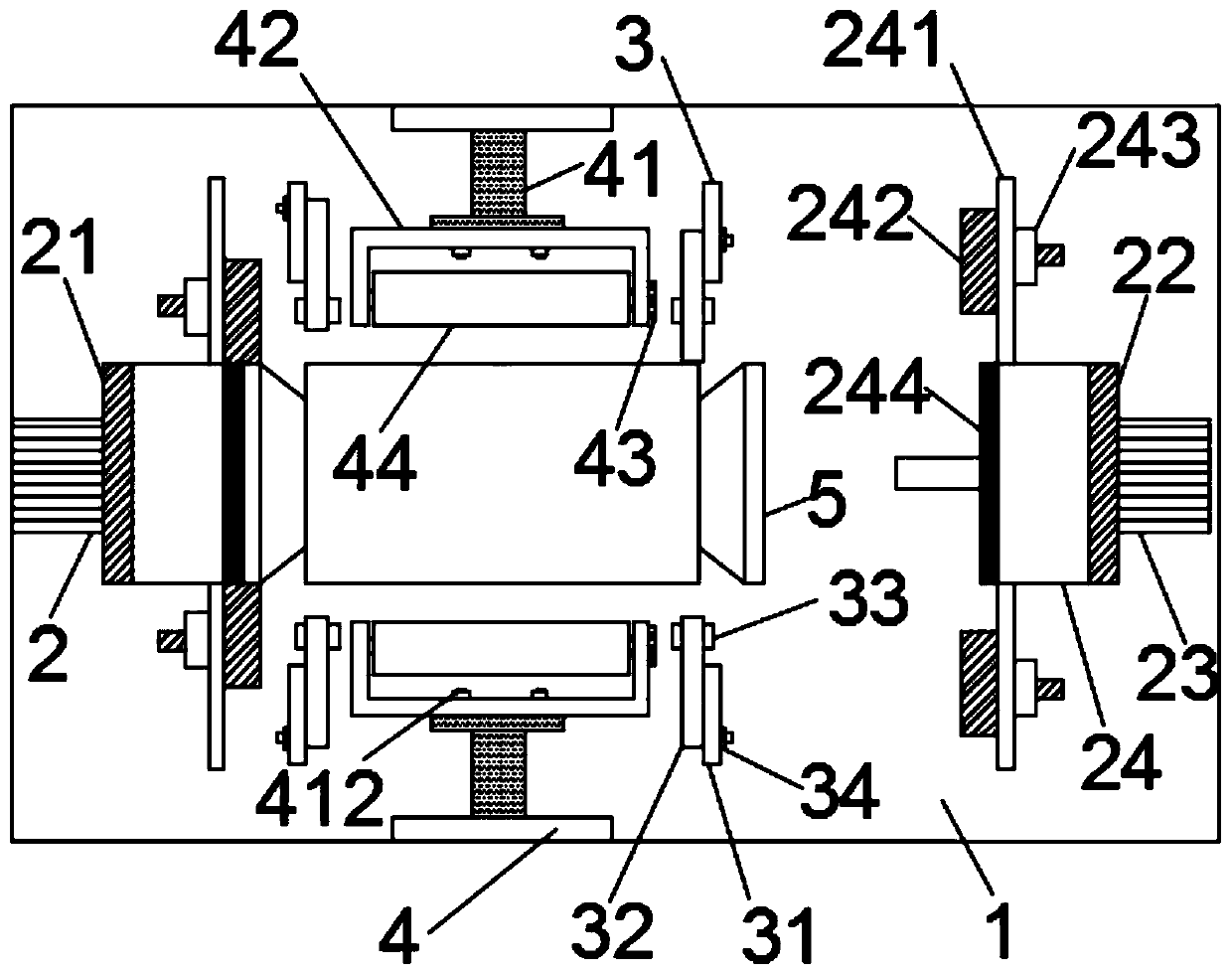

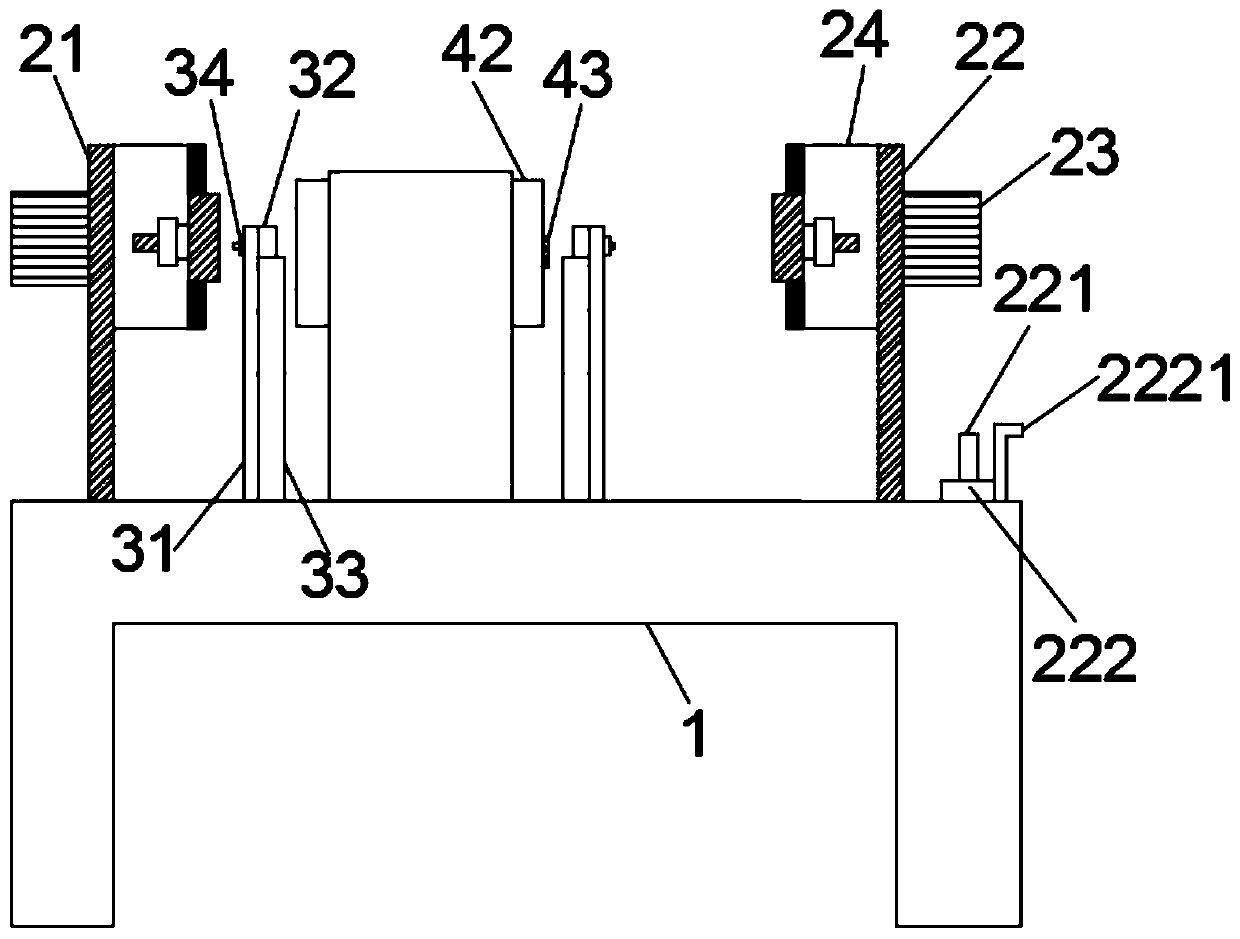

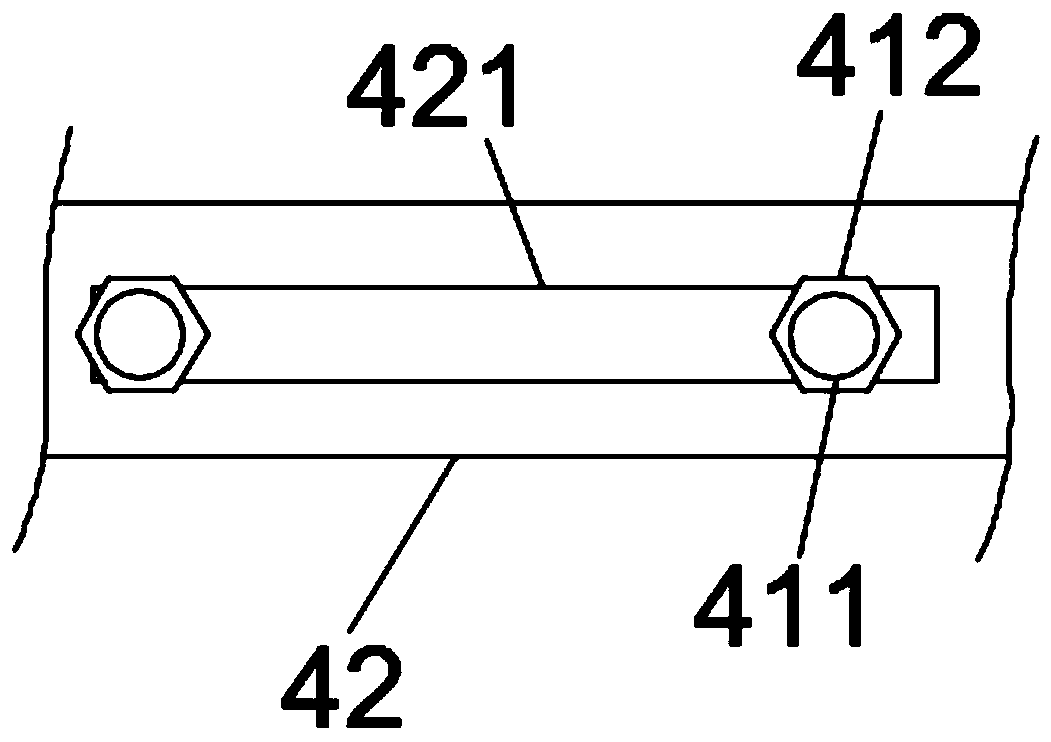

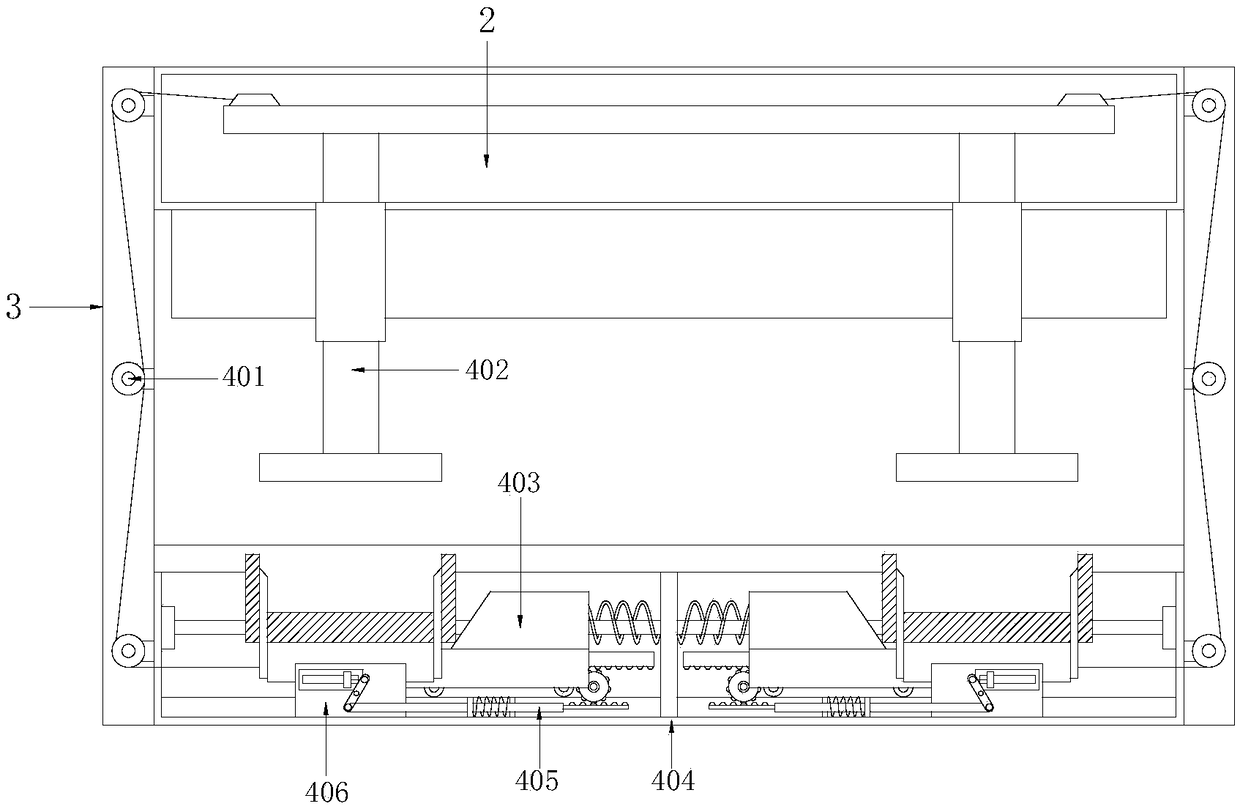

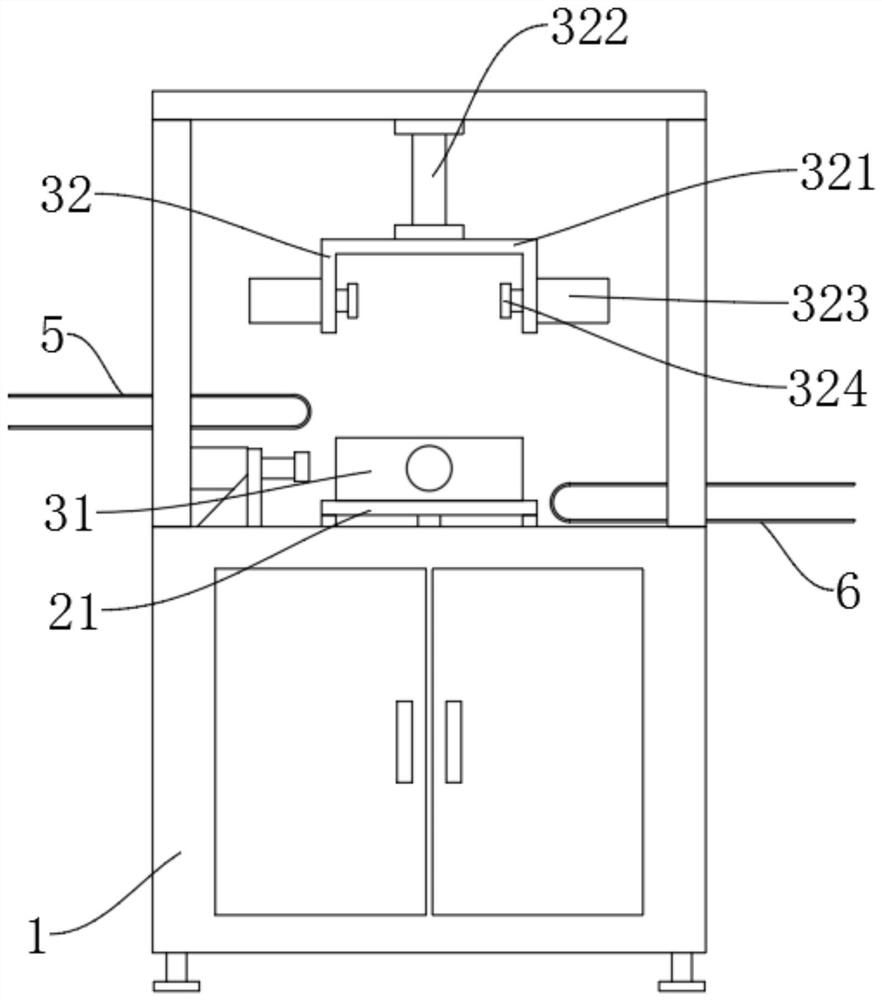

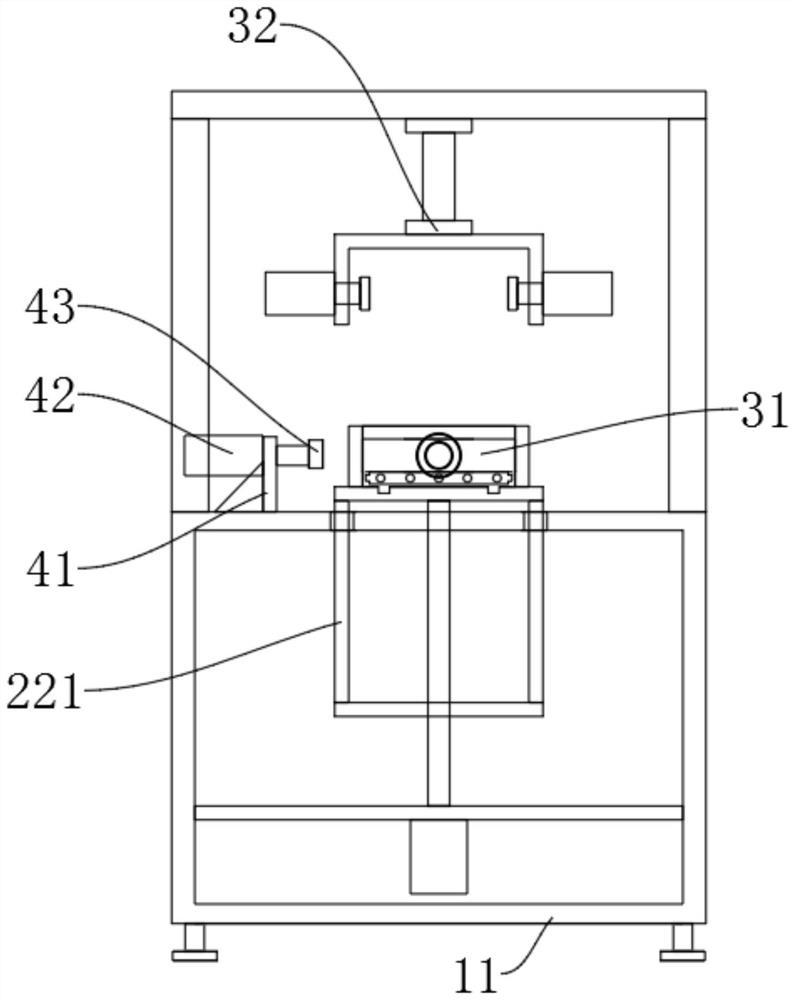

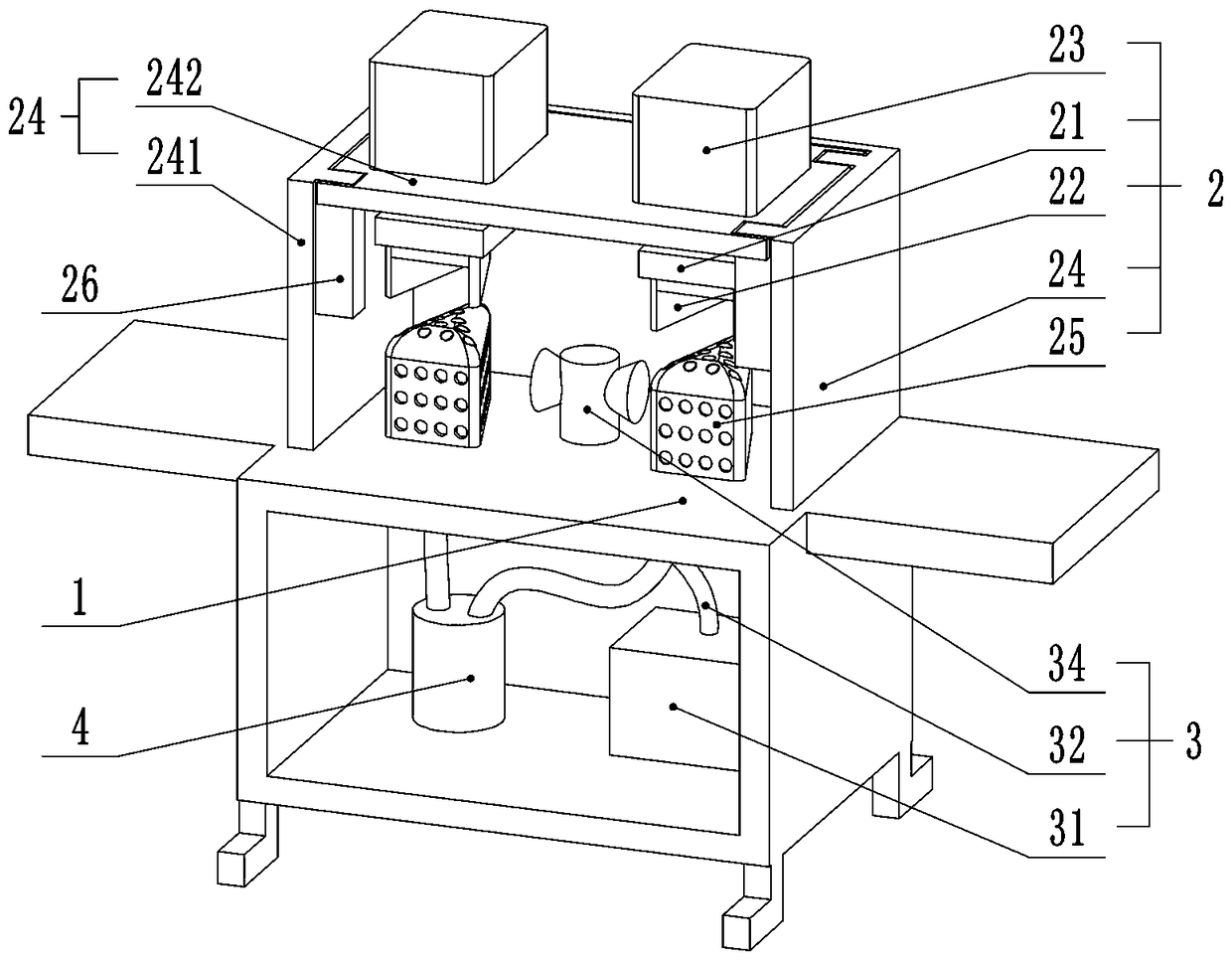

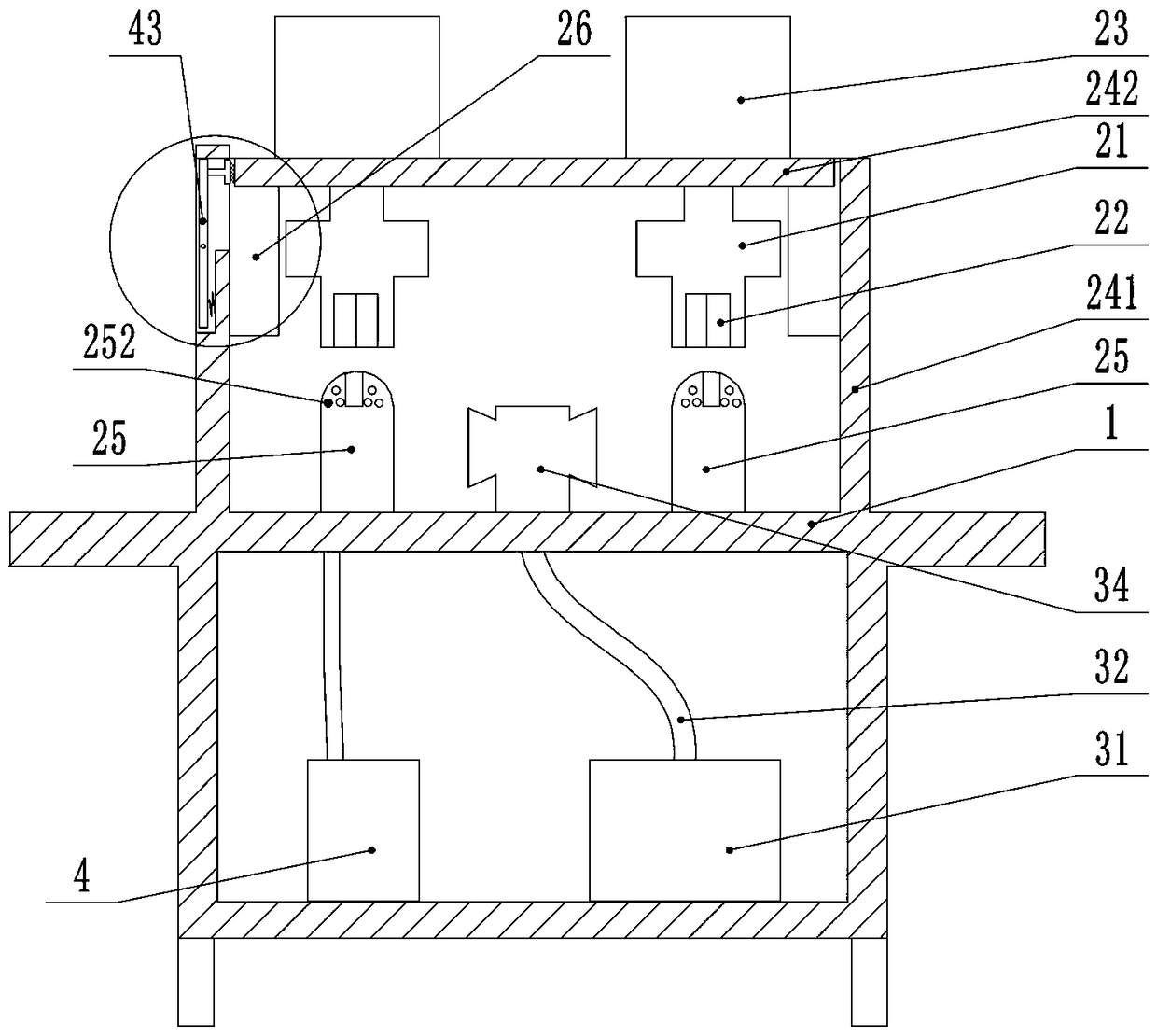

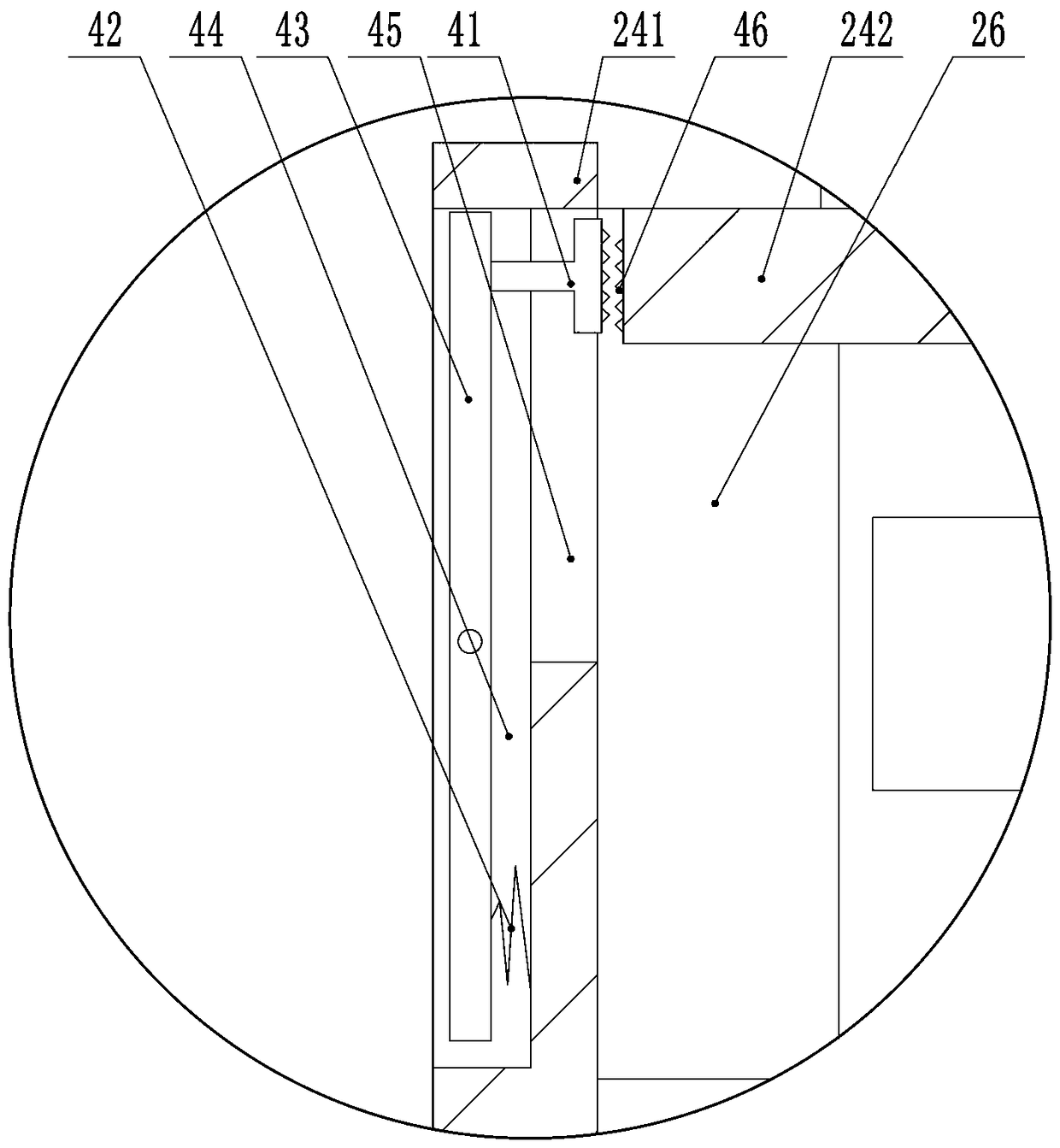

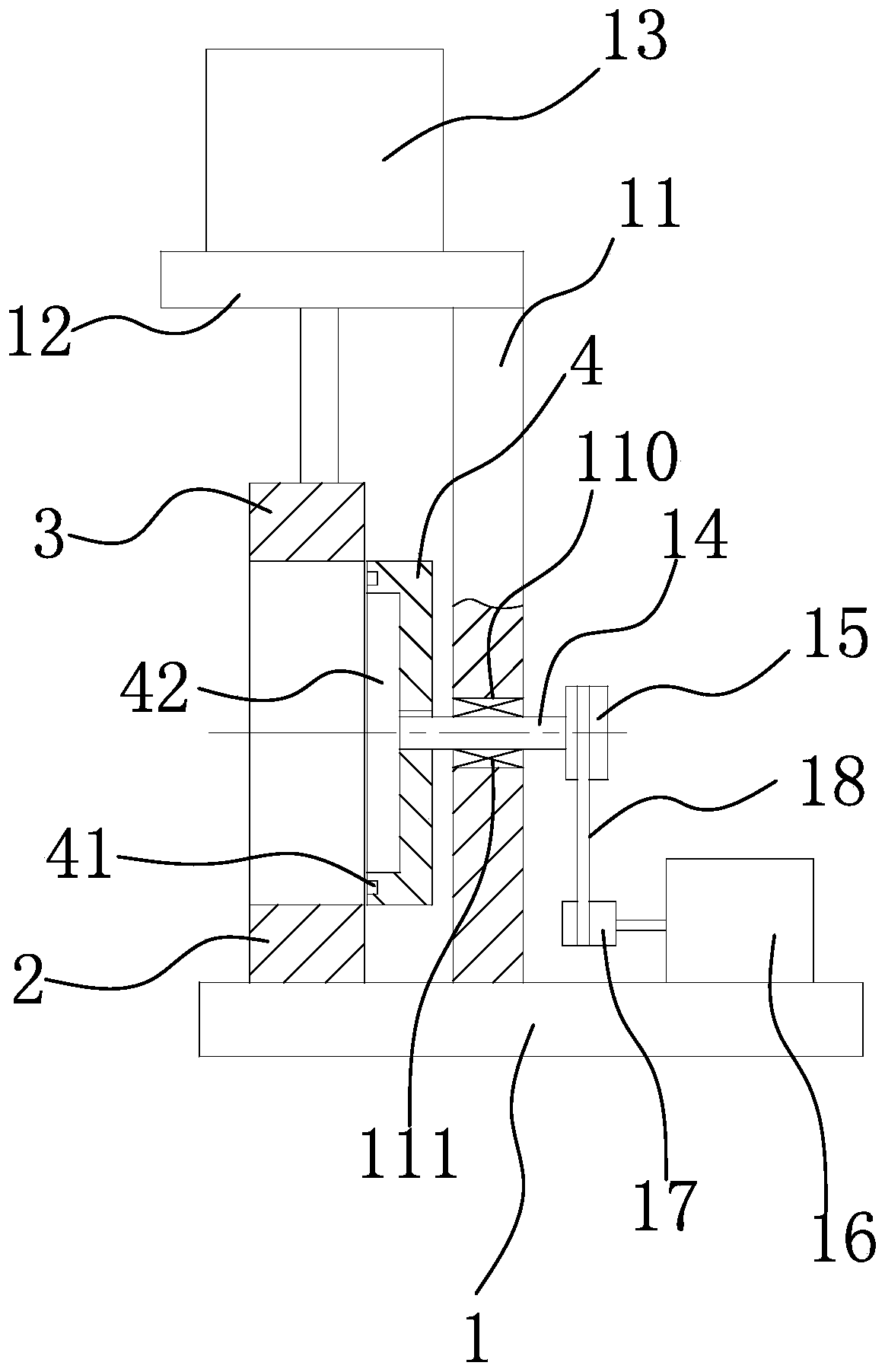

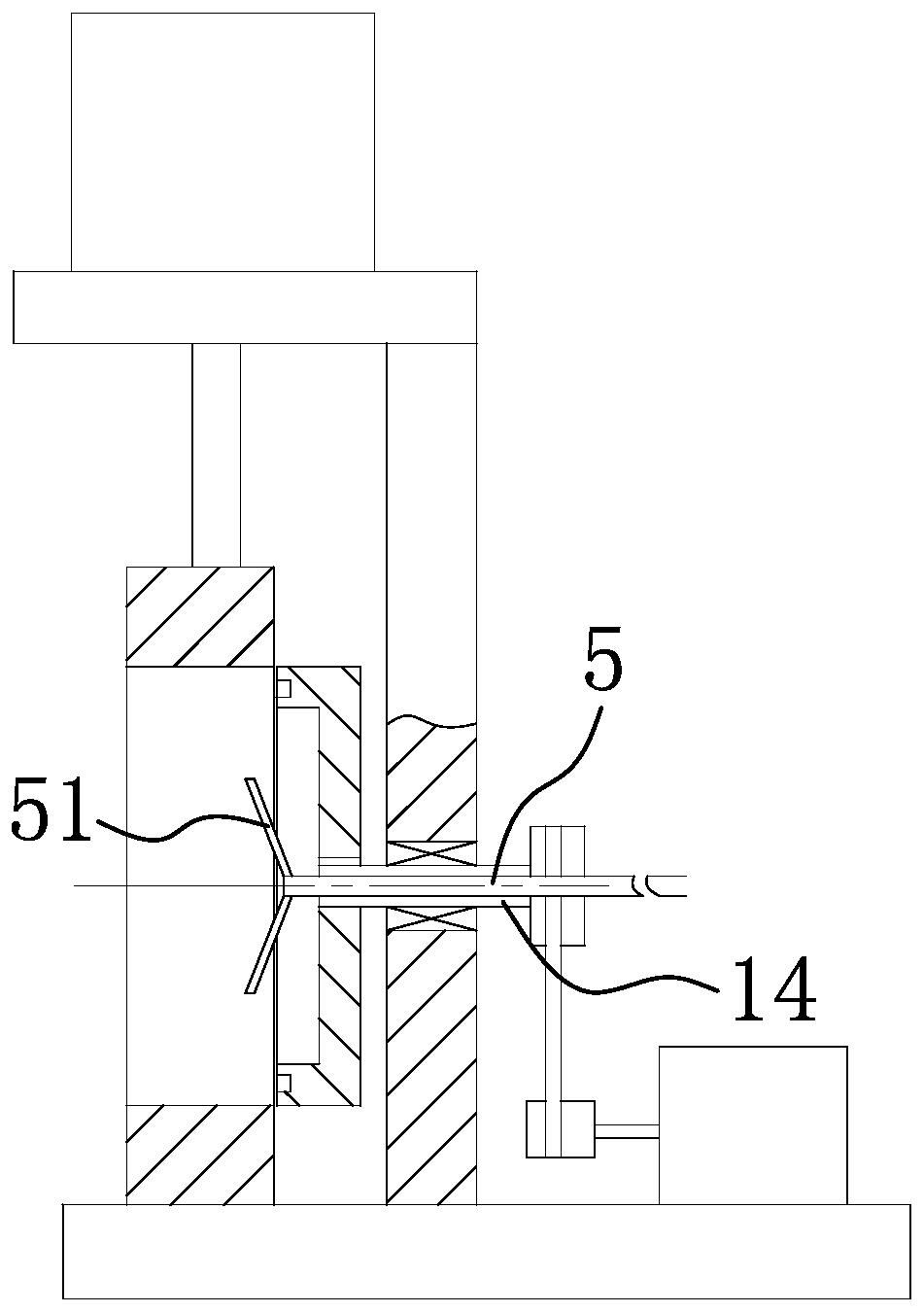

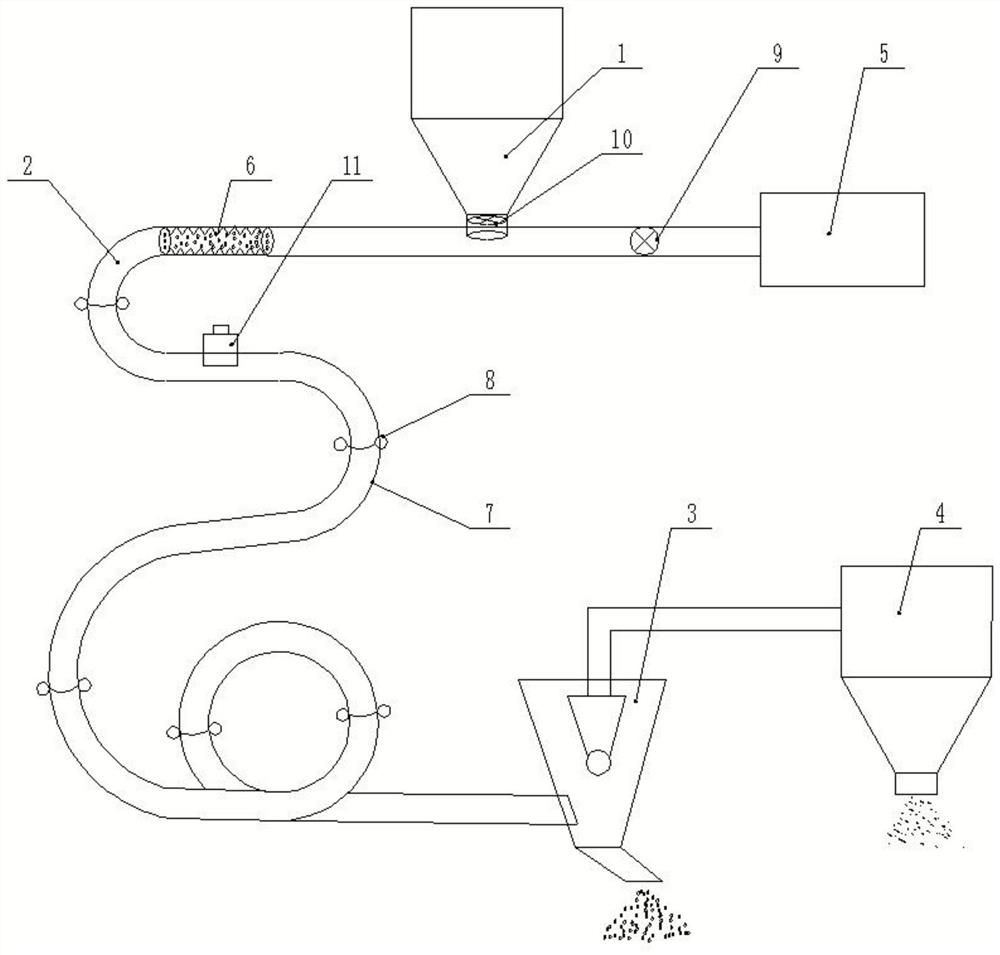

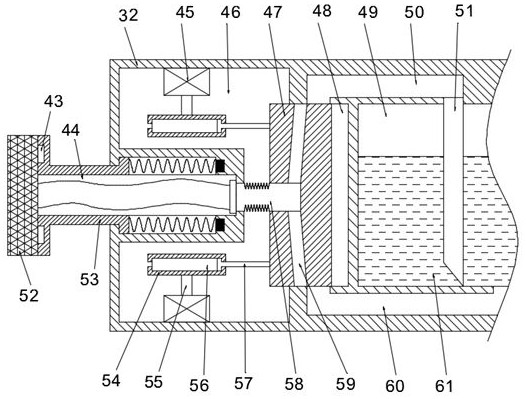

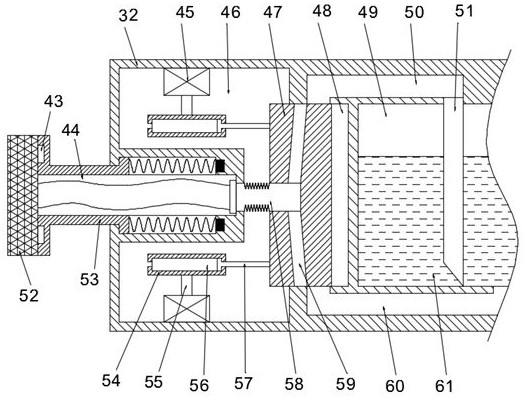

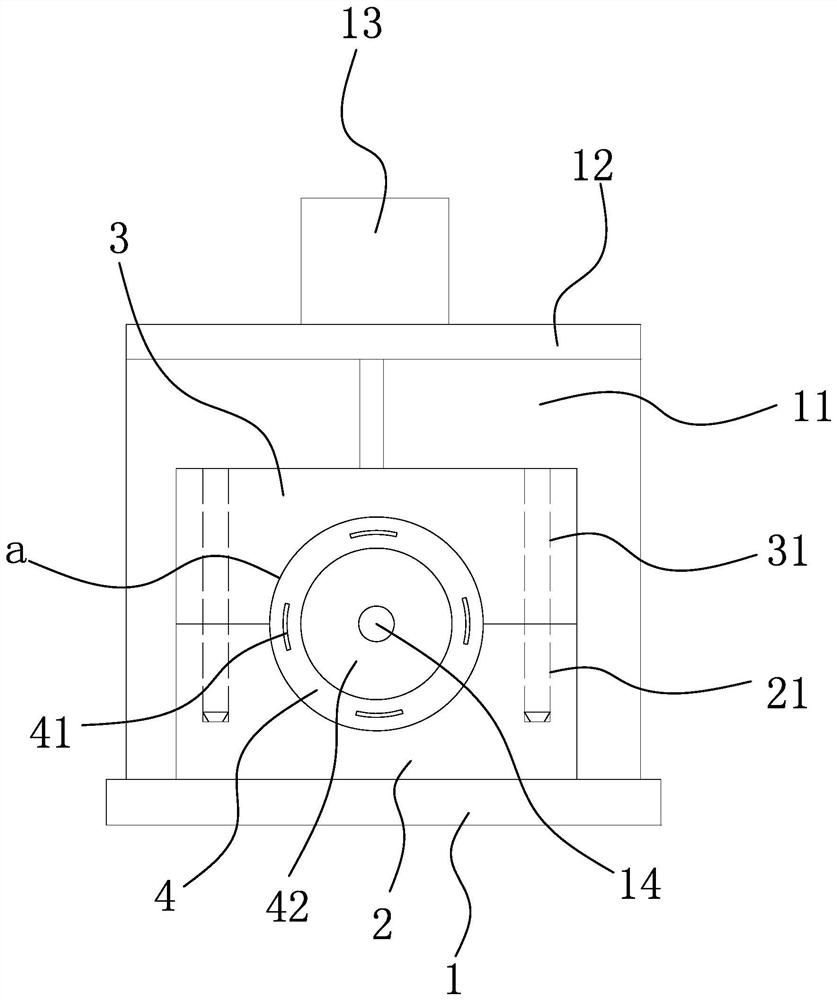

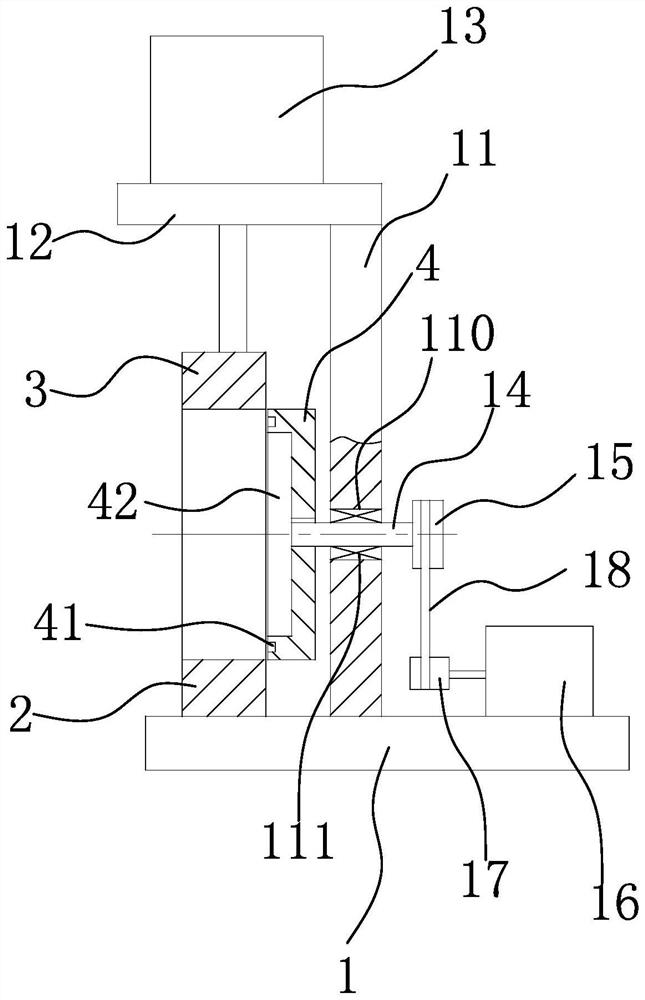

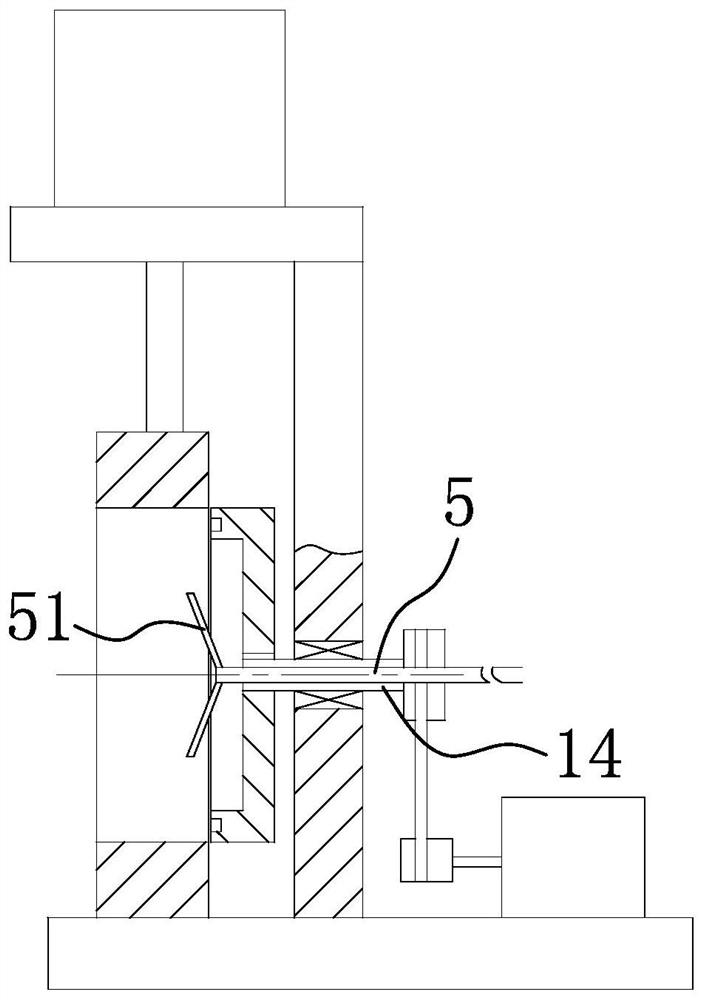

Capacitor shaping device for supercapacitor production

InactiveCN112259384AImprove shaping efficiencyImprove plastic qualityCapacitor manufactureCapacitanceSupercapacitor

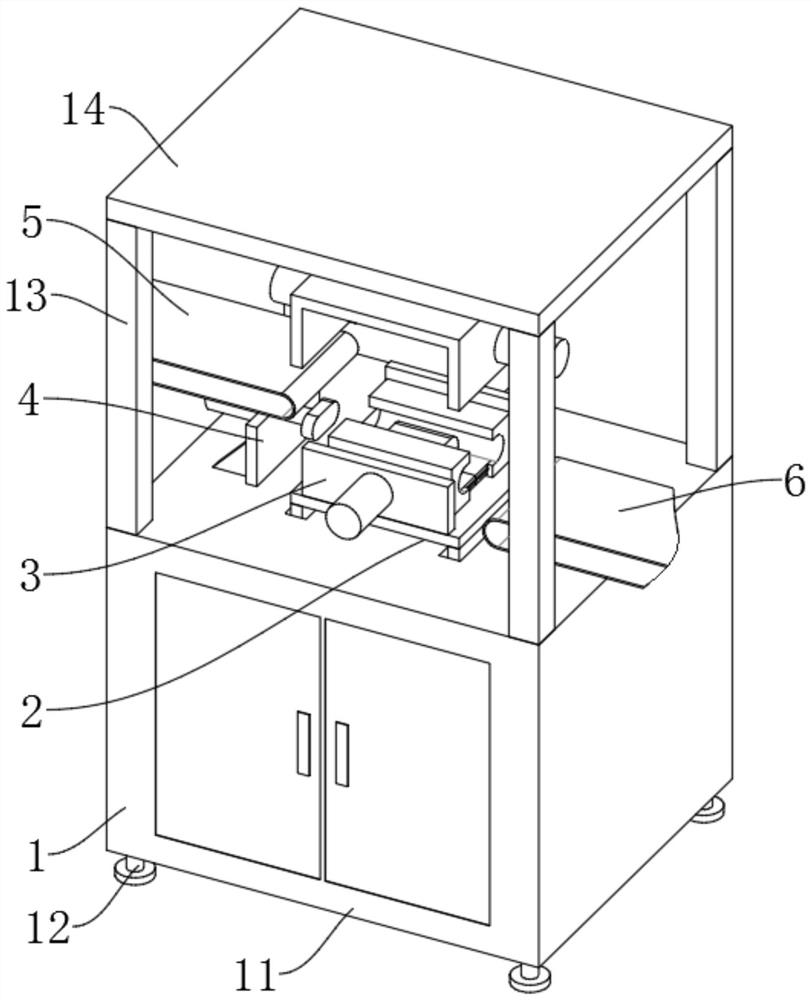

The invention discloses a capacitor shaping device for supercapacitor production, which comprises a supporting mechanism. A lifting mechanism is arranged on the supporting mechanism, a shaping mechanism is arranged on the upper side of the lifting mechanism, the shaping mechanism comprises a first shaping mechanism and a second shaping mechanism, the first shaping mechanism is fixed on the liftingmechanism, the second shaping mechanism is located above the first shaping mechanism, a discharging mechanism is arranged on one side of the first shaping mechanism, the discharging mechanism is connected with the supporting mechanism, and the second shaping mechanism is connected with the supporting mechanism. According to the capacitor shaping device, the first shaping mechanism is moved into the second shaping mechanism through the lifting mechanism, the first air cylinder drives the appearance shaping block to relatively move, the second air cylinder drives the end shaping plate to relatively move, integrated shaping of the appearance surface of a capacitor is conducted, the capacitor shaping efficiency and the capacitor shaping quality are improved, operation is easy and convenient,and time and labor are saved.

Owner:何英

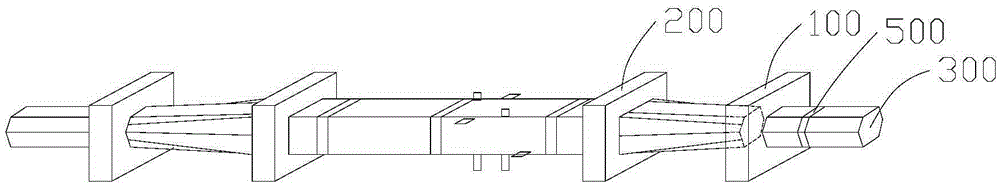

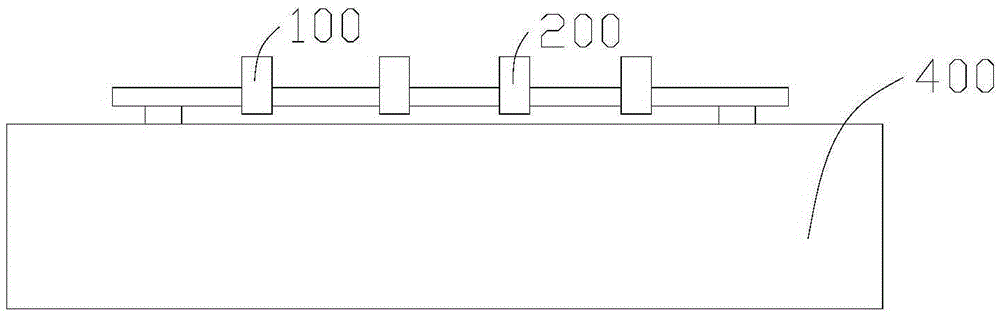

Shaping method and clamp for main cable strand of suspension bridge

ActiveCN105401521AEasy to operateImprove plastic qualityBridge structural detailsBridge erection/assemblyMechanical engineeringBuilding construction

The invention provides a shaping method and clamp for a main cable strand of a suspension bridge, and belongs to the field of engineering equipment. The method is characterized in that steel wires are marked according to the size of the steel wires; the main cable strand comprises a plurality of steel wires, and different steel wires are correspondingly marked; the steel wires are divided into a plurality of areas to be shaped through the marks on the steel wires; the plurality of steel wires are conveyed from the head end to the tail end of an operation platform; when in conveying, the plurality of steel wires in the area to be shaped between the adjacent marks are shaped into regular polygonal structures having different sections. The clamp comprises the operation platform, a regular quadrangular clamp and a regular hexagonal clamp, wherein the regular quadrangular clamp and the regular hexagonal clamp are correspondingly mounted on the operation platform. According to the method and the clamp, the cable strand is shaped in advance in the in-plant processing production stage, so that the mounting position accuracy can be ensured, and the precision meets the construction demand; in addition, the shaping processes at a construction site can be decreased, and the quality of the cable strand is prevented from reduction caused by the site shaping.

Owner:THE THIRD ENG CO LTD OF THE HIGHWAY ENG BUREAU OF CCCC

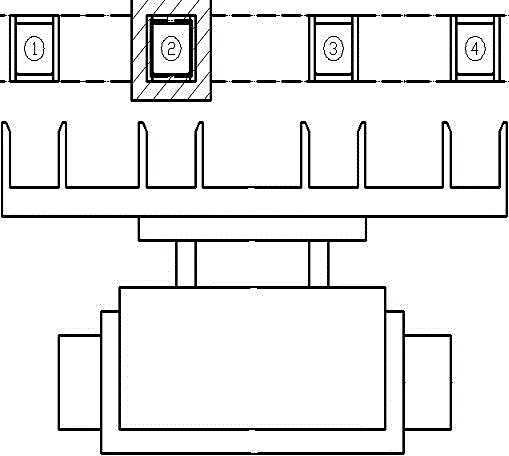

Transformer automatic shaping machine

InactiveCN109821934AImprove shaping efficiencyImprove plastic qualityShaping toolsEjection devicesTransformerLinear drive

The invention discloses a transformer automatic shaping machine. The machine comprises a rack, a bottom plate is connected with the bottom of the rack, the bottom plate is provided with a lower shaping mold, the top of the rack is connected with a linear driving device, an upper shaping mold is connected with a linear driving device, a transformer is placed on the lower shaping mold, and the uppershaping mold is driven to press downwards by the linear driving device to cooperate with the lower shaping mold to complete transformer shaping. The automatic shaping machine further comprises a feeding piece, a transmission mechanism is arranged between the feeding piece and the linear driving device, the feeding piece is driven by the transmission mechanism after transformer shaping is completed and the upper shaping mold is driven to elevated by the linear driving device, and the transformer is pushed forwards by the feeding piece to allow the transformer to fall from the shaping mold. Themachine has the advantages that shaping and feeding are automatically completed, and the shaping efficiency and quality of the transformer are improved.

Owner:HAINING LIANFENG DONGJIN ELECTRONICS

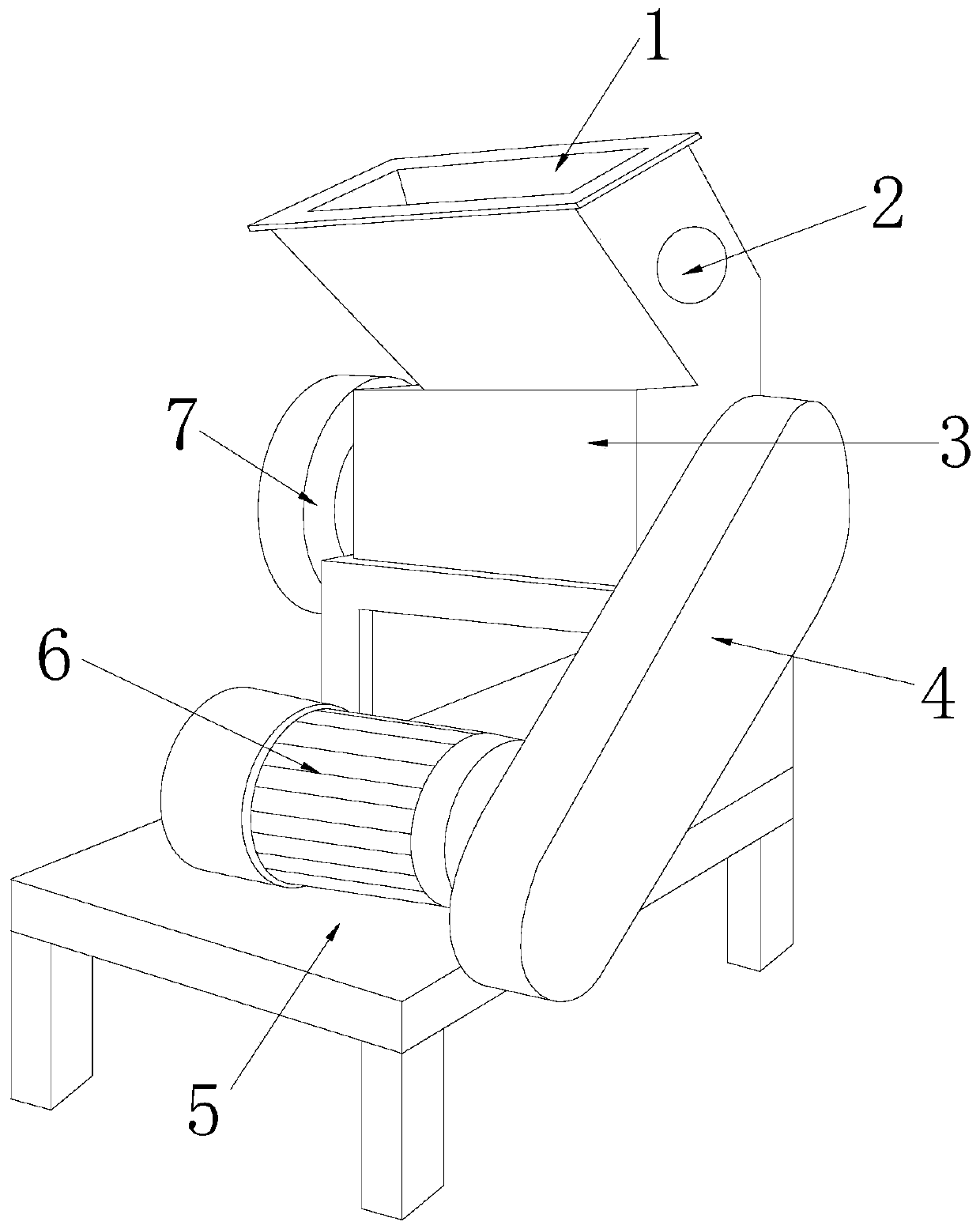

Rubber crushing device for rubber production

InactiveCN111483087AImprove plastic qualityQuality improvementPlastic recyclingMechanical material recoveryElectric machineryStructural engineering

The invention discloses a rubber crushing device for rubber production. The rubber crushing device structurally comprises a feed hopper, a crushing head, a filter bin, a protective cover, a fixing frame, a motor and a driving wheel, wherein the feed hopper is mounted on the filter bin, the protective cover is arranged on a side surface of the filter bin, the driving wheel is arranged on one side,opposite to the protective cover, of the filter bin, and the motor is mounted on the fixing frame. The rubber crushing device has the advantages that a cutter head is driven by an ejector rod to collide with a large-block-shaped plastic runway, the large-block-shaped plastic runway is cut, residual fine gravel and impurities are shaken off through impact force and guided into a main cavity througha guide bin to roll on a filter cartridge, and due to the fact that the mesh size of a mesh layer is smaller than the size of a rubber material crushed by the crushing head, thereby ensuring that theimpurities can pass through meshes and the rubber blocks cannot fall off; and through the arrangement of a one-way channel, recovered fine gravels and impurities in a collecting bin are prevented from falling back into the main cavity, it is guaranteed that the block-shaped plastic runway needing to be crushed in the next step does not contain impurities, and therefore the quality of recycled plastic is improved.

Owner:周会文

Fixing structure of vamp shaping machine

The invention discloses a fixing structure of a vamp shaping machine. The fixing structure comprises a workbench, a softening mechanism and a shaping mechanism, wherein the shaping mechanism comprisesa vibration generator, an upper pressing die, a lower pressing die, an air cylinder and a supporting frame; an adsorption structure is arranged on the lower pressing die, the adsorption structure comprises an air pump, an air cavity is formed in the lower pressing die, and an air suction hole communicated with the air cavity is formed in the upper surface of the lower pressing die; a connecting port is formed in the lower pressing die, and the air pump is connected with the connecting port. When a vamp is shaped, the vibration generator vibrates the upper pressing die, so that when the upperpressing die is in contact with the vamp, the vamp is vibrated, wrinkles on the vamp is vibrated to be flat, then the upper pressing die and the lower pressing die press the vamp, and the vamp is formed after pressing. Air in the air cavity is sucked out through the air pump, and negative pressure is generated on the air suction hole, so that the vamp is attached to and adsorbed on the surface ofthe lower pressing die. During pressing, the vamp is pressed and formed according to a placed state, and deformation cannot be generated in the pressing process, so that the wrinkles of the vamp during pressing and shaping are effectively prevented, and the shaping quality is improved.

Owner:ZHEJIANG SCI-TECH UNIV

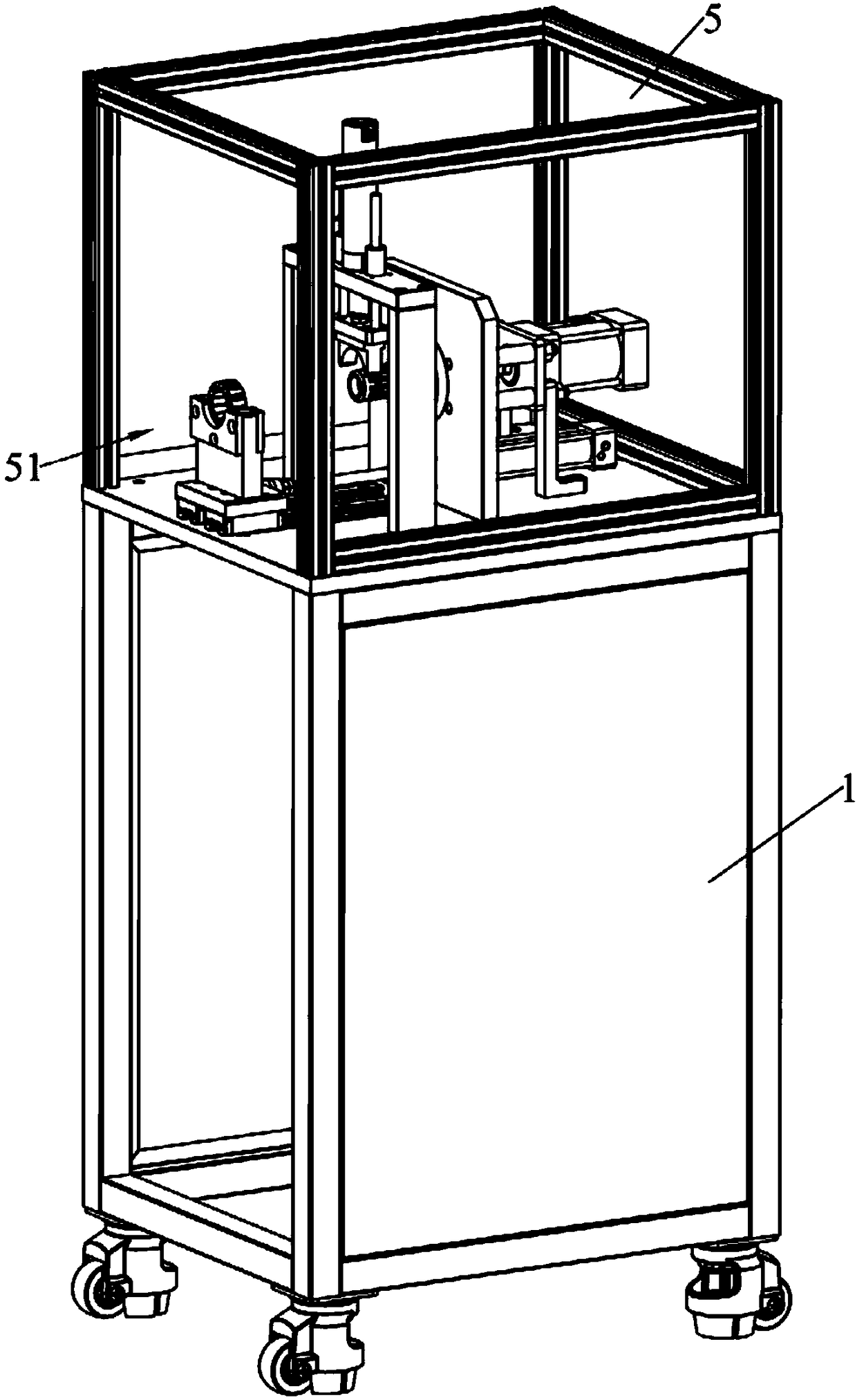

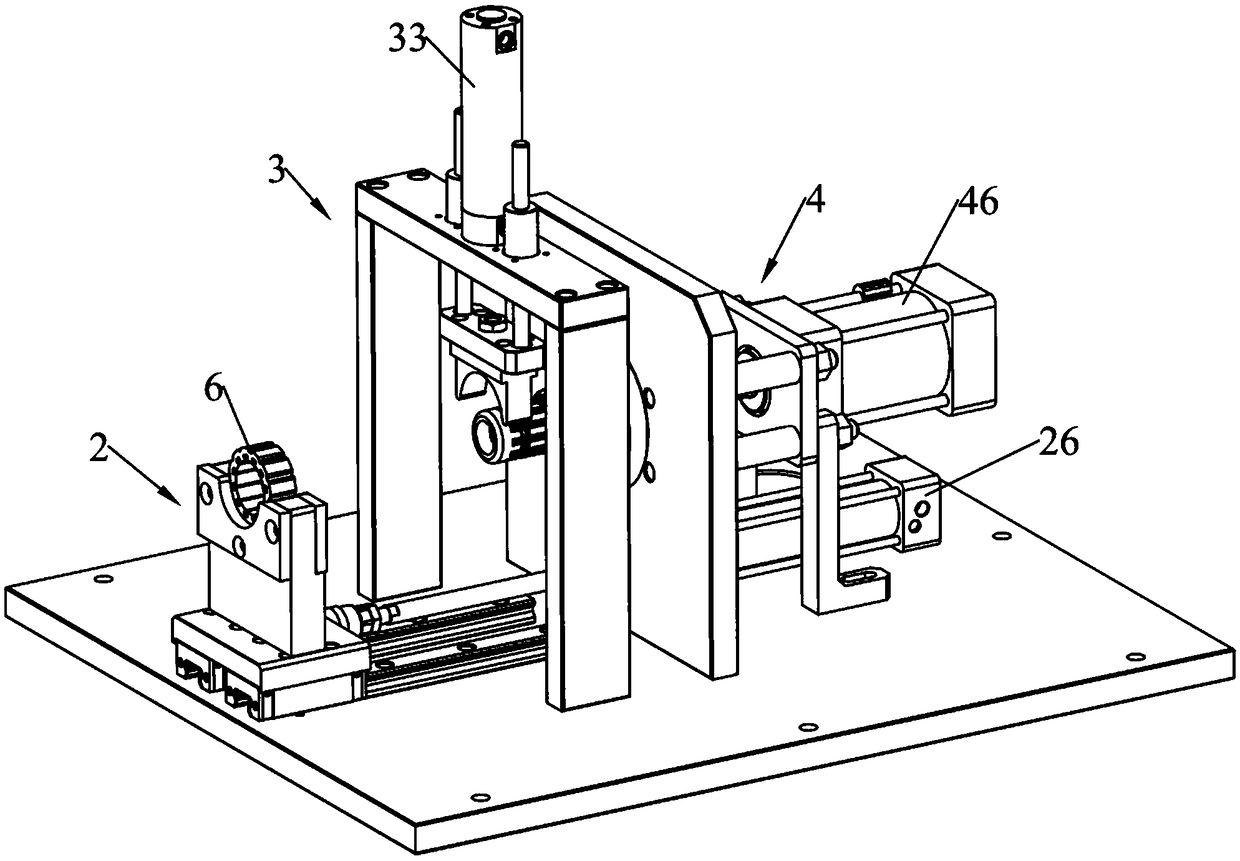

Multi-functional shaping device for kovar alloy frame

The invention discloses a multi-functional shaping device for a kovar alloy frame. The device comprises a feeding device, an expanding device, a retracting device, a discharging device and a moving device. In this way, automatic feeding, shaping and discharging can be achieved, the kovar frame shaping quality is improved, shaping efficiency is improved, and using is convenient.

Owner:SUZHOU DALIKE AUTOMATION TECH

Thin-wall alloy copper sleeve shaping and processing device

The thin-wall alloy copper sleeve shaping and processing device comprises a bottom plate, a vertical plate and a cantilever plate arranged at the upper end of the vertical plate are arranged on the bottom plate, a lower semicircular shaping die positioned below the cantilever plate is arranged on the upper surface of the bottom plate, an upper semicircular shaping die positioned above the lower semicircular shaping die is connected onto the cantilever plate, a vertical guide structure is arranged between the upper semicircular shaping die and the lower semicircular shaping die, a thin-wall alloy copper sleeve shaping hole is formed between the upper semicircular shaping die and the lower semicircular shaping die, a lifting oil cylinder for driving the lower semicircular shaping die to liftis arranged on the cantilever plate, a rotating shaft is arranged in the vertical plate in a penetrating mode, one end of the rotating shaft extends to the outer side of an orifice in the shaping hole of the thin-wall alloy copper sleeve, a reference disc sleeves at one end of the rotating shaft, a plurality of arc-shaped magnets uniformly distributed in the circumference are embedded at the outer edge of one end, close to the shaping hole of the thin-wall alloy copper sleeve, of the reference disc, and the other end of the rotating shaft is connected with a servo driving mechanism.

Owner:嘉善万润精密机械股份有限公司

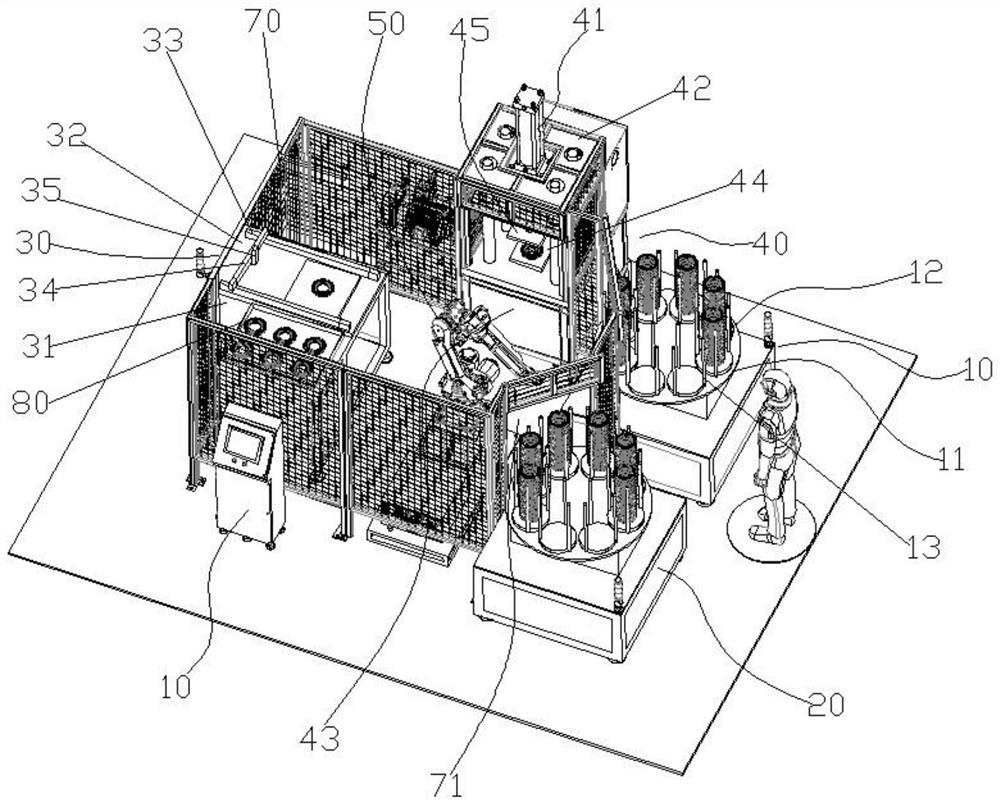

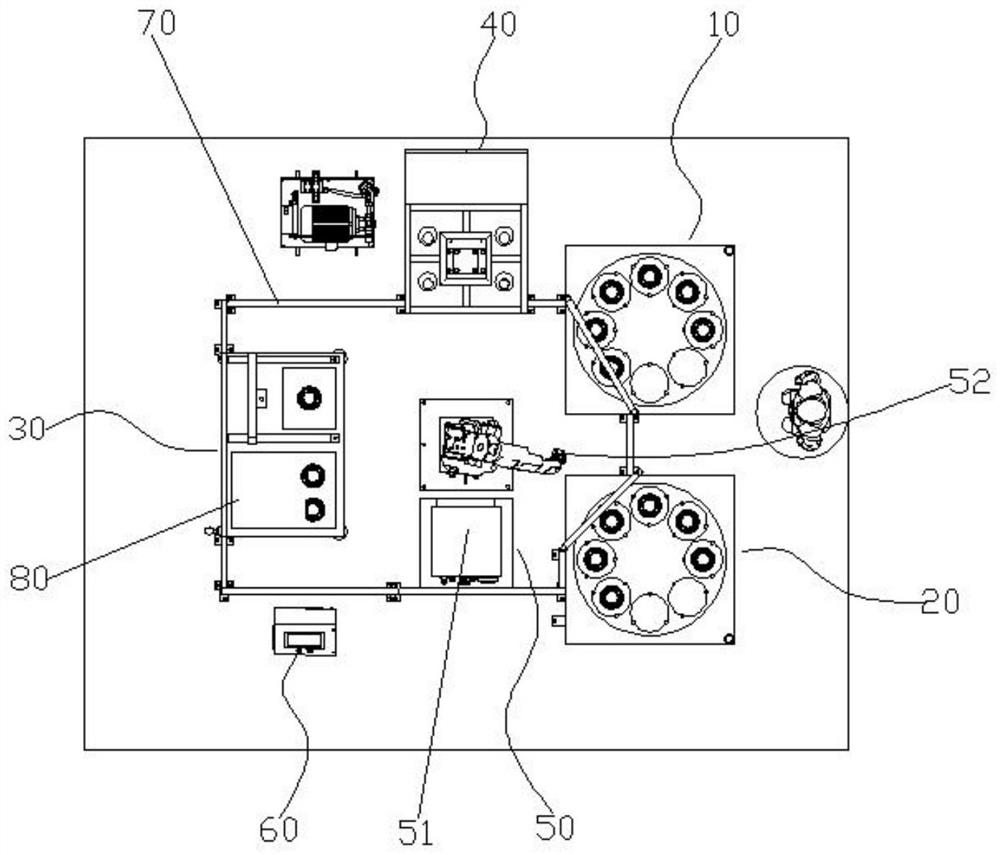

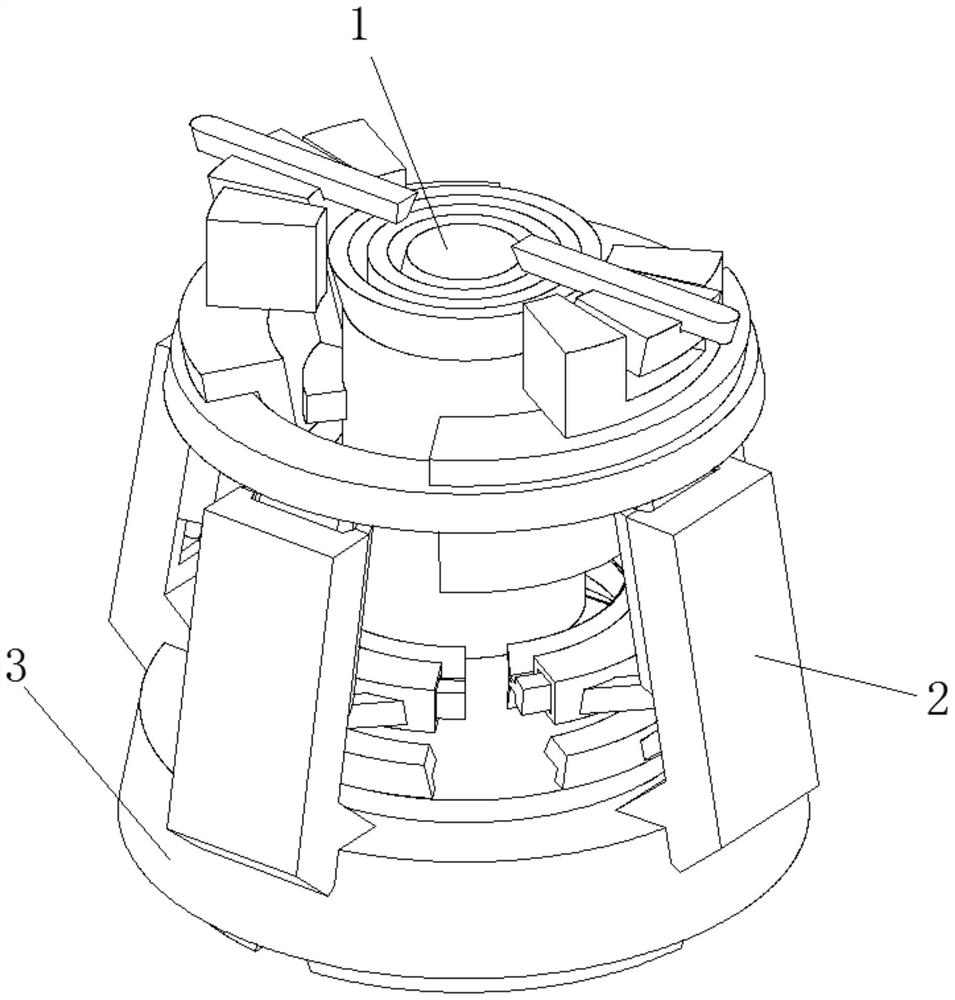

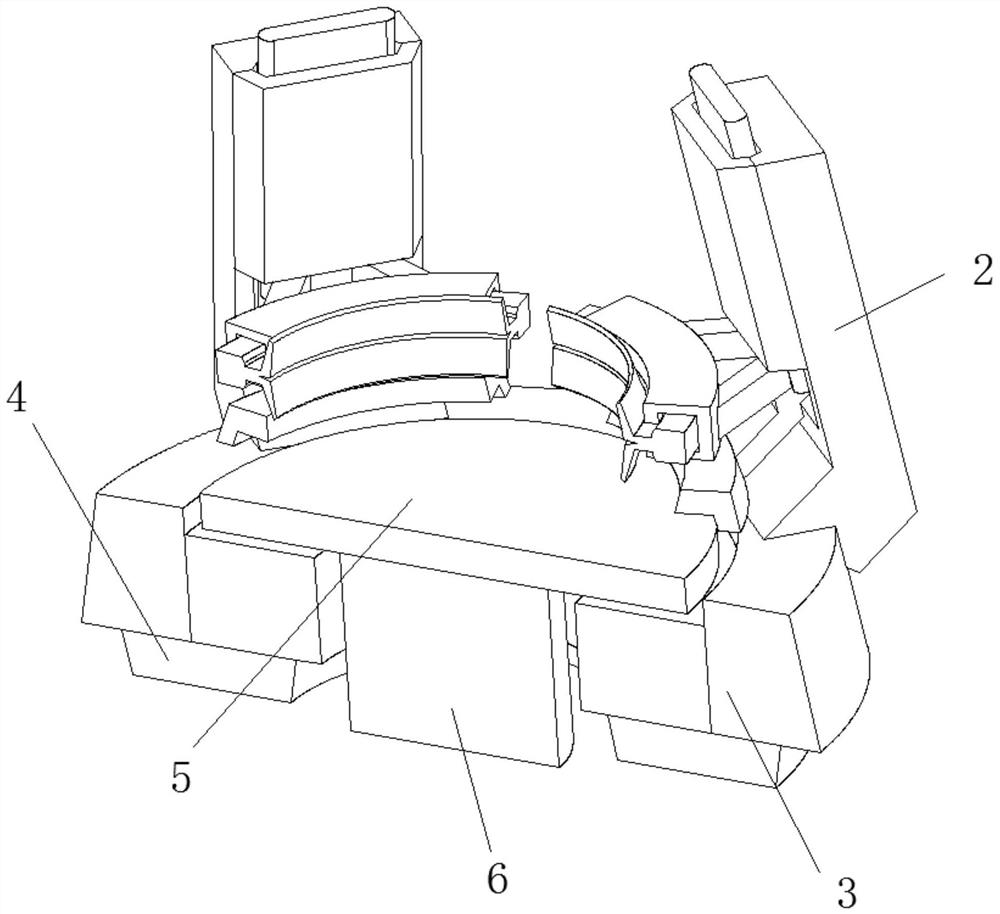

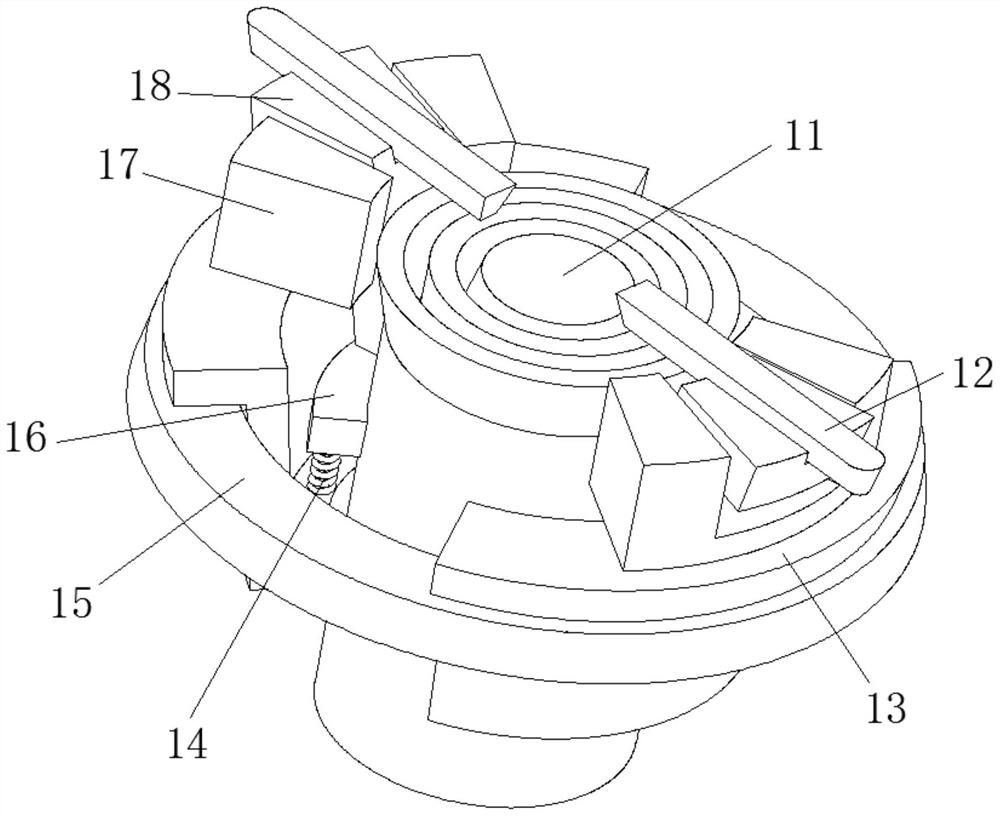

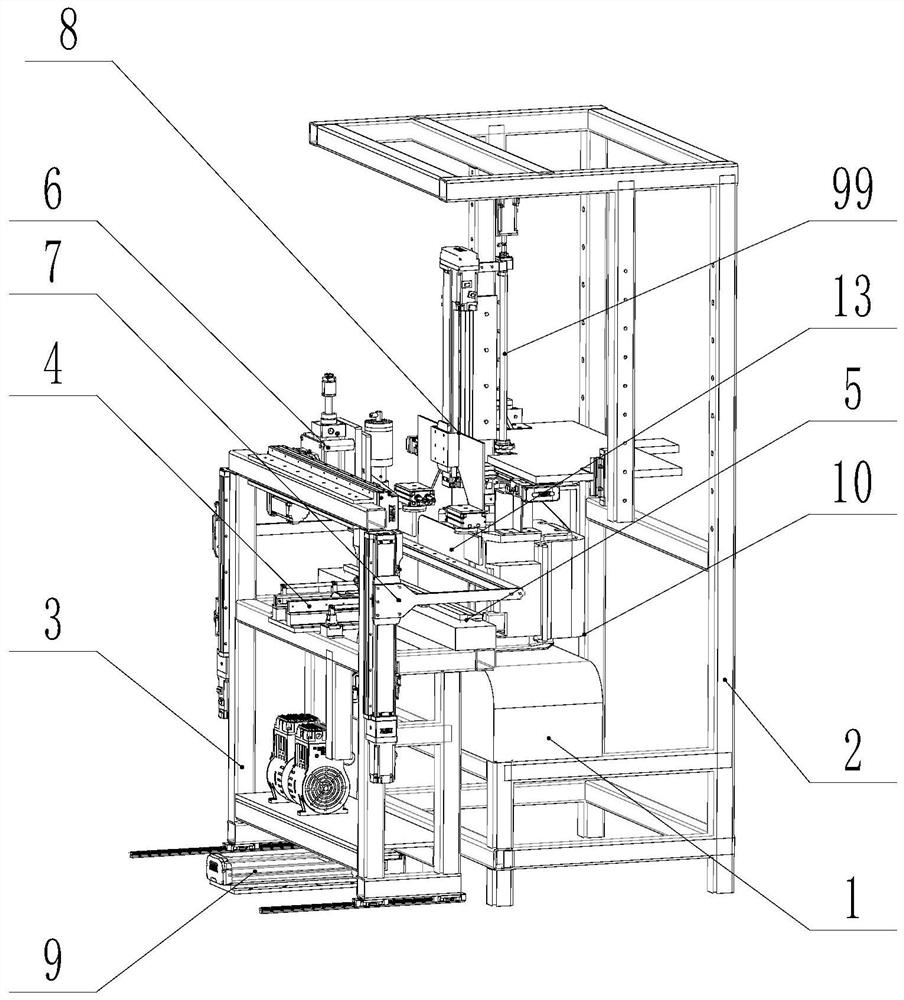

Automatic disc tooth shaping equipment and technological process

PendingCN114713515AReduce labor intensityImprove plastic qualitySortingConveyor partsControl systemSoftware engineering

The invention discloses automatic disc tooth shaping equipment and a technological process. Comprising a feeding mechanism used for feeding disc teeth, a qualified product receiving mechanism used for receiving qualified products, a flatness detecting device used for detecting the flatness of the disc teeth, and a shaping machine used for shaping the disc teeth. The disc tooth carrying mechanism is used for carrying disc teeth; the electric appliance control system is used for integrally controlling the equipment; the disc tooth carrying mechanism comprises a carrying robot and a grabbing jig, and the grabbing jig is installed at the execution end of the carrying robot and used for grabbing disc teeth. The feeding mechanism, the qualified product receiving mechanism, the flatness detection device, the shaping machine, the disc tooth carrying mechanism and the electric appliance control system are all arranged on the periphery of the carrying robot, the automation degree is high, automatic feeding, material carrying, detection and shaping can be carried out, and compared with an existing shaping mode, the working efficiency is greatly improved.

Owner:苏州丰达瑞自动化设备科技有限公司

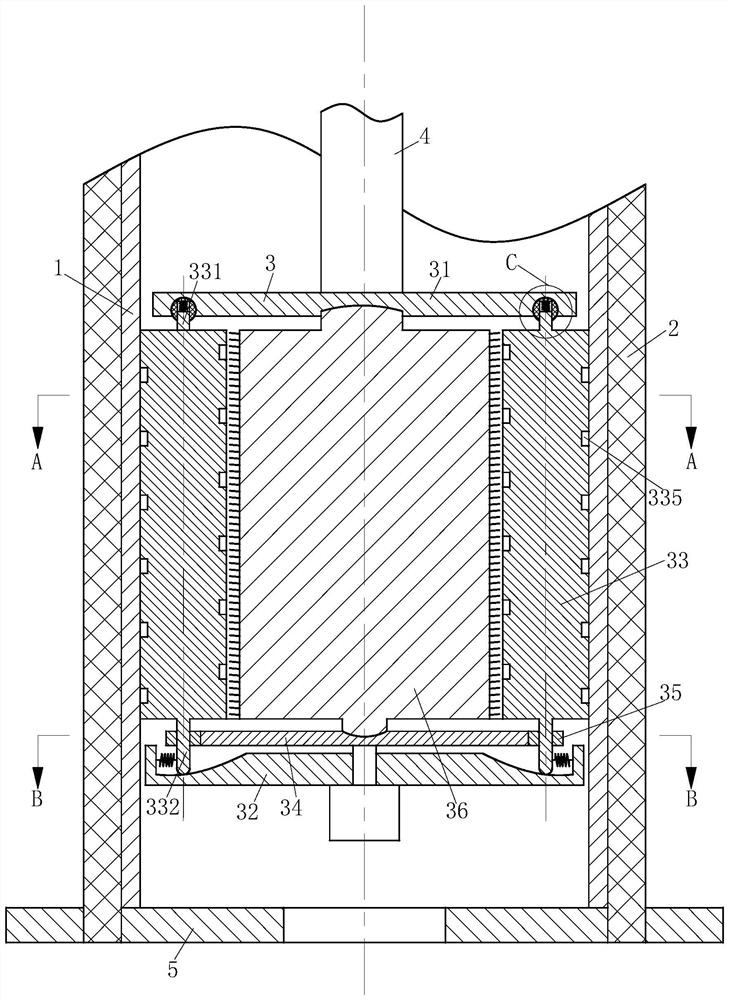

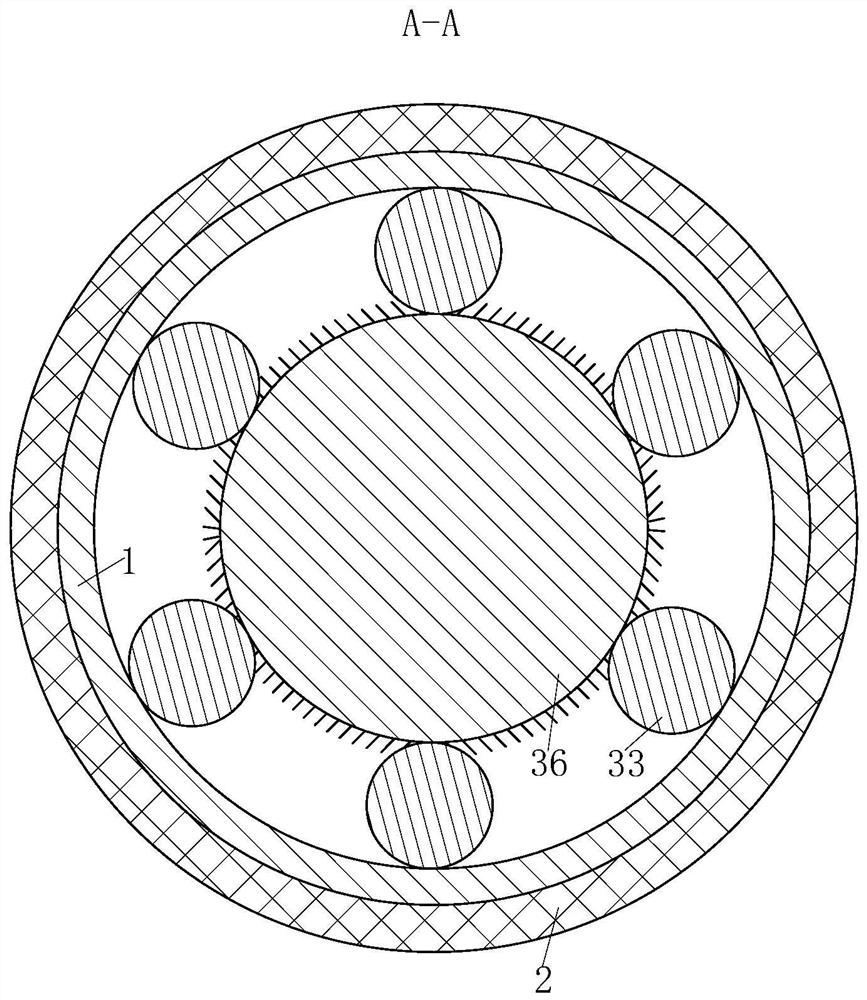

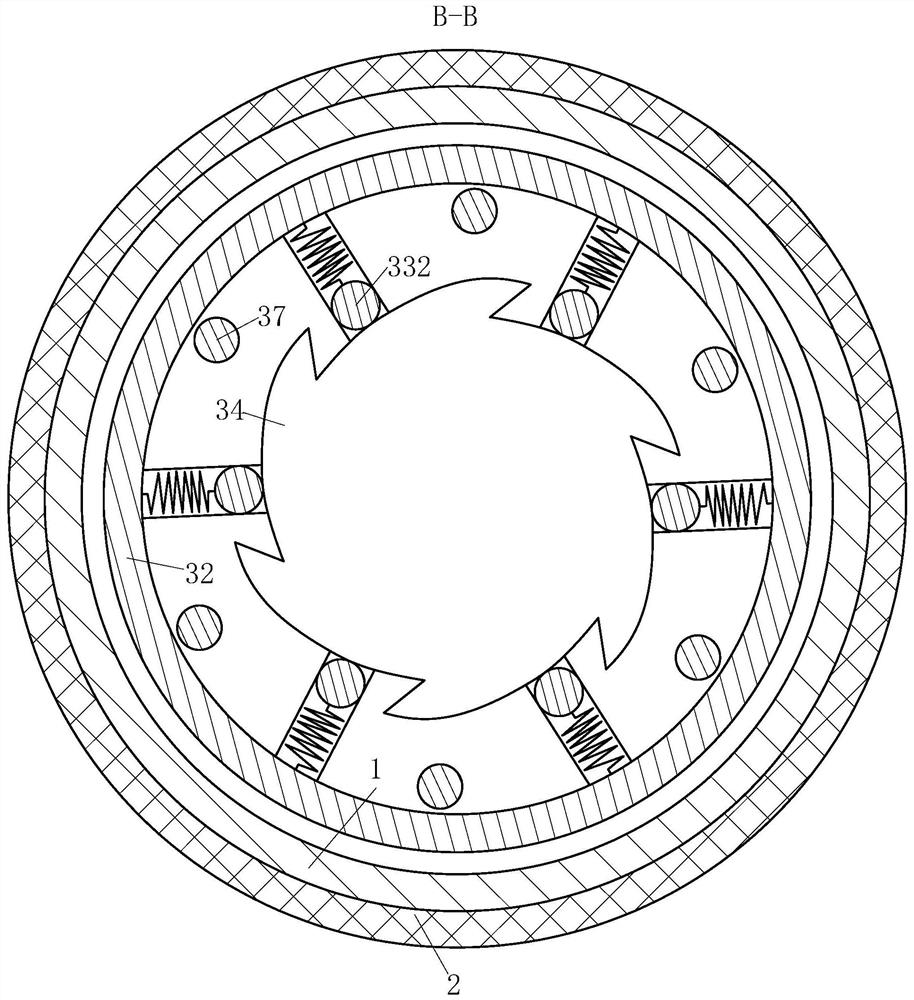

Automatic iron tamping machine tool controlled at high temperature

PendingCN114042850AAchieve cushioningAchieve elasticityPower hammersHammer drivesAutomatic controlControl system

The invention discloses an automatic iron tamping machine tool controlled at the high temperature. The automatic iron tamping machine tool comprises a tamping plate, a base is fixedly connected to the bottom of the tamping plate, a rotating shaft is rotatably connected to an opening in the middle of the tamping plate, a rotating pressing plate is fixedly connected to the top of the rotating shaft, a supporting device is fixedly connected to the side of the upper surface of the tamping plate, an impact hammer device is fixedly connected with the top of the supporting device, the impact hammer device comprises a layered tamping and hammering device, the upper surface of the layered tamping and hammering device is provided with a control sliding shaft, and the control sliding shaft is matched with the layered tamping and hammering device. The invention belongs to the technical field of manufacturing of industrial automatic control system devices. According to the automatic iron tamping machine tool controlled at the high temperature, the control sliding shaft is simply slides on the upper surface of a bent rod plate, so that the knocking effect of the bottom of the layered tamping and hammering device during iron hammering can be effectively operated, and simplicity and automation can be realized, and the service life of the device can be prolonged.

Owner:赵晓伟

Drill pipe shaping device

ActiveCN105880318BEasy to adjustImprove plastic qualityMetal working apparatusHydraulic cylinderEngineering

The invention relates to a shaping device for a drill stem. The shaping device comprises two supporting seats supporting the two ends of the drill stem. A drill stem rotation driving head is installed at one end of the drill stem. Multiple pressing heads are installed above the drill stem and driven by independent hydraulic cylinders. The hydraulic cylinders are installed on a movable supporting plate in a centralized mode. A guide rail is installed below the drill stem. A shaping detection frame is installed on the guide rail in a sliding mode. The shaping detection frame comprises a detection base and a detection rod, wherein the detection base can slide on the guide rail for adjustment, the detection rod is installed on the detection base, the lower end of the detection rod is inserted in an installing hole in the detection base, a spring is installed between the lower end of the detection rod and the bottom of the installing hole, a detection hole is formed in the upper end of the detection rod, and a opposite-type laser sensor used for detecting the detection hole is installed between the two supporting seats. By the adoption of the pressing heads and the hydraulic cylinders, different axial positions of the drill stem can be shaped, and adjustment operation is easy; by the adoption of a laser detection mode, the shaping quality and reliability are improved.

Owner:重庆市潼南区龙泉水利开发有限公司

Shaping system for integrally cutting, crimping and pressing edge

InactiveCN102069383BIncrease productivityImprove plastic qualityOther manufacturing equipments/toolsMechanical engineeringEngineering

The invention discloses a shaping system for integrally cutting, crimping and pressing edge, aiming to provide a shaping system which can finish cutting, crimping and pressing edge in one working procedure by mechanical operation and improve production efficiency and shaping quality. A main rack is provided with a bucket hoisting rack; the position on the main rack, which corresponds to the bucket cover, is respectively provided with an edge cutting mechanism, an edge crimping mechanism and an edge pressing mechanism; a bucket supporting tray is fixedly connected with the rotation shaft of the bucket; the rotation shaft of the bucket is connected with the rotation motor of the bucket by a transmission mechanism; the bucket hoisting rack is provided with a platen fixedly connected with a platen rotation shaft; the plant rotation shaft and the platen elevation driving mechanism can be in rotating connection. The shaping system of the invention can finish cutting, crimping and pressing edge in one working procedure by mechanical operation, improve production efficiency and shaping quality, and lower production cost.

Owner:TIANJIN LYUBOTE ENVIRONMENTAL PROTECTION EQUIP MFG

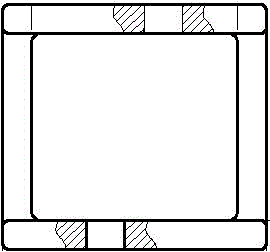

Shaping mechanism of motor shell

The invention discloses a shaping mechanism of a motor shell. The shaping mechanism comprises an upper die holder and a lower die holder, wherein the upper die holder is provided with an upper die plate; the lower die holder is provided with a lower die plate; the lower end face of the upper die plate is provided with a conical groove, the upper end face of the lower die holder is a conical surface, the lower die plate comprises a first lower die plate, a second lower die plate and a locating block, and the first lower die plate, the second lower die plate and the locating block are matched to form a lower shaping cavity; the upper die plate is matched with the lower die plate to form a shaping cavity; as the lower die plate is of a split structure, during shaping, when the size of the shaping cavity has deviation, the second lower die plate can be regulated, and correction of the shaping cavity is achieved, the size and form and location tolerance of the shaping cavity can be guaranteed better, and therefore shaping quality of the motor shell is greatly improved.

Owner:镇江先锋汽车零部件有限公司

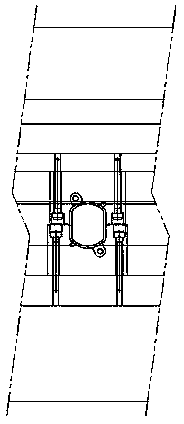

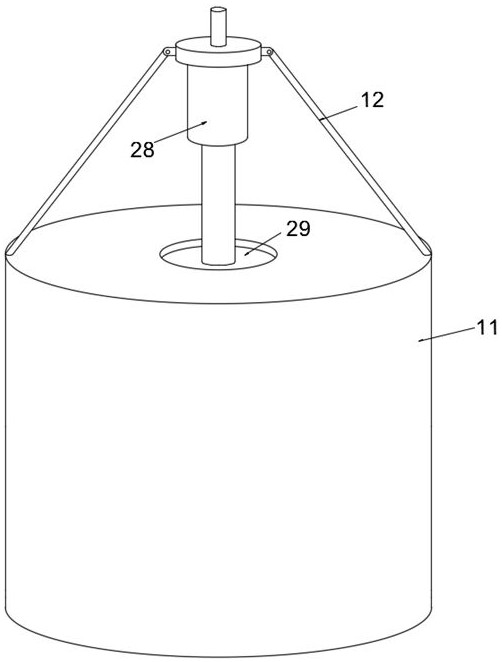

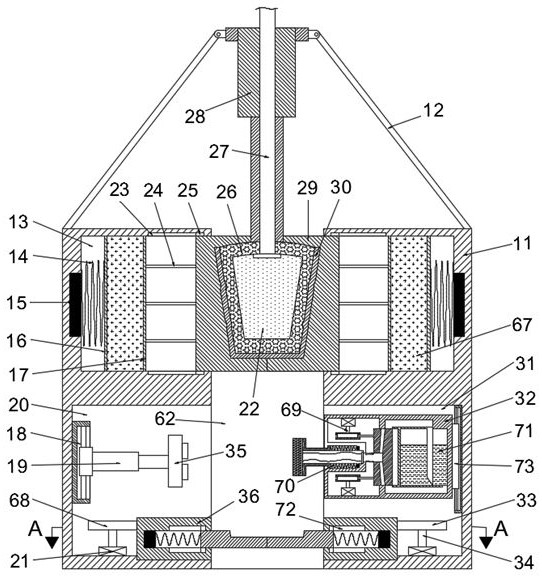

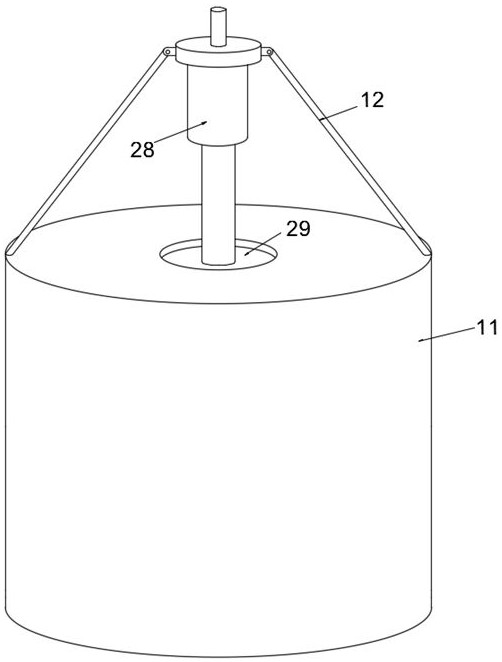

A regenerated aggregate shaping device

ActiveCN111168557BImprove plastic qualityEasy to handleEdge grinding machinesPolishing machinesStructural engineeringAir compressor

The invention discloses a regenerated aggregate shaping device, which comprises a feeding hopper, a shaping pipe, a powder selection mechanism and a dust collector. A liner is arranged on the inner wall of the shaping pipe, and the liner has a convex shape. The autoclaved aerated concrete block aggregate enters the shaping pipe through the feeding hopper, and the air compressor feeds compressed air into the shaping pipe. The aggregate moves along the shaping pipe under the drive of the compressed air, and the inner wall of the shaping pipe is provided with a liner. There are protrusions on the liner facing the axis of the shaping pipeline. Under the friction of the liner and the collision of the protrusions, the edges and corners of the aggregates are ground off, and the abrasives and powder are transported to the In the powder selection mechanism, the powder selection mechanism can separate the aggregate from the powder, the dust collector can collect the powder, the powder selection mechanism outputs the aggregate, the shape of the aggregate after shaping is close to spherical, and the dust collector The powder is collected, so that the surface of the shaped aggregate is clean and dust-free, and the quality of aggregate shaping is improved.

Owner:SHENZHEN HUAWEI ENVIRONMENTAL PROTECTION BUILDINGMATERIAL

Shaping device for bagged FOSB packaging bags

InactiveCN112429305ACompact structureFit closelyPackaging by pressurising/gasifyingWrapper twisting/gatheringPumping vacuumEngineering

The invention discloses a shaping device for bagged FOSB packaging bags. The shaping device comprises a shaping machine frame, a sealing machine frame, a FOSB conveying belt, a vacuumizing device, anopening clamping device, an ultrasonic sealing device, a FOSB front-end upturning device, a FOSB front-end shaping device, a sealing station horizontal driving device and a FOSB back side surface shaping device. The FOSB conveying belt, the FOSB front-end shaping device and the FOSB back side face shaping device are installed on the shaping machine frame, the sealing station horizontal driving device is arranged on the ground on one side of the shaping machine frame, the sealing machine frame is fixed to the movable end of the sealing station horizontal driving device, and the FOSB front-end upturning device, the vacuumizing device, the opening clamping device and the ultrasonic sealing device are all fixed to the sealing machine frame. According to the shaping device for the bagged FOSB packaging bags, the bagged FOSB packaging bags can be vacuumized and automatically shaped, the shaping efficiency is improved, the whole process is fully automatically carried out, and the labor cost is reduced.

Owner:无锡迪渊特科技有限公司

Open metal drum shaping device

ActiveCN113635156AAchieve non-invasive accessImprove work efficiencyLiquid surface applicatorsRevolution surface grinding machinesMechanical engineeringPhysics

The invention discloses an open metal drum shaping device. The open metal drum shaping device comprises a shell, supporting rods which are symmetrically left and right are fixedly arranged on the upper end face of the shell, a first electric telescopic rod is fixedly arranged between the supporting rods, an air pressure pipeline which is through up and down is fixedly arranged in the first electric telescopic rod, and a flexible block is fixedly arranged on the lower end face of the first electric telescopic rod; the open metal drum shaping device is provided with the flexible block, an extrusion block and a filling box, non-invasive taking of a metal drum can be achieved, the concave portion is extruded out, then the extrusion block is hydraulically driven to press the protruding part of the metal drum back to the original position, the filling box supplements the undamaged part of the metal drum completely, and the open metal drum shaping device has the advantages of being convenient to use, high in working efficiency and high in shaping quality; and a fixing block and an annular mounting block are further arranged, so that the metal drum can be fixed and rotated, polishing and filling work can be conveniently carried out, basically non-cutting treatment of the metal drum is assisted to be completed, and the open metal drum shaping device has the beneficial effects that the shaping accuracy is improved, and the quality is improved.

Owner:张家港南光包装容器再生利用有限公司

An open metal barrel shaping device

ActiveCN113635156BAchieve non-invasive accessImprove work efficiencyLiquid surface applicatorsRevolution surface grinding machinesBarrel ShapedEngineering

Owner:张家港南光包装容器再生利用有限公司

A method for welding and shaping the arm frame plate of the transfer buoy

The invention provides a welding and reshaping method of a lightering floating platform cantilever crane plate, and relates to the welding and reshaping method of a large-scale structure plate. Before welding, flame heating is carried out on the position 100-500mm away from a welding line position, the heating width is 10-20mm, and therefore the temperature of a steel plate can reach 300-500 DEG C. Welding is carried out for welding structural steel to the steel plate, back chipping is carried out after welding, then flame heating is carried out on a welding line and the position 100-500mm away from the welding line position, and therefore the temperature of the steel plate can reach 500-700 DEG C, and deformation caused by welding stress can be corrected. The welding and reshaping method reduces deformation of the cantilever crane plate effectively, improves welding quality, is low in production cost and has wide application prospect.

Owner:JIANGSU DINSON HEAVY IND +1

Thin-wall alloy copper sleeve plastic processing device

The thin-walled alloy copper sleeve plastic processing device includes a bottom plate, a vertical plate is arranged on the bottom plate, and a cantilever plate arranged on the top of the vertical plate, a lower semicircle plastic mold located below the cantilever plate is arranged on the upper surface of the bottom plate, and a vertical plate is arranged on the cantilever plate. It is connected with the upper semicircle shaping mold located above the lower semicircle shaping mold, a vertical guide structure is arranged between the upper semicircle shaping mold and the lower semicircle shaping mold, and a thin-walled alloy copper sleeve is formed between the upper semicircle shaping mold and the lower semicircle shaping mold Shaping hole, on the cantilever plate, there is a lifting cylinder to drive the upper semicircle shaping mold up and down, and a rotating shaft is pierced on the vertical plate, one end of the rotating shaft is extended to the outside of the opening in the shaping hole of the thin-walled alloy copper sleeve and is at one end of the rotating shaft A reference disk is set on the sleeve, and a number of evenly distributed arc magnets are inlaid on the outer edge of the end of the reference disk close to the shaping hole of the thin-walled alloy copper sleeve, and the other end of the rotating shaft is connected with the servo drive mechanism.

Owner:嘉善万润精密机械股份有限公司

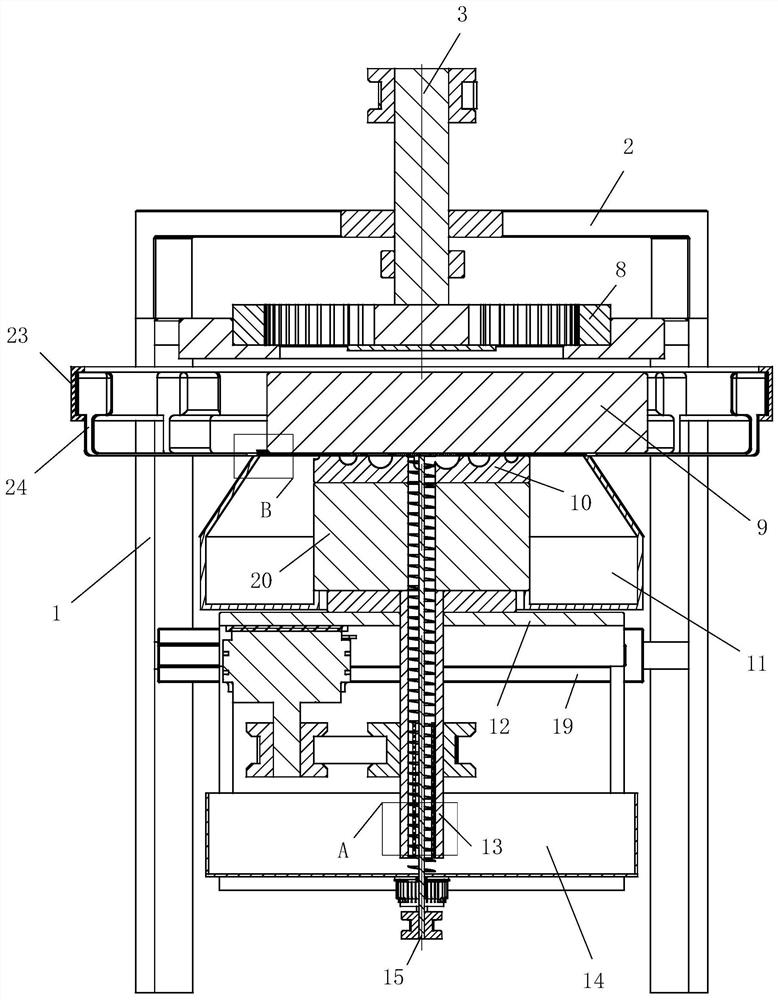

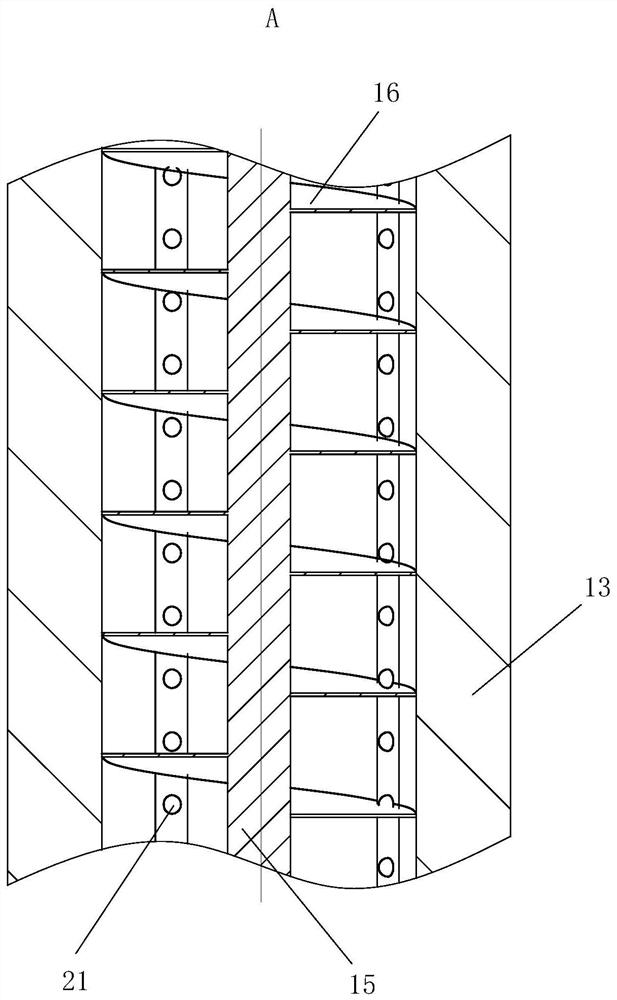

Disc-type silicon carbide shaping machine based on planetary gear train

InactiveCN113414667AGood plastic effectFully automatedEdge grinding machinesGrinding carriagesCarbide siliconElectric machine

The invention belongs to the technical field of photovoltaic manufacturing industry, and particularly relates to a disc-type silicon carbide shaping machine based on a planetary gear train. The disc-type silicon carbide shaping machine comprises a support frame, a top beam, a first rotating shaft, a second rotating shaft, a connecting part, a first gear, a second gear, a gear ring, a rolling disc, a shaping disc, a material collecting frame, a support plate, a hollow cylinder, a feeding frame, a third rotating shaft, a spiral plate, a first motor, a second motor and a third motor. According to the disc-type silicon carbide shaping device, the spiral plate can bring silicon carbide in the feeding frame to the shaping disc by starting the third motor; the first motor is started to enable the grinding disc to rotationally rub and shape the silicon carbide on the shaping disc, so that edges and corners of the silicon carbide are polished to be smooth, the silicon carbide is shaped into spherical particles, and the shaping effect of the shaping machine is improved; and then the second motor is started to drive the shaping disc to rotate, the silicon carbide on the shaping disc can move outwards along a vortex-shaped groove and is automatically discharged into the material collecting frame, so that automation of the shaping machine is achieved.

Owner:周勤

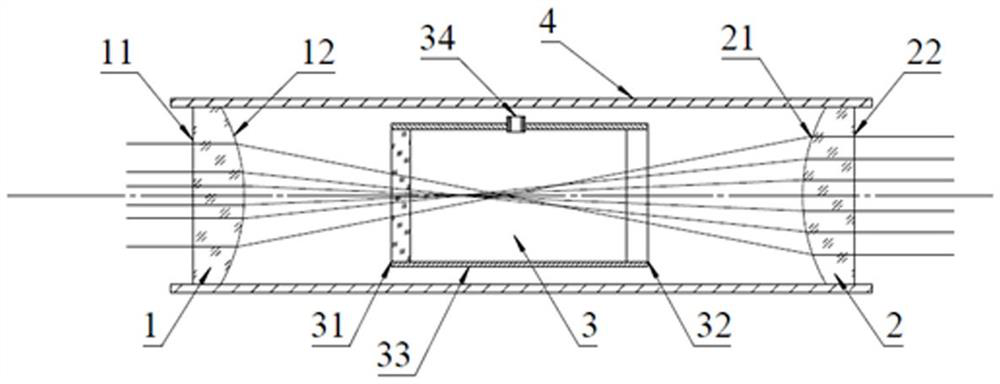

Gaussian beam shaping device

The invention relates to a Gaussian beam shaping device which adopts a positive focal length lens to shape a Gaussian beam, focuses are gathered in a vacuum environment through arrangement of a vacuum assembly on the basis of the positive focal length lens, and air ionization is not caused due to the fact that no air interference exists in the vacuum environment. And the shaping effect and the service life of the shaping device are improved. Meanwhile, components such as a high-transmittance film, a matting device and a heat dissipation device are further added on the basis, so that the performance of the shaping device is further improved. The device disclosed by the invention has a better Gaussian beam shaping effect, meanwhile, the manufacturing process is simple, the device is suitable for batch production, the safety performance is better, and the service life is longer.

Owner:WUHAN YIFI LASER EQUIP CO LTD

A precision metal tank shaping device

The invention belongs to the technical field of metal shaping equipment, and particularly relates to a precise metal tank body shaping device. The precise metal tank body shaping device comprises a tank body, an electromagnetic cylinder, a shaping module, a telescopic module and an annular plate, wherein the electromagnetic cylinder is fixedly arranged on the annular plate, the tank body is fixedly arranged in the electromagnetic cylinder, the telescopic module is fixedly connected with the upper side of the shaping module, the shaping module comprises a first fixing disc, a second fixing disc, rolling wheels, bearings, a stirring plate and a motor, the first fixing plate and the second fixing disc are fixedly connected through a plurality of fixing shafts, the first fixing disc is locatedon the upper side of the second fixing disc, the first fixing disc and the second fixing disc are connected through the six uniformly distributed rolling wheels, the upper ends and the lower ends ofthe rolling wheels are provided with first protrusions and second protrusion, the stirring plate is disc-shaped, the edge of the stirring plate is provided with an equal-angle spiral tooth structure,the motor is fixedly connected with the lower surface of the second fixing disc, and the end part of a motor shaft is fixedly connected with the lower surface of the stirring plate.

Owner:浏阳市鑫利粉末冶金有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com