Expansion machine

A technology of expansion machine and expansion plate, which is applied in the field of expansion machine, can solve the problems of low shaping efficiency, many working hours, and different shapes, and achieve the effects of reducing labor costs, high shaping quality, and high shaping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

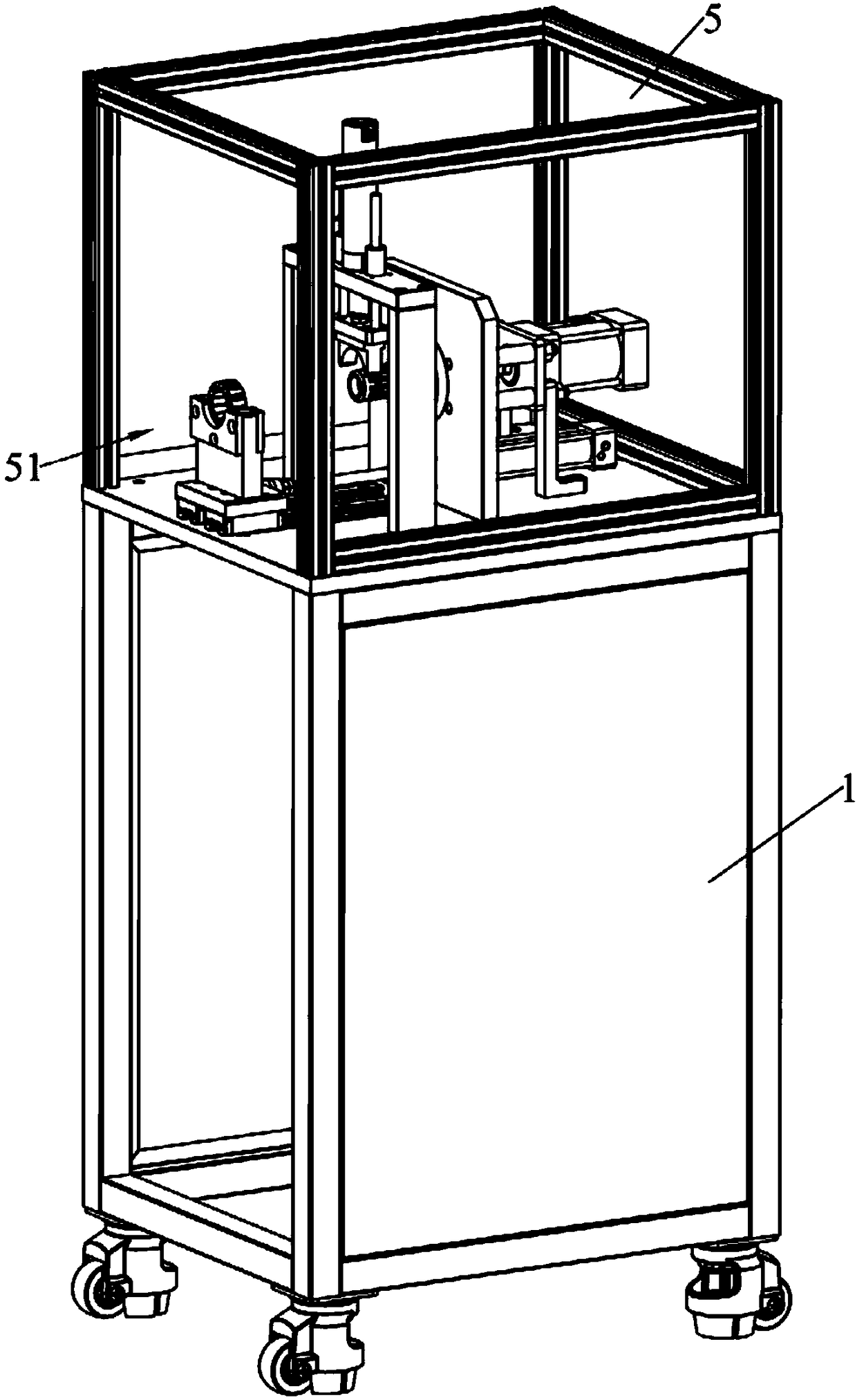

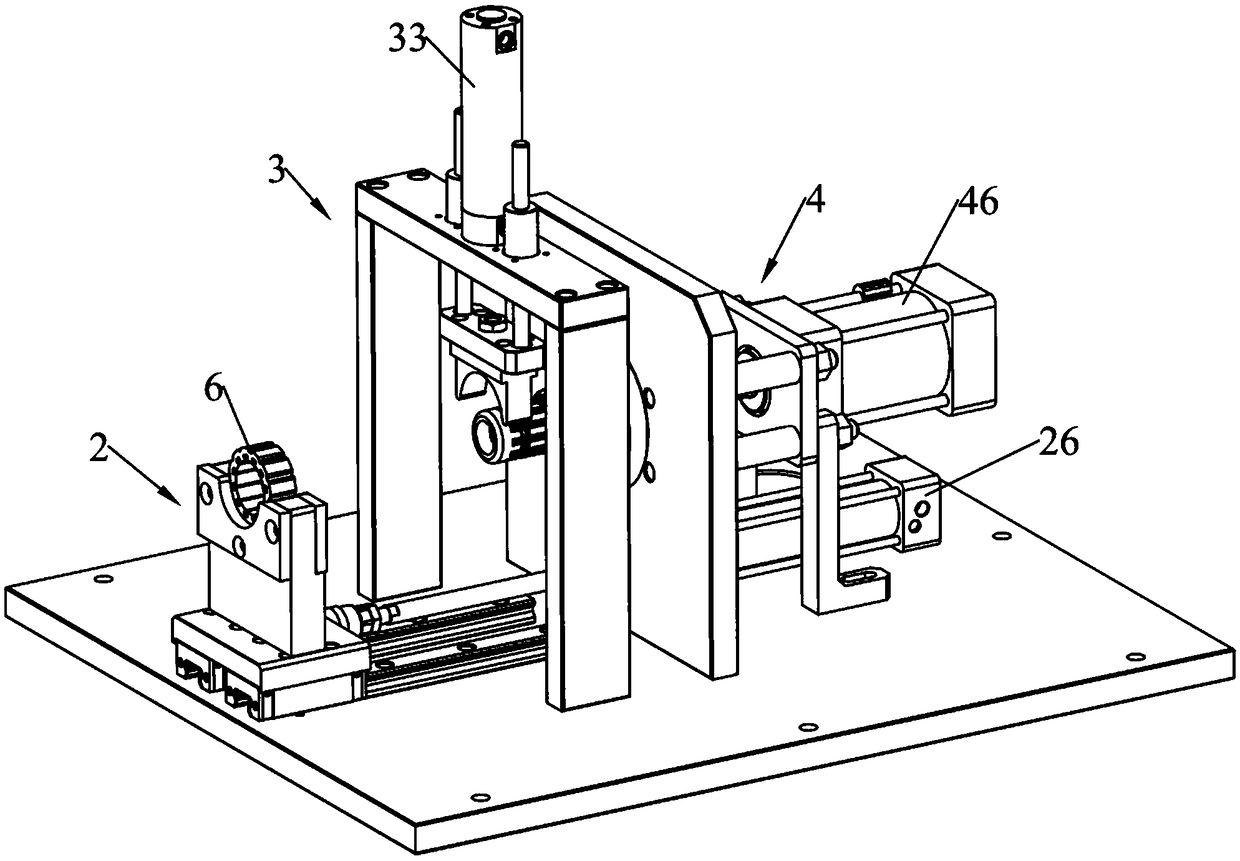

[0041] The invention provides an expanding machine, which is used for shaping the coil after the coil is loaded into the iron core of the stator 6 . Such as figure 1 and figure 2 As shown, the expansion machine includes a machine base 1, a clamping mechanism and an expansion mechanism 4. The control system and the power system for controlling the automatic operation of the clamping mechanism and the expansion mechanism 4 are arranged inside the machine base 1. The top of the machine base 1 is covered with a machine The cover 5 is used to cover the clamping mechanism and the expansion mechanism 4 inside, and an opening 51 is provided on one side of the cover 5 for the stator 6 to be inserted.

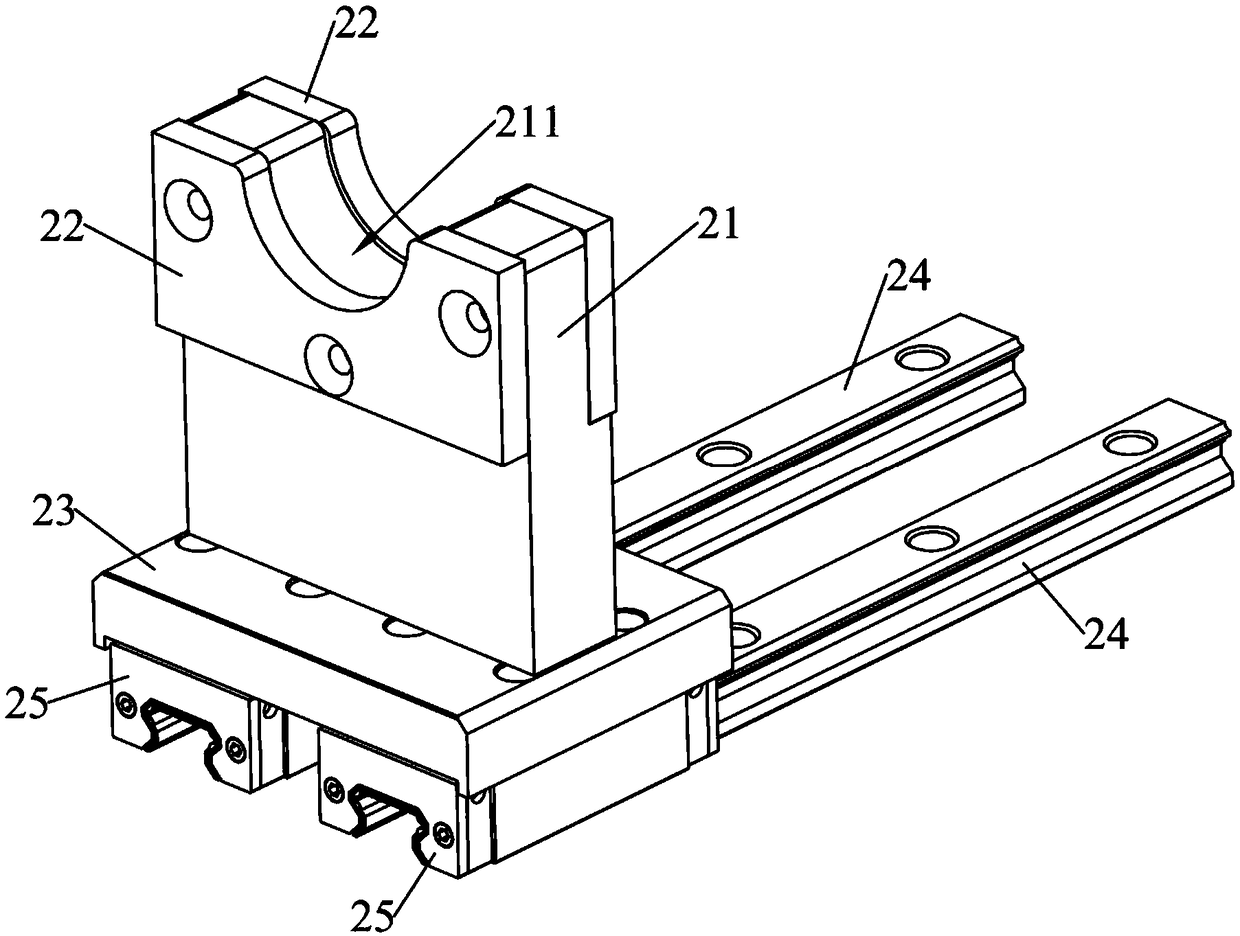

[0042] Such as figure 2 As shown, the clamping mechanism is arranged on the machine base 1, which can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com