Transformer automatic shaping machine

A transformer and shaping machine technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of difficulty in matching the production capacity of the front and rear processes, increased process layout, and difficulties, so as to improve the shaping efficiency and shaping quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

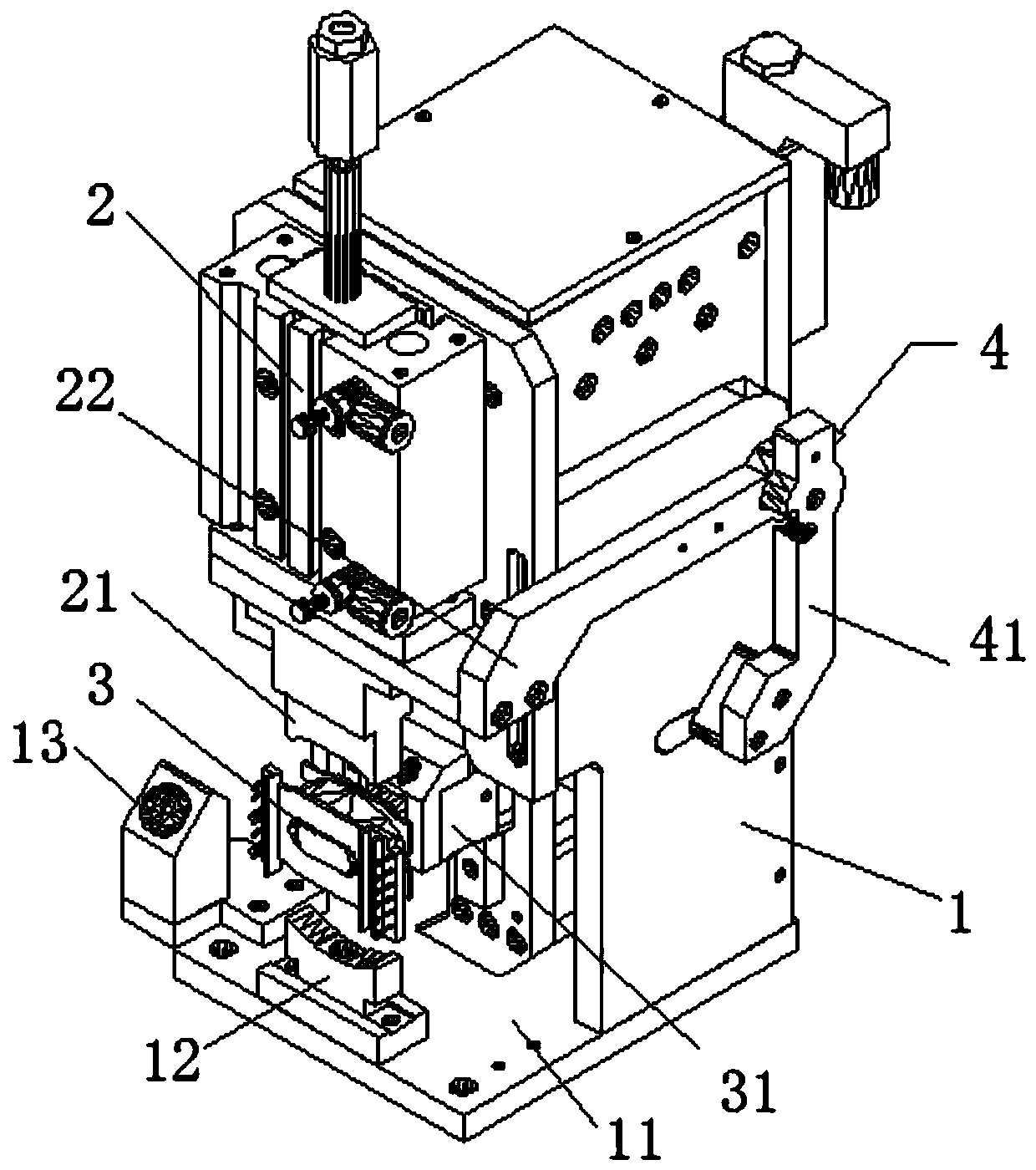

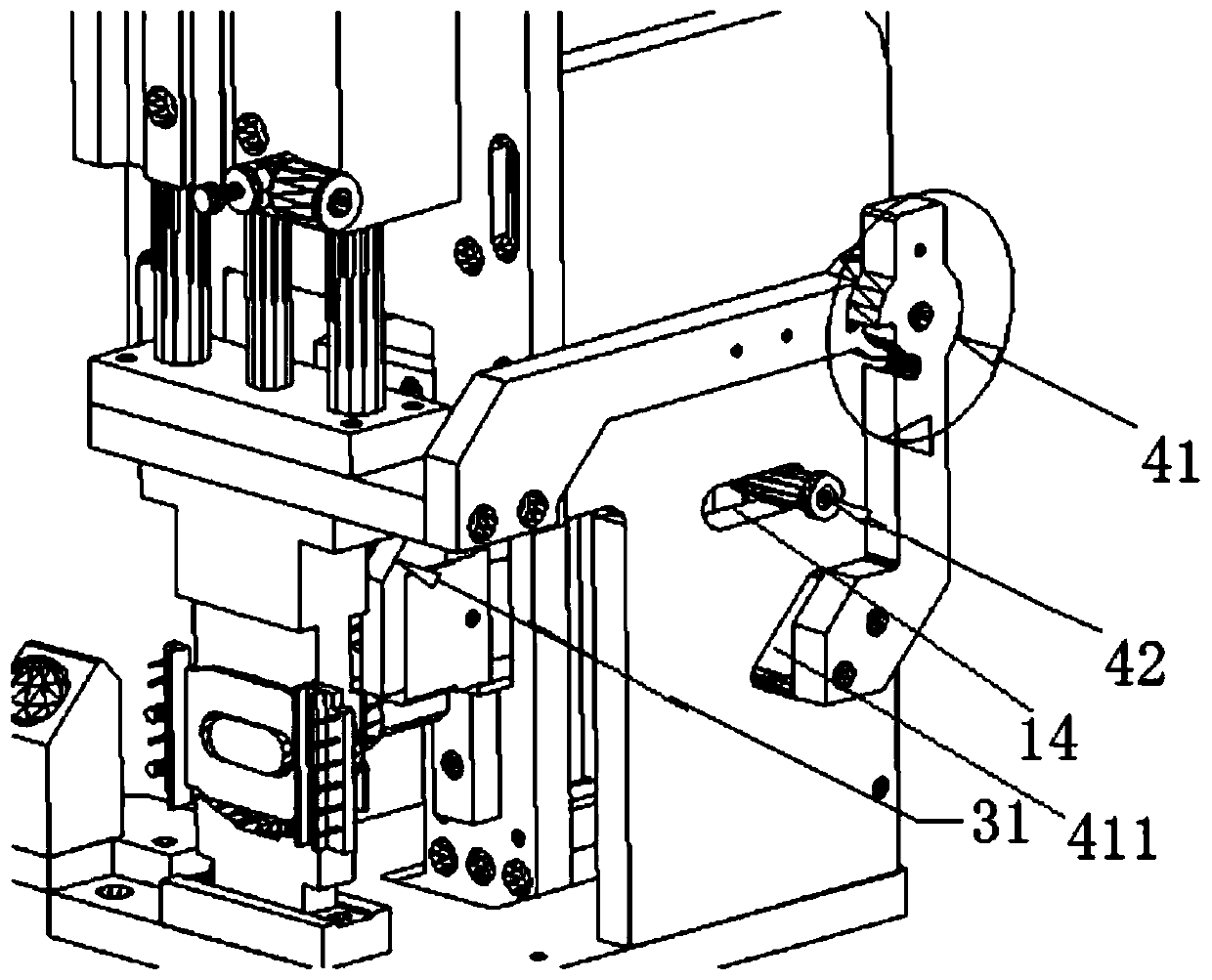

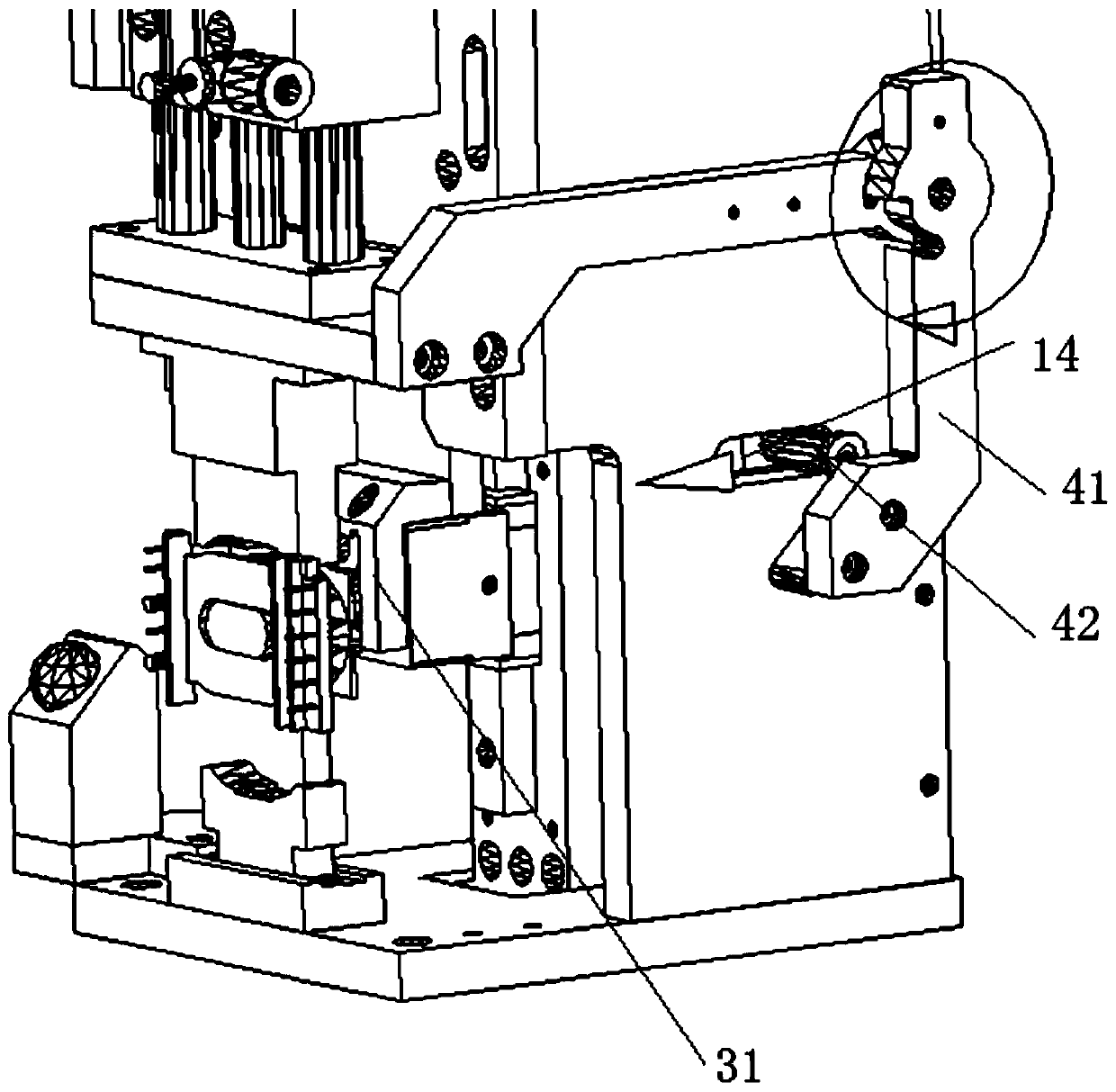

[0015] refer to Figure 1 to Figure 3 As shown, a transformer automatic shaping machine is used to automatically shape the transformer 3 after winding the coil winding. It includes a frame 1, the bottom of the frame is connected with a bottom plate 11, and the bottom plate is provided with a lower shaping mold 12. , the top of the frame is connected to the linear driver 2, the linear driver 2 is connected to the upper shaping mold 21, the transformer 3 is placed on the lower shaping mold 12, and the linear driver 2 drives the upper shaping mold 21 to press down and cooperate with the lower shaping mold 12 Transformer 3 shaping is completed. Both the upper shaping mold 21 and the lower shaping mold 12 have arc-shaped mold cavities, which are fitted and pressed against the curved surface of the transformer winding to achieve shaping. The linear driver 2 is started and stopped by a start switch 13 .

[0016] In order to realize the automatic blanking of the transformer 3 after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com