Shaping method and clamp for main cable strand of suspension bridge

A technology for suspension bridges and fixtures, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as easy damage to the galvanized layer of cable strands, reduced anti-corrosion performance of cable strands, and reduced use safety, so as to improve erection efficiency, The structure is simple and reasonable, ensuring the effect of smooth completion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

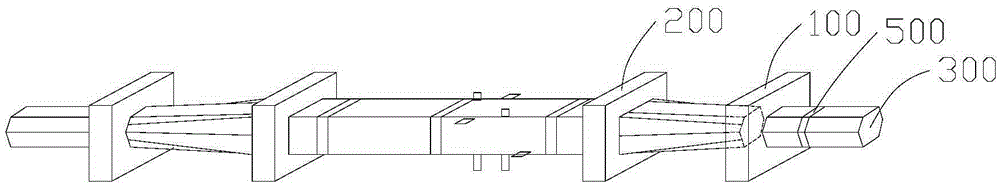

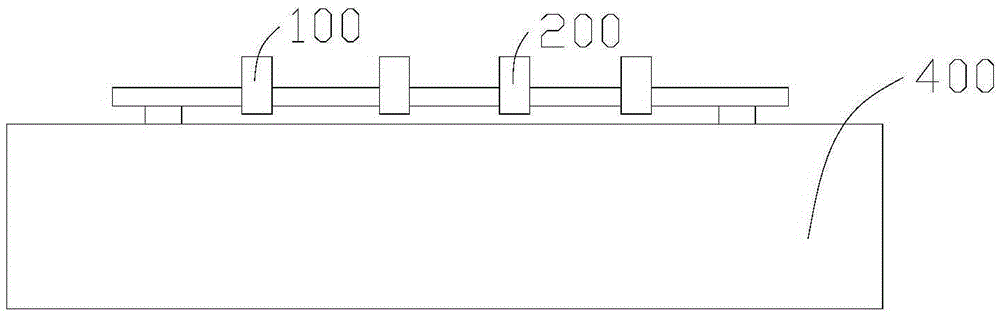

[0031] In the construction of PPWS cable strand erection, there is an important process before the main cable strands enter the saddle, that is, the hexagonal steel wire strands maintained in the manufacturing stage are manually combed into quadrilateral strands with steel tools, and the hexagonal strands are required. The strand retainer and the quadrilateral strand shaper are clamped. After the strands are put into the saddle, use a jack and hardwood to squeeze the strands into the notches of the strands of the saddle, and then release the quadrilateral and hexagonal shapers. During the construction, man-made steel sheet carding cable strands will inevitably damage the galvanized layer of the strands, reduce the anti-corrosion system of the strands, waste a lot of manpower and time, and reduce the productivity of strand erection.

[0032] In view of this, the designer of the present invention has designed a method for shaping the main cable strands of a suspension bridge and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com