Rubber crushing device for rubber production

A pulverizing device and rubber technology, applied in the rubber field, can solve the problems of affecting quality, pulverizing blade wear, blade gap, etc., to achieve the effect of improving the quality of plastics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

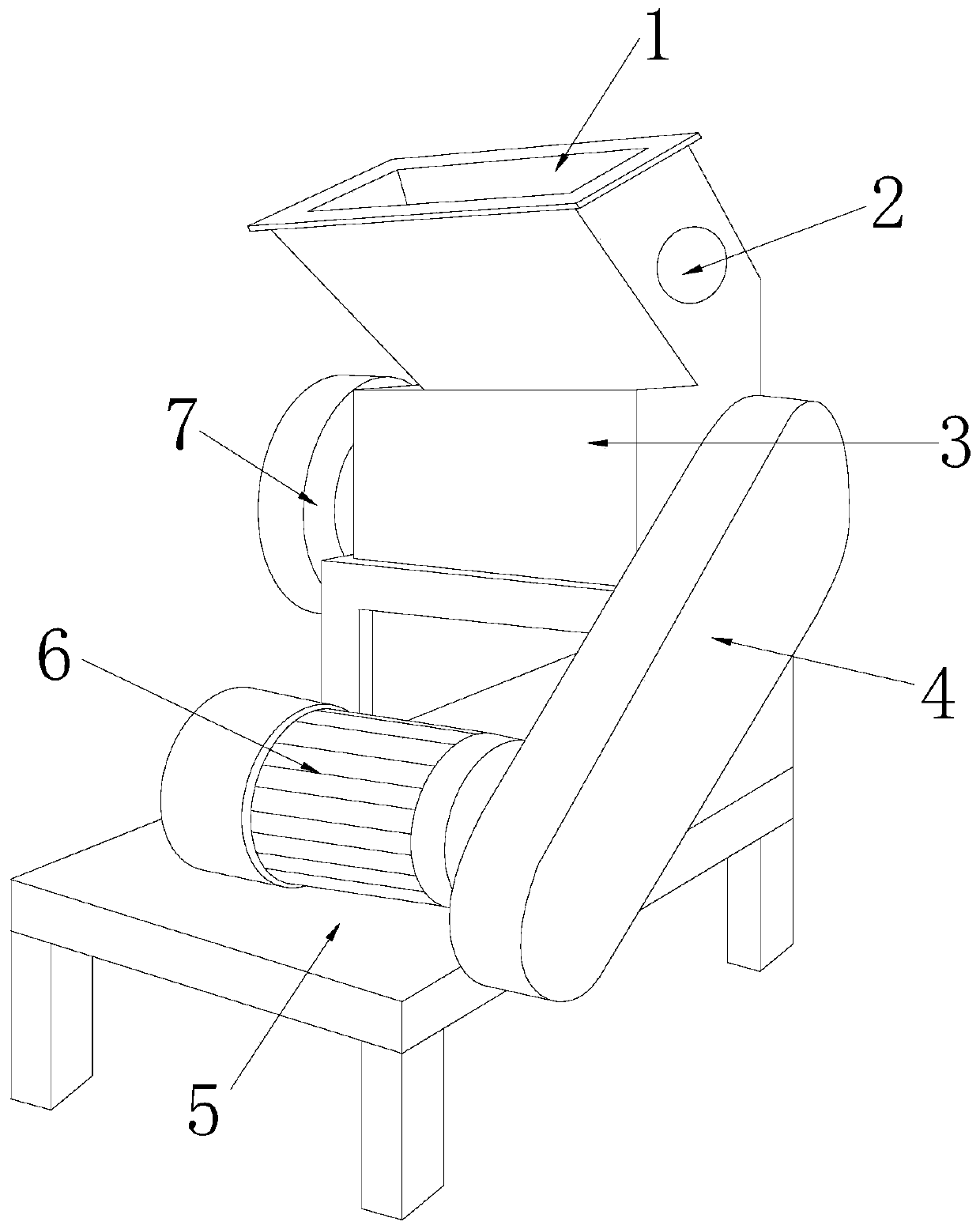

[0026] see Figure 1-Figure 5 , the present invention provides a rubber crushing device for rubber production, the structure of which includes a bucket 1, a crushing head 2, a filter bin 3, a protective cover 4, a fixed frame 5, a motor 6, and a moving wheel 7. The bucket 1 is installed on the filter On the bin 3, a protective cover 4 is provided on the side of the filter bin 3, and a moving wheel 7 is provided on the opposite side of the filter bin 3 to the protective cover 4, and the motor 6 is installed on the fixed frame 5, and the fixed frame 5 is provided with a filter chamber 3, and the bottom of the filter chamber 3 is provided with a crushing chamber, and the crushing chamber will directly output the crushed and screened rubber blocks from the opening;

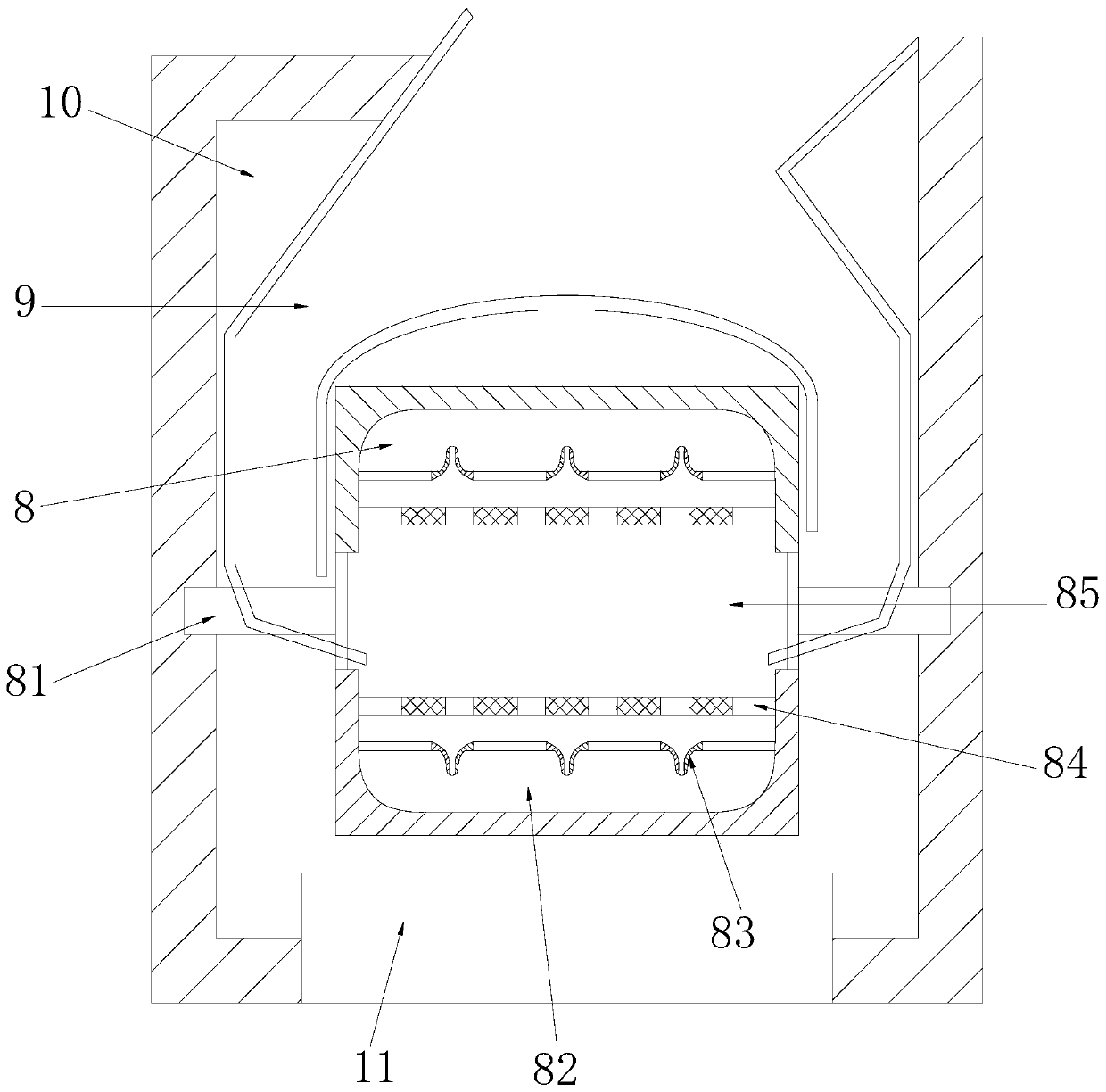

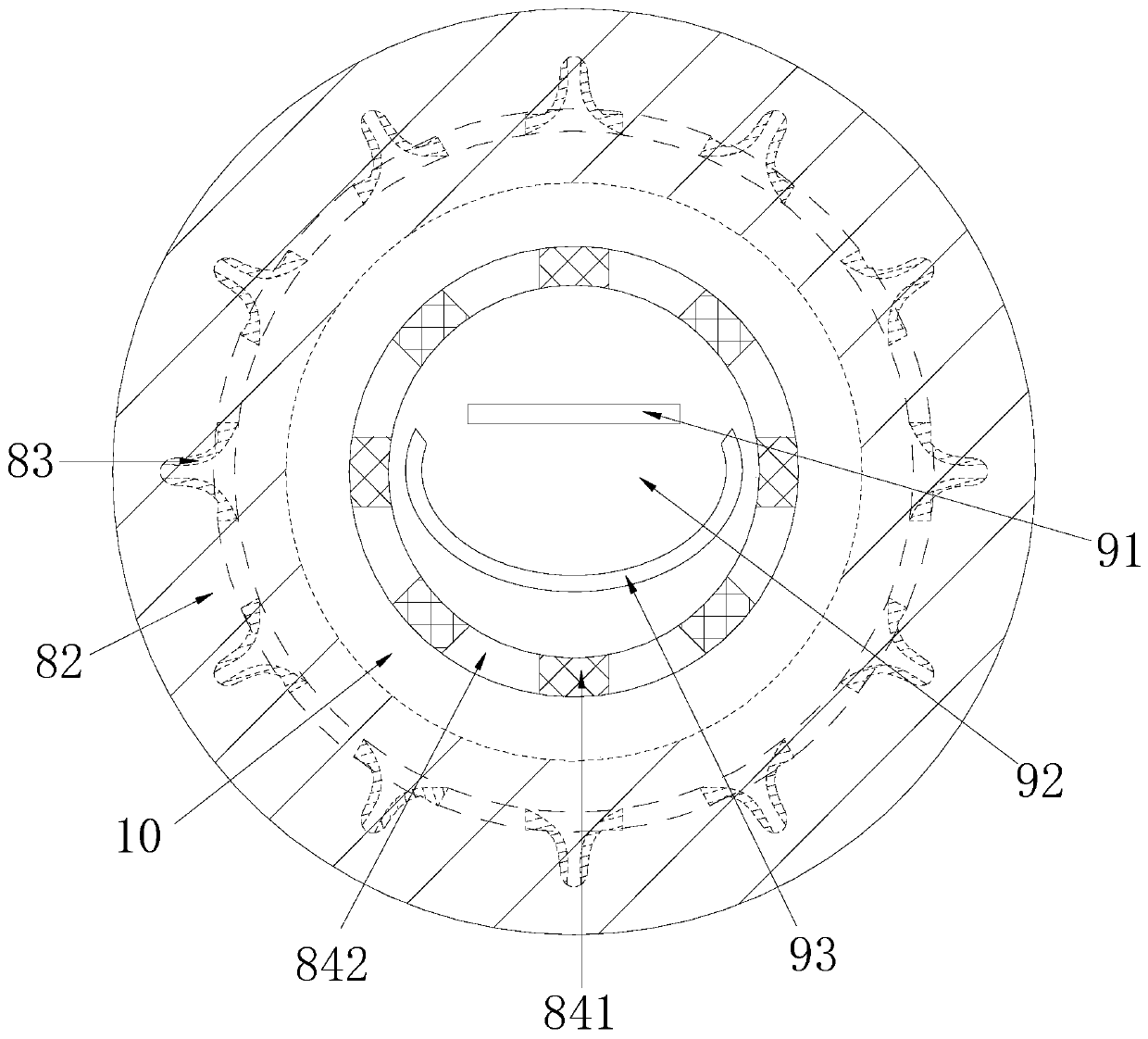

[0027] The filter bin 3 is composed of a screening device 8, a guiding bin 9, a working chamber 10, and an output port 11. The filtering device 8 communicates with the guiding bin 9, and the guiding bin 9 is connected...

Embodiment 2

[0037] see Figure 1-Figure 2 , Figure 5 , the present invention provides a rubber crushing device for rubber production, the structure of which includes a bucket 1, a crushing head 2, a filter bin 3, a protective cover 4, a fixed frame 5, a motor 6, and a moving wheel 7. The bucket 1 is installed on the filter On the bin 3, a protective cover 4 is provided on the side of the filter bin 3, and a moving wheel 7 is provided on the opposite side of the filter bin 3 to the protective cover 4, and the motor 6 is installed on the fixed frame 5, and the fixed frame 5 is provided with a filter chamber 3, and the bottom of the filter chamber 3 is provided with a crushing chamber, and the crushing chamber will directly output the crushed and screened rubber blocks from the opening; the filter chamber 3 is guided by a screening device 8, Bin 9, working chamber 10, and output port 11. The screening device 8 communicates with the guiding bin 9, and the guiding bin 9 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com