A method for welding and shaping the arm frame plate of the transfer buoy

A boom and floating platform technology, which is applied in the field of welding and shaping of large structural plates, can solve the problems of boom plate deformation again, inconvenient operation, and troublesome operation, so as to reduce welding stress and deformation, improve shaping quality, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

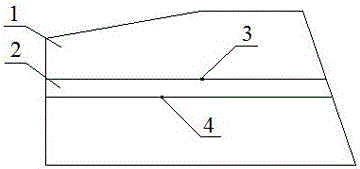

[0027] The specific method and device details and working conditions proposed by the present invention will now be described in detail in conjunction with the illustrations. The main implementation process of the present invention is:

[0028] 1) According to the geometric shape and size requirements of the technical requirements of the drawings, blank and cut the steel plate 1 and section steel 2,

[0029] When blanking and cutting, the geometric shape and size of the steel plate and section steel are guaranteed, and the double-sided groove of the steel plate is 30 0 Leave a root of 2mm, which is convenient for subsequent welding of two or more boom plates. The verticality deviation of the cutting end face is allowed to be ±0.5mm, and the cutting flatness deviation is allowed to be ±0.5mm. The cutting surface is smooth and smooth;

[0030] 2) According to the position of the section steel on the drawing, draw a line on the steel plate 1 to determine the welding position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com