Automatic disc tooth shaping equipment and technological process

A technology of disc teeth and equipment, which is applied in the field of automatic shaping equipment and technological process of disc teeth, can solve the problems of easy generation of errors and low detection accuracy, and achieve the effects of improving shaping quality, improving work efficiency and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

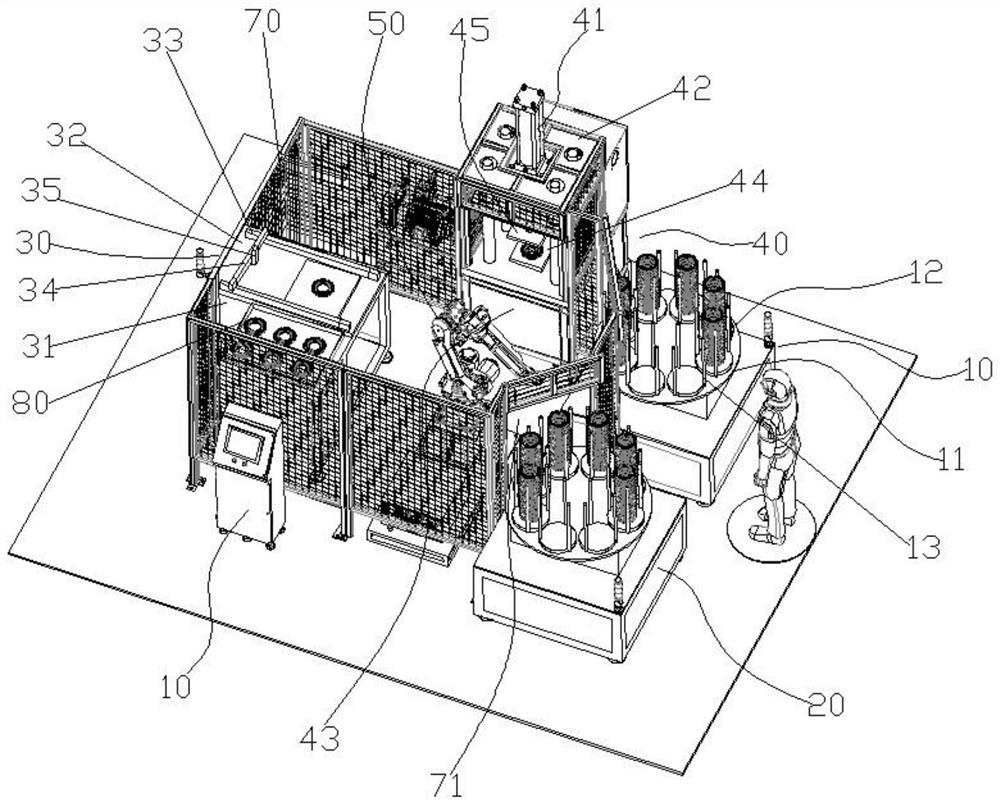

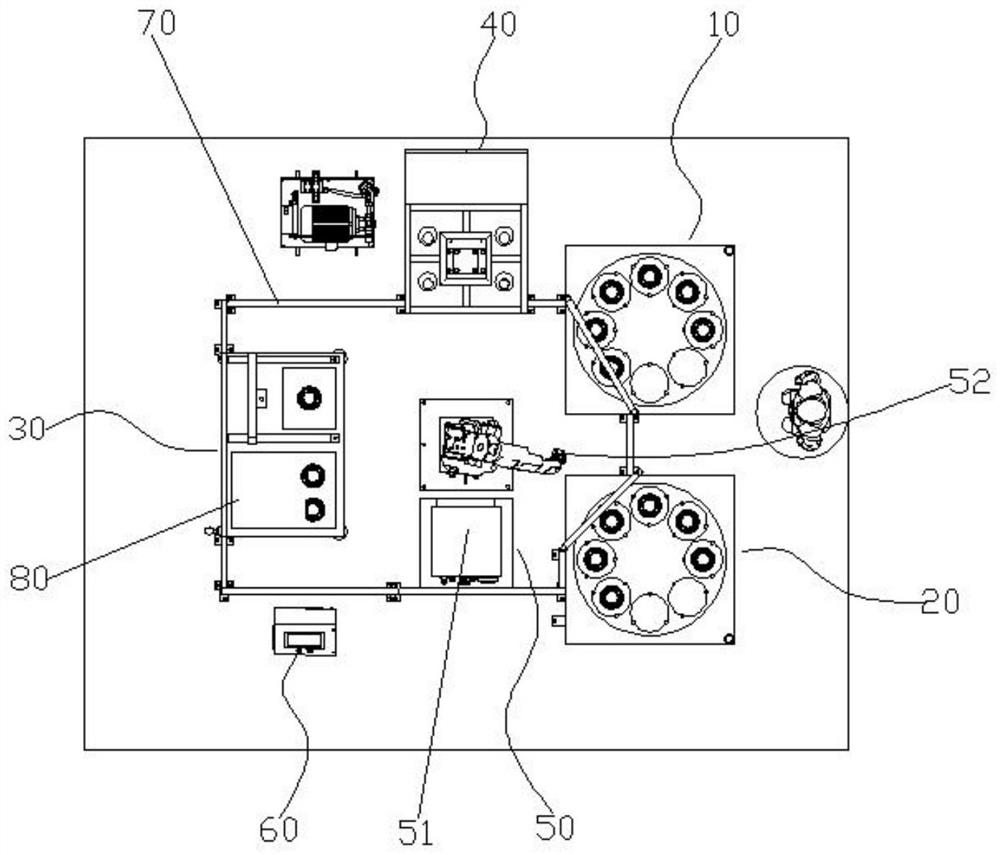

[0028] refer to Figure 1-2 , an automatic shaping equipment for disk teeth, including a feeding mechanism 10 for supplying disk teeth, a qualified product receiving mechanism 20 for receiving qualified products, a flatness detection device 30 for detecting the flatness of the disk teeth, and a For the shaping machine 40 for shaping and processing the disc teeth, the disc gear conveying mechanism 50 for conveying the disc teeth, and the electrical control system 60 for overall control of the equipment;

[0029] The disk tooth handling mechanism includes a handling robot 51 and a grabbing fixture 52, and the grabbing fixture is installed on the execution end of the handling robot for grabbing the disk teeth;

[0030] The feeding mechanism, the qualified product receiving mechanism, the flatness detection device, the shaping machine, the disk-tooth conveying mechanism and the electrical control system are all arranged on the periphery of the handling robot, and the flatness dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com