Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Improve drag reduction efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

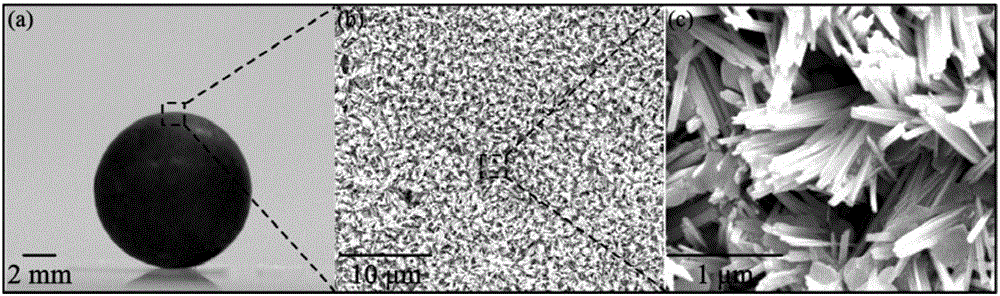

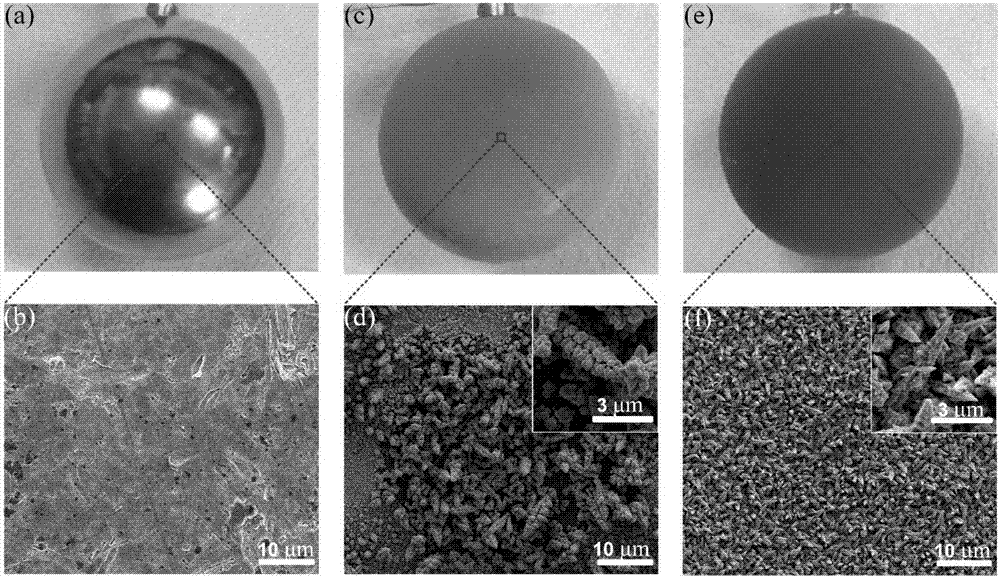

Drag reduction superhydrophobic coating and preparation method thereof

InactiveCN102492942AImprove hydrophobicityAntisepticVacuum evaporation coatingSputtering coatingReduction rateStrong acids

A drag reduction superhydrophobic coating and a preparation method thereof belong to the technical field of functional nanometer material application. A base of the drag reduction superhydrophobic coating adopts electroless metal deposition technique, a precious metal micro-nanometer binary grading composite structure is constructed on the base and decorated by a low surface energy material, a water static contact angle of the coating is larger than 150 degrees, and a rolling angle is smaller than 5 degrees. The drag reduction superhydrophobic coating is used for a model with motive power by itself, running speed of the model is obviously increased, and drag reduction rate is as high as 20%. The drag reduction superhydrophobic coating has good corrosivity resistance and can resist corrosion of strong acid and strong base solutions. The drag reduction superhydrophobic coating has repairability, and the preparation method can enable hydrophobicity of damaged areas to be rapidly recovered in a short period. The preparation method of the drag reduction superhydrophobic coating is simple, short in preparation period, and high in drag reduction rate.

Owner:BEIJING UNIV OF CHEM TECH

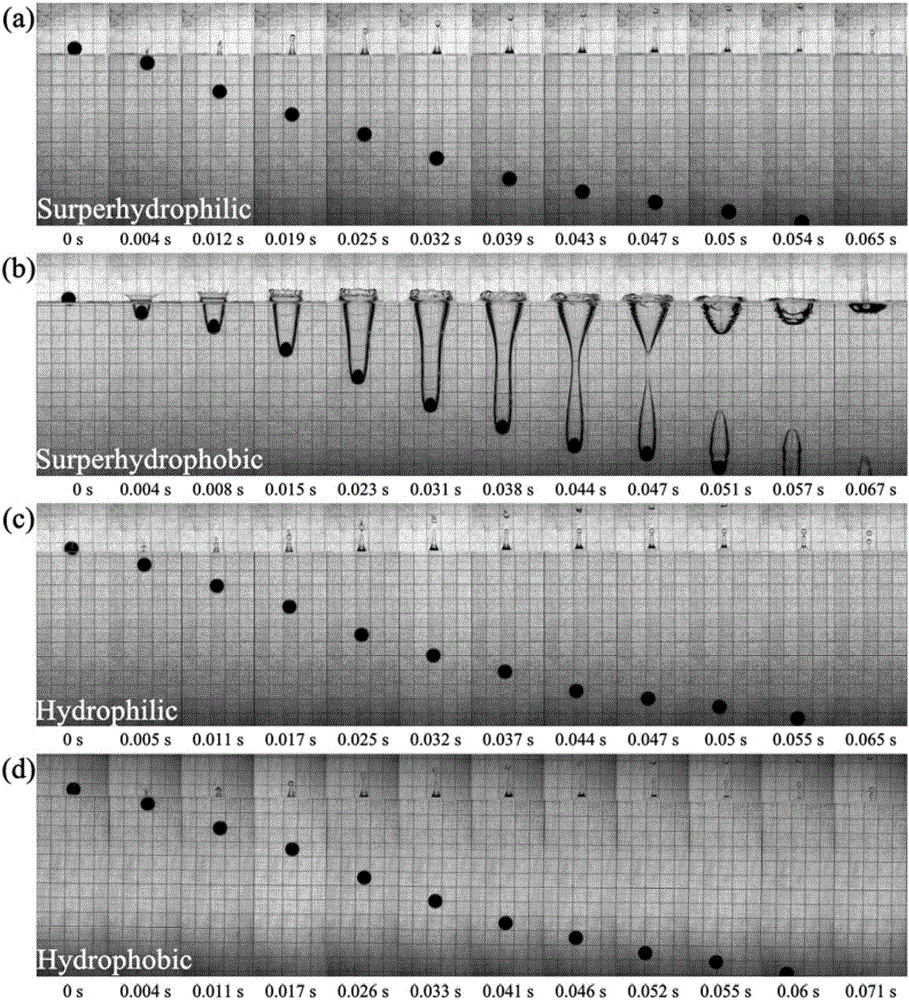

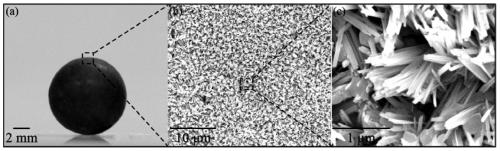

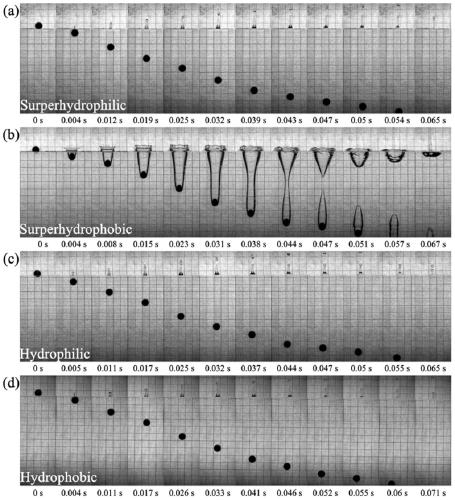

Bionic super-hydrophobic surface, and production method and drag reduction method thereof

ActiveCN105908187ANon-toxic and non-radioactiveImprove underwater drag reduction efficiencyEngineeringHydrophobic surfaces

The invention provides a production method of a bionic super-hydrophobic surface, and a method for carrying out underwater drag reduction by using the hydrophobic interface. A bionic technology is combined with a supercavity drag reduction technology, so the underwater drag reduction efficiency is effectively improved, and the production cost and the maintaining cost are low; and raw materials adopted in the invention are nontoxic and have no radiation effect, so the bionic super-hydrophobic surface has no untoward effects on environment.

Owner:BEIHANG UNIV

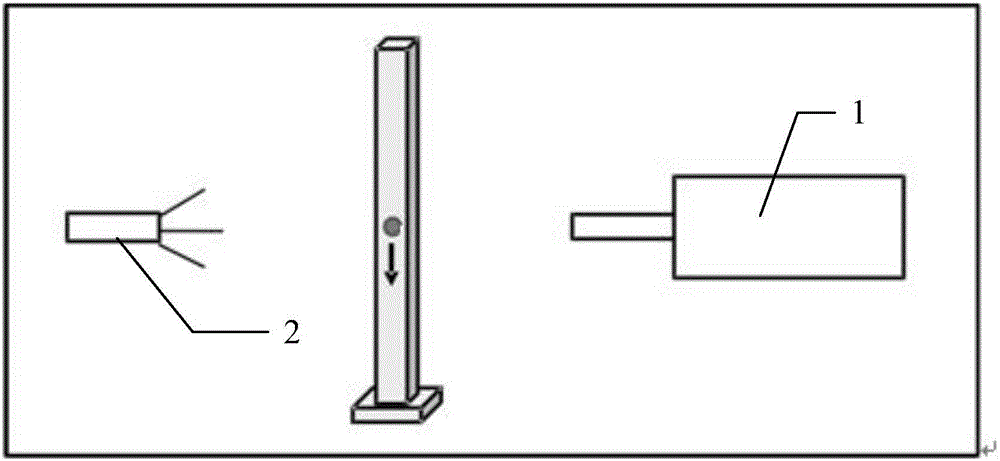

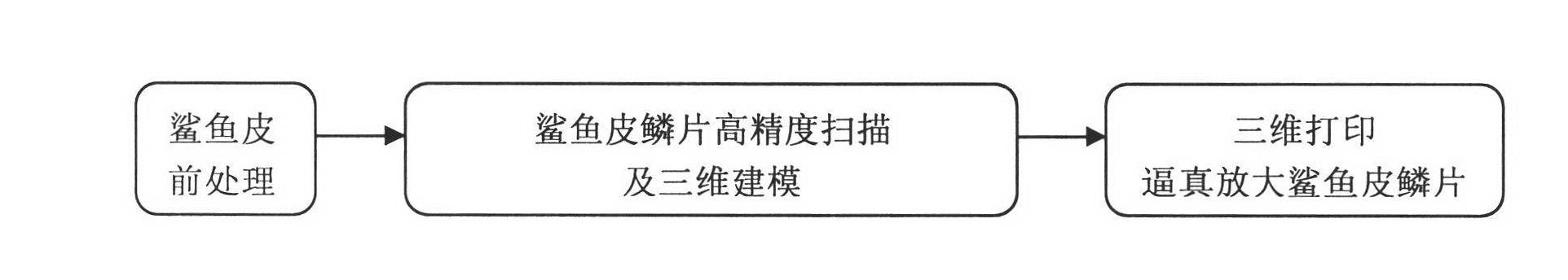

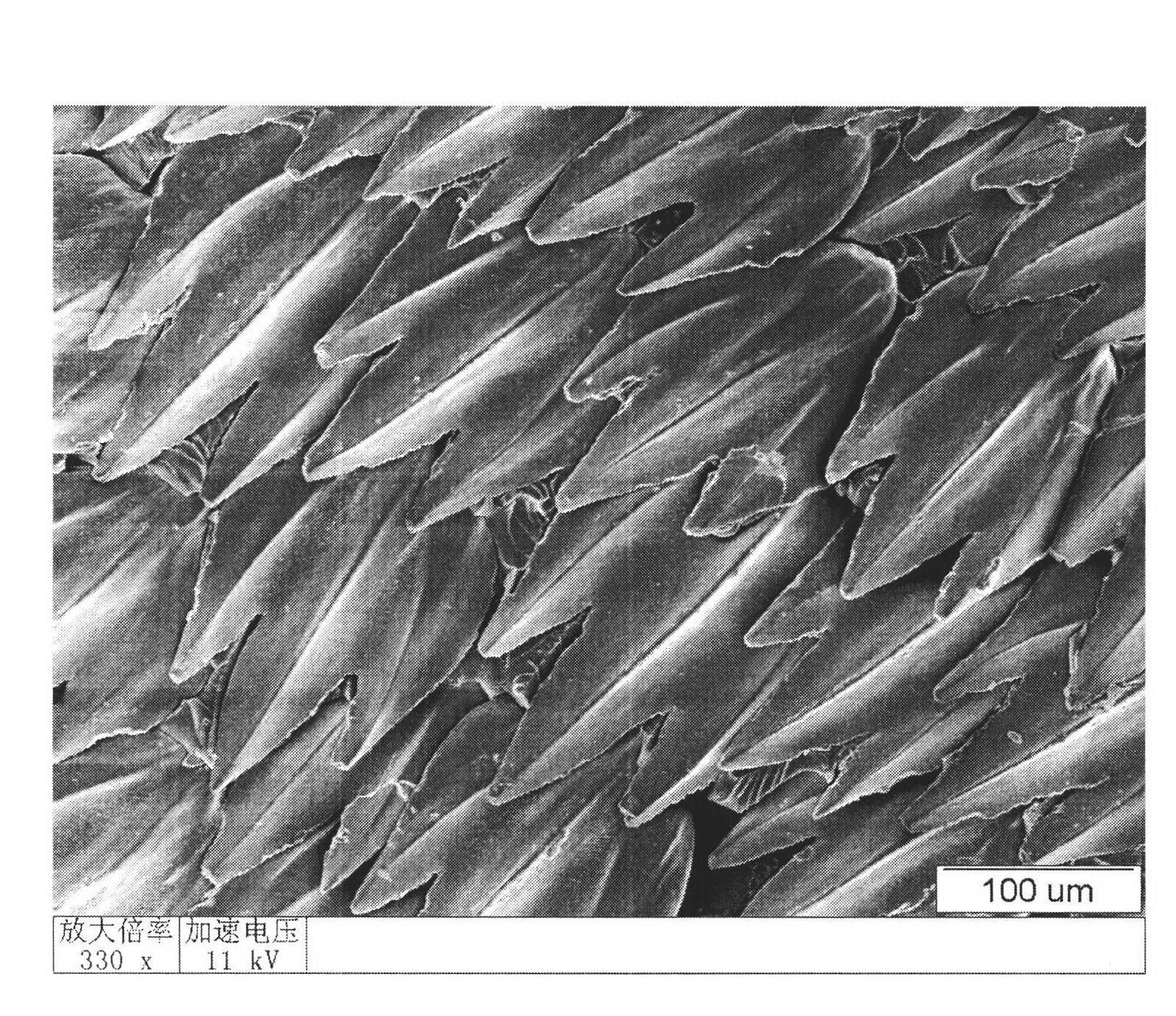

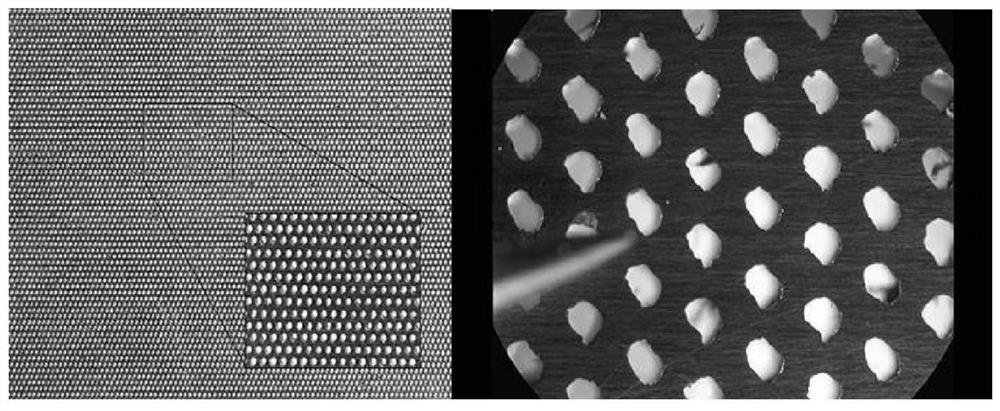

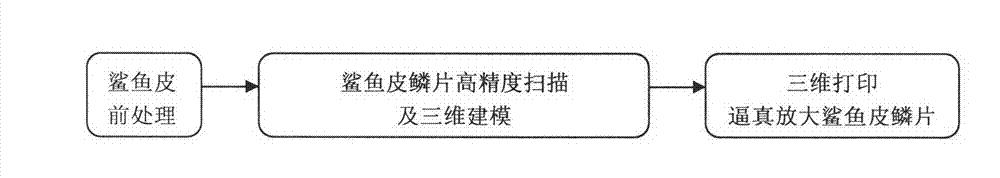

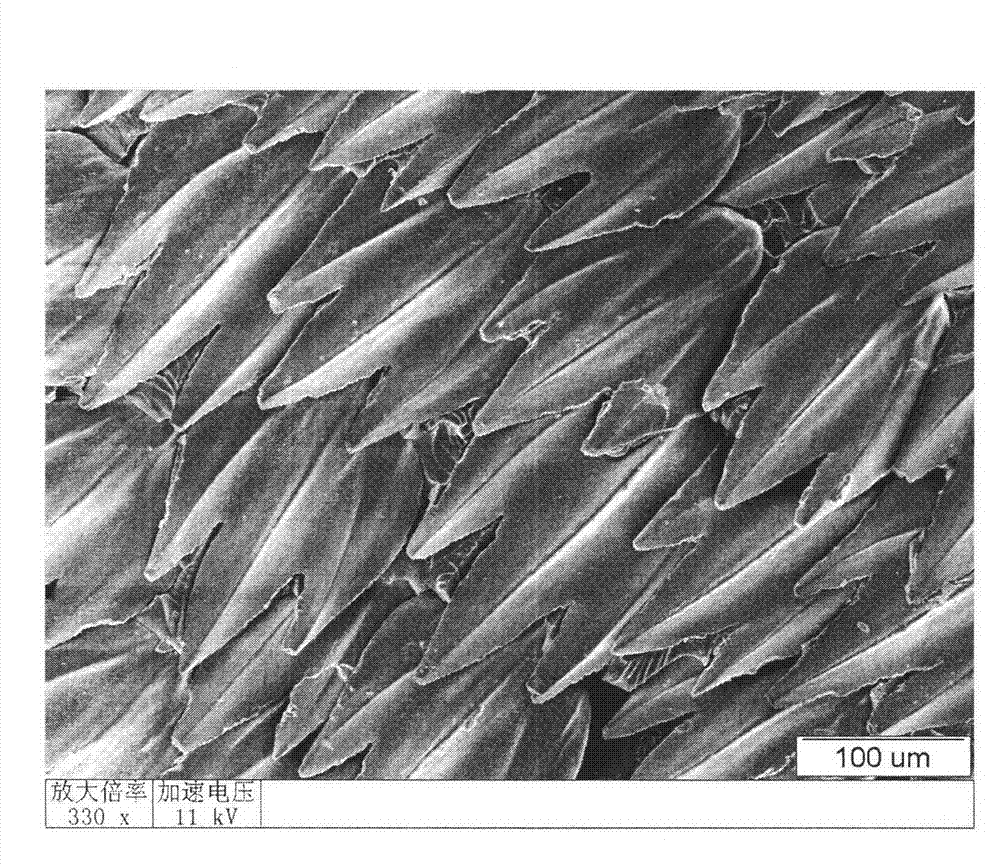

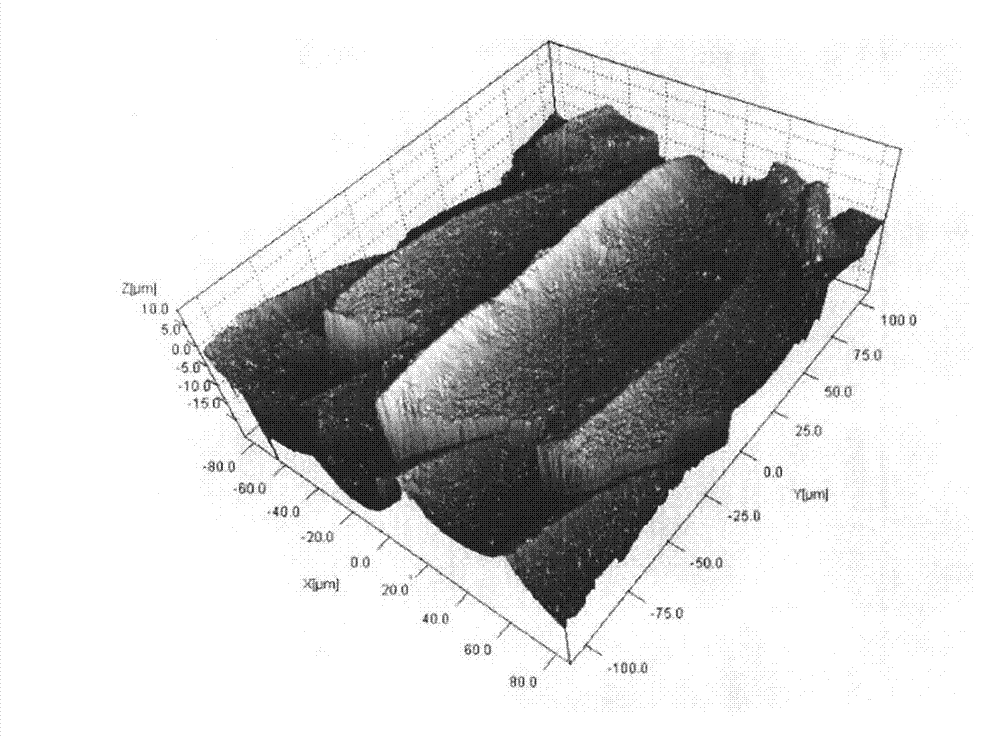

Method for manufacturing amplified vivid sharkskin squama

InactiveCN102102300ARealize arbitrary stretch deformationImprove drag reduction efficiencyTextiles and paperEngineeringViscosity

The invention relates to a method for manufacturing amplified vivid sharkskin squama, which comprises the following steps: 1) pre-treating the sharkskin; 2) precisely scanning the sharkskin squama and three-dimensionally modeling; and 3) three-dimensionally printing the vivid amplified sharkskin squama. By using the method, an amplified model of the vivid sharkskin squama can be acquired by usingthe techniques of high-precise scanning, three-dimensional printing and quick forming. The method is advanced. The vivid sharkskin squama can be directly viewed. In the fluid with high dynamic viscosity, the anti-dragging efficiency of the vivid sharkskin squama can be tested, thereby achieving the anti-dragging efficiency of the vivid sharkskin squama. The method is consistent with the development of the bionic anti-dragging surface manufacturing technique and has wide application prospect and high practical value.

Owner:BEIHANG UNIV

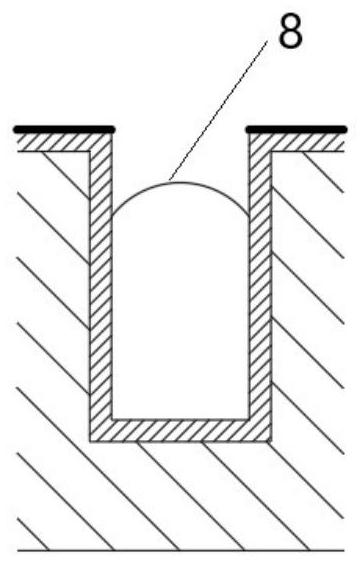

Deep well resistance-reducing packing

InactiveCN102324260AReduce the amount of waterGood water workabilityNon-metal conductorsConductive materialMeth-Polyvinyl alcohol

The invention discloses a deep well resistance-reducing packing which mainly comprises the following components in parts by weight: 10-50 parts of conducting materials, 10-50 parts of curing agent, 0.5-25 parts of leavening agent and 0.1-10 parts of retarding agent, wherein the conducting material is selected from one or more of sodium salts, potassium chloride, calcium chloride and graphite; the curing agent is selected from one or more of polyvinyl alcohol, aluminosilicate (kaolin), sodium silicate, calcium sulfate and cement; the leavening agent is selected from one of polyacrylamide and bentonite; and the retarding agent is selected from one of sodium methylenebisnaphthalenesulfonate and peregal. The deep well resistance-reducing packing has the advantages of saving of 15-30 percent of water quantity, good peaceability with water, no demixing and convenience for site configuration and construction: in addition, no demixing is caused, the solidifying time is prolonged and the flowability and the permeability are enhanced, therefore, no bridging phenomenon is caused during pouring, resistance reduction efficiency is increased, the quantity of deep wells is reduced, and the construction cost is reduced.

Owner:SICHUAN SUNLIGHT INTELLIGENT ELECTRIC EQUIP CO LTD

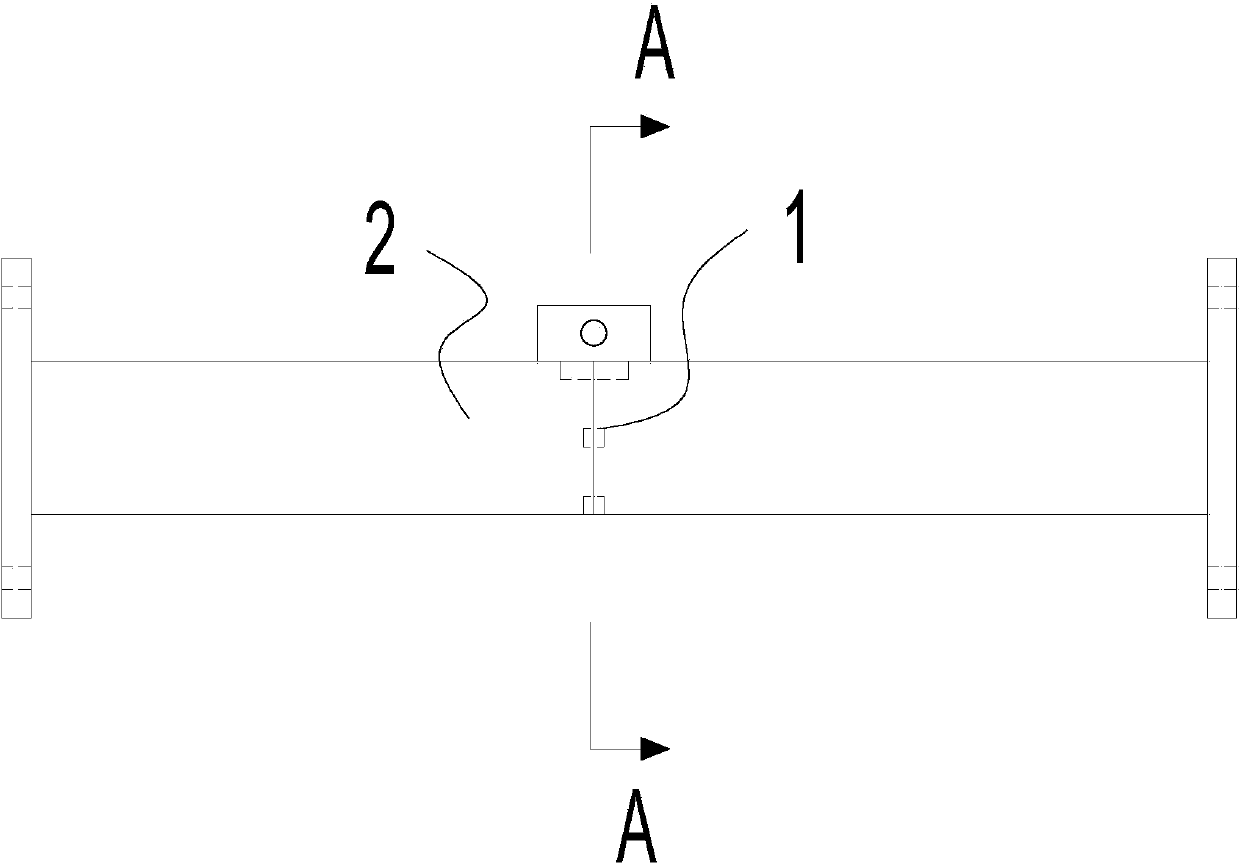

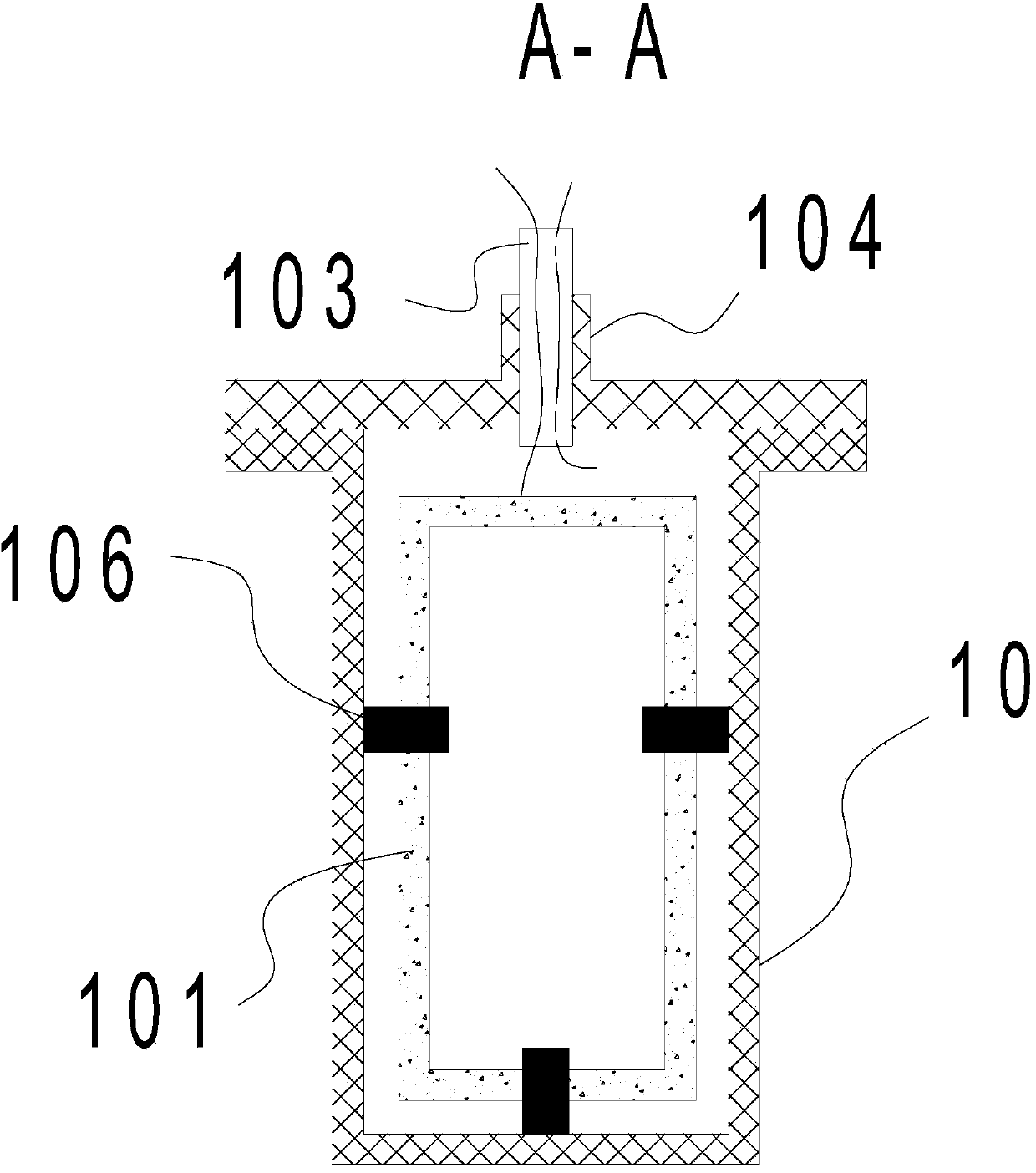

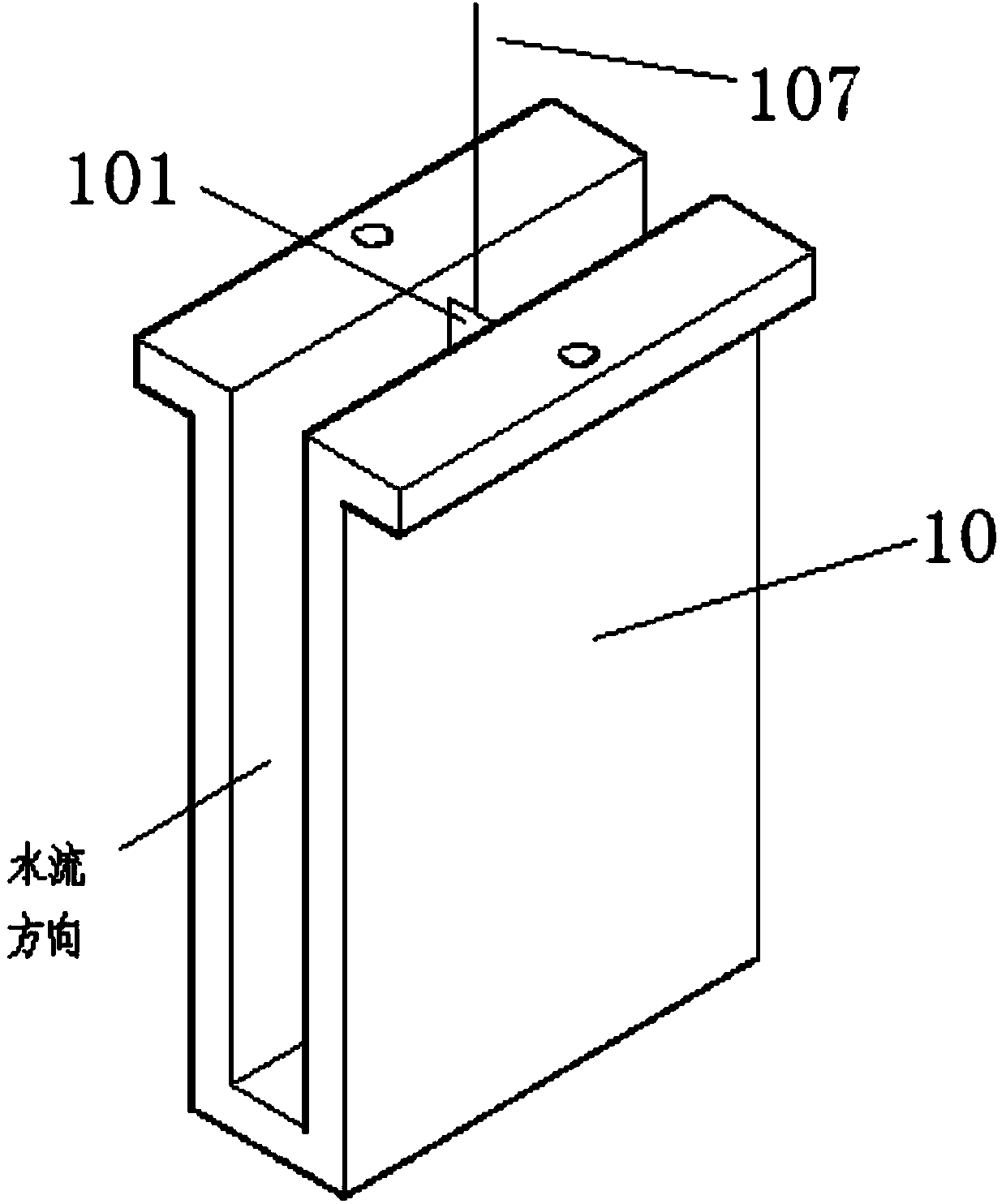

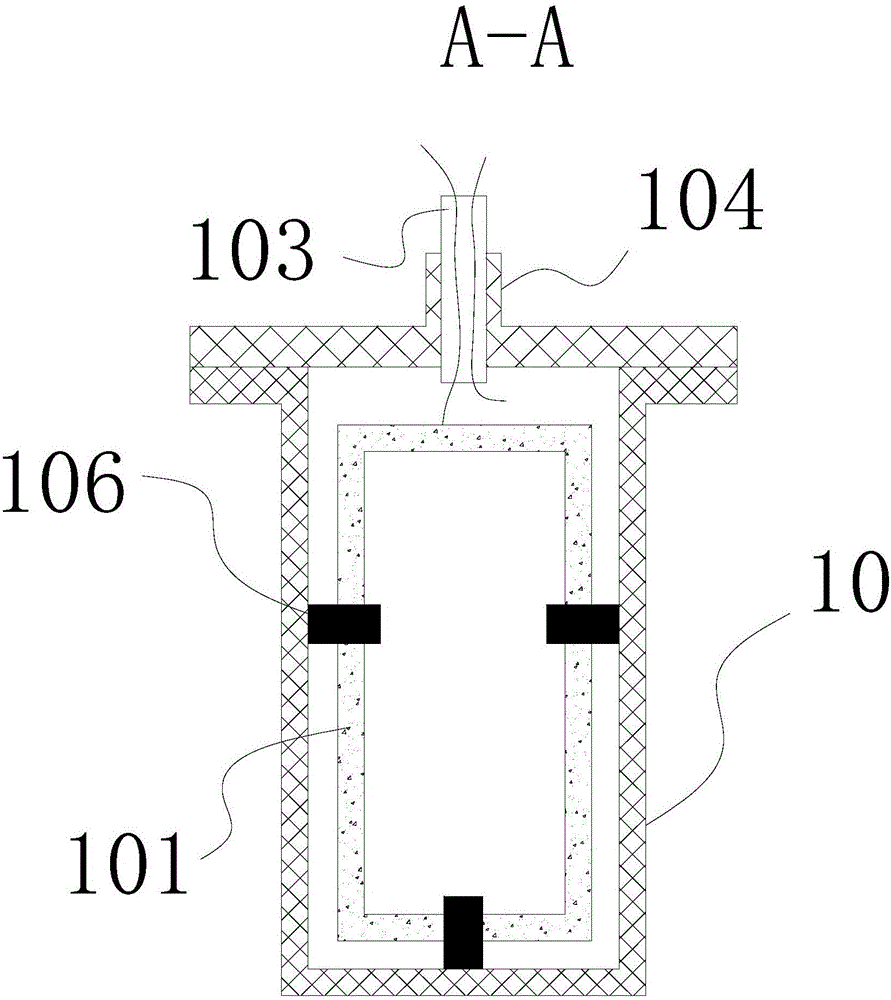

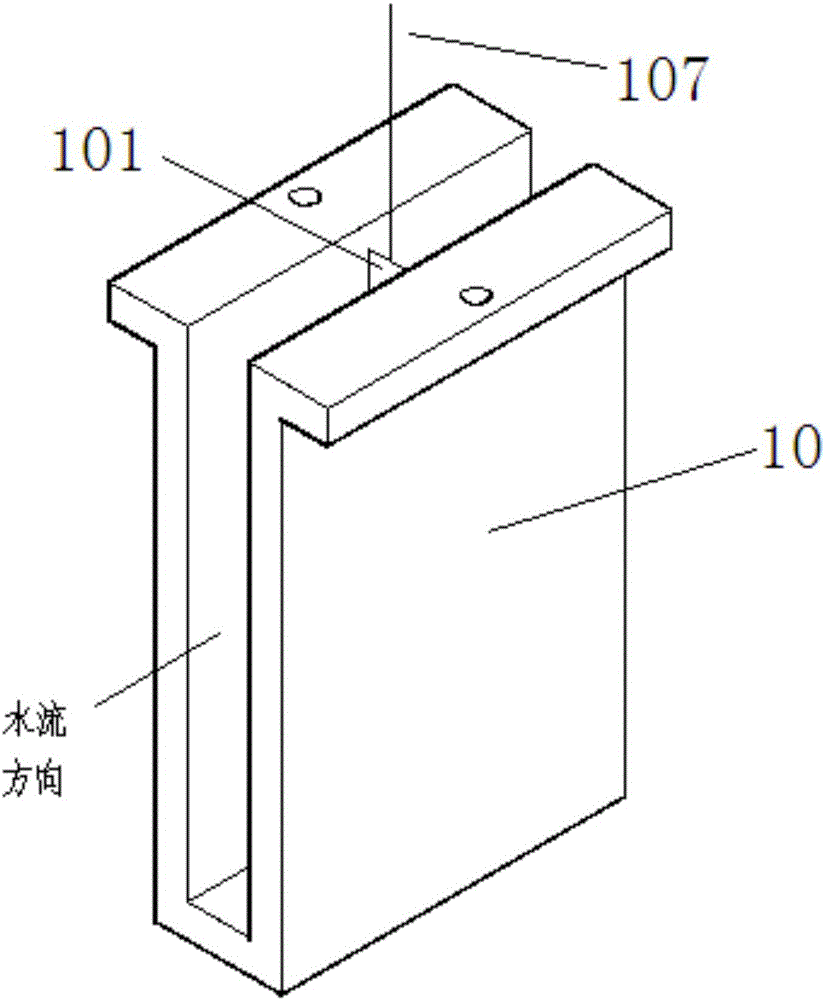

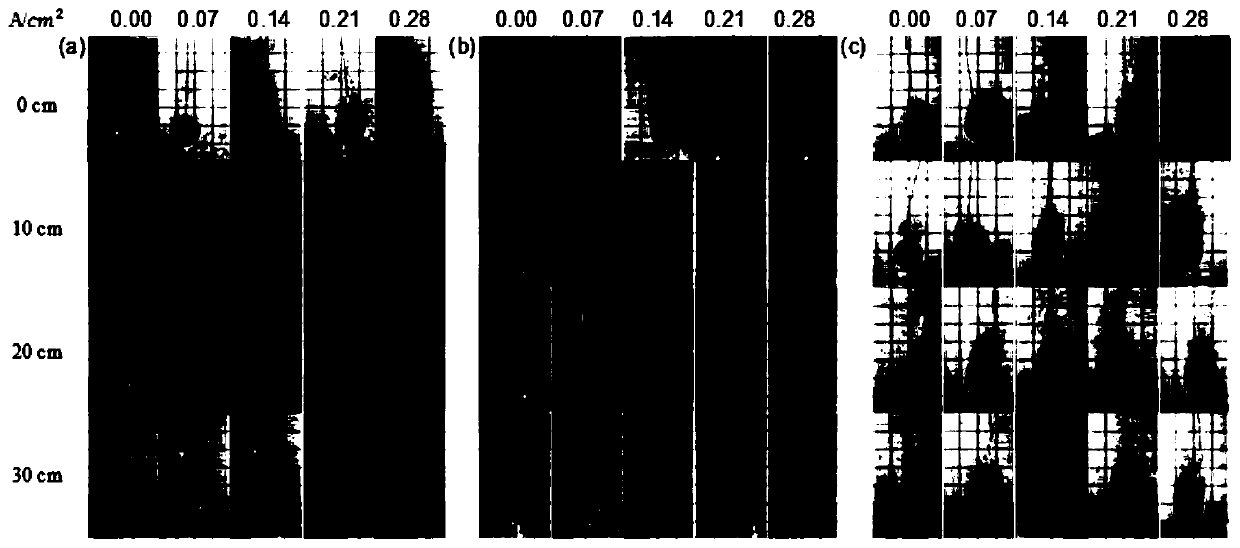

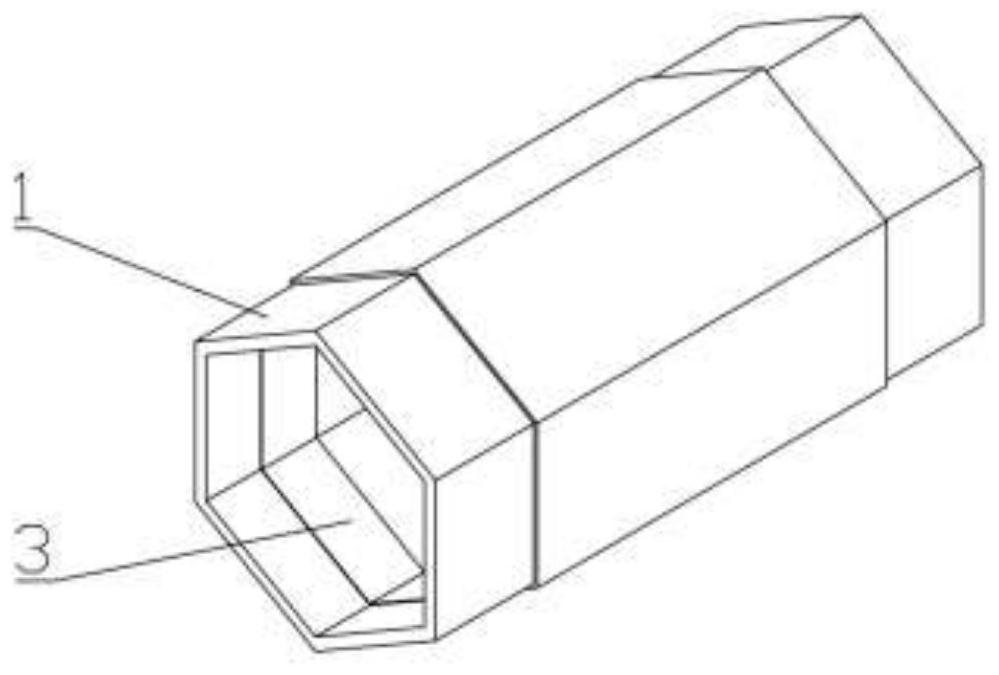

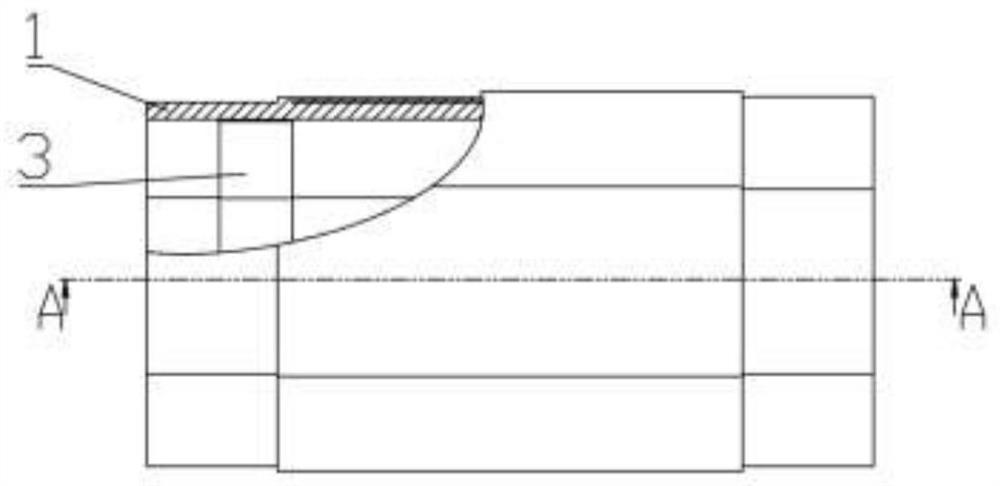

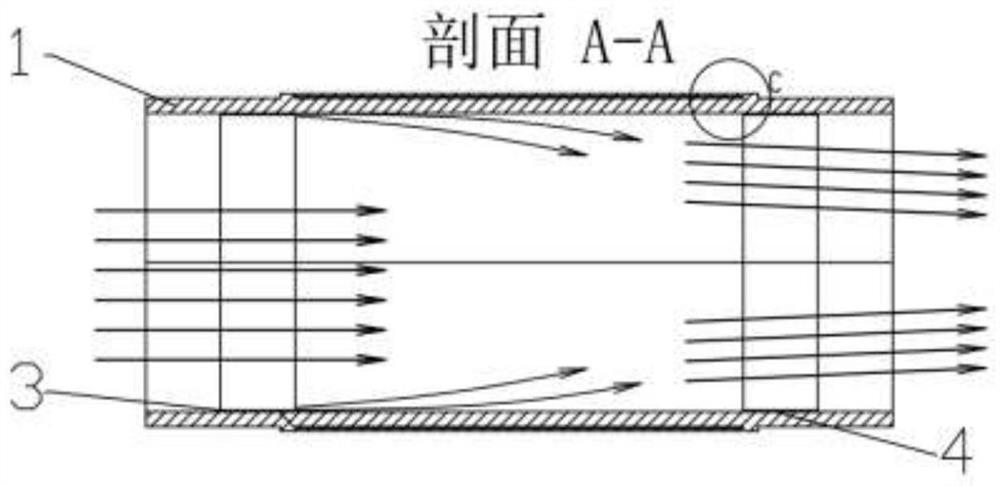

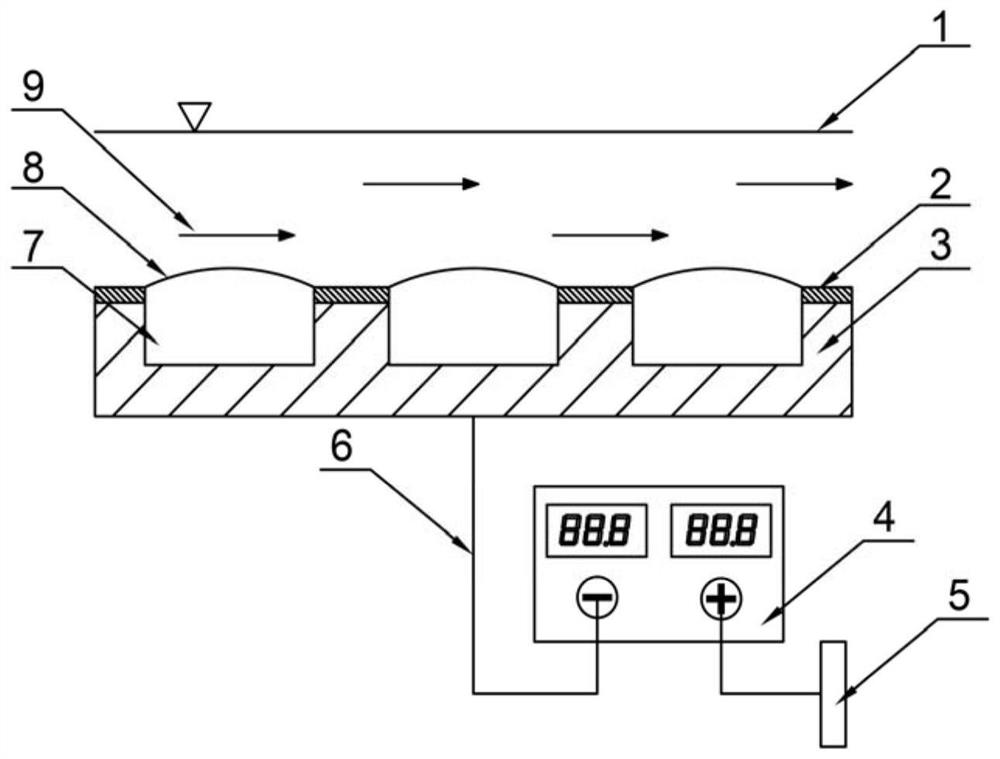

Micro-bubble pipeline flowing drag reduction method and micro-bubble drag-reduced pipeline

ActiveCN104179757AReduce frictional resistanceHigh speedFluid dynamicsPipe elementsElectrolysisMicro bubble

The invention relates to a micro-bubble pipeline drag reduction method. Micro-bubbles are directly generated in a transition layer of a turbulent flow field in a pipeline through electrolysis by an electrolytic ring, the micro-bubbles interact with turbulent flows in the transition layer of the flow field, turbulent flow fluctuation is inhibited, and flowing turbulent flow drag reduction is realized. A micro-bubble drag-reduced pipeline comprises a pipeline body, wherein the section of the pipeline body adopts a rectangular structure, a two-dimensional groove channel is formed in the pipeline of the pipeline body, two ends of the two-dimensional groove channel are connected with the rectangular pipeline body respectively in a sealed manner, the electrolytic ring is arranged in the two-dimensional groove channel and adopts a rectangular frame structure, the electrolytic ring is fixedly arranged in a transition layer area in the two-dimensional groove channel, and a lead of the electrolytic ring extends out of the two-dimensional groove channel to be connected with a power supply. By the aid of interaction of the micro-bubbles and the turbulent flows in the transition layer, the turbulent flow fluctuation is inhibited, the flowing turbulent flow drag reduction is realized, the frictional drag in a liquid pipeline delivery process is reduced, the drag reduction efficiency is improved, unnecessary waste is reduced, and the delivery speed of a fluid is increased as far as possible under the same micro-bubble air quantity.

Owner:SUZHOU QISHUO INFORMATION TECH CO LTD

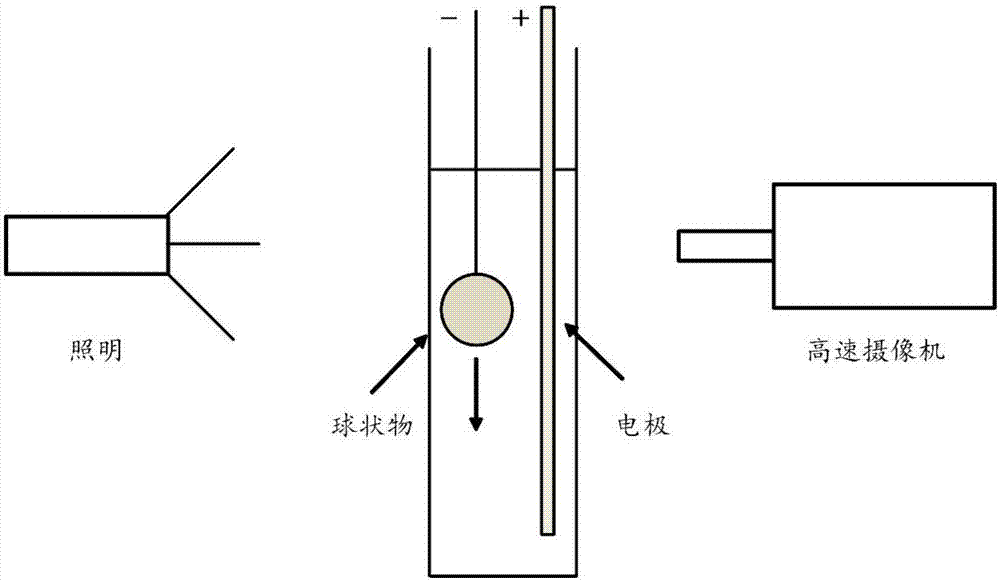

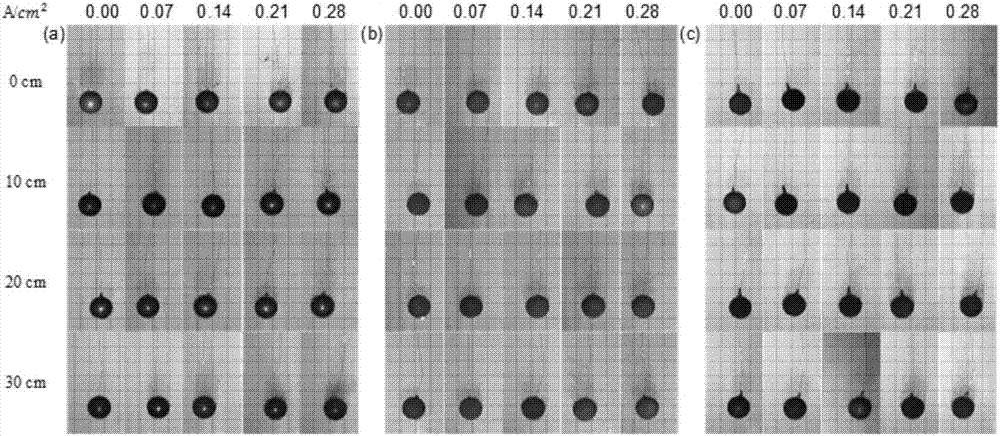

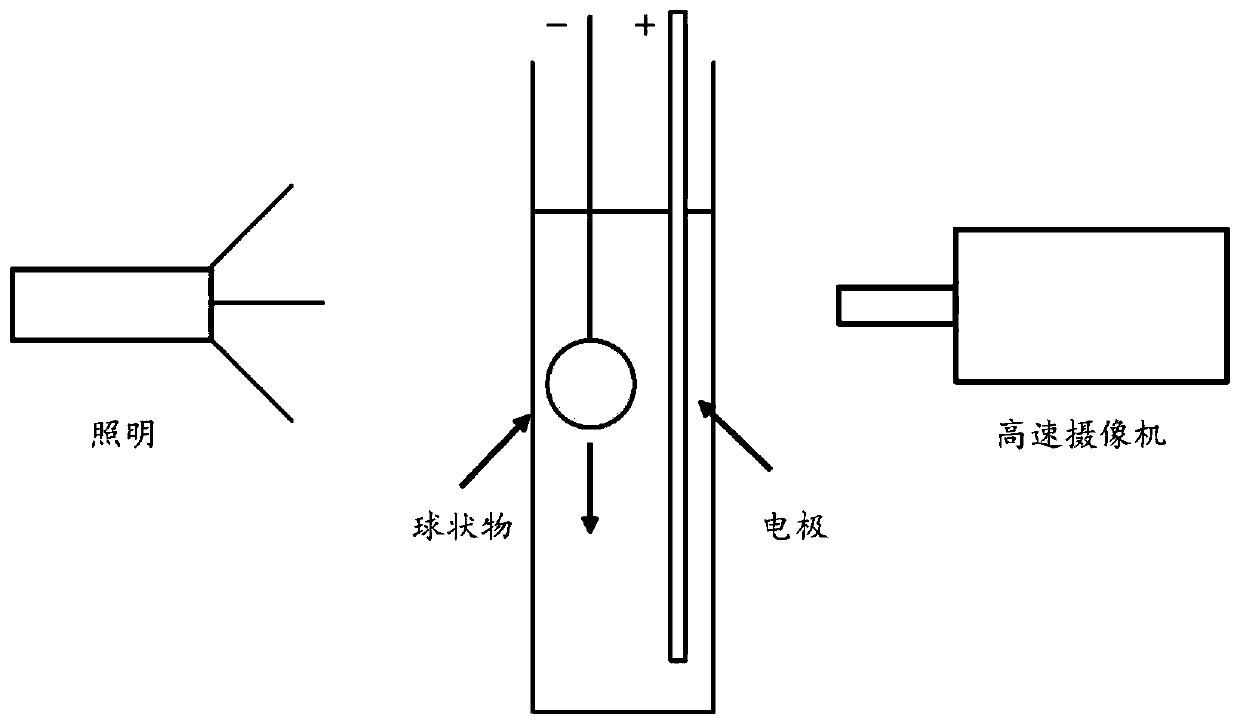

Electrolysis device and application thereof in microbubble resistance reducing technology

ActiveCN107351975AProduce adverse effectsImprove underwater drag reduction efficiencyWatercraft hull designHydrodynamic/hydrostatic featuresMicrobubblesElectrolysis

The invention provides a preparation method for a device which can electrolyze water to prepare hydrogen in the moving process and a method for conducting underwater resistance reducing by adopting hydrogen microbubbles generated by the device. Through the microbubble resistance reducing technology, the resistance of the device when moving underwater is effectively reduced, and manufacturing and implementation are easy. Raw materials used in the preparation process are all free of poison and have no radiation effect, the bubbles are mainly generated in the resistance reducing process, and no adverse effect exists on the environment.

Owner:BEIHANG UNIV

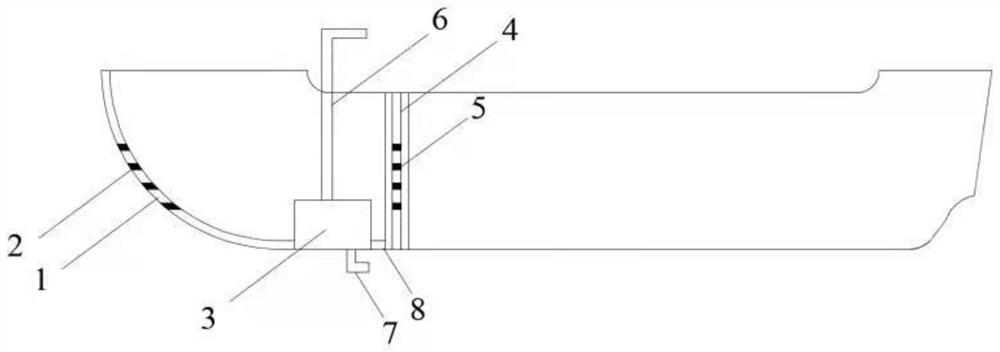

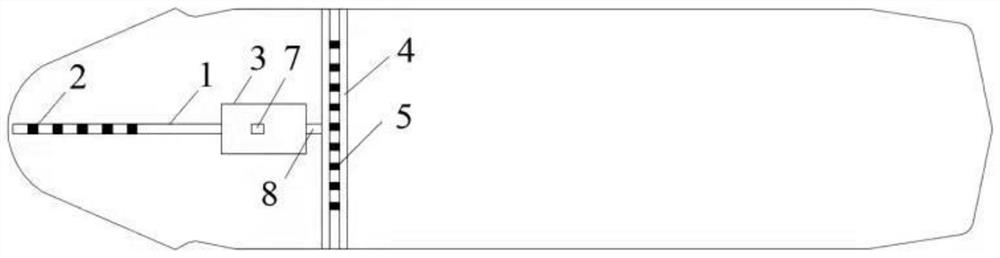

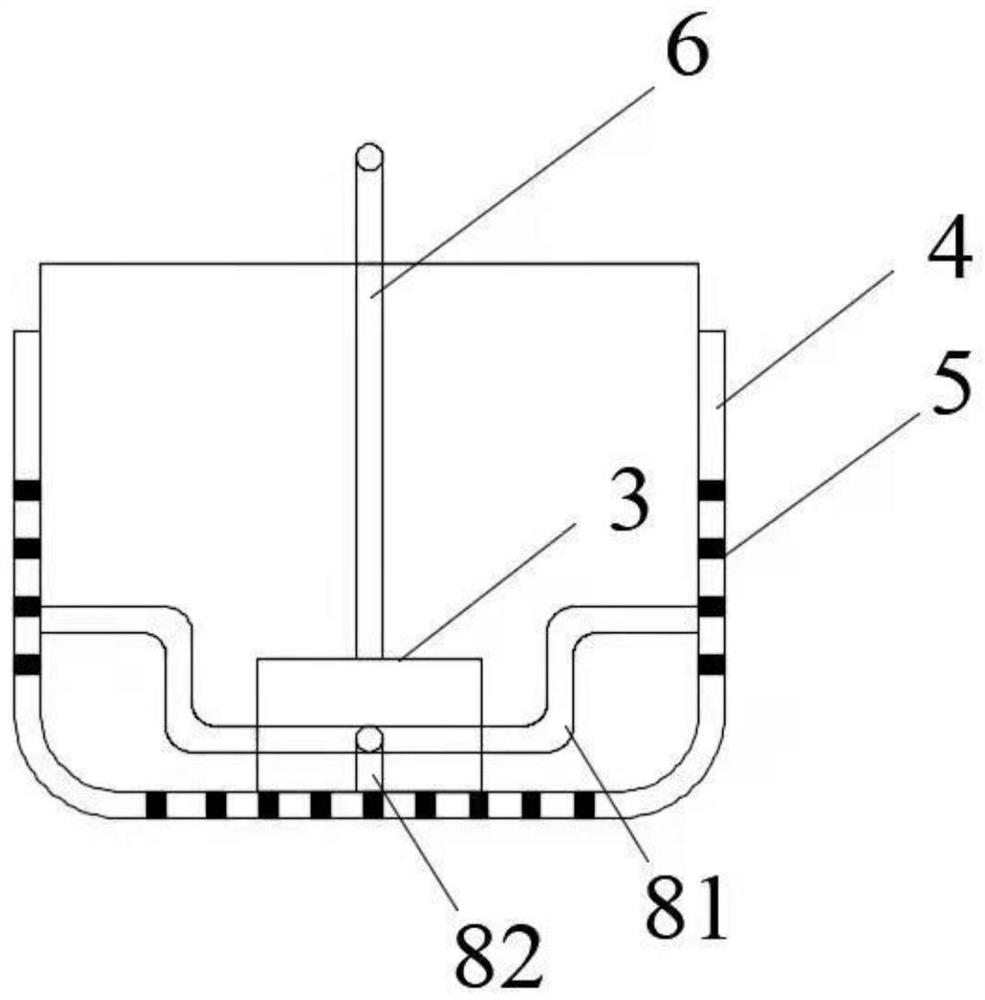

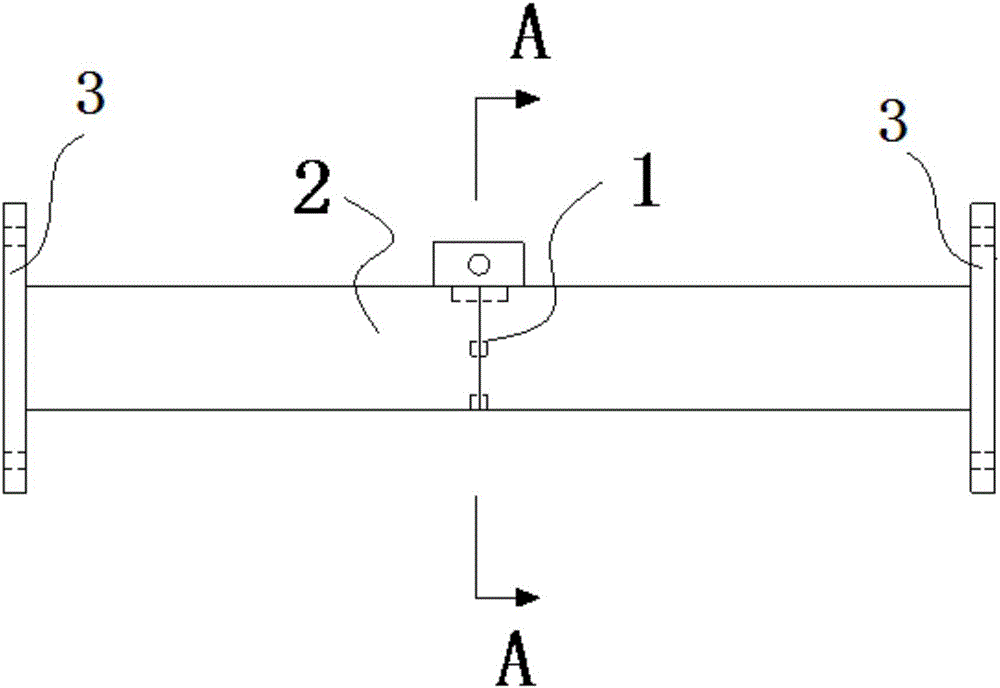

High-speed sailing vehicle combing micro-bubble drag reduction technology and groove surface turbulence drag reduction technology

InactiveCN110203323AReduce resistanceImprove drag reduction efficiencyWatercraft hull designHydrodynamic/hydrostatic featuresMicro bubbleNacelle

The invention relates to a high-speed sailing vehicle combining a micro-bubble drag reduction technology and a groove surface turbulence drag reduction technology. The high-speed sailing vehicle is characterized in that a plurality of parallel grooves which are parallel to each other are formed in the bottom surface of a ship body in the length direction of the ship body, the cross sections of thegrooves are square, U-shaped or V-shaped, the groove height hc of the grooves is equal to the width W of the grooves, the high-speed sailing vehicle further comprises a micro-bubble generation devicearranged inside a cabin, the micro-bubble generation device generates air bubbles and conveys the air bubbles to the bottom of the ship body through air pipes, the air pipes are laid inside the grooves, and exhaust holes are uniformly formed in the length direction of the grooves. According to the high-speed sailing vehicle, the grooves are designed at the bottom of the ship body, and the purposeof reducing the resistance is achieved by changing the flowing structure of the bottom layer of the boundary layer; and meanwhile, the exhaust holes are formed in the grooves, and the bubbles are discharged out of the surfaces of the grooves to generate a dispersed fine air curtain so that the resistance can be further reduced, the combined drag reduction effect can be achieved through the effective combination of the two drag reduction technologies, the drag reduction efficiency is improved, and then the rapidity of the sailing vehicle is improved.

Owner:WUHAN UNIV OF TECH

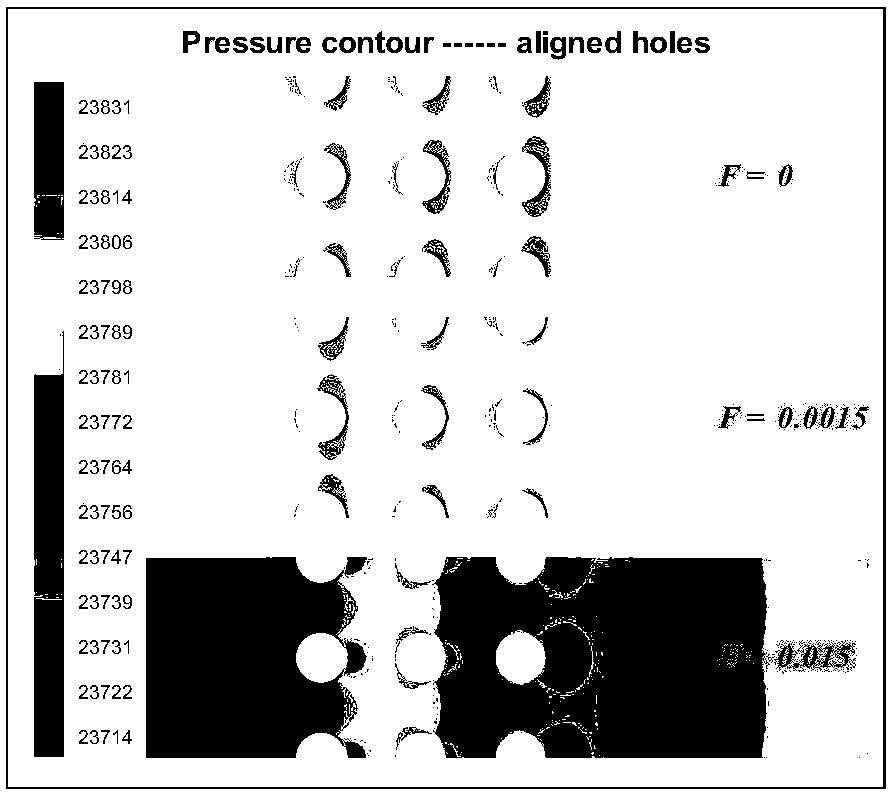

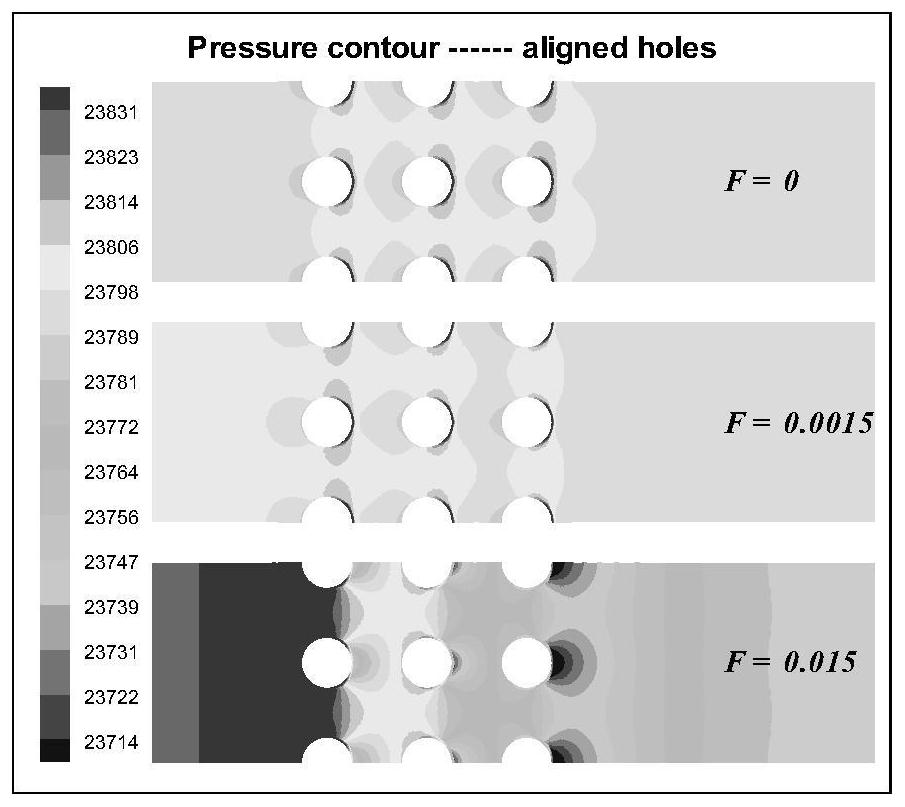

Micro-blowing structure and method for resistance reducing and lift increasing of supercritical airfoil

ActiveCN107933895AReduce consumptionEasy to liftGround installationsAir-flow influencersLow speedManufacturing technology

The invention discloses a micro-blowing structure and method for resistance reducing and lift increasing of a supercritical airfoil and belongs to the technical field of aircraft design. Skins with micro holes are arranged near the rear edge of the lower airfoil surface of the airfoil, micro-blowing is started under the cruising state, the wall face friction resistance in the micro-blowing actingarea is reduced remarkably, and the pressure difference resistance of the airfoil is further reduced through increasing of the pressure intensity in a micro-blowing upstream part, so that the total resistance of the airfoil is reduced; meanwhile, the lift of the airfoil can be increased through pressure intensity increasing caused by micro-blowing of the lower airfoil surface; and finally, the resistance reducing and lift increasing effects can be achieved simultaneously. The micro-blowing technique can be used in wide flowing fields including low-speed airliners, high subsonic speed airlinersand even supersonic aircrafts, and rapid development of manufacturing techniques in recent years provides a guarantee for application of the micro-blowing technique.

Owner:BEIHANG UNIV

The drag reduction method of thixotropic mud

ActiveCN104534167BReduce frictional resistanceImprove drag reduction efficiencyPipe laying and repairCarboxymethyl celluloseSlurry

The invention discloses a drag reduction method of thixotropic slurry, and belongs to the technical field of civil engineering. The method includes the steps: firstly, preparing the thixotropic slurry for drag reduction; secondly, placing stirred thixotropic slurry into a slurry storage tank, forming a grouting hole and connecting a grouting pipeline; thirdly, calculating grouting pressure and selecting a grouting pump; finally, performing grouting. The thixotropic slurry comprises sodium bentonite, carboxymethyl cellulose, sodium carbonate, clean water and an appropriate amount of admixture. Frictional drag of a pipe and soil is decreased by a grouting process, the vertex distance can be increased by 40%-70% after lubrication and drag reduction by the grouting process, drag of a top pipe in work can be effectively reduced, the top pipe with a large caliber and a long distance can continuously extend, and the drag reduction method has the advantages of low cost, easiness in technical implementation and high drag reduction efficiency.

Owner:CHINA MCC17 GRP

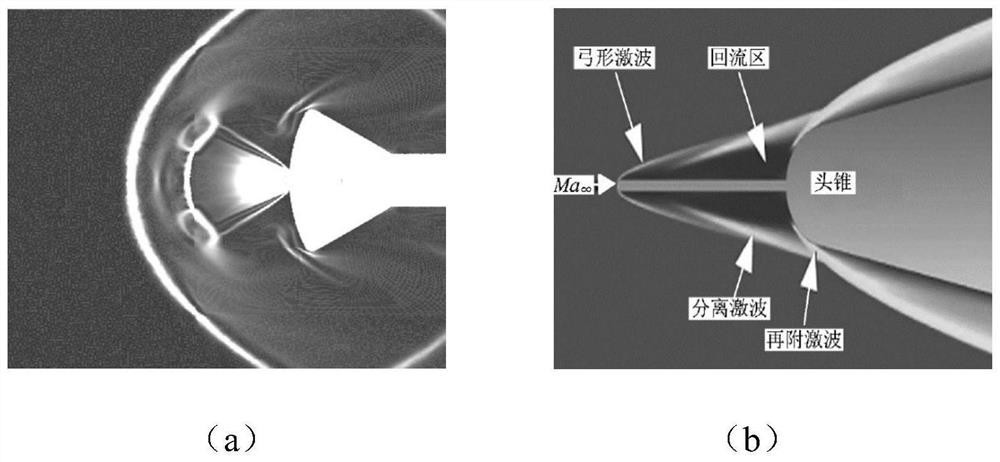

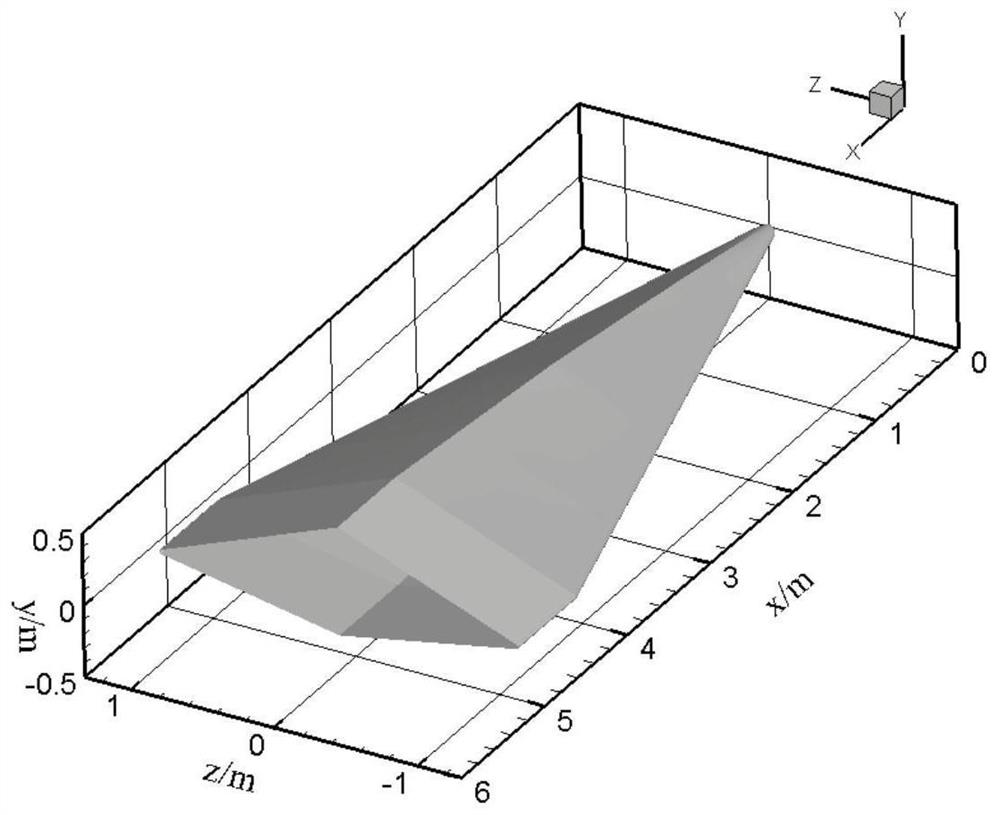

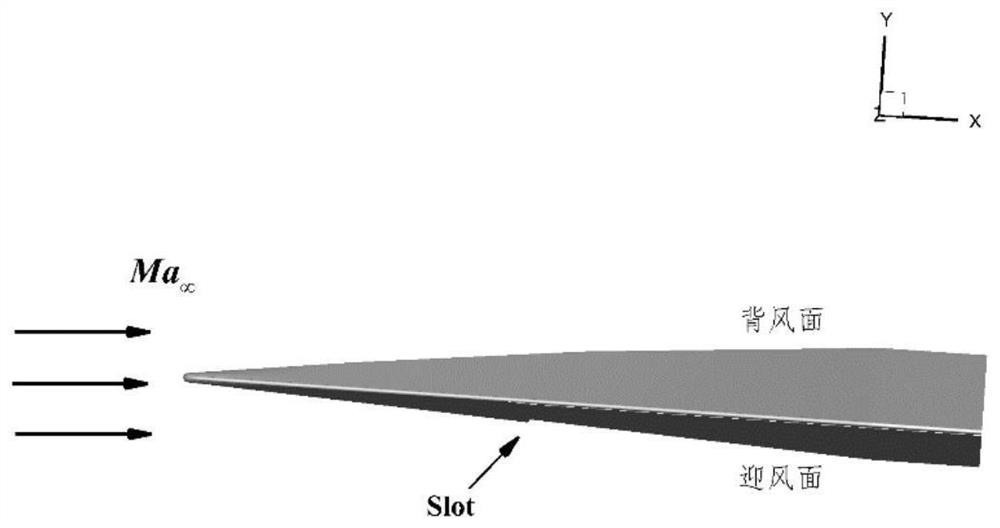

Slit parallel blowing method for drag reduction of hypersonic aircraft

PendingCN112758309AReduce total dragImprove drag reduction efficiencyDrag reductionAir-flow influencersFlight vehicleShock wave

The invention belongs to the field of aircraft design, and particularly relates to a slit parallel blowing method for drag reduction of a hypersonic aircraft; the method comprises the following steps: arranging slits on the windward side of an aircraft, and then blowing air into the boundary layer of the wall surface in parallel through the slits. A novel application scheme of the slit parallel blowing resistance reduction technology is provided for the hypersonic aircraft, the surface friction resistance of the hypersonic aircraft is reduced through the slit blowing technology, and meanwhile the torque characteristic of the hypersonic aircraft is not changed. Different from shock wave resistance reducing modes such as reverse jet flow and installation of a shock wave rod, the main implementation way of the invention is to reduce the frictional resistance of the surface of the hypersonic aircraft by adopting a slit parallel blowing mode, so that the purpose of reducing the total resistance of the aircraft is achieved.

Owner:BEIHANG UNIV

Bionic superhydrophobic surface, its preparation method and drag reduction method

ActiveCN105908187BNon-toxic and non-radioactiveImprove underwater drag reduction efficiencyEngineeringHydrophobic surfaces

The invention provides a production method of a bionic super-hydrophobic surface, and a method for carrying out underwater drag reduction by using the hydrophobic interface. A bionic technology is combined with a supercavity drag reduction technology, so the underwater drag reduction efficiency is effectively improved, and the production cost and the maintaining cost are low; and raw materials adopted in the invention are nontoxic and have no radiation effect, so the bionic super-hydrophobic surface has no untoward effects on environment.

Owner:BEIHANG UNIV

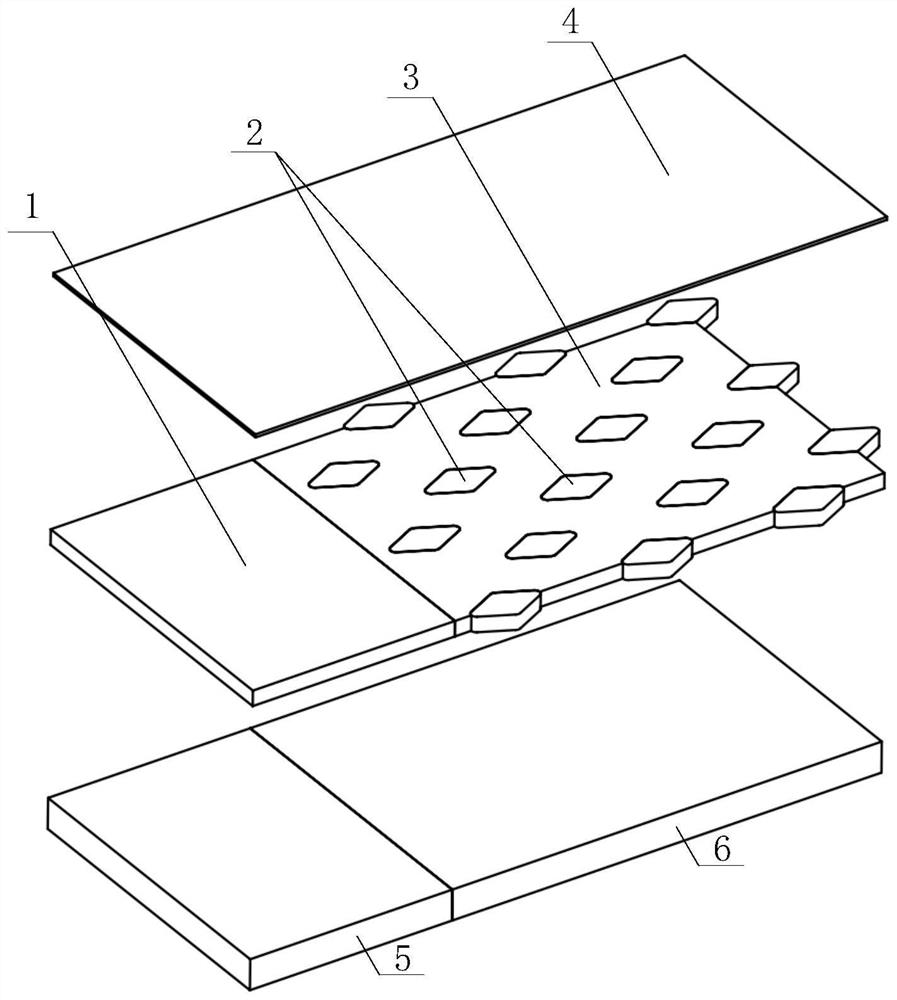

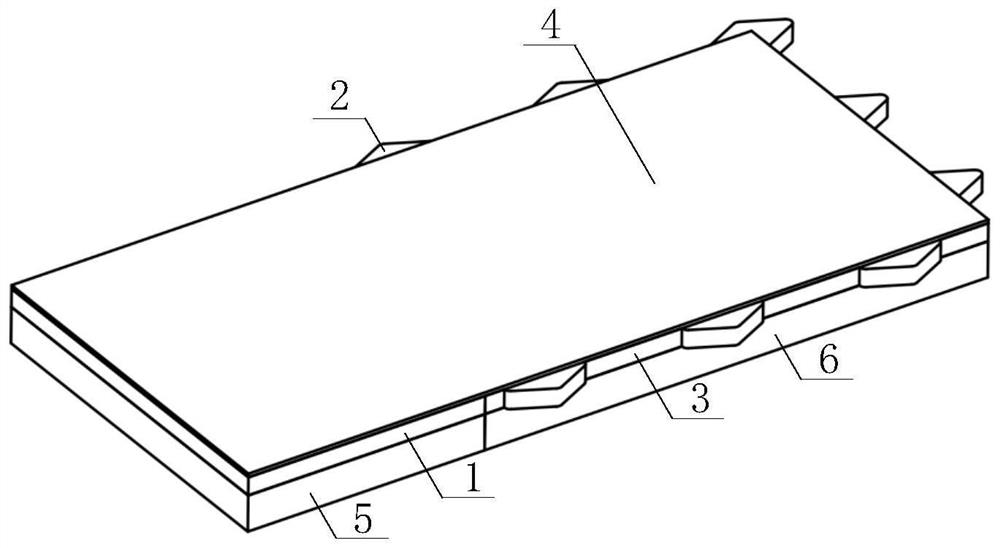

Underwater vehicle bionic dynamic variable-structure skin with intelligent self-adaptive resistance reduction function

ActiveCN114801358APostpone the transitionWith drag reduction adaptive functionWatercraft hull designSynthetic resin layered productsTemperature controlWater flow

The bionic dynamic variable-structure skin comprises a front section and a rear section, each of the front section and the rear section is formed by compositing a top layer, a middle layer and a bottom layer, the top layers of the front section and the rear section are flexible organic polymer films, the bottom layers of the front section and the rear section are ceramic heating pieces, and the ceramic heating pieces are arranged in the middle of the front section and the rear section. The middle layer of the front section is made of a temperature-control phase-change material, the middle layer of the rear section is a metal flat plate, a plurality of rhombic holes are formed in the metal flat plate, and the rhombic holes are filled with the temperature-control phase-change material. The heat production amount can be controlled by adjusting the bottom layer ceramic heating sheet, so that the temperature control phase change material deforms to a corresponding degree, the process that wrinkles of the dolphin skin and body thorns of the dolphin skin change along with the change of the speed of external water flow is simulated, the viscosity of water flow on the surface of the skin can be reduced through redundant heat, and the skin quality is improved. And finally, the skin has a self-adaptive resistance reduction function.

Owner:JILIN UNIV

A microblowing structure and method for supercritical airfoil drag reduction and lift increase

ActiveCN107933895BReduce consumptionEasy to liftGround installationsAir-flow influencersFlight vehicleEngineering

Owner:BEIHANG UNIV

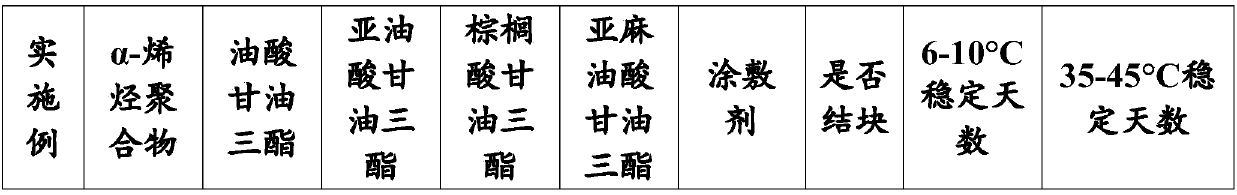

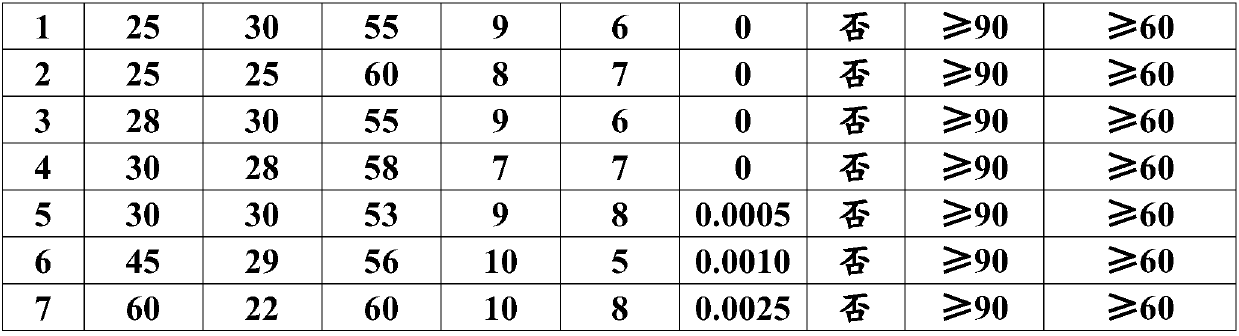

Drag reducer, and preparation method and application thereof

ActiveCN110577819AReduce the impactGood drag reduction effectOther chemical processesPipeline systemsVolumetric Mass DensityEngineering

The invention provides a drag reducer, and a preparation method and an application thereof. The drag reducer has a high drag reduction efficiency; the carrier component of the drag reducer can effectively avoid the phenomena of breakage and the like of the macromolecular chain of an alpha-olefin polymer in the use process; and glyceryl trioleate and glyceryl trilinoleate also added to the drag reducer as carriers can assist in achieving the drag reduction effect, and the carriers also avoid the phenomena of layering or caking of the drag reducer in the storage process, so the blocking phenomenon is avoided. The drag reducer is a green and environmentally-friendly drag reducer, and the added carrier components are mild reagents, so compared with other drag reducers, the prepared drag reducer has no pungent smell, and is popular with operators. Moreover, the drag reducer has a wide application range, is suitable for crude oils and mixed crude oils with various densities, and is also suitable for product oils with high requirements for additives.

Owner:广东粤首新科技有限公司

Alpha-olefin-styrene super molecular weight drag-reduction polymers and process for preparing the same

InactiveCN1566168AHigh solid contentPolymerization conditions improvedPipeline systemsPolymer scienceZiegler–Natta catalyst

The invention discloses an alpha-olefin-styrene super molecular weight drag-reduction polymers for petroleum pipelines and process for preparing the same, wherein alpha-olefin 80-99.9% of the total raw material weight and 0.1-20 wt% of phenylethene are sufficiently mixed, so thin film is formed in the reaction device isolated from air, then 0.002-0.11 wt% of Ziegler-Natta catalyst is distributed uniformly onto the thin film, the reaction temperature is controlled to trigger bulk polymerization reaction.

Owner:PIPECHINA SOUTH CHINA CO

Ship drag reduction system and drag reduction method thereof

InactiveCN114670973AReduce installation difficultyEasy to installWatercraft hull designHydrodynamic/hydrostatic featuresWater flowProw

The ship drag reduction system comprises an incident flow liquid spraying device, an air spraying device, a high-pressure pump and a control device, the incident flow liquid spraying device is installed at the head of a ship and arranged along the middle longitudinal section of the ship, the high-pressure pump is installed at the bottom of the head of the ship, and the incident flow liquid spraying device is located on one side of the high-pressure pump and connected with the high-pressure pump; the air injection device is arranged on the other opposite side of the high-pressure pump and connected with the high-pressure pump, the air injection device is arranged at the bottom and the two opposite sides of the stem in a U shape, and the control device is installed on the ship and connected with the high-pressure pump in a signal mode. The head incident flow resistance reduction device sprays water at the front edge of the ship in an incident flow mode, so that the high-pressure area of the front edge of the ship can be improved, the viscous pressure resistance of the ship is reduced, the resistance reduction mode can be selected according to the advancing speed of the ship, the spraying speed of the resistance reduction device can be controlled, the defect that a traditional resistance reduction mode is single is overcome, and the resistance reduction efficiency is improved; and the gas-liquid dual-purpose high-pressure pump is adopted to generate high-pressure water flow and bubbles, the installation difficulty of the resistance reduction device is reduced, and installation is convenient.

Owner:JIANGSU UNIV OF SCI & TECH

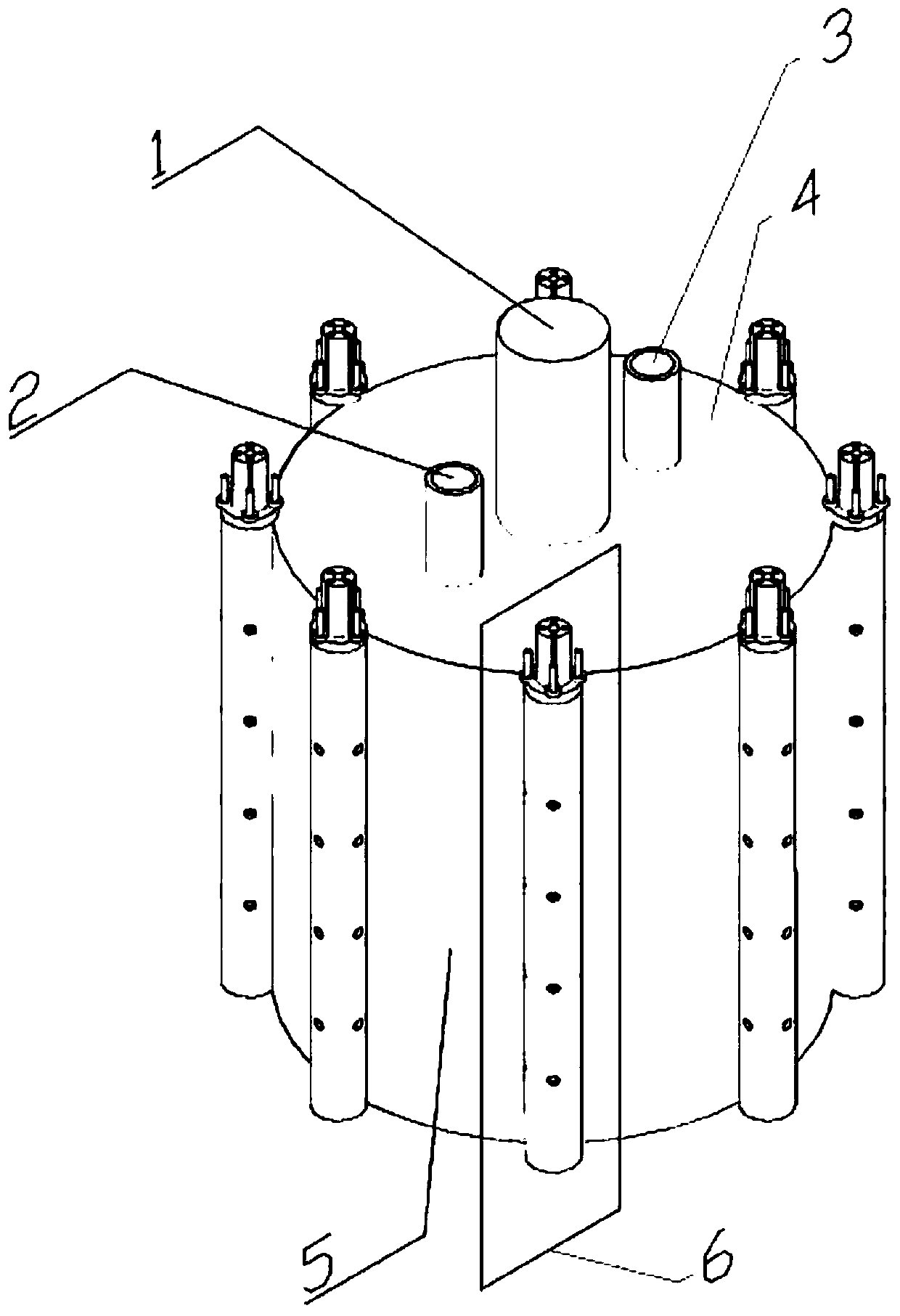

A microbubble drag reducing pipeline

ActiveCN104179757BReduce frictional resistanceHigh speedFluid dynamicsPipe elementsElectrolysisMicrobubbles

The invention relates to a method for reducing drag in a microbubble pipeline. In the transition layer of the turbulent flow field in the pipeline, the microbubbles are directly generated through the electrolysis of the electrolytic ring, and the microbubbles interact with the turbulent flow in the transition layer of the flow field to suppress the turbulent pulsation and realize the flow turbulence. Drag reduction. A micro-bubble drag reduction pipeline, comprising a pipe body, the cross section of which is a rectangular structure, two-dimensional grooves are arranged on the pipeline of the pipe body, and the two ends of the two-dimensional grooves are respectively sealed and connected with the rectangular pipe body. An electrolytic ring is arranged in the two-dimensional channel, and the electrolytic ring has a rectangular frame structure. The electrolytic ring is fixedly arranged in the transition layer area in the two-dimensional channel, and the wire of the electrolytic ring extends out of the two-dimensional channel to connect with the power supply. Relying on the interaction between microbubbles and turbulence in the transition layer, suppress turbulent pulsation, realize flow turbulent drag reduction, reduce frictional resistance during liquid pipeline transportation, improve drag reduction rate, and reduce unnecessary waste. In the same microbubble Increase the delivery speed of the fluid as much as possible under the gas volume.

Owner:苏州至美净新材料科技有限公司

Alpha-olefin-styrene super molecular weight drag-reduction polymers and process for preparing the same

InactiveCN1262567CHigh solid contentPolymerization conditions improvedPipeline systemsPolymer scienceZiegler–Natta catalyst

The invention discloses an alpha-olefin-styrene super molecular weight drag-reduction polymers for petroleum pipelines and process for preparing the same, wherein alpha-olefin 80-99.9% of the total raw material weight and 0.1-20 wt% of phenylethene are sufficiently mixed, so thin film is formed in the reaction device isolated from air, then 0.002-0.11 wt% of Ziegler-Natta catalyst is distributed uniformly onto the thin film, the reaction temperature is controlled to trigger bulk polymerization reaction.

Owner:PIPECHINA SOUTH CHINA CO

An electrolysis device and its application in microbubble drag reduction technology

ActiveCN107351975BProduce adverse effectsImprove underwater drag reduction efficiencyWatercraft hull designHydrodynamic/hydrostatic featuresMicrobubblesElectrolysis

Owner:BEIHANG UNIV

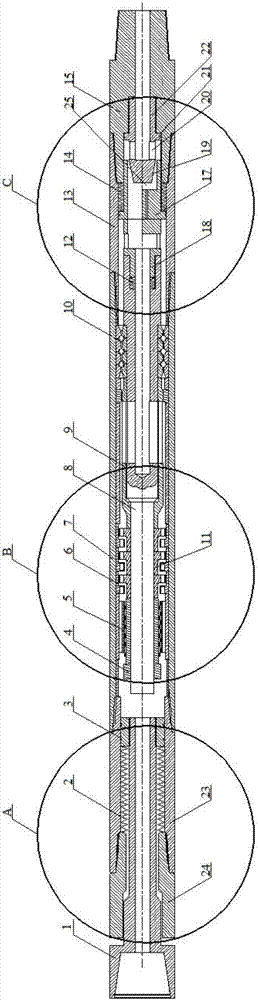

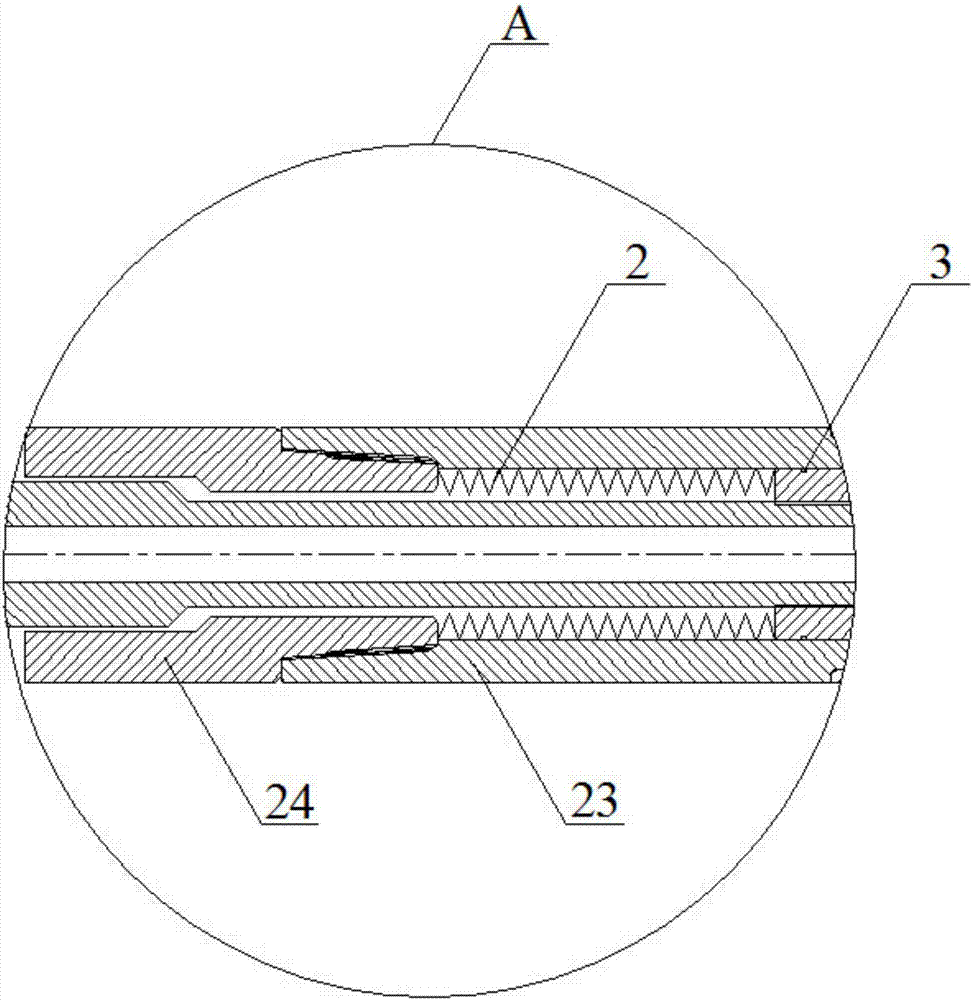

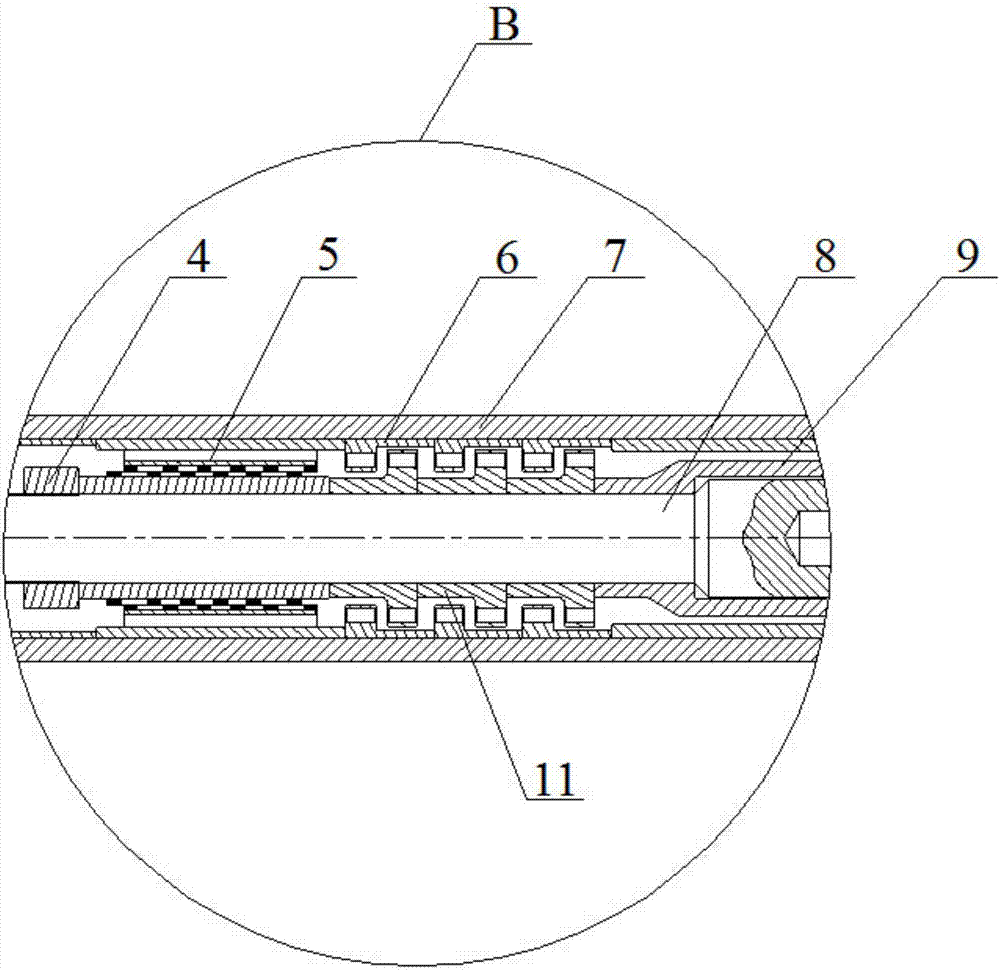

Turbine-powered double-acting hydraulic oscillating drag-reducing drilling tool

InactiveCN105672885BReduce radial vibrationShorten the overall lengthVibration drillingEngineeringTurbine rotor

The invention discloses a turbine power type double-action hydraulic oscillating-drag-reduced drilling jig. The drilling jig comprises a power segment shell, a main shaft, a letdown valve, a supporting seat, a vibrating shaft and a vibration segment shell, wherein a turbine rotor is arranged on the main shaft, and a turbine stator is arranged on the power segment shell; the supporting seat is connected to one end of the power segment shell, and the vibration segment shell is connected to the other end of the power segment shell; one end of the vibrating shaft is clamped at the outer side of the end part of the power segment shell, the other end of the vibrating shaft is located in the vibration segment shell, the end located in the vibration segment shell is in sliding fit with the internal chamber wall of the vibration segment shell, and the vibrating shaft is further provided with an elastic member which enables the vibrating shaft to vibrate; one end, facing to the supporting seat, of the main shaft is connected with a turning valve, and the turning valve is in relative sliding fit with the main shaft along the axial direction of the main shaft; the letdown valve is supported in the power segment shell through the supporting seat, the turning valve and the letdown valve have end faces which are oppositely abutted, and eccentric holes are formed in the opposite end faces of the turning valve and the letdown valve. The turbine power type double-action hydraulic oscillating-drag-reduced drilling jig is of an all-metal structure and can be used in a high-temperature environment.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Method for manufacturing amplified vivid sharkskin squama

InactiveCN102102300BRealize arbitrary stretch deformationImprove drag reduction efficiencyTextiles and paperEngineeringViscosity

The invention relates to a method for manufacturing amplified vivid sharkskin squama, which comprises the following steps: 1) pre-treating the sharkskin; 2) precisely scanning the sharkskin squama and three-dimensionally modeling; and 3) three-dimensionally printing the vivid amplified sharkskin squama. By using the method, an amplified model of the vivid sharkskin squama can be acquired by usingthe techniques of high-precise scanning, three-dimensional printing and quick forming. The method is advanced. The vivid sharkskin squama can be directly viewed. In the fluid with high dynamic viscosity, the anti-dragging efficiency of the vivid sharkskin squama can be tested, thereby achieving the anti-dragging efficiency of the vivid sharkskin squama. The method is consistent with the development of the bionic anti-dragging surface manufacturing technique and has wide application prospect and high practical value.

Owner:BEIHANG UNIV

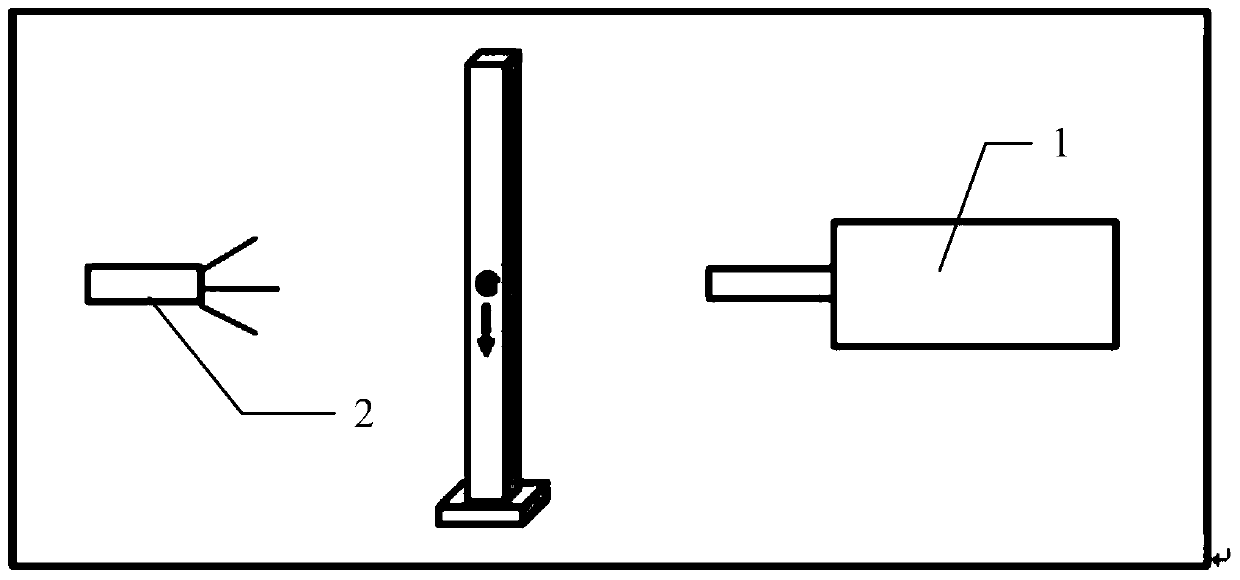

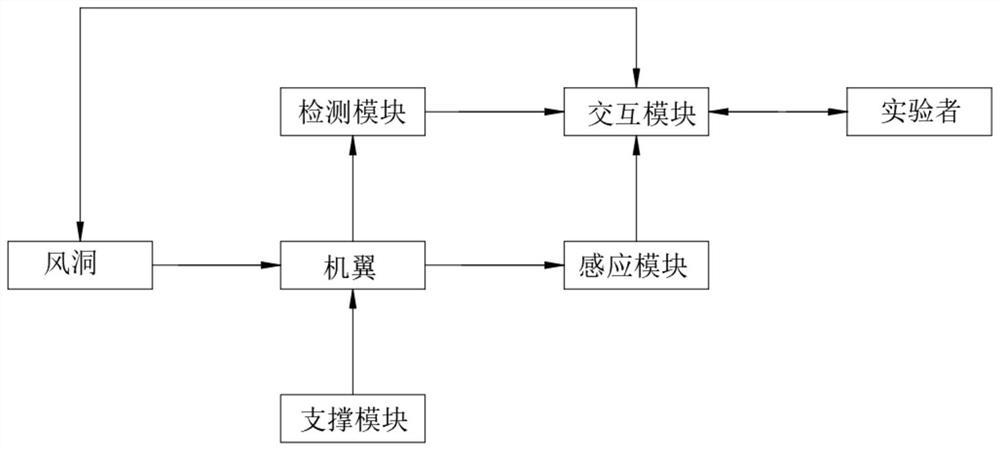

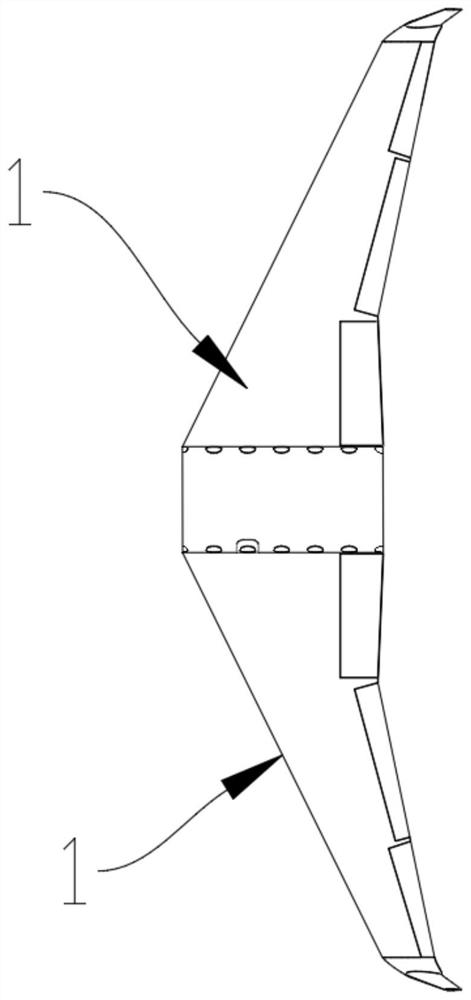

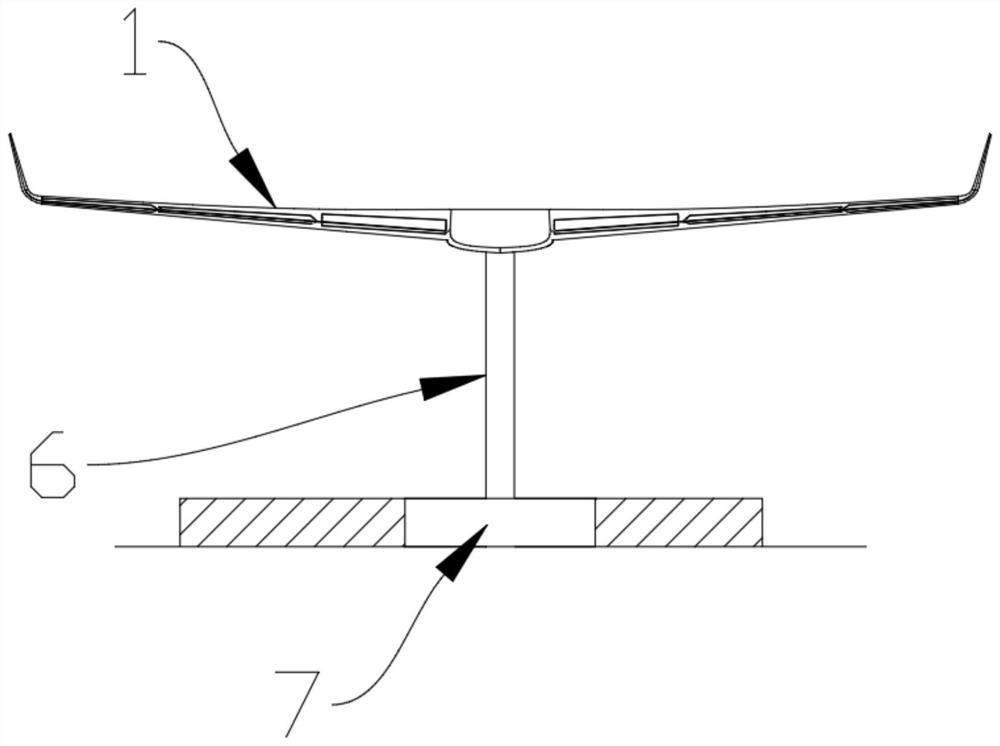

Detection system applied to aerospace fluid active drag reduction experiment

InactiveCN114720081AAdjust drag reduction meansImprove drag reduction efficiencyFluid pressure measurement using piezo-electric devicesSubsonic/sonic/ultrasonic wave measurementStructural engineeringCivil aviation

The invention provides a detection system applied to an aerospace fluid active drag reduction experiment, which comprises a wind tunnel, a wing, a detection module and an induction module, and is characterized in that the detection module is used for detecting fluid at two sides of the wing so as to detect fluid speed data at two sides of the wing; the sensing module is used for sensing the deformation quantity of the wing so as to analyze the resistance reduction capability of the wing; the detection module and the sensing module are arranged on a wing to detect the amplitude and fluid data of the wing; the detection unit comprises a detection component and a resistance reduction component, and the detection probe is used for detecting the fluid speed on the two sides of the wing; and the resistance reduction component is used for adjusting the resistance of the wing so as to cooperatively detect the fluid speed before and after resistance reduction. The resistance of the resistance reduction component is adjusted according to the detection data of the detection unit, so that the change of the wing under the active resistance reduction condition is obtained, the resistance reduction means of the wing can be adjusted by civil aviation, and the resistance reduction efficiency of the wing is improved.

Owner:HUNAN UNIV OF ARTS & SCI

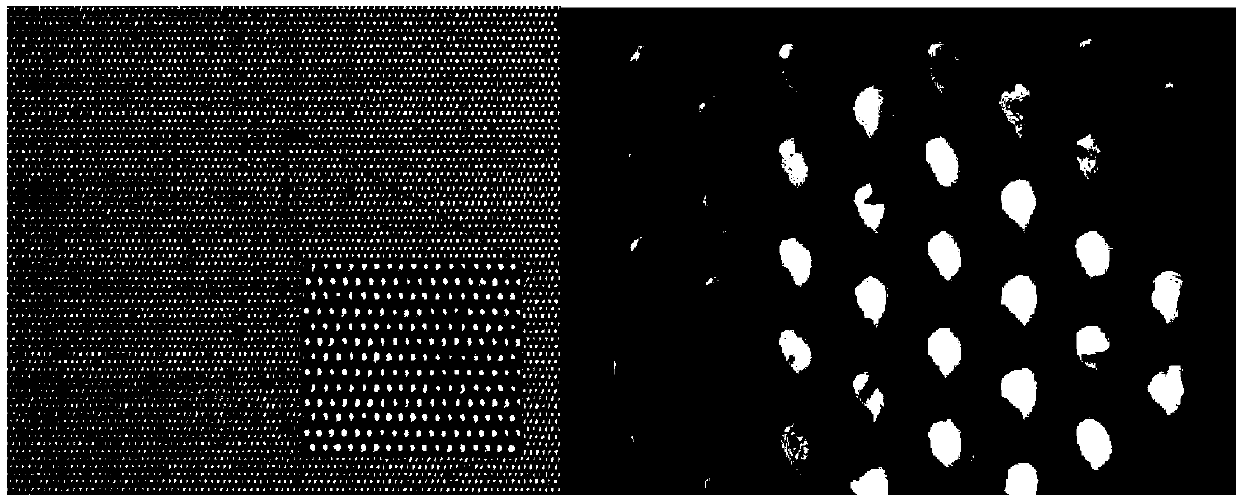

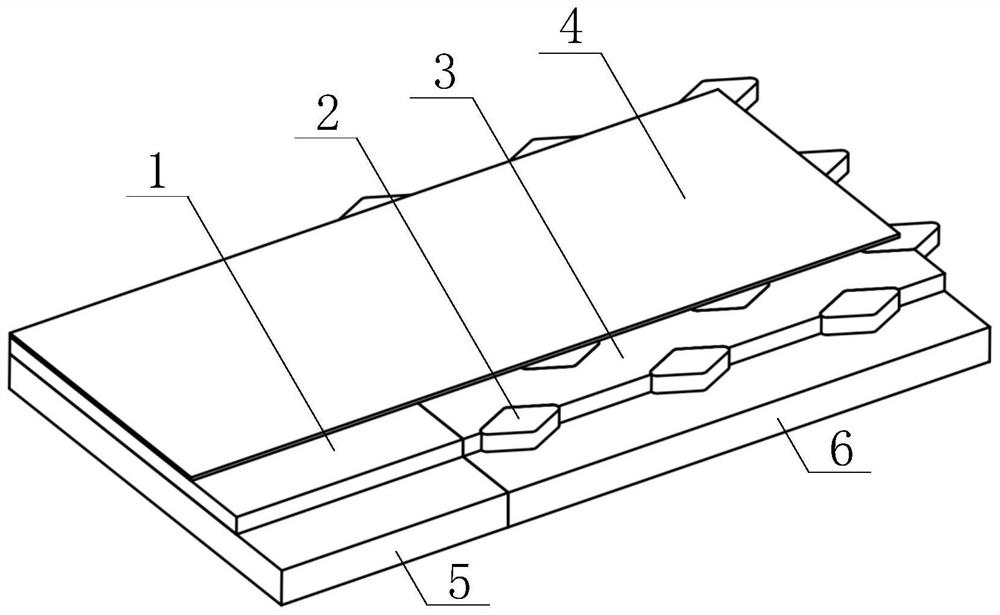

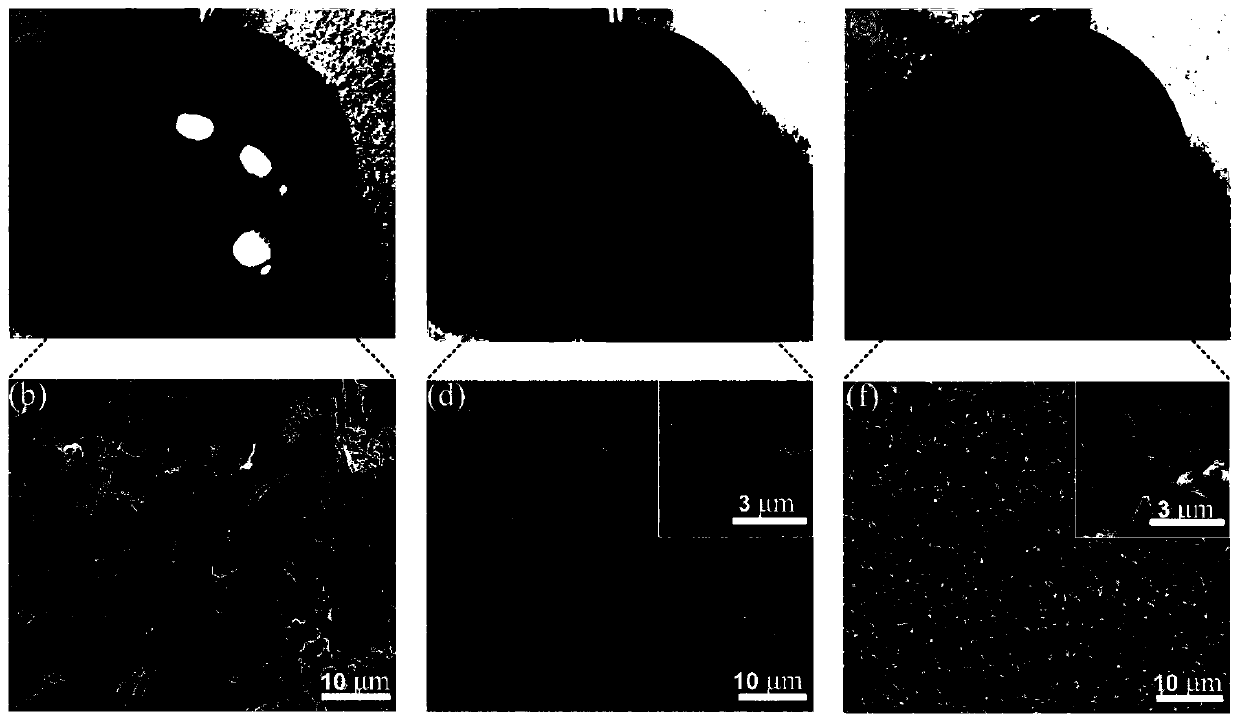

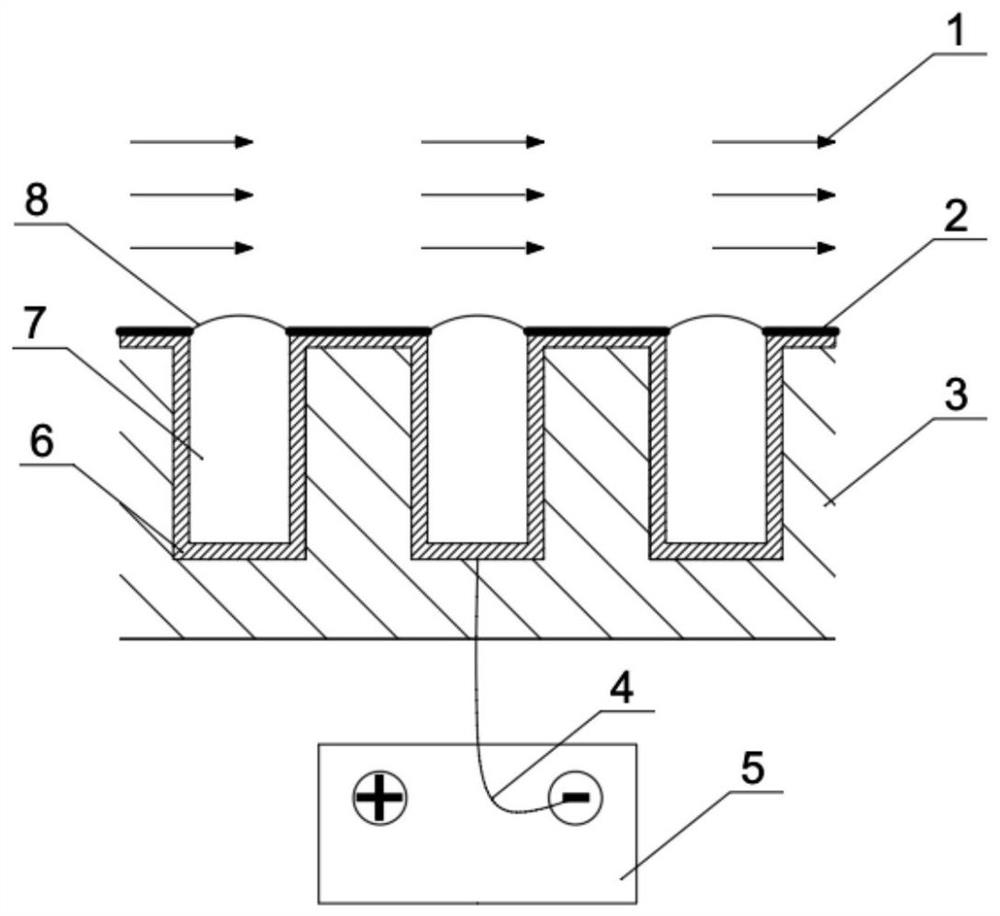

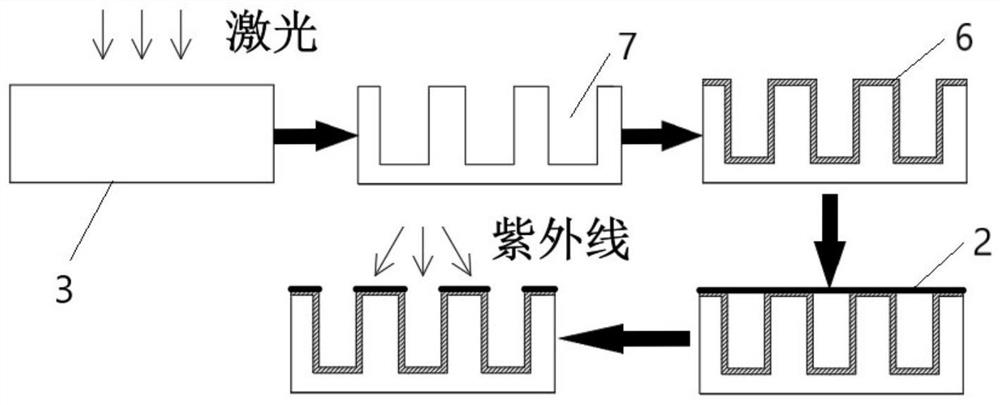

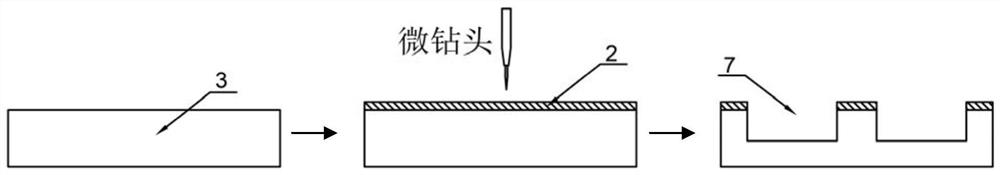

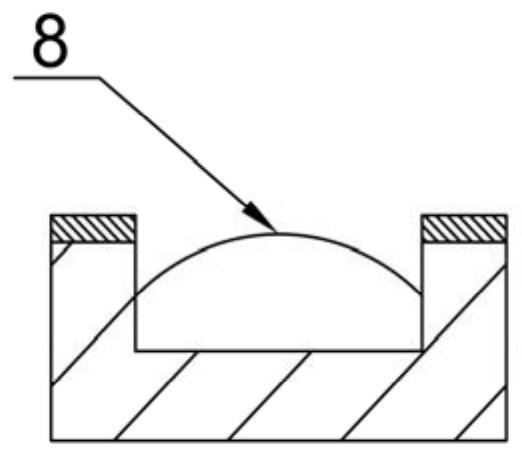

Adaptive electrode wall surface micro-nano pit micro-bubble generating device and manufacturing method thereof

ActiveCN111572705BAchieving Adaptive ControlSolve difficult-to-stay problemsWatercraft hull designHydrodynamic/hydrostatic featuresElectrolysisHemt circuits

An adaptive electrode wall surface micro-nano pit and micro-bubble generating device and a manufacturing method thereof relate to the technical field of active drag reduction of underwater vehicles, including a substrate and a DC power supply, wherein the surface of the substrate is provided with electrode wall micro-nano pits, and an electrode The wall surface of the micro-nano pit on the wall surface and the upper surface of the base body are provided with a sputtered metal layer, the sputtered metal layer on the upper surface of the base body is covered with photoresist, and the sputtered metal layer is connected to the negative electrode of the DC power supply through a power supply wire. By electrolyzing the NaCl solution, self-adaptive replenishment of microbubbles can be achieved without continuous and long-term ventilation. When the microbubbles burst or the gas-liquid interface is lower than the upper end of the laid sputtered metal negative electrode, the device automatically triggers the electrolysis circuit to realize the microbubble. The adaptive control is suitable for surface ships and underwater vehicles; it can stably maintain microbubbles, which is beneficial to practical applications.

Owner:XIAMEN UNIV

Resistance reduction device based on negative pressure type sliding plasma discharge

ActiveCN112954875AIncrease the instantaneous electromotive forceIncrease the number ofPlasma techniquePulsed DCHigh-voltage direct current

The invention discloses a resistance reduction device based on negative pressure type sliding plasma discharge. The resistance reduction device comprises a mounting flat plate, and a plurality of plasma discharge units arranged in a gapless array are mounted on the mounting flat plate; each plasma discharge unit comprises a regular hexagonal tubular dielectric layer, an alternating current electrode and a pulse direct current electrode are arranged along the surface of the inner wall of a regular hexagonal tubular dielectric layer, and a buried electrode is buried in the corresponding regular hexagonal tubular dielectric layer between the alternating current electrode and the pulse direct current electrode; the buried electrodes, the alternating current electrodes and the pulse direct current electrodes are all in a regular hexagonal tube shape; and the plurality of buried electrodes on the mounting panel are connected in parallel and then grounded, the plurality of alternating current electrodes on the mounting panel are connected in parallel and then connected with an alternating current high-voltage power supply, and a plurality of pulse direct current electrodes on the mounting panel are connected in parallel and then connected with a pulse high-voltage direct-current power supply. The device can remarkably improve the flow control effect and achieve the purpose of turbulent flow resistance reduction.

Owner:XIAN UNIV OF TECH

Micro-pit electrolytic micro-bubble generator based on micro-drill hole making on electrode wall

ActiveCN112026983BAchieving Adaptive ControlEffective bondageWatercraft hull designHydrodynamic/hydrostatic featuresElectrolysisUnderwater navigation

The invention relates to an electrolytic microbubble generating device based on a micro-drill-bit micro-pit electrolytic micro-bubble on the electrode wall, and relates to the technical field of active drag reduction of underwater vehicles. It includes a substrate, a carbon rod and a regulated DC power supply. The surface of the substrate is provided with a micro-pit structure on the electrode wall, the upper surface of the substrate is covered with a polyimide coating, and the lower surface of the substrate is connected to a regulated DC power supply through a power wire. The negative pole of the carbon rod is connected to the negative pole of the regulated DC power supply. By electrolyzing NaCl solution, the self-adaptive control of microbubble growth can be realized without continuous and long-term gas injection. When the microbubble breaks, falls off or the gas-liquid interface is lower than the laid polyimide coating, the device will automatically trigger The electrolytic circuit realizes adaptive control of micro-bubbles, and is suitable for surface ships and underwater vehicles; it can stably maintain micro-bubbles, which is beneficial to practical engineering and military applications.

Owner:XIAMEN UNIV

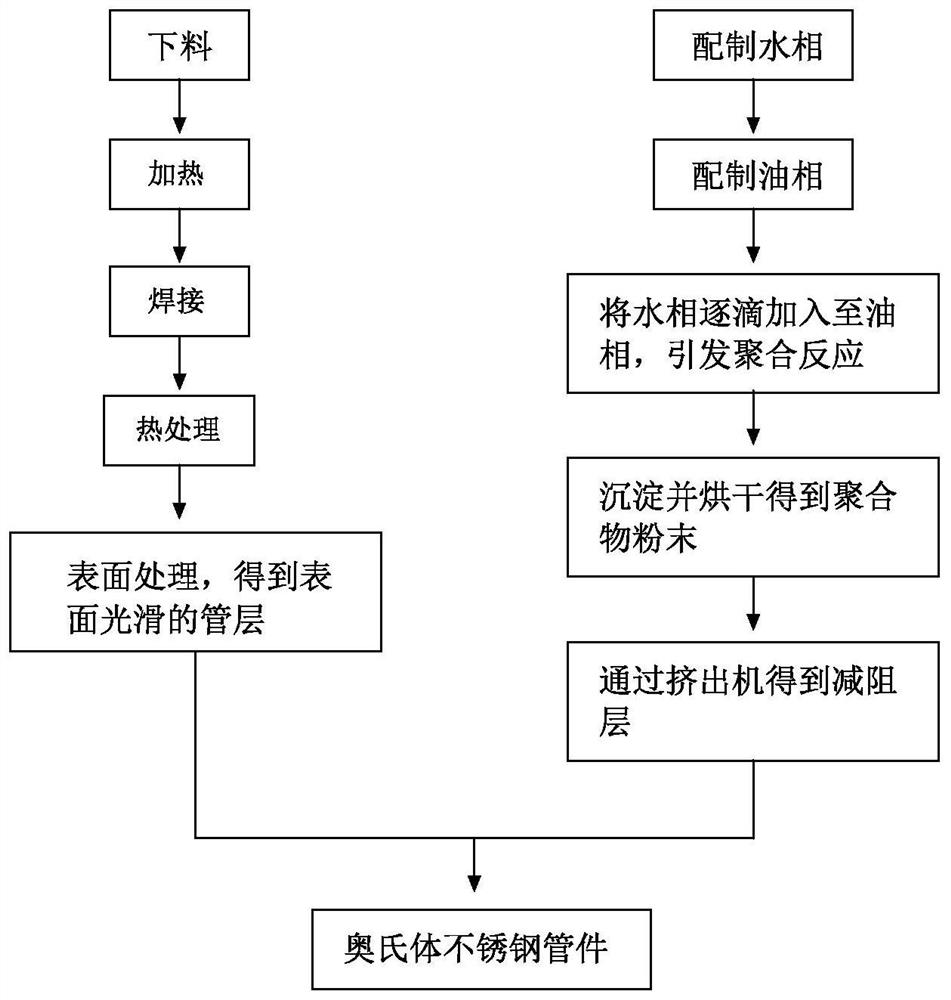

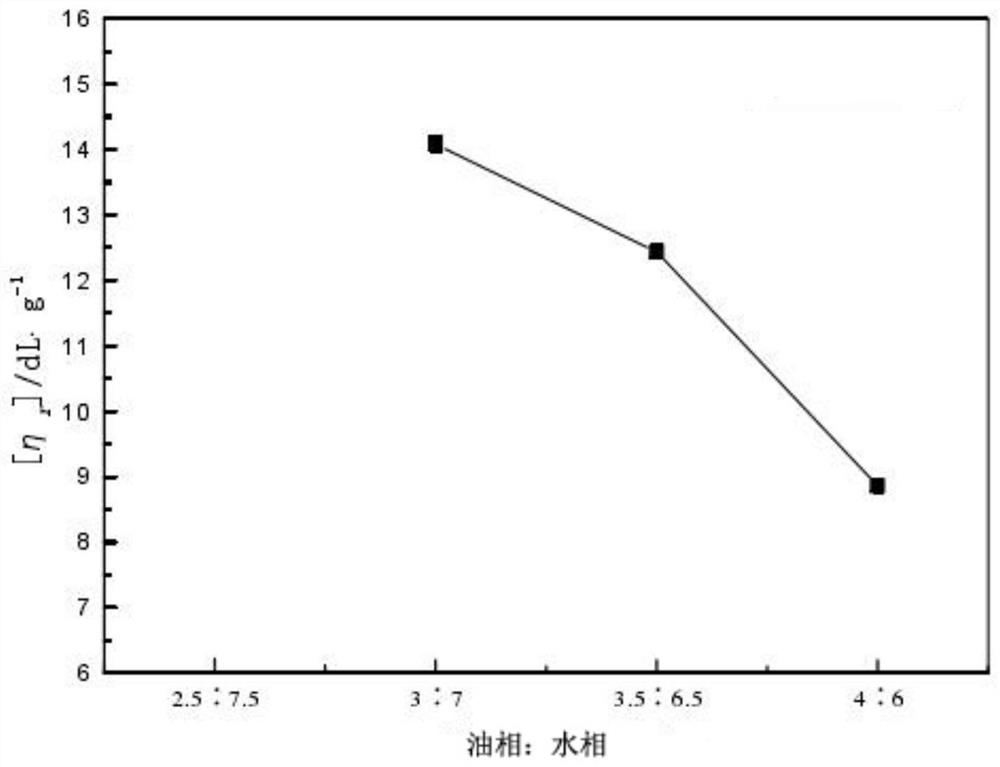

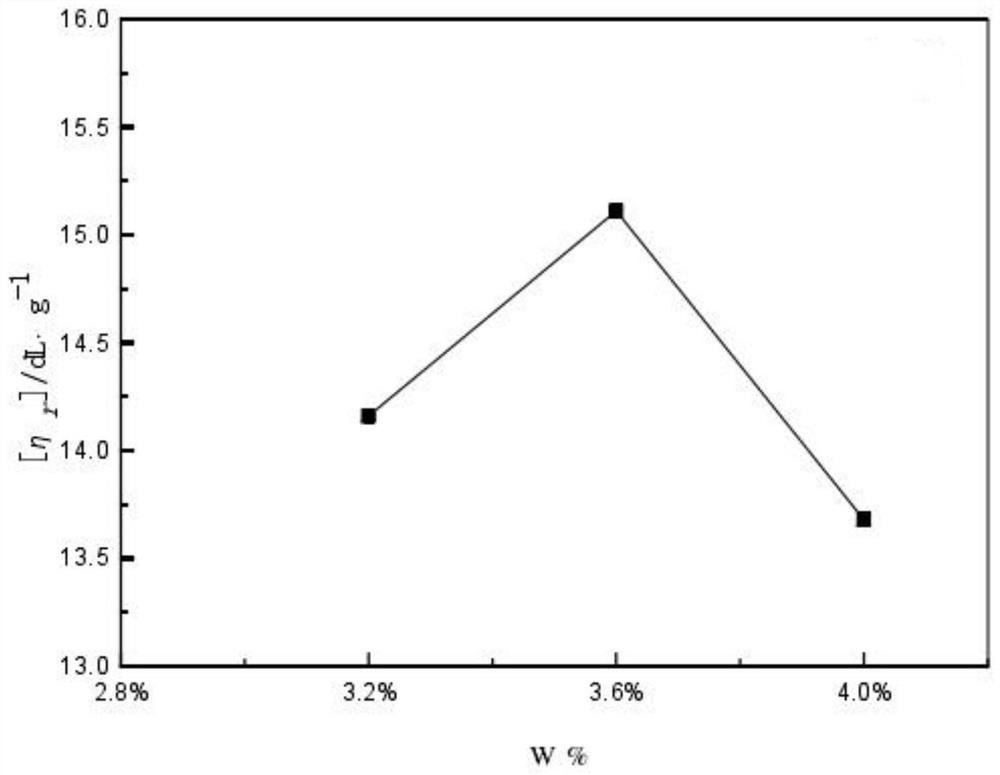

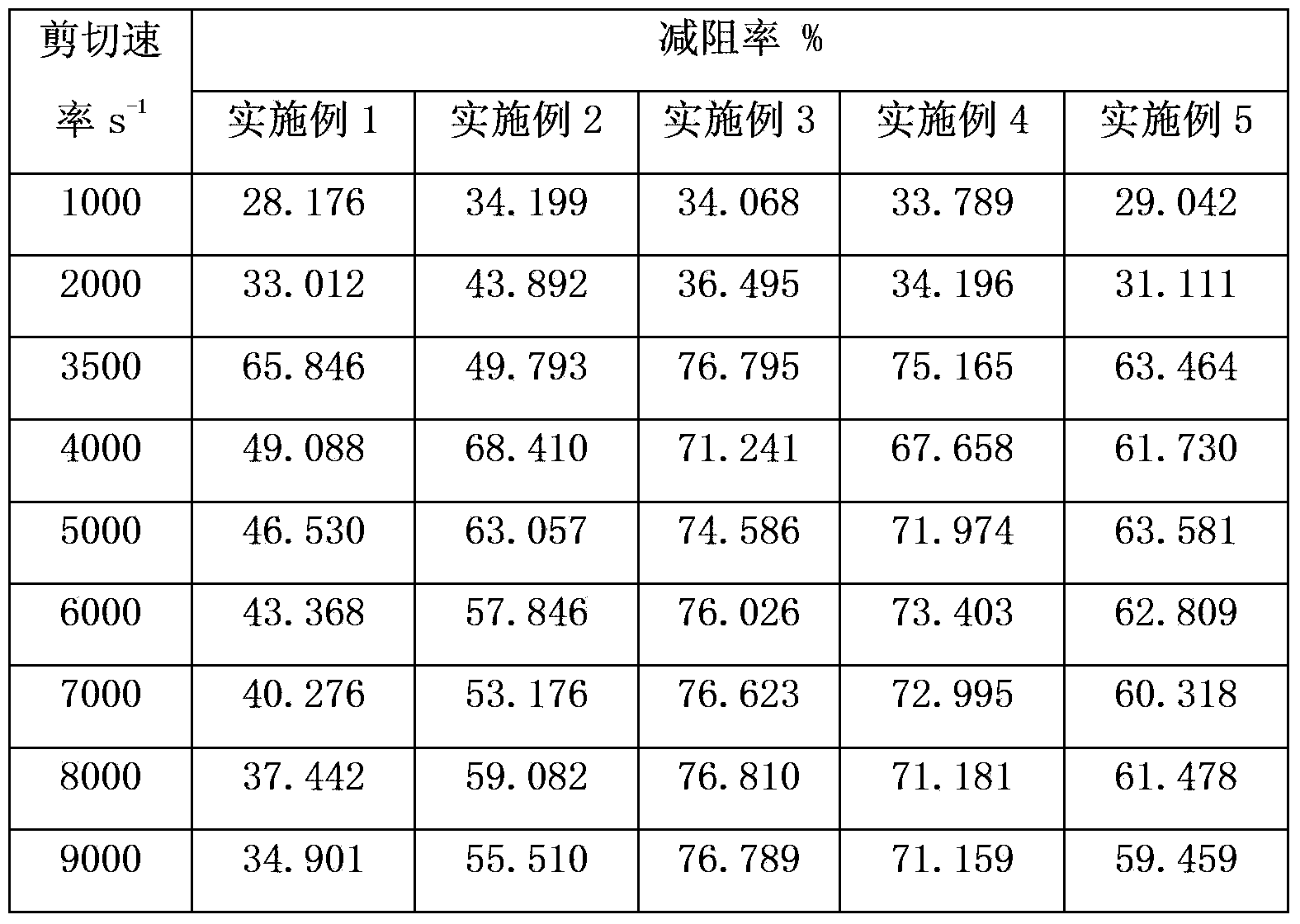

A manufacturing process of austenitic stainless steel pipe fittings

ActiveCN109530475BGuaranteed normal functionInhibition productionFurnace typesRigid pipesManufacturing technologyPipe fitting

The invention discloses a manufacturing technology of an austenitic stainless steel pipe fitting. According to the technology, a pipe layer and a resistance reducing layer embedded in the inner wall of the pipe layer are included; the pipe layer is prepared in the technological steps of blanking, heating, welding, heat treatment and surface treatment; the resistance reducing layer is prepared in the following technological steps that an aqueous phase is prepared, an oil phase is prepared, the prepared oil phase is added to an oil phase reaction still, nitrogen is introduced to displace oxygen,the aqueous phase is added to the oil phase dropwise, nitrogen is introduced to displace oxygen again, then the conductivity is measured, when the conductivity is at the proper value, a polymerization reaction is initiated at a certain temperature, after the initiation temperature is stabilized, the temperature increase continues, and the temperature is kept for a certain period of time to realize complete reaction; after the reaction ends and a product is cooled, polymers are precipitated by the aid of acetone and ethanol alternately, and the polymers are placed into an oven to be dried to form polymer powder; the polymer powder is poured into an extruding machine, and the annular resistance reducing layer is obtained finally. The technology has the advantages and the effects as follows:the dissolution speed is high, uniform dispersion is realized, and the resistance reducing efficiency is high.

Owner:ZHEJIANG JNDIA PIPELINE IND

Weighting water-based fracturing drag reducer

The invention discloses a weighting water-based fracturing drag reducer. The weighting water-based fracturing drag reducer comprises a base solution and a weighting agent, wherein the base solution comprises the following components in percentage by weight: 0.02%-0.1% of drag reducer, 0.5%-0.1% of conditioning agent and the balance of water; and the weighting agent is one or a mixture of more of ZnCl2, Zn(NO3)2, CuC12 and Cu(NO3)2 in arbitrary proportions; and the drag reducer is an inverse emulsion, and the conditioning agent is a methanol solution of 3 percentage by weight of ethyoxyl non-ionic type fluorocarbon surfactant. The novel weighting material is added to the drag reducer, so that the density of the drag reducer is increased, and the liquid column weight of the drag reducer in a pipeline is increased, thus the construction pressure is effectively reduced, the construction risk is reduced, and the construction success is ensured.

Owner:SOUTHWEST PETROLEUM UNIV

Deep well resistance-reducing packing

InactiveCN102324260BReduce the amount of waterEasy on-site configurationNon-metal conductorsConductive materialMeth-Polyvinyl alcohol

The invention discloses a deep well resistance-reducing packing which mainly comprises the following components in parts by weight: 10-50 parts of conducting materials, 10-50 parts of curing agent, 0.5-25 parts of leavening agent and 0.1-10 parts of retarding agent, wherein the conducting material is selected from one or more of sodium salts, potassium chloride, calcium chloride and graphite; thecuring agent is selected from one or more of polyvinyl alcohol, aluminosilicate (kaolin), sodium silicate, calcium sulfate and cement; the leavening agent is selected from one of polyacrylamide and bentonite; and the retarding agent is selected from one of sodium methylenebisnaphthalenesulfonate and peregal. The deep well resistance-reducing packing has the advantages of saving of 15-30 percent of water quantity, good peaceability with water, no demixing and convenience for site configuration and construction: in addition, no demixing is caused, the solidifying time is prolonged and the flowability and the permeability are enhanced, therefore, no bridging phenomenon is caused during pouring, resistance reduction efficiency is increased, the quantity of deep wells is reduced, and the construction cost is reduced.

Owner:SICHUAN SUNLIGHT INTELLIGENT ELECTRIC EQUIP CO LTD

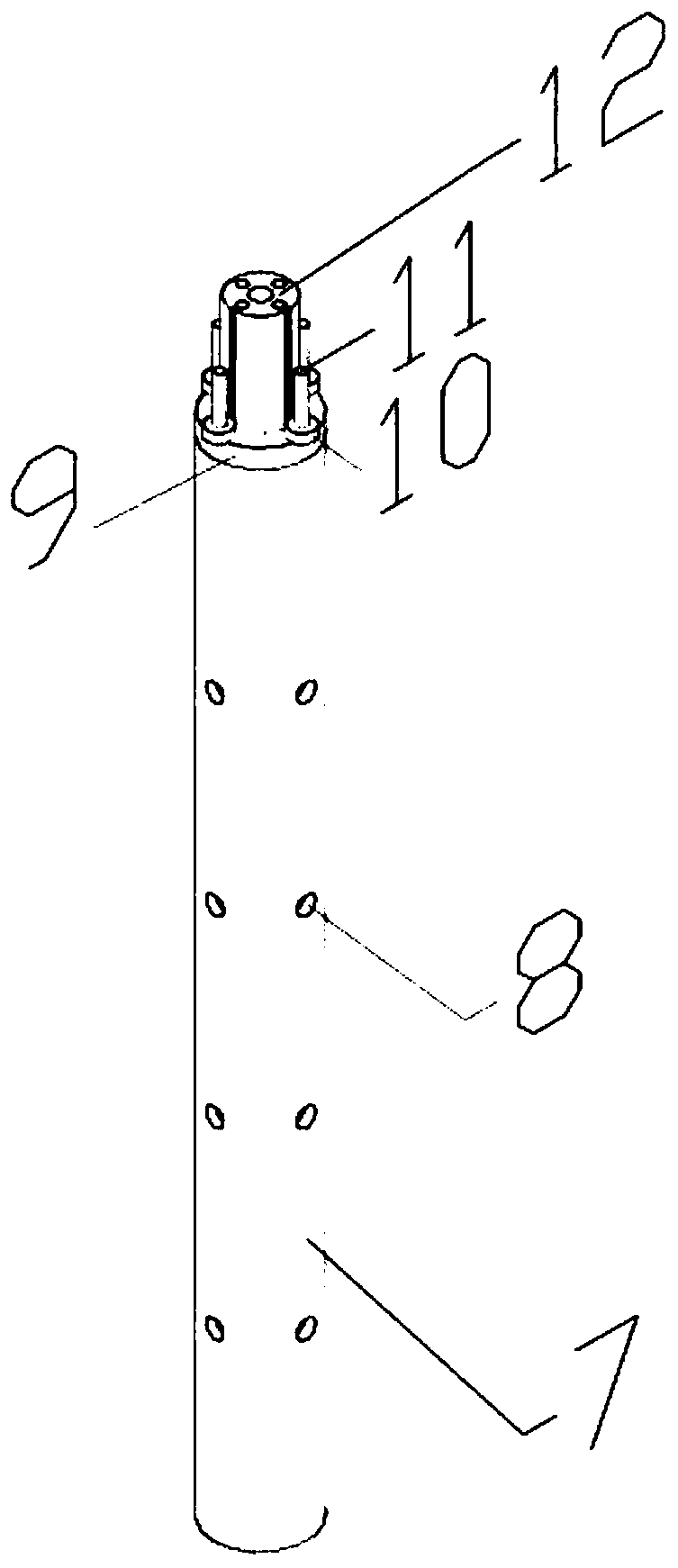

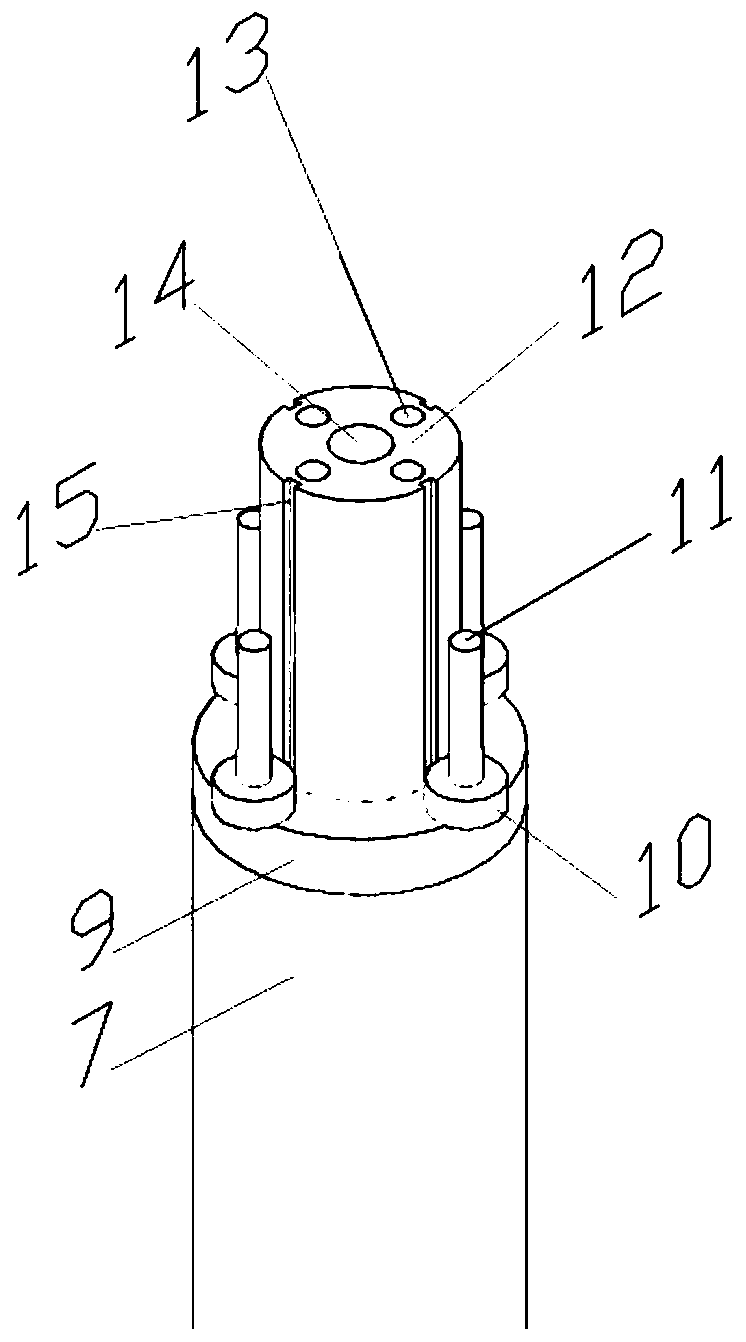

Reinforced spiral pipe and reinforced spiral pipe suction barrel foundation and using method thereof

InactiveCN108086347BImprove drag reduction efficiencyLow Barrel End Drag IncrementFoundation engineeringThree stageEngineering

The invention discloses a strengthened spiral pipe, a strengthened spiral pipe type sucking force barrel foundation and a using method of the strengthened spiral pipe type sucking force barrel foundation. The strengthened spiral pipe comprises an outer sleeve and a core bolt which penetrates the outer sleeve in the longitudinal direction; and the periphery of the sucking force barrel foundation are evenly provided with a plurality of strengthened spiral pipes. The using method includes the steps of (1), self weight sinking; (2), water flushing sinking; (3), correcting; (4) bottom end soil strengthening; (5), layer-by-layer strengthening of soil; (6), taking out of the core bolt; (7), installing of the core bolt: (8), grinding of the inner wall of the outer sleeve: (9), replacing of an inner piston; (10), scattering of bottom soil; (11), layer-by-layer scattering of soil; (12), elevating of the sucking force barrel foundation; and (13), recycling of the sucking force barrel foundation.According to the strengthened spiral pipe, the strengthened spiral pipe type sucking force barrel foundation and the using method of the strengthened spiral pipe type sucking force barrel foundation,control over the three stages of the full-service-life period of the sinking stage, the grouting strengthening stage and the recycling stage of the sucking force barrel foundation is achieved.

Owner:HOHAI UNIV

Water base fracture drag reducer

The invention discloses a water base fracture drag reducer which comprises the following components by percentage: 0.02-0.1% of drag reducer, 0.5-1% of conditioner and the balance of water. The drag reducer is an inverse emulsion which is prepared by the following steps of: dissolving 25 parts of methylacrylic acid dimethylamino ethyl ester chloro quaternary ammonium salt and 12 parts of acrylamide monomer in 25 parts of water; slowing dropwise adding to mixed liquor of 34.9 parts of white oil and 3 parts of span80 or span60; and under initiation of 0.1 part of azodiisobutyronitrile, stirring for 10 hours at 50 DEG C. The conditioner is methanol liquor of an ethoxyl non-ionic fluorocarbon surfactant with weight percentage of 3%. In order to solve the problem that friction of a liquid pipeline in the hydrofracture process is great and construction displacement cannot be effectively improved, the inverse emulsion is used as the drag reducer to reduce the friction of the pipeline in the hydrofracture process, so that the construction displacement is improved and the construction pressure is improved.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com