A manufacturing process of austenitic stainless steel pipe fittings

A kind of austenitic stainless steel, manufacturing technology, applied in the direction of manufacturing tools, pipes/pipe joints/fittings, pipes, etc., can solve the problems of restricting development, low elastic transportation, pipeline transportation capacity can not meet the requirements, etc., to save resources , Improve the conveying capacity and safety factor, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

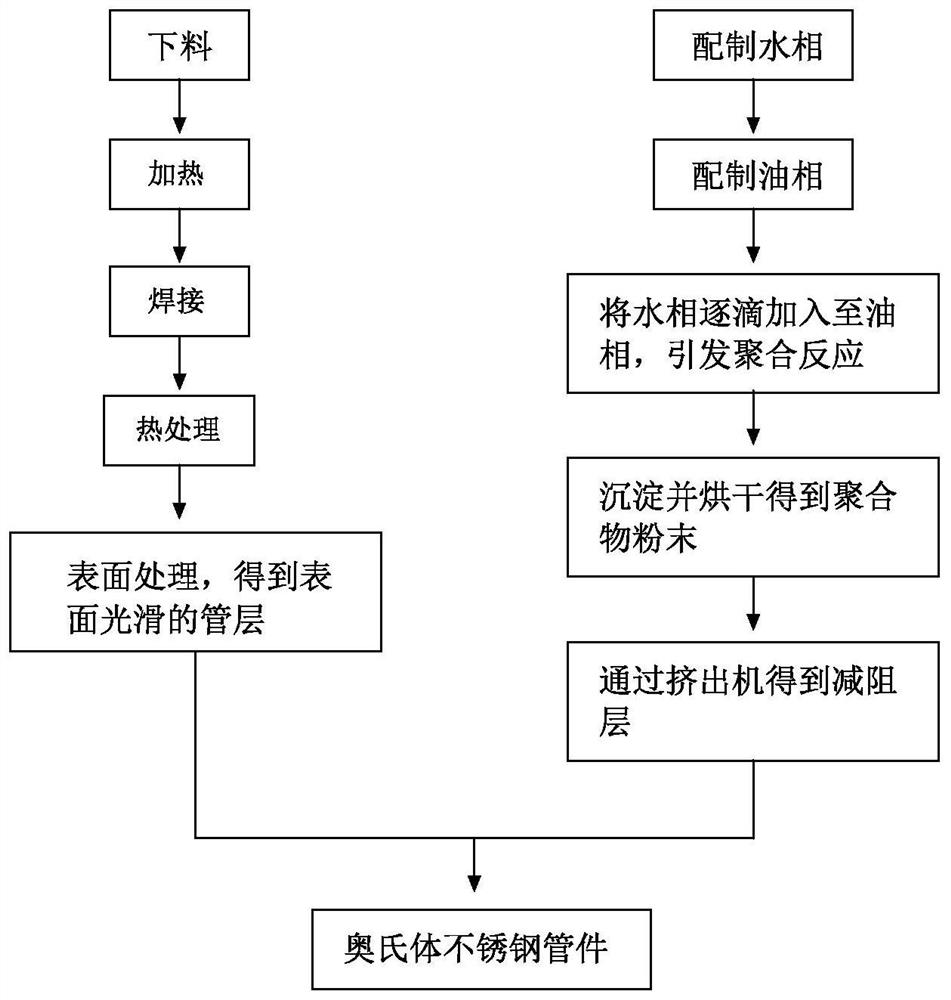

[0044] Such as figure 1 As shown, in the embodiment of the present invention, a manufacturing process of an austenitic stainless steel pipe fitting is proposed, including a pipe layer and a drag reducing layer embedded in the inner wall of the pipe layer, and the pipe layer is made by the following process steps:

[0045] S11, blanking, select the blank of austenitic stainless steel for use;

[0046] S12. Heating. The present invention adopts a hot forming method to meet the deformation requirements of the blank in the forming process. The blank needs to be heated during forming. The present invention uses induction heating to continuously heat the blank so that the blank is heated during motion and completed forming;

[0047] S13, welding, common welding methods for pipe fittings include gas shielded welding, automatic welding, etc. The present invention u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com