Soil contamination remediation agent

A soil pollution and remediation agent technology, applied in the field of soil pollution remediation, to achieve the effects of reducing organic pollutants, reducing raw material costs, and improving the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

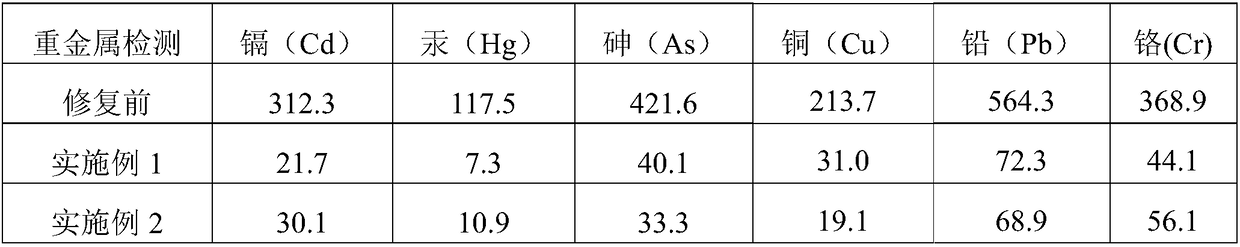

Examples

Embodiment 1

[0044] (1) Grind the phosphorite ore into particles with a particle size of 40 mesh, weigh the crushed phosphorite ore and heat it to 200°C, keep it warm for 1h, continue to heat up to 600°C, keep it warm for 2h, take it out, cool it and put it in a desiccator spare;

[0045] (2) Collect the monosodium glutamate fermentation tail liquid discharged from a certain factory, adjust the pH value to 6, concentrate, and when the volume is reduced to a solid content of 40%, then adopt the centrifugal spray drying method to produce dry solid powder with a particle size of 10 The target particles are ready for use;

[0046] (3) Collect chicken manure from a chicken farm, sprinkle 0.1% urea and 5% superphosphate into compost, and use a stick to make air holes in the heap, cover with plastic cloth to keep warm and keep fertilizer, and turn the heap once after 10 days of composting After stacking and retting for 60 days; then put the organic fertilizer on a sterile plastic film, spread it...

Embodiment 2

[0049] (1) Grind the phosphorite ore into particles with a particle size of 40 mesh, weigh the crushed phosphorite ore, heat it to 400°C, keep it warm for 2 hours, continue to heat up to 700°C, keep it warm for 1 hour, take it out, cool it and put it in a desiccator spare;

[0050] (2) Collect the monosodium glutamate fermentation tail liquid discharged from a certain factory, adjust the pH value to 8, concentrate, and when the volume is reduced to a solid content of 60%, then adopt the centrifugal spray drying method to produce dry solid powder with a particle size of 30 The target particles are ready for use;

[0051] (3) Collect chicken manure from a chicken farm, sprinkle 0.5% urea and 2% superphosphate into compost, and use a stick to make air holes in the pile, cover with plastic cloth to keep warm and keep fertilizer, and turn the pile once after 10 days of composting , after 90 days of stacking and retting; then put the organic fertilizer on a sterile plastic film, sp...

Embodiment 3

[0054] (1) Grind the phosphorite ore into particles with a particle size of 40 mesh, weigh the crushed phosphorite ore, heat it to 400°C, keep it warm for 2 hours, continue to heat up to 700°C, keep it warm for 1 hour, take it out, cool it and put it in a desiccator spare;

[0055] (2) Collect the monosodium glutamate fermentation tail liquid discharged from a certain factory, adjust the pH value to 8, concentrate, and when the volume is reduced to a solid content of 60%, then adopt the centrifugal spray drying method to produce dry solid powder with a particle size of 30 The target particles are ready for use;

[0056] (3) Collect chicken manure from a chicken farm, sprinkle 0.5% urea and 2% superphosphate into compost, and use a stick to make air holes in the pile, cover with plastic cloth to keep warm and keep fertilizer, and turn the pile once after 10 days of composting , after 90 days of stacking and retting; then put the organic fertilizer on a sterile plastic film, sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com