Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Improve connection convenience" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

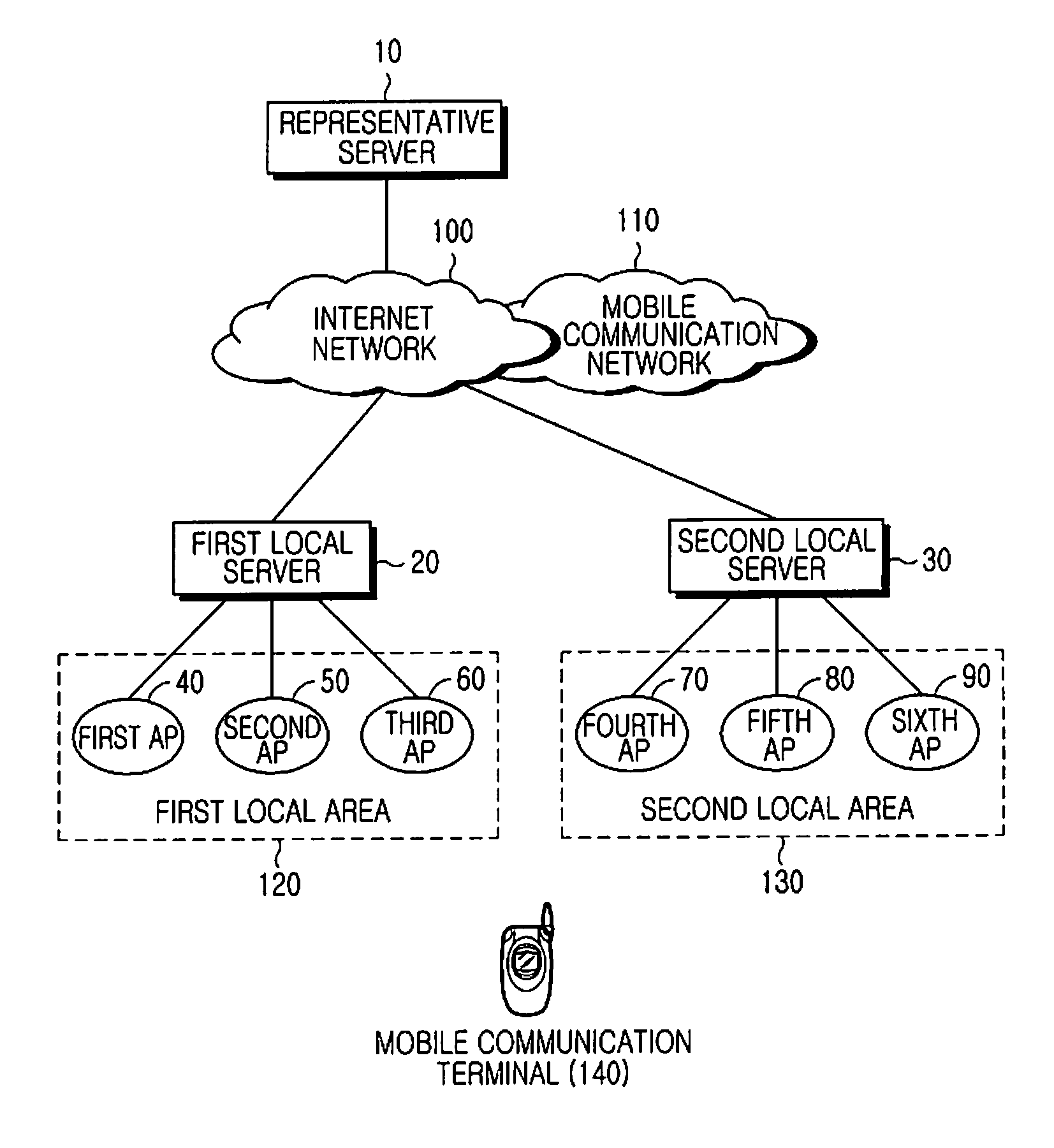

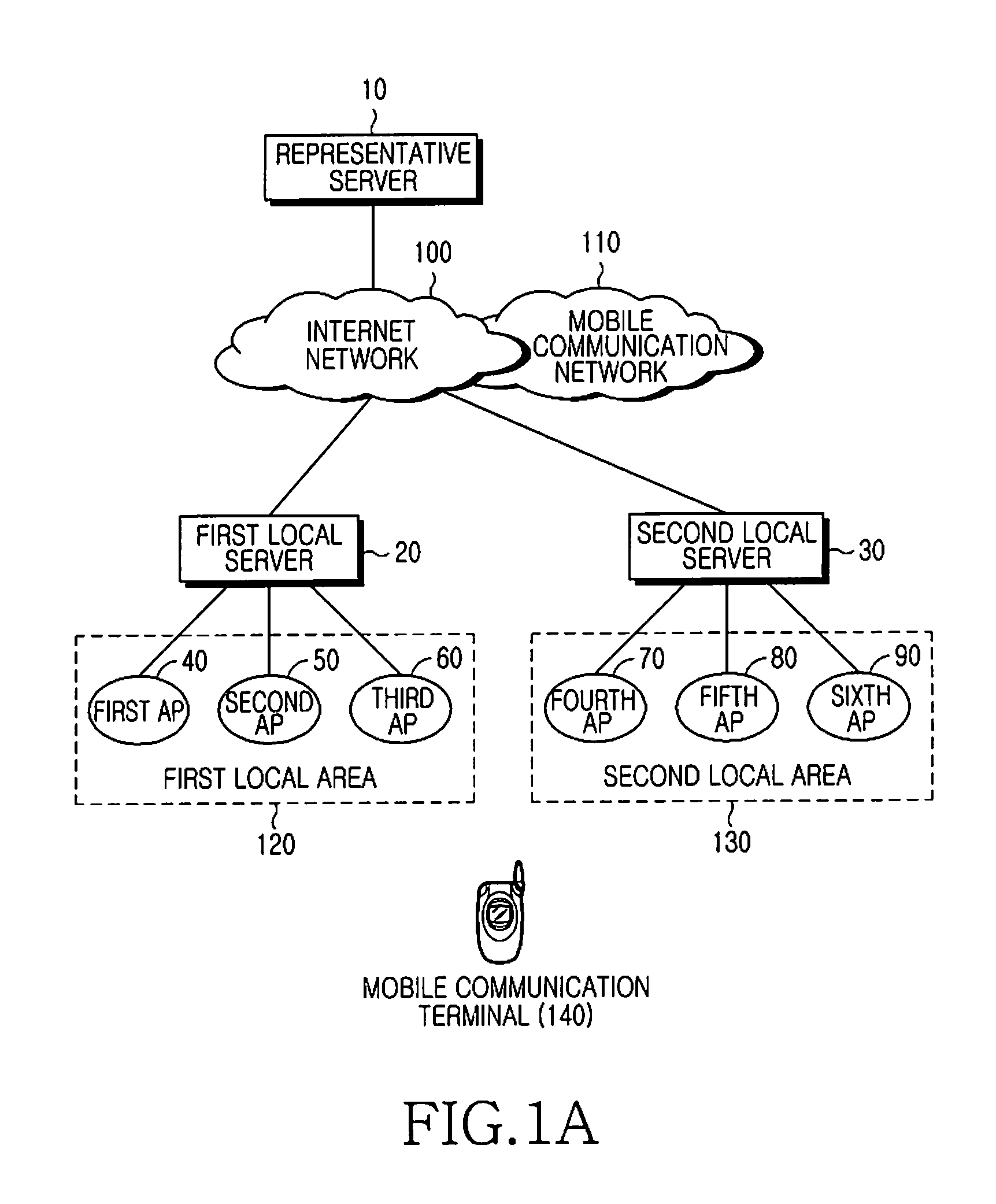

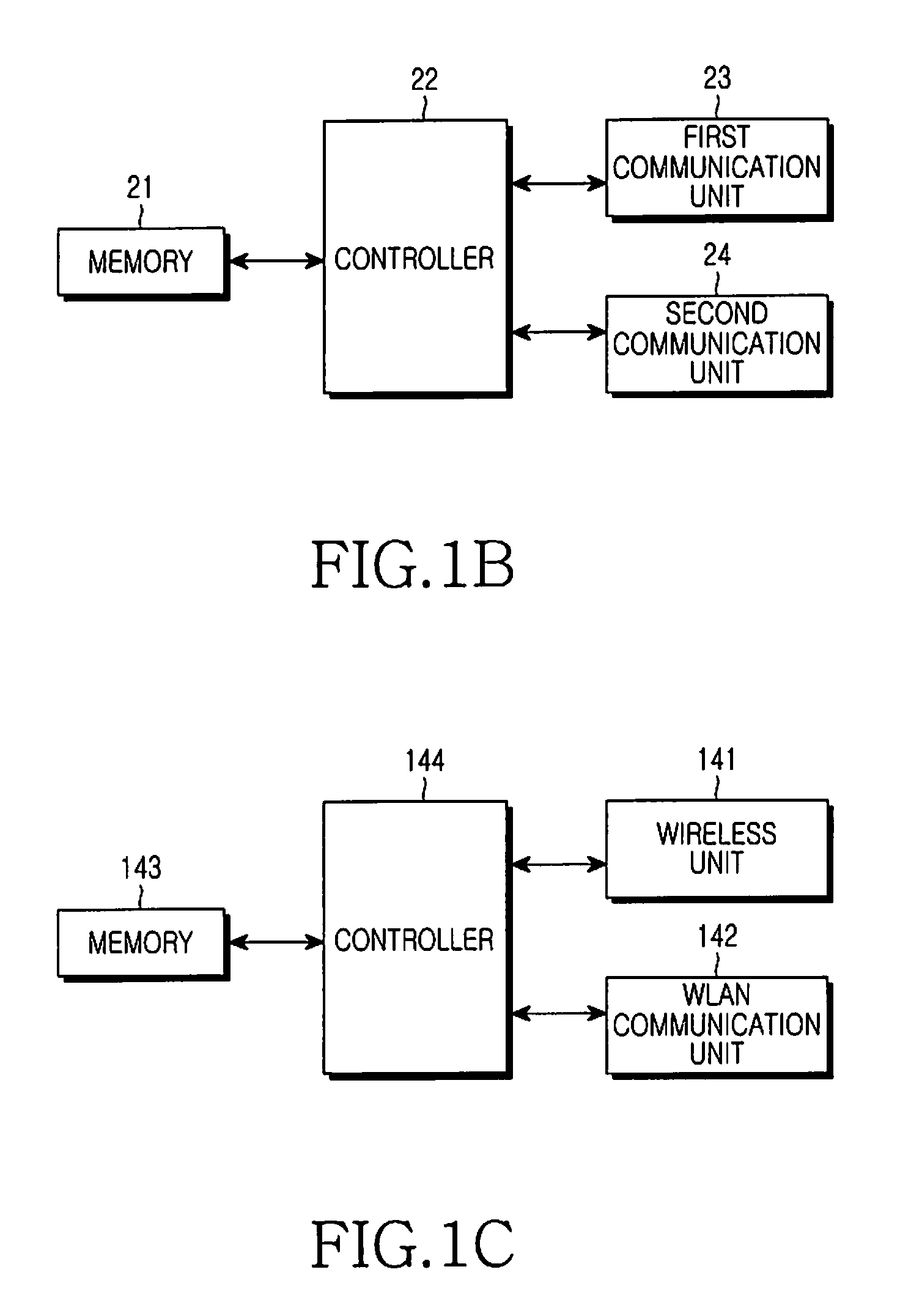

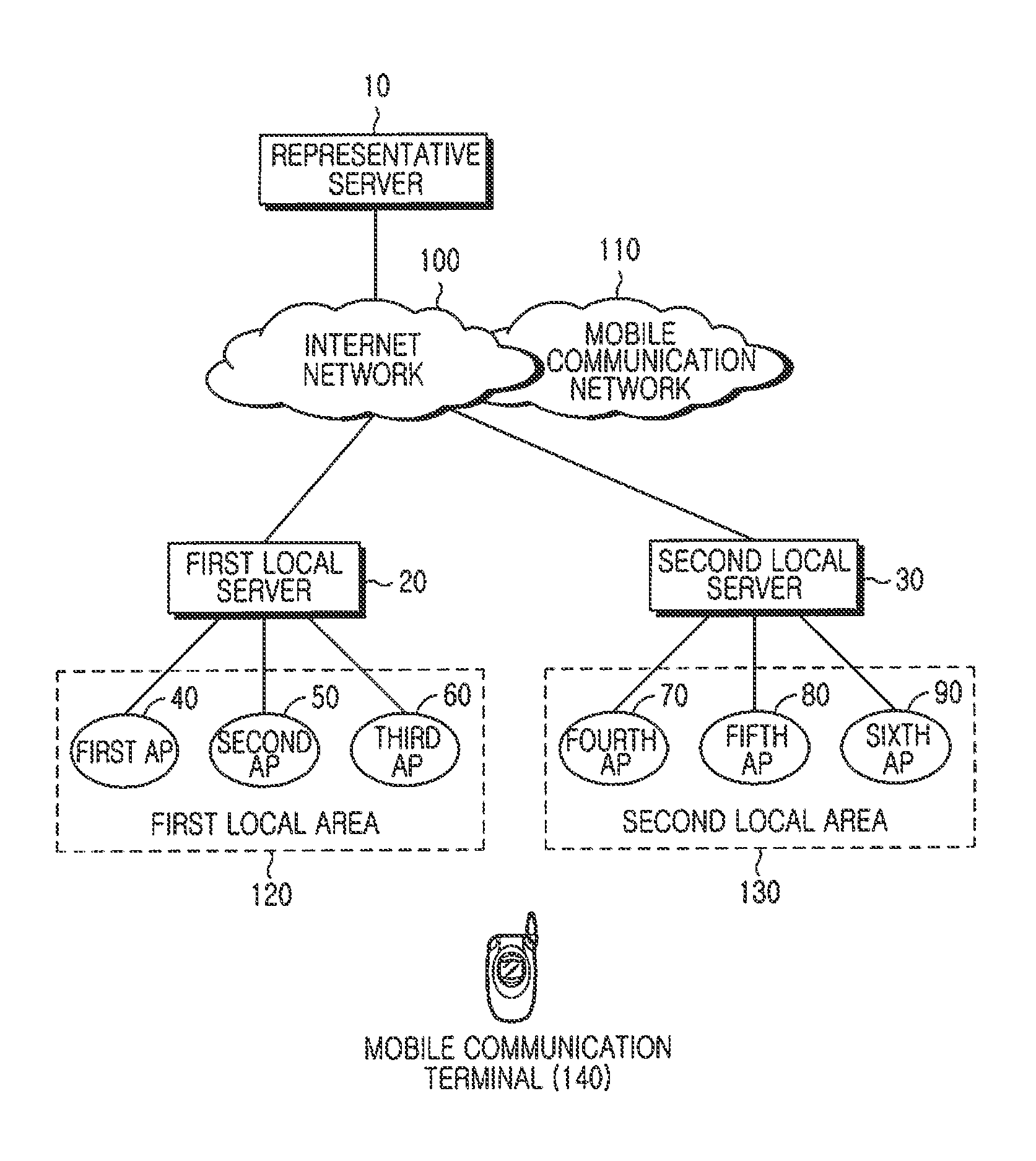

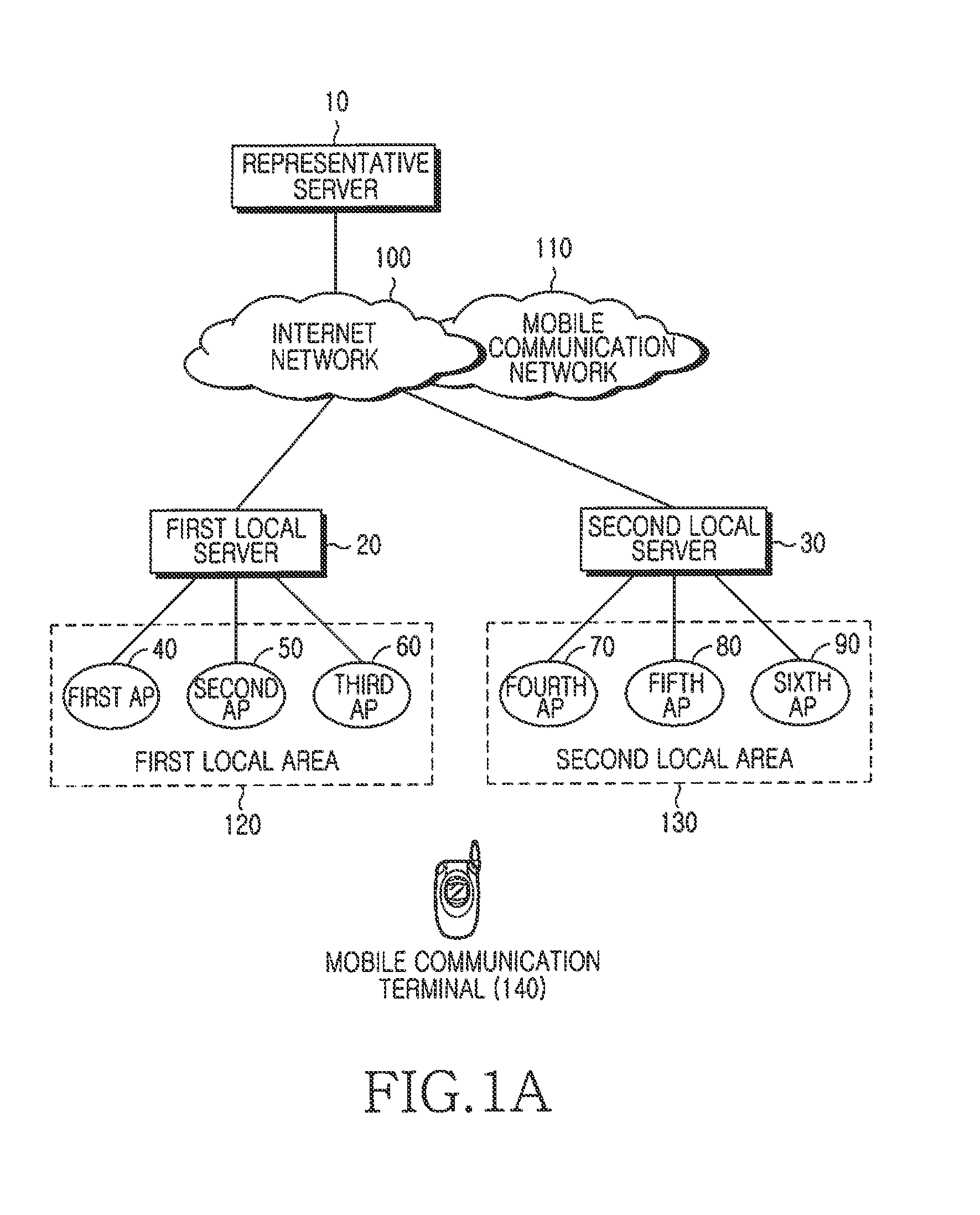

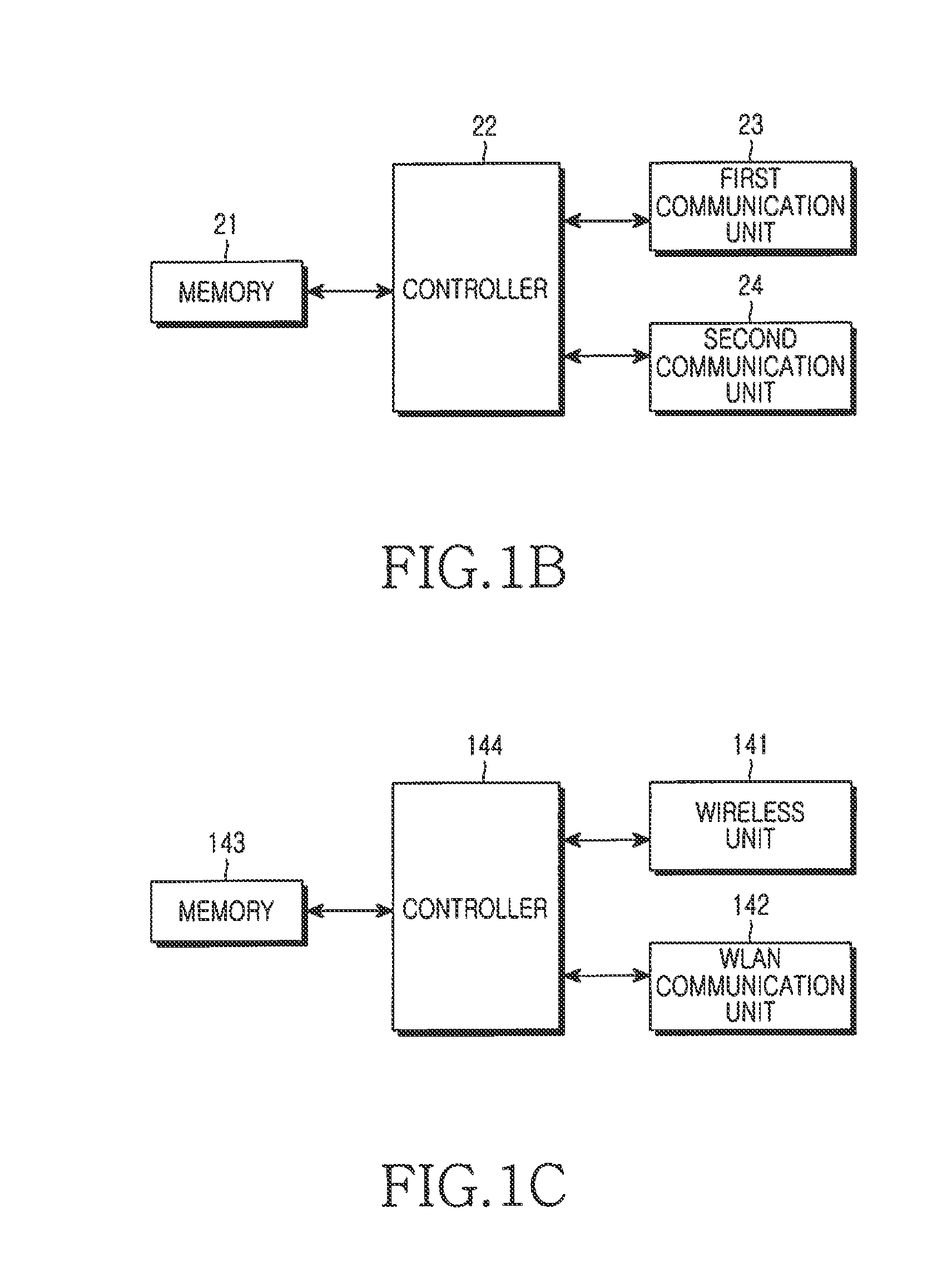

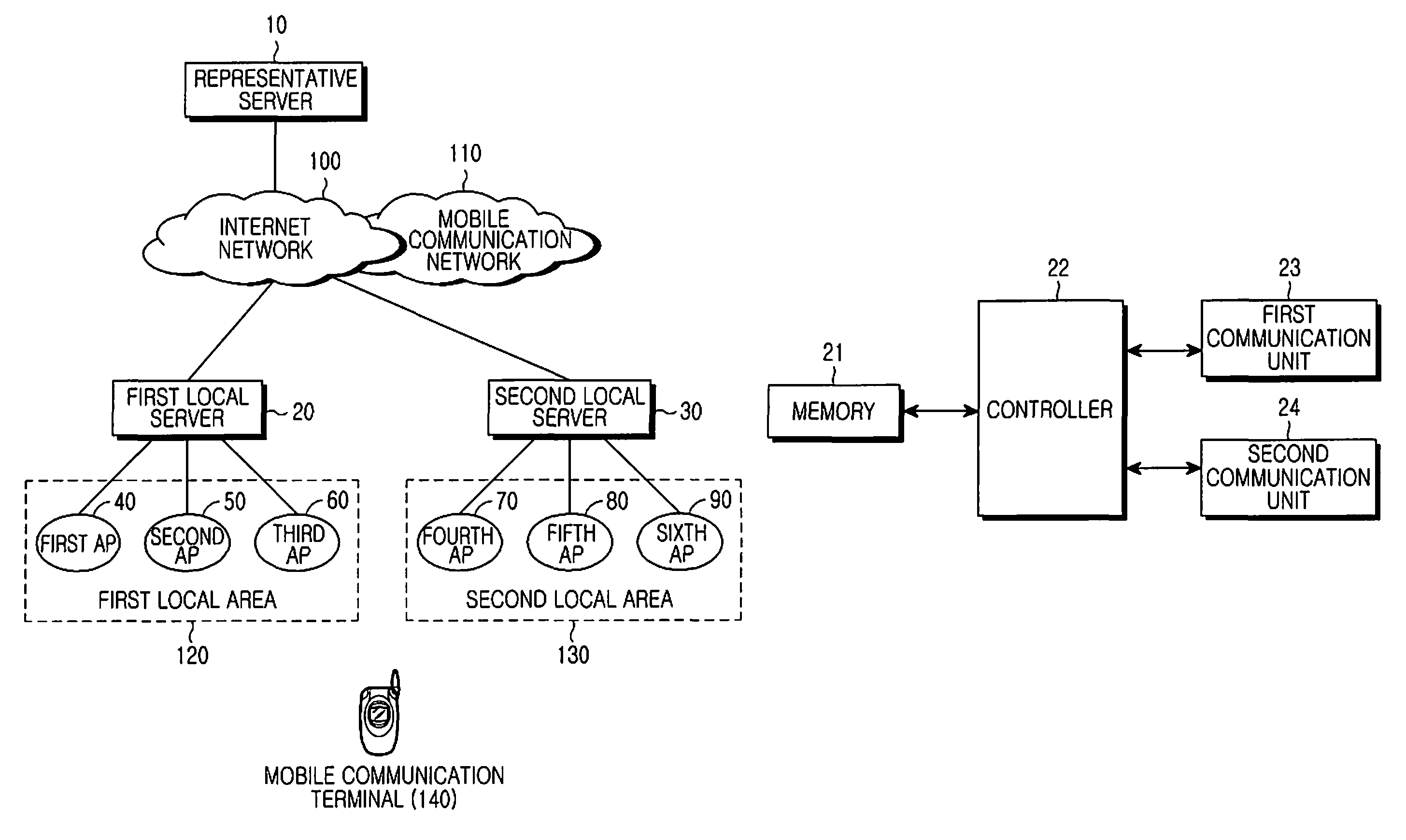

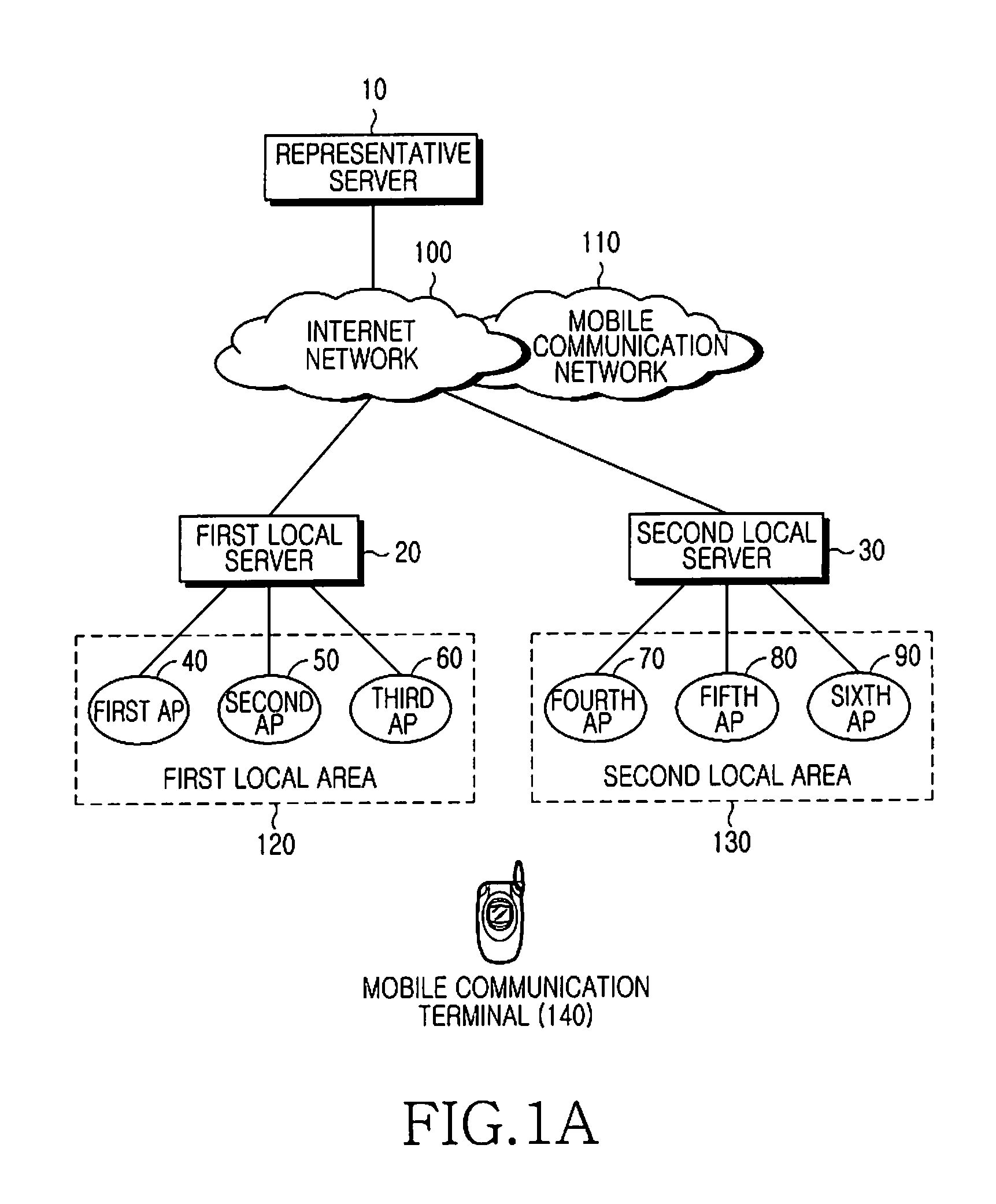

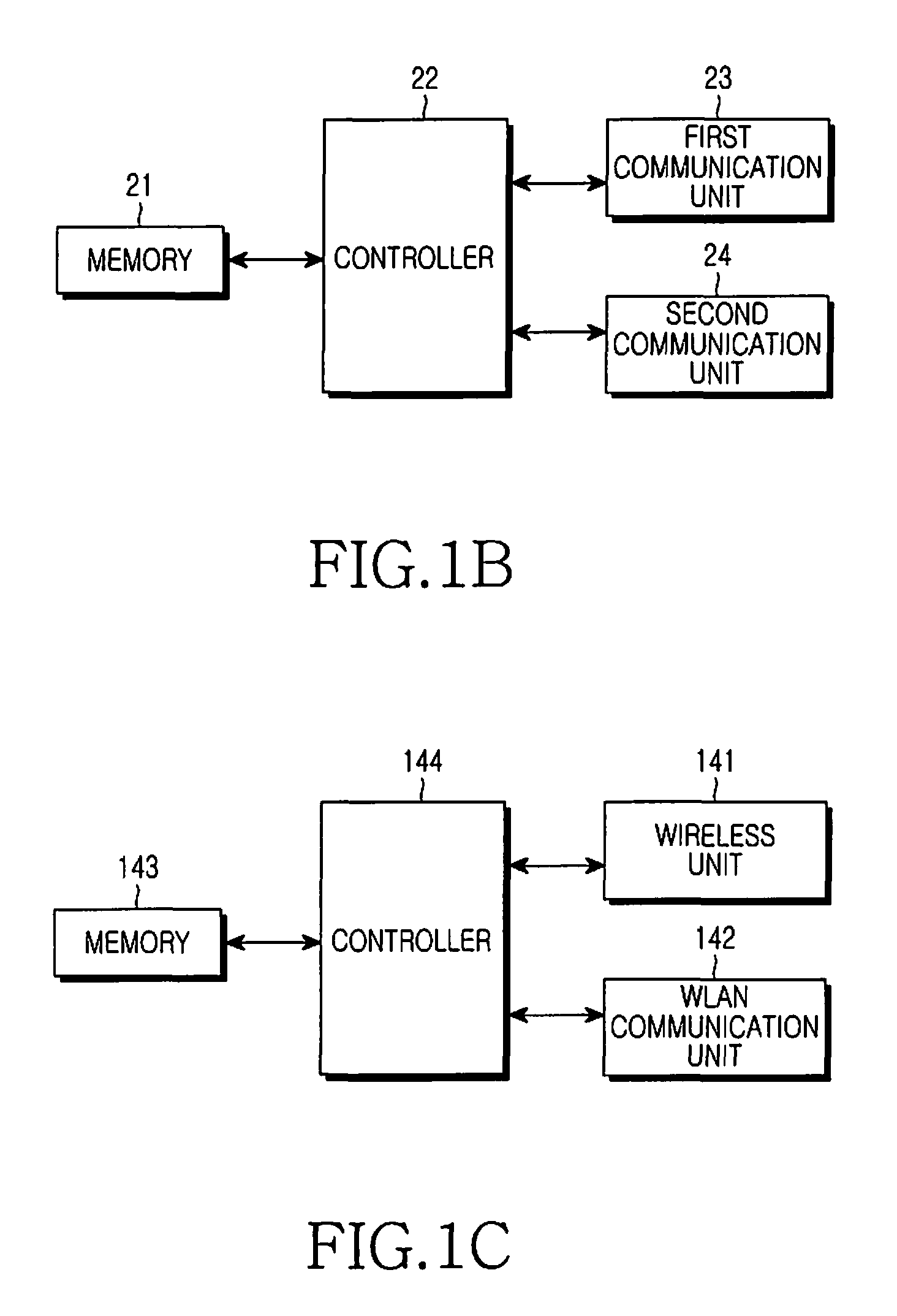

Method and system for connecting mobile communication terminal with access point

InactiveUS20100232409A1Improving connection convenienceImprove connection convenienceData switching by path configurationWireless network protocolsRogue access pointNetworked Transport of RTCM via Internet Protocol

Disclosed is a method for connecting a mobile communication terminal with an access point located in a local area providing a Wireless Local Area Network (WLAN) service in which a server managing the access point compares Media Access Control (MAC) information of the mobile communication terminal or MAC information of the access point transferred from the mobile communication terminal through a mobile communication network with MAC information previously stored in the server and transfers network setting information required for connection to the access point to the mobile communication terminal if the MAC information of the mobile communication terminal or access point is identical to the MAC information previously stored in the server.

Owner:SAMSUNG ELECTRONICS CO LTD

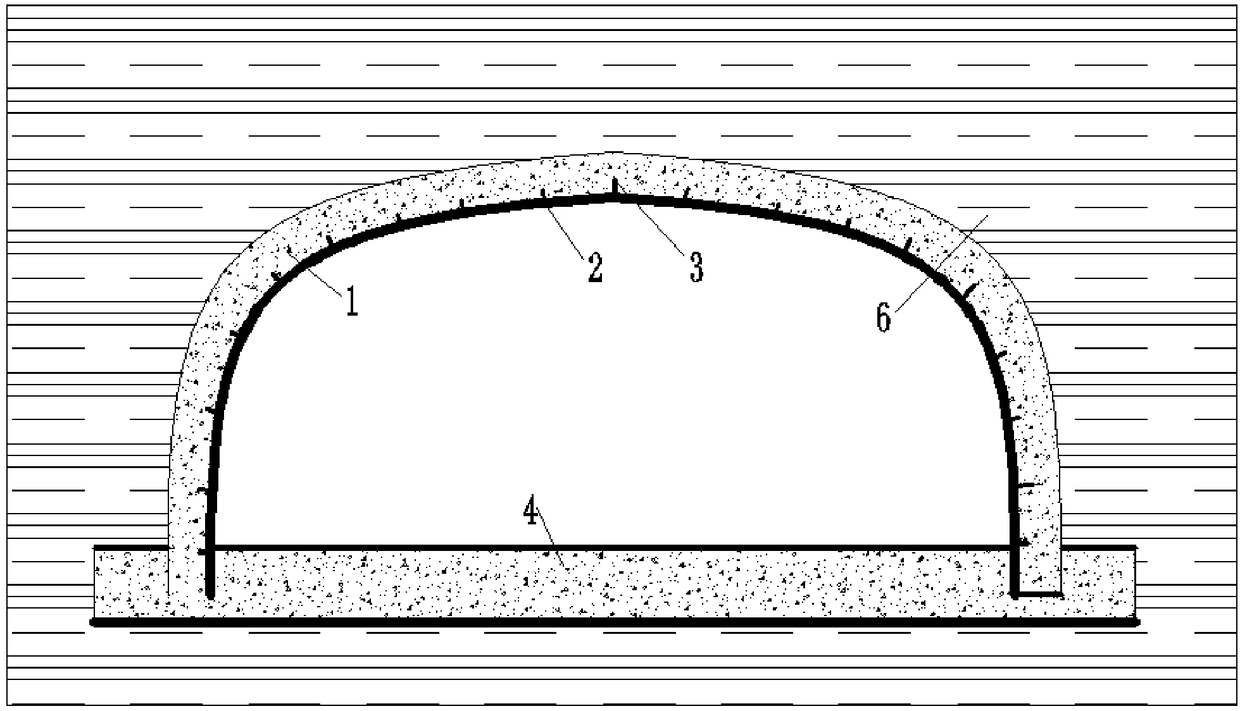

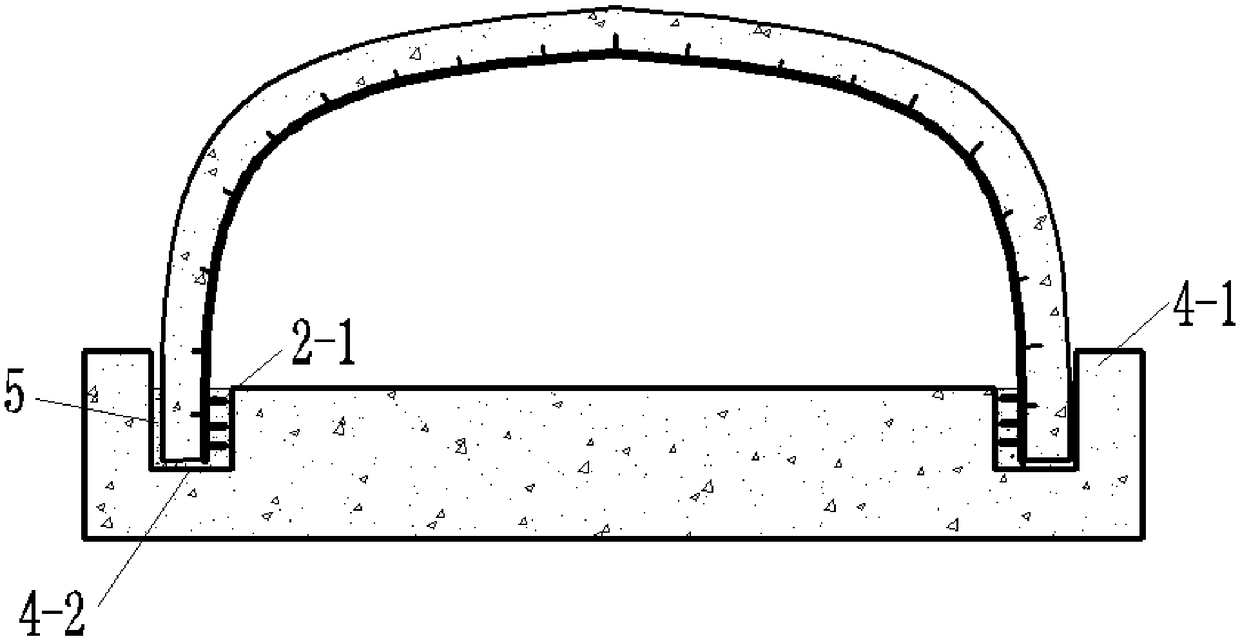

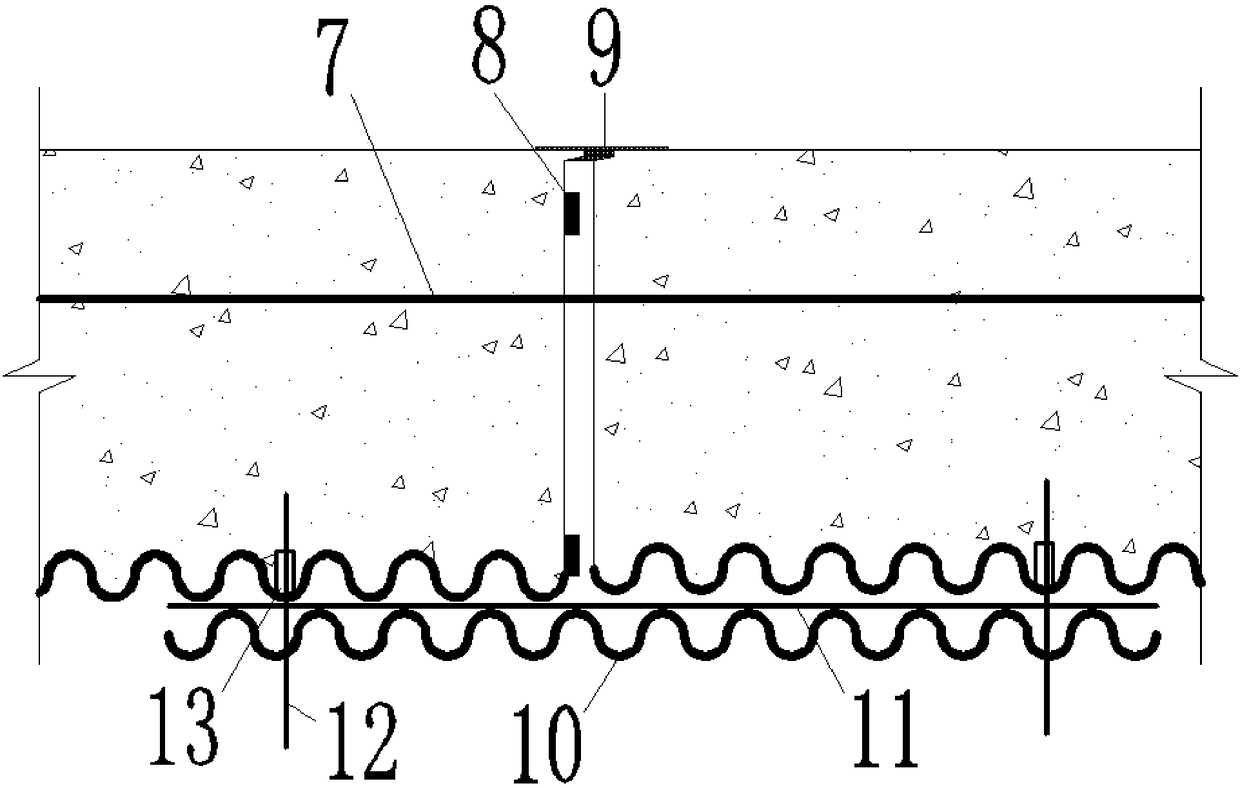

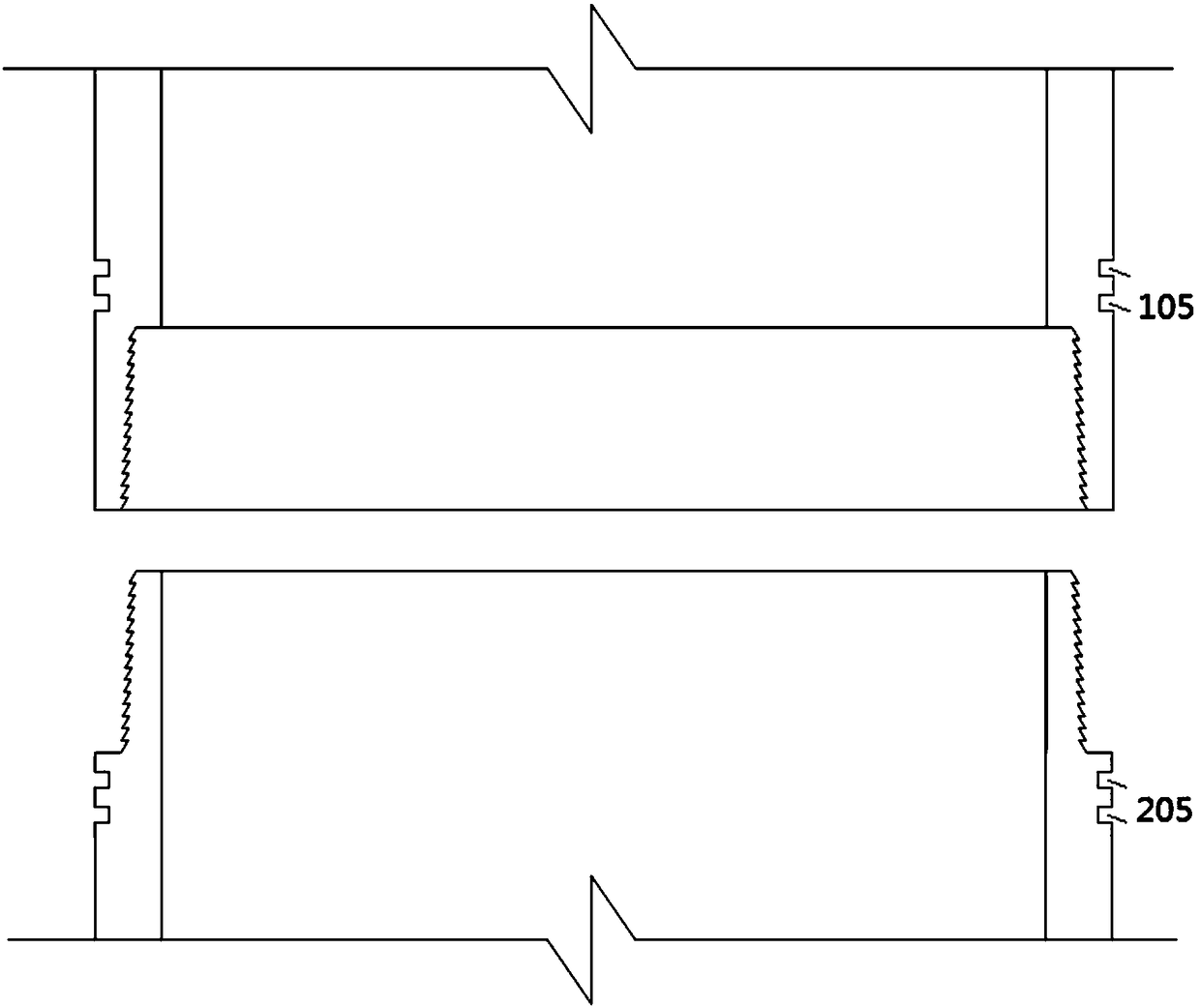

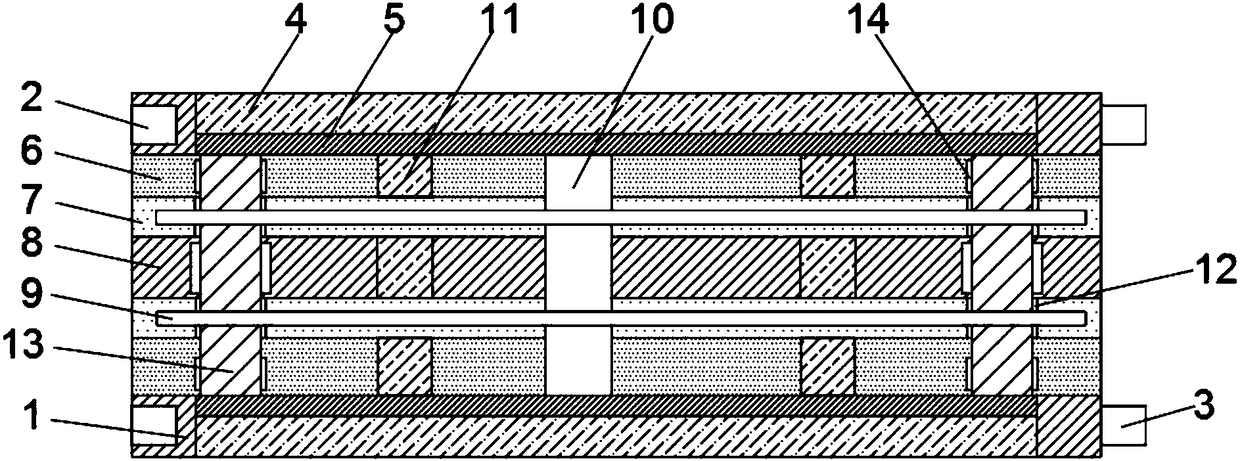

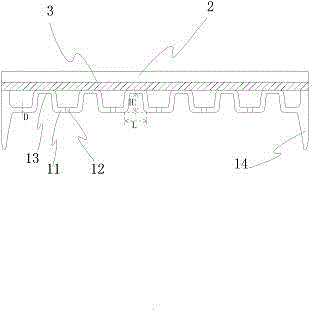

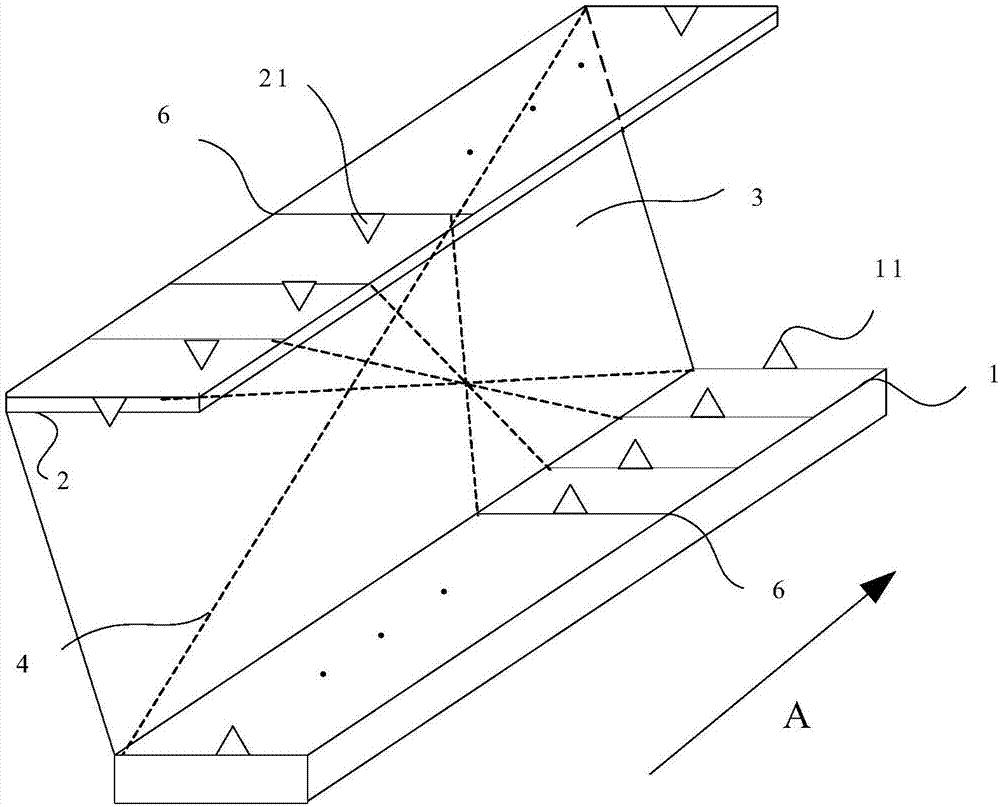

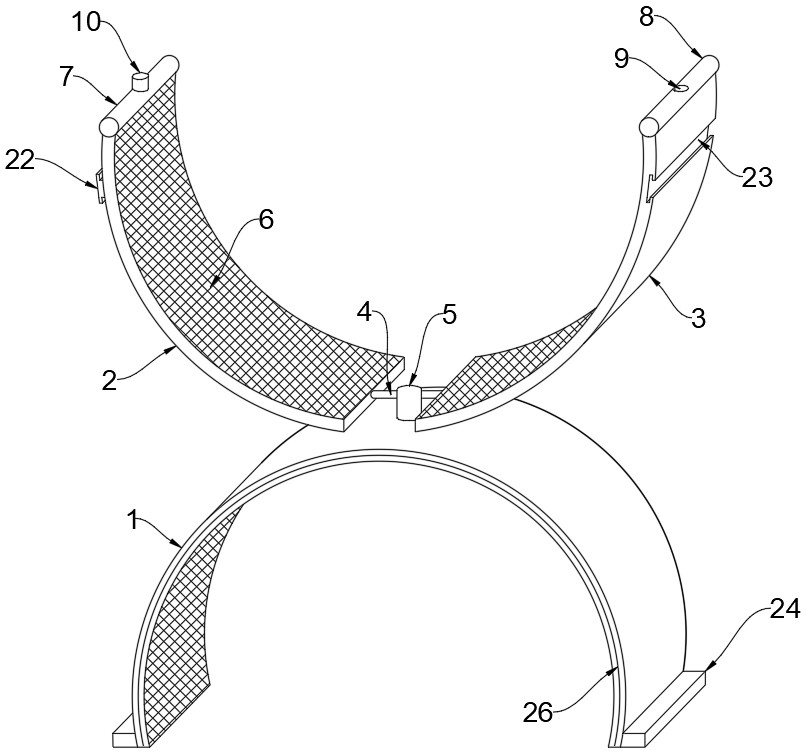

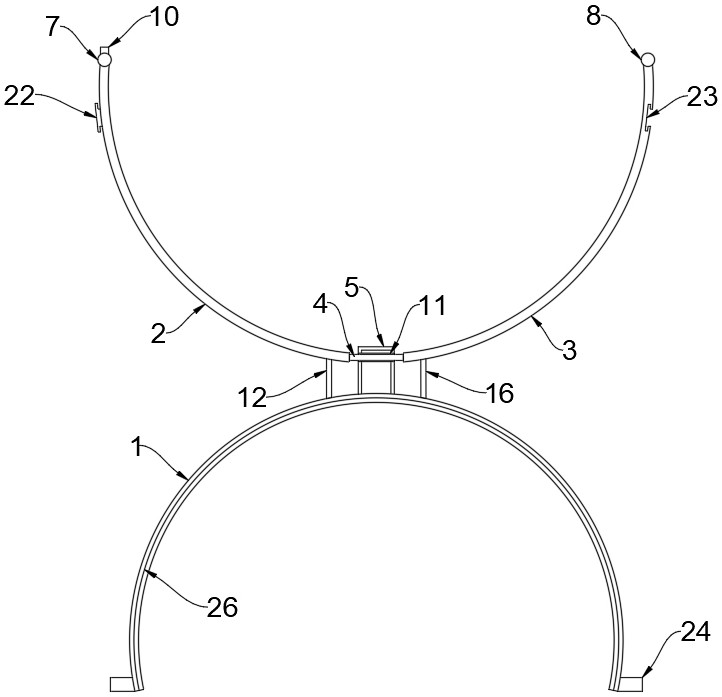

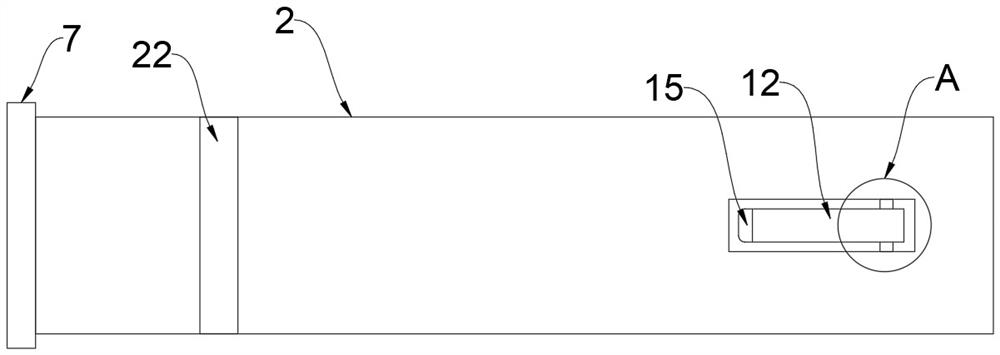

Corrugated steel outside lining concrete structure for underground utility tunnel

InactiveCN108468347AGuaranteed stabilityImprove leak resistanceArtificial islandsUnderwater structuresWater leakageReinforced concrete

The invention discloses a corrugated steel outside lining concrete structure for an underground utility tunnel and relates to underground utility tunnel structures. The problems that existing concretestructures are poor in foundation differential settlement resistance and seepage resistance, fracture and water leakage of connectors of prefabricated tunnels are liable to occur, and corrugated steel tunnel structures are inadequate in stable bearing capacity are solved. The corrugated steel outside lining concrete structure for the underground utility tunnel comprises an outer lining reinforcedconcrete ring, an arch corrugated steel plate and a bottom plate, wherein the outside lining concrete ring covers the outer plate face of the arch corrugated steel plate to form an arch; cup openinggrooves are formed in the transverse left side and the transverse right side of the bottom plate correspondingly; studs are arranged at arch springs of the arch corrugated steel plate; the arc springsare inserted into the cup opening grooves; post-cast arc spring concrete is arranged in the cup opening grooves; and the periphery of the arch and the bottom plate is wrapped with surrounding soil. The corrugated steel outside lining concrete structure is higher in construction speed, and the seepage resistance, the foundation differential settlement resistance and prefabricated section connection convenience of the structure are greatly improved.

Owner:HARBIN INST OF TECH

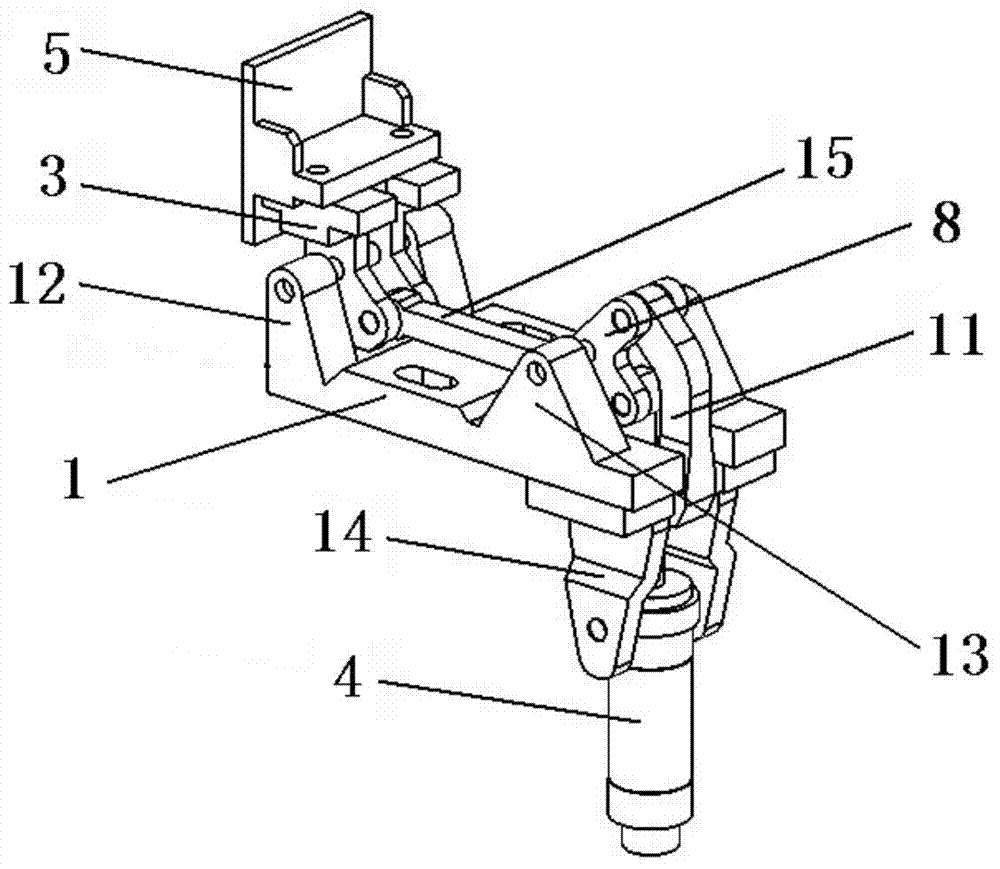

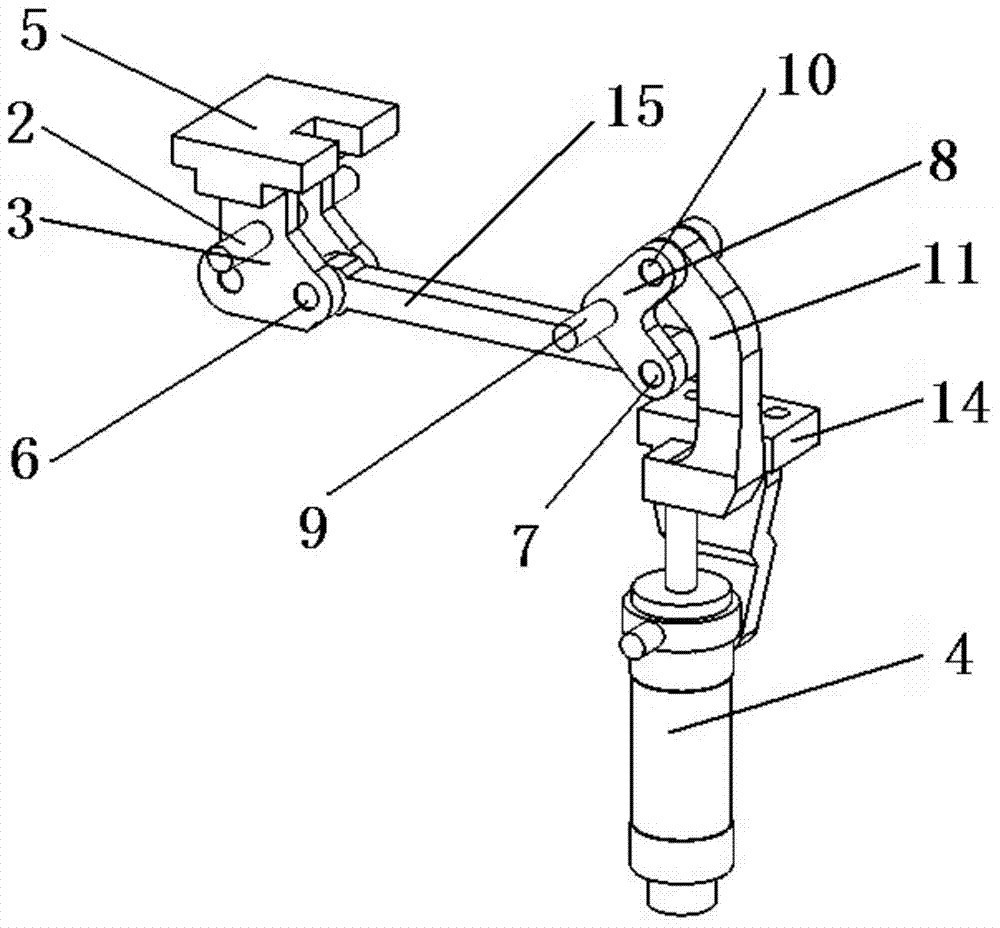

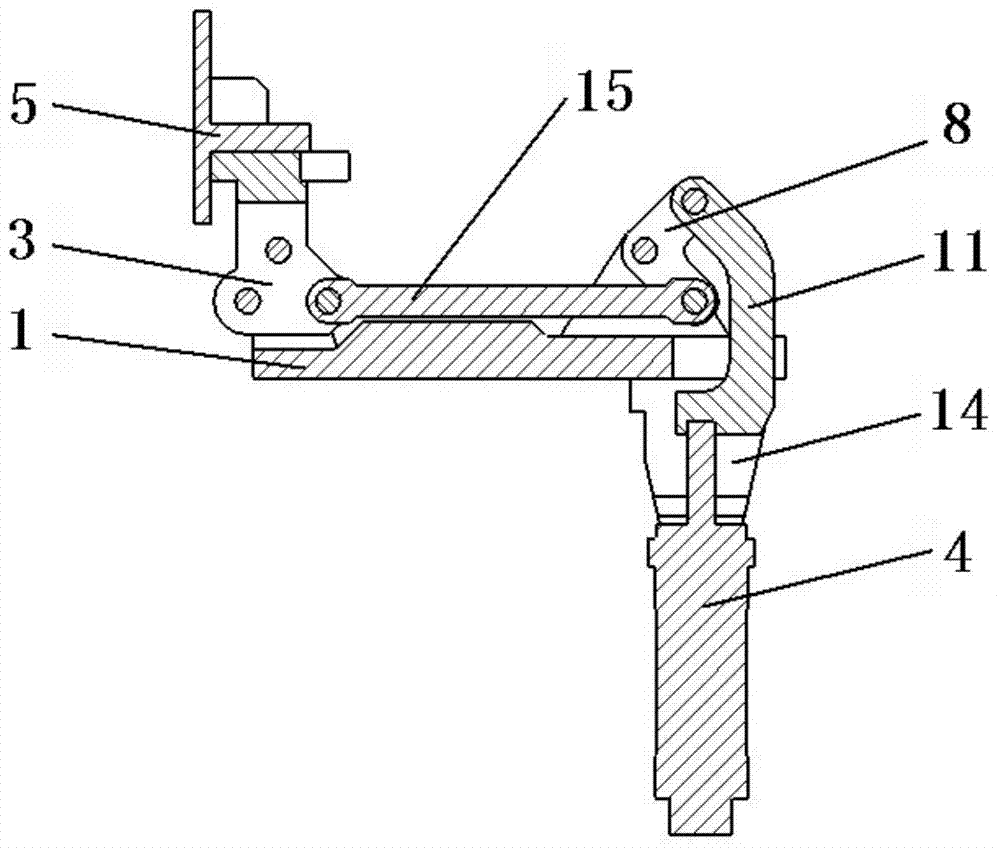

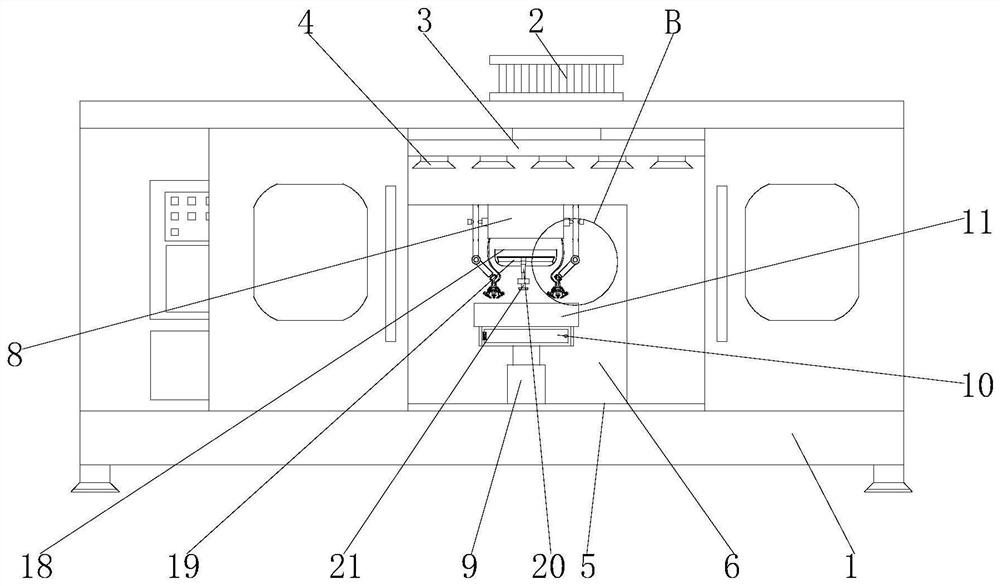

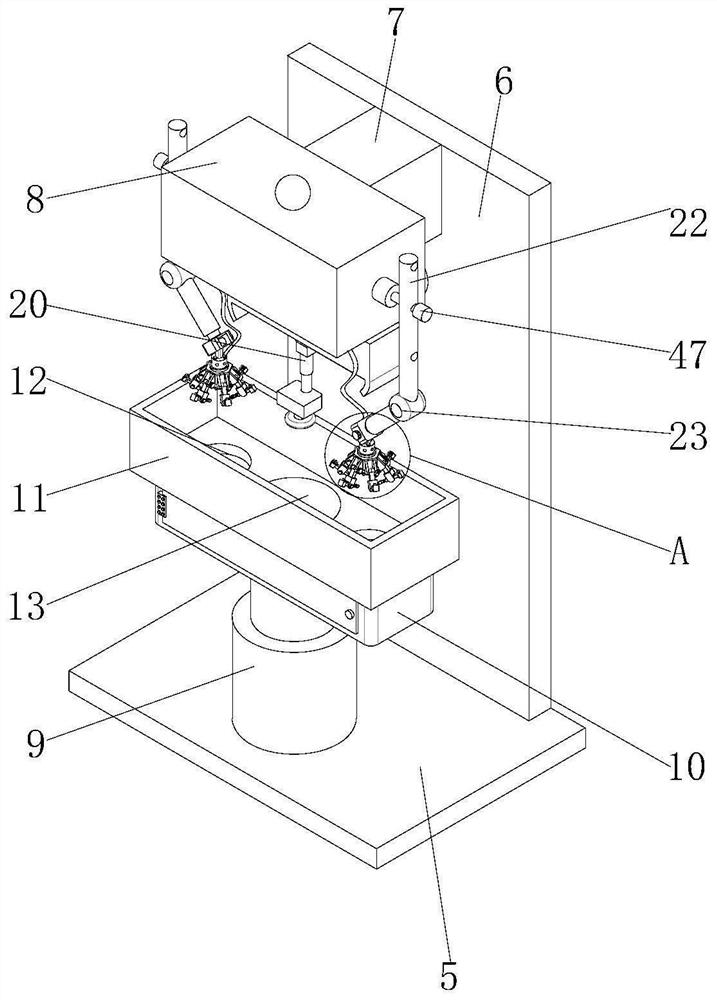

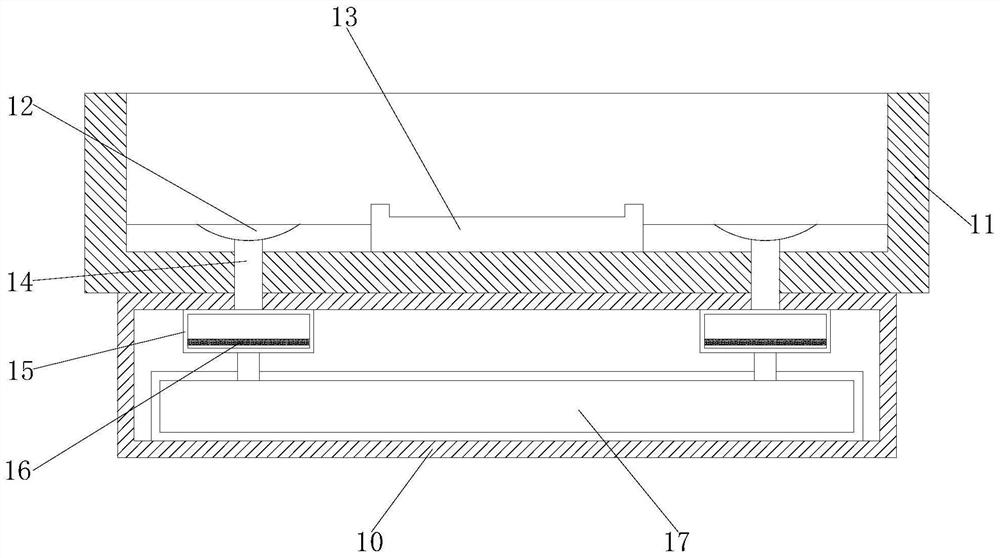

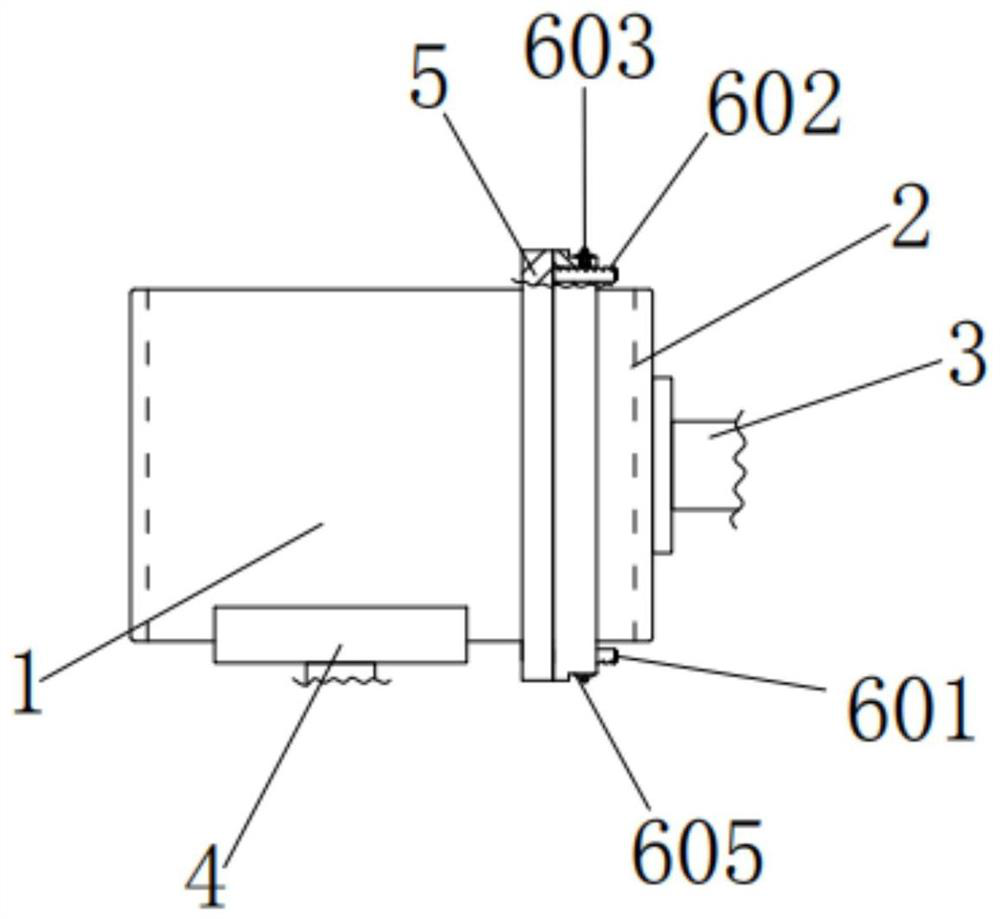

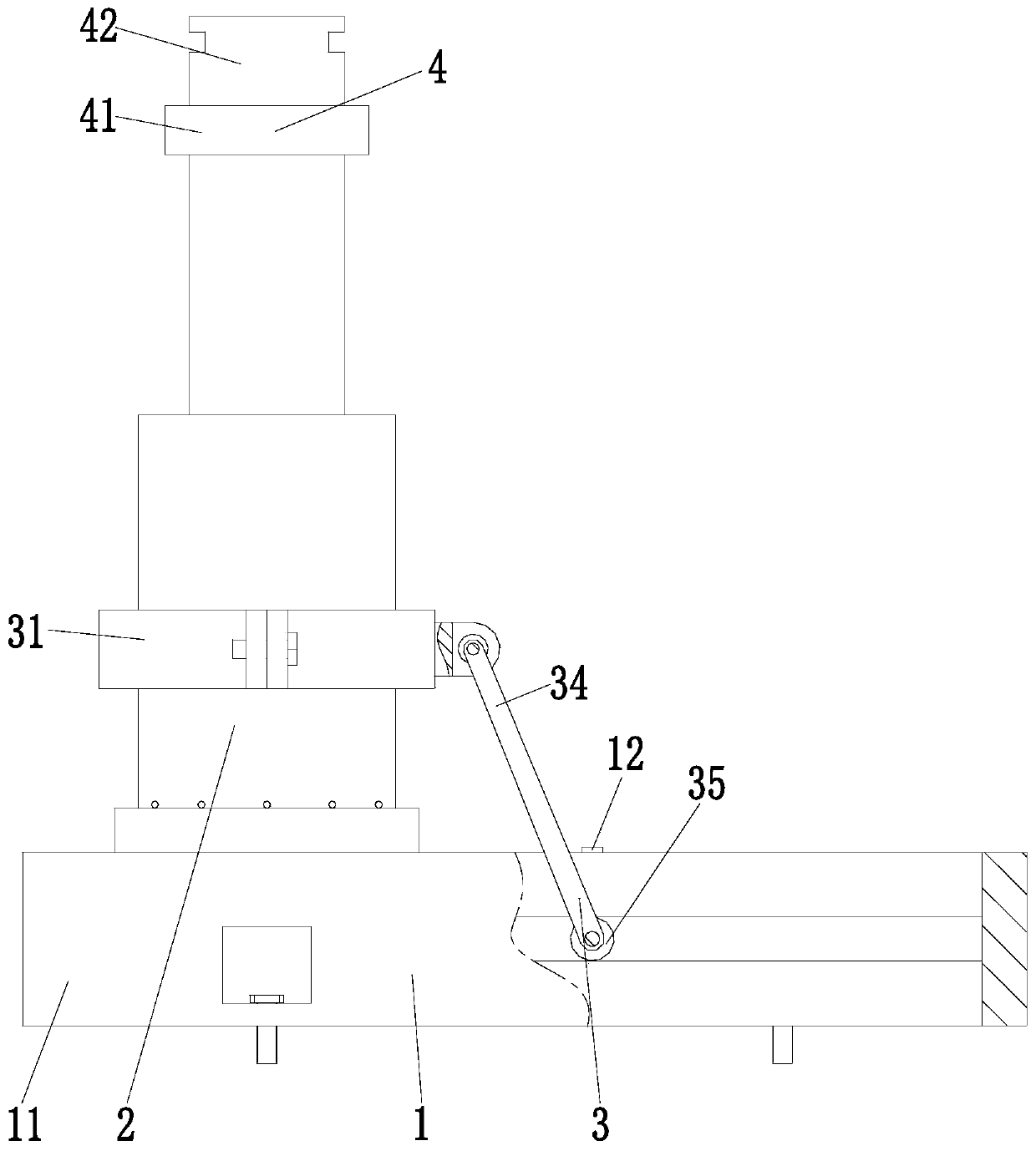

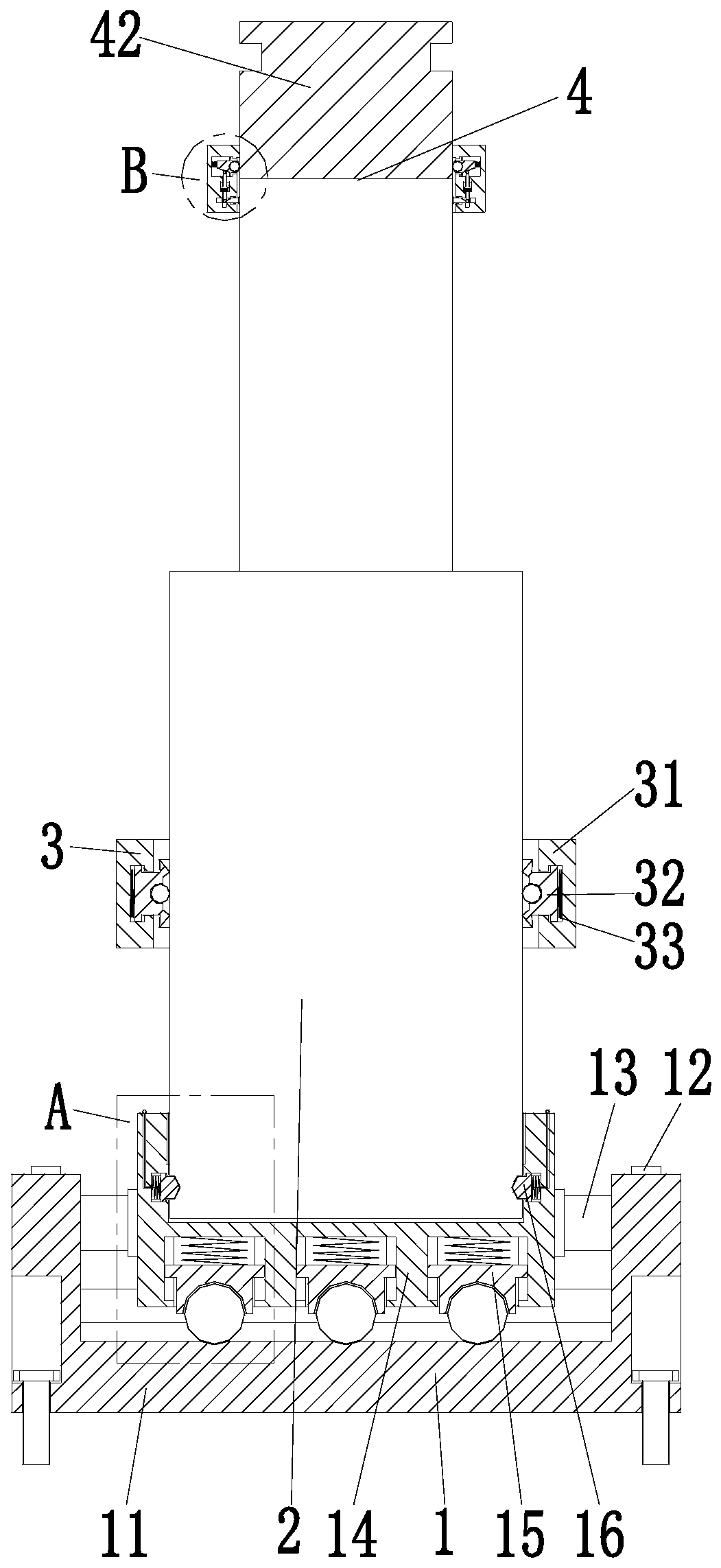

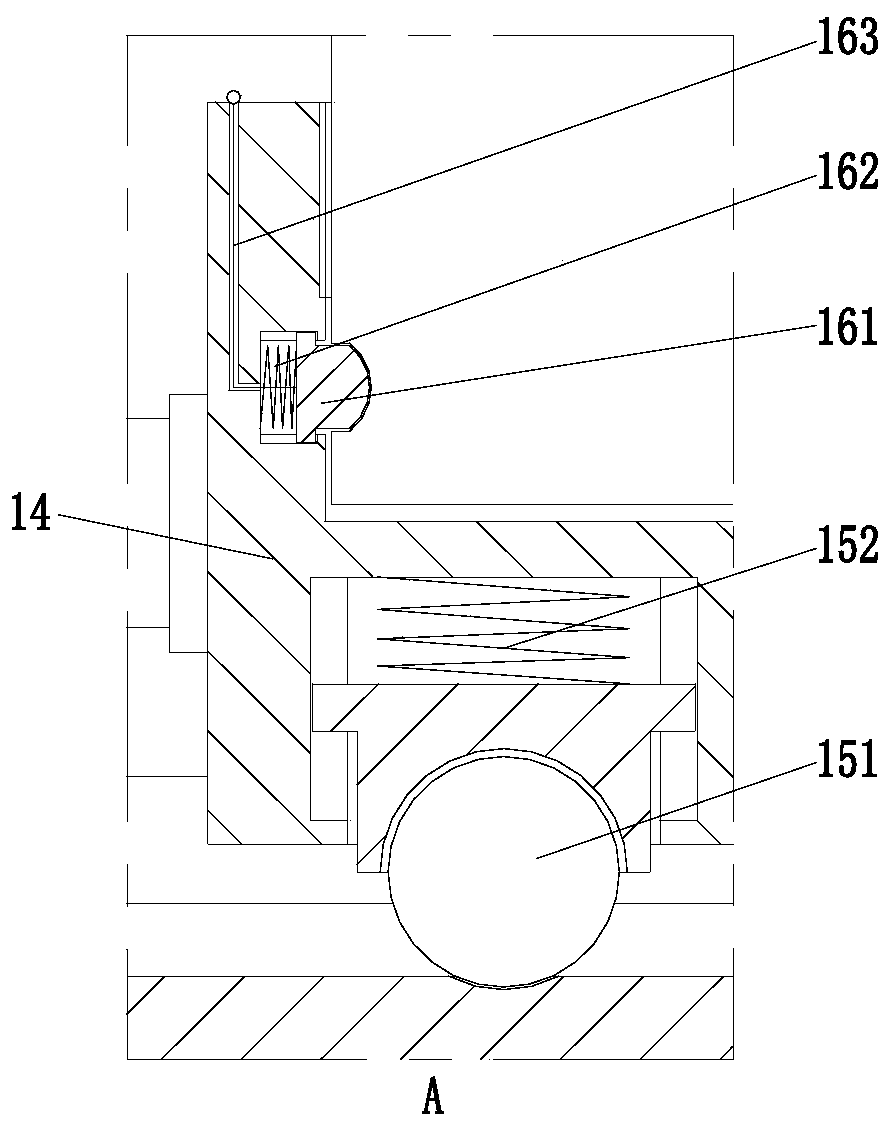

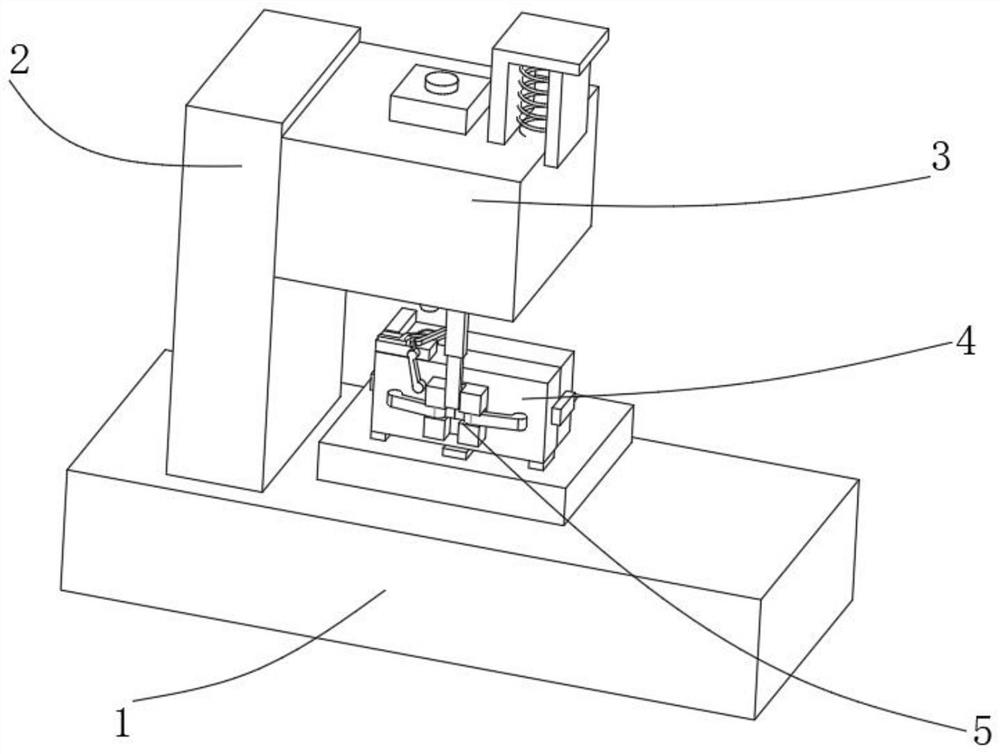

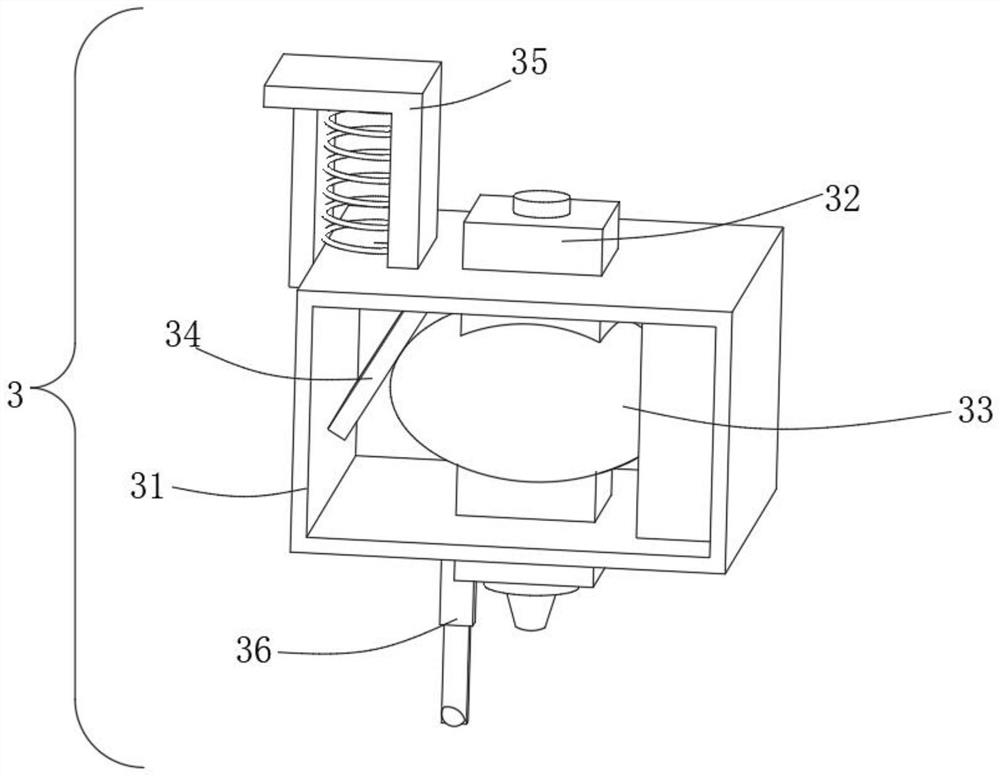

Punch line and material pushing and positioning device thereof

ActiveCN104722669AImprove efficiencyReduce labor intensityMetal-working feeding devicesPositioning devicesTelescopic cylinderManufacturing line

The invention discloses a punch line and a material pushing and positioning device thereof. The material pushing and positioning device comprises an installation seat, a material pushing seat, a material pushing plate, a straight connecting rod, a bent connecting rod, a telescopic cylinder connecting rod and a telescopic cylinder, wherein one end of the installation seat is rotationally connected with the material pushing seat, and the other end of the installation seat is connected with a fixed part of the telescopic cylinder; the material pushing plate in butt joint with a blank is installed at the upper end of the material pushing seat, the lower end of the material pushing seat is rotationally connected with a first end of the straight connecting rod, and a second end of the straight connecting rod is rotationally connected with the lower end of the bent connecting rod; the corner of the bent connecting rod is rotationally connected with the installation seat, the upper end of the bent connecting rod is rotationally connected with the upper end of the telescopic cylinder connecting rod, and the lower end of the telescopic cylinder connecting rod is fixedly connected with a telescopic part of the telescopic cylinder; all rotary shafts are parallel. In this way, the material pushing and positioning device can realize automatic feeding and positioning of blank materials, thereby improving the efficiency of punching production and the automation degree of the punch line, relieving the labor intensity of workers, and guaranteeing the production safety of workers.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

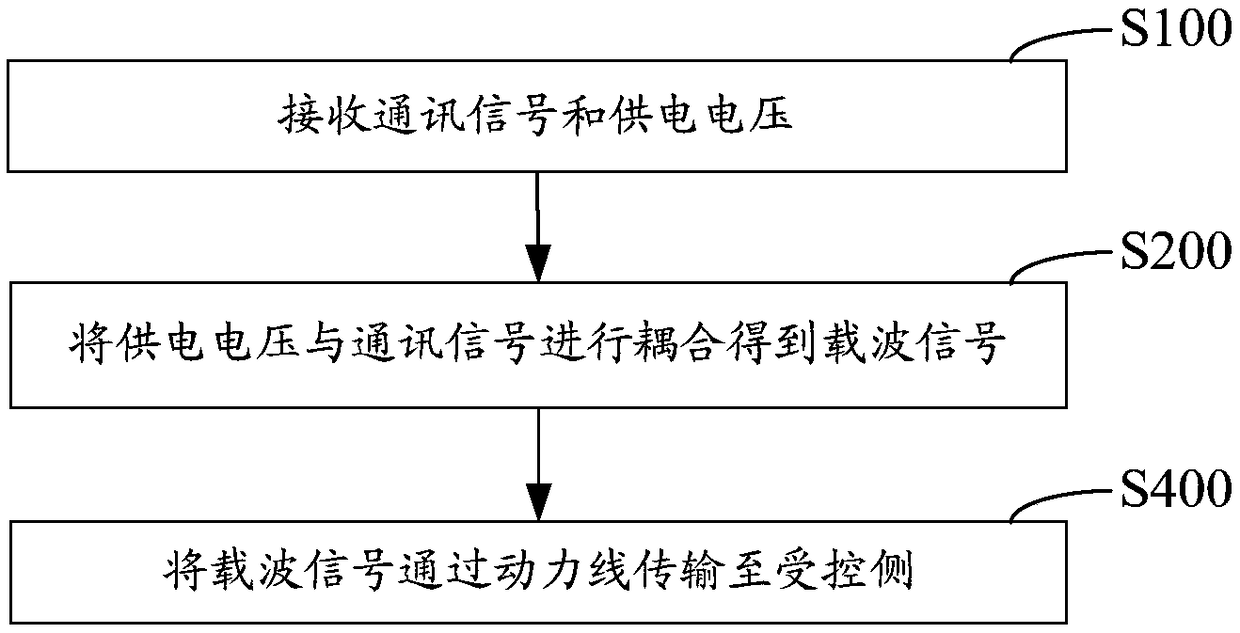

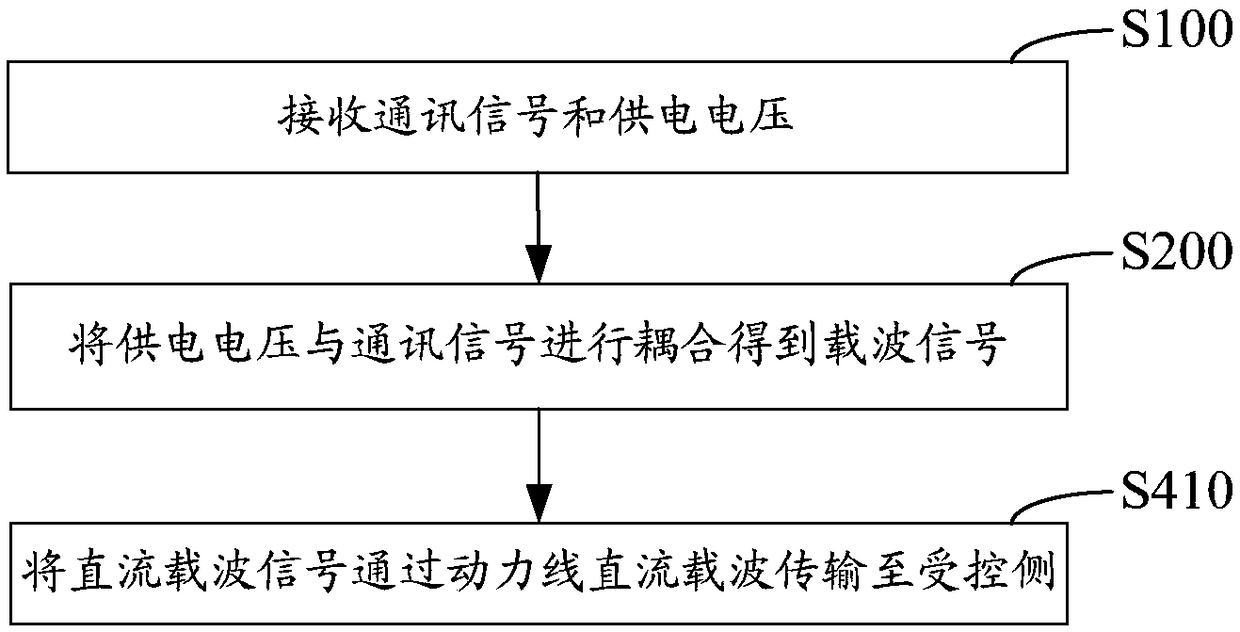

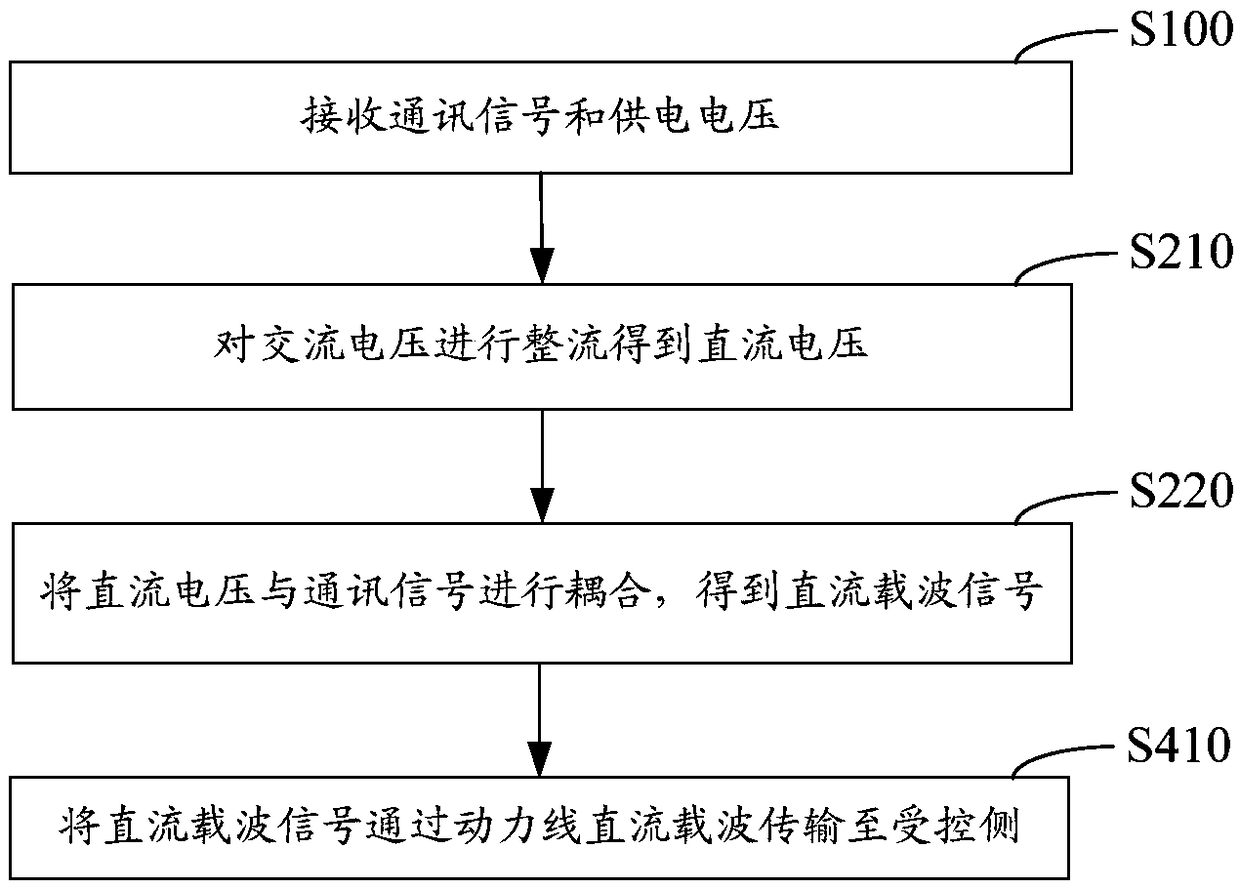

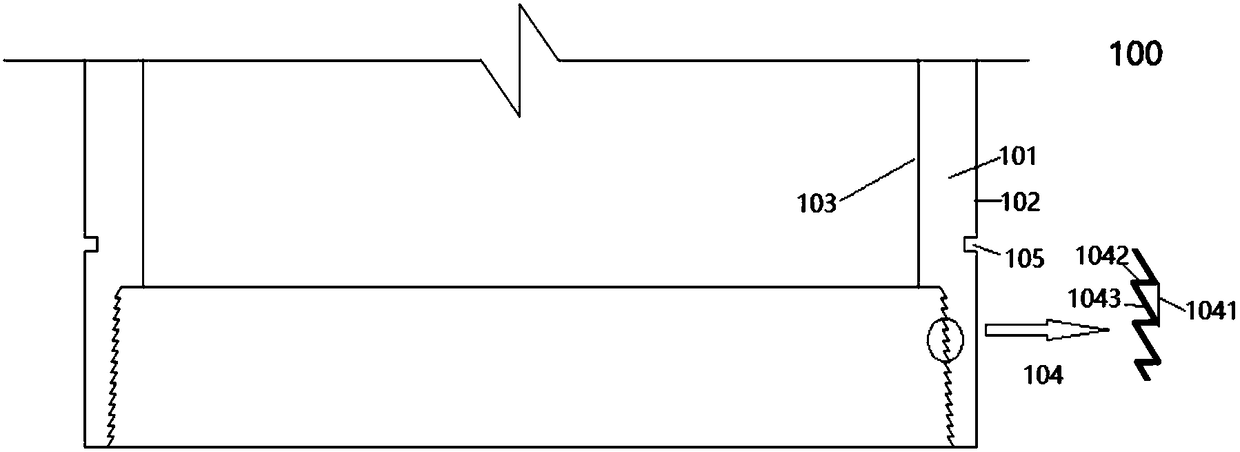

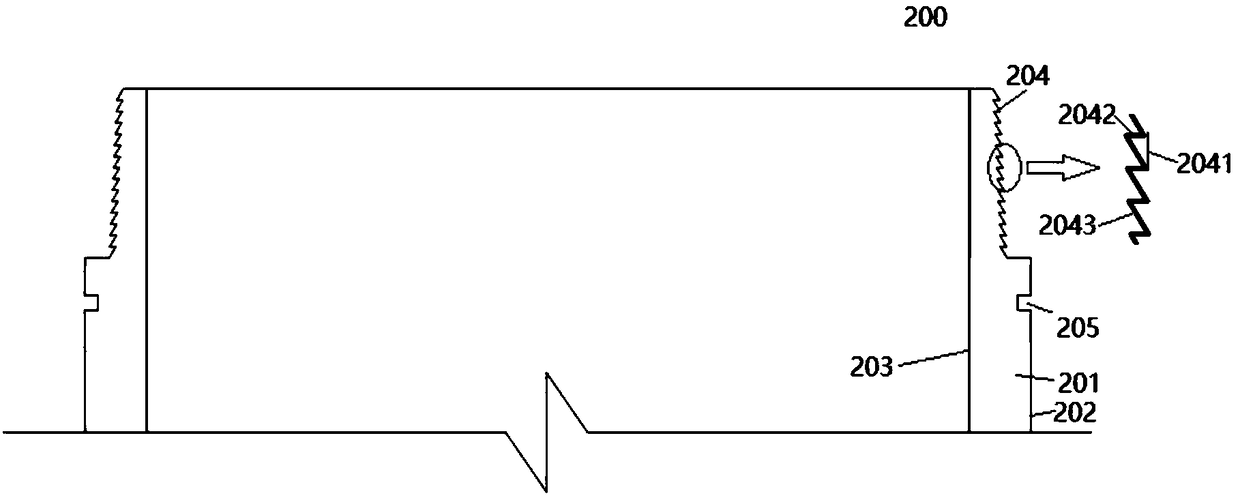

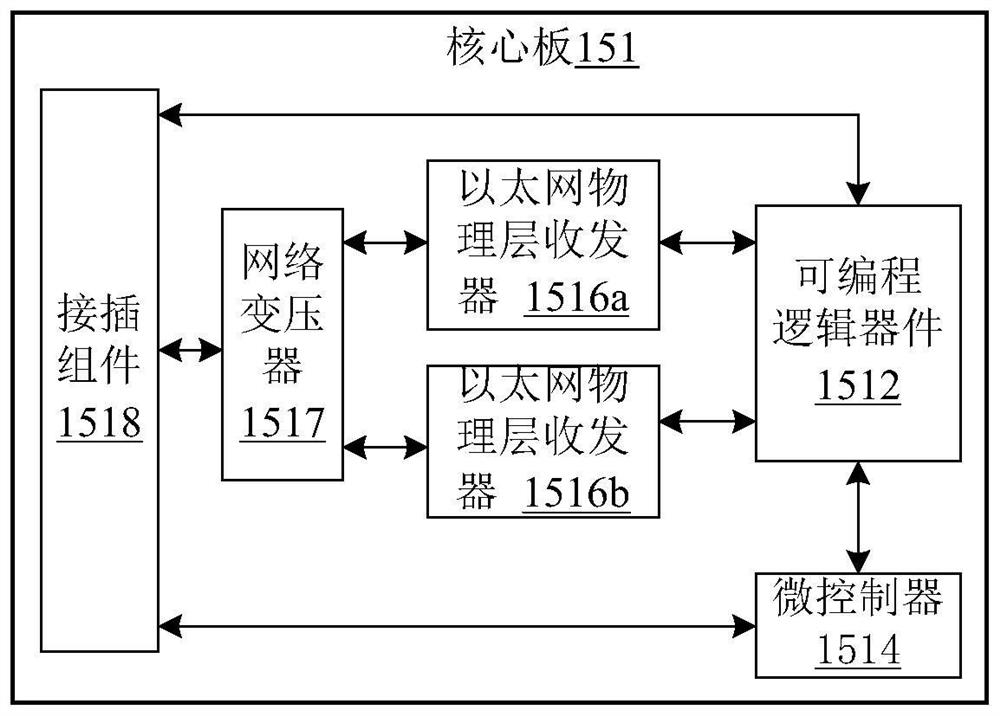

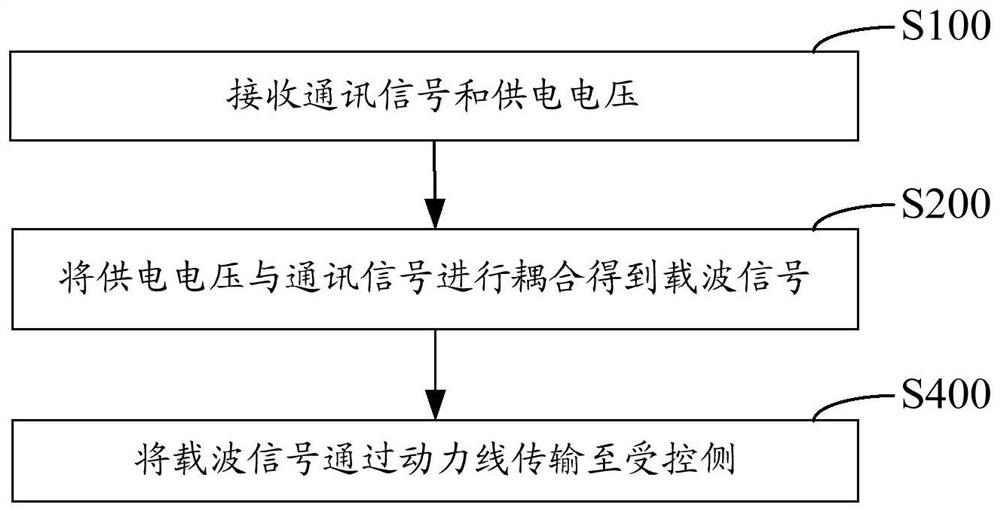

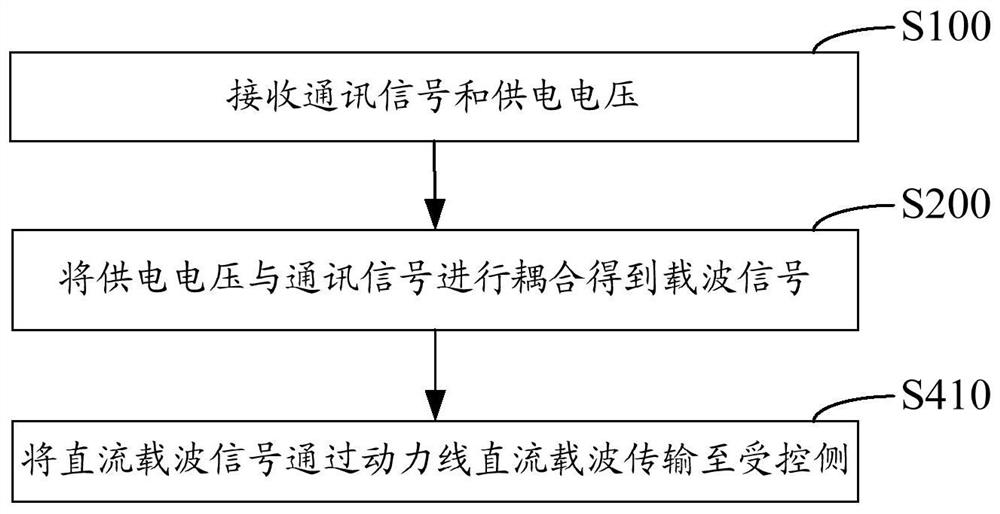

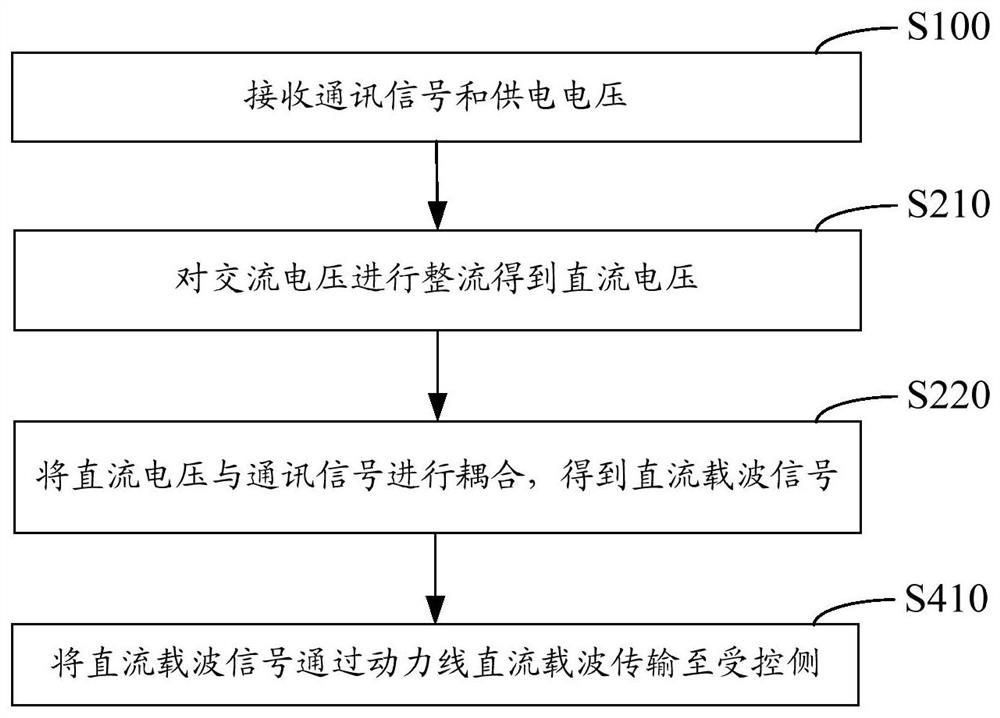

Power line signal transmission method and device and transmission electric equipment

ActiveCN108964706AReduce in quantityReduce connection complexityPower distribution line transmissionCarrier signalEngineering

The invention relates to a power line signal transmission method and device and transmission electric equipment. The method comprises the following steps: receiving a communication signal and power supply voltage; coupling the power supply voltage and the communication signal so as to obtain a carrier signal; and transmitting the carrier signal to the controlled side through the power line. The power supply voltage and the communication signal of the control side are coupled to obtain the carrier signal and then the carrier signal is transmitted to the controlled side through the power line carrier so that power line carrier transmission can be realized, the communication line and the power line can be integrated, the number of connection lines between the control side and the controlled side can be reduced, the connection complexity can be reduced and the connection convenience between the control side and the controlled side can be improved.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

Method and system for connecting mobile communication terminal with access point

ActiveUS20140082698A1Improve connection convenienceDigital data processing detailsData switching by path configurationWireless lanMedia access control

Disclosed is a method for connecting a mobile communication terminal with an access point located in a local area providing a Wireless Local Area Network (WLAN) service in which a server managing the access point compares Media Access Control (MAC) information of the mobile communication terminal or MAC information of the access point transferred from the mobile communication terminal through a mobile communication network with MAC information previously stored in the server and transfers network setting information required for connection to the access point to the mobile communication terminal if the MAC information of the mobile communication terminal or access point is identical to the MAC information previously stored in the server.

Owner:SAMSUNG ELECTRONICS CO LTD

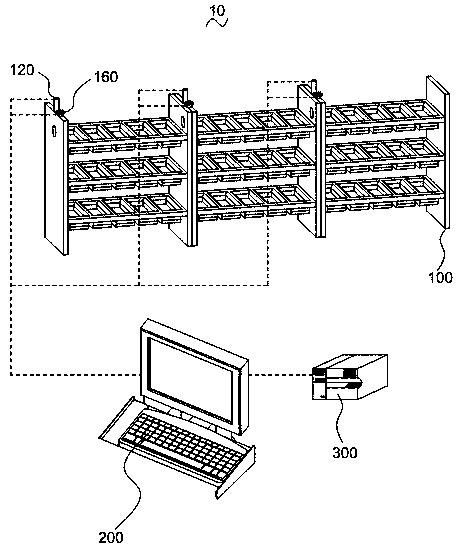

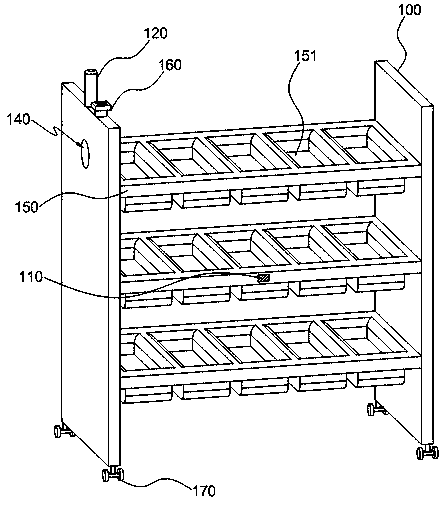

Automatic indication type goods shelf system

PendingCN111232533AEasy to put inImprove connection convenienceStorage devicesShow shelvesStructural engineeringMechanical engineering

The invention provides an automatic indication type goods shelf system. The automatic indication type goods shelf system comprises a plurality of unit goods shelves, a control mechanism and label printing equipment, wherein the plurality of unit goods shelves are sequentially connected, each unit goods shelf is provided with an indicator lamp and an identification code patch, and the information of each identification code patch is different; the control mechanism is electrically connected with the label printing equipment and the indicator lamps; a containing groove is formed in the frame wall of one side of each unit goods shelf, elastic pieces are arranged in the containing grooves of the unit goods shelves, and connecting columns are arranged on the elastic pieces; fixing grooves are formed in the rack walls of the other sides of the unit goods shelves, and magnetic blocks are arranged at the bottoms of the fixing grooves of the unit goods shelves; in every two adjacent unit goodsshelves, the elastic piece of one unit goods shelf is in a pulled state, the connecting column is inserted into the fixing groove of the other unit goods shelf, and the connecting column of one unit goods shelf is magnetically attracted to the magnetic block of the other unit goods shelf. According to the automatic indication type goods shelf system, the warehouse-in and warehouse-out efficiency of materials is improved, and the risk of deviation errors of inventory information is reduced.

Owner:惠州西文思技术股份有限公司

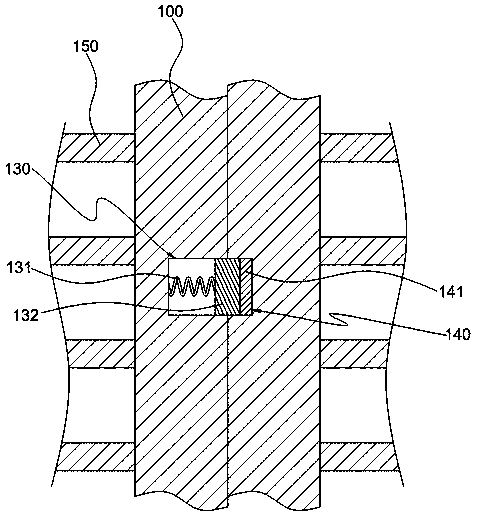

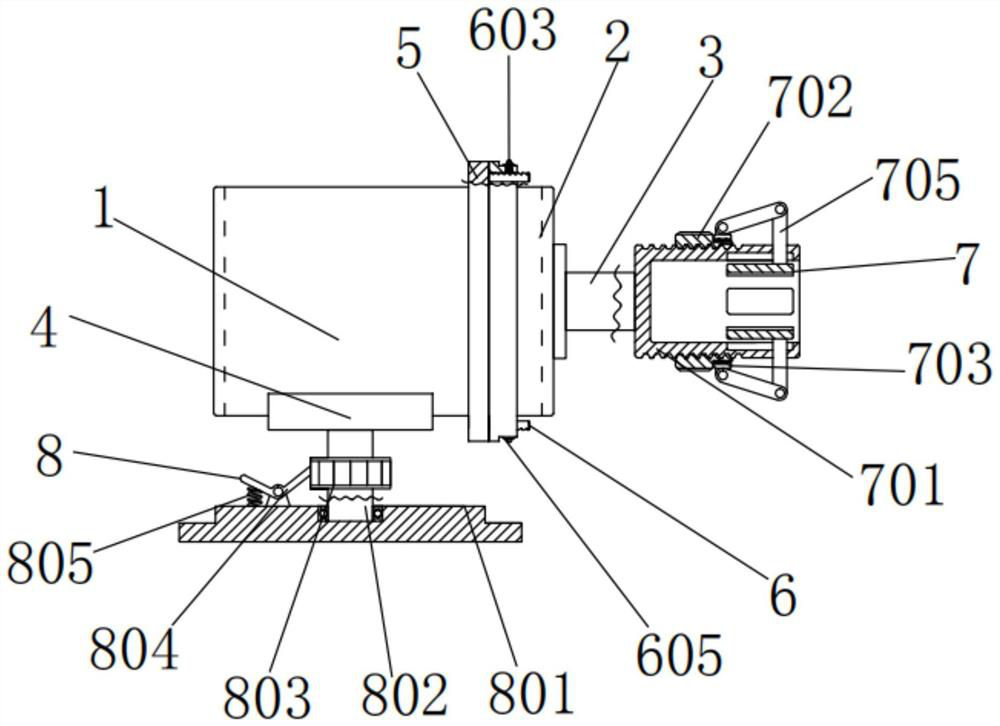

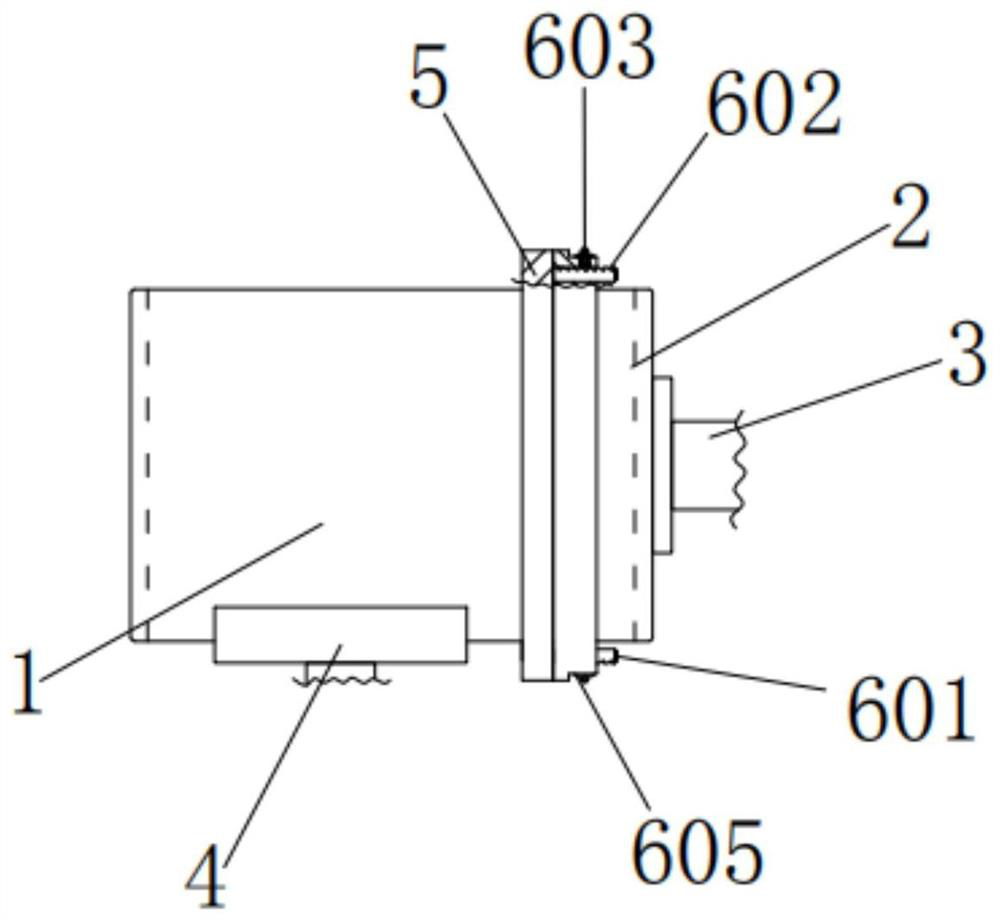

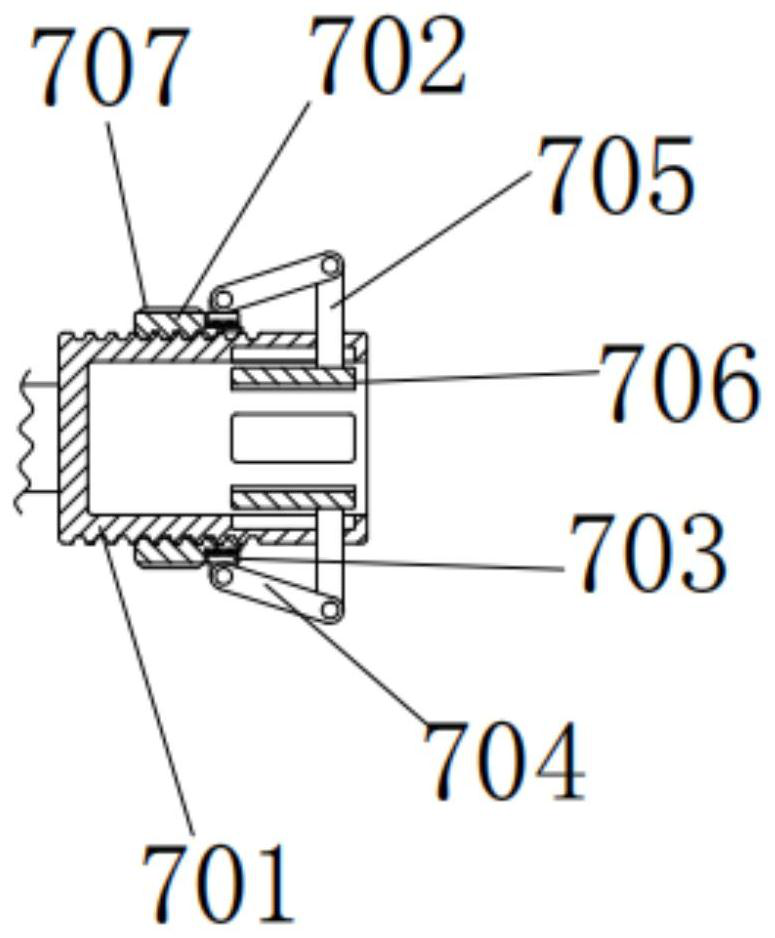

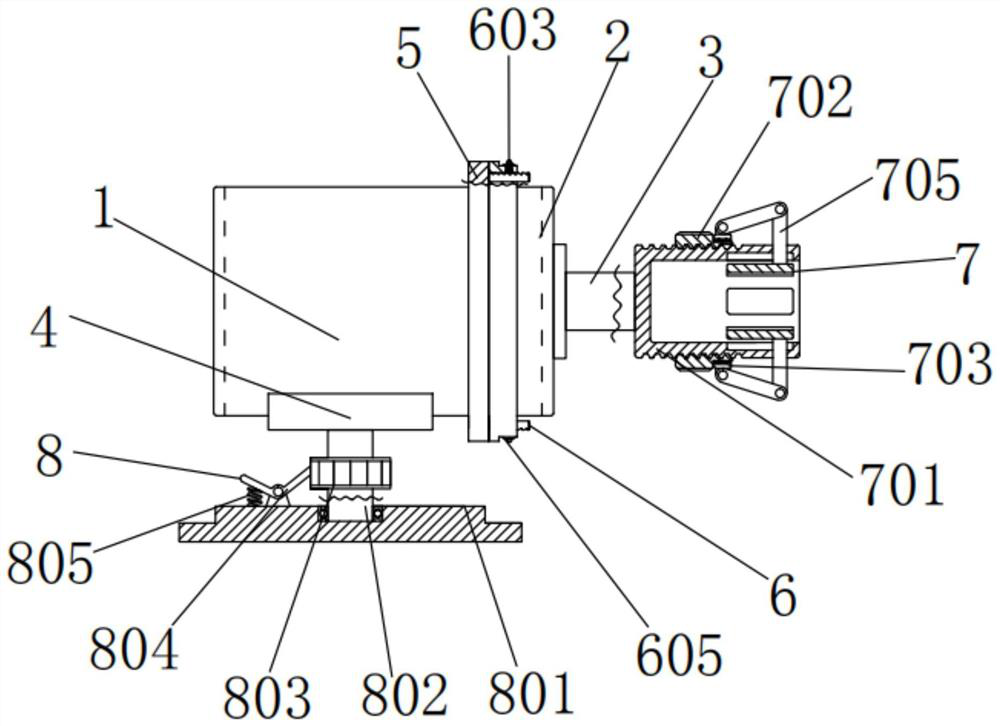

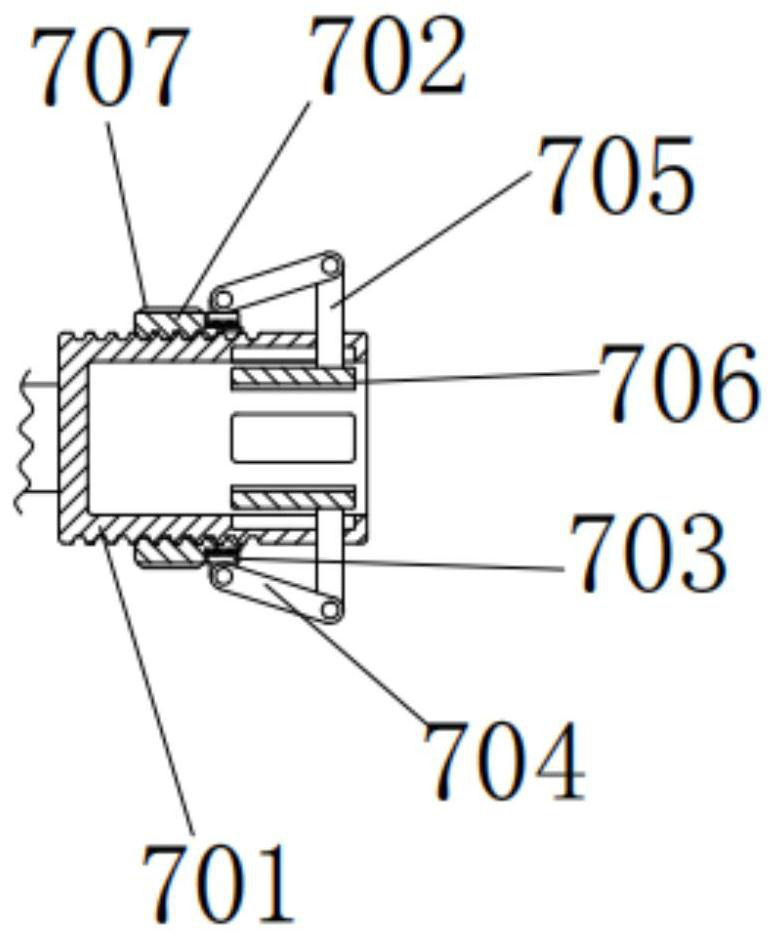

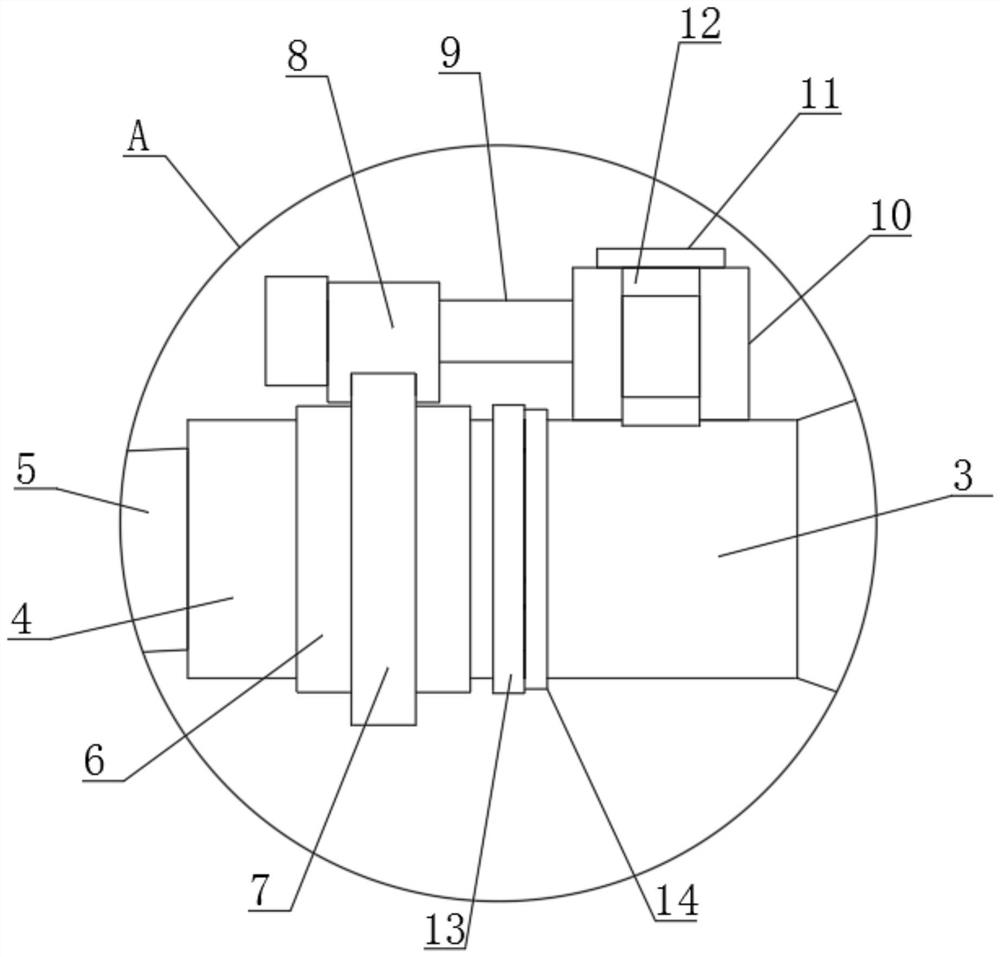

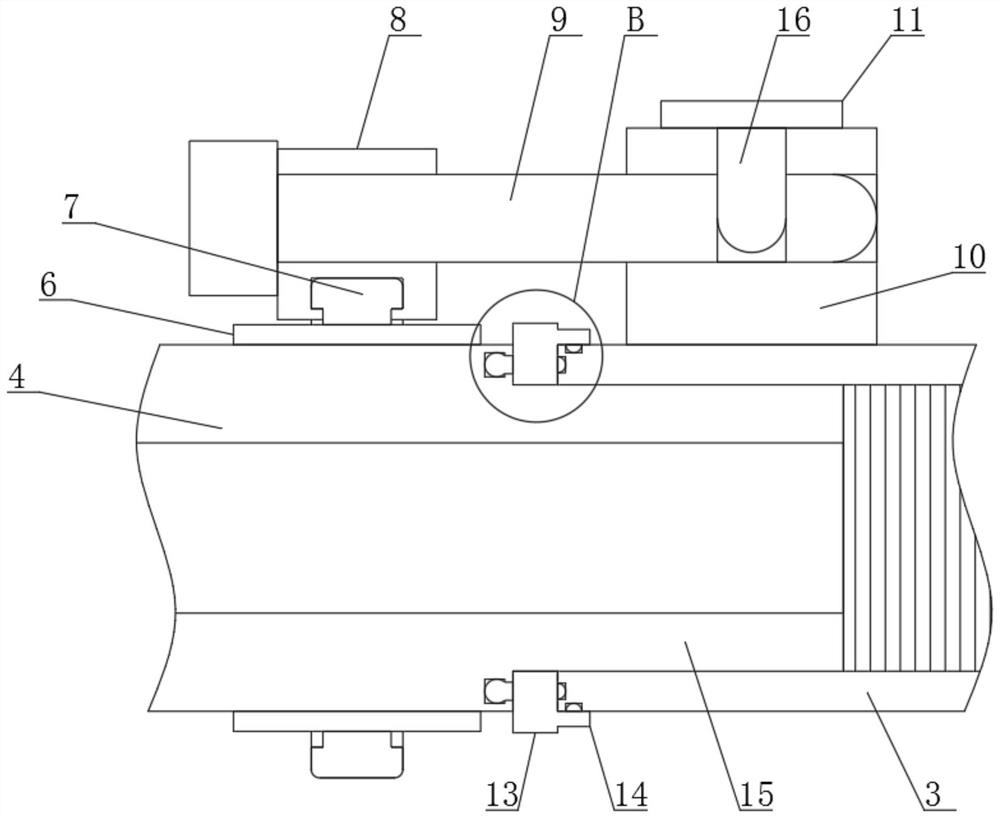

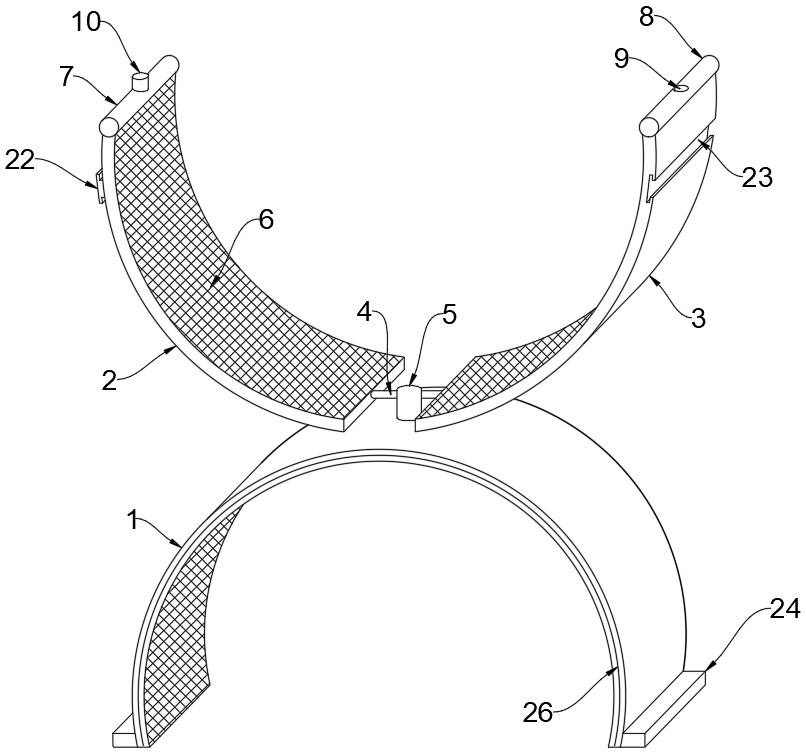

Hybrid excitation doubly salient permanent magnet synchronous motor

InactiveCN112968565AQuick connectionQuick disassemblySynchronous machine detailsMechanical energy handlingElectric machineGear wheel

The invention discloses a hybrid excitation doubly salient permanent magnet synchronous motor. The motor comprises a left shell; and opening and closing assemblies are arranged on the upper side and the lower side of a connecting plate. According to the hybrid excitation doubly salient permanent magnet synchronous motor, one-way locking can be realized when an inserting rod is inserted into a right side connecting plate through clearance fit between the inserting rod and the right side connecting plate and one-way clamping connection between a clamping pin and a clamping groove under the action of a first spring, so that a shell of the motor is quickly disassembled and assembled, and the interior of the motor is conveniently overhauled and maintained; a motor rotating shaft and an external connecting shaft are rapidly connected, and the connecting convenience is improved; the external connecting shaft can be automatically centered while fixing is conducted, so that transmission of the motor rotating shaft and the external connecting shaft is more accurate; the motor can axially rotate with a stand column as the axis after being fixedly installed, and is fixed through clamping connection of a clamping rod and a gear, and therefore, convenience and applicability of installation and use of the motor are improved, and the motor can be applied to more use environments.

Owner:ANQING NORMAL UNIV

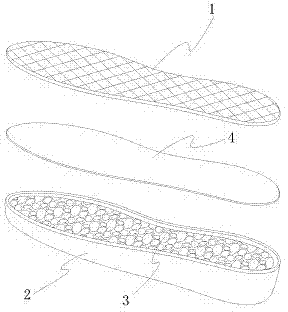

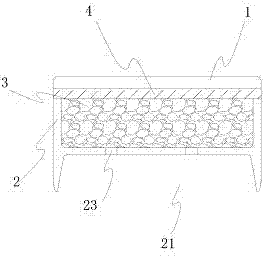

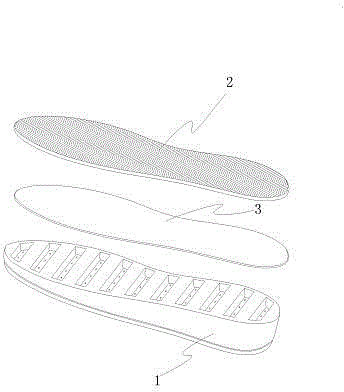

Damping sole

The invention relates to a damping sole which decreases sole laying processes, shortens production cycle, omits glue treatment agents, reduces hazardous substances and environmental pollution and facilitates mass production. The damping sole comprises a rubber outsole and a rubber insole, unvulcanized rubber is placed in a die and heated to medium well to form the rubber outsole and the rubber insole, a filling groove is formed in the rubber insole, exhaust holes are formed in the groove bottom of the filling groove, the inside of the filling groove is filled with elastic materials, an unvulcanized rubber piece is arranged between the rubber outsole and the rubber insole and covers a notch of the filling groove in the rubber insole, the rubber outsole covers the unvulcanized rubber piece, and the rubber insole, the unvulcanized rubber piece and the rubber outsole are vulcanized in the die again and then integrally formed.

Owner:FUJIAN DENGTAI TECH CO LTD

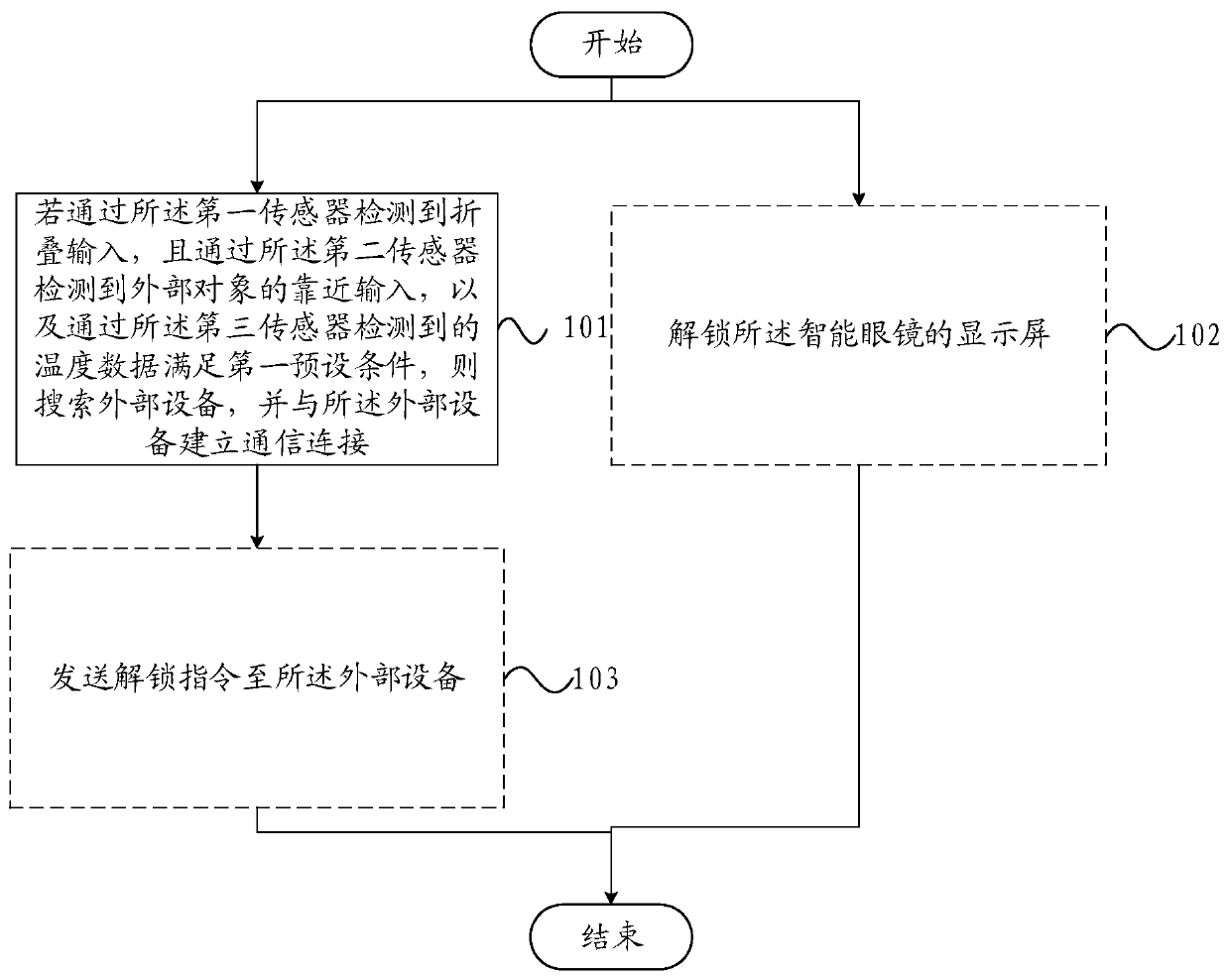

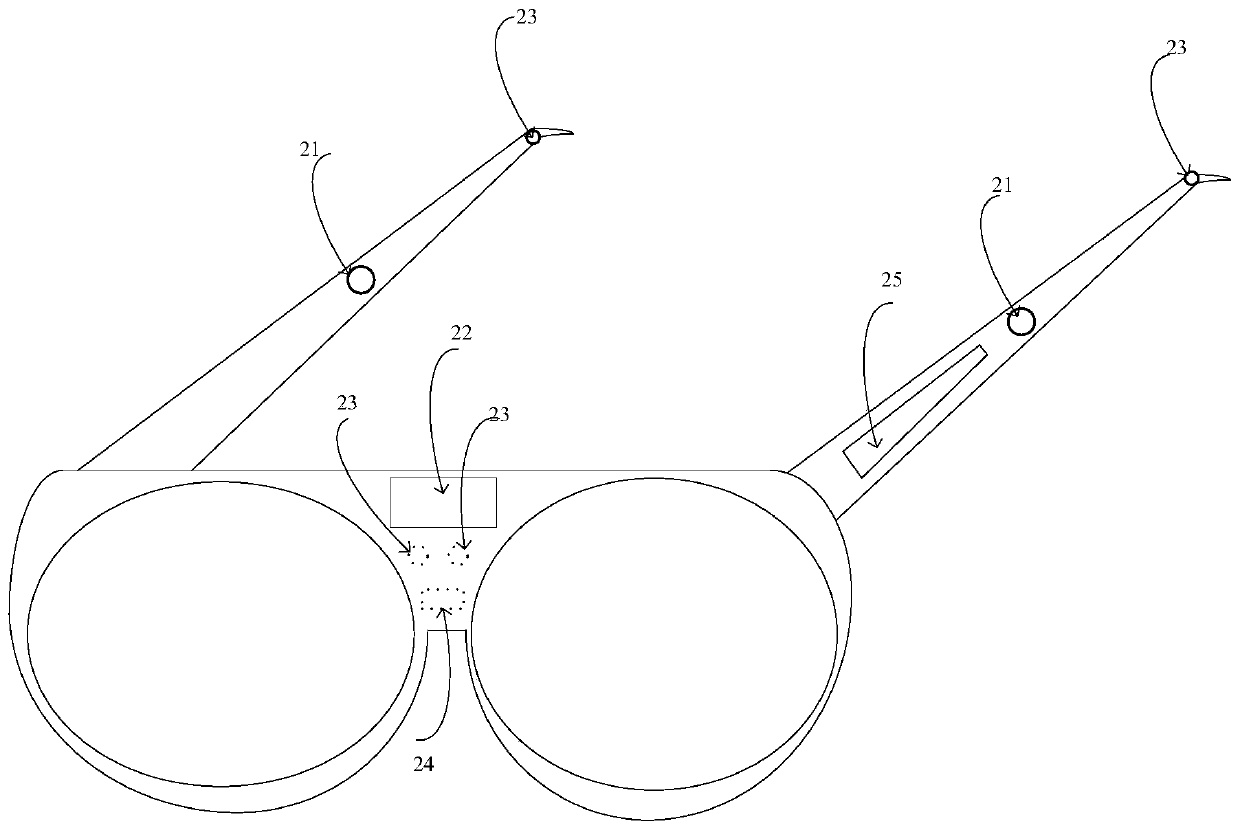

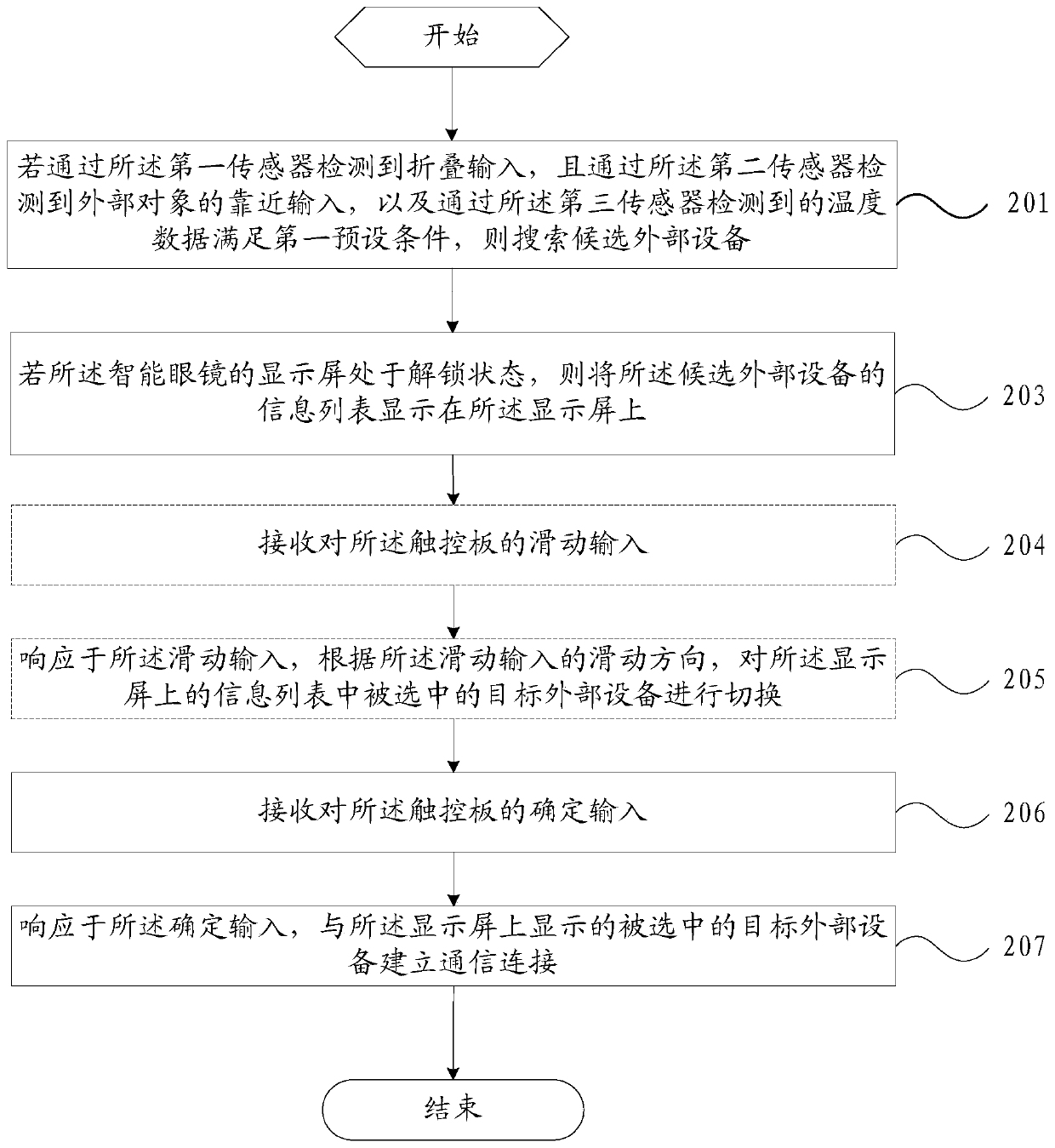

Control method and intelligent glasses

InactiveCN110825223AImprove connection convenienceInput/output for user-computer interactionDigital data authenticationEngineeringSmartglasses

Owner:VIVO MOBILE COMM CO LTD

Water spraying device for milling based on precision numerical control machine tool

InactiveCN112296415AImprove stabilityImprove connection convenienceMilling equipment detailsMaintainance and safety accessoriesNumerical controlPipe fitting

The invention discloses a water spraying device for milling based on a precision numerical control machine tool. The water spraying device comprises a machine tool shell; a dust suction device is fixedly mounted at the top of the machine tool shell; a fixed pipe fitting is fixedly mounted in the machine tool shell; an air diffusion cover is fixedly mounted at the bottom of the fixed pipe fitting;a foundation base is fixedly mounted in the machine tool shell; a fixed plate is fixedly mounted at the top of the foundation base; a telescopic column is fixedly mounted at the top of the foundationbase; a water collecting tank is fixedly mounted at the top of the telescopic column; and a working frame is fixedly mounted at the top of the water collecting tank. By arranging related water collecting holes, connecting pipe fittings, filtering boxes, filtering nets and a collecting box, water flows into the two filtering boxes through the two through holes and then is discharged into the collecting box through the filtering nets and water discharging pipes, used water can be collected and purified for reuse, a certain environment-friendly effect is achieved, and accordingly overall resourcewaste is reduced.

Owner:湄洲湾职业技术学院

Bell socket with clamping groove in outer wall

PendingCN108397622AImprove connection convenienceImprove reliabilitySleeve/socket jointsCouplingsEngineering

Owner:广东管博管道技术科技有限公司

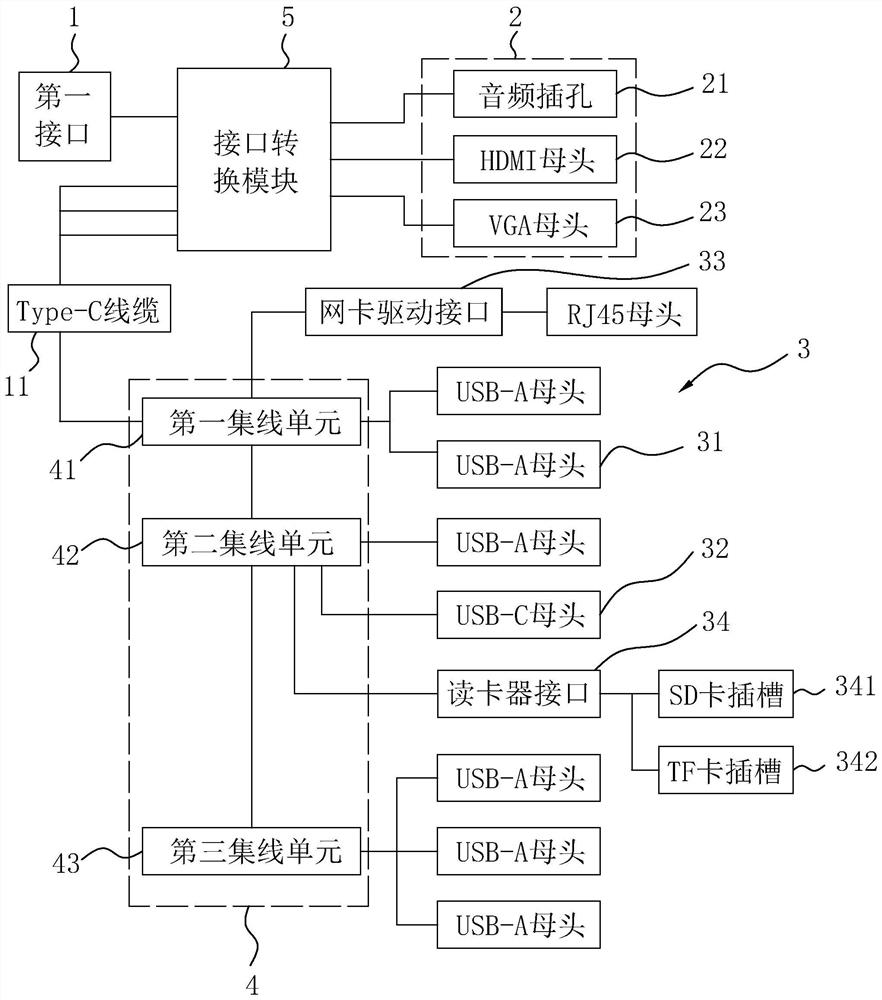

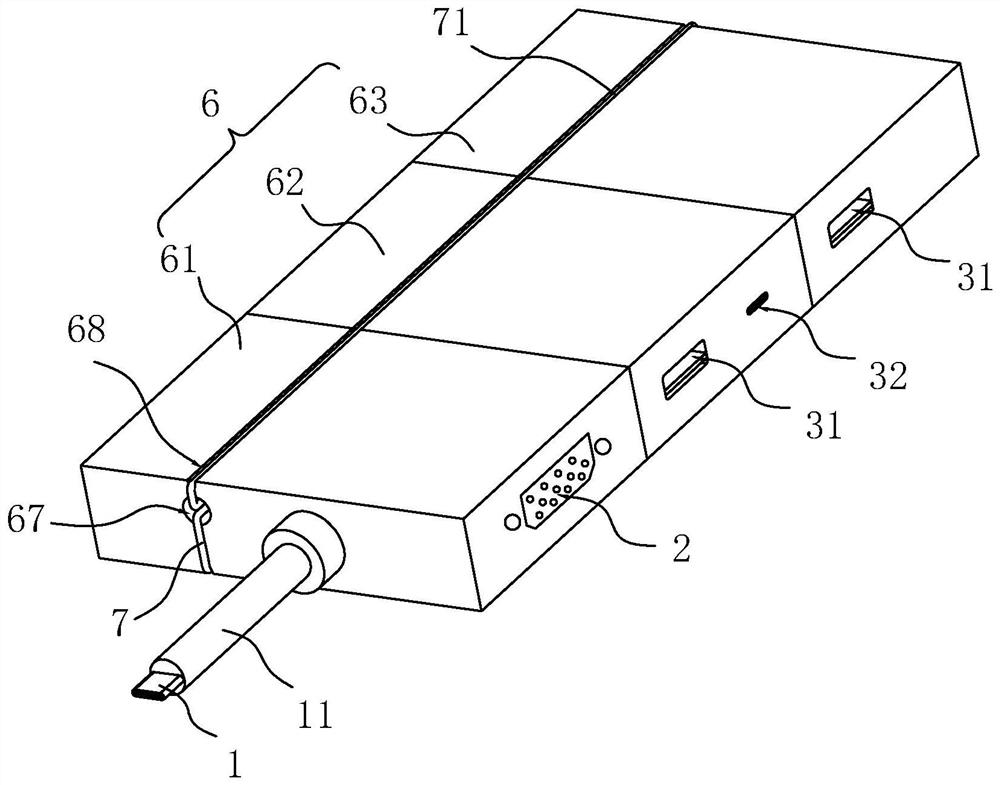

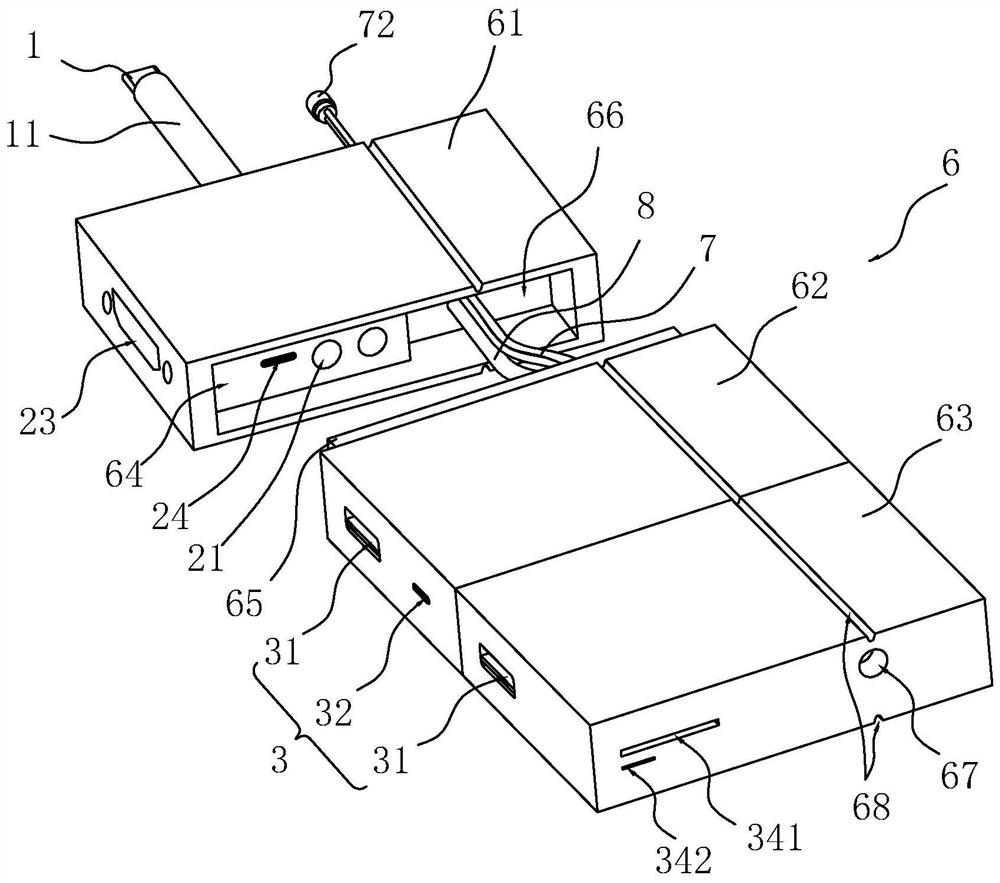

Docking station

PendingCN112882538AImprove connection convenienceDigital data processing detailsData transmissionLaptop

The invention relates to a docking station, which comprises a first interface, a second interface, a third interface, a line concentration control module and an interface conversion module, and is characterized in that the first interface, the second interface and the third interface are correspondingly connected to different terminal devices, so that the different terminal devices establish data transmission connection channels through the interface conversion module and the corresponding interfaces; moreover, the number and types of the second interfaces or the third interfaces can be properly expanded through the line concentration control module, and the connection application range of the first terminal equipment and other equipment can be expanded. The docking station is an external device and can be connected to a first terminal device through a first interface, and the first terminal device can comprise a thin notebook computer; establishing connection between the corresponding second terminal equipment or third terminal equipment and the first terminal equipment through the second interface or the third interface; and the defect that external ports of a thin notebook computer are rare is effectively improved.

Owner:C-SMARTLINK INFORMATION TECH CO LTD

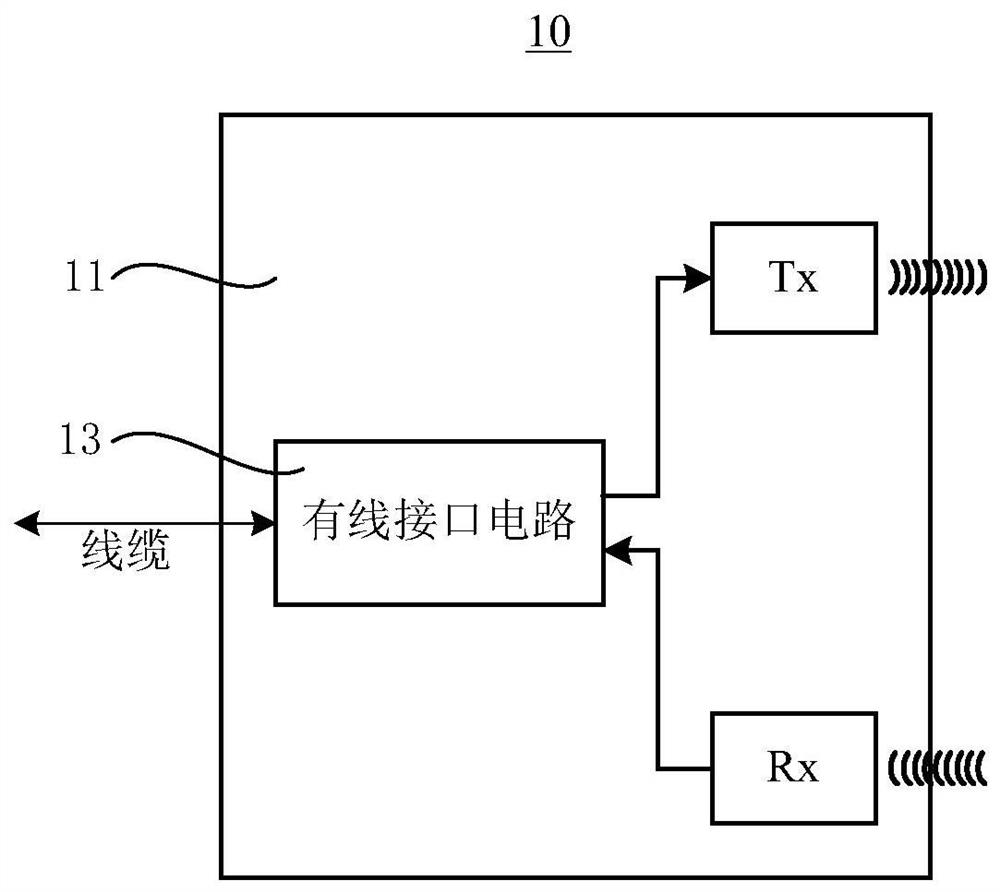

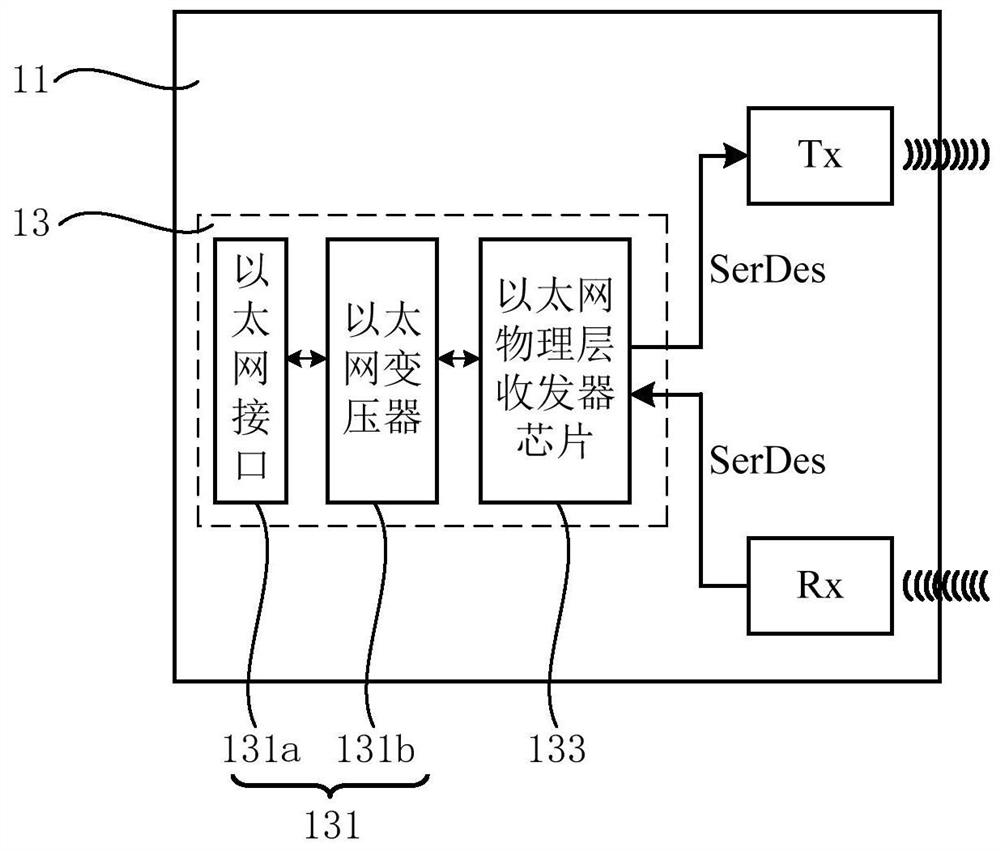

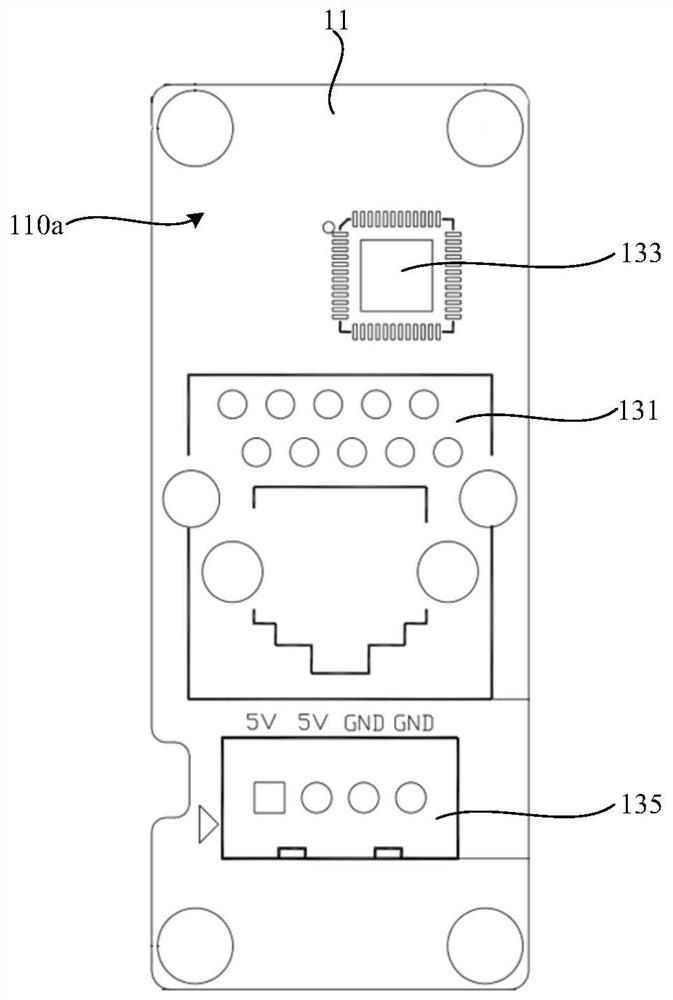

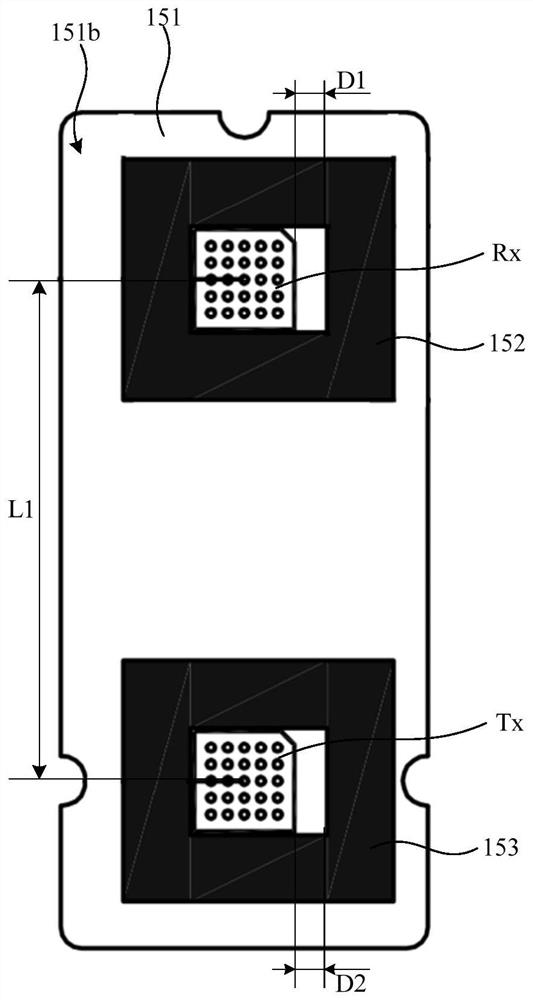

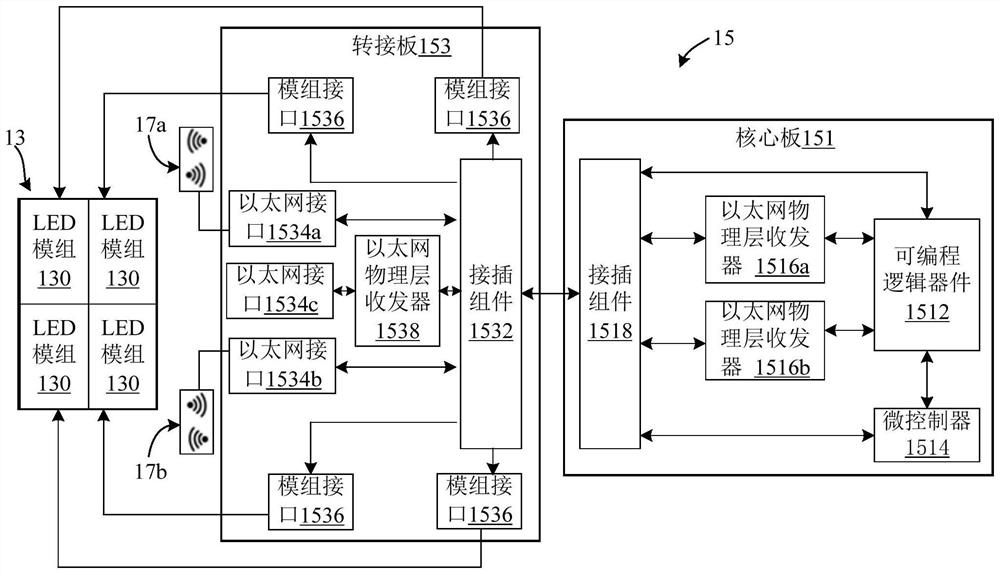

Wireless transceiving device and LED display screen

ActiveCN112311413AImprove connection convenienceAvoid time costStatic indicating devicesTransmissionTelecommunicationsWireless transmission

The embodiment of the invention relates to a wireless transceiving device, which comprises a circuit board; a wired interface circuit arranged on the circuit board; a wireless transmitting chip arranged on the circuit board and electrically connected with the wired interface circuit; and a wireless receiving chip arranged on the circuit board, electrically connected with the wired interface circuit and spaced from the wireless transmitting chip. The wireless sending chip is used for working in a millimeter wave frequency band and outputting data input from the wired interface circuit in a wireless mode, and the wireless receiving chip is used for working in the millimeter wave frequency band and accessing data in a wireless mode and transmitting the data to the wired interface circuit to be output in a wired mode. The wireless transceiving device is suitable for being arranged in a display box body of the LED display screen so as to realize wireless transmission of image data signals between the display box bodies.

Owner:XIAN NOVASTAR TECH

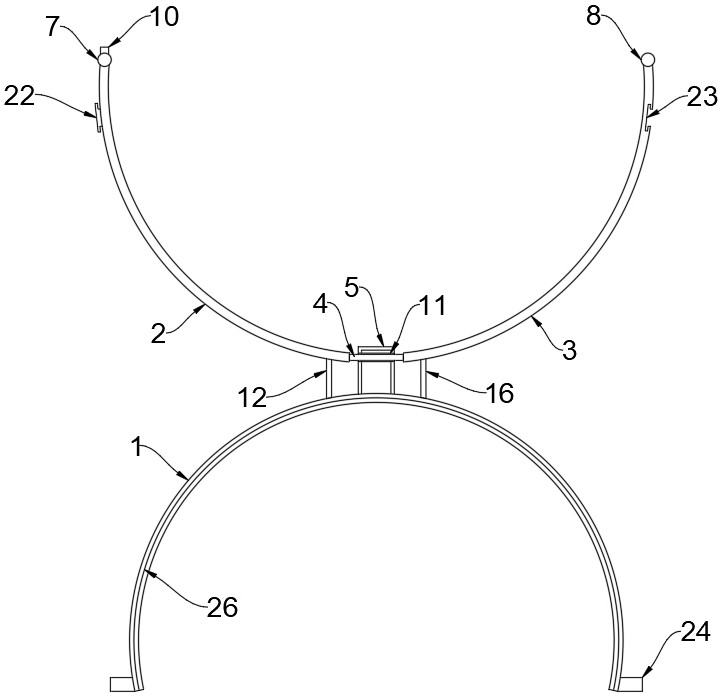

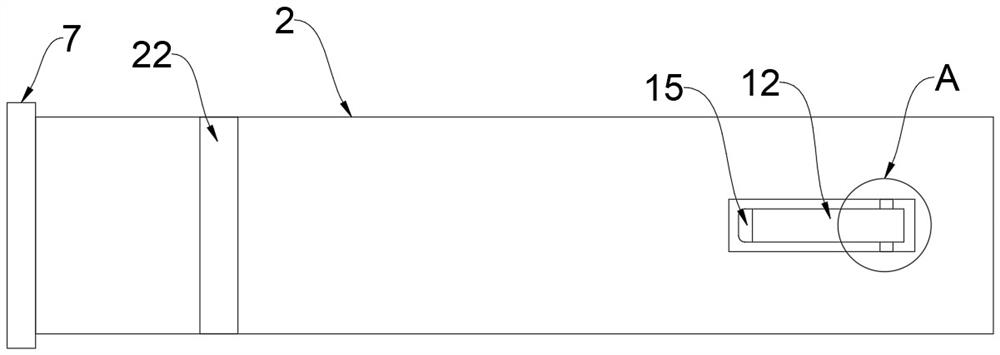

Hybrid excitation doubly salient permanent magnet synchronous motor

InactiveCN113193692AQuick connectionQuick disassemblySynchronous machine detailsMagnetic circuit stationary partsElectric machineGear wheel

The invention discloses a hybrid excitation doubly salient permanent magnet synchronous motor. The motor comprises a left shell, and opening and closing assemblies are arranged on the upper side and the lower side of a connecting plate. According to the hybrid excitation doubly salient permanent magnet synchronous motor, one-way locking can be realized when an inserting rod is inserted into the right side connecting plate through clearance fit between the inserting rod and the right side connecting plate and one-way clamping connection between a clamping pin and a clamping groove under the action of a first spring, so that the shell of the motor is quickly disassembled and assembled, and the interior of the motor is conveniently overhauled and maintained; a motor rotating shaft and an external connecting shaft are rapidly connected, the connecting convenience is improved; the external connecting shaft can be automatically centered while being fixed, so that the transmission of the motor rotating shaft and the external connecting shaft is more accurate; the motor can axially rotate with a stand column as the axis after being fixedly installed, and can be fixed through clamping connection of a clamping rod and a gear, and therefore, convenience and applicability of installation and use of the motor are improved, and the motor can be applied to more use environments.

Owner:ANQING NORMAL UNIV

Method and system for connecting mobile communication terminal with access point

InactiveUS8611318B2Improve connection convenienceData switching by path configurationWireless network protocolsWireless lanMedia access control

Disclosed is a method for connecting a mobile communication terminal with an access point located in a local area providing a Wireless Local Area Network (WLAN) service in which a server managing the access point compares Media Access Control (MAC) information of the mobile communication terminal or MAC information of the access point transferred from the mobile communication terminal through a mobile communication network with MAC information previously stored in the server and transfers network setting information required for connection to the access point to the mobile communication terminal if the MAC information of the mobile communication terminal or access point is identical to the MAC information previously stored in the server.

Owner:SAMSUNG ELECTRONICS CO LTD

Multilayer flexible circuit board for tablet

PendingCN108513434ASave internal spaceIncrease profitPrinted circuits stress/warp reductionElectrical connection printed elementsHeat conductingFlexible circuits

The invention discloses a multilayer flexible circuit board for a tablet, and belongs to the technical field of flexible circuit boards. The multilayer flexible circuit board comprises a protection board, wherein a left side of the protection board is provided with a mounting hole; a right side of the protection board is provided with a plugin column which is matched with the mounting hole; the protection board comprises an outer board substrate layer; one side opposite to the outer board substrate layer is provided with an outer circuit board; the inner cavities of a semi-cured layer and an inner board substrate layer are provided with insulating support blocks; the insulating support blocks are embedded between the outer circuit board and the inner circuit board; one side far away from acircuit connection hole of each insulating support block is provided with a heat-conducting board; the top and the bottom of the heat-conducting board are connected with the outer circuit board and the inner circuit board respectively; assembly slots are formed in the joints of the semi-cured layer, the inner board substrate layer and the heat-conducting board; and left and right side walls of the heat-conducting board are provided with heat-dissipating sheets. Through adoption of the multilayer flexible circuit board, the utilization rate of the circuit board on the inner layer is increased,and meanwhile relatively good impact effect and heat-dissipation effect are achieved.

Owner:扬州市玄裕电子有限公司

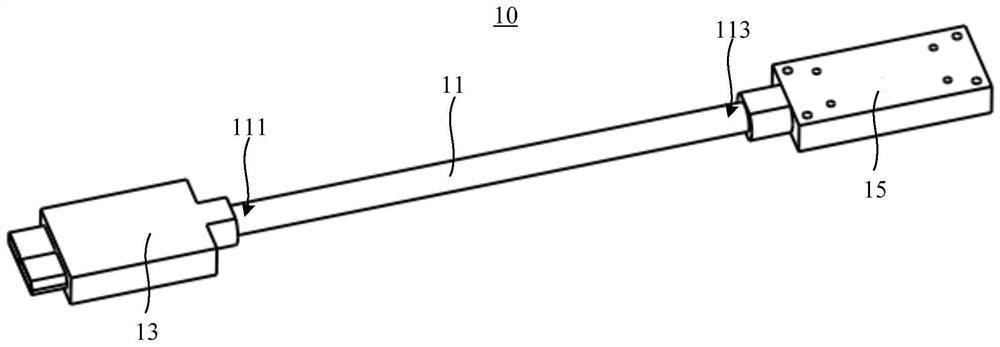

Wireless transceiver and LED display screen

ActiveCN112398500AImprove connection convenienceAvoid time costTransmissionIdentification meansWireless transceiverTransceiver

The embodiment of the invention relates to a wireless transceiver. The wireless transceiver comprises a flexible cable which is used for transmitting a data signal and a power supply signal and provided with a first end and a second end opposite to the first end, and the first end is provided with a USB interface; a main body part which comprises a circuit board, a wireless transmitting chip and awireless receiving chip, and the wireless transmitting chip and the wireless receiving chip are arranged on the circuit board; the wireless transmitting chip and the wireless receiving chip are arranged at intervals in the length direction of the circuit board and are electrically connected with the second end of the flexible cable through the circuit board, and the working frequency of the wireless transmitting chip and the working frequency of the wireless receiving chip are located in a millimeter wave frequency band. The wireless transceiver is suitable for being installed in a display box body of the LED display screen so as to achieve wireless transmission of image data signals between the display box bodies.

Owner:XIAN NOVASTAR TECH

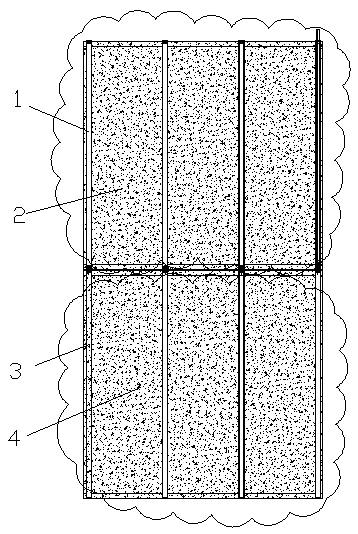

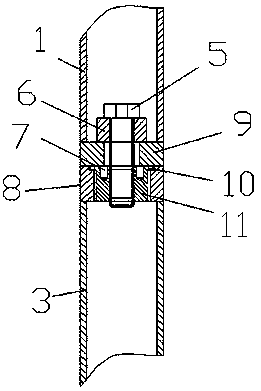

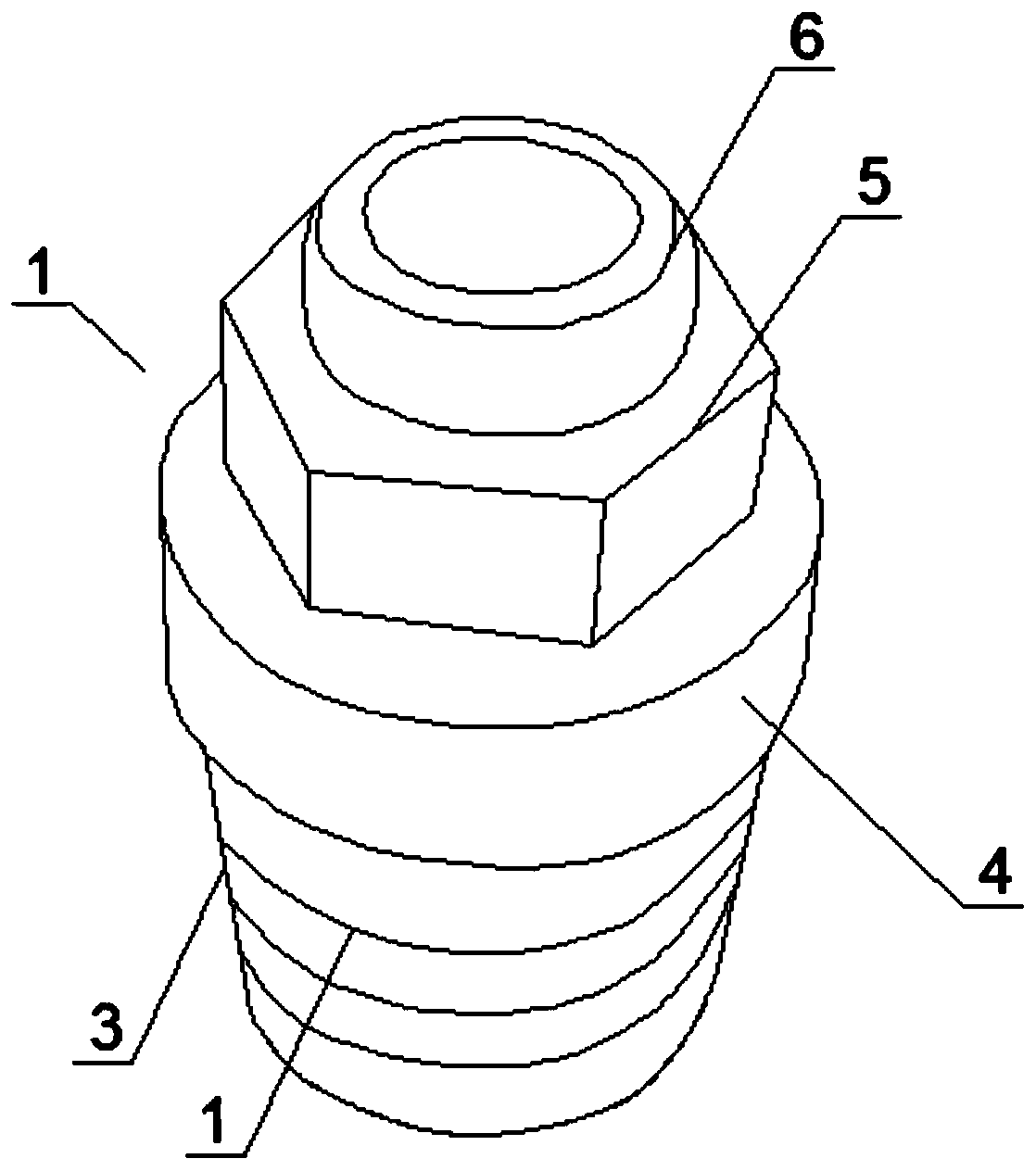

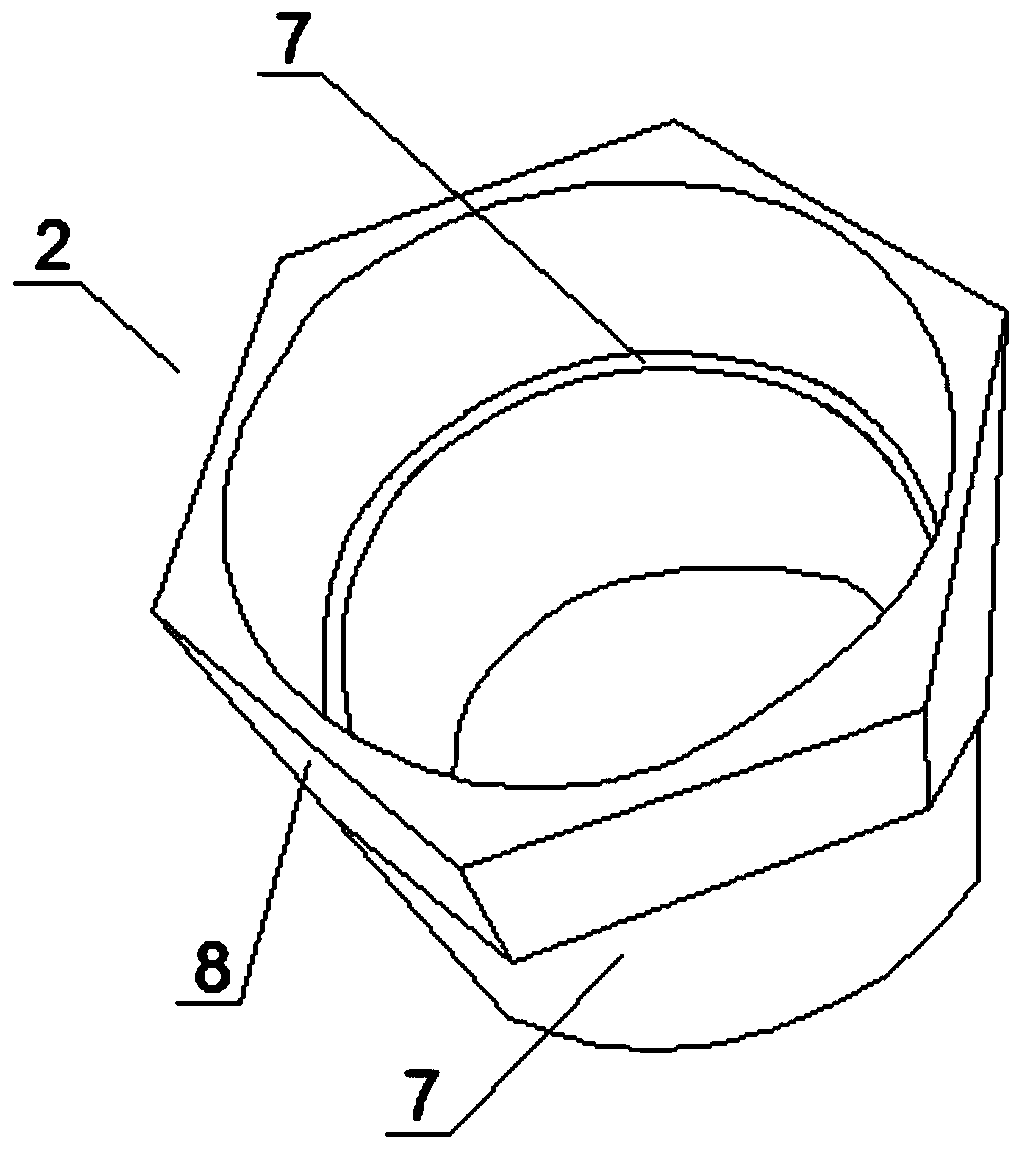

Fabricated building component connecting device

PendingCN108442535AImprove connection convenienceEasy to detectBuilding constructionsSteel tubePrecast concrete

The invention discloses a fabricated building component connecting device, comprising first components, second components and component connecting devices. Each component connecting device comprises afirst steel tube, a second steel tube, nuts and bolts. The first steel tubes are respectively arranged in the first components, and the second steel tubes are respectively arranged in the second components and correspond to the first steel tubes end-to-end correspondingly. The tail ends of the first steel tubes and the second steel tubes are respectively provided with lower end plates, and the front ends of the first steel tubes and the second steel tubes are provided with upper end plates. A through hole is formed in each lower end plate. The bolts penetrate through the lower end plates fromthe first steel tubes and connect with the nuts in the upper end plates of the second steel tubes. According to the fabricated building component connecting device, the connection convenience of precast concrete fabricated building and steel construction fabricated building is improved, and the effective connection of the parts which should be joined of the steel construction fabricated buildingcomponents is ensured.

Owner:江培刚

Fire hose connector

Owner:应急管理部四川消防研究所

Hydraulic oil cylinder convenient to install and fix

InactiveCN111255769AImprove stabilityAvoid shakingFluid-pressure actuatorsHydraulic cylinderHydraulic ram

The invention provides a hydraulic oil cylinder convenient to install and fix. The hydraulic oil cylinder includes a fixing unit, a hydraulic cylinder body, a supporting unit and an external connection unit; the lower end of the hydraulic cylinder body is installed on the fixing unit in a clamping mode, the outer wall on the middle part of the hydraulic cylinder body is connected with the supporting unit, the other end of the supporting unit is installed on the fixing unit in a sliding fit mode, and the top end of the hydraulic cylinder body is connected with the external connection unit. Thehydraulic oil cylinder can solve the mainly existing problems of existing hydraulic oil cylinders during use that a, when the hydraulic oil cylinders are fixed to external connecting pieces, the connection is not firm, and looseness and falling are caused when the hydraulic oil cylinders are connected with external components; and the top ends of the hydraulic oil cylinders are each of a straighttube type and difficult to be connected and fixed to the external components; and b, after installation and use, the hydraulic oil cylinders can only be subjected to linear movement in a fixed direction in most cases, so that great limitations are caused in the using process of the hydraulic oil cylinders.

Owner:倪立秧

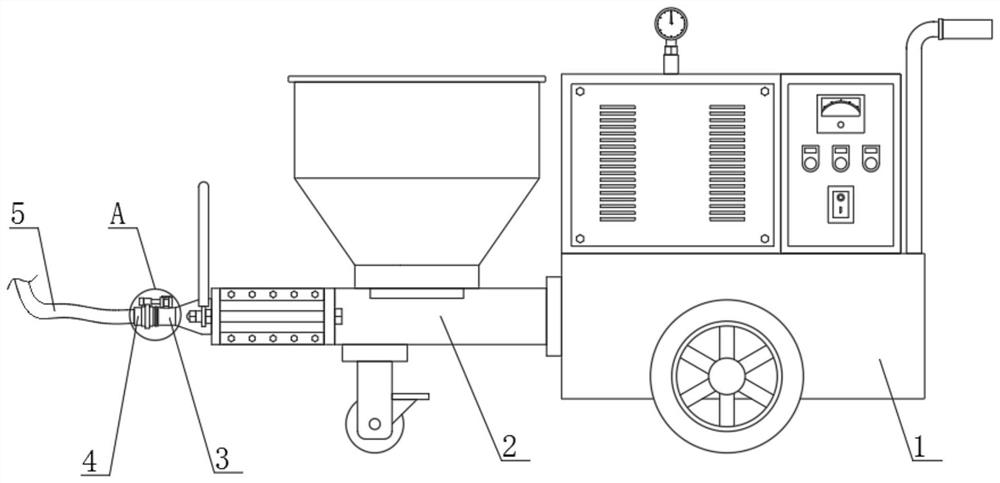

Outer wall decorative surface construction device for building construction and use method

ActiveCN114215315AImprove connection stabilityImprove running stabilityBuilding constructionsConstruction engineeringStructural engineering

The invention discloses an outer wall decorative surface construction device for building construction and a using method, the outer wall decorative surface construction device comprises a machine body and a spraying pipe, a machine pipe is arranged on the surface of one side of the machine body, a connecting base is fixed to the end of the machine pipe, and a connector connected with the connecting base is fixed to the end of the spraying pipe; an integrated threaded end is arranged at the end of the connector, the threaded end is screwed into the inner side of the connecting base, an anti-disengaging mechanism is arranged between the connector and the connecting base, and the anti-disengaging mechanism comprises a base sleeve, a T-shaped anti-disengaging pin, a pin base, a top plate and a base ring; by arranging the anti-falling mechanism, the connecting stability between the connecting head and the connecting base can be improved, the connecting head is prevented from falling off from the connecting base in the use period, and therefore the overall operation stability of the construction spraying machine is improved, and a guarantee is brought to construction work of operators; and through the arranged sealing structure, the sealing performance of the connecting position of the connector and the connecting base can be improved, and spraying raw materials are prevented from leaking.

Owner:宿令雁

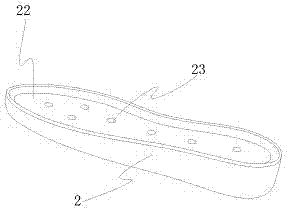

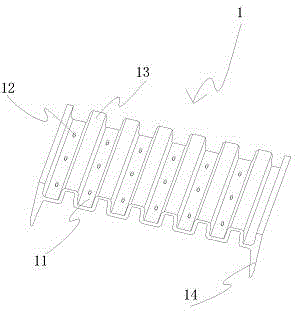

Shock absorption and ventilation shoe sole

InactiveCN104473374AGood compatibilityShorten the production cycleSolesVulcanizationHazardous substance

The invention relates to a shoe sole and provides a shock absorption and ventilation shoe sole. According to the shock absorption and ventilation shoe sole, the number of shoe sole gluing procedures is reduced, the production cycle is shortened, glue treating agents are not needed, hazardous substances and environment pollution are reduced, and mass production is facilitated. The shock absorption and ventilation shoe sole comprises a rubber midsole and a rubber outsole, and the rubber midsole and the rubber outsole are shaped by placing unvulcanized rubber in molds, heating the rubber in a medium well mode and vulcanizing the rubber. The rubber midsole is of a hollowed-out frame shape formed by n-shaped parts, the n-shaped parts are uniformly arranged in the transverse direction of the rubber midsole side by side, vent holes are formed in convex platforms of the n-shaped parts, and connecting portions between the adjacent n-shaped parts constitute concave platforms. An unvulcanized rubber sheet is further arranged between the concave platforms of the rubber midsole and the rubber outsole, the concave platforms are covered with the unvulcanized rubber sheet, and the unvulcanized rubber sheet is covered with the rubber outsole. The rubber midsole, the unvulcanized rubber sheet and the rubber outsole are integrally formed through in-mold vulcanization again.

Owner:FUJIAN DENGTAI TECH CO LTD

Wire harness clamp of two-layer overturning structure

ActiveCN113258518AImprove convenienceImprove stabilityElectrical apparatusNon-rotating vibration suppressionPhysicsMechanical engineering

Owner:南昌大学第一附属医院

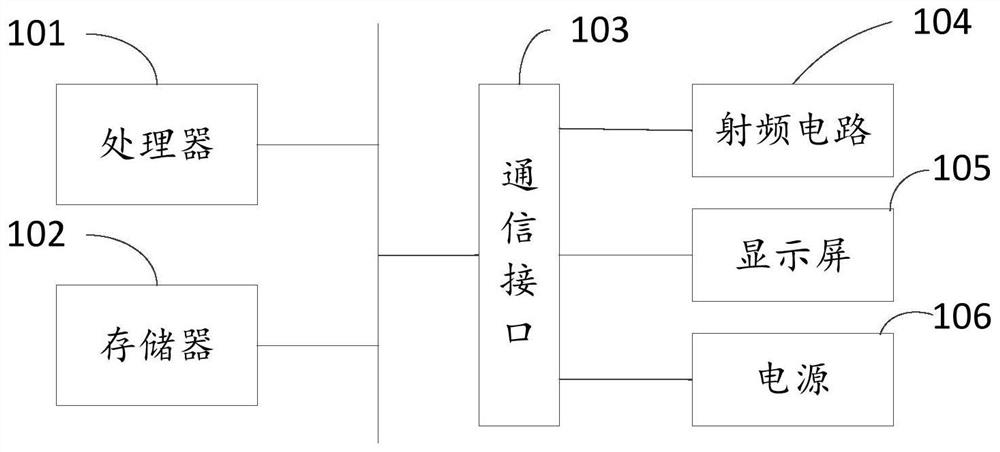

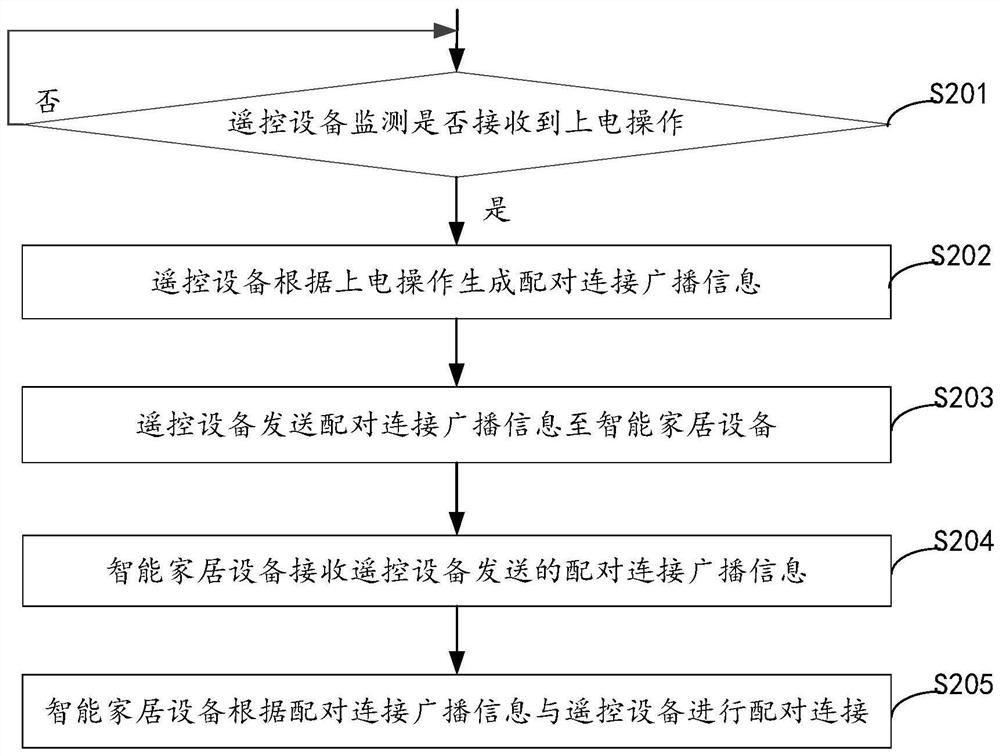

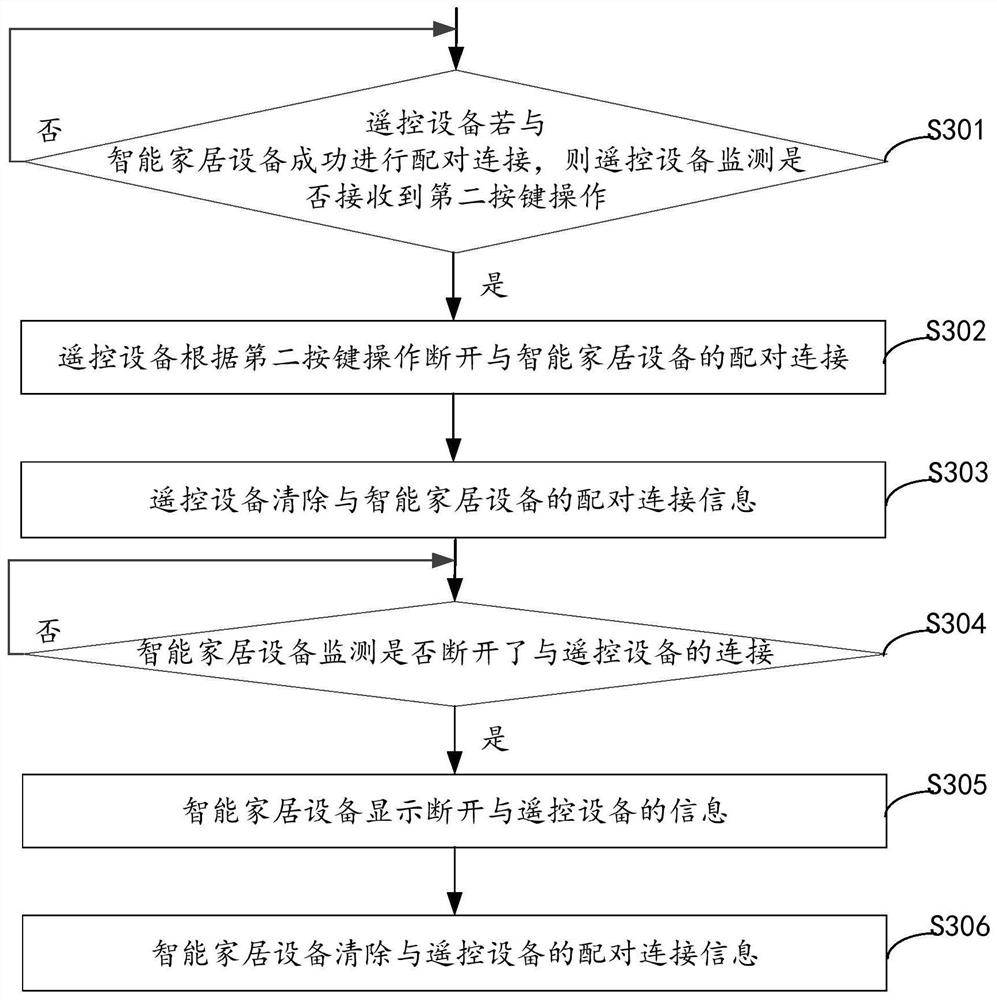

Connection method and device, remote control equipment, smart home equipment and storage medium

PendingCN112787900ASolve the problem of low connection convenienceImprove user experienceData switching by path configurationShort range communication serviceRemote controlDevice Monitor

The invention relates to the technical field of smart home, and discloses a connection method and device, remote control equipment, smart home equipment and a computer readable storage medium. The remote control device monitors whether the power-on operation is received, if the power-on operation is monitored to be received, the pairing connection broadcast information is generated according to the power-on operation, and then the pairing connection broadcast information is sent to the smart home device; the smart home device receives the pairing connection broadcast information sent by the remote control device, and performs pairing connection with the remote control device according to the received pairing connection broadcast information; the problem of low connection convenience of the remote control equipment and the intelligent household equipment in the prior art is solved.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

Circuit board connector and electronic device

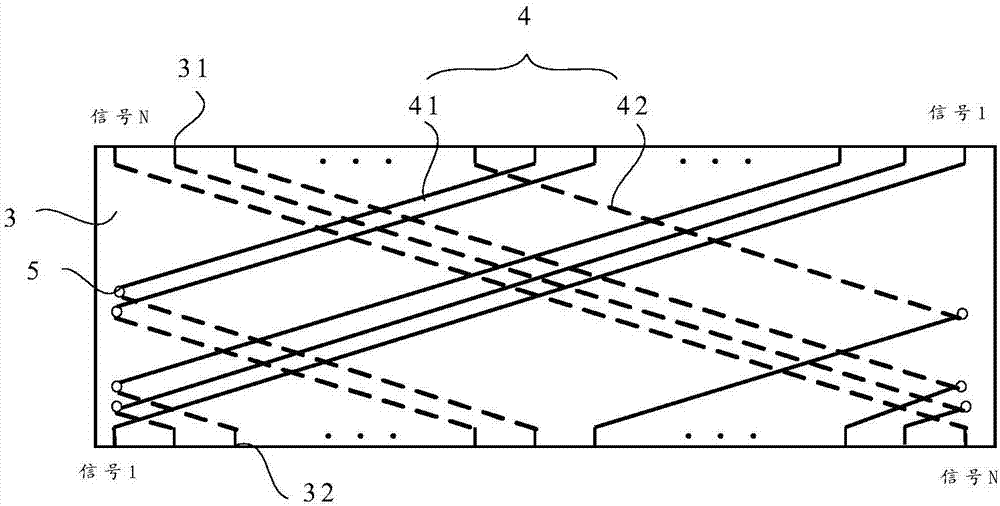

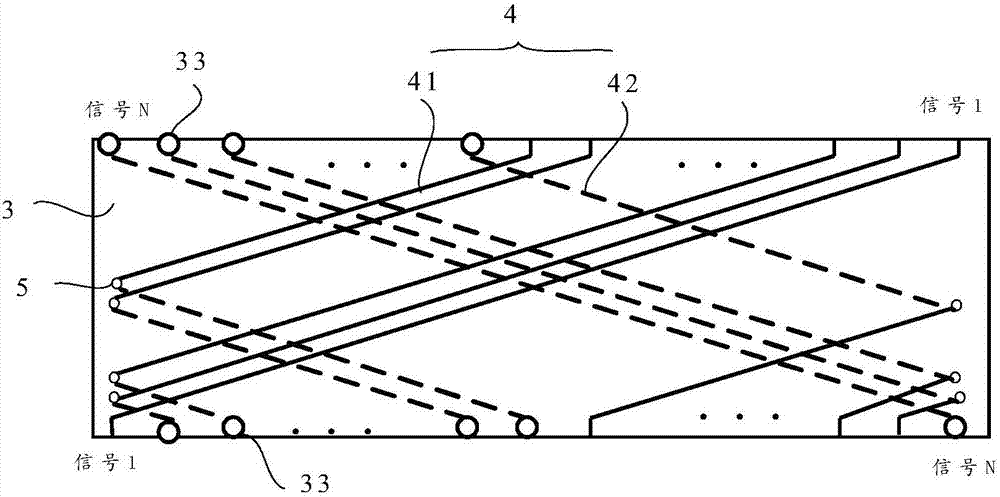

ActiveCN107359439ALow mutual interferenceDoes not increase thicknessCoupling device connectionsElectricityFlexible circuits

The invention discloses a circuit board connector and an electronic device, which are used for avoiding undesirable phenomena such as a short circuit in an electronic device due to reverse insertion of a flexible circuit board. The circuit board connector comprises a main body provided with N first conductive connection points; a cover plate provided with second conductive connection points arranged in one-to-one correspondence with the first conductive connection points, and arranged by the serial numbers thereof from N to 1 along the same direction as the first conductive connection points which are arranged by the serial numbers thereof from 1 to N; and an electrical connection board provided with wiring traces for electrically connecting the first conductive connection points with the second conductive connection points of the same serial numbers, wherein, each of the wiring traces at least for connecting the first conductive connection points numbered from 2 to N-1 with the second conductive connection points of the corresponding serial numbers includes a first portion located in a first plane of the electrical connection board and a second portion located in a second plane of the electrical connection board, with the first portion and the second portion being connected through a via hole, and in these wiring traces, the wiring traces in the same plane do not intersect with one another.

Owner:芜湖天马汽车电子有限公司

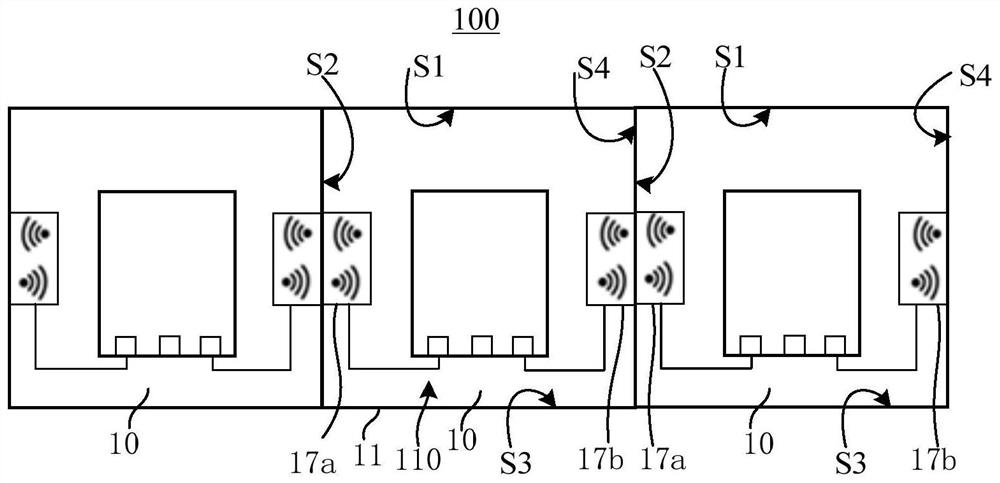

LED display screen and LED display system

PendingCN112331129ASimplified installation convenienceImprove connection convenienceStatic indicating devicesWireless transmissionLED display

The embodiment of the invention relates to an LED display screen. The LED display screen comprises a plurality of cascaded display box bodies. Each display box body comprises a box body frame which isprovided with a first side face, a second side face and a containing space located between the first side face and the second side face; an LED display unit; a module controller which is arranged inthe containing space, is electrically connected with the LED display unit, and is provided with a pair of first Ethernet interfaces and a second Ethernet interface; and a pair of wireless transmissionmodules which are arranged on the first side surface and the second side surface respectively and are connected with the pair of first Ethernet interfaces through cables. The working frequency of each wireless transmission module is located in a millimeter wave frequency band. The embodiment of the invention further provides an LED display system using the LED display screen.

Owner:XIAN NOVASTAR TECH

Power line signal transmission method, device and transmission electric equipment

ActiveCN108964706BReduce in quantityReduce connection complexityPower distribution line transmissionTelecommunicationsSignal on

The present application relates to a power line signal transmission method, device and transmission electrical equipment. The method includes: receiving a communication signal and a power supply voltage; coupling the power supply voltage and the communication signal to obtain a carrier signal; and transmitting the carrier signal to the controlled side through a power line. By coupling the power supply voltage on the control side with the communication signal, the carrier signal is obtained, and then the carrier signal is transmitted to the controlled side through the power line carrier to realize the power line carrier transmission. The communication line and the power line can be integrated, thereby reducing The number of connection lines between the control side and the controlled side reduces the connection complexity and improves the connection convenience between the control side and the controlled side.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

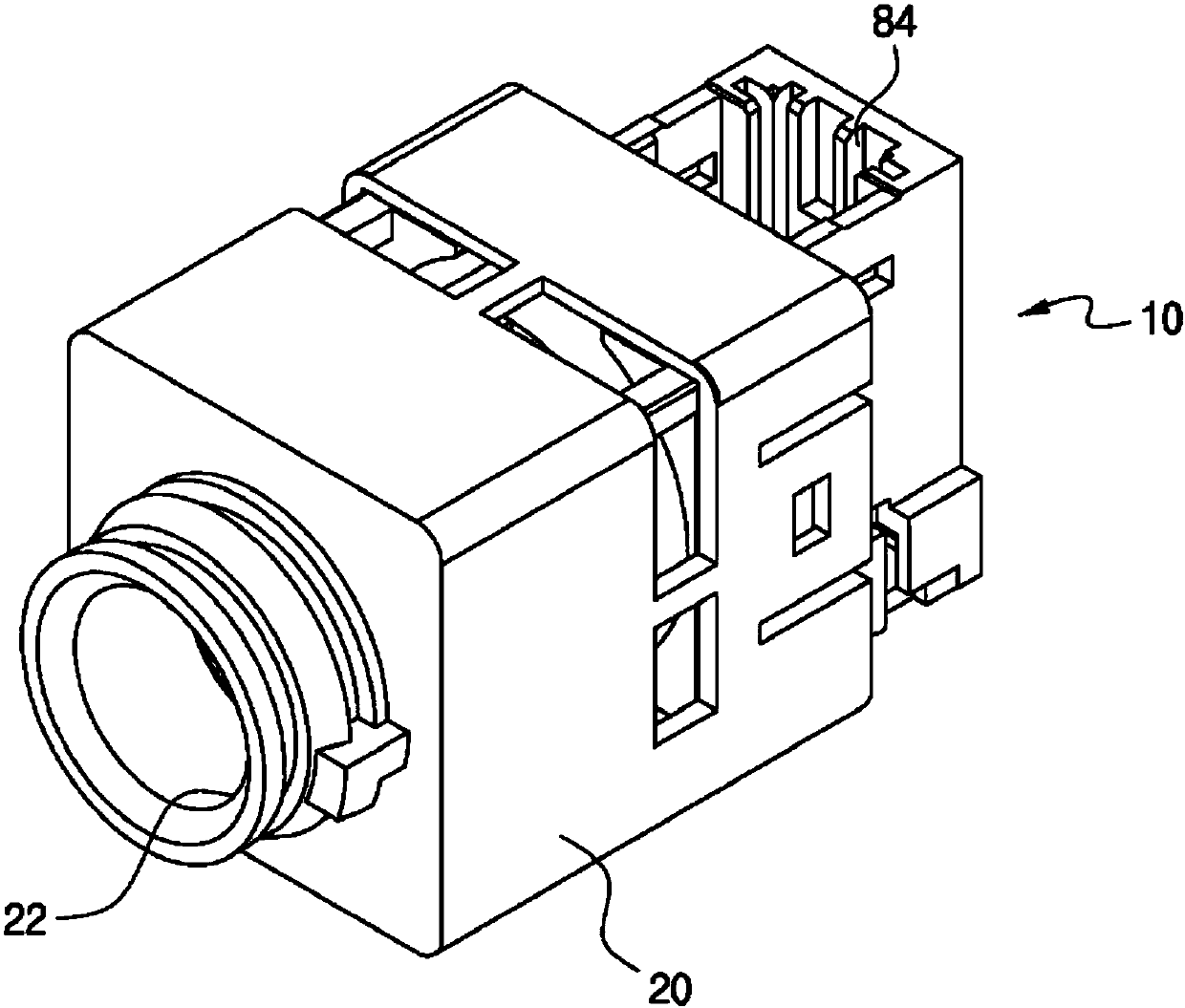

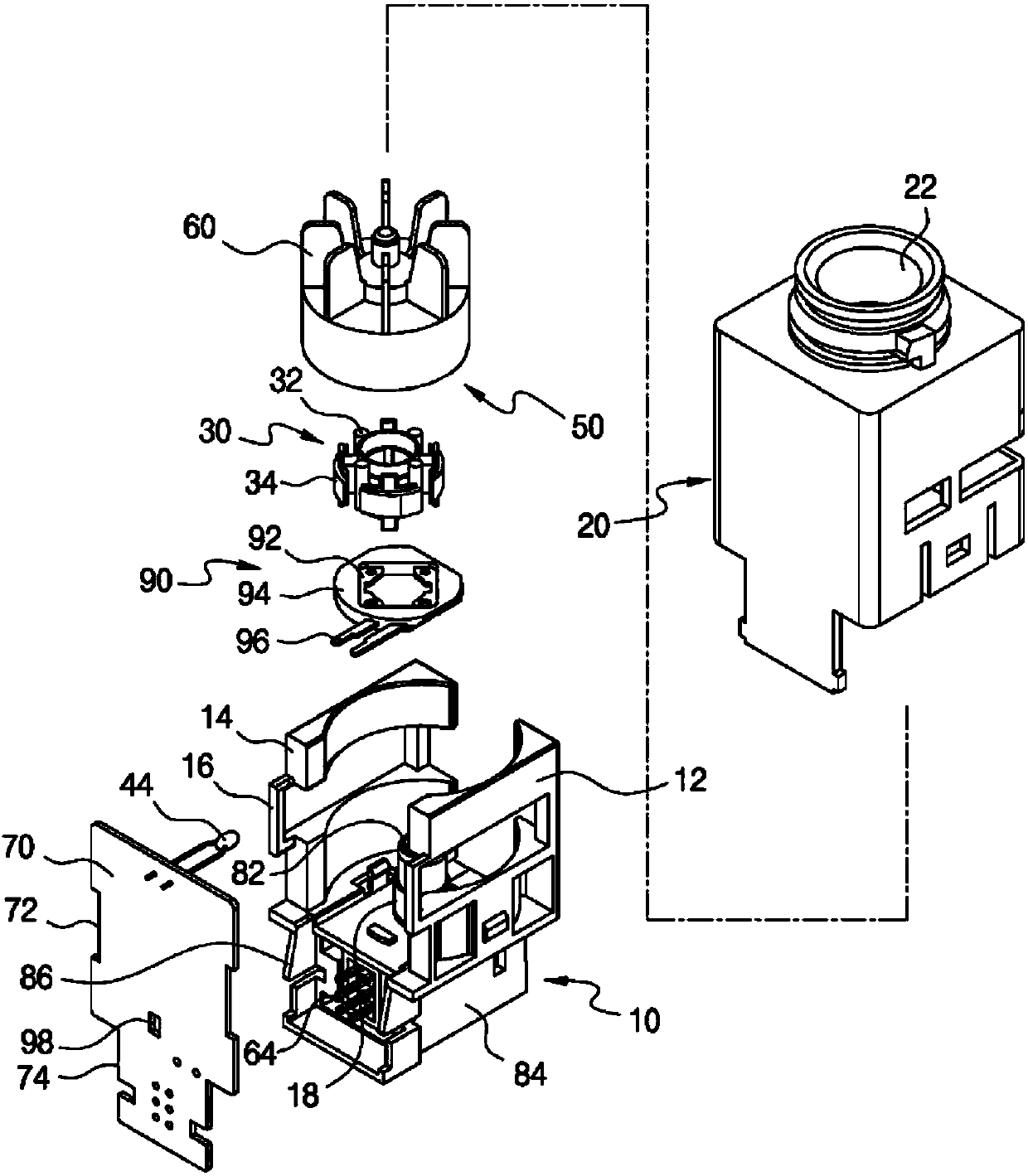

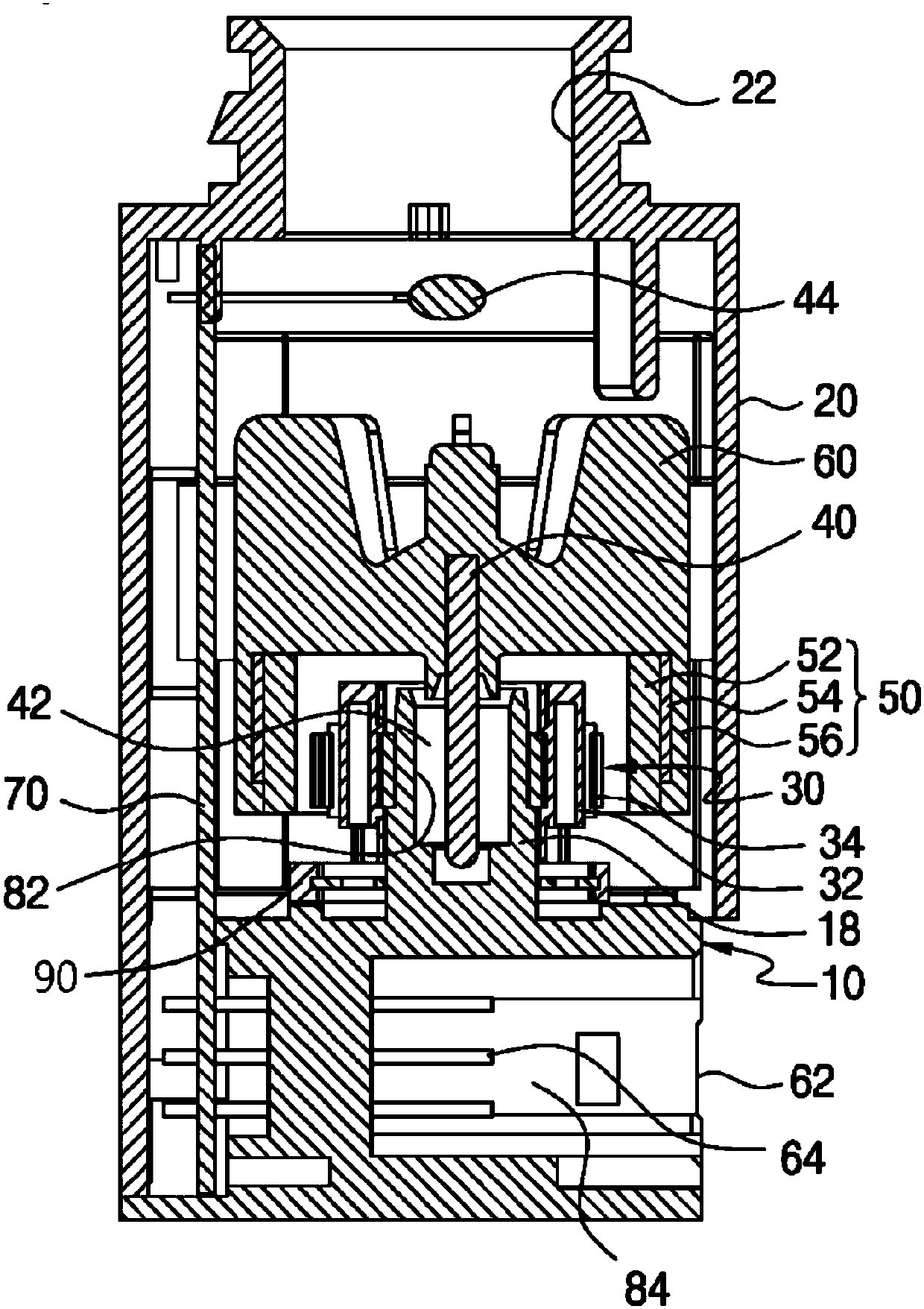

In-car sensor assembly for air conditioning device

ActiveCN107852065AReduce in quantitySimplify the assembly processAssociation with control/drive circuitsAir-treating devicesImpellerEngineering

The present invention relates to an in-car sensor assembly for an air conditioning device. The in-car sensor assembly comprises: a body; a stator fixed to the body; a rotor arranged to have a predetermined gap from the outer surface of the stator; an impeller fixed to the rotor and supported on the body to be able to rotate by a rotating shaft; and a main circuit board, which is mounted on an openside surface of the body to be erected vertically, and which controls the stator. According to the present invention, the number of components can be reduced, and the assembly process can be simplified.

Owner:AMOTECH

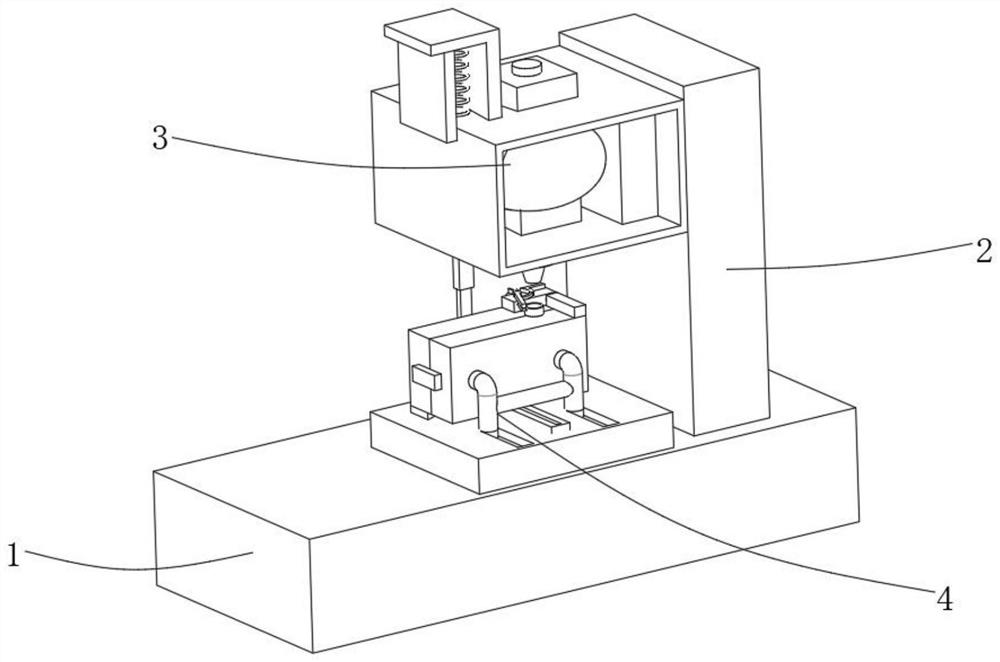

Injection molding equipment for plastic connecting piece on UV printer

PendingCN114683472APrecise control of injection volumeSolve the problem of dripping ingredientsComputer printingInjection device

The invention discloses injection molding equipment for a plastic connecting piece on a UV printer, and relates to the technical field of printer part machining. The injection molding equipment for the plastic connecting piece on the UV printer comprises a first base, a fixing rod is fixed to the right side of the upper surface of the first base, an injection device is slidably connected to the side wall of the fixing rod, a mold device is fixed to the middle of the upper surface of the first base, and an auxiliary demolding device is fixed to the back face of the mold device. According to the injection molding equipment for the plastic connecting piece on the UV printer, after the injection device slides to the position above the mold device, an L-shaped extrusion rod is pressed, and a pressing plate rotates anticlockwise, so that a colloid extrusion bin is extruded, and raw materials in the colloid extrusion bin are fed into the mold device through an injection opening; the problem that in the prior art, raw materials can drip everywhere is solved, and the advantage that the injection amount of the raw materials can be accurately controlled through an extrusion injection mode can be achieved.

Owner:阳文清

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com