Damping sole

A groove bottom and rubber technology, applied in shoe soles, footwear, apparel, etc., can solve the problems of outsole and midsole edge misalignment, unfavorable mass production, physical injury of workers, etc., to reduce weight and reduce labor intensity. , the effect of avoiding harm to the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

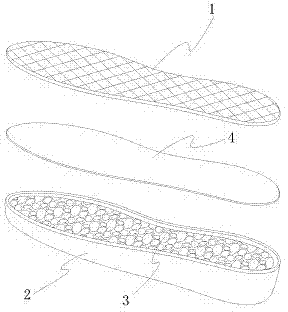

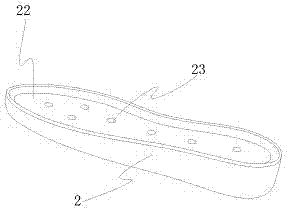

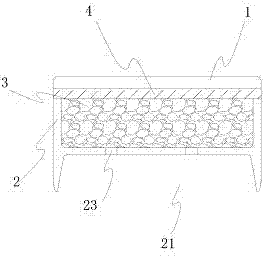

[0018] refer to Figure 1 to Figure 3 , the embodiment of the present invention discloses that a shock-absorbing shoe sole includes a rubber outsole 1 and a rubber midsole 2. The rubber outsole 1 and the rubber midsole 2 are placed in a mold with unvulcanized rubber and heated to seven The shape formed by vulcanization when mature; the rubber outsole 1 is sheet-shaped; the cross-sectional shape of the rubber midsole 2 is H-shaped, and the rubber midsole of the H-shaped structure has an upper groove 21 and a lower groove respectively located on its upper and lower sides. Groove, the groove side of the upper groove 21 can be used for the connection between the follow-up sole and the upper, which can improve the convenience of connection between the follow-up sole and the upper, and is convenient for processing. The lower groove is a filling groove 22, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com